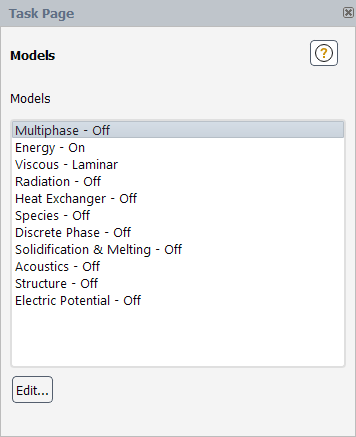

The Models task page allows you to set various generic model settings.

Important: This feature offers reduced functionality when running Fluent under the Pro capability level.

Controls

- Models

contains a listing of the various models available in Ansys Fluent.

You can double-click an item in the Models list to open the corresponding dialog box, or you can select the item in the list and click the Edit... button.

- Multiphase

- selecting this item and clicking the Edit... button opens the Multiphase Model Dialog Box.

- Energy

- selecting this item and clicking the Edit... button opens the Energy Dialog Box.

- Viscous

- selecting this item and clicking the Edit... button opens the Viscous Model Dialog Box.

- Radiation

- selecting this item and clicking the Edit... button opens the Radiation Model Dialog Box.

- Heat Exchanger

- selecting this item and clicking the Edit... button opens the Heat Exchanger Model Dialog Box.

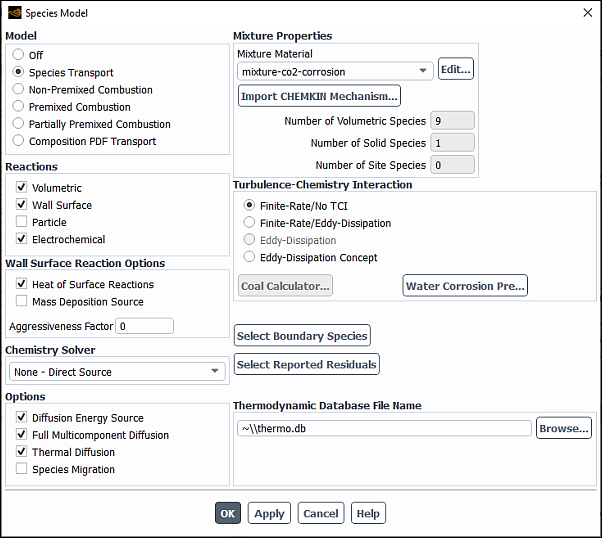

- Species

- selecting this item and clicking the Edit... button opens the Species Model Dialog Box.

The following models are made available, depending on your setup of the Species dialog box.

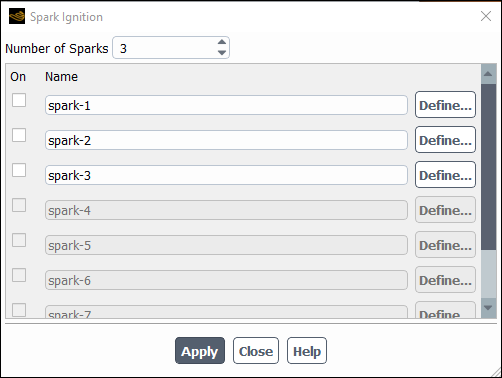

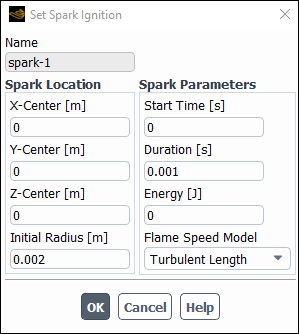

Spark Ignition - selecting this item and clicking the Edit... button opens the Spark Ignition Dialog Box. Note that spark ignition is only available for transient calculations.

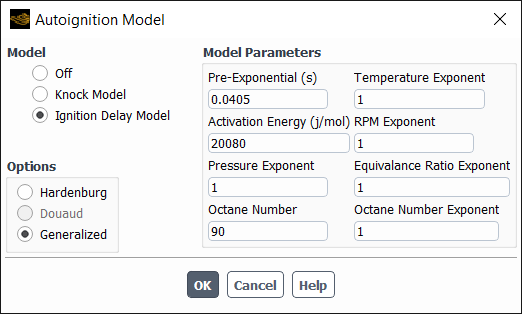

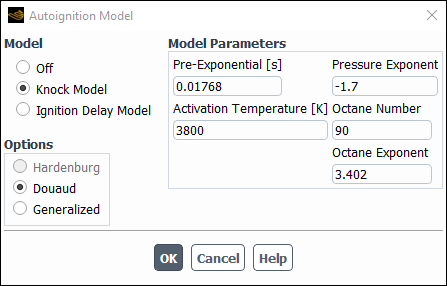

Autoignition - selecting this item and clicking the Edit... button opens the Autoignition Model Dialog Box. Note that autoignition is only available for transient calculations.

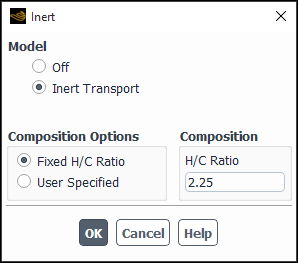

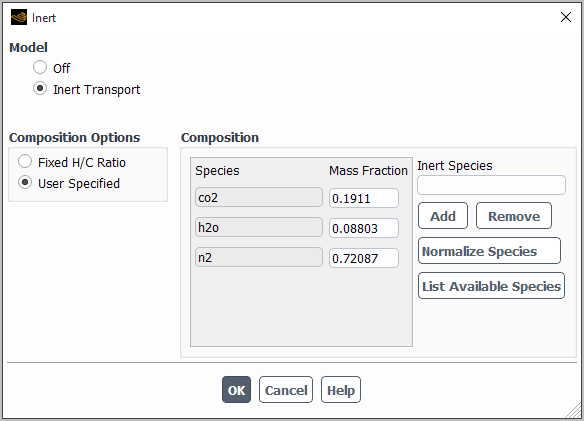

Inert - selecting this item and clicking the Edit... button opens the Inert Dialog Box. Note that the inert model is only available when the non-premixed or partially premixed model is selected in the Species Model dialog box, or when a PDF file is read.

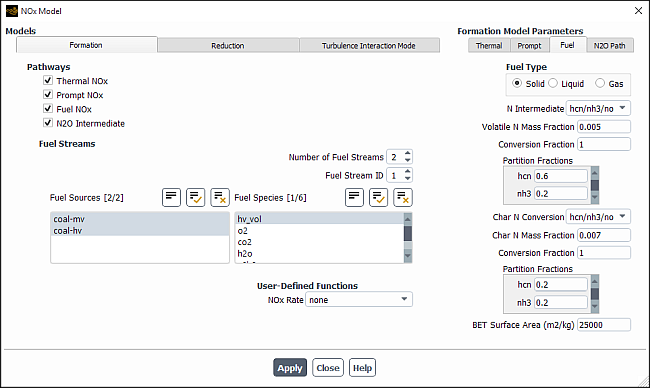

NOx - selecting this item and clicking the Edit... button opens the NOx Model Dialog Box. Note that the NOx model is not compatible with premixed combustion.

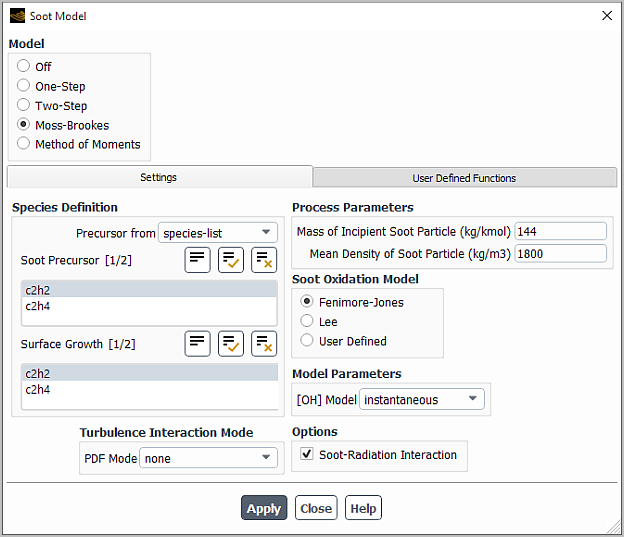

Soot - selecting this item and clicking the Edit... button opens the Soot Model Dialog Box. Note that none of the soot models are compatible with premixed combustion.

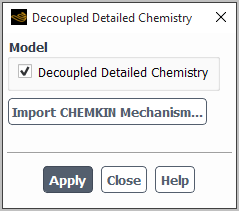

Decoupled Detailed Chemistry - selecting this item and clicking the Edit... button opens the Decoupled Detailed Chemistry Dialog Box.

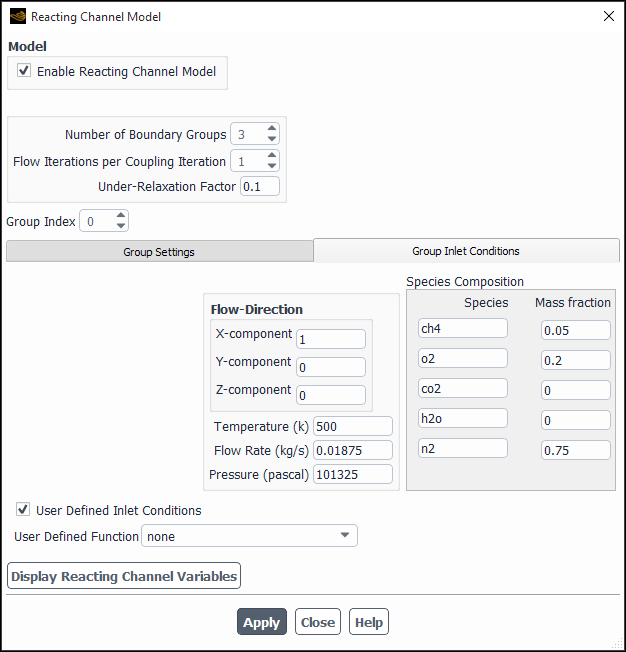

Reacting Channel Model - selecting this item and clicking the Edit... button opens the Reacting Channel Model Dialog Box.

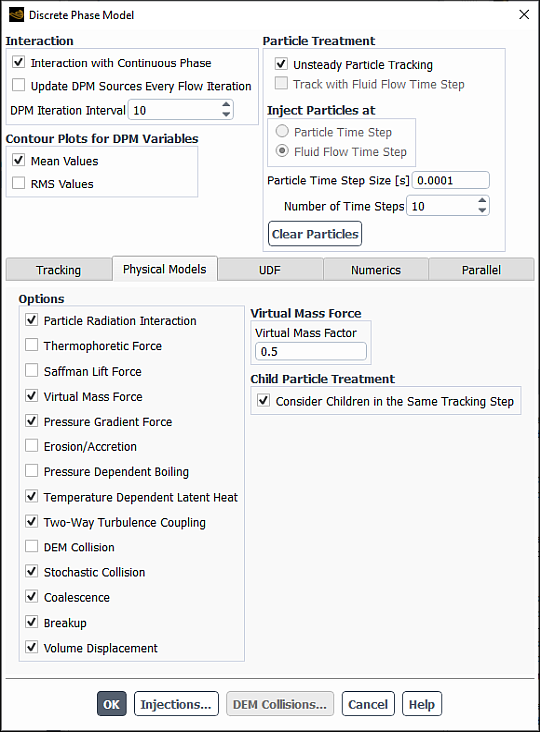

- Discrete Phase

- selecting this item and clicking the Edit... button opens the Discrete Phase Model Dialog Box.

- Solidification & Melting

- selecting this item and clicking the Edit... button opens the Solidification and Melting Dialog Box.

- Acoustics

- selecting this item and clicking the Edit... button opens the Acoustics Model Dialog Box.

- Structure

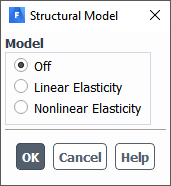

- selecting this item and clicking the Edit... button opens the Structural Model Dialog Box.

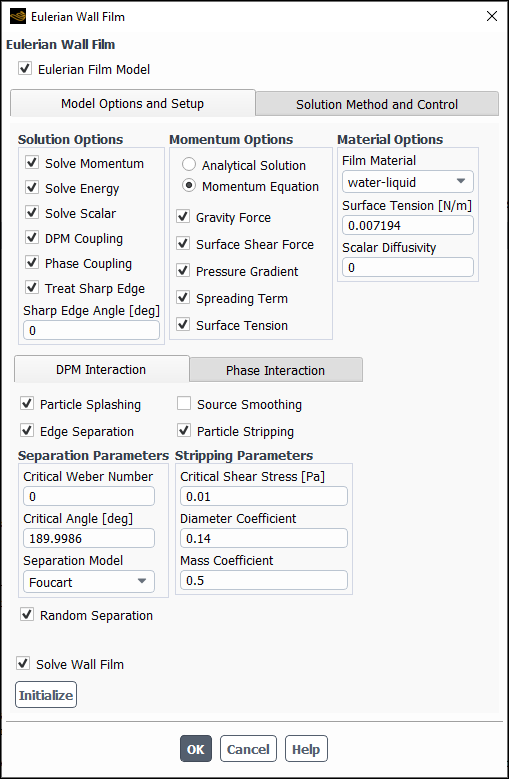

- Eulerian Wall Film

- selecting this item and clicking the Edit... button opens the Eulerian Wall Film Dialog Box.

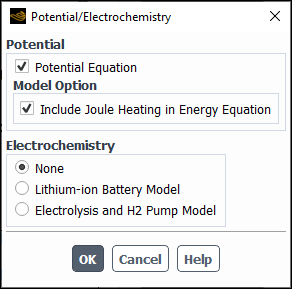

- Electric Potential

- selecting this item and clicking the Edit... button opens the Potential/Electrochemistry Dialog Box.

- Edit...

opens the dialog box corresponding to the selected item in the Models list.

For additional information, see the following sections:

- 51.4.1. Multiphase Model Dialog Box

- 51.4.2. Energy Dialog Box

- 51.4.3. Viscous Model Dialog Box

- 51.4.4. Radiation Model Dialog Box

- 51.4.5. View Factors and Clustering Dialog Box

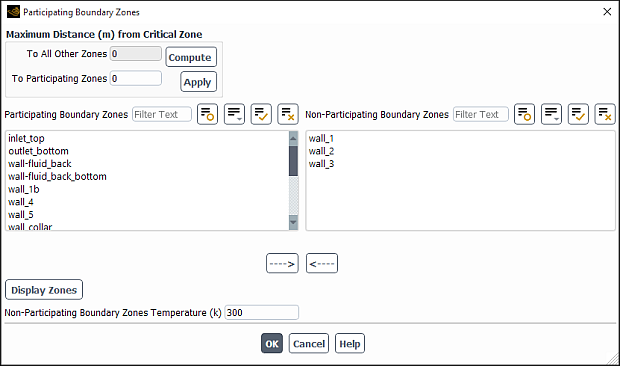

- 51.4.6. Participating Boundary Zones Dialog Box

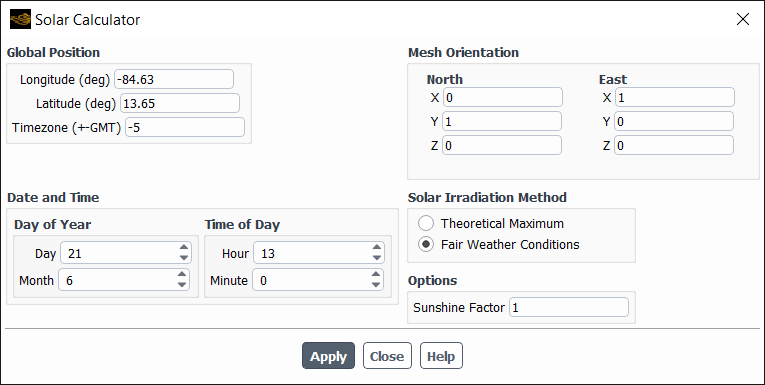

- 51.4.7. Solar Calculator Dialog Box

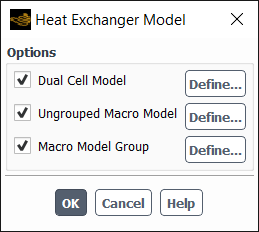

- 51.4.8. Heat Exchanger Model Dialog Box

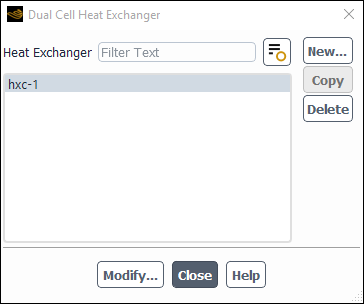

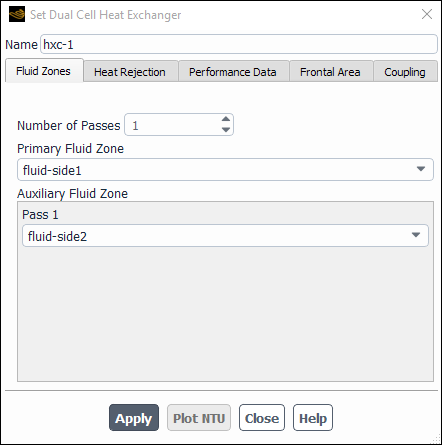

- 51.4.9. Dual Cell Heat Exchanger Dialog Box

- 51.4.10. Set Dual Cell Heat Exchanger Dialog Box

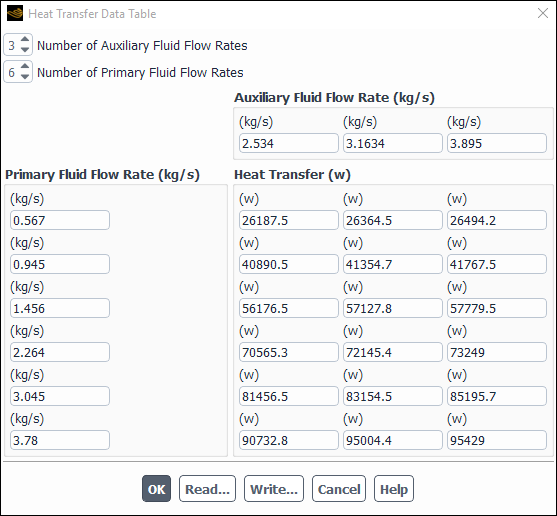

- 51.4.11. Heat Transfer Data Table Dialog Box

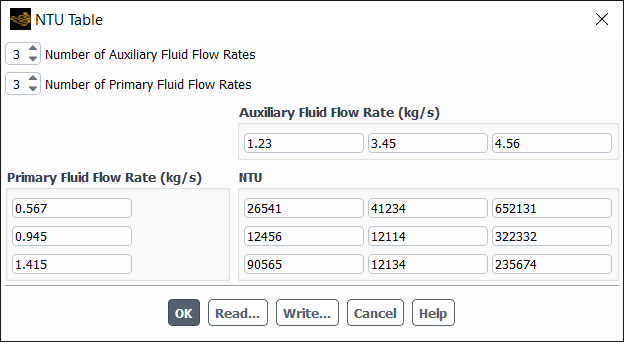

- 51.4.12. NTU Table Dialog Box

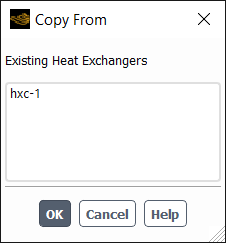

- 51.4.13. Copy From Dialog Box

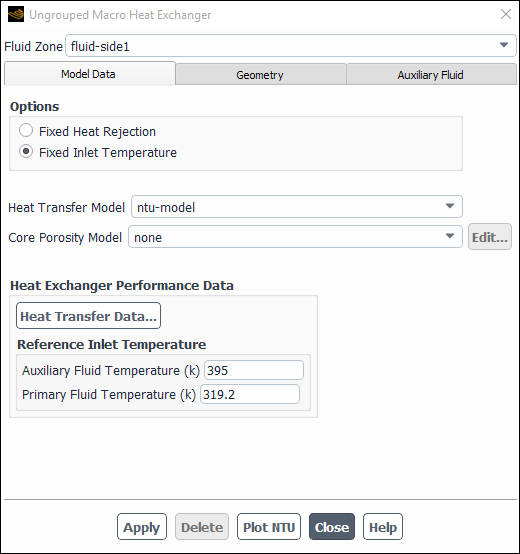

- 51.4.14. Ungrouped Macro Heat Exchanger Dialog Box

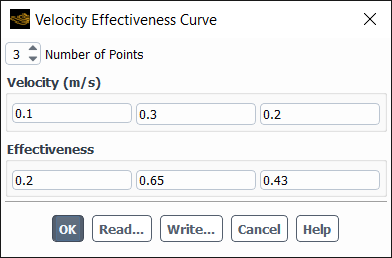

- 51.4.15. Velocity Effectiveness Curve Dialog Box

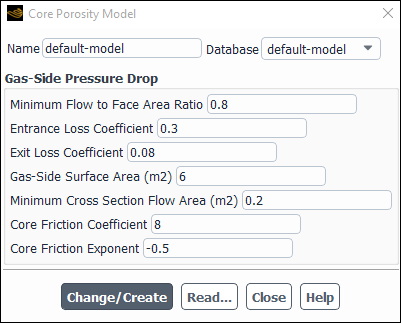

- 51.4.16. Core Porosity Model Dialog Box

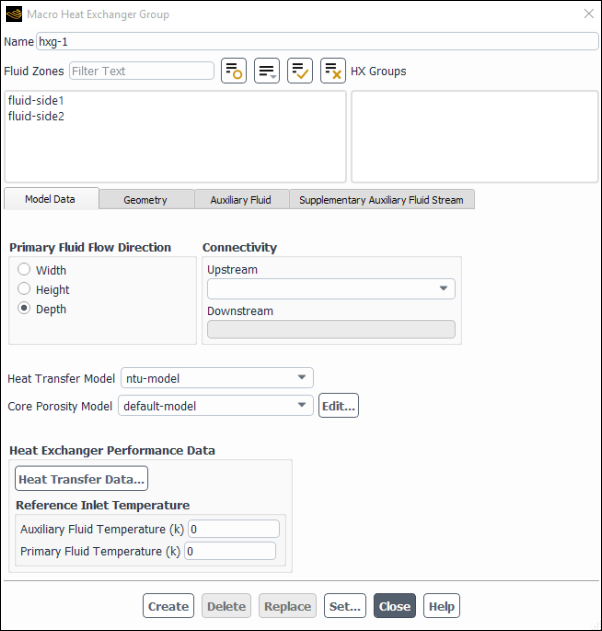

- 51.4.17. Macro Heat Exchanger Group Dialog Box

- 51.4.18. Species Model Dialog Box

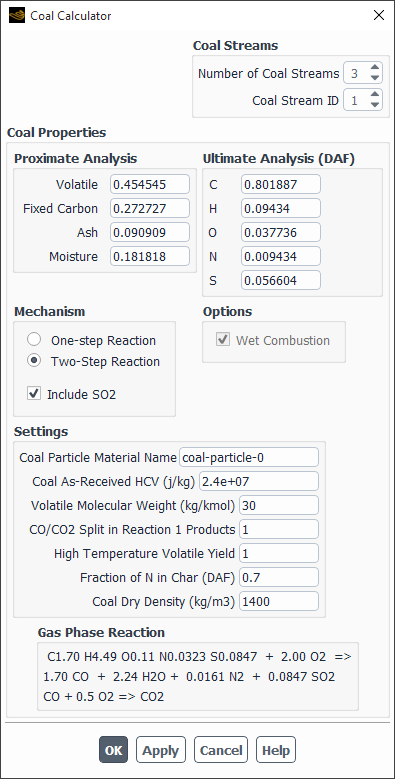

- 51.4.19. Coal Calculator Dialog Box

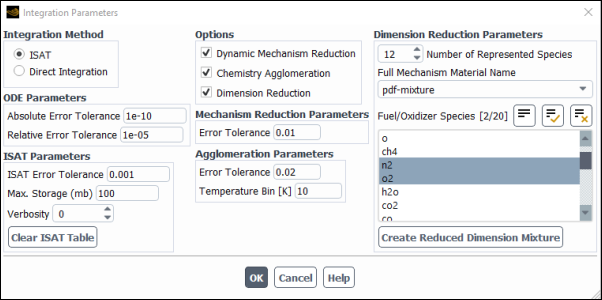

- 51.4.20. Integration Parameters Dialog Box

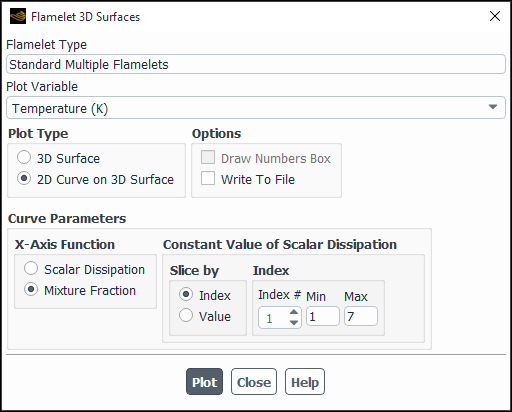

- 51.4.21. Flamelet 3D Surfaces Dialog Box

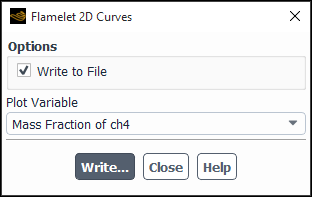

- 51.4.22. Flamelet 2D Curves Dialog Box

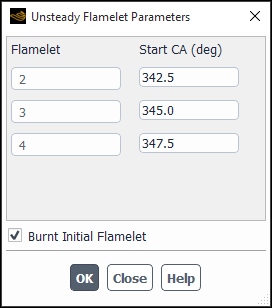

- 51.4.23. Unsteady Flamelet Parameters Dialog Box

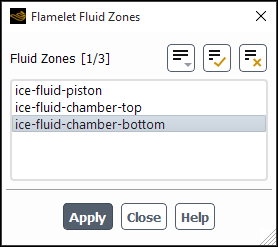

- 51.4.24. Flamelet Fluid Zones Dialog Box

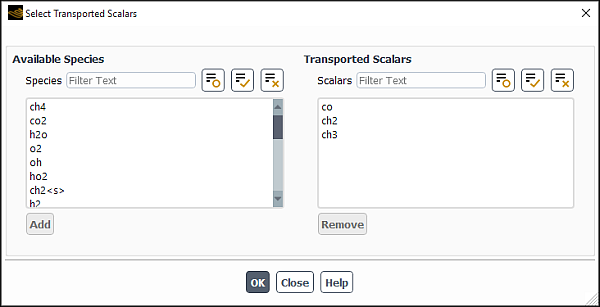

- 51.4.25. Select Transported Scalars Dialog Box

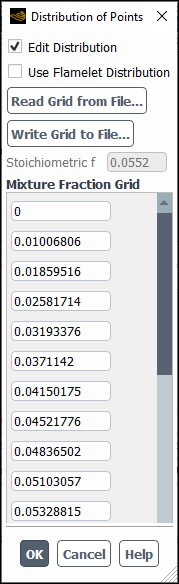

- 51.4.26. Distribution of Points Dialog Box

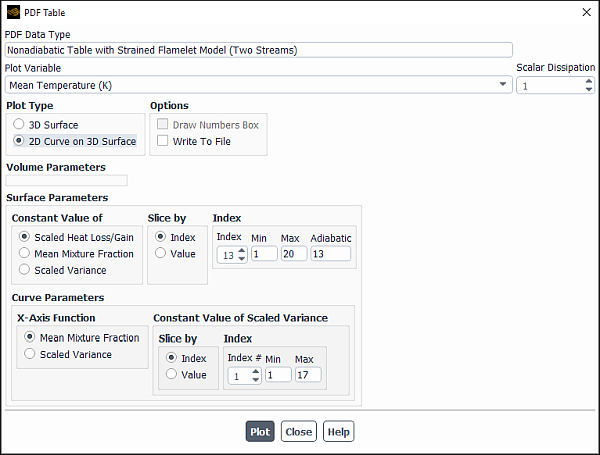

- 51.4.27. PDF Table Dialog Box

- 51.4.28. Spark Ignition Dialog Box

- 51.4.29. Set Spark Ignition Dialog Box

- 51.4.30. Autoignition Model Dialog Box

- 51.4.31. Inert Dialog Box

- 51.4.32. NOx Model Dialog Box

- 51.4.33. Soot Model Dialog Box

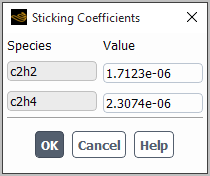

- 51.4.34. Sticking Coefficients Dialog Box

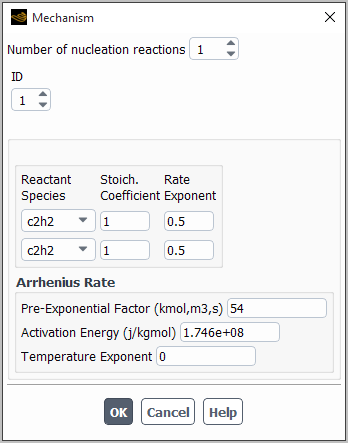

- 51.4.35. Mechanism Dialog Box

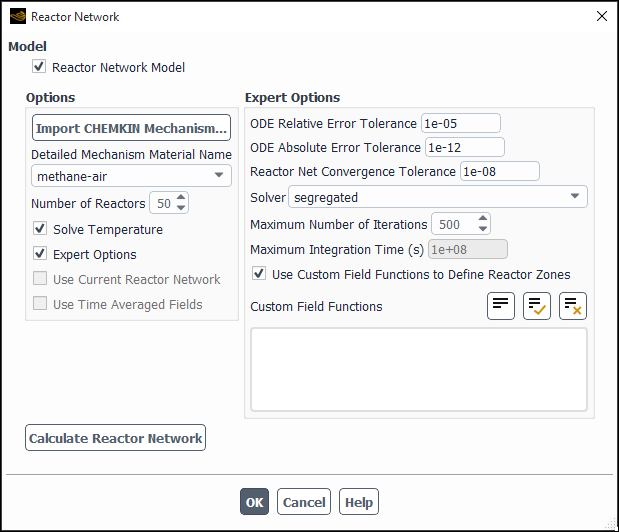

- 51.4.36. Reactor Network Dialog Box

- 51.4.37. Decoupled Detailed Chemistry Dialog Box

- 51.4.38. Reacting Channel Model Dialog Box

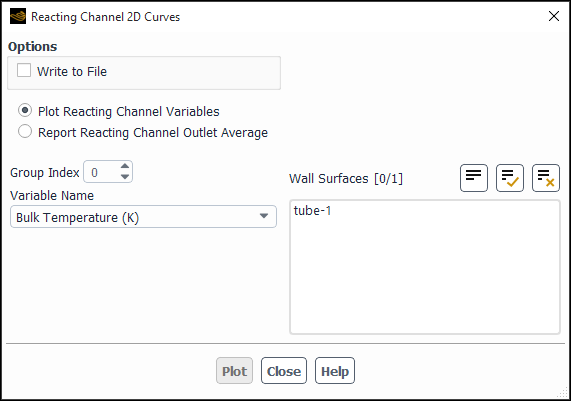

- 51.4.39. Reacting Channel 2D Curves Dialog Box

- 51.4.40. Discrete Phase Model Dialog Box

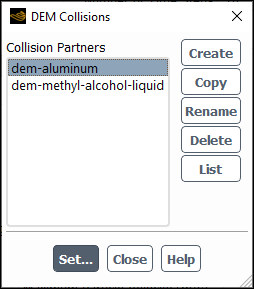

- 51.4.41. DEM Collisions Dialog Box

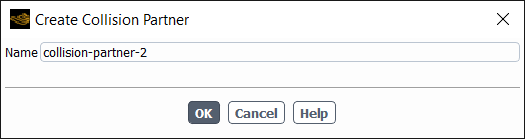

- 51.4.42. Create Collision Partner Dialog Box

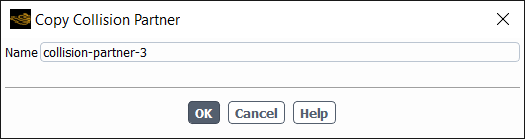

- 51.4.43. Copy Collision Partner Dialog Box

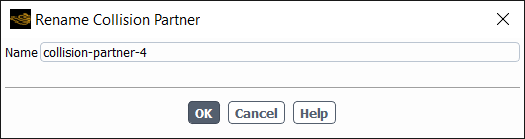

- 51.4.44. Rename Collision Partner Dialog Box

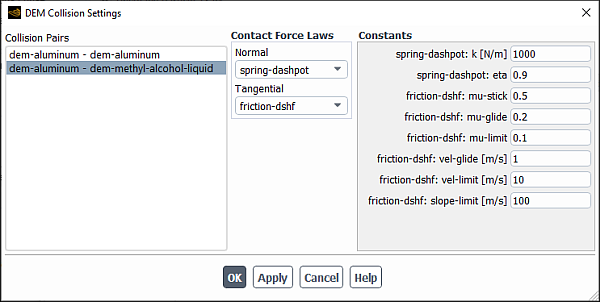

- 51.4.45. DEM Collision Settings Dialog Box

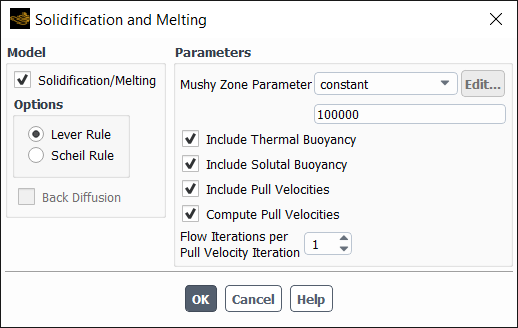

- 51.4.46. Solidification and Melting Dialog Box

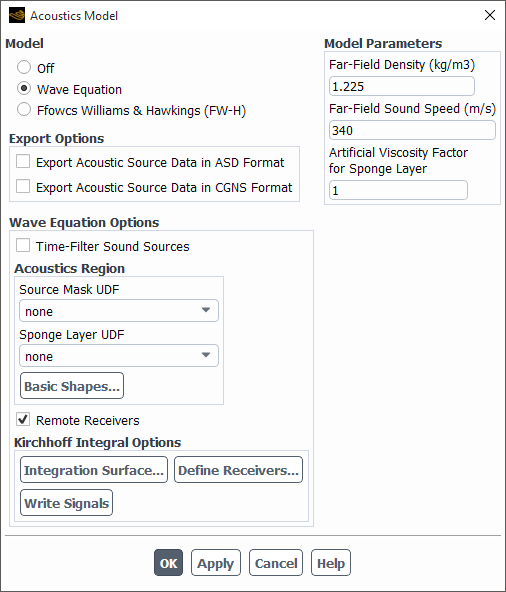

- 51.4.47. Acoustics Model Dialog Box

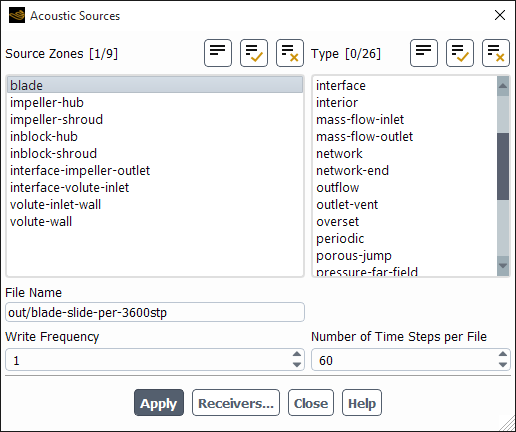

- 51.4.48. Acoustic Sources Dialog Box

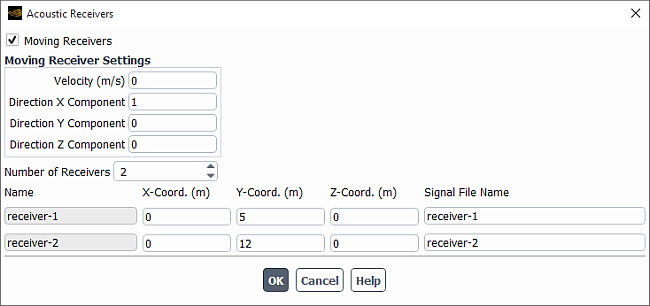

- 51.4.49. Acoustic Receivers Dialog Box

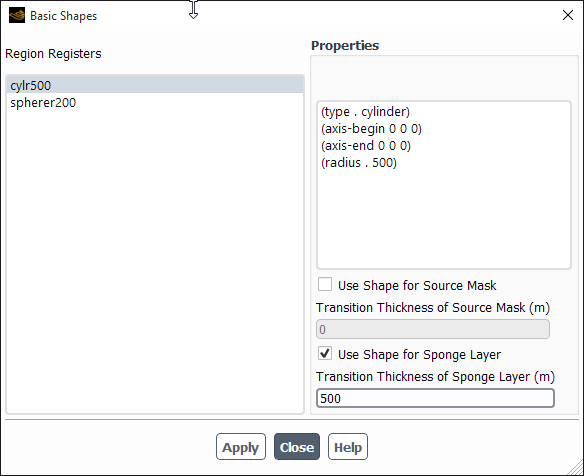

- 51.4.50. Basic Shapes Dialog Box

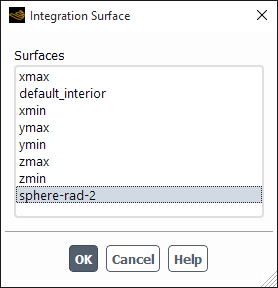

- 51.4.51. Integration Surface Dialog Box

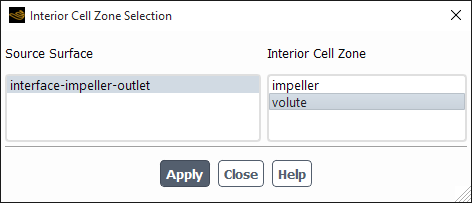

- 51.4.52. Interior Cell Zone Selection Dialog Box

- 51.4.53. Structural Model Dialog Box

- 51.4.54. Eulerian Wall Film Dialog Box

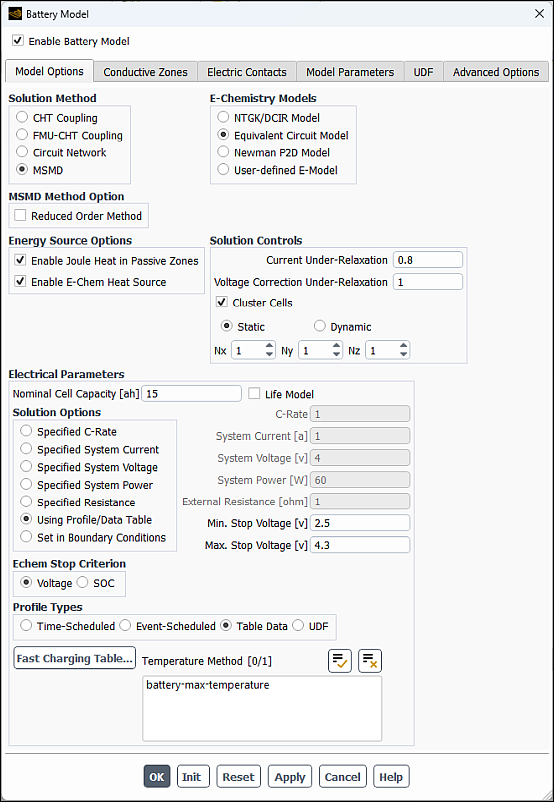

- 51.4.55. Battery Model Dialog Box

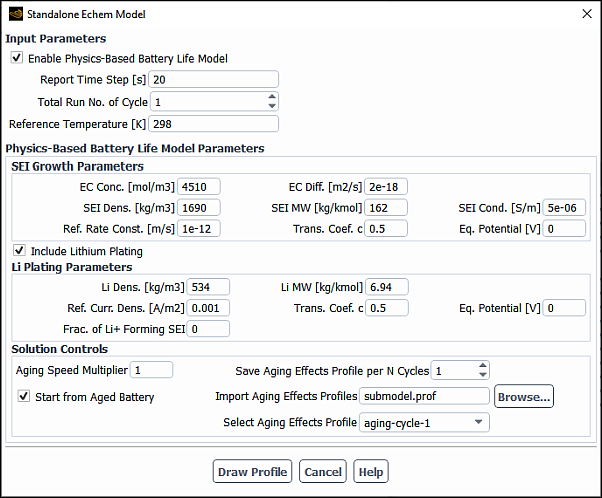

- 51.4.56. Standalone Echem Model Dialog Box

- 51.4.57. Potential/Electrochemistry Dialog Box

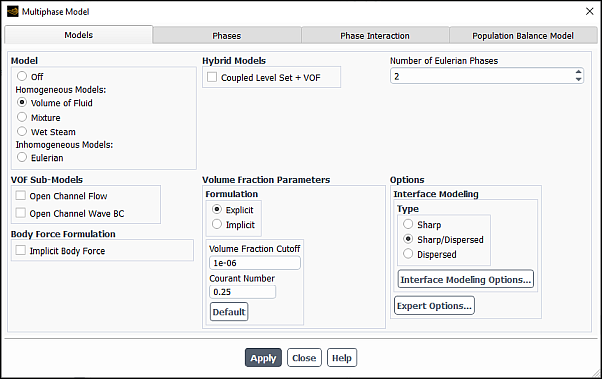

The Multiphase Model dialog box allows you to set parameters for modeling multiphase flow. See Enabling the Multiphase Model – Using the Singhal et al. Expert Cavitation Model for details.

Controls

- Apply

saves the settings specified in the current tab.

Important: When setting up your case, if you have made changes in the current tab, you should click the button to make them effective before moving to the next tab. Otherwise, the relevant models may not be available in the other tabs, and your settings may be lost.

- Models

tab allows you to select a multiphase model and adjust model controls.

- Model

allows you to select one of four multiphase models.

- Off

disables the calculation of multiphase flow.

- Volume of Fluid

enables the VOF model described in Volume of Fluid (VOF) Model Theory in the Theory Guide. See Setting Up the VOF Model for details about using the model. This is available only with the pressure-based solver.

- Mixture

enables the mixture model described in Mixture Model Theory in the Theory Guide. See Setting Up the Mixture Model for details about using the model. This is available only with the pressure-based solver.

- Eulerian

enables the Eulerian model described in Eulerian Model Theory in the Theory Guide. See Setting Up the Eulerian Model for details about using the model. This is available only with the pressure-based solver.

- Wet Steam

enables the wet steam model described in Wet Steam Model Theory in the Theory Guide. See Setting Up the Wet Steam Model for details about using the model.

Important: When General Turbo Interfaces (GTI) are used, available models reduce to Wet Steam only.

For details on the different GTI types, see Blade Row Interaction Modeling.

- Number of Eulerian Phases

allows you to specify the number of phases for the multiphase calculation. You can specify up to 20 phases.

- Coupled Level Set + VOF

allows you to apply an interface tracking method that couples the level set method with the VOF formulation.

- Volume Fraction Parameters

contains parameters related to the VOF and Eulerian model. This section of the dialog box will appear only when Volume of Fluid or Eulerian is the selected Model.

- Formulation

allows you to select the desired volume tracking formulation.

- Explicit

enables the Euler explicit formulation, described in The Explicit Formulation in the Theory Guide. See Choosing Volume Fraction Formulation for more information.

- Implicit

enables the implicit formulation, described in The Implicit Formulation in the Theory Guide. See Choosing Volume Fraction Formulation for more information.

- Volume Fraction Cutoff

specifies a cutoff limit for the volume fraction values. The value that you provide is used as the lower cutoff for the volume fraction. All volume fraction values in the domain below this cutoff value are set to zero. The upper cutoff is calculated as (1.0 - lower cutoff). All volume fraction values above the upper cutoff value are set to 1.0. The default value is 1e-6.

Important: The Volume Fraction Cutoff value can be specified when using the Explicit formulation for volume fraction.

- Courant Number

specifies the maximum Courant number allowed near the free surface. This item will not appear if the Implicit Scheme is selected. See Setting Time-Dependent Parameters for the Explicit Volume Fraction Formulation for details.

- Model Parameters

contains options related to the Mixture model.

- Slip Velocity

enables/disables the calculation of slip velocities for the secondary phases as described in Relative (Slip) Velocity and the Drift Velocity in the Theory Guide. See also Solving a Homogeneous Multiphase Flow.

- Flow Regime Modeling

enables/disables the flow regime modeling as described in Using the Flow Regime Modeling. See also Flow Regime Modeling in the Fluent Theory Guide. This option is available only when Slip Velocity is enabled.

- Regime Transition Modeling

contains options for modeling flow regime transition. This group box is available only with the Eulerian multiphase model.

- Algebraic Interfacial Area Density (AIAD)

allows you to enable the algebraic interfacial area density model and sets its parameters (see Using the Algebraic Interfacial Area Density (AIAD) Model for details).

- Generalized Two Phase Flow (GENTOP)

allows you to enable the GENTOP model and set its parameters (see Steps for Using the GENTOP Model for details).

- Hybrid Models

contains options related to the Eulerian model.

- Dense Discrete Phase Model

allows you to include the Dense Discrete Phase model (see Including the Dense Discrete Phase Model for details). Enabling this model automatically enables the DPM model.

- Multi-Fluid VOF Model

allows you to include the multi-fluid VOF model (see Including the Multi-Fluid VOF Model for details). The multi-fluid VOF model allows the modeling of interface sharpening schemes and free surface flow.

- Sub-Models

is a group box that contains options for the boiling model.

- Boiling Model

when enabled, includes the boiling effects in your simulation (see Including the Boiling Model for details).

- Boiling Options...

opens the Boiling Model dialog box (see Including the Boiling Model for details). This item is available only when the Boiling Model is selected.

- Number of Discrete Phase

allows you to specify the number of discrete phases when the Dense Discrete Phase Model option is enabled.

- Body Force Formulation

contains an additional option for body force calculations.

- Implicit Body Force

enables the implicit body force treatment described in Including Body Forces.

- VOF Sub-Models

contains additional sub-models that can be applied when using the VOF model.

- Open Channel Flow

enables the model to study the effects of open channel flow. See Open Channel Flow in the Theory Guide and Modeling Open Channel Flows for details.

- Open Channel Wave BC

enables the model to set specific parameters for a particular boundary for open channel wave boundaries. This option is not available for axisymmetric cases. See Open Channel Wave Boundary Conditions in the Theory Guide and Modeling Open Channel Wave Boundary Conditions for details.

- Options

contains additional modeling options.

- Interface Modeling

contains settings for how to model interfaces for the VOF model, Mixture multiphase model, and Eulerian with Multi-Fluid VOF enabled. See Interface Modeling Type for details.

- Type

allows you to select the type of interface modeling to be performed. You can choose between Sharp, Dispersed, or a hybrid Sharp/Dispersed when both types of interfaces may be present, or when the interface is mildly sharp. See Interface Modeling Type for more details.

- Interfacial Anti-Diffusion

enables an anti-diffusion treatment at the interface when using the Sharp interface modeling type. This can be used to reduce the effects of numerical diffusion that may occur with coarse meshes, high-aspect ratio cells, or large jumps in cell volume near the interface.

- Interface Modeling Options...

opens the Interface Modeling Options dialog box from which you can enable Zonal Discretization and/or Phase Localized Discretization.

- Expert Options...

opens the Expert Options dialog box which contains settings for VOF time advancement when using the Explicit formulation. Here you can set the Sub-Time Step Calculation Method and enable Solve VOF Every Iteration. See Expert Options for details.

- Phases

tab allows you to define the phases for your simulation. See Steps for Setting Cell Zone Conditions for details.

- Phases

contains a list of all of the phases in the problem from which you can select the phase you want to define or modify. A phase can be a Primary Phase or a Secondary Phase. You cannot change a phase from primary to secondary, or vice versa. Instead, you can redefine the properties of the primary phase to reflect the new phase designated as primary, and redefine the secondary phases accordingly as well.

- Add Phase

adds a new phase in your simulation.

- Delete Phase

deletes the selected phase.

- Phase Setup

is a group box where you can define the properties of the selected primary or secondary phase.

- Name

specifies the name of the phase.

- ID

displays the ID number of the phase. You will need this number only if you are writing a user-defined function. See the separate Fluent Customization Manual for details about writing user-defined functions for multiphase applications.

- Phase Material

contains a drop-down list of available materials, from which you can select the appropriate one for this phase. This control is not available for the DDPM.

- Edit...

opens the Edit Material Dialog Box for the selected Phase Material, where you can modify its properties.

- Granular

(secondary phase) indicates whether or not this is a solid phase. This item appears only for the Eulerian model.

- Packed Bed

(secondary phase only) indicates whether or not the granular phase is a packed bed. This option appears only if Granular is selected.

- Interfacial Area Concentration

(secondary phase only) is used to predict mass, momentum and energy transfers through the interface between the phases. See Interfacial Area Concentration in the Theory Guide for details. This option is not available if Granular is selected.

- Granular Temperature Model

(secondary phase only) lists the granular temperature models.

- Phase Property

enables phase property model for granular temperature.

- Partial Differential Equation

enables partial differential equation model for granular temperature. See Granular Temperature in the Theory Guide for details.

- Volume Fraction Approaching Packing Limit

prevents the unlimited accumulation of particles, which are operating at packing limit conditions. This options is available only for the DDPM.

- Transition Factor

is specified as either a constant or a user-defined function. The default value is assumed to be 0.75, which corresponds to the closest sphere packing for monosized spheres (a factor of 4/3). In other words, the transition criterion is based on the local particle volume fraction of the given discrete phase and is specified as a factor multiplied by the maximum packing limit (also a user specified value). This control appears only when Volume Fraction Approaching Packing Limit is selected.

- Diameter

(secondary phase only) specifies the diameter of the particles. You can select constant in the drop-down list and specify a constant value, or select user-defined to use a user-defined function. See the separate Fluent Customization Manual for details about user-defined functions. The Diameter appears for both the mixture model and the Eulerian model. This control is not available for the DDPM.

- Granular Properties

(secondary phase only) contains a list of granular phase-specific properties. This section of the dialog box will not appear for the VOF model. This list is only if Granular is selected.

- Granular Viscosity

specifies the kinetic part of the granular viscosity of the particles (

in Equation 14–362 in the Theory Guide). You can select constant (the default) in the drop-down list and specify a constant value, select syamlal-obrien to compute the value using Equation 14–364 in the Theory Guide, select gidaspow to compute the value using Equation 14–365 in the Theory Guide, or select user-defined to use a user-defined function. Note the following:

If you select filtered for Drag Coefficient, then Granular Viscosity is set automatically to filtered. The granular viscosity will be calculated as described in The Filtered Two-Fluid Model in the Fluent Theory Guide.

If you select user-defined, your user-defined function must include both the kinetic portion and the collisional portion of the viscosity in the value it returns.

- Granular Bulk Viscosity

specifies the solids bulk viscosity (

in Equation 14–195 in the Theory Guide). You can select constant (the default) in the drop-down list and specify a constant value, select lun-et-al to compute the value using Equation 14–366 in the Theory Guide, or select user-defined to use a user-defined function. Note that if you select filtered for Drag Coefficient, then Granular Bulk Viscosity is set to zero automatically.

- Frictional Viscosity

specifies a shear viscosity based on the viscous-plastic flow (

in Equation 14–362 in the Theory Guide). By default, the frictional viscosity is neglected, as indicated by the default selection of none in the drop-down list. If you want to include the frictional viscosity, you can select constant and specify a constant value, select schaeffer to compute the value using Equation 14–367 in the Theory Guide, or select user-defined to use a user-defined function.

- Angle Of Internal Friction

specifies a constant value for the angle

used in Schaeffer’s expression for frictional viscosity (Equation 14–367 in the Theory Guide). This parameter is relevant only if you have selected schaeffer or user-defined for the Frictional Viscosity.

- Frictional Pressure

specifies the pressure gradient term,

, in the granular-phase momentum equation. Choose none to exclude frictional pressure from your calculation, johnson-et-al to apply Equation 14–371 in the Theory Guide, syamlal-et-al to apply Equation 14–268 in the Theory Guide, based-ktgf, where the frictional pressure is defined by the kinetic theory [38]. The solids pressure tends to a large value near the packing limit, depending on the model selected for the radial distribution function. You must hook a user-defined function when selecting the user-defined option. See the separate Fluent Customization Manual for information on hooking a UDF.

- Frictional Modulus

can be set as derived, or as a user-defined function. This is defined as Equation 26–17.

- Friction Packing Limit

specifies a threshold volume fraction at which the frictional regime becomes dominant. The default value is 0.61.

- Granular Conductivity

specifies the solids conductivity. You can select syamlal-obrien, gidaspow, constant or user-defined.

- Granular Temperature

specifies temperature for the solids phase and is proportional to the kinetic energy of the random motion of the particles. You can choose the algebraic, constant, dpm-averaged,or user-defined option. dpm-averaged is available only when using the Dense Discrete Phase Model (DDPM). Note that if you select filtered for Drag Coefficient, then Granular Temperature is set to zero automatically.

- Solids Pressure

specifies the pressure gradient term,

, in the granular-phase momentum equation. Choose either the lun-et-al, the syamlal-obrien, the ma-ahmadi, or the user-defined option. Note that if you select filtered for Drag Coefficient, then Solids Pressure is set automatically to filtered. The solid pressure will be calculated as described in The Filtered Two-Fluid Model in the Fluent Theory Guide.

- Radial Distribution

specifies a correction factor that modifies the probability of collisions between grains when the solid granular phase becomes dense. Choose either the lun-et-al, the syamlal-obrien, the ma-ahmadi, the arastapour, or a user-defined option. Note that if filtered is selected for Drag Coefficient, then Radial Distribution is set automatically to filtered. In the simulation, the radial distribution will be set to zero since the filtered two-fluid model is not based on kinetic theory.

- Elasticity Modulus

is defined as

(51–1)

with

.

Choose either the derived or user-defined options.

- Packing Limit

specifies the maximum volume fraction for the granular phase. For monodispersed spheres the packing limit is about 0.63, which is the default value in Ansys Fluent. In polydispersed cases, however, smaller spheres can fill the small gaps between larger spheres, so you may need to increase the maximum packing limit.

- Phase State

is a group box where you can select either Liquid or Gas phase state. This item is available only when Flow Regime Modeling is selected in the Models tab (Model Parameters group box).

- Phase Morphology

is a group box where you can select from the following phase morphology options:

Continuous

Dispersed (secondary phase only)

Hybrid

This item is available only when Flow Regime Modeling is selected in the Models tab (Model Parameters group box).

- Interfacial Area Concentration Properties

(secondary phase only) contains a list of phase-specific properties. This list is available only if Interfacial Area Concentration is selected. This section of the dialog box will not appear for the VOF, mixture, or DDPM multiphase models.

- Min/Max Diameter

are the limits of the bubble diameters.

- Breakage Kernel

allows you to specify the breakage kernel. You can select none, constant, hibiki-ishii, ishii-kim, yao-morel, or user-defined. The three options, hibiki-ishii, ishii-kim, and yao-morel are described in detail in Interfacial Area Concentration in the Theory Guide.

- Coalescence Kernel

allows you to specify the coalescence kernel. You can select none, constant, hibiki-ishii, ishii-kim, yao-morel, or user-defined. The three options, hibiki-ishii, ishii-kim, and yao-morel are described in detail in Interfacial Area Concentration in the Theory Guide.

- Nucleation Rate

is a source term for the interfacial area concentration that models the rate of formation of the dispersed phase. You can choose from constant or user-defined. If the Boiling Model option is enabled when using the Eulerian multiphase model, you can also select yao-morel. The yao-morel option is described in Yao-Morel Model in the Theory Guide.

- Surface Tension

specifies the attractive forces between the interfaces.

- Critical Weber Number

will need to be specified if you selected yao-morel for the Breakage Kernel.

- Dissipation Function

gives you the option to choose the formula which calculates the dissipation rate used in the hibiki-ishii and ishii-kim models. You can choose constant, wu-ishii-kim, fluent-ke, and user-defined for the dissipation function.

- Hydraulic Diameter

is the value used in Equation 26–19. This is available when the wu-ishii-kim formulation is selected as the Dissipation Function. .

- Phase Interaction

tab allows you to define the interaction between phases.

- Interaction Domain ID

displays the ID number of the interaction domain. You will need this number only if you are writing a user-defined function. See the separate Fluent Customization Manual for details about writing user-defined functions for multiphase applications.

- Forces

tab allows you to specify forces acting between the phases.

- Phase Pairs

is a list of all of the phase pairs in the problem from which you can select the pair and define the forces between the phases.

- Global Options

contains controls that apply along phase interface in each pair of phases.

- Shaver-Podowski Lift Correlation

(Eulerian Multiphase model only) when enabled, improves the accuracy of the prediction of the void peak near the wall and overall robustness for cases where lift force, turbulent dispersion, and wall lubrication are included. See Including the Lift Correlation for more information.

- Virtual Mass Implicit Options

specifies what form of the implicit method to use. Default models the entire virtual mass force while Option 2 and Option 3 model truncated expressions which may further improve convergence. This option appears only when the Virtual Mass Coefficient is set to a nonzero value in the Force Setup group box.

- Surface Tension Force Modeling

includes the effects of surface tension along the fluid-fluid interface.

- Model

contains two surface tension models from which to choose.

- Continuum Surface Force

adds the surface tension to the VOF calculation, which results in a source term in the momentum equation. This method is available only for the VOF and Eulerian models.

- Continuum Surface Stress

is an alternative way to modeling surface tension in a conservative manner compared to the continuum surface force method. This method is available only for the VOF and Eulerian models.

- Adhesion Options

contains options to include wall and jump adhesion.

- Wall Adhesion

enables the specification of a wall adhesion angle. (The angle itself, as defined in Figure 26.21: Measuring the Contact Angle, will be specified in the Wall Dialog Box.)

- Jump Adhesion

enables the treatment of the contact angle specification at the porous jump boundary. (The angle itself will be specified in the Porous Jump Dialog Box.)

- Force Setup

contains a list of forces specified for the selected pair of phases. By default, the forces in the Force Setup group box are set to none. Depending on your case, the following forces can be defined:

Drag Coefficient: You can select the appropriate drag function from the Coefficient drop-down list and drag factor from the Modification drop-down list. See Specifying the Drag Function and Drag Modification for information about the available options. This input is available only for the Eulerian and mixture models only.

Lift Coefficient: Specifies the lift function for each pair of phases. See Defining the Phases for the Eulerian Model for information about the available options. This input is available only for the Eulerian model.

Wall Lubrication: Specifies the wall lubrication model for each primary-secondary phase pair. See Including the Wall Lubrication Force for information about the available options. This input is available only for Eulerian two-phase flows with a non-granular phase.

Turbulent Dispersion: Specifies the turbulent dispersion model for each primary-secondary phase pair. See Including the Turbulent Dispersion Force for information about the available options. This input is available only for the Eulerian model.

Turbulence Interaction: Specifies the turbulence interaction model for each primary-secondary phase pair. See Including Turbulence Interaction Source Terms for information about the available options. This input is available only for the Eulerian model.

Virtual Mass Coefficient: Specifies the virtual mass coefficient for each pair of phases. See Including the Virtual Mass Force for details. This input is available only for the Eulerian model.

Slip Velocity: Specifies the slip velocity function for each secondary phase with respect to the primary phase. See Defining the Phases for the Mixture Model for information about the available options. This input is available only for the mixture multiphase model.

Surface Tension Coefficients: Specify the surface tension coefficient,

in Equation 14–23 and Equation 12–58 in the Theory Guide, for each pair of phases. See Defining the Phases for the VOF Model for details. This input is available only for the Eulerian model.

Restitution Coefficient: Specifies the restitution coefficient for collisions between each pair of granular phases, and for collisions between particles of the same granular phase. It is relevant only if two or more granular phases are involved. See Defining the Phases for the Eulerian Model for information about the available options.

- Heat, Mass, Reactions

tab contains the following tabs:

- Heat

tab displays the Heat Transfer Coefficient inputs. See Including Heat Transfer Effects for information about the available options. This tab is active only for the Eulerian model when the energy equation is active.

- Heat Transfer Coefficient

specifies the heat transfer coefficient function between each pair of phases. See Including Heat Transfer Effects for information about the available options.

- Mass

tab displays the Mass Transfer Function inputs.

- Number of Mass Transfer Mechanisms

specifies the number of mass transfer mechanisms in your simulation. See Including Mass Transfer Effects for information about the available options.

- Reactions

tab allows you to define multiple heterogeneous reactions and stoichiometry.

- Total Number of Heterogeneous Reactions

specifies the total number of reactions (volumetric reactions, wall surface reactions, and particle reactions). See Specifying Heterogeneous Reactions for information about the available options.

- Heterogeneous Stiff Chemistry Solver

is used in inter-phase reaction mechanisms containing numerically stiff reactions. This option can improve convergence and is available for transient Eulerian multiphase simulations.

- Reaction Name

allows you to enter a name for the reaction.

- ID

enables you to set the reaction ID for each reaction.

- Number of Reactants

allows you to specify the number of reactants that are involved in the reaction.

- Number of Products

allows you to specify the number of products that are involved in the reaction.

- Phase

drop-down list allows you to select the phase that is involved in the reaction.

- Species

drop-down list allows you to select the species.

- Stoich. Coefficient

allows you to set the stoichiometric coefficient.

- Reaction Rate Function

allows you to choose rate exponents for an Arrhenius-type reaction, a user-defined function, or a population balance mechanism for the reaction rate.

- Interfacial Area

tab displays the Interfacial Area settings to predict interfacial area between the phases. This tab appears only for the Mixture multiphase model with interphase mass transfer and the Eulerian multiphase model. See Defining the Algebraic Interfacial Area Concentration and Using an Algebraic Interfacial Area Model for information about the available options.

- Discretization

tab allows you to use the diffusive and anti-diffusive discretization procedure across the distinct interfaces.

- Phase Localized Compressive Scheme

enables the compressive discretization scheme in Ansys Fluent, where the degree of diffusion/sharpness is controlled through the value of the slope limiters. This item will appear only for the VOF model and for the Eulerian model with Multi-Fluid VOF Model enabled.

- Slope Limiters

are values equating to specific discretization schemes. For each pair of phases, you can enter a value of 0, 1, or 2, or any value between 0 and 2. Depending on the value you use, first order upwind, second order upwind, compressive, or the blended scheme will be applied. Refer to Table 26.11: Slope Limiter Discretization Scheme to equate each value of the slope limiter with a discretization scheme. For more information, refer to Discretizing Using the Phase Localized Compressive Scheme.

- Model Transition

displays the VOF-to-DPM Model Transition inputs. This tab is available only when a DPM injection is set as described in Setting up the VOF-to-DPM Model Transition.

- Number of Model Transition Mechanisms

specifies the number of VOF-to-DPM model transition mechanisms in your simulation. See Setting up the VOF-to-DPM Model Transition for information about the available options.

- Population Balance

tab contains controls for setting population balance simulations. This tab is displayed for the mixture and Eulerian multiphase models. See Population Balance Model for details.

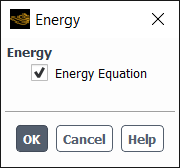

The Energy dialog box allows you to set parameters related to energy or heat transfer in your model.

Controls

- Energy

contains inputs related to the modeling of energy.

- Energy Equation

enables/disables the calculation of energy in the model.

- Energy Modes

contains inputs related to the alternative energy modeling modes.

- Two-Temperature Model

enables/disables the Two-Temperature Model. Only available for the density-based solver.

The Viscous Model dialog box allows you to set parameters for inviscid, laminar, and turbulent flow. See Steps in Using a Turbulence Model for details about using this dialog box.

Important: This feature offers reduced functionality when running Fluent under the Pro capability level.

Controls

- Model

contains options for specifying the viscous model.

- Inviscid

specifies inviscid flow.

- Laminar

specifies laminar flow.

- Spalart-Allmaras

specifies turbulent flow to be calculated using the Spalart-Allmaras model. (See Spalart-Allmaras Model in the Theory Guide for background about this model. See Setting Up the Spalart-Allmaras Model for details about using this model.)

- k-epsilon

specifies turbulent flow to be calculated using one of three

-

models. (See Standard, RNG, and Realizable k-ε Models in the Theory Guide for background about this model. See Setting Up the k-ε Model for details about using this model.)

- k-omega

specifies turbulent flow to be calculated using one of two

-

models. (See Standard, BSL, and SST k-ω Models in the Theory Guide for background about these models. See Setting Up the k-ω Model for details about using this model.)

- Transition k-kl-omega

specifies turbulent flow to be calculated using the Transition

-

-

model. (See k-kl-ω Transition Model in the Theory Guide for background about this model. See Setting Up the Transition k-kl-ω Model for details about using this model.)

- Transition SST

specifies turbulent flow to be calculated using the Transition SST model. (See Transition SST Model in the Theory Guide for background about this model. See Setting Up the Transition SST Model for details about using this model.)

- Reynolds Stress

specifies turbulent flow to be calculated using the RSM. (See Reynolds Stress Model (RSM) in the Theory Guide for background about this model. See Setting Up the Reynolds Stress Model for details about using this model.)

- Scale-Adaptive Simulation (SAS)

specifies turbulent flow to be calculated using the SAS model in combination with the SST

-

model. (See Scale-Adaptive Simulation (SAS) Model in the Theory Guide for background about this model. See Setting Up Scale-Adaptive Simulation (SAS) Modeling for details about using this model.)

- Detached Eddy Simulation

specifies turbulent flow to be calculated using the DES model. (See Detached Eddy Simulation (DES) in the Theory Guide for background about this model. See Setting Up the Detached Eddy Simulation Model for details about using this model.)

- Large Eddy Simulation

(3D only) specifies turbulent flow to be calculated using the LES model. (See Large Eddy Simulation (LES) Model in the Theory Guide for background about this model. See Setting Up the Large Eddy Simulation Model for details about using this model.)

- Spalart-Allmaras Production

contains options for the Spalart-Allmaras model. This portion of the dialog box will appear only if Spalart-Allmaras is selected as the Model.

- Vorticity-Based

selects the vorticity-based calculation of the deformation tensor

(see Equation 4–22 in the Theory Guide).

- Strain/Vorticity-Based

selects the strain/vorticity-based calculation of the deformation tensor

(see Equation 4–24 in the Theory Guide).

- k-epsilon Model

contains options for specifying which of the

-

models is to be used. This portion of the dialog box will appear only if k-epsilon is selected as the Model.

- Standard

selects the standard

-

model, described in Standard k-ε Model in the Theory Guide and Setting Up the k-ε Model.

- RNG

selects the RNG

-

model, described in RNG k-ε Model. in the Theory Guide and Setting Up the k-ε Model.

- Realizable

selects the realizable

-

model, described in Realizable k-ε Model in the Theory Guide and Setting Up the k-ε Model.

- RNG Options

specifies parameters that affect the solution of problems solved with the RNG

-

model. This portion of the dialog box will appear only if RNG is selected as the k-epsilon Model.

- Differential Viscosity Model

specifies whether or not the low-Reynolds-number RNG modifications to turbulent viscosity should be included. By default, this option is turned off. It is likely to have an effect only when the near-wall regions in the domain are well resolved in terms of mesh density. See Differential Viscosity Modification for details.

- Swirl Dominated Flow

specifies whether or not the RNG modification to turbulent viscosity for swirling flows should be included. This option is available only in 3D and 2D axisymmetric swirl solvers, and it can yield improved predictions when solving flows with significant swirl. See Swirl Modification for details.

- k-omega Model

contains options for specifying which of the

-

models is to be used. This portion of the dialog box will appear only if k-omega is selected as the Model.

- Standard

selects the standard

-

model, described in Standard k-ω Model in the Theory Guide and Setting Up the k-ω Model.

- GEKO

selects the generalized

-

model, described in Generalized k-ω (GEKO) Model in the Theory Guide and Setting up the Generalized k-ω (GEKO) Model.

- BSL

selects the baseline (BSL)

-

model, described in Baseline (BSL) k-ω Model in the Theory Guide and Setting Up the k-ω Model.

- SST

selects the shear-stress transport (SST)

-

model, described in Shear-Stress Transport (SST) k-ω Model in the Theory Guide and Setting Up the k-ω Model.

- k-omega Options

specifies parameters that affect the solution of problems solved with the

-

models. This portion of the dialog box will appear only if k-omega is selected as the Model.

- Low-Re Corrections

specifies whether corrections that improve the accuracy in predicting low Reynolds number flows should be included. This option is available only for the

-

models and the stress-omega RSM model. See Low-Re Corrections for details.

- Shear Flow Corrections

specifies whether corrections that improve the accuracy in predicting free shear flows should be included. This option is available only for the standard

-

model and the stress-omega RSM model. See Shear Flow Corrections for details.

- Transition SST Options

allows you to include the Roughness Correlation of rough walls as described in Transition SST and Rough Walls in the Theory Guide.

- Roughness Correlation

when enabled allows you to specify the Geometric Roughness Height as a constant value.

- Reynolds-Stress Model

specifies the various Reynolds stress models (RSM).

- Linear Pressure-Strain

enables the linear pressure-strain model. See Linear Pressure-Strain Model in the Theory Guide for details.

- Quadratic Pressure-Strain

enables the quadratic pressure-strain model for superior performance in a range of basic shear flows, including plane strain, rotating plane shear, and axisymmetric expansion/contraction. See Quadratic Pressure-Strain Model in the Theory Guide for details. Note that this option cannot be used with the Wall Reflection Effects option or the Enhanced Wall Treatment.

- Stress-Omega

enables a stress-transport model that is based on the omega equations and LRR model [173]. This model is ideal for modeling flows over curved surfaces and swirling flows. See Stress-Omega Model in the Theory Guide for details.

- Stress-BSL

enables a linear model for the pressure-strain term like the Stress-Omega model, but solves the scale equation from the baseline (BSL)

-

model, and thus removes the free-stream sensitivity observed with the Stress-Omega model. Like the Stress-Omega model, it is recommended for modeling flows over curved surfaces and swirling flows. See Stress-BSL Model in the Theory Guide for details.

- Reynolds-Stress Options

specifies parameters that affect the solution of problems solved with the Reynolds stress model. This portion of the dialog box will appear only if Reynolds Stress is selected as the Model.

- Wall BC from k Equation

enables the explicit setting of boundary conditions for the Reynolds stresses near the walls, using the values computed with Equation 4–260 in the Theory Guide. See Solving the k Equation to Obtain Wall Boundary Conditions for details. This option is on by default.

- Wall Reflection Effects

enables the calculation of the component of the pressure strain term responsible for the redistribution of normal stresses near the wall. See Including the Wall Reflection Term for details. Note that this option is not available if you have enabled the Quadratic Pressure-Strain Model.

- RANS Model

contains options for the subgrid-scale model used by the Detached Eddy Simulation Model. This portion of the dialog box will appear only if Detached Eddy Simulation Model is selected as the Model.

- Spalart-Allmaras

enables the Spalart-Allmaras RANS model. See Detached Eddy Simulation (DES) in the Theory Guide for details.

- Realizable k-epsilon

enables the Realizable

-

RANS model. See Detached Eddy Simulation (DES) in the Theory Guide for details.

- SST k-omega

enables the SST

-

RANS Model. See Detached Eddy Simulation (DES) in the Theory Guide for details.

- DES Options

contain the option to include a delayed Detached Eddy Simulation.

- Delayed DES

is useful for RANS meshes with high aspect ratios in the boundary layer. This option preserves the RANS model throughout the boundary layer. (See Delayed Detached Eddy Simulation (DDES) for details.)

- Subgrid-Scale Model

contains options for the subgrid-scale model used by the LES model. This portion of the dialog box will appear only if Large Eddy Simulation is selected as the Model.

- Smagorinsky-Lilly

selects the Smagorinsky-Lilly subgrid-scale model described in Subgrid-Scale Models in the Theory Guide.

- WALE

selects the Wall-Adapting local Eddy-Viscosity model described in Wall-Adapting Local Eddy-Viscosity (WALE) Model in the Theory Guide.

- WMLES

selects the algebraic Wall-Modeled LES model described in Algebraic Wall-Modeled LES Model (WMLES) in the Theory Guide.

- WMLES S-Omega

selects the algebraic Wall-Modeled LES

-

model described in Algebraic WMLES S-Omega Model Formulation in the Theory Guide.

- Kinetic-Energy Transport

selects the dynamic kinetic energy subgrid-scale model described in Dynamic Kinetic Energy Subgrid-Scale Model in the Theory Guide.

- LES Model Options

contains options for the Large Eddy Simulation model. This portion of the dialog box will appear only if Large Eddy Simulation is selected as the Model.

- Dynamic Stress

enables the dynamic stress model. It is available for selection when the Smagorinsky-Lilly is selected, and is enabled (and cannot be disabled) when the Kinetic-Energy Transport is selected.

- Dynamic Energy Flux

enables the dynamic energy flux model. It is available when the LES model option Dynamic Stress is enabled.

- Dynamic Scalar Flux

enables the dynamic computation of turbulent Sc (

in Equation 8–5 in the Theory Guide). See Definition of the Mixture Fraction in the Theory Guide for details. It is available when the LES model option Dynamic Stress is enabled.

- Dynamic Fvar

enables the dynamic mixture fraction variance model. It is available when Non-Premixed Combustion or Partially Premixed Combustion is selected in the Species Model Dialog Box. See The Non-Premixed Model for LES in the Theory Guide for details.

- Near-Wall Treatment

specifies the near-wall treatment to be used for modeling turbulence. See Near-Wall Treatments for Wall-Bounded Turbulent Flows in the Theory Guide for details about the available methods. This portion of the dialog box will appear if k-epsilon or Reynolds Stress is selected as the Model.

- Standard Wall Functions

enables the use of standard wall functions (described in Standard Wall Functions in the Theory Guide).

- Scalable Wall Functions

enables the use of scalable wall functions (described in Scalable Wall Functions in the Theory Guide).

- Non-Equilibrium Wall Functions

enables the use of non-equilibrium wall functions (described in Non-Equilibrium Wall Functions in the Theory Guide).

- Enhanced Wall Treatment

enables the use of the enhanced wall treatment (described in Enhanced Wall Treatment ε-Equation (EWT-ε) in the Theory Guide). Note that this option will not appear if you have enabled the Quadratic Pressure-Strain Model under Reynolds-Stress Options.

- Menter-Lechner

enables the use of the Menter-Lechner near-wall treatment (described in Menter-Lechner ε-Equation (ML-ε) in the Theory Guide). Note that this option is only available when k-epsilon is selected for the Model.

- User-Defined Wall Functions

enables you to hook a user-defined function, used to define the Law of the Wall. See User-Defined Wall Functions in the Theory Guide for more information.

- Enhanced Wall Treatment Options

allows you to include pressure gradient or thermal effects in the calculation. See Near-Wall Treatments for Wall-Bounded Turbulent Flows in the Theory Guide.

- Pressure Gradient Effects

enables the effect of pressure gradient.

- Thermal Effects

enables thermal effects in the calculation. This option appears only if the energy equation is enabled.

- Options

contains general options for viscous modeling.

- Viscous Heating

(if enabled) includes the viscous dissipation terms in the energy equation. This option is recommended when you are solving a compressible flow. Note that this option is always turned on when one of the density-based solvers is used; you will not be able to turn it off.

- Low-Pressure Boundary Slip

includes slip boundary conditions for velocity and temperature for modeling fluid flow at very low pressures as in semiconductor fabrication devices. See Slip Boundary Formulation for Low-Pressure Gas Systems in the Theory Guide. This option is available only for laminar flows.

- Buoyancy Effects

enables the inclusion of buoyancy effects. See Including Buoyancy Effects on Turbulence for details. Only available for non-isothermal flow and when a nonzero gravitational acceleration has been specified in the Operating Conditions Dialog Box.

- Curvature Correction

when enabled, modifies the turbulence production term to sensitize the standard eddy-viscosity models to the effects of streamline curvature and system rotation. This is available for the Spalart-Allmaras, k-epsilon, k-omega, Transition SST, Scale-Adaptive Simulation, and Detached Eddy Simulation with the SST k-omega model.

- Curvature Correction Options

Includes options related to curvature corrections.

- CCURV

specifies a coefficient used in the curvature correction term to influence the strength of the curvature correction if needed for a specific flow. Can be a constant or specified via UDF.

- Corner Flow Correction

when enabled, accounts for secondary flows found in rectangular channels, pipes of non-circular cross-section, and wing-body-junction type geometries in the plane normal to the main flow direction into the corner along the bisector.

- Corner Flow Correction Options

Includes options related to corner flow corrections.

- CCORNER

Sets the strength of the quadratic term of the corner flow correction. The default value is 1. Can be a constant or specified via UDF.

- Compressibility Effects

when enabled, can improve the prediction of free shear layers at high Mach numbers. This is available when the compressible form of the ideal gas law or the real-gas model is activated for k-epsilon, k-omega, Transition k-kl-omega, Reynolds Stress, Scale-Adaptive Simulation, and Detached Eddy Simulation with the Realizable k-epsilon model. For details, see Model Enhancements.

- Mixture Drift Force

includes the effect of turbulent drift velocity when using the Mixture model. See Modeling Turbulence. Note that this option is only available when using the Mixture model with Slip Velocity enabled in the Multiphase Model dialog box. See Including Mixture Drift Force.

- Production Kato-Launder

when enabled, the Kato-Launder modification for the production term limits the production term in the turbulence equation. For details see, Production Limiters for Two-Equation Models in the Fluent Theory Guide.

- Production Limiter

when enabled, limits the production term in the turbulence equation. For details, see Production Limiters for Two-Equation Models in the Fluent Theory Guide.

- Transition Options

contains options for transition modeling.

- Transition Model

selects the transition model. You can enable the gamma-transport-eqn model (also known as the Intermittency Transition model). For details, see Intermittency Transition Model in the Theory Guide.

- Include Crossflow Transition

includes the effects of crossflow instability. For details, see Transport Equations for the Intermittency Transition Model in the Theory Guide.

- Turbulence Multiphase Model

contains options for multiphase turbulence models. This portion of the dialog box will appear if Eulerian is selected as the Model in the Multiphase Model Dialog Box.

- Mixture

specifies the (default) mixture turbulence model.

- Dispersed

specifies the dispersed turbulence model.

- Per Phase

specifies the calculation of a set of turbulence equations for each phase.

See Turbulence Models in the Theory Guide for details about the available multiphase turbulence models.

- GEKO Options

contains options for the GEKO model.

- Wall Distance Free

Selects the wall distance free version of the GEKO model.

- CSEP

Specifies

- parameter to optimize flow separation from smooth surfaces.

- CNW

Specifies

- parameter to optimize flow in non-equilibrium near wall regions (such as heat transfer or

).

- CMIX

Specifies

- parameter to optimize strength of mixing in free shear flows.

- CJET

Specifies

- parameter to optimize free shear layer mixing (optimize free jets independent of mixing layer).

- Blending Function

Specifies the blending function,

, which deactivates these parameters inside boundary layers.

See Generalized k-ω (GEKO) Model in the Fluent Theory Guide for details about the GEKO model options.

- Model Constants

contains constants used in the equations for turbulence. See Spalart-Allmaras Model, Standard k-ε Model, RNG k-ε Model, k-kl-ω Transition Model, Transition SST Model, Realizable k-ε Model, Reynolds Stress Model (RSM), Standard k-ω Model, Shear-Stress Transport (SST) k-ω Model, and Large Eddy Simulation (LES) Model in the Theory Guide for details about these constants.

- Cb1

(only for the Spalart-Allmaras model) is the constant

in Equation 4–19 in the Theory Guide.

- Cb2

(only for the Spalart-Allmaras model) is the constant

in Equation 4–15 in the Theory Guide.

- Cv1

(only for the Spalart-Allmaras model) is the constant

in Equation 4–17 in the Theory Guide.

- Cw2

(only for the Spalart-Allmaras model) is the constant

in Equation 4–28 in the Theory Guide.

- Cw3*

(* only for the Spalart-Allmaras model) is the constant

in Equation 4–27 in the Theory Guide.

- Cprod

(only for the Spalart-Allmaras model when the Strain/Vorticity-Based Production option is used) is the constant

in Equation 4–24 in the Theory Guide.

- Cmu

(only for the standard or RNG

-

model, the RSM, or the

-

-

Transition model) is the constant

that is used to compute

.

- C1-Epsilon

(only for the standard or RNG

-

model or the RSM) is the constant

used in the transport equation for

.

- C2-Epsilon

(only for the standard, RNG, or realizable

-

model or the RSM) is the constant

used in the transport equation for

.

- C3-Epsilon

(only for the dispersed or per-phase

-

multiphase models) is the constant

in Equation 14–412 in the Theory Guide.

- C-lambda

(only for the

-

-

Transition model) is the constant

in the definition of the effective length,

- CR

(only for the

-

-

Transition model) is the constant

used in the definition of

, where

represents the averaged effect of the breakdown of streamwise fluctuations into turbulence during bypass transition

- ANAT

(only for the

-

-

Transition model) is the constant

- ATS

(only for the

-

-

Transition model) is the constant

- CNAT, crit

(only for the

-

-

Transition model) is the constant

- CTS, crit

(only for the

-

-

Transition model) is the constant

- CRNAT

(only for the

-

-

Transition model) is the constant

- Anu

(only for the

-

-

Transition model) is the constant

- CINT

(only for the

-

-

Transition model) is the constant

- Cw1

(only for the

-

-

Transition model) is the constant

- Cw3**

(**only for the

-

-

Transition model) is the constant

- Calpha-teta

(only for the

-

-

Transition model) is the constant

- Ctaul

(only for the

-

-

Transition model) is the constant

- SDR Prandtl Number

(only for the standard

-

model and the

-

-

Transition model) is the effective "Prandtl" number for the transport of the specific dissipation rate,

.

- Ca1

(only for the Transition SST model)

- Ca2

(only for the Transition SST model)

- Ce1

(only for the Transition SST model)

- Ce2

(only for the Transition SST model)

- C_thetat

(only for the Transition SST model)

- C_s1

(only for the Transition SST model)

- Intermit. Prandtl #)

(only for the Transition SST model)

- Re_theta. Prandtl #)

(only for the Transition SST model)

- C Shielded DES

(only for the SDES or SBES model) is a constant that serves the same purpose as

in the DDES turbulence model (see Equation 4–284 in the Theory Guide).

- Csdes

(only for the SDES or SBES model) is

, as described in Shielded Detached Eddy Simulation (SDES) in the Theory Guide.

- Cwale

(only for the WALE subgrid-scale model of the LES or SBES model) is

, as described in Wall-Adapting Local Eddy-Viscosity (WALE) Model in the Theory Guide.

- CREAL (GEKO)

(only for the GEKO model) is

, as described in Generalized k-ω (GEKO) Model in the Fluent Theory Guide.

- CNW_SUB (GEKO)

(only for the GEKO model) is

, as described in Generalized k-ω (GEKO) Model in the Fluent Theory Guide.

- CJET_AUX (GEKO)

(only for the GEKO model) is

, as described in Generalized k-ω (GEKO) Model in the Fluent Theory Guide.

- CBF_TUR (GEKO)

(only for the GEKO model) is

, as described in Generalized k-ω (GEKO) Model in the Fluent Theory Guide.

- CBF_LAM (GEKO)

(only for the GEKO model) is

, as described in Generalized k-ω (GEKO) Model in the Fluent Theory Guide.

- Swirl Factor

sets the value of

in Equation 4–46 in the Theory Guide. This item appears for the RNG

-

model when the Swirl Dominated Flow option is turned on.

- Alpha*_inf

(only for the standard, BSL, or SST

-

model, and the Transition SST model) is the constant

in Equation 4–75 in the Theory Guide.

- Alpha_inf

(only for the standard, BSL, or SST

-

model, and the Transition SST model) is the constant

in Equation 4–83 in the Theory Guide.

- Alpha_0

(only for the standard, BSL, or SST

-

model with the Low-Re Corrections option enabled) is the constant

in Equation 4–83 in the Theory Guide.

- Beta*_inf

(only for the standard, BSL, or SST

-

model, and the Transition SST model) is the constant

in Equation 4–88 in the Theory Guide.

- Beta_i

(only for the standard

-

model) is the constant

in Equation 4–96 in the Theory Guide.

- R_beta

(only for the standard, BSL, or SST

-

model) is the constant

in Equation 4–88 in the Theory Guide.

- R_k

(only for the standard, BSL, or SST

-

model with the Low-Re Corrections option enabled) is the constant

in Equation 4–75 in the Theory Guide.

- R_w

(only for the standard, BSL, or SST

-

model with the Low-Re Corrections option enabled) is the constant

in Equation 4–83 in the Theory Guide.

- Zeta*

(only for the standard, BSL, or SST

-

model when the Compressibility Effects option is enabled) is the constant

in Equation 4–87 in the Theory Guide.

- Mt0

(only for the standard, BSL, or SST

-

model when the Compressibility Effects option is enabled) is the constant

in Equation 4–97 in the Theory Guide.

- a1

(only for the SST

-

model, and the Transition SST model) is the constant

in Equation 4–118 in the Theory Guide.

- Beta_i (Inner)

(only for the BSL or SST

-

model, and the Transition SST model) is the constant

in Model Constants in the Theory Guide.

- Beta_i (Outer)

(only for the BSL or SST

-

model, and the Transition SST model) is the constant

in Model Constants in the Theory Guide.

- Cs

is a constant that depends on the turbulence model. For LES, it is the Smagorinsky constant

in Equation 4–307 in the Theory Guide. For SAS, it is the high wave number damping coefficient

in Equation 4–270 in the Theory Guide.

- C1-PS

(only for RSM) is the constant

in Equation 4–231 in the Theory Guide.

- C2-PS

(only for RSM) is the constant

in Equation 4–232 in the Theory Guide.

- C1’-PS

(only for RSM) is the constant

in Equation 4–233 in the Theory Guide.

- C2’-PS

(only for RSM) is the constant

in Equation 4–233 in the Theory Guide.

- C1-SSG-PS

(only for RSM with the Quadratic Pressure-Strain Model) is the constant

in Equation 4–242 in the Theory Guide.

- C1’-SSG-PS

(only for RSM with the Quadratic Pressure-Strain Model) is the constant

in Equation 4–242 in the Theory Guide.

- C2-SSG-PS

(only for RSM with the Quadratic Pressure-Strain Model) is the constant

in Equation 4–242 in the Theory Guide.

- C3-SSG-PS

(only for RSM with the Quadratic Pressure-Strain Model) is the constant

in Equation 4–242 in the Theory Guide.

- C3’-SSG-PS

(only for RSM with the Quadratic Pressure-Strain Model) is the constant

in Equation 4–242 in the Theory Guide.

- C4-SSG-PS

(only for RSM with the Quadratic Pressure-Strain Model) is the constant

in Equation 4–242 in the Theory Guide.

- C5-SSG-PS

(only for RSM with the Quadratic Pressure-Strain Model) is the constant

in Equation 4–242 in the Theory Guide.

- Prandtl Number

(only for the Spalart-Allmaras model) is the constant

in Equation 4–15 in the Theory Guide.

- TKE Prandtl Number

(only for the standard or realizable

-

model, the standard

-

model, the

-

-

Transition model, or the RSM) is the effective "Prandtl" number for transport of turbulence kinetic energy

. This effective Prandtl number defines the ratio of the momentum diffusivity to the diffusivity of turbulence kinetic energy via turbulent transport.

- TKE (Inner) Prandtl #

(only for the BSL or SST

-

model, and the Transition SST model) is the effective "Prandtl" number for the transport of turbulence kinetic energy,

, inside the near-wall region. See Modeling the Turbulent Viscosity in the Theory Guide for details.

- TKE (Outer) Prandtl #

(only for the BSL or SST

-

model, and the Transition SST model) is the effective "Prandtl" number for the transport of turbulence kinetic energy,

, outside the near-wall region. See Modeling the Turbulent Viscosity in the Theory Guide for details.

- TDR Prandtl Number

is the effective "Prandtl" number for transport of the turbulent dissipation rate,

, for the standard or realizable

-

model or the RSM. This effective Prandtl number defines the ratio of the momentum diffusivity to the diffusivity of turbulence dissipation via turbulent transport.

- SDR (Inner) Prandtl #

(only for the BSL or SST

-

model, and the Transition SST model) is the effective "Prandtl" number for the transport of the specific dissipation rate,

, inside the near-wall region. See Modeling the Turbulent Viscosity in the Theory Guide for details.

- SDR (Outer) Prandtl #

(only for the BSL or SST

-

model, and the Transition SST model) is the effective "Prandtl" number for the transport of the specific dissipation rate,

, outside the near-wall region. See Modeling the Turbulent Viscosity in the Theory Guide for details.

- Dispersion Prandtl Number

(only for the

-

multiphase models) is the effective "Prandtl" number for the dispersed phase,

. See Turbulence Models in the Theory Guide for details.

- Energy Prandtl Number

(for any turbulence model except the RNG

-

model) is the turbulent Prandtl number for energy,

, in Equation 4–250 in the Theory Guide. (This item will not appear for the LES model if the Dynamic Energy Flux option has been enabled, or for premixed or partially premixed combustion models.) For non-premixed and partially premixed combustion, the energy Prandtl Number is set equal to the PDF Schmidt Number.

- Wall Prandtl Number

(for all turbulence models) is the turbulent Prandtl number at the wall,

in Equation 4–343 in the Theory Guide. (This item will not appear for adiabatic premixed combustion or partially premixed combustion models.)

- Turbulent Schmidt Number

(for turbulent species transport calculations using any turbulence model except the RNG

-

model) is the turbulent Schmidt number,

, in Equation 7–4 in the Theory Guide. (This item will not appear for the LES model if the Dynamic Scalar Flux option has been enabled.)

- PDF Schmidt Number

(for non-premixed or partially premixed combustion calculations using any turbulence model) is the model constant

in Equation 8–5 in the Theory Guide.

- Production Limiter Clip Factor

This coefficient is used by the Production Limiter. For details, see Equation 4–436 in the Fluent Theory Guide.

- User-Defined Transition Correlations

(only for the Transition SST model) allows you to select the user-defined correlations for F_length, Re_thetac, Re_thetat.

- User-Defined Functions

allows you to select the user-defined functions for various constants.

- Turbulent Viscosity

appears for Spalart Allmaras,

-

,

-

, DES, SDES with BSL / SST models, and SBES with BSL / SST. You can select the user-defined functions for turbulent viscosity in the drop-down list.

- Prandtl Numbers, Prandtl and Schmidt Numbers

contains a list of relevant Prandtl and Schmidt numbers for which you can select user-defined functions.

- TKE Prandtl Number

allows you to select a user-defined function to define the TKE Prandtl number for the standard and realizable

-

models and the standard

-

model.

- TDR Prandtl Number

allows you to select a user-defined function to define the TDR Prandtl number for the standard and realizable

-

models.

- Energy Prandtl Number

allows you to select a user-defined function to define the turbulent Prandtl number for energy, when energy is enabled for all turbulence models except the RNG

-

model. (This item will not appear for the LES model if the Dynamic Energy Flux option has been enabled.)

- Wall Prandtl Number

allows you to select a user-defined function to define the turbulent Prandtl number at the wall for all turbulence models when energy is enabled.

- Turbulent Schmidt Number

allows you to select a user-defined function to define the turbulent Schmidt number when species transport is enabled for all turbulence models except the RNG

-

model. (This item will not appear for the LES model if the Dynamic Scalar Flux option has been enabled.)

- SDR Prandtl Number

allows you to select a user-defined function to define the SDR Prandtl number for the standard

-

model.

- Subgrid-Scale Turbulent Viscosity

allows you to select a user-defined function for the subgrid-scale turbulent viscosity for the LES model.

- Scale-Resolving Simulation Options

allows you to combine two turbulence models, which are applied on the appropriate regions of the flow domain. For additional information, see Scale-Resolving Simulation (SRS) Models.

- Scale-Adaptive Simulation (SAS)

allows you to apply SAS in combination with the following

-based URANS models: the Standard or BSL

-

model, the Transition SST model, and the

-based Reynolds stress models. For additional information, see Setting Up Scale-Adaptive Simulation (SAS) Modeling.

- Detached Eddy Simulation (DES)

allows you to apply DES in combination with the BSL

-

model and Transition SST model. For additional information, see Detached Eddy Simulation (DES).

- Stress Blending (SBES) / Shielded DES

allows you to apply SBES or SDES in combination with the BSL

-

model, SST

-

model, and Transition SST model. See Stress-Blended Eddy Simulation (SBES) and Shielded Detached Eddy Simulation (SDES) in the Theory Guide for details.

- Shielding Functions

allows you to select the shielding functions (SST F1 Function, SST F2 Function, DDES, and IDDES) for the Detached Eddy Simulation model with the BSL

-

model, SST

-

model, and Transition SST model. (see Shielding Functions for the BSL / SST / Transition SST Detached Eddy Simulation Model for details).

- SBES / SDES Options

allows you to define the following settings as part of the SBES or SDES model:

- Hybrid Model

specifies that the hybrid RANS-LES model used is either SDES (Shielded DES model), SBES (Stress-Blended Eddy Simulation model), or SBES with User-Defined Function. See Including the SDES or SBES Model with RANS Models for details.

- Subgrid-Scale Model

contains options for the subgrid-scale model used in the LES region of your Stress-Blended Eddy Simulation. This portion of the dialog box will appear only if SBES or SBES with User-Defined Function is selected as the Hybrid Model.

- Smagorinsky-Lilly

selects the Smagorinsky-Lilly subgrid-scale model described in Subgrid-Scale Models in the Theory Guide.

- Dynamic Smagorinsky

selects the Smagorinsky-Lilly subgrid-scale model (described in Subgrid-Scale Models in the Theory Guide) with the dynamic stress model enabled.

- WALE

selects the Wall-Adapting local Eddy-Viscosity model described in Wall-Adapting Local Eddy-Viscosity (WALE) Model in the Theory Guide.

- WMLES S-Omega

selects the algebraic Wall-Modeled LES

-

model described in Algebraic WMLES S-Omega Model Formulation in the Theory Guide.

- Update Interval k-omega

Sets the number of time steps between updates of the

-

part of the SBES model.

- Turbulence Damping Options

is a group box where you can enable Turbulence Damping to include the turbulence damping effects in multiphase simulations, which is required for better resolution of velocity gradients in the vicinity of fluid-fluid interface. When this option is enabled, you will need to specify Damping Factor (default = 10). This item is available for the VOF and Mixture models and for the Eulerian multiphase model with the Multi-Fluid VOF model selected. See Turbulence Damping for details.

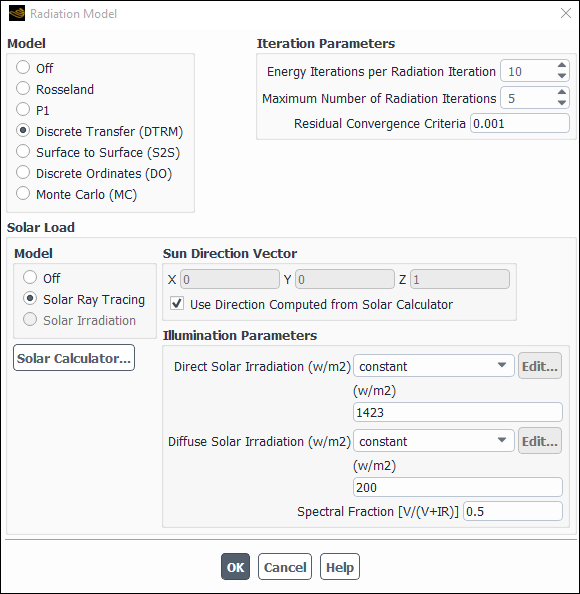

The Radiation Model dialog box allows you to select a model for radiation heat transfer and set the associated parameters. See Using the Radiation Models – Defining Non-Gray Radiation for the DO Model for details about the items below.

Controls

- Model

indicates which model, if any, is used to calculate radiation heat transfer. See Modeling Radiation for details about modeling radiation heat transfer.

- Off

disables the calculation of radiation heat transfer.

- Rosseland

enables the Rosseland radiation model.

- P1

enables the P-1 radiation model.

- Discrete Transfer (DTRM)

enables the discrete transfer radiation model (DTRM).

- Surface to Surface (S2S)

enables the surface-to-surface (S2S) radiation model.

- Discrete Ordinates (DO)

enables the discrete ordinates (DO) radiation model.

- Monte Carlo (MC)

enables the Monte Carlo (MC) radiation model.

- DO/Energy Coupling

allows you to couple the energy and DO intensity equations at each cell, solving them simultaneously. See Defining Non-Gray Radiation for the DO Model for details.

- Iteration Parameters

contains parameters related to the DTRM, S2S, and the DO models. This portion of the dialog box will appear only if Discrete Transfer (DTRM), Surface to Surface (S2S), or Discrete Ordinates (DO) is selected as the Model.

- Energy Iterations per Radiation Iteration

controls the frequency with which the radiation terms are updated as the continuous phase solution proceeds. The Energy Iterations per Radiation Iteration parameter is set to 10 by default. This implies that the radiation calculation is performed once every 10 iterations of the solution process. Increasing the number can speed the calculation process, but may slow overall convergence.

- Maximum Number of Radiation Iterations

controls the maximum number of iterations of the radiation calculation during each global iteration. The default setting of 5 means that the radiosity will be updated up to 5 times. The actual number of iterations will be less if the residual convergence criterion is exceeded at any point during these iterations.

This item appears only when Discrete Transfer or Surface to Surface is selected as the Model.

- Residual Convergence Criteria

determines when the radiation intensity update is converged. It is defined as the maximum normalized change in the surface intensity from one radiation iteration to the next (see Equation 16–4).

This item appears only when Discrete Transfer or Surface to Surface is selected as the Model.

- Target Number of Histories

determines the number of photon histories to be tracked for the Monte Carlo simulation. Too small of a number will produce "speckled" results. Increasing the target number of histories produces a smoother and more accurate solution, but at the expense of higher computation effort.

This item appears only when Monte Carlo is selected.

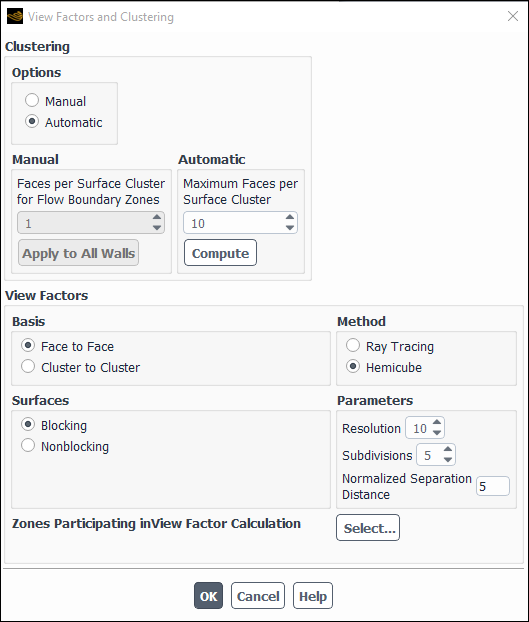

- View Factors and Clustering

contains parameters related to the S2S model. This portion of the dialog box will appear only if Surface to Surface is selected as the Model. See Setting Up the S2S Model for more information about the use of these parameters.

- Settings...

opens the View Factors and Clustering Dialog Box, in which you can set parameters related to surface clusters and view factors.

- Compute/Write/Read...

allows you to compute the view factors, write the computed view factors to a file, and read the file into Ansys Fluent. When you click Compute/Write/Read..., The Select File Dialog Box will open so that you can specify a name for the file where Ansys Fluent should save the view factors after computing them, and indicate whether the files should be saved in binary format.

- Read Existing File...

opens The Select File Dialog Box, in which you can specify the file from which Ansys Fluent should read view factors.

- Angular Discretization

contains parameters for angular discretization and pixelation for the DO model. This portion of the dialog box will appear only if Discrete Ordinates is selected as the Model. See Setting Up the DO Model for more information about the use of these parameters.

- Theta Divisions, Phi Divisions

define the number of control angles used to discretize each octant of the angular space (see Figure 5.3: Angular Coordinate System in the Theory Guide).

- Theta Pixels, Phi Pixels

are used to control the pixelation that accounts for any control volume overhang (see Figure 5.7: Pixelation of Control Angle in the Theory Guide and the figures and discussion preceding it).

- Radiation Mesh Options

This portion of the dialog box will appear only if the Monte Carlo model is selected.

- Target Cells Per Volume Cluster

Coarsens the radiation mesh used by the MC model. See Setting Up the MC Model for more information about the use of this parameter.

- Non-Gray Model

contains parameters related to the non-gray P-1, DO, or MC model. This portion of the dialog box will appear only if P1, Discrete Ordinates, or Monte Carlo is selected as the Model. See Setting Up the P-1 Model with Non-Gray Radiation, Defining Non-Gray Radiation for the DO Model, or Setting Up the MC Model for more information about the use of these parameters.

- Number of Bands

specifies the number of bands for the non-gray radiation.

- Wavelength Intervals (n=1)

contains inputs that define each wavelength band. (It appears only when the Number of Bands is nonzero.) For each band, you can specify a Name, as well as the Start and End wavelength of the band in

m. Note that the wavelength bands are specified for vacuum (

). Ansys Fluent will automatically account for the refractive index in setting band limits for media with

different from unity.

- Solar Load

contains parameters related to solar load model that can be used to calculate radiation effects from the sun’s rays that enter a computational domain. It is available only for the 3D version of Ansys Fluent. See Solar Load Model for more information about the use of these parameters.

- Model

indicates which model is used to calculate radiation effects.

- Off

disables the calculation of solar radiations.

- Solar Ray Tracing

enables the solar ray tracing algorithm

- DO Irradiation

enables the DO irradiation option. Select Discrete Ordinates under Model before selecting this option.

- Solar Calculator

opens the Solar Calculator Dialog Box.

- Sun Direction Vector

contains the components of sun direction vector.

- X, Y, Z

are the components of the sun direction vector.

- Use Direction Computed from Solar Calculator

enables the use of direction vector computed from the solar calculator.

- Illumination Parameters

contains illumination options.

- Direct Solar Irradiation

is the amount of energy per unit area due to direct solar irradiation.

- Diffuse Solar Irradiation

is the amount of energy per unit area due to diffuse solar irradiation.