Both the knock and the ignition delay models are treated similarly in Ansys Fluent, in that they share the same infrastructure. These models belong to the family of single equation autoignition models and use correlations to account for complex chemical kinetics. They differ from the eight step reaction models, such as Halstead’s “Shell” model [229], in that only a single transport equation is solved. The source term in the transport equation is typically not stiff, therefore making the equation relatively inexpensive to solve.

This approach is appropriate for large simulations where geometric accuracy is more important than fully resolved chemical kinetics. The model can be used on less resolved meshes to explore a range of designs quickly, and to obtain trends before utilizing more expensive and presumably more accurate chemical mechanisms in multidimensional simulations.

Autoignition is modeled using the transport equation for an

Ignition Species, ,

which is given by

(10–7) |

where is a “mass

fraction” of a passive species representing radicals that form

when the fuel in the domain breaks down.

is

the turbulent Schmidt number. The term

is

the source term for the ignition species, which has a form,

where corresponds

to the time at which fuel is introduced into the domain. The

term is a correlation of ignition delay with the

units of time. Ignition has occurred when the ignition species reaches

a value of 1 in the domain. It is assumed that all the radical species

represented by

diffuse at

the same rate as the mean flow.

Note that the source term for these radical species is treated differently for knock and ignition delay. Furthermore, the form of the correlation of ignition delay differs between the two models. Details of how the source term is treated are covered in the following sections.

When modeling knock or ignition delay, chemical energy in the fuel is released when the ignition species reaches a value of 1 in the domain. For the knock model, two correlations are built into Ansys Fluent. One is given by Douaud [147], while the other is a generalized model that reproduces several correlations, given by Heywood [242].

In order to model knock in a physically realistic manner, the

source term is accumulated under appropriate conditions in a cell.

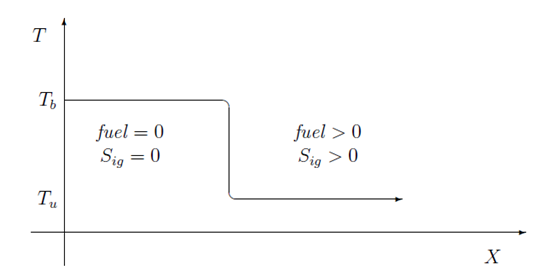

Consider the one dimensional flame in Figure 10.1: Flame Front Showing Accumulation of Source Terms for the Knock

Model. Here, the flame is

propagating from left to right, and the temperature is relatively

low in front of the flame and high behind the flame. In this figure, and

represent

the temperatures at the burned and unburned states, respectively.

The ignition species accumulates only when there is fuel. In the premixed

model, the fuel is defined as

, where

is the progress variable.

If the progress variable has a value of zero, the mixture is considered

unburned. If the progress variable is 1, then the mixture is considered

burned.

When the ignition species reaches a value of 1 in the domain, knock has occurred at that point. The value of the ignition species can exceed unity. In fact, values well above that can be obtained in a short time. The ignition species will continue to accumulate until there is no more fuel present.

An extensively tested correlation for knock in SI engines is given by Douaud and Eyzat [147]:

(10–8) |

where is the octane number of the fuel,

is the absolute pressure in atmospheres and

is the temperature in Kelvin.

A generalized expression for is also available that

can reproduce many existing Arrhenius correlations. The form of the

correlation is

(10–9) |

where is the pre-exponential (with units in seconds),

RPM is the engine speed in cycles per minute and

is the fuel/air equivalence

ratio.

Once ignition has occurred in the domain, the knock event is modeled by releasing the remaining fuel energy with a single-step Arrhenius reaction. An additional source term, which burns the remaining fuel in that cell, is added to the rate term in the premixed model. The reaction rate is given by

(10–10) |

where = 8.6×1011, and

= 15078 These values are chosen to reflect single-step reaction rates appropriate for propane as described in Amsden

[16]. The rate at which the fuel is consumed is limited such that a completely unburned cell will burn during three of the current time steps. Limiting the reaction rate is done purely for numerical stability.

When modeling ignition delay in diesel engines, chemical reactions are allowed to occur when the ignition species reaches a value of 1 in the domain. For the ignition delay model, two correlations are built into Ansys Fluent, one given by Hardenburg and Hase [235] and the other, a generalized model that reproduces several Arrhenius correlations from the literature.

If the ignition species is less than 1 when using the ignition delay model, the chemical source term is suppressed by not activating the combustion model at that particular time step; therefore, the energy release is delayed. This approach is reasonable if you have a good high-temperature chemical model, but do not want to solve for typically expensive low temperature chemistry.

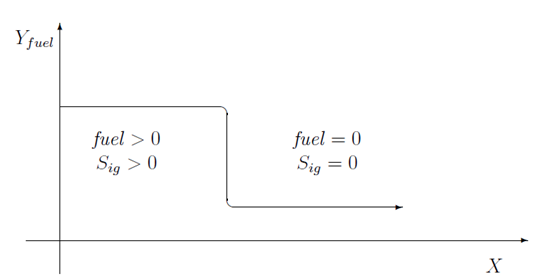

In order to model ignition in a physically realistic manner, the source term is accumulated under appropriate conditions in a cell. Consider the one dimensional spray in Figure 10.2: Propagating Fuel Cloud Showing Accumulation of Source Terms for the Ignition Delay Model.

Figure 10.2: Propagating Fuel Cloud Showing Accumulation of Source Terms for the Ignition Delay Model

Here, the spray is propagating from left to right and the fuel

mass fraction is relatively low in front of the spray and high behind

the spray. If there is no fuel in the cell, the model will set the

local source term to zero, nevertheless, the value of can be nonzero due to convection and diffusion.

If fuel is present in the cell, there are two built-in options in Ansys Fluent to calculate the local source term. The first correlation was done by Hardenburg and Hase and was developed at Daimler Chrysler for heavy duty diesel engines. The correlation works over a reasonably wide range of conditions and is given by

(10–11) |

where is in seconds,

is 0.36,

is engine speed in revolutions per minute,

is the effective

activation energy and

is the pressure exponent. The

expression for the effective activation energy is given by

(10–12) |

Table 10.1: Default Values of the Variables in the Hardenburg Correlation

| Variable |

| |

|

|

| Default | 618,840 | 25 | 0.36 | 0.63 |

The second correlation, which is the generalized correlation, is given by Equation 10–9 and is available for ignition delay calculations.

If the ignition species is greater than or equal to 1 anywhere in the domain, ignition has occurred and combustion is no longer delayed. The ignition species acts as a switch to turn on the volumetric reactions in the domain. Note that the ignition species “mass fraction” can exceed 1 in the domain, therefore, it is not truly a mass fraction, but rather a passive scalar that represents the integrated correlation as a function of time.