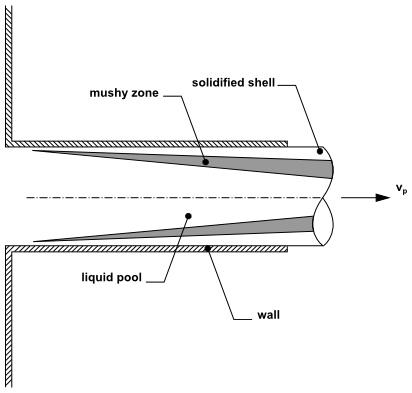

In continuous casting processes, the solidified matter is usually continuously pulled out from the computational domain, as shown in Figure 15.1: "Pulling" a Solid in Continuous Casting. Consequently, the solid material will have a finite velocity that must be accounted for in the enthalpy-porosity technique.

As mentioned in Momentum Equations, the enthalpy-porosity approach treats the solid-liquid mushy zone as a porous medium with porosity equal to the liquid fraction. A suitable sink term is added in the momentum equation to account for the pressure drop due to the porous structure of the mushy zone. For continuous casting applications, the relative velocity between the molten liquid and the solid is used in the momentum sink term (Equation 15–6) rather than the absolute velocity of the liquid.

The exact computation of the pull velocity for the solid material is dependent on Young’s modulus and Poisson’s ratio of the solid and the forces acting on it. Ansys Fluent uses a Laplacian equation to approximate the pull velocities in the solid region based on the velocities at the boundaries of the solidified region:

(15–22) |

Ansys Fluent uses the following boundary conditions when computing the pull velocities:

At a velocity inlet, a stationary wall, or a moving wall, the specified velocity is used.

At all other boundaries (including the liquid-solid interface between the liquid and solidified material), a zero-gradient velocity is used.

The pull velocities are computed only in the solid region.

Note that Ansys Fluent can also use a specified constant value or custom field function for the pull velocity, instead of computing it. See Procedures for Modeling Continuous Casting of the User's Guide for details.