This section describes how to use Ansys Fluent modeling capabilities based on the multi-scale multi-domain (MSMD) method. Only the procedural steps related to battery modeling are shown here. For information about inputs related to other models used in conjunction with the battery model, see the appropriate sections for those models in the Ansys Fluent Fluent User's Guide. For more details on the modeling approach, refer to Battery Model in the Fluent Theory Guide.

Information about using the model is presented in the following sections:

- 31.2.1. Limitations

- 31.2.2. Geometry Definition

- 31.2.3. Setting up the Battery Model

- 31.2.4. Using Parameter Estimation Tools

- 31.2.5. Initializing the Battery Model

- 31.2.6. Modifying Material Properties

- 31.2.7. Solution Controls for the MSMD Battery Model

- 31.2.8. Predefined Report Definitions for the Battery Model

- 31.2.9. Postprocessing the MSMD Battery Model

Note the following limitations when using the MSMD Battery model:

For battery pack simulations, all batteries in the pack must be identical initially, having the same battery type with the same initial conditions.

For battery pack simulations, all batteries in the pack must have the nPmS connection pattern; that is, n batteries connected in parallel, and then m such units connected in series.

A conductive zone must be continuous. Disconnected zones cannot be grouped as one entity.

System positive and negative tabs must be continuous surfaces. Disconnected faces cannot be grouped together as one entity.

The positive and negative tabs must be connected by either the real tab/busbar conductive volumes or the virtual connections defined through a file.

In the MSMD and Cell Network frameworks, the negative and positive current collectors, anode, and cathode are not resolved, and the battery is regarded as a homogeneous body. The computational mesh does not have to be adjusted to all layers present in the battery domain. The following zones have to be identified when creating the battery mesh:

Cell

Tab

Busbar (for battery pack cases with real battery connections)

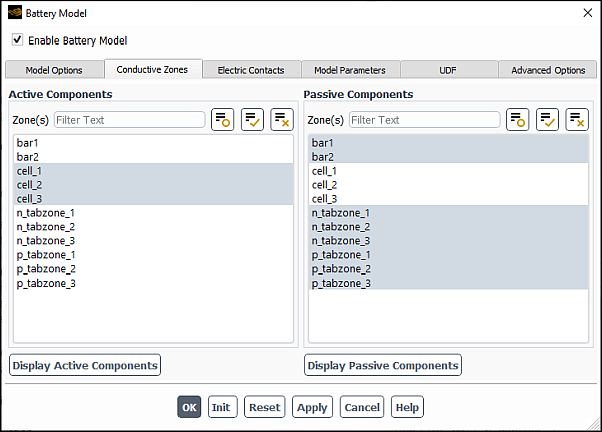

Electro-chemical reactions occur in cell zones, which are defined in the Active Components selection list in the Battery Model dialog box (Conductive Zones tab). Tab and busbar zones only conduct electric current and are defined in the Passive Components selection list. See Specifying Conductive Zones for details.

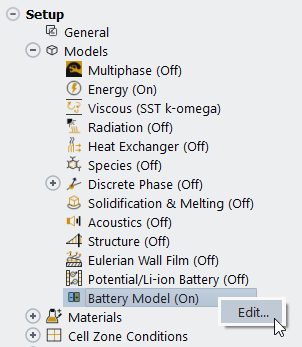

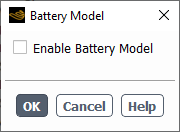

To enable the battery model, in the Outline View under the Models branch, right-click Battery Model and click Edit... in the menu that opens.

Setup → Models →

Battery Model

Edit...

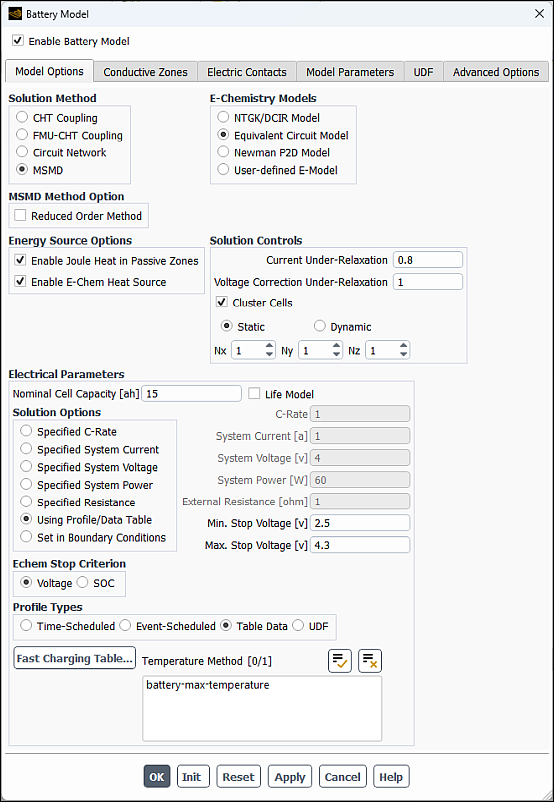

In the Battery Model dialog box that opens, select the Enable Battery Model check box to activate the model.

The Battery Model dialog box expands to reveal additional model options and solution controls.

The inputs for the battery model are entered using the following tabs:

- Model Options

contains the general model settings to define problems using the battery model.

- Conductive Zones

allows you to select zones for the active, tab and busbar components.

- Electric Contacts

allows you to define the contact surface and external connectors.

- Model Parameters

is where you specify the parameters to be used for solving the model equations.

- UDF

is where you can hook your user-defined functions.

- Advanced Options

allows you to quickly check the selected electrochemical submodel behavior in a standalone mode, and also to use various advanced modeling capabilities. See Specifying Advanced Options for more information.

Note: When setting up the model, you can click the Apply button to save your input values and your choices for your model. To restore the last saved settings for all tabs, click the Reset button.

For additional information, see the following sections:

- 31.2.3.1. Specifying Battery Model Options

- 31.2.3.2. Specifying Conductive Zones

- 31.2.3.3. Specifying Electric Contacts

- 31.2.3.4. Specifying Battery Model Parameters

- 31.2.3.5. Hooking User-Defined Functions

- 31.2.3.6. Specifying Advanced Options

- 31.2.3.7. Specifying External and Internal Short-Circuit Resistances

- 31.2.3.8. Setting a Battery Swelling Case

In the Model Options tab, you can select the electrochemical battery submodel and set various model options, solution controls, and electrical parameters.

Select the solution method.

For Solution Method, if you select:

CHT coupling: A uniform heat source will be distributed within each battery's active zone. You need to specify the heat source directly. None or one potential equation will be solved, depending on whether Joule heating in passive zones is included or not. See CHT Coupling Method in the Fluent Theory Guide for more information about this method.

FMU-CHT coupling: A uniform heat source will be distributed within each battery's active zone. The heat source is computed from the functional mockup unit (FMU). None or one potential equation will be solved, depending on whether Joule heating in passive zones is included or not. See FMU-CHT coupling method in the Fluent Theory Guide for more information about this method.

Circuit Network: A uniform heat source will be distributed within each battery's active zone, the heat source is computed from an electric circuit network in Fluent. None or one potential equation will be solved, depending on whether Joule heating in passive zones is included or not. See Circuit Network Solution Method in the Fluent Theory Guide for more information about this method.

MSMD: If the Reduced Order Method option is not enabled in the MSMD Method Option group box, two potential equations will be solved during each iteration in the simulation. See MSMD Solution Method in the Fluent Theory Guide for more information about this method.

If you want to obtain a faster solution, select Reduced Order Method in the MSMD Method Option group box. This will enable the solver to run faster using the reduced order method (ROM). You can use this option if the two conditions listed in Reduced Order Solution Method (ROM) are met. Note that, prior to using the ROM, you must first run a simulation without this option for at least three time steps. Ansys Fluent will use these results as reference potential fields for the ROM method.

If you have selected Circuit Network or Reduced Order Method, set Number of Sub-Steps/Time Step. Using this value, you can specify the ratio of the time steps for thermal and electro-chemistry calculations. For example, if the Number of Sub-Steps/Time Step is set to

10, the solver will use one tenth of the CFD time step for the electro-chemistry calculation.Important: The internal short circuit treatment requires two potential equations to be solved. For this reason, it can only be used with the MSMD solution method, but not with the ROM method.

Select the electrochemistry model. The following submodels are available in Ansys Fluent under the E-Chemistry Models group box:

- NTGK/DCIR Model

is an empirical model. This is the simplest and the least expensive model. It also requires the fewest model inputs. The model uses the same NTGK method as that used by the Single-Potential Empirical model. However, in this case, it solves two potential equations continuously instead of one potential equation with a jump condition at the separator over all conductive zones. The model cannot accurately capture the battery's dynamic (inertial) response.

- Equivalent Circuit Model

is a semi-empirical model. It has limited capability for predicting the battery dynamic behavior.

- Newman P2D Model

is the most comprehensive physics-based battery model. It is computationally expensive, and it requires extensive user input of battery-related fundamental information.

- User-defined E-Model

is the user-specified electrochemical submodel. To be able to use this option in the Fluent MSMD method framework, you must provide the

void user_defined_echem_model()function in the customizablecae_user.csource code file.

Optionally, you can enable the following Energy Source Options:

Enable Joule Heat in Passive Zones (default) in order to include the Joule heating source in the thermal energy Equation 19–3 in the battery passive conducting zones, including tabs and busbars,

Enable Joule Heat in Active Zones (default) in order to include the Joule Heating source in the thermal energy equation Equation 19–3.

Enable E-Chem Heat Source (default) in order to include the heat source due to electrochemistry in the thermal energy equation Equation 19–3.

Specify the following settings in the Solution Controls group box:

Set Current Under-Relaxation Factor. The volumetric current density used in the two potential equations are under-relaxed according to this factor. The default value of

0.8may be sufficient for most cases. The values in the range of 0.8–1.0 are recommended.Set Voltage Correction Under-Relaxation Factor. The default value of 1.0 is acceptable for most cases. You should reduce this value only if the convergence difficulty occurs during the solution of the potential equations.

(Equivalent Circuit Model and Newman P2D Model) Select the Cluster Cells check box to enable cell clustering and then define it using one of the following methods:

Static

When you select Static, you can specify the number of clusters Nx , Ny , and Nz in X, Y, and Z directions respectively. The solver will divide the active zone of every battery cell into Nx x Ny x Nz clusters and solve the electrochemical sub-model in each cluster using the cluster-averaging information.

The static clustering method is purely geometry-based. Clusters are formed before a simulation is run and they remain fixed in the simulation.

The default values for Nx , Ny , and Nz are 1, 1, and 1, respectively. For the initial run, the default settings are recommended.

Dynamic

When you select Dynamic, you can define the Number of Clusters and specify the Target Variable, which could be voltage or temperature. You can also define your own target variable by writing a

DEFINE_BATTERY_CLUSTERUDF. SeeDEFINE_BATTERY_CLUSTERin the Fluent Customization Manual for details.The dynamic clustering is done before the beginning of every time step and the clusters are formed dynamically during the simulation. The solver finds the range of the target variable in the active zone of a battery cell, and then divide this range into the specified number of clusters. Each control volume in the battery cell is grouped into a cluster according to its target variable value.

In the Electrical Parameters group box, specify the following operating conditions:

Set the Nominal Cell Capacity (the capacity of the battery cell).

If you want to model the battery capacity changes over time and over repeated discharging and charging cycles, enable the Life Model option and then set up the life model as described in Setting the Life Model.

For the Solution Options, you can:

Select Specified C-Rate and then specify C-Rate, which is the hourly rate at which a battery is discharged. A positive value means discharging C-rate and a negative value means charging C-rate. In this case, the total current at the cathode tabs is fixed as the product of C-Rate and Nominal Capacity, while the electrical potential is anchored at zero on the anode tabs. Note that the computation of current from the C-rate is always based only on the single battery's nominal capacity and does not account for the battery's connection information. For example, in a 2P2S module case, if you want to completely drain the fully charged module in one hour, you need to set the C-rate to 2.

Select Specified System Current and then specify System Current applied at the cathode tabs. A positive value means discharging current and a negative value means charging current.

Select Specified System Voltage and then specify System Voltage applied to the cathode tab. The anode tab has a voltage of 0 V.

Select Specified System Power and then specify System Power. If you specify the total power output from your battery, the Fluent solver will ensure that the product of the system current and voltage equals the system power. A positive value means discharging power output and a negative value means charging power input.

Select Specified Resistance and then specify External Resistance in an external short-circuit simulation. If you specify the external electric resistance in Ohm, the Fluent solver will ensure that the ratio of the system voltage to the system current equals the specified external resistance.

Select Set in Boundary Conditions and then set the UDS boundary conditions directly, for example, the voltage value or the current value (specified flux), using the Boundary Conditions task page in Ansys Fluent for the specific face zone.

Select Using Profile/Data Table and then specify a profile or data table as described in Specifying a Profile or Data Table.

For Echem Stop Criterion, you can:

Select the Voltage method and specify Min Stop Voltage and Max Stop Voltage, or

Select the SOC method and specify Min Stop SOC and Max Stop SOC.

In a battery simulation, the stop criterion is checked after every time step. For the voltage method, battery's cell voltage is checked against the minimum and maximum stop voltage. For the SOC method, the SOC level in a battery is checked. Once the stop criterion is met, the simulation stops automatically.

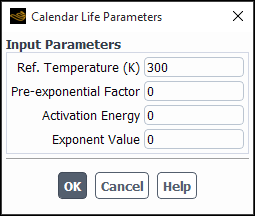

If you have selected the Life Model option (Electrical Parameters group box), you must specify the following life model parameters:

- Calender Time

is the storage time (

in Equation 19–45 in the Fluent Theory Guide). You can use any units that are consistent with the kinetics quantities you specify in the Calendar Life Parameters dialog box (see Figure 31.3: The Calendar Life Parameters Dialog Box).

- Cycle Number

is the number of cycles that the battery has experienced so far (

in Equation 19–46 in the Fluent Theory Guide).

- Operation Temperature

is the average temperature to which the battery has been exposed over time and over its previous discharging/charging cycle (

in Equation 19–45 and Equation 19–46 in the Fluent Theory Guide). Note that this temperature is not the same as the battery temperature during CFD simulations.

- Calendar Life Parameters

are the calendar-life-related parameters that can be specified in the Calendar Life Parameters dialog box that opens when you click the button.

The following Input Parameters are available:

Ref. Temperature: Is the reference temperature under which these kinetics parameters are obtained (

in Equation 19–45 in the Fluent Theory Guide).

Pre-exponential Factor: Is

in Equation 19–45 in the Fluent Theory Guide.

Activation Energy: Is

in Equation 19–45 in the Fluent Theory Guide).

Exponent Value: Is the time exponent factor (

in Equation 19–45 in the Fluent Theory Guide).

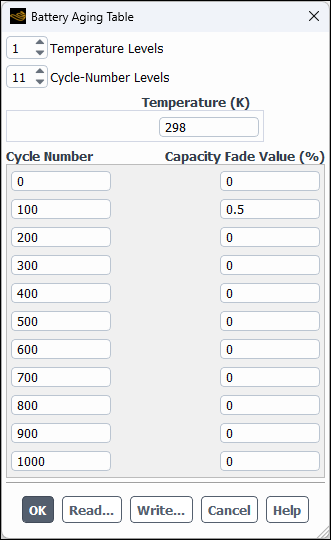

- Battery Aging Table

is a 2D lookup table for capacity fade factors at different temperatures and cycle numbers. All values are entered in the Battery Aging Table dialog box that opens by clicking the button (for example Figure 31.3: The Calendar Life Parameters Dialog Box).

For the NTGK model, you can specify the following inputs in the Battery Aging Table dialog box:

Temperature Levels

Cycle-Number Levels

Values of Temperature

Values of Cycle-Number

Capacity fade values for each cycle-temperature pair

You can specify up to 20 Temperature Levels and Cycle-Number Levels.

You can use the Write... button to store the 2D lookup table to a file in a text format, which you can use later by clicking the Read... button and using the Select File dialog box that opens. You can also generate your own 2D lookup text file and read it into Ansys Fluent. Both the compact scheme and the plain text format can be used when reading or writing a table from/to a file. Refer to Using Tables in the Battery Model for more information about these table formats. The capacity fade values will be automatically populated in the Battery Aging Table dialog box.

If you have select Using Profile/Data Table (Solution Options group box), you can use one of the following options in the Profile Types group box:

Time-Scheduled

Event-Scheduled

Table Data

This option can be used to specify a fast charging electric current profile as a 2D lookup table. Further details are provided below.

UDF

You can use the UDF option to define the electric load type and value using a

DEFINE_BATTERY_ELOAD_PROFILEUDF. The UDF option is used if the time-scheduled and event-scheduled profile cannot cover the profile you want to use. SeeDEFINE_BATTERY_ELOAD_PROFILEin the Fluent Customization Manual for information aboutDEFINE_BATTERY_ELOAD_PROFILE.

For the Time-Scheduled or Event-Scheduled options, you must provide time-dependent or event-dependent input (respectively) for the C-rate, current, voltage, or power. The time-scheduled and event-scheduled profiles enable you to change the electric load type and electric value in the simulation on the fly. When either the Time-Scheduled or Event-Scheduled profile type is selected, you can browse to the ASCII text file with either the .dat or .txt file extension that you generated beforehand. The inputs for the Time-Scheduled and Event-Scheduled profiles are described below.

Time-Scheduled Profile Specification

The Time-Scheduled profile file must be organized in three columns:

Time

Electric load value

Electric load type

The electric load type is defined by an integer number:

0: C-rate1: Current2: Voltage3: Power4: External electric resistance

For example, the below time-scheduled profile:

0 15 1 500 15 1 500.1 60 3 1000 60 3 1000.1 -1 0 1500 -1 0

specifies the following battery charging scenario:

The battery is discharged at 15 A for the first 500 seconds.

The battery discharge continues at 60 W for the next 500 seconds.

The battery is charged at a constant 1 C-rate for the last 500 seconds.

Note:

For current, power, or C-rate, a positive value means discharging and a negative value means charging.

The unit of the variables in the input file is always SI.

Ansys Fluent solver uses linear interpolation of your time-scheduled profile data in the problem simulation. If you want to capture a sudden change in the profile accurately, use smaller time gaps to describe the profile.

Event-Scheduled Profile Specification

The Event-Scheduled profile file must be organized in the following five columns:

Electric load type

Just as in the time-scheduled profile, the electric load type is defined by an integer number:

0: C-rate1: Current2: Voltage3: Power4: External electric resistanceElectric load value

Forwarding condition

The forwarding condition (FC) is defined by an integer number:

1: Time > FC_Value2: I < FC_Value (discharging current minimum)3: I > FC_Value (charging current maximum)4: V < FC_Value (system voltage minimum)5: V > FC_Value (system voltage maximum)6: P < FC_Value (discharging power minimum)7: P > FC_Value (charging power maximum)8: Time Duration > FC_Value (Time Duration)Forwarding condition value

Stop flag

The stop flag is an integer value of 0 or 1, where 0 specifies that the run should continue to the next event entry line, and 1 specifies that the run should end.

For example, the below event-scheduled profile:

0 1 4 3.5 0 0 0 8 300 0 1 -15 5 4.1 0 2 4.1 3 -1 1

specifies the following scenario:

The battery is discharged at 1 C rate until the voltage reaches 3.5 V.

The battery is at rest for 300 seconds.

The battery is charged at constant current 15 A until the voltage reaches 4.1 V.

The battery keeps charging at 4.1 V until the current is greater -1 A. The simulation stops after reaching this point.

Note:

For current, power, or C-rate, a positive value means discharging and a negative value means charging.

The unit of the variables in the input file is always SI.

Any time-scheduled profile can be rewritten in an event-scheduled profile format, but not vice-versa. The example shown in the time-scheduled profile can be redefined in an event-scheduled profile format as follows.

1 15 1 500 0 3 60 1 1000 0 0 -1 1 1500 1

Both profile types can be read into Ansys Fluent. You can choose the most convenient one to use in your specific application.

Table Data Specification

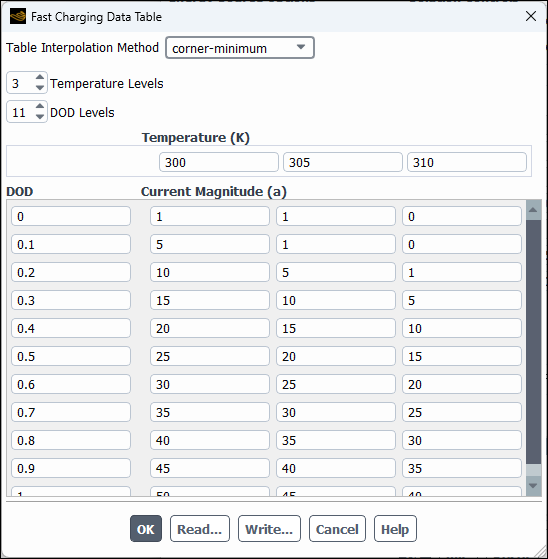

The fast charging 2D lookup table defines the charging current as a function of battery's average DOD and temperature. To use this specification method follow the steps below:

Create one or more report definitions of temperature.

In the Temperature Method list, select the report definition(s) to be used in the lookup table.

The lookup table will be searched for all selected temperature definitions, and the minimum value will be used as the charging current.

Click

In the Fast Charging Data Table dialog box that opens, specify the following inputs.

Select the Table Interpolation Method from the following options:

bilinear

The bilinear interpolation method is used to find charging current value given a DOD and a temperature value.

staircase-floor

For a given temperature, the current changes as a staircase and the lower DOD value is used. Linear interpolation is used for temperature.

staircase-ceiling

The DOD ceiling value is used. Linear interpolation is used for temperature.

corner minimum

The lowest conner value is used from the lookup table.

The interpolated value for charging current are different for different methods. The example below shows the charging current data for two temperature levels of and two DOD levels.

T=300 K T=310 K DOD=0.2 10 5 DOD=0.3 20 10 The interpolated value of charging current for T=305K and DOD=0.25 will be:

Bilinear: Charging Current = ((20+10)/2+(5+10)/2)/2= 11.25

Staircase-floor: Charging Current = (10+5)/2 =7.5

Staircase-ceiling: Charging Current = (20+10)/2 = 15

Corner-minimum: Charging Current = 5

Enter values for the following table parameters:

Temperature Levels

DOD Levels

Values of Temperature

Values of DOD

values of Current Magnitude for each DOD level and temperature

2D and 3D lookup tables are used in the battery model to specify various quantities as tabular functions of other solution variables when the tabular input option is available. Lookup tables are tab- or space-delimited ASCII text files that support the following formats:

Plain text format (files with extension .txt)

A 2D table must contain the following entries:

Row 1 – Header keyword “

x-values”Row 2 - x-value points

Row 3 – Header keyword “

y-values”Row 4 - y-values points

Row 5 – Header keyword “

table-values”Row 6 and all consecutive rows - table input data

An example of the 2D table for capacity fade factors at two temperature levels and three cycles-number levels is shown below:

x-values 300 310 y-values 0 100 200 table-values 0 0 0.1 0.15 0.2 0.25A 3D table is used only for specifying internal resistance data. For each electric current level, a 2D table of resistance values at different temperature and DOD levels must be provided. The table must include the following data:

Keyword “

z-value” followed by a current value at the first electric current level2D table for the first electric current level. see the description above of 2D tables

Keyword “

z-value” followed by a current value at the second electric current level2D table for the second electric current level

Etc.

An example of the 3D table is shown below:

z-value -10 x-values 300 310 y-values 0 0.5 1.0 table-values 111 112 121 122 131 132 z-value 0 x-values 300 310 y-values 0 0.5 1.0 table-values 211 212 221 222 231 232 z-value 10 x-values 300 310 y-values 0 0.5 1.0 table-values 311 312 321 322 331 332Compact scheme format (files with extension other than .txt, for example .tab)

In this format, each data group is enclosed in parentheses, and the input values within each group are separated by spaces and/or tabs.

In the following example, the same 2D table for capacity fade factors shown above is written in the compact format:

((300 310) (0 100 200) ((0 0) (0.1 0.15) ( 0.2 0.25)))

The first group of numbers

(300 310)contains x-value points, which are the temperature levels. The second group of numbers(1 100 200)contains y-value points, which are the cycle numbers. The third group contains table entry values where each sub-group in parentheses represents a row of data in the table.The 3D table containing internal resistance data shown in the example above can be written in the compact format as follows:

((-10 0 10) (((300 310) (0 0.5 1.0) ((112 112) (121 122) (131 132))) ((300 310) (0 0.5 1.0) ((212 212) (221 222) (231 232))) ((300 310) (0 0.5 1.0) ((312 312) (321 322) (331 332)))) 0)The first group of data

(-10 0 10)contains three electric current values. The second group includes three 2D lookup tables for the three electrical current levels. In each 2D table, the temperature array is listed first, followed by the DOD array and then by the resistance values for each temperature-DOD pair. The last digit in the list indicates the interpolation method.0denotes the bilinear interpolation, which must always be used for this particular table.

Usually if you transfer table data from one simulation to another, you can use the compact scheme format. If you prepare table data manually through a file, the plain text format is more readable and may be a better choice.

The Conductive Zones tab of the Battery Model dialog box allows you to specify the active, tab, and busbar zones.

In the Conductive Zones tab, select the appropriate zones for the Active Components and Passive Components. Passive components include battery tab zones and busbars used to connect tabs of different batteries. You can visualize all active or passive zones by using the Display Active Components or Display Passive Components button, respectively. This opens the Mesh Display dialog box where all relevant components are selected automatically.

Battery cells are modeled as active zones; and battery tabs and busbars are modeled as passive zones. Electrochemical reactions occur only in the active zones. The potential field is solved in both active and passive zones.

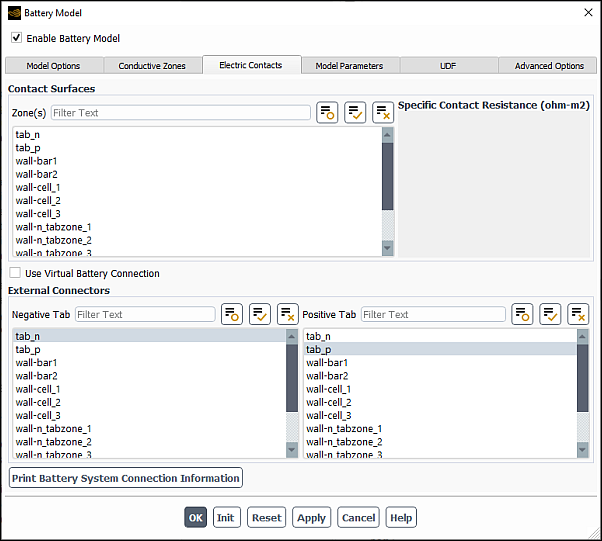

The Electric Contacts tab of the Battery Model dialog box allows you to set the properties of the Contact Surfaces and the External Connectors.

If you want to consider contact resistance, select zones for the Contact Surfaces and set the Specific Contact Resistance for any selected contact surface.

When using real connections, define the system negative and positive tabs under External Connectors.

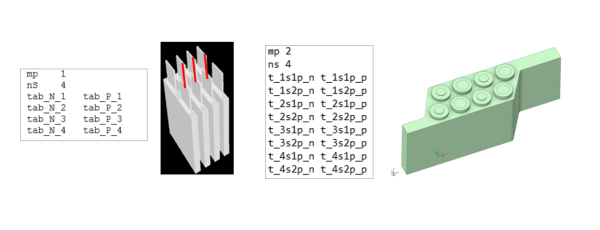

When using the virtual connection option in a battery pack simulation, select the Use Virtual Battery Connection check box and in the Specify connection file text-entry box that appears, enter the filename containing the virtual connection definition.

The following input formats can be used:

tab surface-based format

active zone volume-based format

The tab surface-based format for the connection definition file is as follows:

mP 2 nS 2 tab_N_1P1S tab_P_1P1S tab_N_2P1S tab_P_2P1S tab_N_1P2S tab_P_1P2S tab_N_2P2S tab_P_2P2S

where:

The first line specifies the number of parallel batteries in a stage (mP).

The second line specifies the number of stages in series in a pack (nS).

The remaining lines contain pairs of the face names of the negative and positive tabs for each battery. The battery data are listed in the following order: 1P1S ... mP1S to 1PnS ... mPnS.

For the above battery connection file example, the battery solver establishes the 2P2S connection pattern.

The following figure shows the different resulting connection patterns for the different connection data.

Once all conductive zones and the positive and negative tabs have been defined, Ansys Fluent automatically detects the battery network connection.

The active zone volume-based format for the connection definition is as follows:

mP 1 nS 4 cell_1 cell_2 cell_3 cell_4

where:

The first line specifies the number of parallel batteries in a stage (mP).

The second line specifies the number of stages in series in a pack (nS).

The remaining lines contain the names of the active battery zones in the order of: 1P1S ... 1PnS to mP1S ... mPnS.

You should use one line only for each battery. If a battery active zone includes multiple cell volumes, list all of them in one line separated by space, for example:

mP 1 nS 4 cell_1_a cell_1_b cell_1_c cell_2 cell_3_a cell_3_b cell_3_c cell_4

Note: The active zone volume-based connection file can only be used for cases that involve the Circuit Network solution method without the Joule heating effects. This is because the electric current flow passage is not determined in a battery pack. Consequently, the potential field, and therefore the Joule heating effect, cannot be solved.

When you import either format of the connection file, Ansys Fluent automatically detects the type of the format. If the active zone volume-based format is used, the solver enables the Circuit Network solution method and disables the Joule heating effects. The zones in the active and passive components listed under the Conductive Zones tab are updated automatically according to the information provided in the connection file.

After you have defined all the conductive zones or modified zone related data, click Print Battery System Connection Information, and review the battery connection information printed in the Ansys Fluent console window for any errors. If necessary, re-define the connections in the Conductive Zones and Electric Contacts tabs.

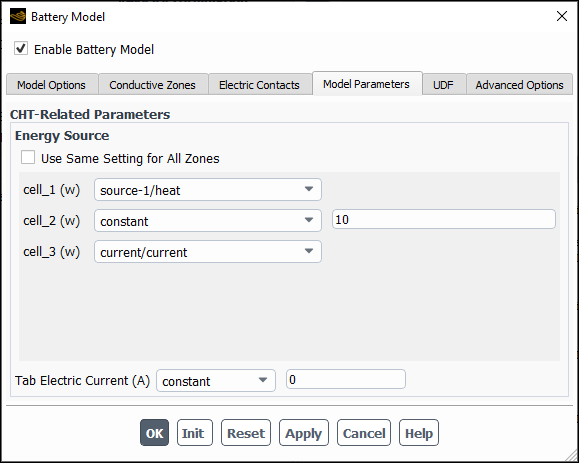

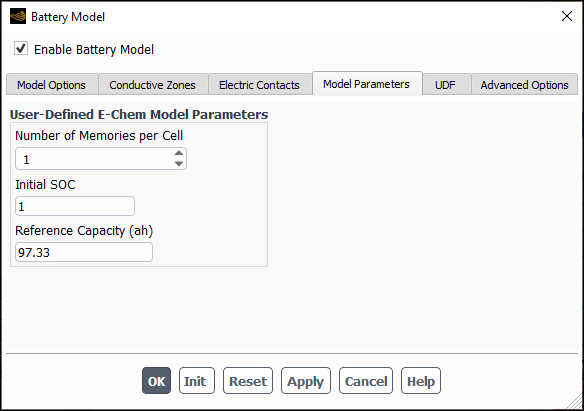

The Model Parameters tab of the Battery Model dialog box allows you to specify the submodel-specific parameters. The Model Parameters tab contains only the entry fields for parameters related to either the solution method or electrochemical submodels you have chosen in the Model Option tab. A detailed description of inputs for each submodel is given in the sections that follow.

You need to specify the following CHT-Related Parameters:

total Energy Source for each battery active zone

(if you want to consider the Joule heating in passive zones) Tab Electric Current

For both heat source and tab electric current, you can use either constant data type or any of the imported transient profiles.

If constant is selected, you need to specify a value in the adjacent field.

To use transient profiles for energy sources, you first need to read all profile files into your simulation as outlined in Reading Profile Files. Once the profiles have been imported into your analysis, their names automatically appear in the drop-down lists for each active zone and for tab electric current. The profile file format conforms to the Ansys Fluent built-in transient profiles described in Transient Cell Zone and Boundary Conditions. The below example shows the file format of a tabular transient profile (.ttab).

energy-source 2 4 0 time energy-source 0 5.0 100 5.0 100.1 10.0 10000 10.0

In this example, the first line contains the profile name, followed by the number of fields, the number of lines, and the flag indicating whether the profile is periodic.

The second line contains all the field names. One of the field names must be

time for the profile to be correctly recognized.

The remaining rows contain the profile data.

All the imported profiles will be saved within the Ansys Fluent case file.

If in a pack simulation, the same heat source is used for all active zones, you can select Use Same Settings for All Zones and define only one set of data. Ansys Fluent will automatically update all zones with the same cell information.

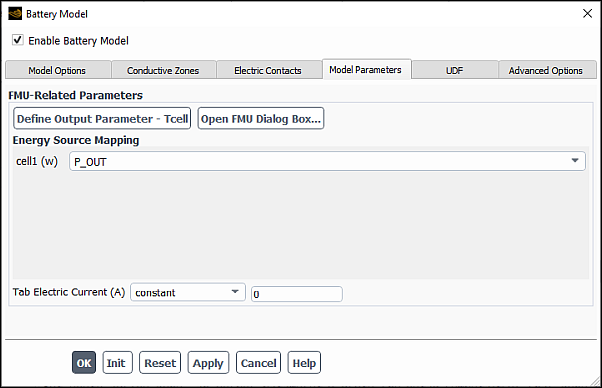

In the FMU-Related Parameters group box, click the Define Output Parameter- Tcell button.

Fluent creates an output parameter, the average zone temperature, for each active zone.

Click Open FMU Dialog Box... and then use the cell average temperatures that have been generated in the previous step to define the FMU input parameters in the Parameters dialog box. Refer to Coupled Simulations in Ansys Fluent with Functional Mock-up Unit (FMU) Files for details on the FMU file importing procedure.

Once the FMU file importing is complete, you can define the following parameters:

For each battery active zone, under Energy Source Mapping, select an appropriate FMU output parameters that have been imported in the previous step to be an energy source term.

If the Joule heating is considered, specify Tab Electric Current. Similar to the CHT Coupling solution method, you can choose either constant or any of the imported transient profile. See Inputs for the CHT Coupling Method for more information.

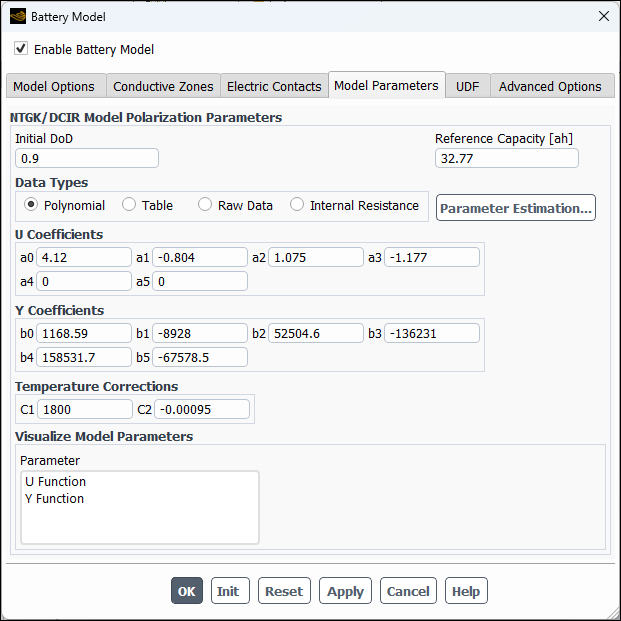

For the NTGK/DCIR Model, define the following operating conditions:

Specify the following NTGK model parameters:

Initial DoD: Is the battery initial DOD at

=0. The default value of

0for Initial DoD indicates the fully-charged state of the battery cell.Reference Capacity: Is the capacity of the battery that is used in experiments to obtain the model parameters (

in Equation 19–5). Nominal and reference capacities may have different values.

Specify

and

model parameters in Equation 19–7 using one of the following:

Polynomial data type

Table data type

Raw Data data type

Parameter Estimation tool

or directly define the battery internal resistance by using the Internal Resistance data type.

If you selected Polynomial in the Data Types group box, enter polynomial coefficients for

,

, and temperature correction in Equation 19–7 directly in the U Coefficients and Y Coefficients group boxes.

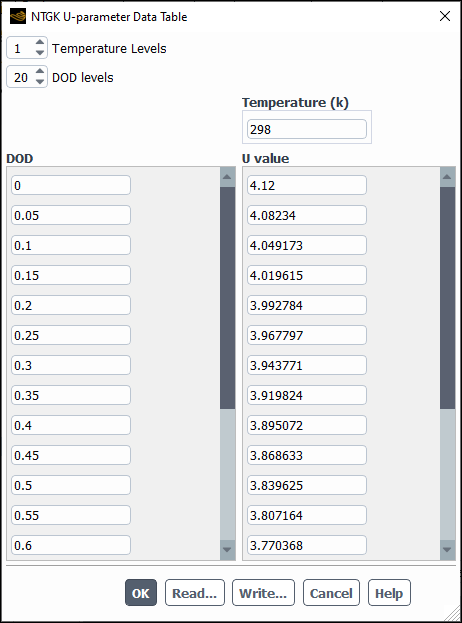

If you selected Table in the Data Types group box, define a 2D lookup table for each NTGK model parameter.

Tabular data are entered in the corresponding parameter data table dialog box that opens by clicking the relevant button (U Table... or Y Table...) in the NTGK Parameter Data Table group box (see Figure 31.11: NTGK U-parameter Data Table Dialog Box).

For each NTGK model parameter, you can specify up to 50 DOD levels and 20 temperature levels. For each DOD-temperature pair, you must enter the corresponding model parameter value. Each table can be exported to or imported from a file by clicking Write or Read, respectively, in the parameter data table dialog box. Both the compact scheme and the plain text format can be used when reading or writing a table from/to a file. Refer to Using Tables in the Battery Model for more information about these table formats.

Note: The model parameters for the NTGK Model Polarization Parameters are based on battery cell polarization test curves. Obtaining model parameters (other than the default values) can be dependant on your battery configuration and material properties. The default values are taken from Kim’s paper 313. If you model a battery having a different design, you must provide a different set of battery parameters.

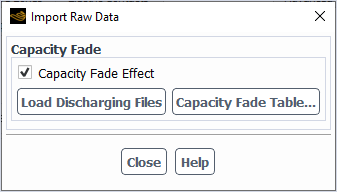

If you selected Raw Data in the Data Types group box, you need to import a set of testing data (discharging curves under different temperature and C-rate) by clicking the button.

In the Import Raw Data dialog box that opens, you can import testing data files by clicking the button and then using the Select File dialog box to read the files into your Fluent case.

If you want to include the capacity fade effect into your simulation, enable Capacity Fade Effect. After you import the testing data, the capacity fade table is populated automatically. You can review the table by clicking Capacity Fade Table..., but you cannot modify it.

Each capacity fade factor in the capacity fade table is computed from the test data as:

After you import test data files, no other information is needed. The Ansys Fluent solver stores the

U~Irelationship from the test data and will use it during the battery simulation.Note: The raw data treatment depends on whether the capacity fade effect is included or not. If you enable or disable the Capacity Fade Effect option, you need to load the data files again to re-process it.

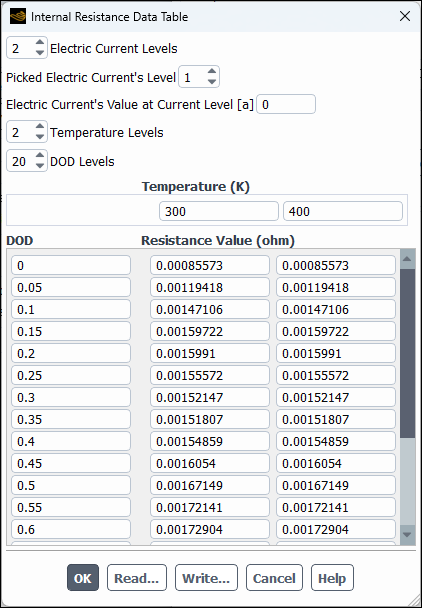

If you selected Internal Resistance in the Data Types group box, you need to define the internal resistance table and specify other parameters in the DCIR Method Settings group box.

Click the button.

In the dialog box that opens, enter the table data.

Specify the number of Electric Current Levels.

Set the Selected Current Level for which you want to define internal resistance points.

Enter a value for the Current for the selected current level.

Specify values for the following table parameters:

Temperature Levels

DOD Levels

Values of Temperature

Values of DOD

Values of Current Magnitude for each DOD level and temperature

A positive value means discharging current and a negative value means charging current. In this way, you can use different internal resistance when simulating charging and discharging.

Repeat steps 2 through 4 for each current level.

You can write a table data into a file or fill the table by importing data from a file. Both the compact scheme and the plain text format can be used when reading or writing a table from/to a file. Refer to Using Tables in the Battery Model for more information.

If you want to include the open circuit potential, enable U Table, click the U Table... button, and in the NTGK Parameter Data Table dialog box that opens (see Figure 31.11: NTGK U-parameter Data Table Dialog Box), enter U values for each DOD-temperature pair.

Note: If the U-table is not provided, you can use only either the current or C-rate electrical load condition. In addition, only single battery or pure serial battery connection can be simulated.

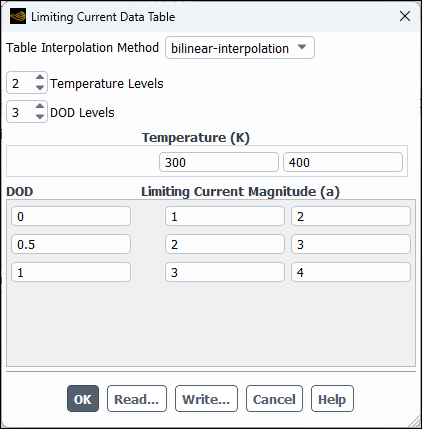

(cases with no fast charging) If you want to limit current in your simulation, perform the following steps:

Enable Limiting Current.

In the Temperature Method list, select the report definition(s) to be used in the lookup table.

Click the Current Limiting Table... button.

In the Limiting Current Data Table dialog box that opens, specify a 3D table of the limiting current values.

The inputs are similar to those in the Fast Charging Data Table dialog box described in Specifying a Profile or Data Table.

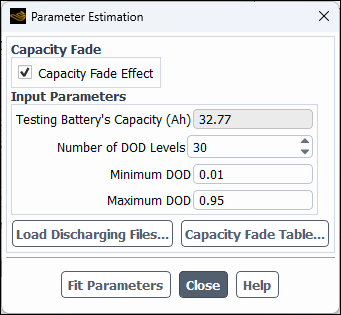

If you want to use the parameter estimation tool to fit

and

from testing data, click the Parameter Estimation... button.

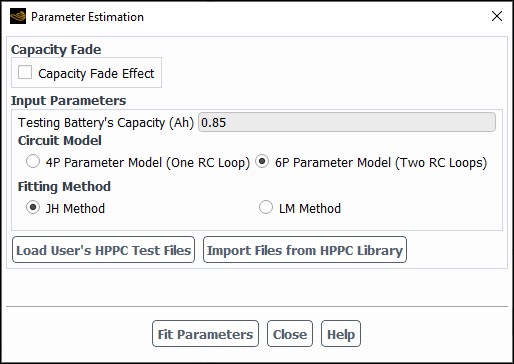

In the Parameter Estimation dialog box that opens, you need to specify the following Input Parameters:

Testing Battery's Capacity

This value is copied from the Reference Capacity (Model Parameters tab). You need to verify it is correct; otherwise, go back to the Model Parameters tab to modify it.

Number of DOD Levels

The number of DOD levels is a number between 10 and 20. The default 20 is a good choice for all cases. The required discharging data are battery's discharging curves at different constant C-rates. You can use testing data at different temperatures. For each C-rate, you must provide a separate file in text format. At least two input files with data at different C-rates are required to get meaningful fitting results.

Minimum DOD: Minimum battery's DOD level used in the fitting. The default value is 0.01, which is suitable for most cases.

Maximum DOD: Maximum battery's DOD level used in the fitting. The default value is 0.95, which is suitable for most cases.

Corresponding discharging data (as further described)

If you want to consider the capacity fade effect in your simulation, enable Capacity Fade Effect.

After the parameter fitting process is complete, the capacity fade table is populated automatically. You can review the table by clicking Capacity Fade Table..., but you cannot modify it. The fitting results (

and

parameters) are dependent upon whether the capacity fade effect is considered or not. If you have modified the state of Capacity Fade Effect, you need to re-fit the model parameters.

To import all the testing files, click the Load Discharging Files button and use the Select File dialog box that opens to read multiple testing data files. The selected testing files will be listed at the bottom of the Select File dialog box. If you accidentally select the wrong file, you can use the Remove button to remove it from the selected testing file list.

An example of an input file is shown below.

Crate 1.0 Temperature 300.0 1.0000e+00 4.1097e+00 2.0000e+00 4.1094e+00 3.0000e+00 4.1092e+00 ... 3.6000e+01 4.1010e+00 ...

The first line of the file starts with

Cratefollowed by a C-rate value separated by a space. The second line starts withTemperaturefollowed by a value. The lines that follow contain pairs of space-separated time-voltage values.After testing files are imported, click the Fit Parameters button to run the NTGK parameter estimation tool.

If you provide testing data files at different temperatures, the parameter estimation tool will perform the fitting for each temperature level. Ansys Fluent will report the fitted results in the console and automatically pass them in a table data type to the parameter data table dialog boxes. The Table data type will be automatically selected in the Battery Model dialog box. This will allow you to consider the temperature-dependent effect.

If you use testing data from only one temperature level, the fitting results in both polynomial and table data types will be filled in the Battery Model dialog box. In this case, the Polynomial data type is the default data type. However, you can use either data type in your simulation.

(optional) Visualize and check the resulting fitted curves of the battery discharge data at different temperatures and C-rates to detect any issues with the fitting process.

Once the fitting is complete, the Parameter Estimation dialog box expands to reveal the Visualize Fitting Results group box containing the Temperature and C rate selection lists. You can display curves of the fitted discharge data and the experimental data from your input files at different temperatures and C-rates by selecting a pair of desired values from the Temperature and C rate lists. The corresponding curves will be automatically plotted in the graphics window.

Click Close in the Parameter Estimation dialog box.

Note: The NTGK parameter estimation tool can also be accessed through the text user interface (TUI) as described in Using the Parameter Estimation Tool for the NTGK Model in the TUI.

(Polynomial or Table data type only) You can visualize the resulting

and

parameters varying with DOD by selecting U Function or Y Function from the Parameter list (Visualize Model Parameters group box) and clicking the Plot button. The resulting curves at temperatures you provided will be plotted in the graphics window.

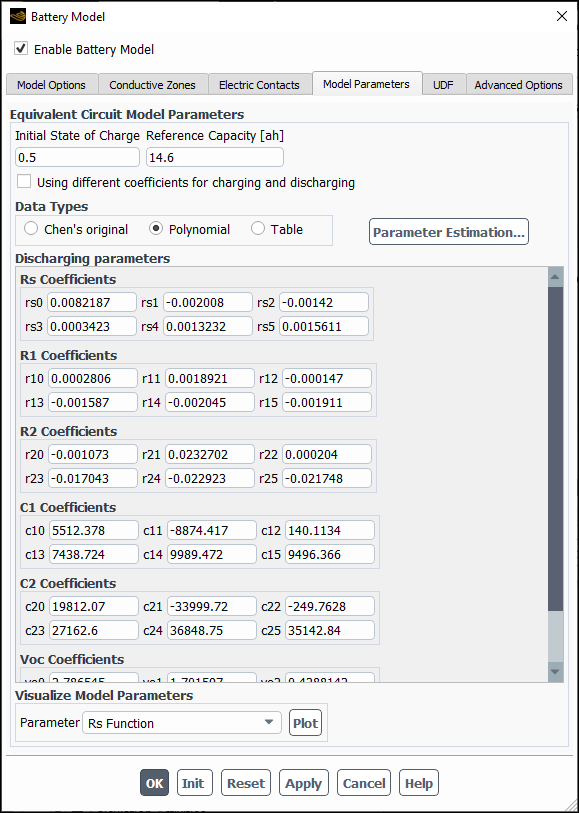

For the Equivalent Circuit Model (ECM), define the following operating conditions:

Specify the following Equivalent Circuit Model parameters:

Initial State of Charge: Is the battery initial SOC at

=0. The default value of

1for Initial State of Charge indicates the fully-charged state of the battery cell.Reference Capacity: Is the capacity of the battery that is used in experiments to obtain model parameters (

in Equation 19–9). Note that nominal and reference capacities may have different values.

Specify resistors' resistances (Rs, R1, and R2), capacitors' capacitances (C1 and C2), and the open circuit voltage (Voc) using one of the following:

Chen's original data type

Polynomial data type

Table data type

Parameter Estimation tool

Note: The values of model parameters for the Equivalent Circuit Model are battery specific and need to be specified before conducting a simulation. The default values are taken from Chen (see ECM Model for details). If you model a battery of different design, you should specify a different set of battery parameters.

If you selected Chen's original in the Data Types group box, you need to specify all coefficients in Equation 19–11.

If you selected Polynomial in the Data Types group box, you need to directly specify polynomial coefficients in Equation 19–10.

If you selected Table in the Data Types group box, you need to define a 2D lookup table for each ECM parameter. See Inputs for the NTGK/DCIR Model for more information on how to define model parameters in a table data type.

(optional) You can enable the Use Different Coefficient for Charging and Discharging option and specify the coefficients for charging parameters.

If you want to use the parameter estimation tool to fit the parameters from testing data, click the Parameter Estimation button.

In the Parameter Estimation dialog box that opens, you need to specify the following Input Parameters:

Testing Battery's Capacity

This value is copied from Reference Capacity (Model Parameters tab). You need to verify it is correct; otherwise, go back to the Model Parameters tab to modify it.

Circuit Model (4P Parameter Model (One RC Loop) or 6P Parameter Model (Two RC Loop))

Fitting Method (JH or LM Method)

The Jiang-Hu (JH) method uses only the testing data from the relaxation time period, and the Levenberg-Marquardt (LM) method uses the testing data from both the pulse and relaxation time periods. The JH method uses the approach from paper [69], and the LM method uses the general Levenberg-Marquardt method.

Corresponding HPPC testing data (as further described)

If you want to consider the capacity fade effect in your simulation, enable Capacity Fade Effect.

If this option is enabled, you need to import HPPC testing files for the discharging curves. The format of the discharging curve is the same as used for the NTGK parameter estimation tool. After you load files for the discharging curves, the capacity fade table is populated automatically. You can review the table by clicking Capacity Fade Table..., but you cannot modify it.

Load HPPC files into your case.

The required testing data are battery's HPPC data at different SOC and temperature. For each SOC and temperature level, you must provide a separate file in text format.

At least one valid SOC level testing data is required per temperature level. For good simulation results, the range of SOC levels used in the testing should cover the SOC range simulated in the CFD runs.

The file format must follow the format as shown in the below example:

SOC 1.0 I 14.6 Temperature 300.0 1.0000e-01 4.2292e+00 2.0000e-01 4.2292e+00 ... 1.1800e+01 4.1041e+00 ...

The first line of the file starts with

SOCfollowed by a SOC value separated by a space. The second line contains the pulse current information (Ifollowed by a pulse current value). The third line provides temperature information (keywordTemperaturefollowed by a value). The remaining lines contain pairs of space-separated time-voltage values. The input data must include data from the rest period, the pulse period, and the relaxation period in the testing.You can load HPPC files in one of the following ways:

If you have data from the battery's HPPC test, you can load them into your case by clicking the button.

In the Select File dialog box that opens, browse to the directory where the test files reside.

Select all the files obtained from different temperature and SOC levels you want to use in the parameter estimation tool (use Ctrl or Shift to select multiple files).

The selected testing files will be automatically added to the list of the files at the bottom of the Select File dialog box. If you accidentally selected the wrong file, you can use the button to remove it from the selected testing file list.

Click .

See The Select File Dialog Box for details.

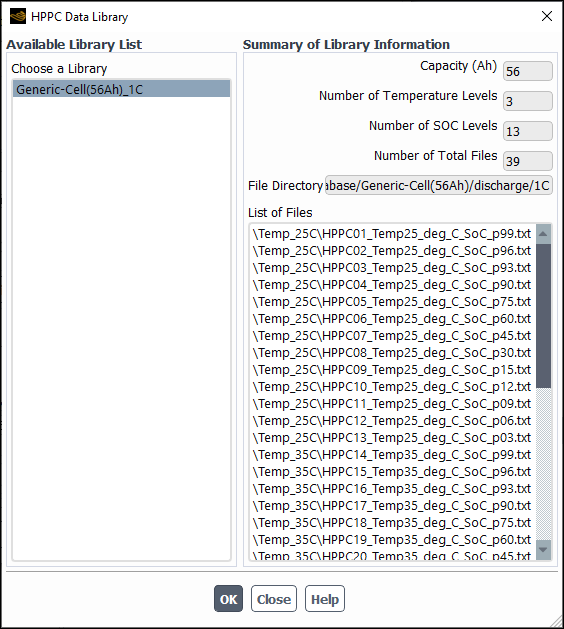

You can load test files from the HPPC library provided by Ansys Fluent by clicking the button.

In the HPPC Data Library dialog box that opens, you can select a library from the Available Library List. The related information is displayed in the Summary of Library Information group box. Clicking will import the library files into your case.

See The HPPC Library for more information.

After testing files are imported, click the Fit Parameters button to run the ECM parameter estimation tool. The fitting results will be passed to the Battery Model dialog box automatically.

If you provide testing data files at different temperatures, the parameter estimation tool will perform the fitting for each temperature level. Ansys Fluent will report the fitted results in the console and automatically pass them in a table data type to the parameter data table dialog boxes. The Table data type will be automatically selected in the Battery Model dialog box (Model Parameters tab). This will allow you to consider the temperature-dependent effect.

If you use testing data from only one temperature level, the fitting results in both polynomial and table data types will be transferred to the Battery Model dialog box and to the parameter data table dialog boxes, respectively. In this case, the Polynomial data type will be automatically selected as default in the Battery Model dialog box. However, you can use either data type in your simulation.

If your testing data contains both discharging and charging curves, the ECM parameter estimation tool will be run twice—once for the discharging curves, and once for the charging curves. After the fitting is complete, the Use Different Coefficient for Charging and Discharging button will be automatically selected, and the fitting results for each subset of data will be automatically transferred to the Battery Model dialog box and displayed in the corresponding Discharging Parameters and Charging Parameters group boxes (Model Parameters tab).

Note:Because the parameter estimation tool attempts to calculate six or four ECM model parameters from a non-linear data regression process for each SOC curve, the testing data for each SOC curve should be sufficiently large in order to obtain a good fitting.

The parameter estimation tool always fits the experimental data into either six parameters used in the Chen's circuit shown in Figure 19.1: Electric Circuits Used in the ECM Model or four parameters in the reduced Chen's circuit with only one RC loop.

To obtain optimal fitting of HPPC testing data, you can try different combinations of the circuit model and the fitting method. The six-parameter circuit model has more physics, but the four-parameter circuit model is generally more robust. As for the fitting method, the JH method is in general more robust than LM method. You can start with the six-parameter model, and then, if the fitting results are not satisfactory, switch to the four parameter model.

(optional) Visualize and check the resulting fitted curves of the battery HPPC data at different temperatures and SOC to detect any issues with the fitting process.

Once the fitting is complete, the Parameter Estimation dialog box expands to reveal the Visualize Fitting Results group box containing the Temperature and State of Charge selection lists. You can display curves of the fitted data and the experimental data from your input files at specific temperatures and C-rates by selecting a pair of values from the Temperature and State of Charge lists. The corresponding curves will be automatically plotted in the graphics window.

When the data contains both discharging and charging curves, you can select either Discharging Data or Charging Data to visualize the corresponding subset of data. The Temperature and State of Charge lists will be updated accordingly.

Note the following when you are using the LM fitting method:

The LM method is a non-linear fitting method. To have a better fitting result with this method, the JH method is always run first to provide an initial condition for the fitting parameters. When you plot fitted curves, the fitting result from the JH method will also be plotted for your reference.

If the fitting fails, a warning message will be printed in the console window, and the fitted curve for the LM method will not be plotted.

Click Close in the Parameter Estimation dialog box.

Note: The ECM parameter estimation tool can also be accessed through the text user interface (TUI) as described in Using the Parameter Estimation Tool for the ECM Model in the TUI.

(Chen's original, Polynomial, or Table data type only) You can visualize the resulting resistors' resistances (Rs, R1, and R2), capacitors' capacitances (C1 and C2), and the corresponding time constants (R1*C1 and R2*C2) varying with DOD by selecting an appropriate function from the Parameter drop-down list (Visualize Model Parameters group box) and clicking the Plot button. The resulting curves will be plotted in the graphics window.

Ansys Fluent provides a small HPPC library that you can use for importing HPPC test data into your case. Currently, the library contains only a single battery, called Generic-Cell. In future releases, the library will be expanded to include commonly used batteries. The purpose of the Generic-Cell library is to show the folder structure of test files as further described.

The Ansys Fluent HPPC library is located in the following directory:

path/fluent24.2.0/addons/msmdbatt/hppc_database/

where

path

is the Ansys Fluent installation

directory (for example, C:\Program Files\ANSYS

Inc\v242\fluent\fluent24.2.0).

In a standard HPPC test, a pulse of current is applied to a battery at a particular temperature and SOC level, and the voltage response of the battery is measured. The voltage response curve depends on:

the nature of the pulse (discharging or charging)

the magnitude of the current

the temperature level

the SOC level of the battery

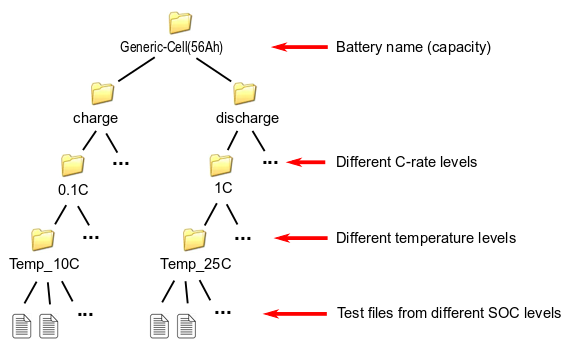

To reflect such testing procedure, the test files are organized in the folder structure as shown in Figure 31.19: Overview of the Folder Structure in the HPPC Library.

The naming convention is as follows:

The battery name can be any string. The capacity of the battery must be put in the parenthesis with a number followed by the unit "Ah".

The names of the first-level folder must be discharge and charge.

The number of the second- and third-level folders and their names can be arbitrary.

You can create your own library following the outlined conventions and put it in the hppc_database folder. The name of your library will appear in the HPPC Data Library dialog box. This way, the HPPC library can be expanded with the proprietary data and shared between colleagues within an organization.

Note: Currently, the parameter estimation tool can only take data from the discharge branch and only handle data from one C-rate level. Data from different C-rate levels are treated as different battery libraries. You should select the library with the C-rate level close to that at which the battery is operating in your application. The charge branch is not used so far. However, support for the charge branch is expected in future releases as the solver capability will be expanded in Ansys Fluent.

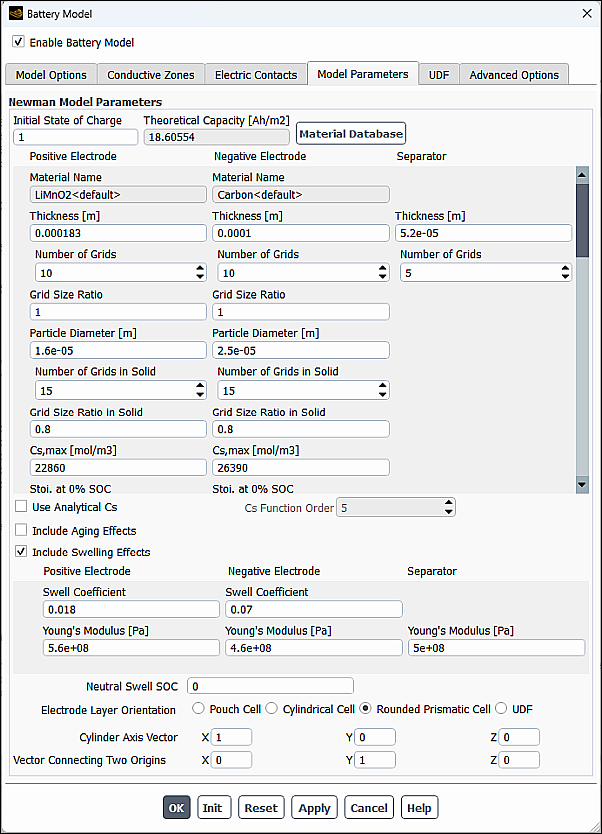

Theoretical Capacity is computed automatically from the Newman input parameters you specify and reported in the Model Parameters tab.

Specify the following settings in the Model Parameters for the Newman’s P2D model:

Specify Initial State of Charge. The default value of

1for Initial State of Charge indicates the fully-charged state of the battery cell.Specify the following parameters in the Positive Electrode, Negative Electrode, and Separator columns:

- Thickness

are

,

, and

in Equation 19–30.

- Number of Grids

is a number of grid points used to discretize the positive electrode, negative electrode, and separator zones.

- Grid Size Ratio

is used to create a biased mesh. The default value of 1 corresponds to a uniform mesh.

- Particle Diameter

is the particle diameter of the active material.

- Number of Grids in Solid

is the number of grid points used to discretize the sphere of particles.

- Grid Size Ratio in Solid

is used to create a biased mesh for the solid phase. The default value of 1 corresponds to a uniform mesh.

- Cs,max

is the maximum concentration of Lithium in the solid phase (used in Equation 19–20).

- Stoi. at 0% SOC

is the stoichiometry at 0% SOC that is used to compute theoretical capacity and initial lithium concentration in the electrode.

- Stoi. at 100% SOC

is the stoichiometry at 100% SOC that is used to compute theoretical capacity and initial lithium concentration in the electrode.

- Init. Cs

is the initial lithium concentration in the electrode.

- Init. Ce

is the initial lithium concentration in the electrolyte phase.

- VOF of Electrolyte

is the volume fraction of the electrolyte material in the electrode,

in Equation 19–21.

- Filler Fraction

is the volume fraction of the filler material in the electrode,

in Equation 19–28.

- Ds

is the diffusion coefficient of lithium ion in the electrode at reference temperature

=25°C,

in Equation 19–21.

- Activation Energy E_d

is

in Equation 19–21.

- Brugg

is the Bruggeman tortuosity exponent,

in Equation 19–21.

- Conductivity

is the electric conductivity,

in Equation 19–21.

- Ref. Rate Constant

is the rate constant at reference temperature

=25°C,

in Equation 19–21.

- Activation Energy E_r

is

in Equation 19–21.

- Trans. Coef. a

is the charge transfer coefficient at anode,

in Equation 19–20.

- Trans Coef. c

is the charge transfer coefficient at cathode,

in Equation 19–20.

- OCP

is the open circuit potential of the electrode material,

in Equation 19–19. Usually, it is a function of state of lithiation (sol)

/

. It can be defined by a piece-wise linear function or a UDF.

- De

is the diffusion coefficient of Li+ in the electrolyte phase,

in Equation 19–21.

- t+ Factor

is the transference number of lithium ion,

in Equation 19–21.

- Ionic Cond

is the ionic conductivity,

in Equation 19–22.

- Activity Term

Is the activity related term,

in Equation 19–23.

You can specify the open circuit potentials, the diffusion coefficients, the conductivities, the transference number of lithium ion, and the activity related term as a constant, a piecewise-linear function, or a polynomial function. Alternatively, you can specify a user-defined function (UDF) for these parameters. For more information, see

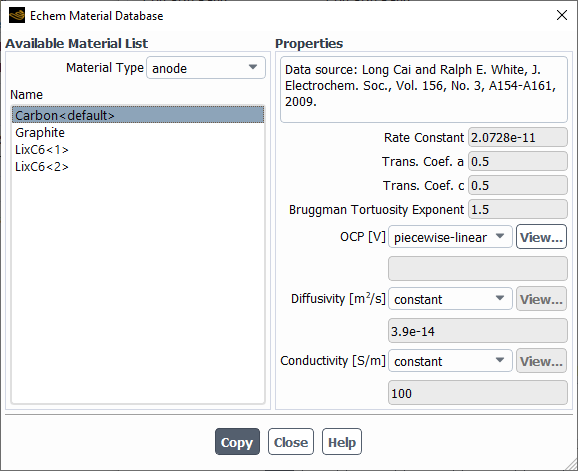

DEFINE_BATTERY_PROPERTYin the Fluent Customization Manual.Some of the above inputs are related to the material properties. You can use the Ansys Fluent echem material database that offers commonly-used anode, cathode, and electrolyte materials.

If you want to import material properties from the material database:

Click the Material Database button.

In the Echem Material Database dialog box that opens, select the Material Type from the following options:

anode

electrolyte

cathode

From the Name selection list, select the material that you want to copy.

The properties of the selected material are displayed in the Properties group box for information only.

Click Copy.

The names and the properties of the selected materials are copied to the correspondent fields in the Newman Model Parameters group box.

Note: The Ansys Fluent echem material database is saved in an ASCII file located at <installation directory>/fluent/fluent24.2.0/addons/msmdbatt/lib/echem_database.scm, where <installation directory> is where you installed the software. You can modify the data in the database or add more materials into that file if you want to build up your own material database.

If you want to use the reduced order method to solve the lithium diffusion equation in solid [90], select the Use Analytical Cs check box and enter the value for the Cs Function Order.

By default, Ansys Fluent discretizes the lithium conservation equation and solves it numerically.

If you want to include aging effects into the Newman's P2D model simulation as steady-state input profiles:

Select the Include Aging Effects check box.

(optional) Import customized aging effect profiles by either entering the file name in the Import Aging Effects Profile text entry field or using the Browse... button to select it.

Once you have imported the aging effects profile, they will be automatically stored with your case file.

Note: If the aging effects profiles have been generated by running the physics-based battery life model in the standalone mode as described in Simulating the Aging Process of a Battery (Standalone Mode), these profiles are automatically available in your case, and you do not need to import them into your case.

From the Select Aging Effects Profiles drop-down list, select a profile for the battery aging conditions.

The battery aging information (such as SEI concentration, surface film resistance, and porosity) stored in the selected profile will be used in the Newman's P2D model calculation. For theoretical background about the physics-based battery life model, see Physics-Based Battery Life Model in the Fluent Theory Guide.

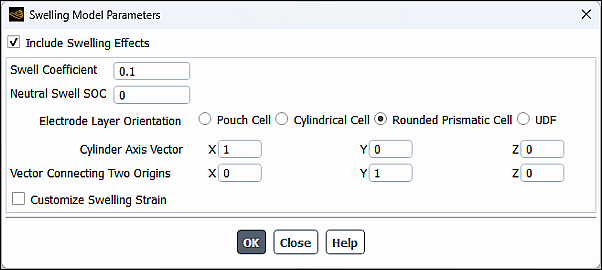

If you want to consider the deformation of the battery during charge and discharge:

Enable Include Swelling Effects.

The dialog box expands to reveal the swelling modeling parameters.

Specify the following parameters in the Positive Electrode, Negative Electrode, and Separator columns below the Include Swelling Effects check box:

- Swell Coefficient

is the volume growth rate of the active material particles with respect to the normalized particle lithium concentration,

in Equation 19–69 in the Fluent Theory Guide.

- Young's Modulus

is

in Equation 19–72, Equation 19–79, and Equation 19–80 in the Fluent Theory Guide.

- Neutral Swell SOC

is the battery’s state of charge when swelling is considered neutral.

When the swelling effects are included, Thickness, Particle Diameter, VOF of Electrolyte, and Filler Fraction for positive electrode, negative electrode, and, when applicable, separator are specified at the Neutral Swell SOC. During the echem model swelling calculations, their true values will fluctuate around the values you entered.

Specify the Electrode Layer Orientation (

in Equation 16–38 in the Fluent Theory Guide).

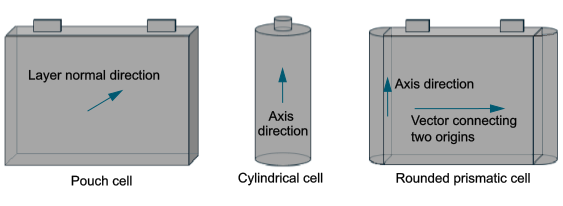

The following orientation types are available (see Figure 31.22: Electrode Layer Orientation):

Pouch Cell

For the Pouch Cell geometry type, you need to specify the X, Y, Z components of the Layer Normal Vector, which is the unit vector normal to the battery electrode sandwich layer surface.

Cylindrical Cell

For the Cylindrical Cell geometry type, you need to specify the X, Y, Z components of the Cylinder Axis Vector.

Rounded Prismatic Cell

For the Rounded Prismatic Cell geometry type, you need to specify the X, Y, Z components of two vectors - the Cylinder Axis Vector and the Vector Connecting Two Origins of the prismatic cell.

UDF

This option allows you to specify an electrode layer orientation for more complex battery geometry via the

DEFINE_BATTERY_SWELL_LAYER_Nuser-defined function. SeeDEFINE_BATTERY_SWELL_LAYER_Nin the Fluent Customization Manual for more information.

For steps on setting a swelling simulation, see Setting a Battery Swelling Case.

Note: Model parameters are battery specific. The default values are taken from Cai & White [90]. To simulate a battery of different design, you should provide a user-specified set of battery parameters.

The following parameters are available under User-Defined E-Chem Model Parameters:

- Number of Memories per Cell

is the number of submodel parameters that need to be saved per computational cell during a simulation.

- Initial SOC

is the value of the battery initial state of charge.

- Reference Capacity

is the battery capacity (Ah).

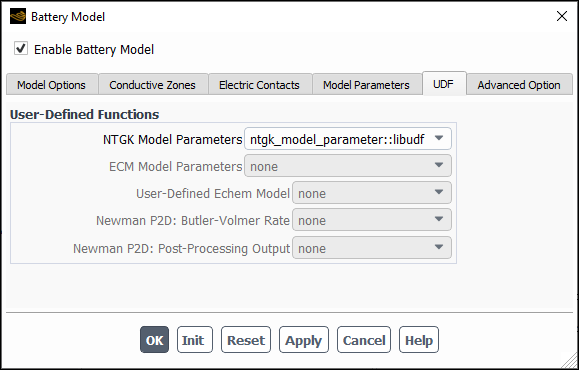

In the UDF tab, you can customize various battery model parameters by hooking up your user-defined functions (UDFs).

Refer to Battery Model DEFINE Macros in the Fluent Customization Manual for a list

of all available UDFs for specific battery models, their detailed descriptions and examples on

how to use them.

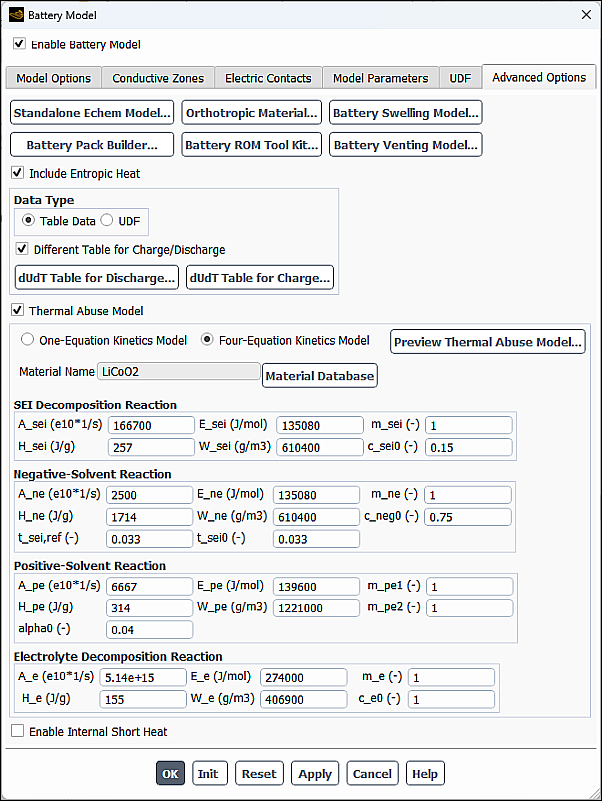

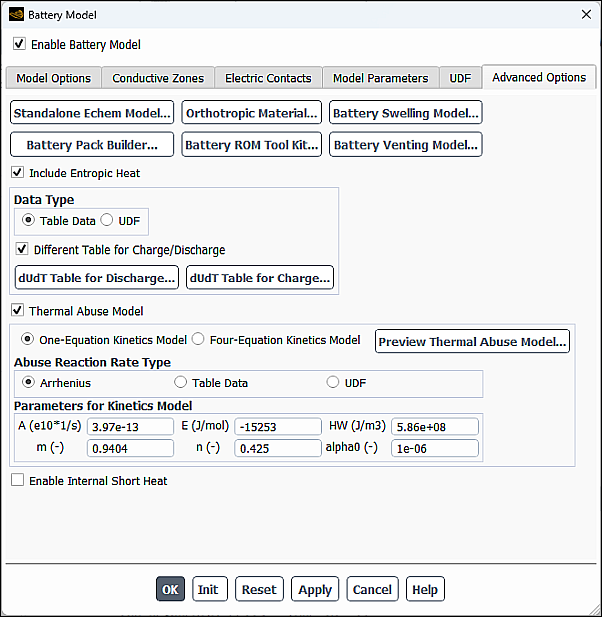

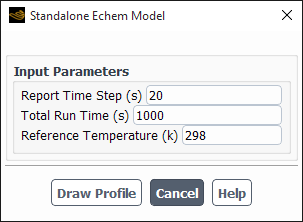

Using the Advanced Options tab of the Battery Model dialog box, you can:

Check the selected electrochemical model behavior before running the CFD case by performing a quick simulation of the electrochemical model in a standalone mode

Run the physics-based battery life model to simulate the aging process of a battery through electric load cycles in a standalone mode

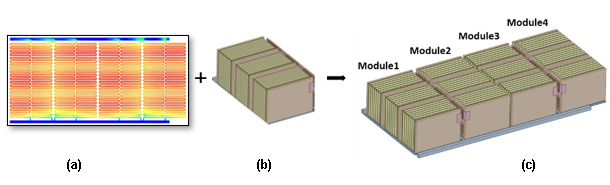

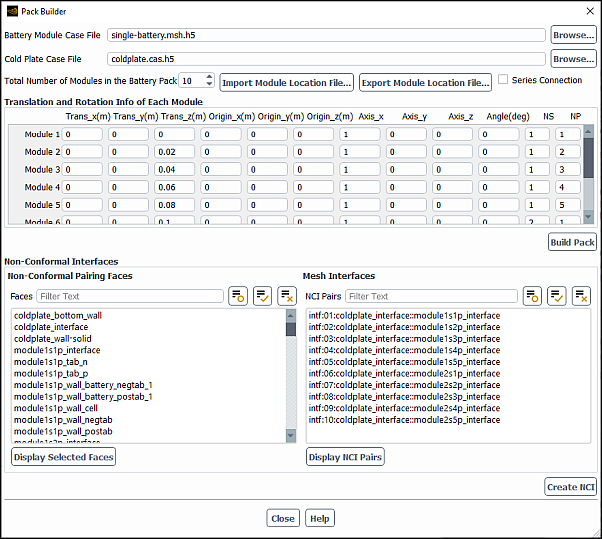

Use the Battery Pack Builder tool to construct a battery pack from existing Ansys Fluent simulations of the battery module and cold plate

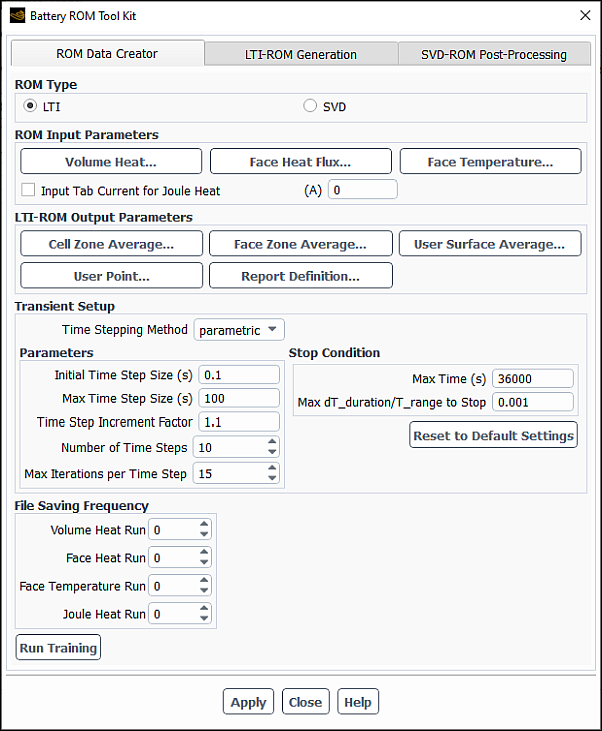

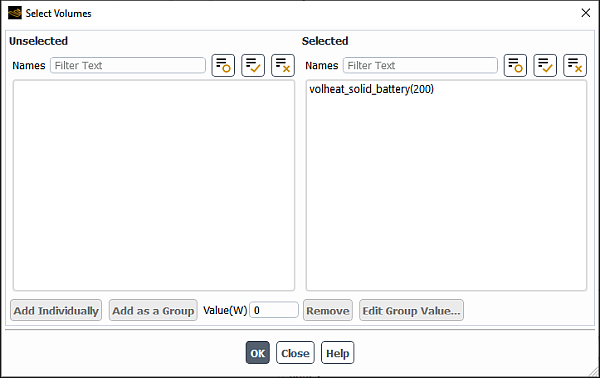

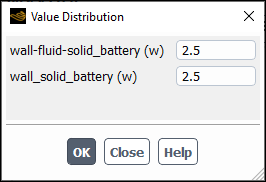

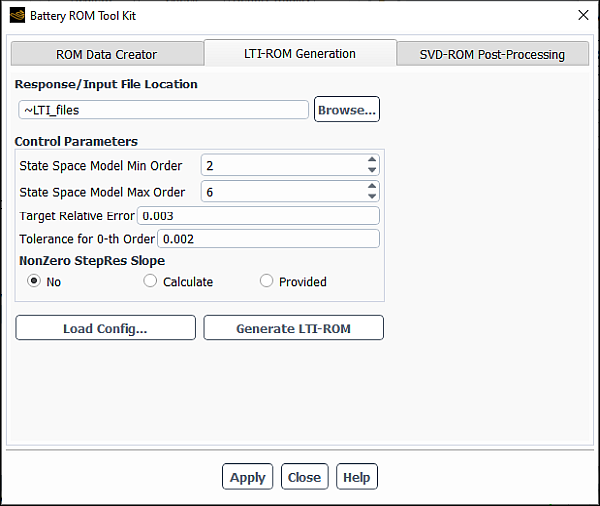

Create LTI-ROM or SVD-ROM training data and load SVD-ROM results into Ansys Fluent for postprocessing

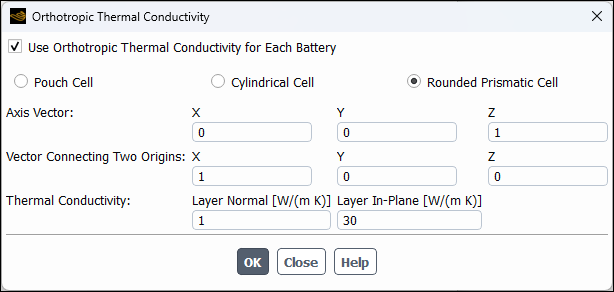

Define orthotropic thermal conductivity for all battery active zones

(NTGK and ECM models only) Enable and set the empirical-based battery swelling model for an FSI coupled simulation

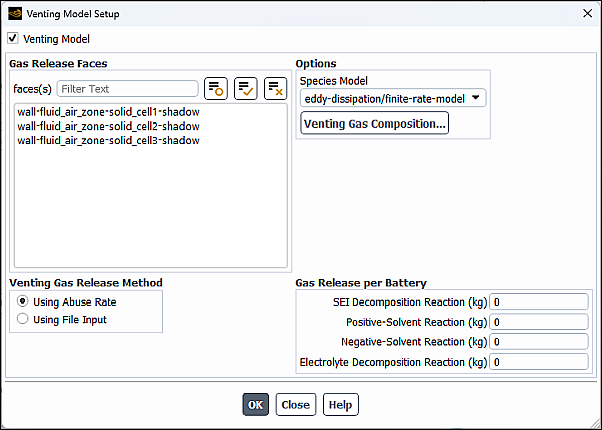

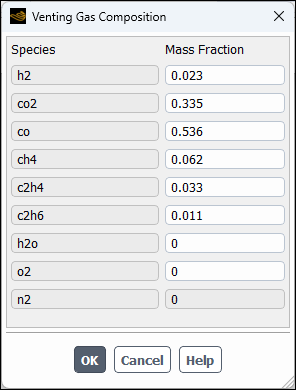

Enable and set the battery venting model

Include the entropic heat term in the battery thermal analysis when any of the electro-chemical submodels is used

Perform thermal abuse analysis

For additional information, see the following sections:

- 31.2.3.6.1. Running the Standalone Echem Model

- 31.2.3.6.2. Simulating the Aging Process of a Battery (Standalone Mode)

- 31.2.3.6.3. Using the Battery Pack Builder Tool

- 31.2.3.6.4. Using the Battery ROM Tool Kit

- 31.2.3.6.5. Defining Orthotropic Thermal Conductivity

- 31.2.3.6.6. Using the Empirical-Based Battery Swelling Model

- 31.2.3.6.7. Battery Venting Model

- 31.2.3.6.8. Including the Entropic Heat Effects

- 31.2.3.6.9. Using the Thermal Abuse Model

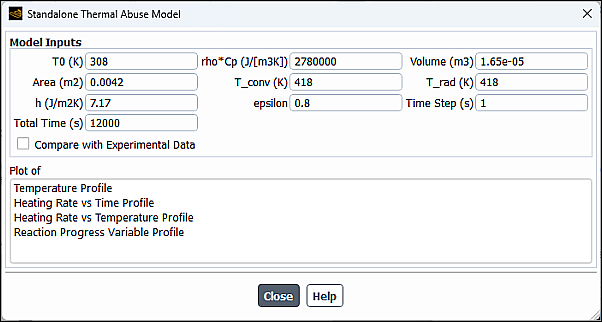

Prior to running a coupled electrochemical-thermal simulation, you should perform a quick analysis of your electrochemical model by simulating it in a standalone mode. The standalone model calculation uses the operating conditions that you have specified in the Model Options tab (such as electric load type and value) and the echem model parameters that you have defined in the Model Parameters tab. This preliminary analysis will allow you to confirm the electrochemical behavior of the selected submodel and, if necessary, adjust the model settings.

To run the echem model in a standalone mode:

Click .

In the Standalone Echem Model dialog box that opens, specify the following parameters:

Report Time Step: The time interval at which the results will be saved and reported.

Total Run Time: The total time for running the stand-alone model simulation.

Reference Temperature: The temperature level at which you want to simulate your electrochemical model.

(Neman’s P2D model with battery swelling effects only) Mechanical Load Type: The external mechanical load that causes electrode elastic deformation (see Modeling Swelling in the E-Chem Standalone Mode in the Fluent Theory Guide for more information). You can select and specify the following load types:

External Pressure: The external normal force exerted on the battery electrode layer end,

in Equation 19–78 in the Fluent Theory Guide. A positive value represents compression.

Total Deformation: The percentage of the total thickness change of the battery electrode layer, the right-hand side of Equation 19–79 in the Fluent Theory Guide.

External Stiffness: The effective stiffness of external constraint applied to the battery electrode layer,

in Equation 19–80 in the Fluent Theory Guide.

Initiate the electrochemical model simulation by clicking .

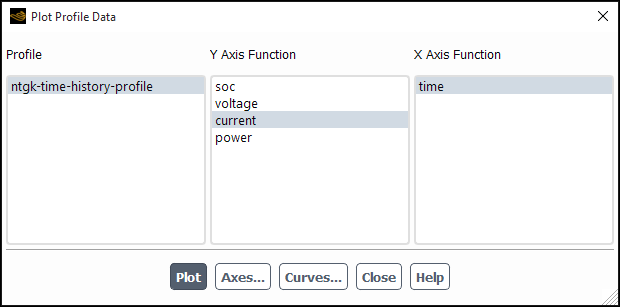

Once the calculation is complete, the Plot Profile Data dialog box opens.

Using the Plot Profile Data dialog box, visualize and analyze the results of the standalone echem model simulation. Different profiles are available for different electrochemical models.

For the NTGK model, a time history profile, called ntgk-time-history-profile, is generated after the calculation is complete. You can draw the X-Y plots of the following variables as a function of time:

soc: the battery state of charge (SOC)

voltage: the battery voltage

current: the battery electric current

power: the battery power output

For the ECM model, a time history profile, called ecm-time-history-profile, will be generated. In addition to the variables available for the NTGK model, you can also draw the X-Y plots of the following variables as a function of time:

v1:

in Equation 19–9

v2:

in Equation 19–9

For the Newman P2D model, the following two profiles will be generated:

Time history profile p2d-time-history-profile

Spatial field profile called p2d-field-profile

For the p2d-time-history-profile profile, you can plot the time history profile for the following variables:

current (see above)

voltage (see above)

power (see above)

ce_x=0

ce_x=lp

ce_x=lps

ce_x=lpsn

cs_x=0

cs_x=lp

cs_x=lps

cs_x=lpsn

phis_x=0

phis_x=lp

phis_x=lps

phis_x=lpsn

phie_x=0

phie_x=lp

phie_x=lps

phie_x=lpsn

where ce is the lithium-ion concentration in electrolyte phase at different locations x=0 denotes the location of the outside face of the positive electrode x=lp denotes the interface of the positive electrode and separator x=lps denotes the interface between the separator and negative-electrode x=lpsn denotes the outside face of the negative electrode cs is the lithium concentration at the surface of the active material in electrode at different locations phis is the electric potential in the electrode solid phase at different locations phie is the electric potential in the electrolyte liquid phase at different locations For the p2d-field-profile profile, you can plot the spatial profiles of the following variables at the end of the simulation:

phi_e: the electric potential in electrolyte phase

phi_s: the electric potential in electrode phase

ce: the lithium-ion concentration in electrolyte phase

cs_center: the lithium concentration in the center of the active electrode particles

cs_average: the average lithium concentration in the active electrode particles

cs_surf: the lithium concentration at the surface of the active electrode particles

Note: SI units are always used for all the variables in the X-Y plot.

In practical Newman’s P2D model simulations of battery aging through electric load cycles, the physics-based battery life model is solved on the electrode scale in the standalone mode. Further, the standalone simulation results can be included in a 3D CFD simulation to account for the battery aging effects as described in Inputs for the Newman’s P2D Model. For more information about the theory behind the physics-based battery life model, see Physics-Based Battery Life Model in the Fluent Theory Guide.

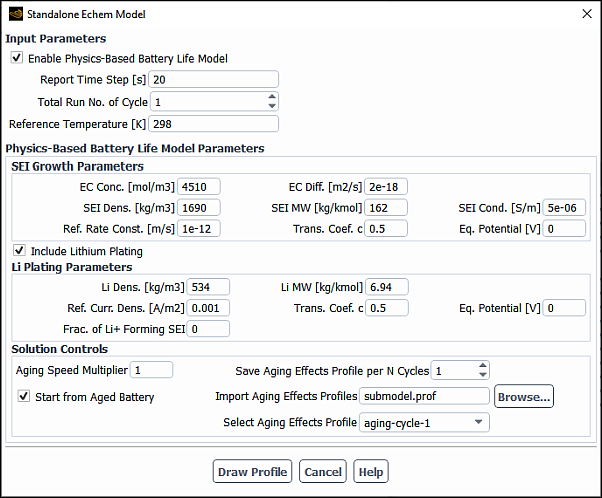

To run the physics-based battery life model in the standalone mode:

In the Model Options tab of the Battery Model dialog box, select Newman P2D Model as the E-chemistry model.

In the Solution Options group box, select Using Profile.

In the Profile Types group box, select either Time-Scheduled or Event-Scheduled and specify a profile file to define the boundary conditions of a single electric load cycle.

In the Advanced Options tab, click Run Echem Model Standalone….

In the Standalone Echem Model dialog box, select Enable Physics-Based Battery Life Model. The dialog box expands to reveal relevant model inputs in the Physics-Based Battery Life Model Parameters group box.

In addition to specifying Report Time Step and Reference Temperature (see Running the Standalone Echem Model for their definitions), specify Total Run No. of Cycle, which is the number of times the electric load profile you provided earlier is automatically looped over during the simulation.

Note: Prior to using a large number of cycles, you should run a test with a small number of cycles (for example, less than 20) as a sanity check and an estimation of computational time.

Set up the Physics-Based Battery Life Model Parameters.

In the SEI Growth Parameters group box, you can specify:

- EC Conc.

is the concentration of ethylene carbonate (EC) in the bulk electrolyte;

in Equation 19–58 in the Fluent Theory Guide.

- EC Diff.

is the diffusivity of EC;

in Equation 19–58 in the Fluent Theory Guide.

- SEI Dens.

is the density of solid-electrolyte-interface (SEI);

in Equation 19–60-Equation 19–62 in the Fluent Theory Guide.

- SEI MW

is the molecular weight of SEI;

in Equation 19–60-Equation 19–62 in the Fluent Theory Guide.

- SEI Cond.

is the ionic conductivity of SEI;

in Equation 19–56 in the Fluent Theory Guide.

- Ref. Rate Const.

is the rate constant of SEI formation reaction;

in Equation 19–61 in the Fluent Theory Guide.

- Trans. Coef. c.

is the cathodic charge transfer coefficient of SEI formation reaction;

in Equation 19–56 in the Fluent Theory Guide.

- Eq. Potential

is the equilibrium potential of SEI formation reaction;

in Equation 19–56 in the Fluent Theory Guide.

If you want to include the effects of lithium plating in your simulation, select Include Lithium Plating and then specify the following Lithium Plating Parameters:

- Li Dens.

is the density of plated lithium;

in Equation 19–60-Equation 19–62 in the Fluent Theory Guide.

- Li MW

is the molecular weight of plated lithium;

in Equation 19–60-Equation 19–62 in the Fluent Theory Guide.

- Ref. Curr. Dens.

is the transfer current density of lithium deposition reaction;

in Equation 19–57 in the Fluent Theory Guide.

- Trans. Coef. c.

is the cathodic charge transfer coefficient of lithium deposition reaction;

in Equation 19–57 in the Fluent Theory Guide.

- Eq. Potential

is the equilibrium potential of lithium deposition reaction;

in Equation 19–57 in the Fluent Theory Guide.

- Frac. of Li forming SEI

is the fraction of deposited lithium ions that becomes SEI;

in Equation 19–54 and Equation 19–55 in the Fluent Theory Guide.

In the Solution Controls group box, specify controls you want to use in your simulation.

Enter the Aging Speed Multiplier, which will be applied as a scaling factor to the cycle-to-cycle increment of the SEI and plated lithium concentrations after each cycle.

In the Save Aging Effects Profile per N Cycles number entry box, specify the cycle interval at which the aging effects profiles are saved.

If you want to start your simulation from an aged battery rather than from a new one, select Start from Aged Battery.

Enter the name of the file that contains the aging effects profiles in the Import Aging Effects Profile text entry field or use the Browse... button to select it. See below for more information about aging effects profile files.

Note: When you select Start from Aged Battery, you do not need to import your customized profile file each time you run a battery simulation in the standalone mode. Once imported, the aging effects profile is stored within the case file until deleted manually or overwritten by importing a profile with the same name.

From the Aging Effects Profiles drop-down list, select a profile for the simulation initial conditions.

Initiate the electrochemical model simulation by clicking Draw Profile.

Once the simulation is complete, the aging effects profiles generated in a standalone simulation will be automatically loaded into Ansys Fluent and can be visualized and analyzed using the Plot Profile Data dialog box that opens. See Running the Standalone Echem Model for more information about the Plot Profile Data dialog box.

The following variables generated by the physics-based battery life model are saved in the time-history profile called p2d-time-history-profile and in the cycle-history profile called aging-cycle-history-profile:

cs_sei_x=lps: Concentration of SEI (mol/m3)cs_li_x=lps: Concentration of plated lithium (mol/m3)r_film_x=lps: Surface resistance of the anode particle (Ohm-m2)theoretical_capacity: Theoretical capacity of the battery electrode layer (Ah/m2)

Here,

x=lpsdenotes the interface between the separator and the negative-electrode.Note: The cycle-history profile saves the battery aging variables at the end of each electric load cycle, that is, whenever the standalone simulation reaches the end of the Time-Scheduled or Event-Scheduled profile you specified in the Battery Model dialog box.

Aging Effects Profiles

The 1D spatial results of the physics-based battery life model are saved in aging effects

profiles, which are Ansys Fluent built-in format profiles (see Profiles for more information about profile files). In the standalone mode, all the generated aging

effects profiles are saved in the file called aging-field-profile.prof.

The profiles are named aging-cycle-,

where number

is the cycle number. Each profile contains the following field variables sampled

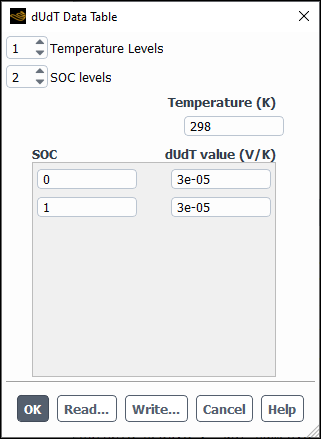

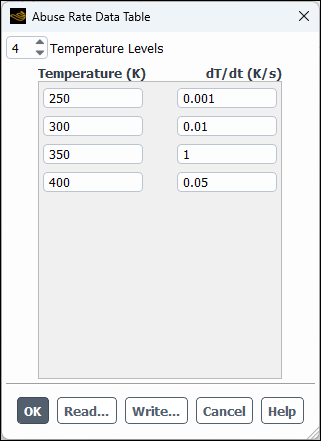

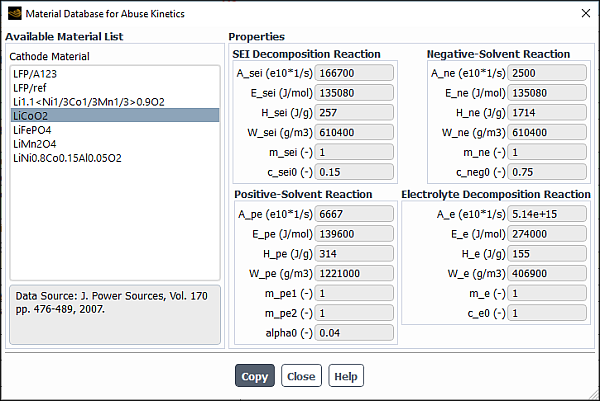

at the cycle end:number