The dialog boxes described in this section can be accessed through the ribbon, from the tabs other than the File ribbon tab.

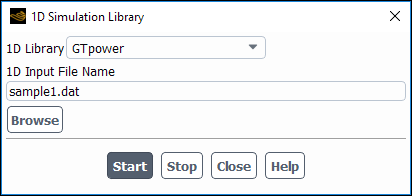

- 52.2.1. 1D Simulation Library Dialog Box

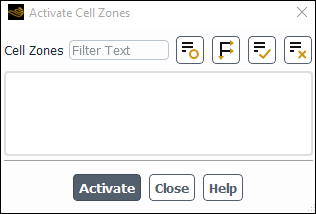

- 52.2.2. Activate Cell Zones Dialog Box

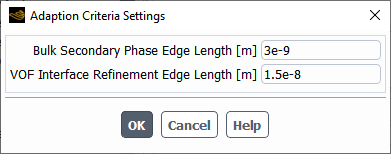

- 52.2.3. Adaption Criteria Settings Dialog Box

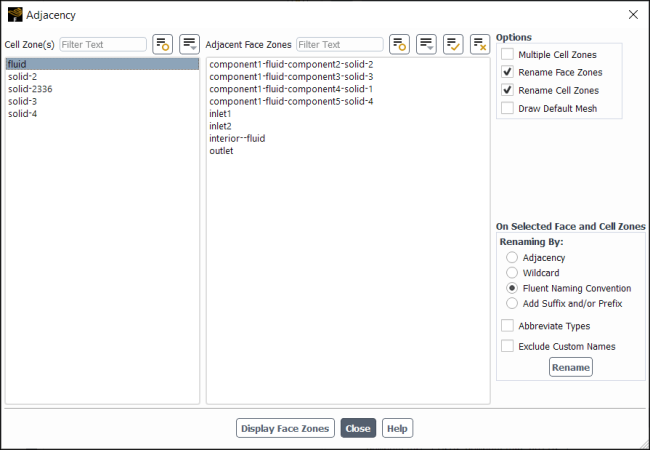

- 52.2.4. Adjacency Dialog Box

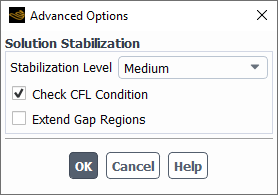

- 52.2.5. Advanced Options Dialog Box

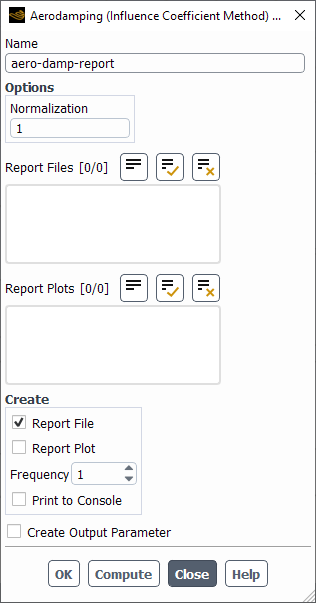

- 52.2.6. Aerodamping (Influence Coefficient Method) Report Definition Dialog Box

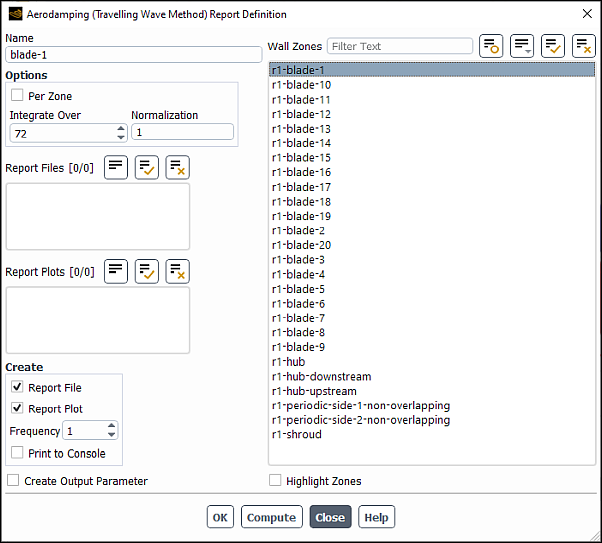

- 52.2.7. Aerodamping (Travelling Wave Method) Report Definition Dialog Box

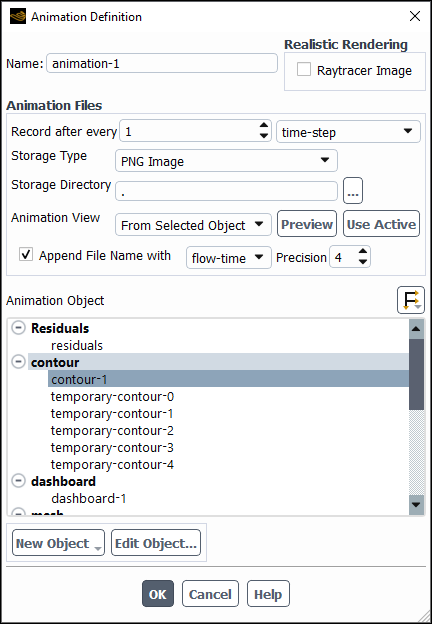

- 52.2.8. Animation Definition Dialog Box

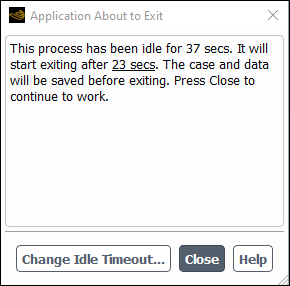

- 52.2.9. Application About to Exit Dialog Box

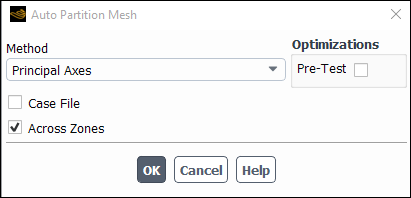

- 52.2.10. Auto Partition Mesh Dialog Box

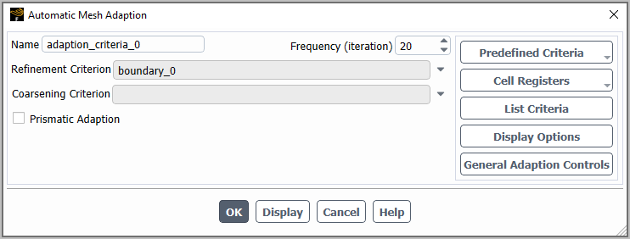

- 52.2.11. Automatic Mesh Adaption Dialog Box

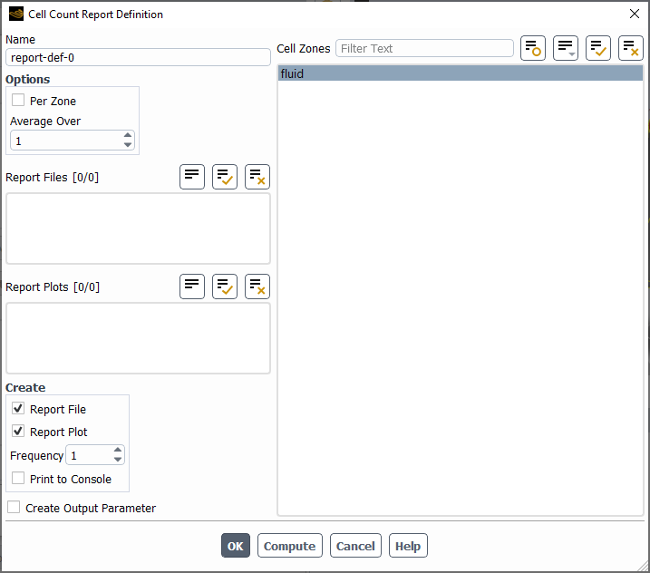

- 52.2.12. Cell Count Report Definition Dialog Box

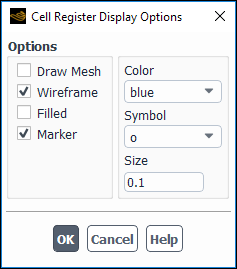

- 52.2.13. Cell Register Display Options Dialog Box

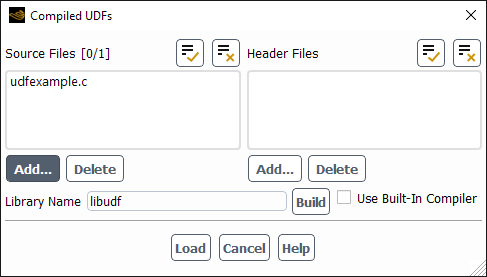

- 52.2.14. Compiled UDFs Dialog Box

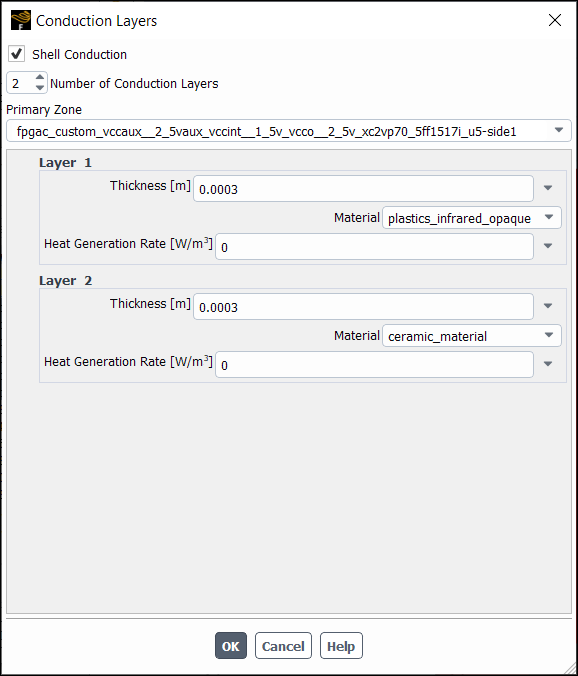

- 52.2.15. Conduction Layers Dialog Box

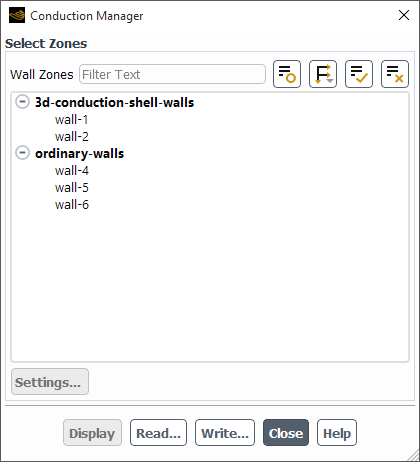

- 52.2.16. Conduction Manager Dialog Box

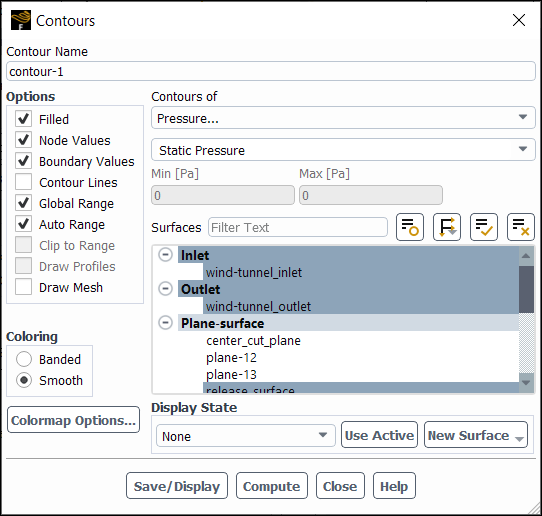

- 52.2.17. Contours Dialog Box

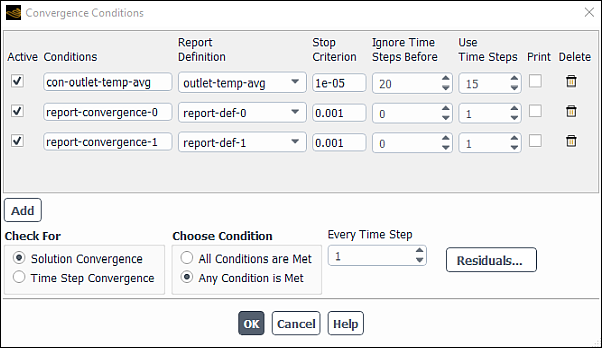

- 52.2.18. Convergence Conditions Dialog Box

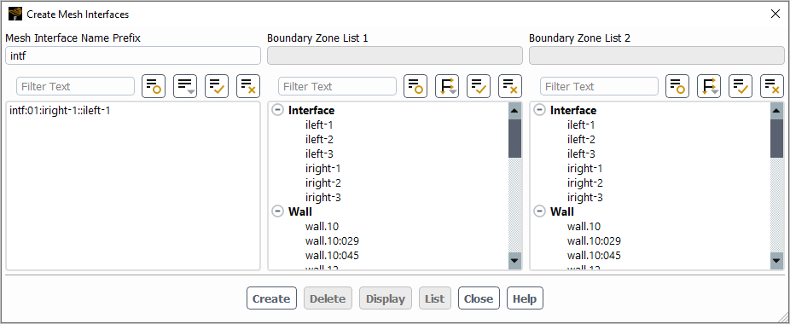

- 52.2.19. Create Mesh Interfaces

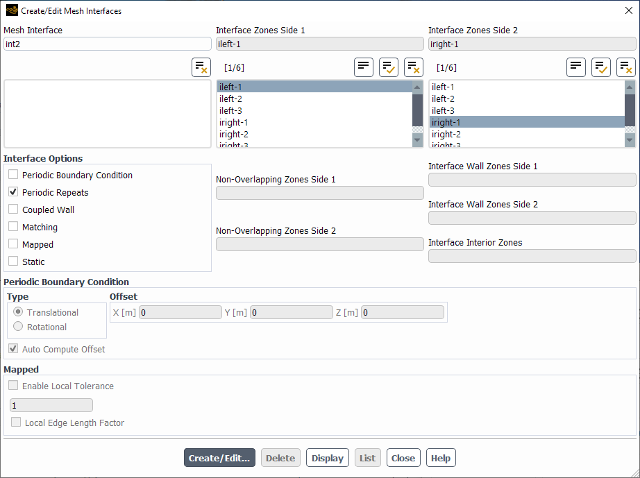

- 52.2.20. Create/Edit Mesh Interfaces Dialog Box

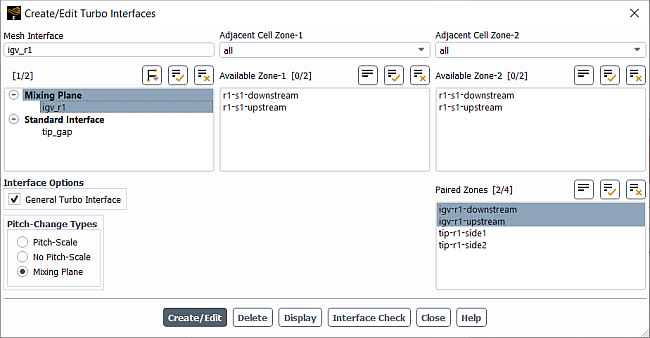

- 52.2.21. Create/Edit Turbo Interfaces Dialog Box

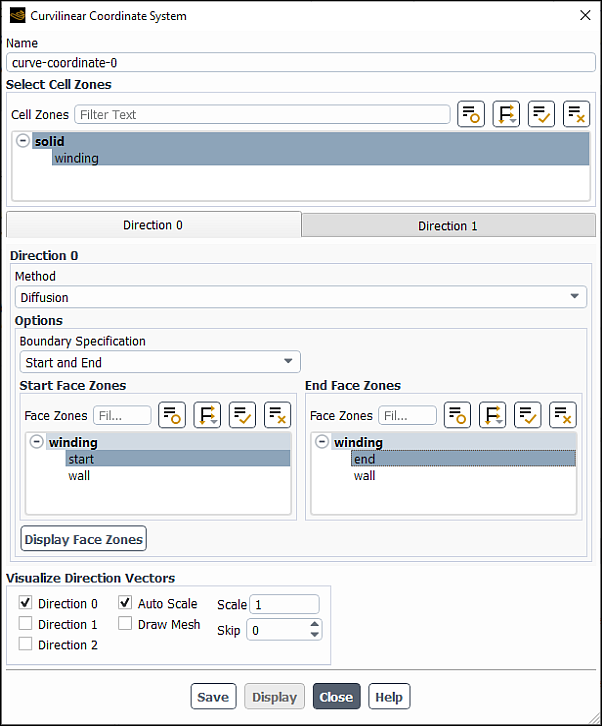

- 52.2.22. Curvilinear Coordinate System Dialog Box

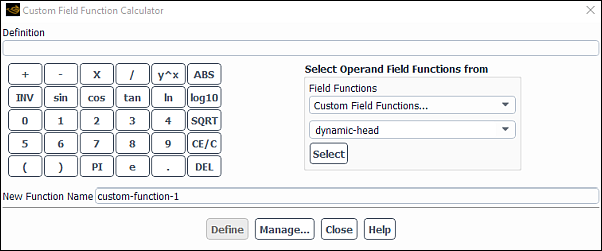

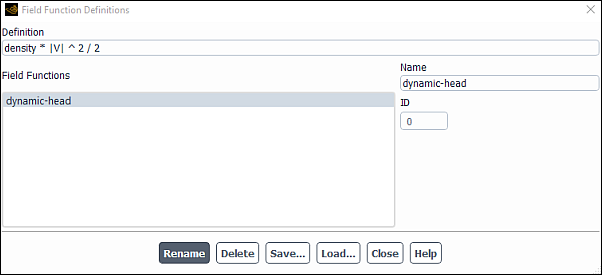

- 52.2.23. Custom Field Function Calculator Dialog Box

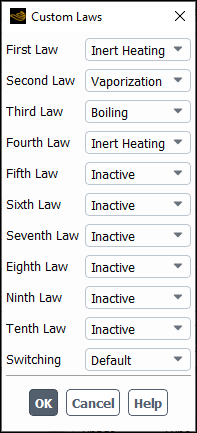

- 52.2.24. Custom Laws Dialog Box

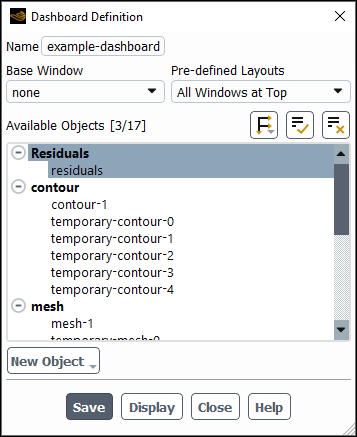

- 52.2.25. Dashboard Definition Dialog Box

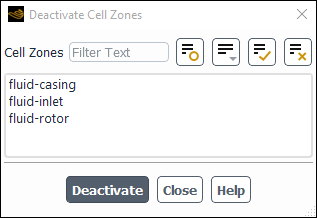

- 52.2.26. Deactivate Cell Zones Dialog Box

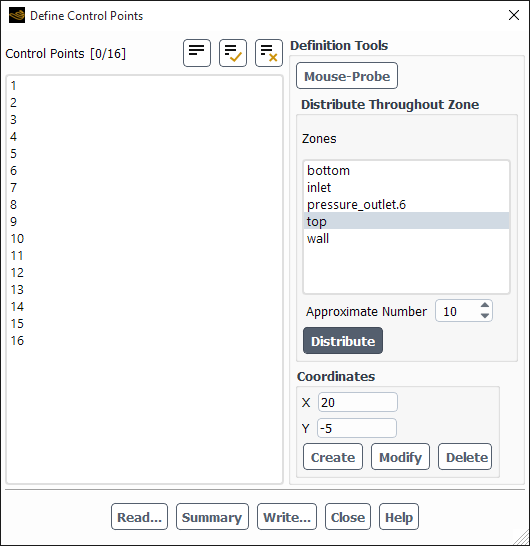

- 52.2.27. Define Control Points Dialog Box

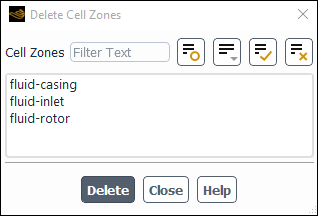

- 52.2.28. Delete Cell Zones Dialog Box

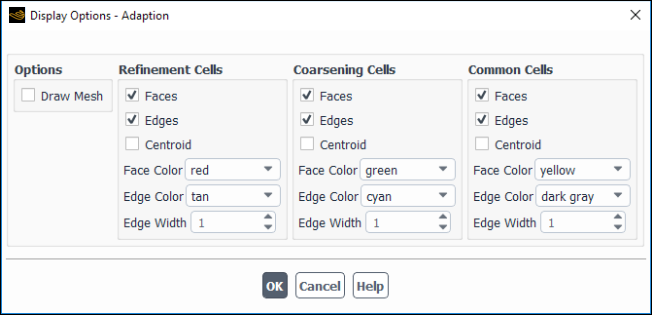

- 52.2.29. Display Options - Adaption Dialog Box

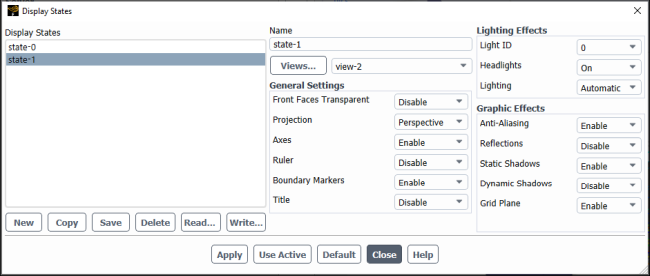

- 52.2.30. Display States Dialog Box

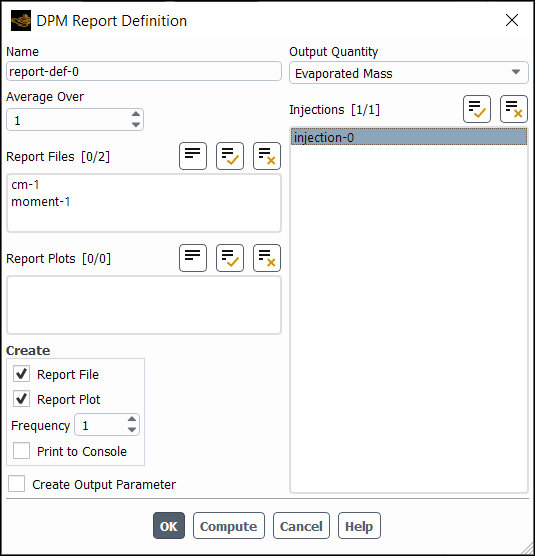

- 52.2.31. DPM Report Definition Dialog Box

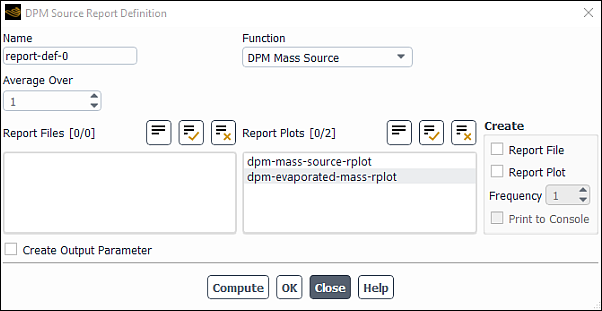

- 52.2.32. DPM Source Report Definition Dialog Box

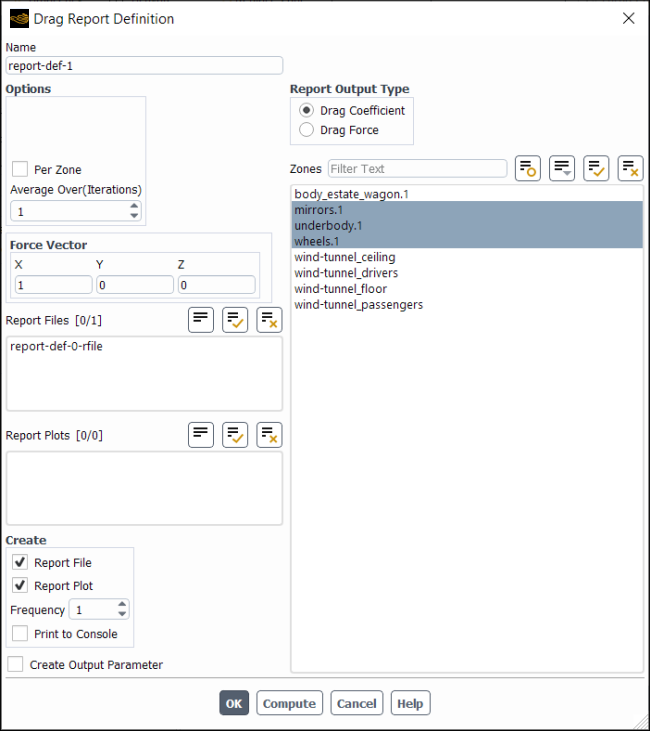

- 52.2.33. Drag Report Definition Dialog Box

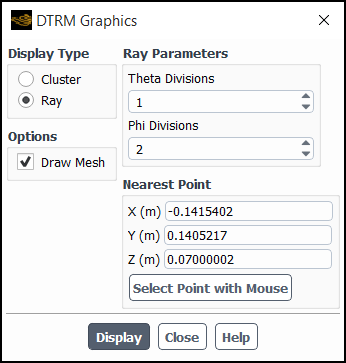

- 52.2.34. DTRM Graphics Dialog Box

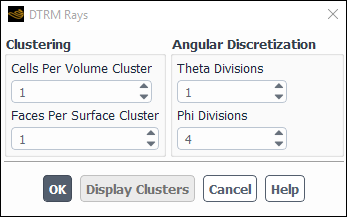

- 52.2.35. DTRM Rays Dialog Box

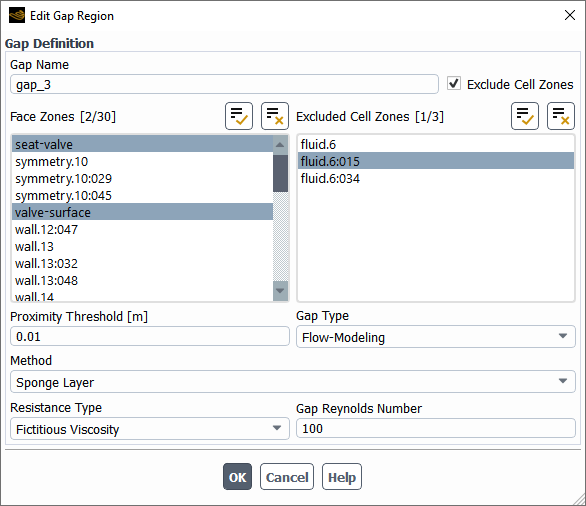

- 52.2.36. Edit Gap Region Dialog Box

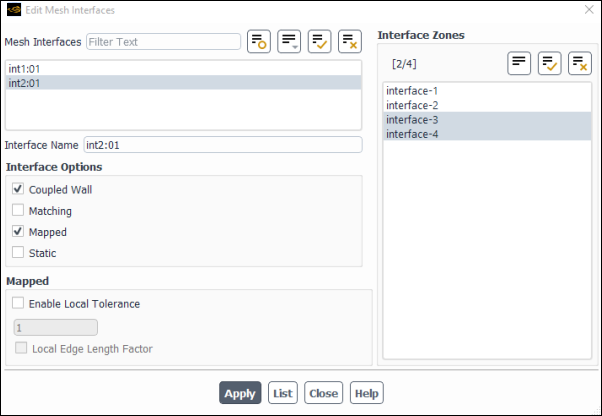

- 52.2.37. Edit Mesh Interfaces Dialog Box

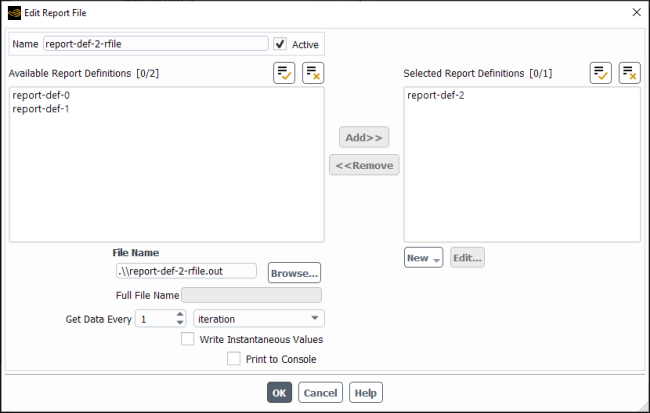

- 52.2.38. Edit Report File Dialog Box

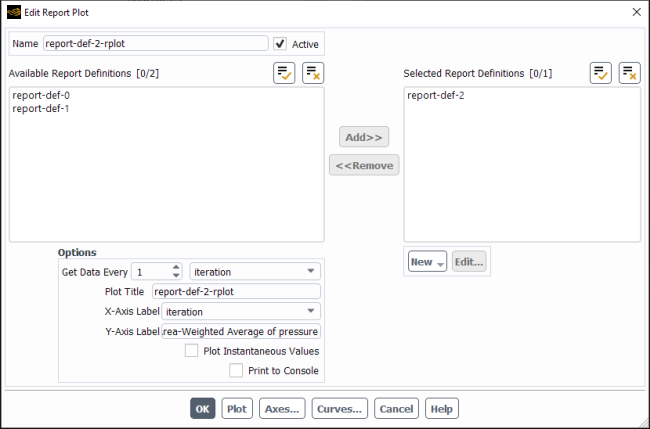

- 52.2.39. Edit Report Plot Dialog Box

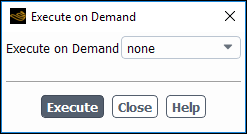

- 52.2.40. Execute on Demand Dialog Box

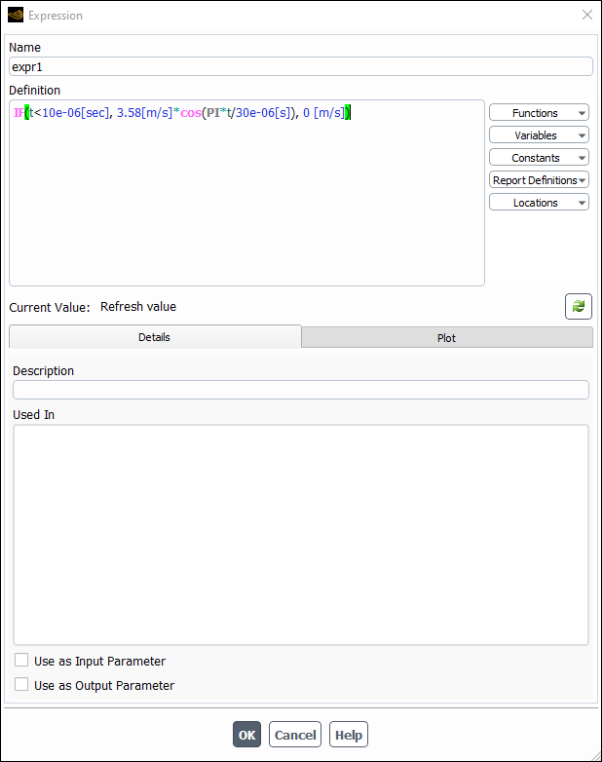

- 52.2.41. Expression Dialog Box

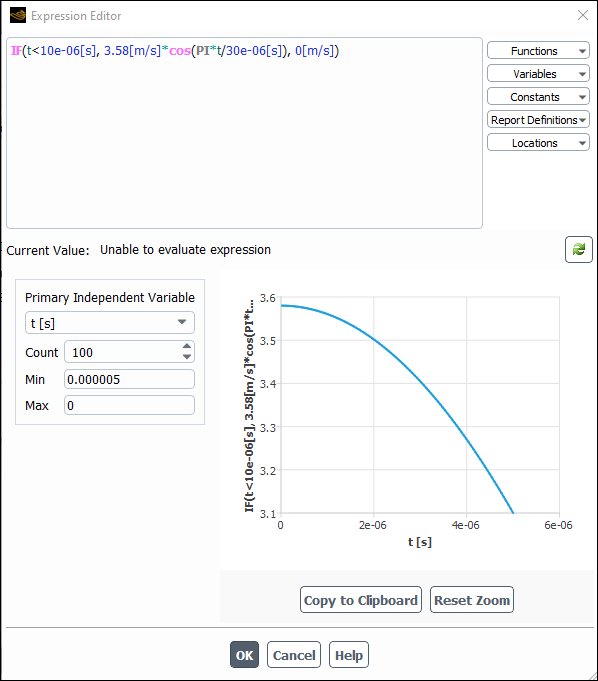

- 52.2.42. Expression Editor Dialog Box

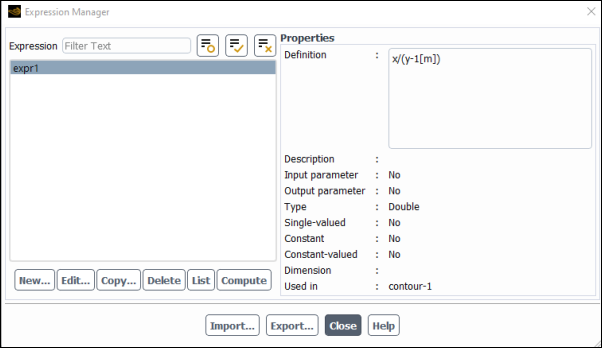

- 52.2.43. Expression Manager Dialog Box

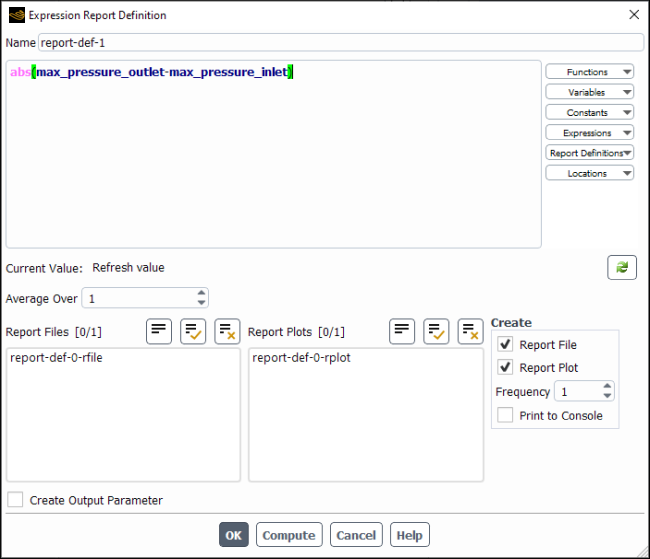

- 52.2.44. Expression Report Definition Dialog Box

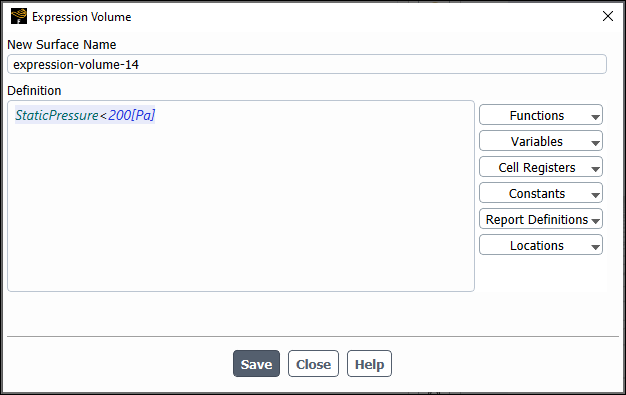

- 52.2.45. Expression Volume Dialog Box

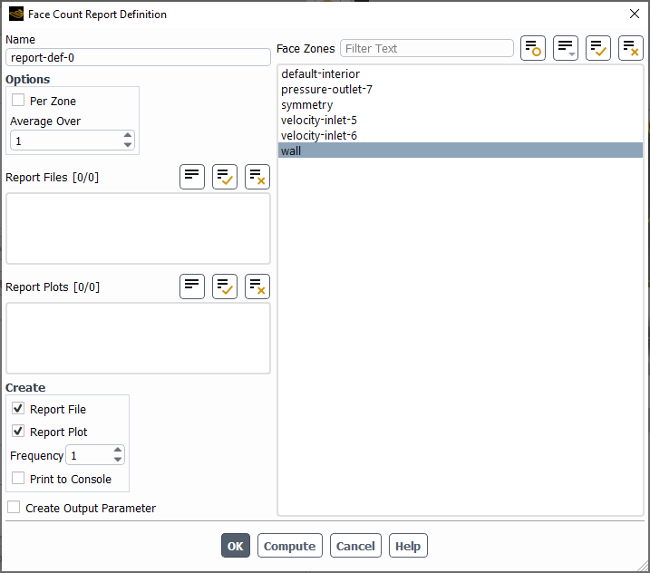

- 52.2.46. Face Count Report Definition Dialog Box

- 52.2.47. Field Function Definitions Dialog Box

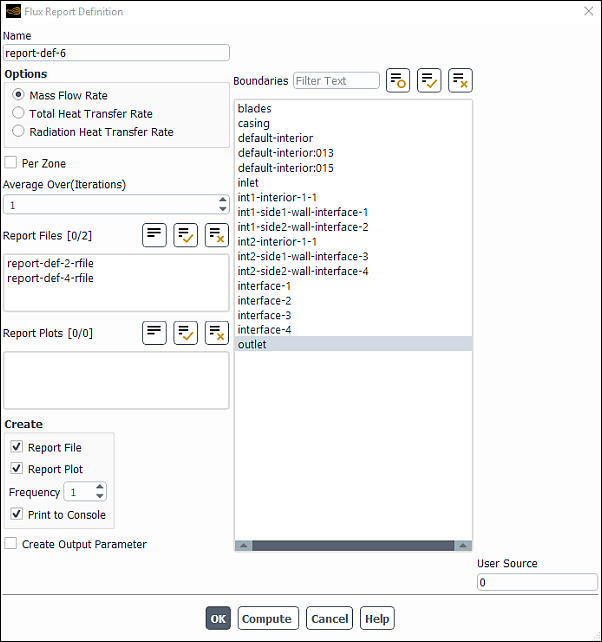

- 52.2.48. Flux Report Definition Dialog Box

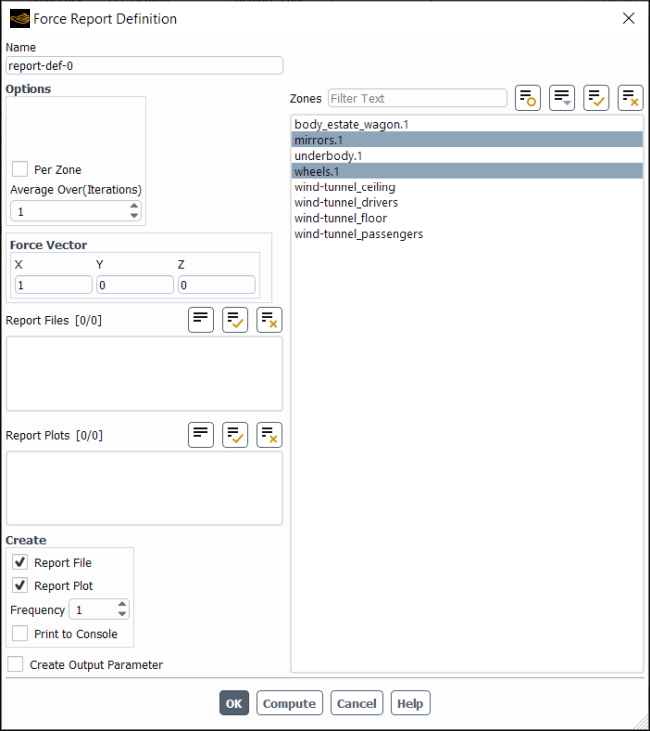

- 52.2.49. Force Report Definition Dialog Box

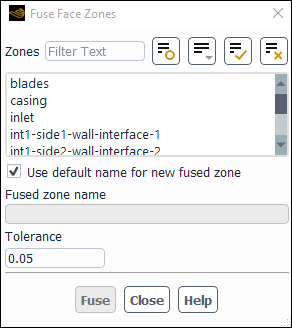

- 52.2.50. Fuse Face Zones Dialog Box

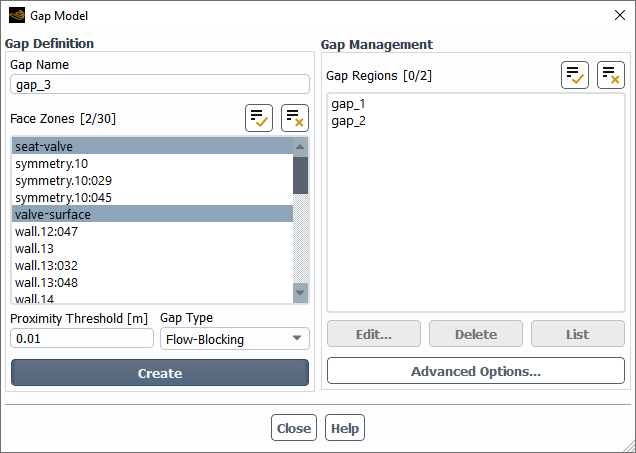

- 52.2.51. Gap Model Dialog Box

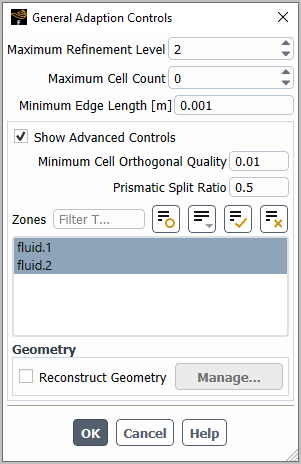

- 52.2.52. General Adaption Controls Dialog Box

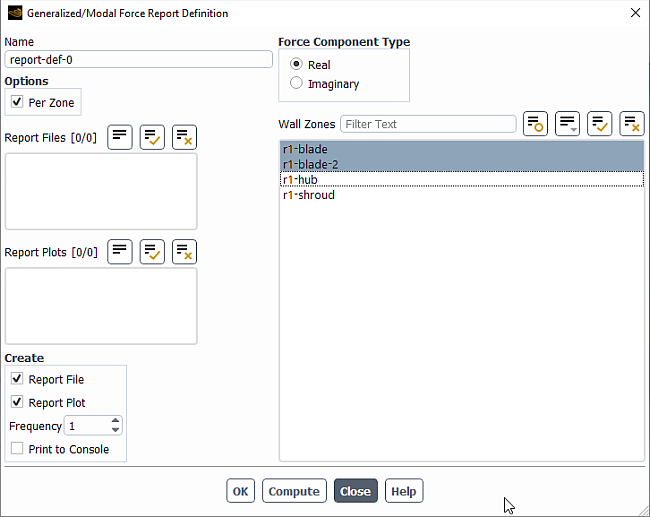

- 52.2.53. Generalized/Modal Force Report Definition Dialog Box

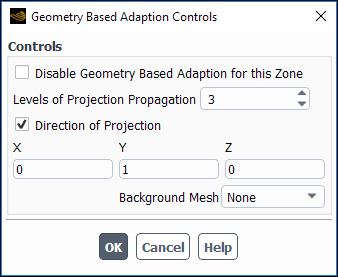

- 52.2.54. Geometry Based Adaption Controls Dialog Box

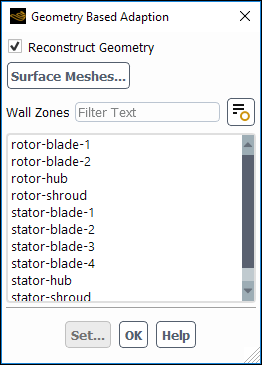

- 52.2.55. Geometry Based Adaption Dialog Box

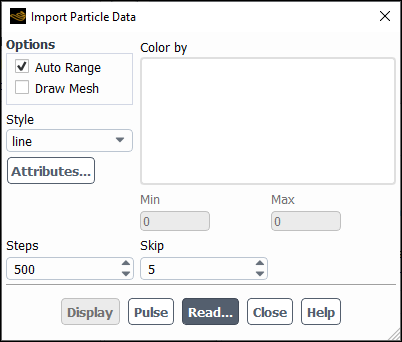

- 52.2.56. Import Particle Data Dialog Box

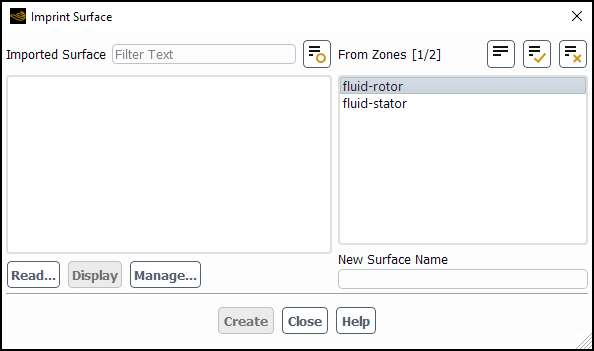

- 52.2.57. Imprint Surface Dialog Box

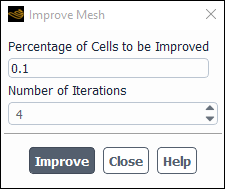

- 52.2.58. Improve Mesh Dialog Box

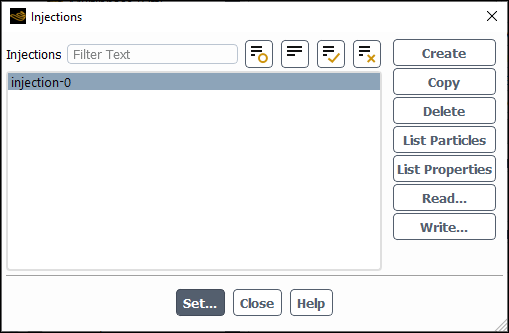

- 52.2.59. Injections Dialog Box

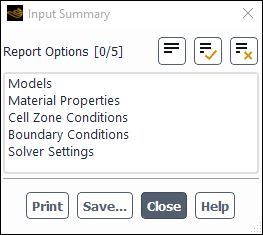

- 52.2.60. Input Summary Dialog Box

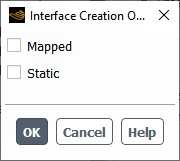

- 52.2.61. Interface Creation Options Dialog Box

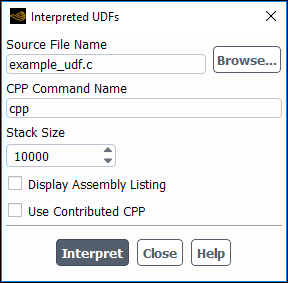

- 52.2.62. Interpreted UDFs Dialog Box

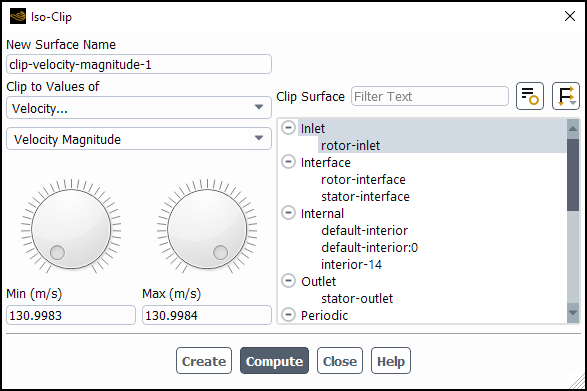

- 52.2.63. Iso-Clip Dialog Box

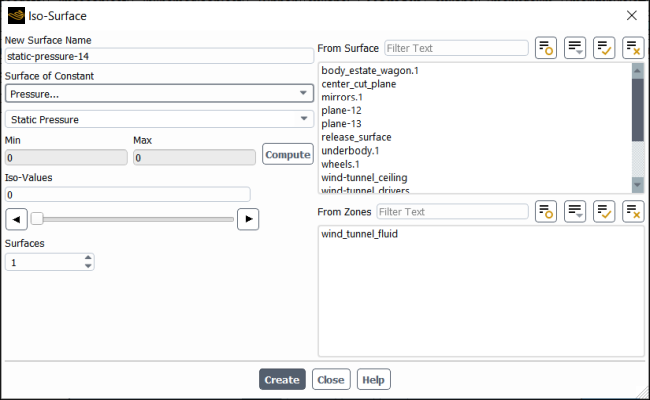

- 52.2.64. Iso-Surface Dialog Box

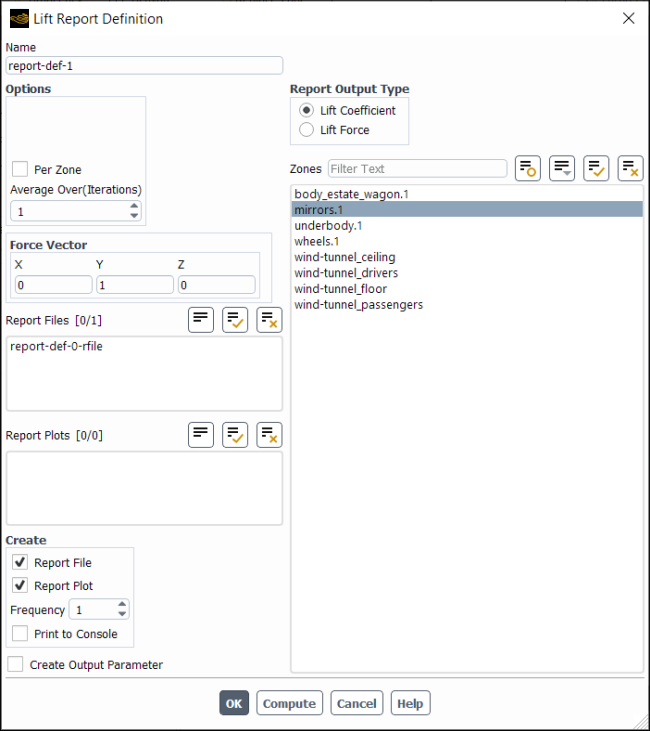

- 52.2.65. Lift Report Definition Dialog Box

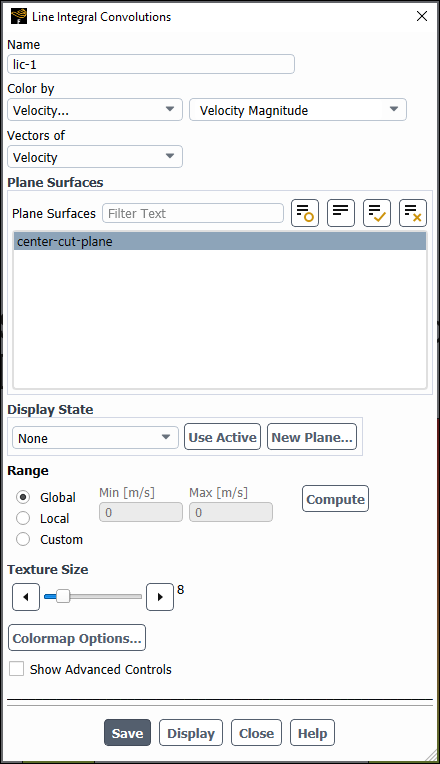

- 52.2.66. Line Integral Convolutions Dialog Box

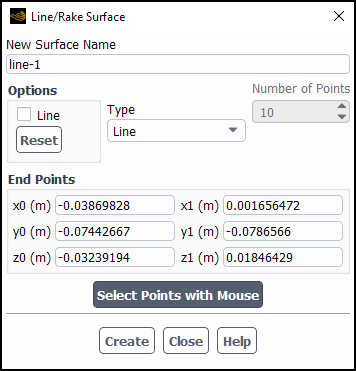

- 52.2.67. Line/Rake Surface Dialog Box

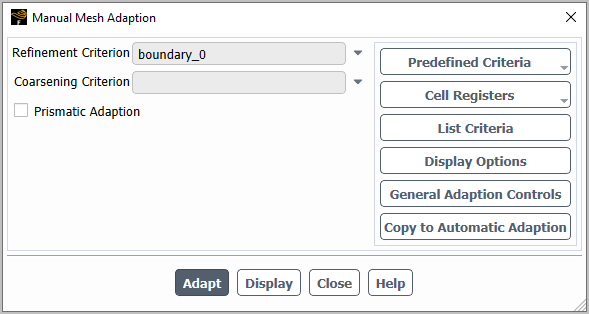

- 52.2.68. Manual Mesh Adaption Dialog Box

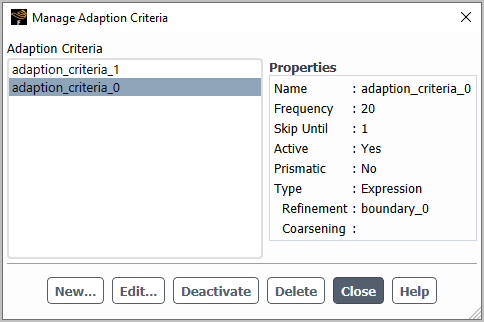

- 52.2.69. Manage Adaption Criteria Dialog Box

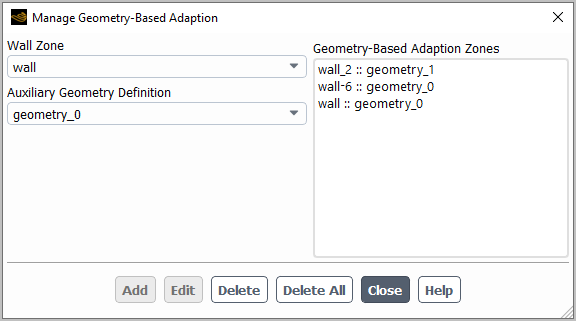

- 52.2.70. Manage Geometry-Based Adaption Dialog Box

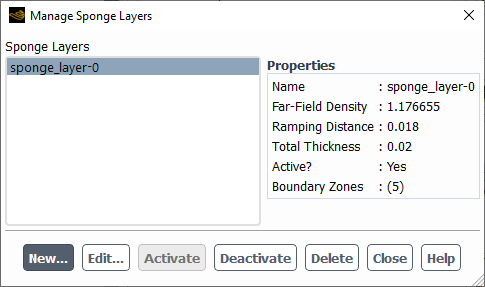

- 52.2.71. Manage Sponge Layers Dialog Box

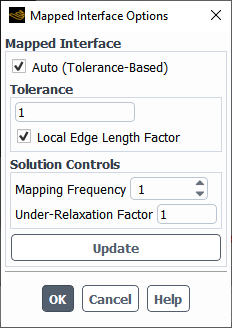

- 52.2.72. Mapped Interface Options Dialog Box

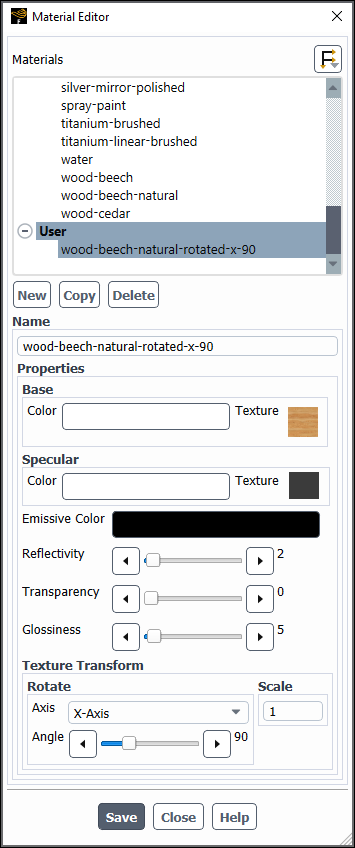

- 52.2.73. Material Editor Dialog Box

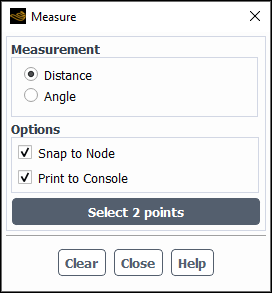

- 52.2.74. Measure Dialog Box

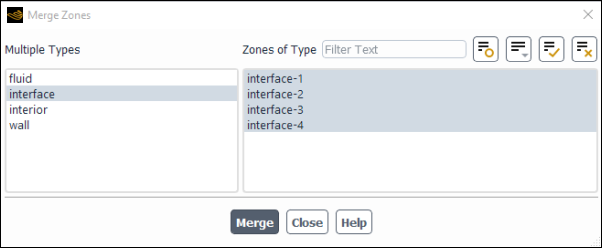

- 52.2.75. Merge Zones Dialog Box

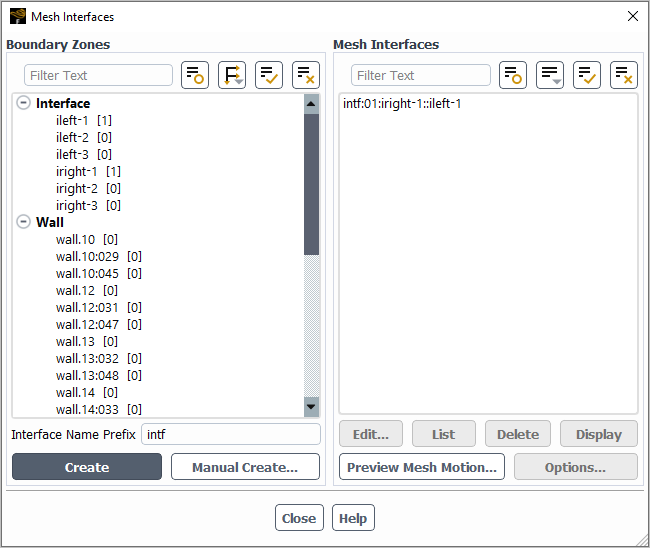

- 52.2.76. Mesh Interfaces Dialog Box

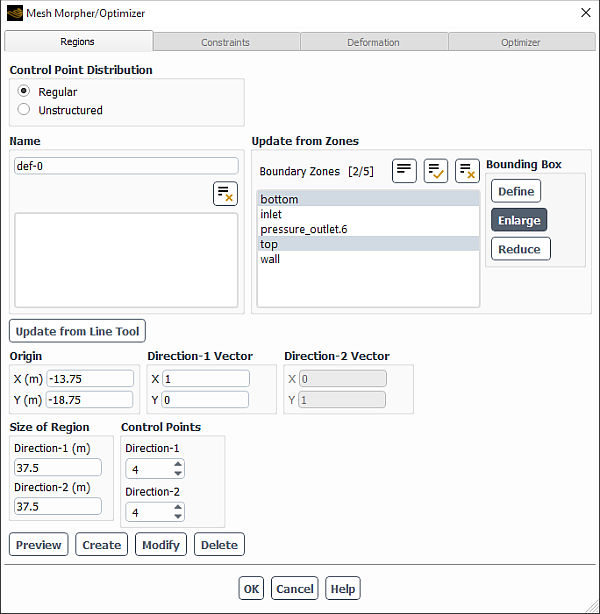

- 52.2.77. Mesh Morpher/Optimizer Dialog Box

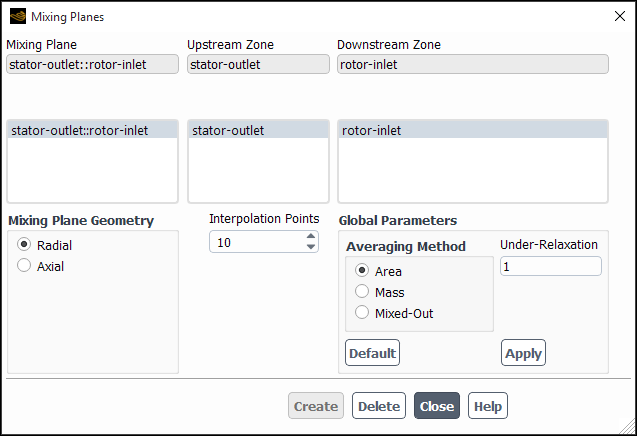

- 52.2.78. Mixing Planes Dialog Box

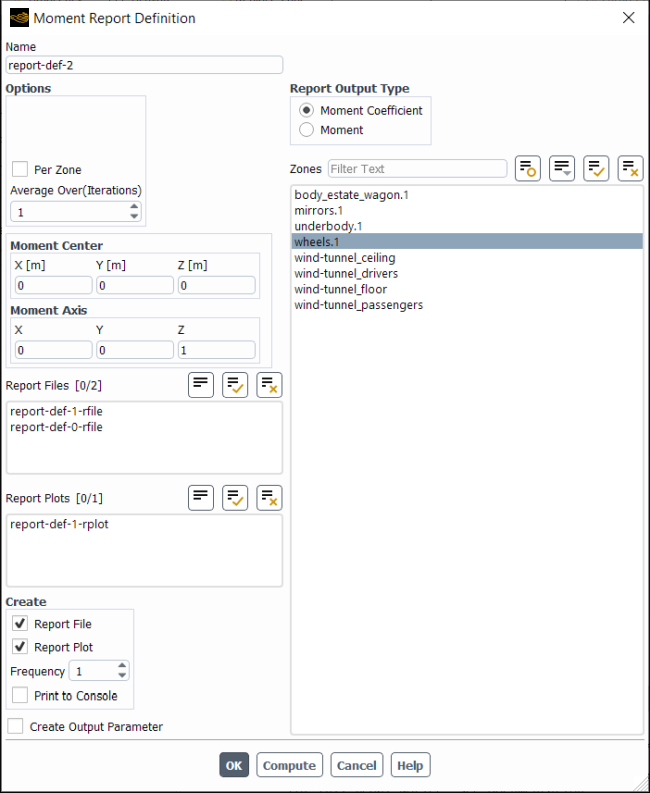

- 52.2.79. Moment Report Definition Dialog Box

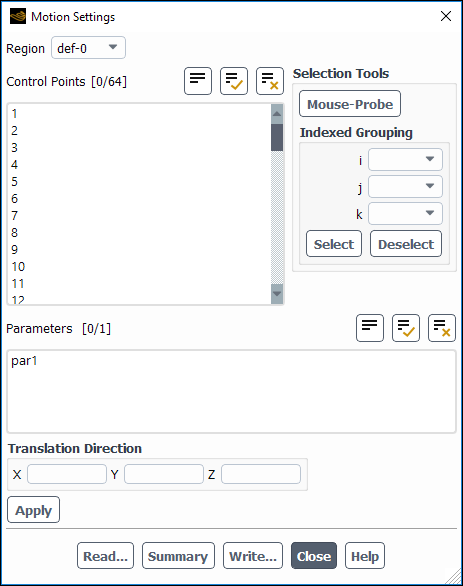

- 52.2.80. Motion Settings Dialog Box

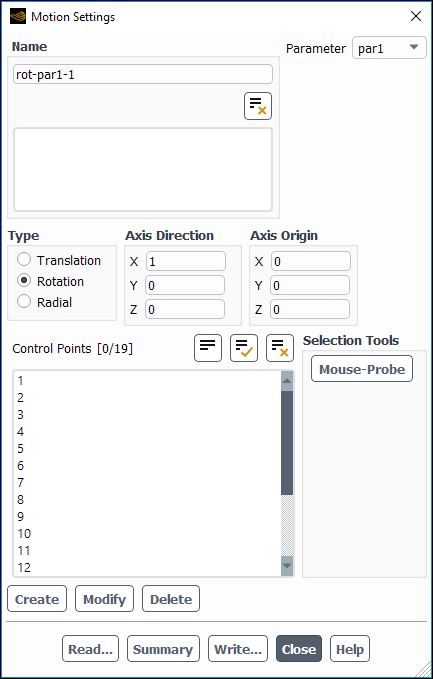

- 52.2.81. Multi Edit Dialog Box

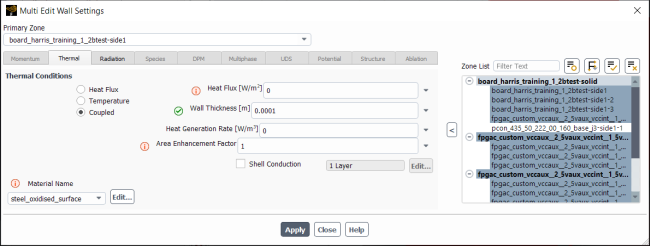

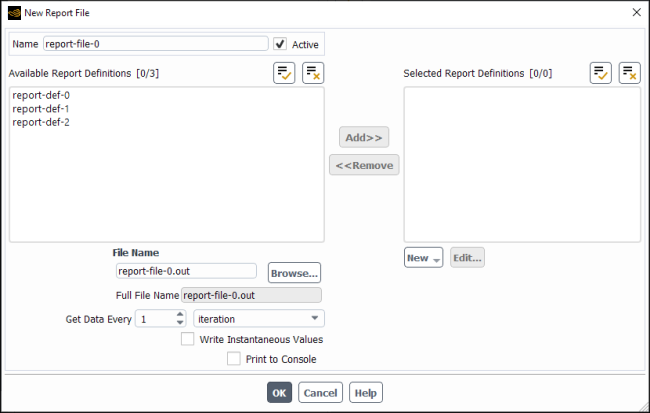

- 52.2.82. New Report File Dialog Box

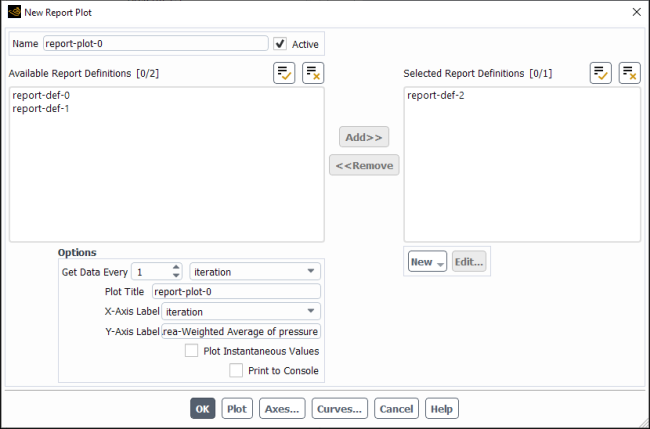

- 52.2.83. New Report Plot Dialog Box

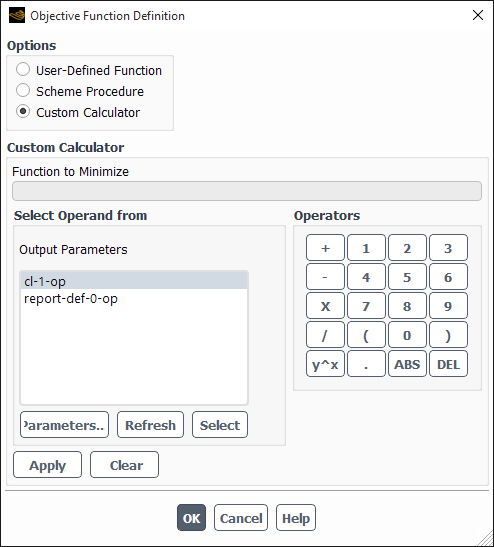

- 52.2.84. Objective Function Definition Dialog Box

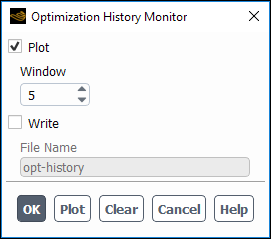

- 52.2.85. Optimization History Monitor Dialog Box

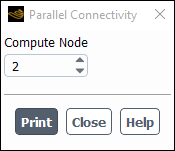

- 52.2.86. Parallel Connectivity Dialog Box

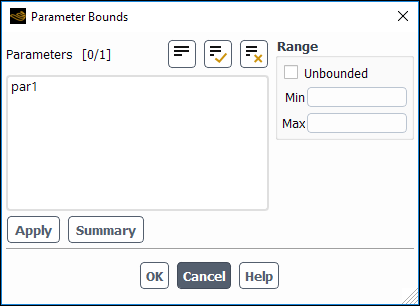

- 52.2.87. Parameter Bounds Dialog Box

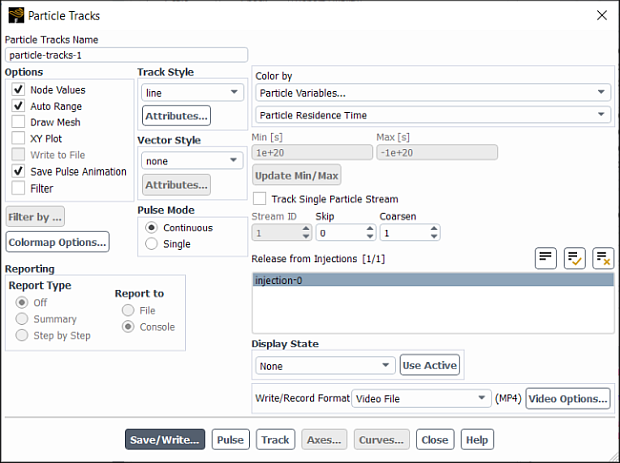

- 52.2.88. Particle Tracks Dialog Box

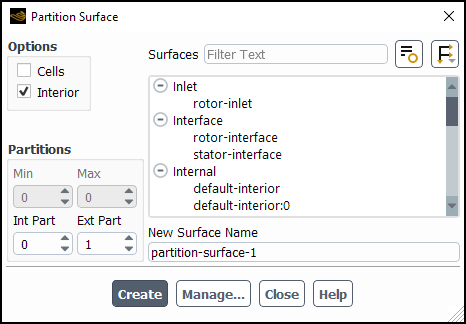

- 52.2.89. Partition Surface Dialog Box

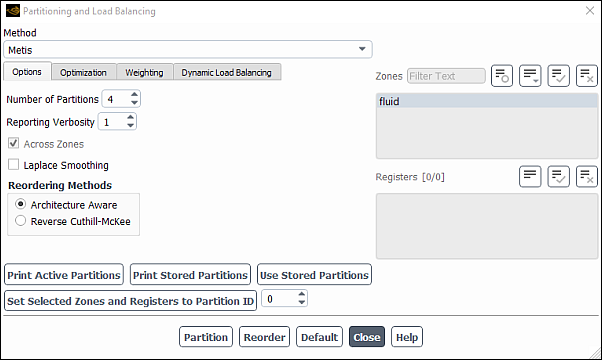

- 52.2.90. Partitioning and Load Balancing Dialog Box

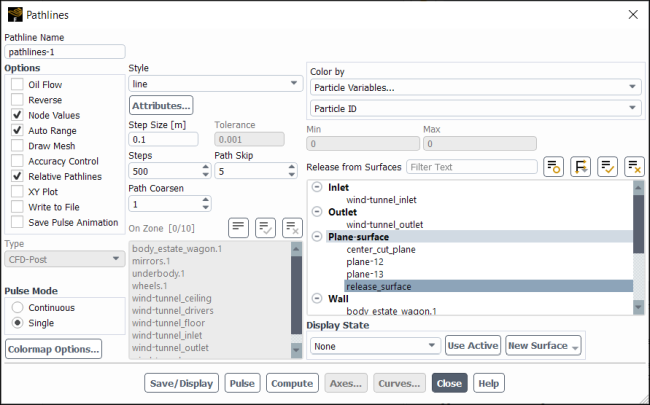

- 52.2.91. Pathlines Dialog Box

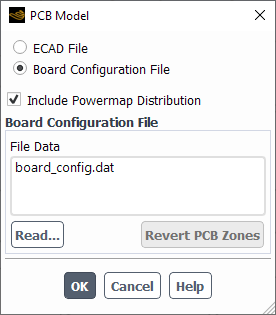

- 52.2.92. PCB Model Dialog Box

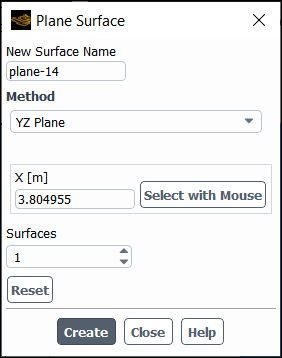

- 52.2.93. Plane Surface Dialog Box

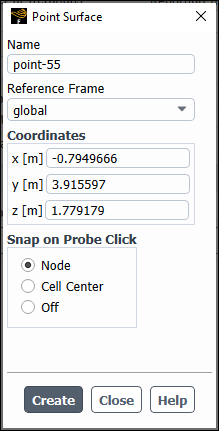

- 52.2.94. Point Surface Dialog Box

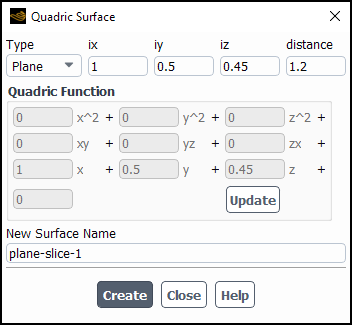

- 52.2.95. Quadric Surface Dialog Box

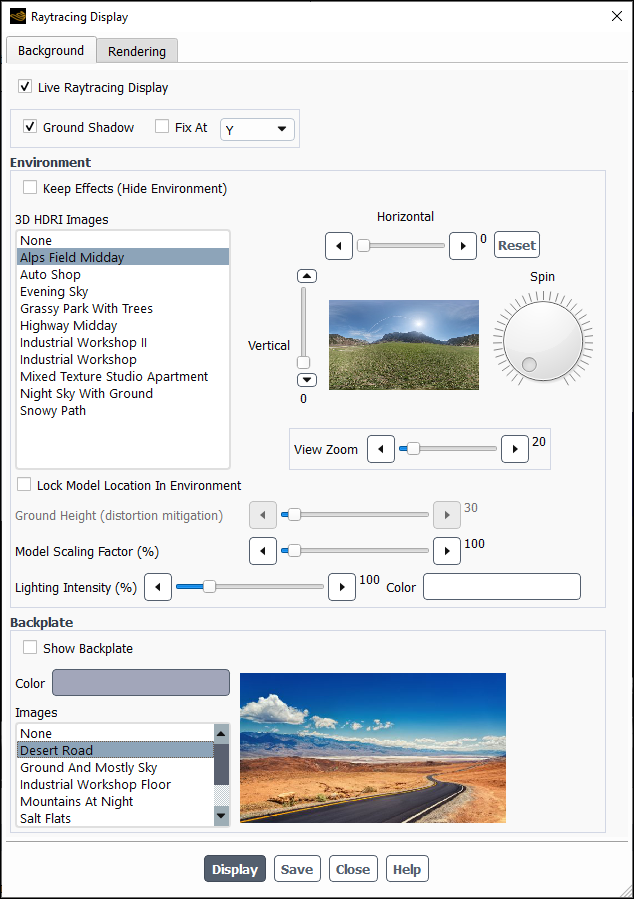

- 52.2.96. Raytracing Display Dialog Box

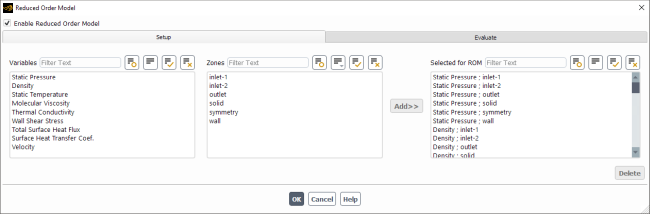

- 52.2.97. Reduced Order Model Dialog Box

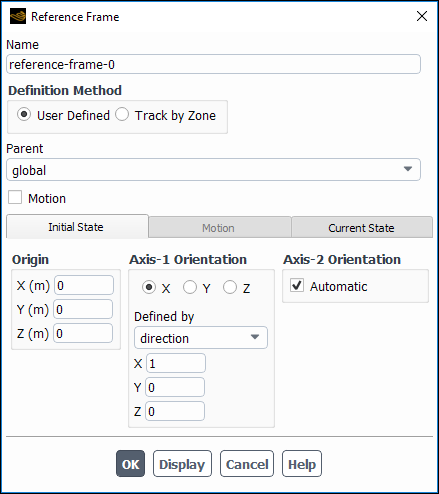

- 52.2.98. Reference Frame Dialog Box

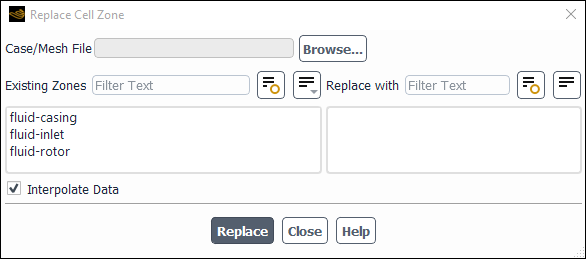

- 52.2.99. Replace Cell Zone Dialog Box

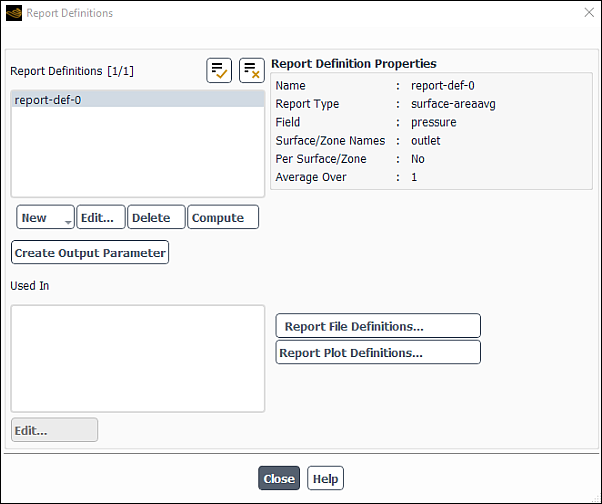

- 52.2.100. Report Definitions Dialog Box

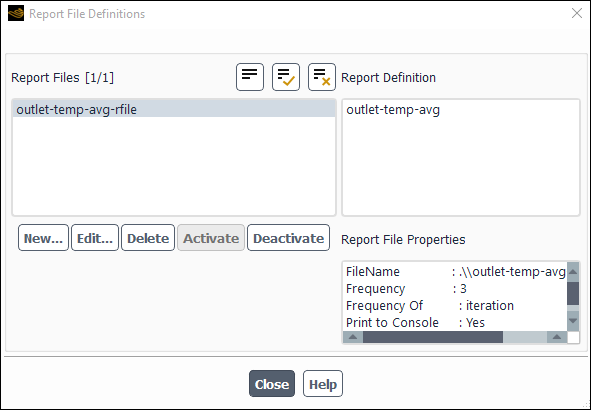

- 52.2.101. Report File Definitions Dialog Box

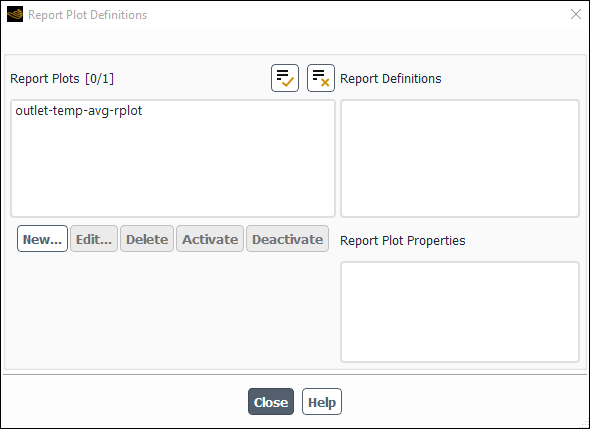

- 52.2.102. Report Plot Definitions Dialog Box

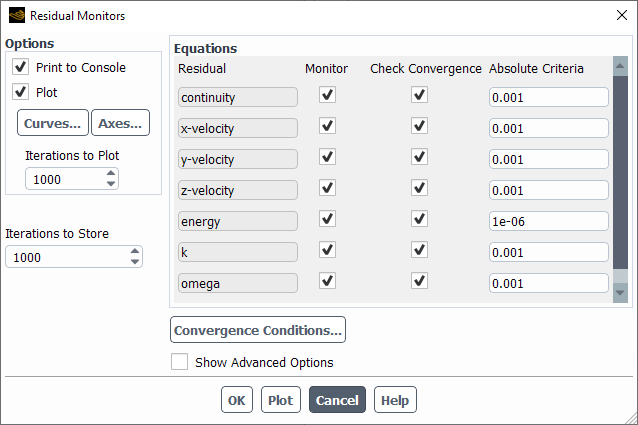

- 52.2.103. Residual Monitors Dialog Box

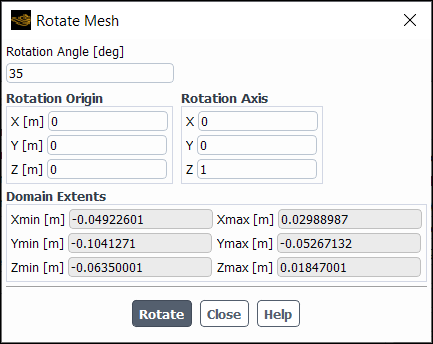

- 52.2.104. Rotate Mesh Dialog Box

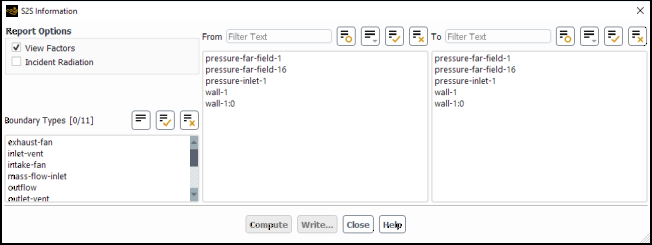

- 52.2.105. S2S Information Dialog Box

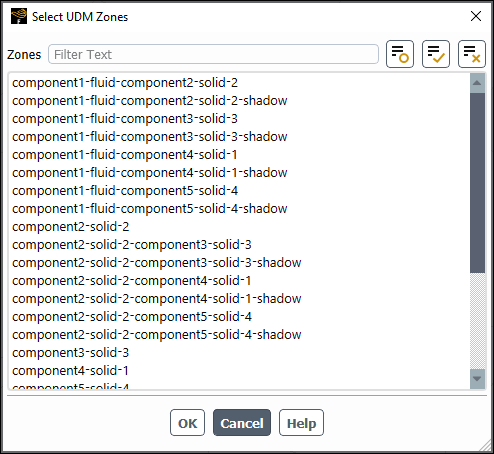

- 52.2.106. Select UDM Zones Dialog Box

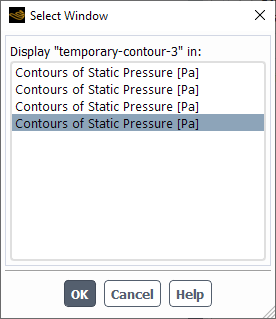

- 52.2.107. Select Window Dialog Box

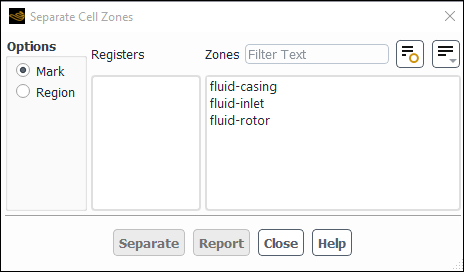

- 52.2.108. Separate Cell Zones Dialog Box

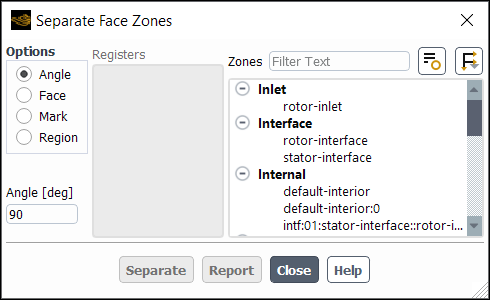

- 52.2.109. Separate Face Zones Dialog Box

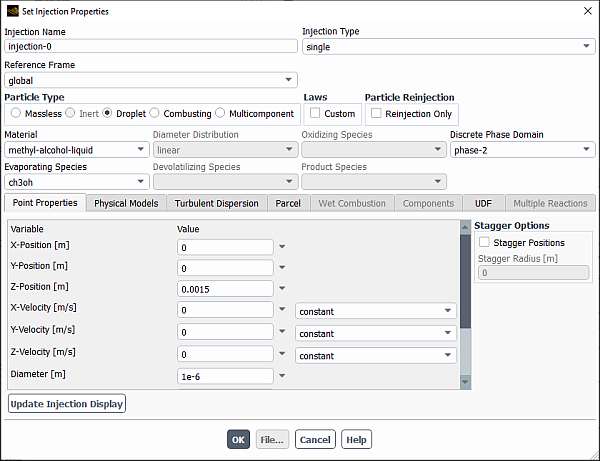

- 52.2.110. Set Injection Properties Dialog Box

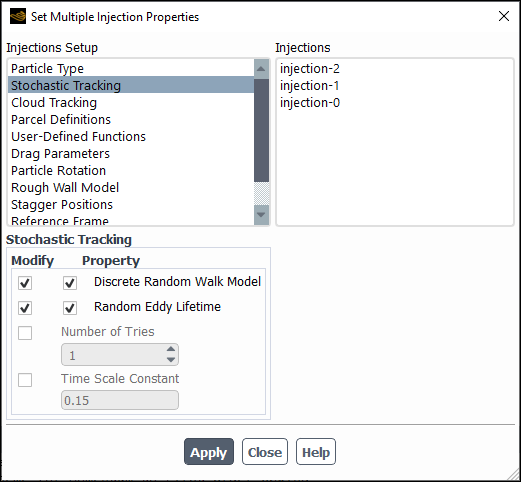

- 52.2.111. Set Multiple Injection Properties Dialog Box

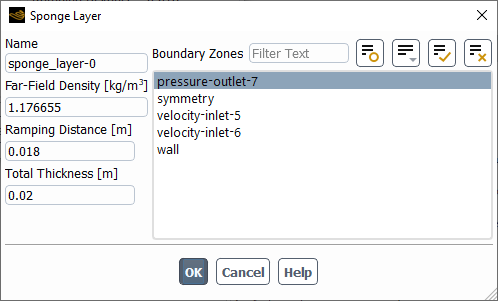

- 52.2.112. Sponge Layer Dialog Box

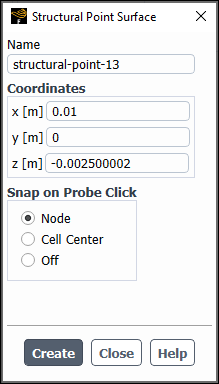

- 52.2.113. Structural Point Surface Dialog Box

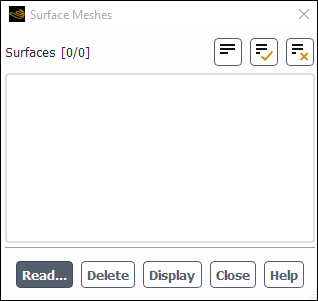

- 52.2.114. Surface Meshes Dialog Box

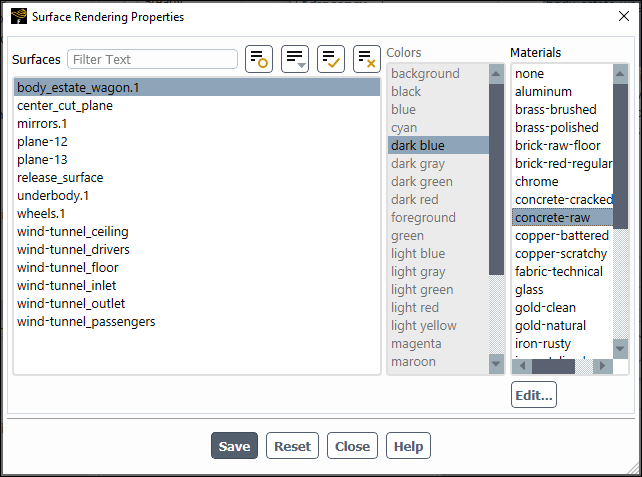

- 52.2.115. Surface Rendering Properties Dialog Box

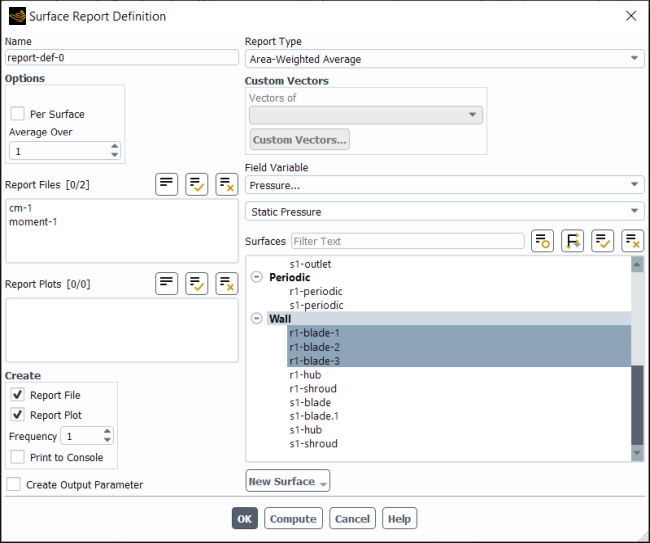

- 52.2.116. Surface Report Definition Dialog Box

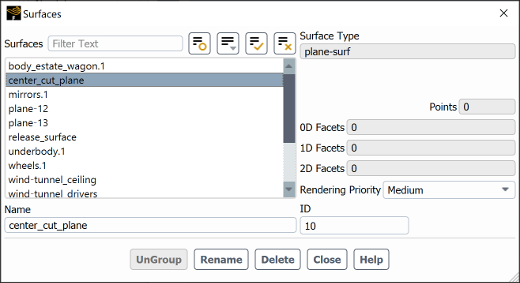

- 52.2.117. Surfaces Dialog Box

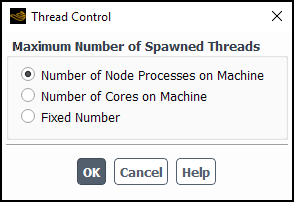

- 52.2.118. Thread Control Dialog Box

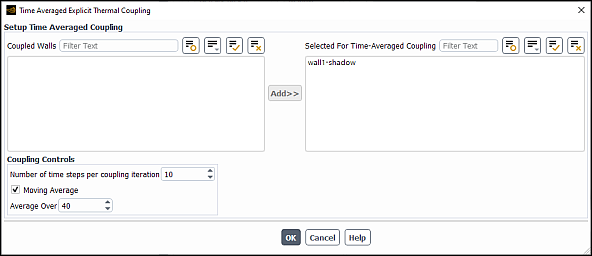

- 52.2.119. Time Averaged Explicit Thermal Coupling Dialog Box

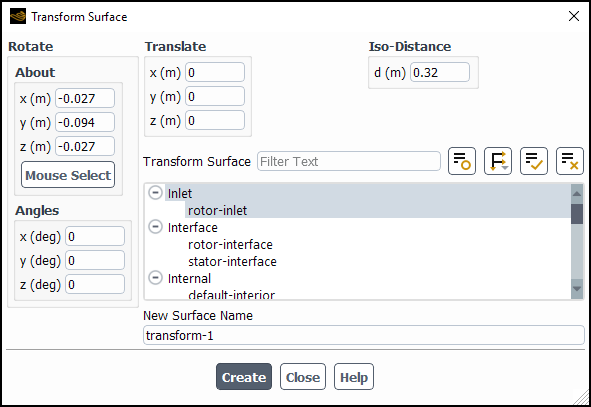

- 52.2.120. Transform Surface Dialog Box

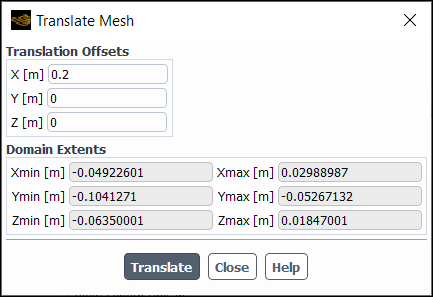

- 52.2.121. Translate Mesh Dialog Box

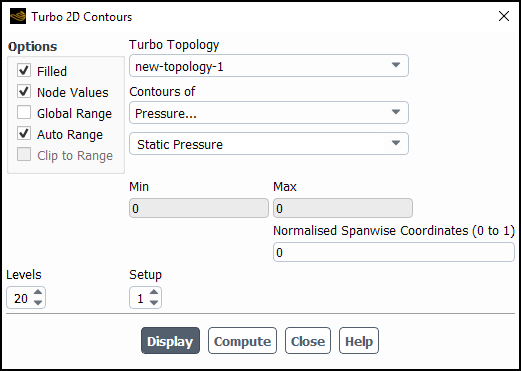

- 52.2.122. Turbo 2D Contours Dialog Box

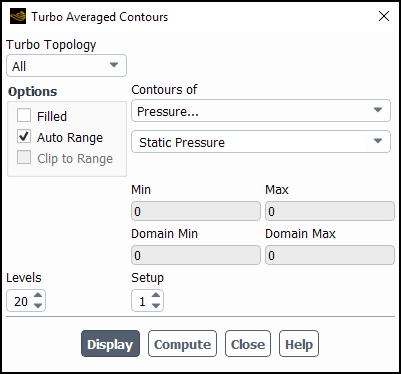

- 52.2.123. Turbo Averaged Contours Dialog Box

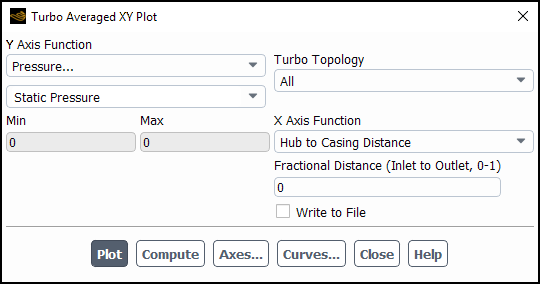

- 52.2.124. Turbo Averaged XY Plot Dialog Box

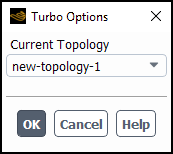

- 52.2.125. Turbo Options Dialog Box

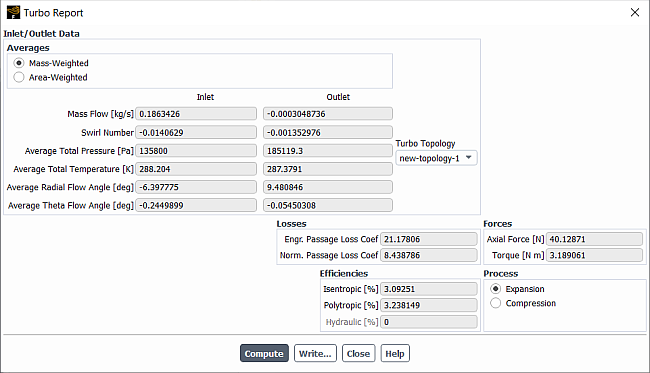

- 52.2.126. Turbo Report Dialog Box

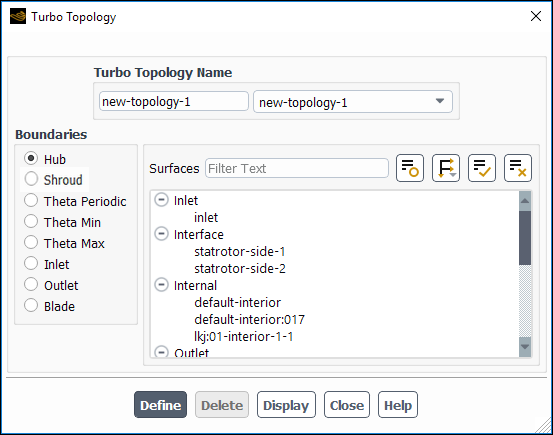

- 52.2.127. Turbo Topology Dialog Box

- 52.2.128. UDF Library Manager Dialog Box

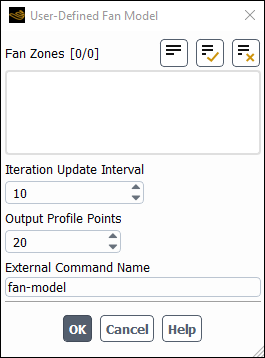

- 52.2.129. User-Defined Fan Model Dialog Box

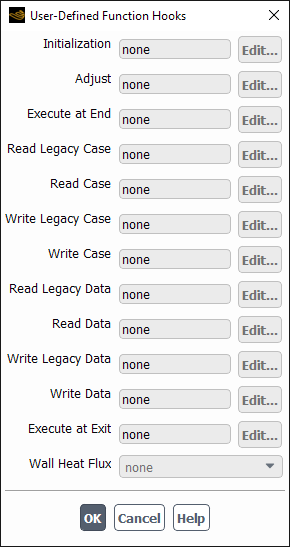

- 52.2.130. User-Defined Function Hooks Dialog Box

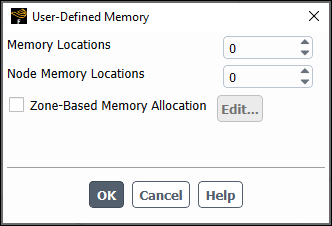

- 52.2.131. User-Defined Memory Dialog Box

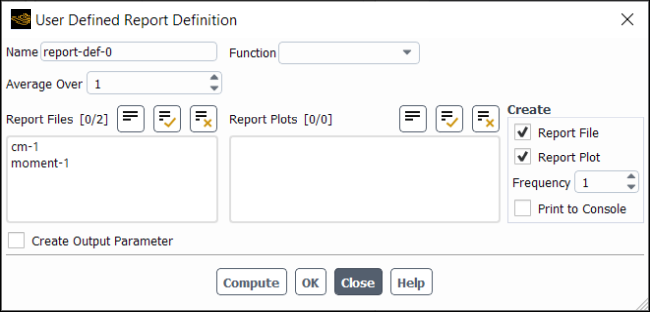

- 52.2.132. User Defined Report Definition Dialog Box

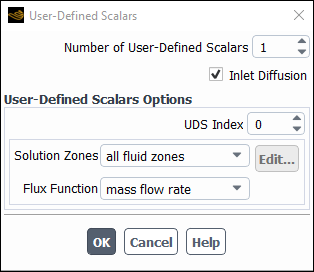

- 52.2.133. User-Defined Scalars Dialog Box

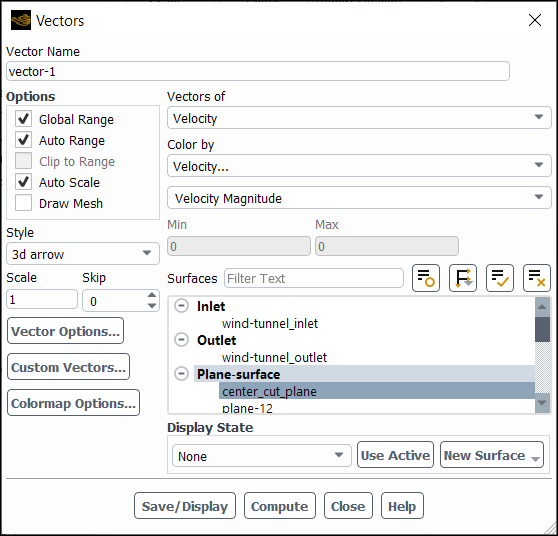

- 52.2.134. Vectors Dialog Box

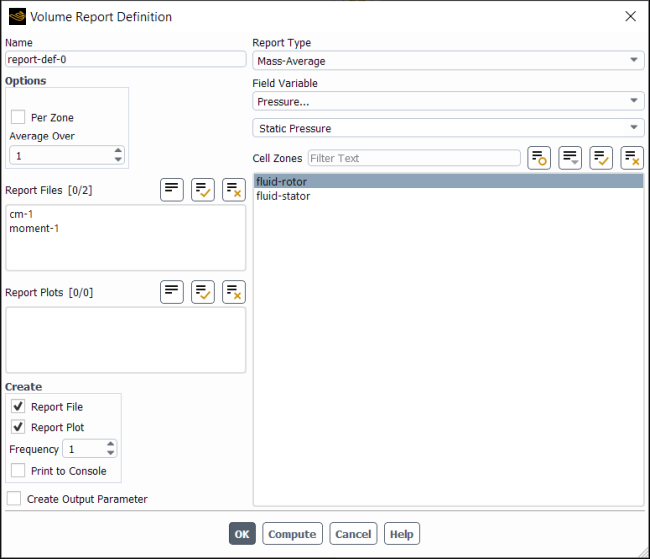

- 52.2.135. Volume Report Definition Dialog Box

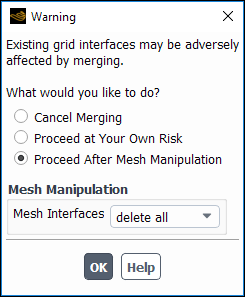

- 52.2.136. Warning Dialog Box

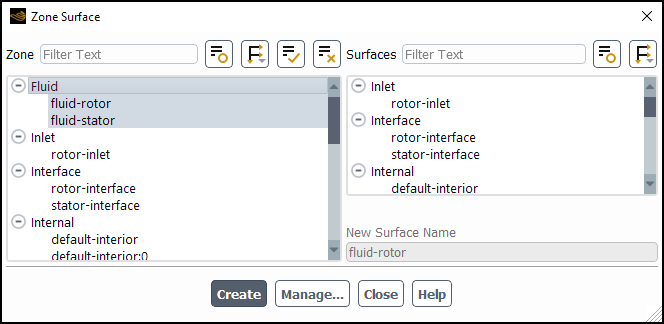

- 52.2.137. Zone Surface Dialog Box

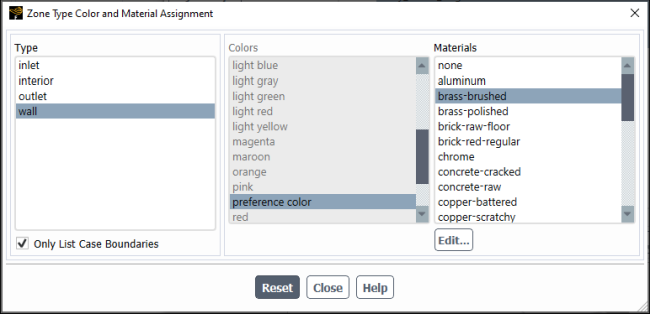

- 52.2.138. Zone Type Color and Material Assignment Dialog Box

The 1D Simulation Library dialog box allows you to set parameters related to coupling between Ansys Fluent and GT-POWER or WAVE. See Coupling Boundary Conditions with GT-POWER or Coupling Boundary Conditions with WAVE for details about the items below.

User Defined → Model Specific

→ 1D Coupling...

Controls

- 1D Library

specifies the type of library to be used. (Currently only GTpower and WAVE are available.)

- 1D Input File Name

specifies the name of the GT-POWER or WAVE input file.

- Start

starts up GT-POWER or WAVE and generates Ansys Fluent user-defined functions for each boundary in the input file.

- Stop

unlinks the shared library.

The Activate Cell Zones dialog box allows you to activate a single cell zone or multiple zones. See Activating Zones for details.

Domain → Zones

→ Activate...

Controls

- Cell Zones

contains a list of cell zones from which you can select the zone to be activated.

- Activate

activates the selected cell zones.

The Adaption Criteria Settings dialog box allows you to complete the setup of an adaption criterion when you have made a selection from the Predefined Criteria drop-down list in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box; the Adaption Criteria Settings dialog box opens automatically, and is used to define necessary settings or parameters in the refinement / coarsening criterion expression or overset adaption settings. See Refining and Coarsening and Predefined Criteria for Adaption for details.

Controls

(when setting up the Cell Distance predefined criterion under Boundary Layer...)

- Boundary Zones

specifies the boundary zones where adjacent cell layers will be split for boundary layer adaption. The selections are used in a boundary register named boundary_cell_distance that is selected in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box.

- Cell Layers to Split

specifies the number of cell layers that will be split for boundary layer adaption. The value you enter is used in a boundary register named boundary_cell_distance that is selected in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box.

(when setting up the Flame Indicator predefined criterion under Combustion...)

- Include Vortex Indicator

specifies that the magnitude of vorticity is included as part of the criteria for refinement and coarsening.

- Spark Region Refinement

enables refinement in a temporary spherical spark region at the start of the simulation (which will then later be coarsened back to the original mesh).

- Time

sets the maximum time during which refinement is applied to the spark region, as part of the Spark Region Refinement option. The value you enter will automatically update an expression named spark_<ID>, which is a parameter in the flame_refinement_<ID> expression used in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

- Centroid X

sets the x-coordinate for the center of the spark region as part of the Spark Region Refinement option. The value you enter will automatically update a cell register named spark_region, which is used in an expression named spark_<ID> that is a parameter in the flame_refinement_<ID> expression used in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

- Centroid Y

sets the y-coordinate for the center of the spark region as part of the Spark Region Refinement option. The value you enter will automatically update a cell register named spark_region, which is used in an expression named spark_<ID> that is a parameter in the flame_refinement_<ID> expression used in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

- Centroid Z

sets the z-coordinate for the center of the spark region as part of the Spark Region Refinement option. The value you enter will automatically update a cell register named spark_region, which is used in an expression named spark_<ID> that is a parameter in the flame_refinement_<ID> expression used in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

- Radius

sets the radius of the spherical spark region as part of the Spark Region Refinement option. The value you enter will automatically update a cell register named spark_region, which is used in an expression named spark_<ID> that is a parameter in the flame_refinement_<ID> expression used in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

(when setting up the Volume of Fluid predefined criterion under Multiphase...)

- Minimum Cell Length Scale

sets the minimum cell length scale for refinement. By default this is set to the minimum cell edge length in the initial mesh. It is used to automatically update the cell volume in an expression named vof_refinement_<ID> that is used in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

(when setting up the VOF-to-DPM [Generic] predefined criterion under Multiphase...)

- Number of Cells Across Resolved Droplet

sets the number of cells across the resolved droplet (

). It is used to automatically update the cell volume (as described in the definition that follows) used in the vof_to_dpm_refinement_<ID> expression that is used in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

- Minimum Resolved Droplet Diameter

sets the minimum diameter of droplets that are resolved in the simulation (

). By default this is set to the minimum cell edge length in the initial mesh. It is used (with the Number of Cells Across Resolved Droplet setting) to automatically update the cell volume used in the vof_to_dpm_refinement_<ID> expression, by setting it to

. This expression is then used in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

(when setting up the VOF-to-DPM [Advanced] predefined criterion under Multiphase...)

- Bulk Secondary Phase Edge Length

specifies an edge length that is cubed in order to define the minimum cell volume that initiates refinement in the secondary phase. This volume is used in an expression named vof_to_dpm_refinement_1 that is used in the Refinement Criterion field in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

- VOF Interface Refinement Edge Length

specifies an edge length that is cubed in order to define minimum / maximum cell volume that initiates refinement / coarsening at the VOF interface. This volume is used in expressions named vof_to_dpm_refinement_1 and vof_to_dpm_coarsening_1, which are then used in the Refinement Criterion and Coarsening Criterion fields, respectively, in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

(when setting up the Overset predefined criterion)

- Orphan Adaption

enables adaption that attempts to remove orphan cells. For details, see Marking for Orphan Adaption.

- Size Adaption

enables adaption that reduces size mismatches between donor and receptor cells. For details, see Marking for Size Adaption.

- Maximum Length Scale Ratio

sets the threshold (

) used as part of the Size Adaption option to determine which cells are marked for adaption based on donor-receptor cell size differences. This is set to 3 by default.

- Gap Adaption

enables adaption that increases the mesh resolution in gaps as needed (in order to prevent the creation of orphan cells). For details, see Marking for Gap Adaption.

- Gap Resolution

specifies the target (minimum) gap resolution used as part of the Gap Adaption option when marking cells for gap adaption. This is set to 4 by default.

- Coarsening

enables the coarsening of the mesh when mesh refinement is no longer needed.

(when setting up the Goal-Based Error Indicator predefined criterion under Aerodynamics...)

- Set Up Goal...

Opens the Adjoint Observables dialog box where you can select, edit, or create the desired observable.

- Skip Initial Adjoint Advancement Before Adaption

When enabled, if the adjoint solution is calculated, the mesh adaption will ignore the computationally expensive initial adjoint iterations which are specified by Initial Adjoint Iterations before Adaption.

- Initial Adjoint Iterations Before Adaption

This specifies the number of adjoint iterations in the initial adjoint calculation before the first mesh adaption.

- Adjoint Iterations Before Adaption

This specifies the number of adjoint iterations during the adjoint calculation before each mesh adaption.

- Number of Modes for Adjoint Advancement

This specifies the number of modes in the Krylov subspace used to approximate the solution. A larger value will help to converge the adjoint solution at the expense of memory cost and potentially more computational time.

- Smoothing Steps Before Adaption

A larger value will lead to smoother adaption.

- Reset Adaption History

Deletes any previous adaption history.

- Print Adaption History

Prints the goal-based adaption history in the console.

The Adjacency dialog box allows you to identify, display, and rename face zones based on their adjacency to a selected cell zone. You can also rename cell zones by zone type and ID, by wildcard, and by adding prefixes/suffixes. See Managing Adjacent Zones for details.

Domain → Zones

→ Adjacency...

Controls

- Cell Zone(s)

contains a list of the cell zones for which you can find adjacent face zones.

- Adjacent Face Zones

contains a list of the face zones that are adjacent to the selected cell zones.

- Options

contains relevant options for adjacency.

- Multiple Cell Zones

allows you to select multiple cell zones at once. The zones listed in Adjacent Face Zones will be the union of all zones adjacent to the selected cell zones.

- Rename Face Zones

allows you to rename selected face zones based on adjacency, zone type, wild card, or add a prefix/suffix.

- Rename Cell Zones

allows you to rename selected cell zones based zone type and ID, wild card, or by adding a prefix/suffix.

- Draw Default Mesh

brings up the Mesh Display Dialog Box where you can specify zones of the mesh to be permanently displayed as you display or hide face zones from within the Adjacency dialog box. This can be helpful in cases where the mesh is very complex. If this option is not enabled, only the zones selected in Adjacent Face Zones will be displayed when you click Display Face Zones.

- On Selected Face Zones

contains controls for renaming face zones that are selected in Adjacent Face Zones. For details on the renaming methods, refer to Renaming Zones Using the Adjacency Dialog Box.

- Renaming By:

contains options for how you can rename surfaces.

- Adjacency

renames the selected face zones incorporating the name of the adjacent cell zone and the face zone type when you click .

- Fluent Naming Convention

renames the selected surface to be a combination of the surface type and the surface ID when you click . Cell zones are renamed to be a combination of the zone type and the zone ID.

- Wildcard

renames the selected face zones or cell zones based on a pattern match string in the From field and a replacement string in the To field.

- Add Suffix and/or Prefix

adds the provided text in the Suffix or Prefix field to either the beginning or end of the selected zone name(s). Click to add the provided text at the end of the name and click to add the provided text at the beginning of the name.

- Abbreviate Types

uses abbreviations for the zone types when renaming rather than the full zone type text.

- Exclude Custom Names

excludes from renaming any zones that do not match a recognized naming pattern. This can be useful to prevent inadvertently replacing a meaningful name.

- Displace Face Zones

displays the face zones selected in Adjacent Face Zones.

The Advanced Options dialog box provides advanced options for a simulation that uses the gap model to simulate flow through narrow gaps that open or close over time (such as in a valve). It is opened by clicking in the Gap Model Dialog Box. See also Controlling Flow in Narrow Gaps for Valves and Pumps.

Controls

- Solution Stabilization

allows you to define solution stabilization settings for the gap model.

- Stabilization Level

allows you to define the level of solution stabilization for the gap model simulation. For each level, the solver adjusts the numerical settings, discretization schemes, under-relaxations, AMG settings, and so on, and controls the flow behavior in vicinity of the gap regions. The cost of computation increases with higher levels. Note that these changes are applied globally to all gap regions, and a level other than None will override the local stabilization applied by default to flow-modeling regions that use the Sponge Layer method.

- Check CFL Condition

enables the automatic determination of a desirable acoustic Courant (CFL) number based on the selected Stabilization Level, and then provides a warning message in the console if this CFL number would require you to specify a smaller time step for the calculation in order to improve the solver stability.

- Extend Gap Regions

enables the extending of the gap regions by including additional cells in the vicinity of the gap interfaces during marking. This is useful when the default shape of the marked cells is negatively affecting solution stability or convergence behavior.

For more details, see ICM Method Post-processing.

Solution → Reports

→ Definitions → New

→ Aeromechanics Report → Aerodamping

(Influence Coefficient Method)...

Controls

- Name

specifies the name of the report definition.

- Options

contains options for your aerodamping report definition.

- Normalization

Sets the normalization factor for the damping value.

- Report Files

lists all of the report files where you can write the report definition data.

- Report Plots

lists all of the report plots where you can plot the report definition data (assuming this report has the same units as the other report definitions included in the selected report plot).

- Create

- Report File

creates a new report file that includes this report definition.

- Report Plot

creates a new report plot that includes this report definition.

- Frequency

specifies how frequently the report definition is written, plotted, or printed to the console.

- Print to Console

prints the value of the report definition to the console.

- Create Output Parameter

creates an output parameter for this report definition with the name

<report definition name>-op.- OK

creates the report definition.

- Compute

computes the value of the report definition at the selected zone(s) and prints to the console.

For more details, see TWM Method Post-processing.

Solution → Reports

→ Definitions → New

→ Aeromechanics Report → Aerodamping

(Travelling Wave Method)...

Controls

- Name

specifies the name of the report definition.

- Options

contains options for your aerodamping report definition.

- Per Zone

If you are modeling multiple (main) blades, enables the damping value to be calculated for each dynamic mesh zone (which encompasses one main blade and possibly accompanying splitter blades).

- Integrate Over

sets the number of time steps over which to integrate when calculating the damping value; a suggested value is the number of time steps per period..

- Normalization

Sets the normalization factor for the damping value.

- Report Files

lists all of the report files where you can write the report definition data.

- Report Plots

lists all of the report plots where you can plot the report definition data (assuming this report has the same units as the other report definitions included in the selected report plot).

- Create

- Report File

creates a new report file that includes this report definition.

- Report Plot

creates a new report plot that includes this report definition.

- Frequency

specifies how frequently the report definition is written, plotted, or printed to the console.

- Print to Console

prints the value of the report definition to the console.

- Create Output Parameter

creates an output parameter for this report definition with the name

<report definition name>-op.- Wall Zones

contains a selectable list of valid walls zones for aerodamping report.

- OK

creates the report definition.

- Compute

computes the value of the report definition at the selected zone(s) and prints to the console.

The Animation Definition dialog box allows you to specify a graphics object that will be captured during the solution calculation so that it may be played back as an animation during postprocessing.

Solution → Activities

→ Create → Solution

Animations...

Controls

- Name

name of the animation definition.

- Realistic Rendering

option for enhancing the appearance of the animation object by using a raytracer for realistic lighting effects.

- Raytracer Image

indicates that animation images will use a raytracing renderer for enhanced image quality. Refer to Realistic Rendering Using Raytracing for additional information on raytracing.

- Animation Files

controls for how animation files are stored.

- Record after every

specifies the frequency that images are captured during the calculation. You can select whether the frequency is Iteration, Time Step (transient only) or Flow Time (transient only) from the drop-down.

- Storage Type

drop-down list with the available formats for storing the animation images.

- None

no images are saved. This option is intended for use with embedded window dashboards (Embedded Graphics Window Dashboards).

- In Memory

the image files associated with the animation will lost when you exit Fluent.

- PPM Image

Fluent will save the animation images in PPM Image format (

.ppm), which is 2D.- HSF File

Fluent will save the animation images in HSF file format (

.hsf), which is 3D.- PNG Image

Fluent will save the animation images in PNG file format (

.png), which is 2D.- JPEG Image

Fluent will save the animation images in JPEG file format (

.jpg), which is 2D.- TIFF Image

Fluent will save the animation images in tagged image file format (TIFF—

.tif), which is 2D.

- Storage Directory

shows the location where the animation images will be stored if the Storage Type is set to any of the types other than In Memory.

Note: Animation files are written to the same directory as the case file, by default. This is stored as a relative path, represented by a dot (.), so that when a case file is shared, animation files are written to an appropriate location.

If you manually specify a path, then what you are specifying is an absolute path that will not automatically be updated if the case file is shared or run from another directory.

- Animation View

specifies the animation object orientation that will be used when the animation images are capture during the calculation.

- views drop-down

list with all of the defined views.

- Preview

displays the selected animation object in a reserved graphics window.

- Use Active

saves the current view in the active graphics window and automatically selects it for use in the animation definition.

- Append File Name with

indicates that the Name of the animation files will have either the time-step, flow-time, or iteration appended. The drop-down menu allows you to specify which one.

- Precision

indicates the number of decimal places included when the flow-time is appended.

- Animation Object

lists the defined graphics objects that may be selected for animation.

- New Object

drop-down list allowing you to create new graphics objects for animating.

Mesh... opens the Mesh Display Dialog Box.

Contours... opens the Contours Dialog Box.

Vectors... opens the Vectors Dialog Box.

Pathlines... opens the Pathlines Dialog Box.

Particle Tracks... opens the Particle Tracks Dialog Box.

Scene... opens Figure 40.50: The Scene Dialog Box.

XY Plot... opens the Solution XY Plot Dialog Box.

Report Plot... opens the New Report Plot Dialog Box.

allows you to edit the selected graphics object.

creates the animation definition and/or saves settings changes and closes the dialog box.

The Application About to Exit dialog box gives you chance to stop the Ansys Fluent session from saving and exiting as the session approaches the idle timeout set in the Set Idle Timeout Dialog Box. Refer to Having the Session Close After Sitting Idle for additional information.

Controls

- Change Idle Timeout...

opens the Set Idle Timeout Dialog Box.

The Auto Partition Mesh dialog box allows you to set the parameters for automatic partitioning when reading an unpartitioned mesh into the parallel solver. See Partitioning the Mesh Automatically for details.

Parallel → General → Auto Partition...

Controls

- Method

contains a drop-down list of the recursive partition methods that can be used to create the mesh partitions. The choices include the Cartesian Axes, Cartesian Strip, Cartesian X-Coordinate, Cartesian Y-Coordinate, Cartesian Z-Coordinate, Cartesian R Axes, Cartesian RX-Coordinate, Cartesian RY-Coordinate, Cartesian RZ-Coordinate, Cylindrical Axes, Cylindrical R-Coordinate, Cylindrical Theta-Coordinate, Cylindrical Z-Coordinate, Metis, Polar Axes, Polar R-Coordinate, Polar Theta-Coordinate, Principal Axes, Principal Strip, Principal X-Coordinate, Principal Y-Coordinate, Principal Z-Coordinate, Spherical Axes, Spherical Rho-Coordinate, Spherical Theta-Coordinate, and Spherical Phi-Coordinate techniques, which are described in Mesh Partitioning Methods.

- Case File

allows you to use a valid existing partition section in a case file (that is, one where the number of partitions in the case file divides evenly into the number of compute nodes). You need to turn off the Case File option only if you want to change other parameters in the Auto Partition Mesh dialog box.

- Across Zones

allows partitions to cross zone boundaries (the default). If turned off, it will restrict partitioning to within each cell zone. This is recommended only when cells in different zones require significantly different amounts of computation during the solution phase, for example if the domain contains both solid and fluid zones.

- Optimizations

contains an option to enable pre-testing.

- Pre-Test

instructs Fluent to test all coordinate directions and choose the one which yields the fewest partition interfaces for the final bisection. Note that this option is available only when you choose Principal Axes or Cartesian Axes as the partitioning method.

The Automatic Mesh Adaption dialog box allows you to create and edit criteria that Fluent will use to adapt your mesh during a calculation. See Refining and Coarsening for details.

Domain → Adapt →

Automatic...

Controls

- Name

specifies the name of the adaption criteria.

- Frequency

defines the frequency of the adaption that will be applied for this criteria during the calculation.

- Refinement Criterion

specifies the cell register or expression that Fluent will use during the calculation to determine which cells to refine.

- Coarsening Criterion

specifies the cell register or expression that Fluent will use during the calculation to determine which cells to coarsen.

- Prismatic Adaption

specifies that prismatic cells are adapted anisotropically. This option is only available with the PUMA adaption method.

allows you to select from a list of commonly used criteria for adapting the mesh (for a description of the list, see Predefined Criteria for Adaption); if one is selected, Fluent will automatically generate cell registers and/or expressions for refinement and coarsening, and define the settings in the Automatic Mesh Adaption dialog box and General Adaption Controls Dialog Box as needed. Depending on your selection, you may be prompted to complete the setup by defining fields in the Adaption Criteria Settings Dialog Box.

allows you to create new cell registers and manage existing ones, which may then be selected from the Refinement Criterion and/or Coarsening Criterion drop-down lists.

prints to the console the number of cells marked for refinement, the number of cells marked for coarsening, and the number marked for both operations.

opens the Display Options - Adaption Dialog Box.

opens the General Adaption Controls Dialog Box, where you can specify the general settings that Fluent uses when adapting the mesh.

The Cell Count Report Definition dialog box allows you to create a report definition for the reporting of a cell count (that is, the number of cells within one or more cell zones), as described in Mesh Report Definitions.

Solution → Reports

→ Definitions → New

→ Mesh Report → Cell Count...

Controls

- Name

specifies the name of the report definition.

- Options

- Per Surface

enables the reporting of the cell count individually for each of the selected zones (rather than reporting the sum from all of the selected zones).

- Average Over

specifies the number of iterations / time steps over which the cell count is averaged when written, plotted, and/or printed. The default value of

1means that no averaging is performed (that is, only the current cell count is reported), and higher values yields a running average. When the iteration / time step number is lower than the specified value, Fluent calculates the average of the available cell count values.- Retain Instantaneous Values

enables the retention of instantaneous values in any report file definition or report plot definition that is associated with this report definition. This option is only available if Average Over is set to a value greater than

1.

- Report Files

allows you to select existing report file definitions to which you want to write cell count data from this report definition.

- Report Plots

allows you to select existing report plot definitions to which you want to include cell count data from this report definition. Note that the units used in these report plots may not be suitable for the cell count data.

- Create

- Report File

creates a new report file definition for the data from this report definition.

- Report Plot

creates a new report plot definition for the data from this report definition.

- Frequency

specifies how frequently the report definition is written, plotted, and/or printed to the console.

- Print to Console

enables the printing of the cell count data from this report definition to the console during the calculation.

- Create Output Parameter

creates an output parameter for this report definition with the name <report_definition_name>

-op.- Cell Zones

allows you to select the cell zones for which you want to report the number of cells.

- OK

creates / saves the report definition.

- Compute

computes the cell count within the selected zone(s) and prints to the console.

The Cell Register Display Options dialog box allows you to customize the display of cell registers.

You can access this dialog box by clicking in any of the cell register dialog boxes.

Controls

- Options

contains check buttons that control the drawing of the mesh and the type of graphical tool used to display register cells.

- Draw Mesh

toggles the ability to draw the mesh with the cell register display. This command opens the Mesh Display Dialog Box, which allows you to select the desired surface or zone meshes to be displayed with the register cells.

- Wireframe

toggles the display of the cell wireframe.

- Filled

toggles the solid shading of the cell wireframe.

- Marker

toggles the display of the cell marker.

- Color

is a drop-down list of colors for the wireframe or marker for the cells.

- Symbol

is a drop-down list of symbols that can be used cell marker.

- Size

is a real number entry for the size of the cell marker. A symbol of size 1.0 is 3.0% of the height of the display screen.

The Compiled UDFs dialog box allows you to open a library of compiled user-defined functions. See the separate Fluent Customization Manual for details.

User Defined → User Defined

→ Functions → Compiled...

Controls

- Source Files

contains a list of source files.

- Header Files

contains a list of header files.

- Add...

opens the Select File dialog box.

- Delete

deletes the selected file from the list.

- Library Name

specifies the name of the library to be created.

- Use Built-In Compiler

enables the use of a built-in compiler (Clang) when the button is clicked. This option / compiler is available for Windows only, and is provided as part of the Fluent installation. It is recommended that you enable this option when the compiler you installed on your machine is older and no longer supported. Note that the built-in compiler is used automatically if Fluent determines that you have not installed Microsoft Visual Studio or Clang on your computer, whether this option is enabled or not.

- Build

builds the library and compiles the user-defined function.

- Load

opens the specified library and loads the user-defined function.

The Conduction Layers dialog box allows you to define the conduction settings for either a single Wall dialog box or all of the walls selected in the Wall Zones list of the Conduction Manager Dialog Box. See Shell Conduction and Managing Conduction Walls for details about the items below.

The Conduction Layers dialog box is opened from either the Wall Dialog Box or the Conduction Manager Dialog Box.

Controls

- Shell Conduction

enables/disables shell conduction for the selected wall(s).

- Number of Shell Conduction Layers

allows you to define the number of layers that make up the wall(s).

- Primary Zone

sets a wall to copy conduction settings from to the other selected walls.

- Layer 1, Layer 2...

allows you to define the settings for each layer. Note that Layer 1 refers to the layer closest to the fluid / solid adjacent to the wall zone, and layers with higher numbers are further away.

- Thickness

sets the thickness of the layer for the calculation of the thermal resistance. Each layer must have a nonzero thickness. Note that non-shell walls with a specified Thickness will be treated as thin walls.

- Material Name

sets the material type for the layer/wall. The conductivity of the material is used for the calculation of thermal resistance. Materials are defined using the Materials Task Page.

- Heat Generation Rate

sets the rate of heat generation in the layer. Note that you have the option of defining the heat generation rate using a user-defined function (UDF) that utilizes the

DEFINE_PROFILEmacro; for more information on creating and using user-defined functions, see the Fluent Customization Manual.

The Conduction Manager dialog box allows you to manage, define, and display conduction zones all in one location.

Physics → Model Specific

→ Conduction Manager...

Controls

- Select Zones

contains the list of conduction zones (1d thin walls and 3d shell walls) and ordinary walls.

- Wall Zones

contains a list of wall zones.

- Settings...

opens the Conduction Layers Dialog Box, where you can define the conduction properties of the walls selected in the Wall Zones list.

- Display

displays the selected walls in the graphics window.

- Read...

allows you to define your conduction settings by reading a

.csvfile.- Write...

allows you to write your saved conduction settings to a

.csvfile.

The Contours dialog box controls the display of contour and profile plots. See Displaying Contours and Profiles for details about the items below.

Results → Graphics

→ Contours → New...

Note:

The "global"/non-persistent form of graphics objects is hidden by default. If this interrupts your workflow, you can make them available by enabling the Expose legacy non-persistent graphics option in the Graphics branch of Preferences (accessed via File>Preferences...).

(When you click Edit... instead of New..., it opens the "global"/non-persistent version of the Contours dialog box. This version of the dialog box does not have a Name field and it is not saved with the case file.

You are encouraged to use the persistent version that is accessed by clicking New....

Controls

- Contour Name

is the name for a contour plot definition. You can specify a name or use the default name

contour-. This control appears only for contour plot definitions.id- Options

contains the check buttons that set various contour display options.

- Filled

toggles between filled contours and line contours.

- Node Values

toggles between using scalar field values at nodes and at cell centers for computing the contours. When the Filled option is off, Node Values is always on. See Choosing Node or Cell Values and Node or Boundary Values and Node Values for details.

- Boundary Values

enabling overwrites the node values (on boundaries) with a simple average of the boundary face values. Refer to Choosing Node or Cell Values and Node or Boundary Values for more information.

- Contour Lines

combines filled contours with line contours. This option is only available when both the Filled and Node Values options are enabled.

- Global Range

toggles between basing the minimum and maximum values on the range of values on the selected surfaces (off), and basing them on the range of values in the entire domain (on, the default).

- Auto Range

toggles between automatic and manual setting of the contour range. Any time you change the Contours of selection, Auto Range is reset to on.

- Clip to Range

determines whether or not values outside the prescribed Min/ Max range are contoured when using Filled contours. If selected, values outside the range will not be contoured. If not selected, values below the Min value will be colored with the lowest color on the color scale, and values above the Max value will be colored with the highest color on the color scale. See Specifying the Range of Magnitudes Displayed for details.

- Draw Profiles

causes the addition of a profile plot to the contour plot. The Profile Options Dialog Box is opened when Draw Profiles is selected.

Note: Draw Profiles is only available for the non-persistent/"global" version of the Contours dialog box that does not have a Name field. This version of the dialog box is opened by:

Right-clicking Contours in the Outline View tree and selecting Edit... (located under the Results branch).

Clicking Contours and selecting Edit... under Graphics in the Results ribbon tab.

- Draw Mesh

toggles between displaying and not displaying the mesh. The Mesh Display Dialog Box is opened when Draw Mesh is selected.

- Coloring

specifies how the contours appear.

- Banded

the contour coloring features distinct color bands corresponding to the colormap.

- Smooth

the contours feature a smooth transition between colors.

- Colormap Options...

opens the Colormap Dialog Box, allowing you to customize the colormap for this graphics object.

- Contours of

contains a list from which you can select the scalar field to be contoured.

- Min

shows the minimum value of the scalar field. If Auto Range is off, you can set the minimum by typing a new value.

- Max

shows the maximum value of the scalar field. If Auto Range is off, you can set the maximum by typing a new value.

- Surfaces

contains a list from which you can select the surfaces on which to draw contours. For 2D cases, if no surface is selected, contouring is done on the entire domain. For 3D cases, you must always select at least one surface.

- Display State

specifies the display state that is associated with this graphics object.

- drop-down list of display states

selectable list of all the existing display states associated with this case.

creates a display state that matches the settings of the active graphics window and assigns it to this graphics object (this association is only saved after you click ).

- New Surface

is a drop-down list button that contains a list of surface options:

- Point

opens the Point Surface Dialog Box.

- Line/Rake

opens the Line/Rake Surface Dialog Box.

- Plane

opens the Plane Surface Dialog Box.

- Quadric

opens the Quadric Surface Dialog Box.

- Iso-Surface

opens the Iso-Surface Dialog Box.

- Iso-Clip

opens the Iso-Clip Dialog Box.

- Structural Point

opens the Structural Point Surface Dialog Box.

- Display

draws the contours in the active graphics window.

- Compute

calculates the scalar field and updates the Min and Max values (even when Auto Range is off).

- Save/Display

plots the contour in the active graphics window and saves the contour plot definition. This button appears only for contour plot definitions and replaces the Display button.

The convergence conditions facility allows you to set convergence conditions on the solution based on the values from report definitions (surface, volume, lift, drag, and so on). See Convergence Conditions for details on setting up the Convergence Conditions dialog box.

Note: If you are solving a transient case, the Convergence Conditions dialog box will relabel some fields since the transient case uses time-steps rather than iterations. These alternate labels are indicated below.

Solution → Reports

→ Conditions...

Controls

- Active

check box for deactivating/activating individual convergence conditions.

- Conditions

name of the convergence condition.

- Report Definition

name of the report definition used in judging convergence.

- Stop Criterion

specifies the criterion below which the solution is considered to be converged.

- Ignore Iterations Before | Ignore Time Steps Before

ignores the first few iterations/time-steps if you expect the solution to fluctuate initially.

- Use Iterations | Use Time Steps

specifies the number of previous iterations/time-steps to be included in the report definition convergence check.

- Check For

specify whether Fluent checks for convergence at every time step or every iteration.

- Solution Convergence

Fluent checks for solution convergence at every time step.

- Time Step Convergence

Fluent checks for solution convergence at every iteration.

- Choose Condition

to select the convergence conditions.

- All Conditions are Met

The solution is considered to be converged if all of the convergence conditions’ criteria are satisfied, including those in the Residual Monitors Dialog Box.

- Any Condition is Met

The solution is considered to be converged if any of the convergence conditions’ criteria is satisfied, including those in the Residual Monitors Dialog Box.

- Every Iteration | Every Time-Step

to select how often convergence checks are done.

The Create Mesh Interfaces dialog box allows you to easily create many mesh interfaces between boundary zones that do not currently overlap (for example, for a sliding mesh simulation), as described in Manually Creating Many Non-Overlapping Mesh Interfaces. Note that if you only want to create mesh interfaces between boundary zones that currently overlap, you should instead use the Mesh Interfaces Dialog Box. For details, see Using a Non-Conformal Mesh in Ansys Fluent.

The Create Mesh Interfaces dialog box is opened by ensuring that

the default one-to-one interface creation method is enabled (using the

define/mesh-interfaces/one-to-one-pairing? text command) and

clicking the button in the Mesh Interfaces Dialog Box.

Controls

- Mesh Interface Name Prefix

contains a text entry box in which you can specify the prefix used in the names of all the mesh interfaces created when you click the button, and a list from which you can select existing mesh interfaces.

- Boundary Zone List 1, Boundary Zone List 2

allows you to select the zones that you want to pair up to make mesh interfaces. Note that mesh interfaces will be created for every possible combination between these two lists, regardless of whether the zones in question currently overlap. (You cannot edit the top fields; the names in these fields will be the name of the last zone you selected in the list below it.)

creates mesh interfaces for every possible combination between the zones selected under Boundary Zone List 1 and Boundary Zone List 2, regardless of whether the zones in question currently overlap.

deletes the mesh interfaces selected from the list under Mesh Interface Name Prefix.

allows you to display selected interface zones or mesh interfaces in the graphics window. Note that after you have selected a mesh interface, you can modify what zones are displayed by selecting / deselecting zones under Boundary Zone List 1 and/or Boundary Zone List 2.

prints information about the mesh interfaces selected in the list under Mesh Interface Name Prefix in the console.

The Create/Edit Mesh Interfaces dialog box allows you to manually create mesh interfaces for use with sliding meshes (see Using Sliding Meshes) or multiple reference frames (see Mesh Setup for a Multiple Moving Reference Frame), or for meshes with non-conformal boundaries (see Non-Conformal Meshes). This dialog box requires you to decide which interface zones make up both sides of each mesh interface. While it is possible to create every type of many-to-many mesh interface using this dialog box, it is only necessary when you want your interface to use the periodic or periodic repeats option; for all other types it is more convenient to automatically create interfaces using the Mesh Interfaces Dialog Box, especially when you have many interface zones and/or are unfamiliar with their names / locations. For details, see Using a Non-Conformal Mesh in Ansys Fluent.

The Create/Edit Mesh Interfaces dialog box

is opened by disabling the default one-to-one interface creation method (using the

define/mesh-interfaces/one-to-one-pairing? text command) and

clicking the button in the Mesh Interfaces Dialog Box.

Controls

- Mesh Interface

contains a text entry box in which you can set the name of the mesh interface, and a list from which you can select an existing mesh interface.

- Interface Zones Side 1, Interface Zones Side 2

contain selectable lists for the interface zones that make up the mesh interface and informational fields that show the names of the zones you selected in each list. (You cannot edit the top fields; the names in these fields will be the names of the zones you selected in the list below it.)

- Interface Options

contains options related to the interface type.

- Periodic Boundary Condition

allows you to create a non-conformal periodic boundary condition interface. Note that the Matching option is enabled by default with such periodic mesh interfaces.

- Periodic Repeats

should be enabled when each of the two cell zones has a single pair of conformal or non-conformal periodics adjacent to the interface. This option is typically used in conjunction with the sliding mesh model, when simulating the interface between a rotor and stator; it allows Ansys Fluent to treat the interface between the sliding and non-sliding zones as periodic where the two zones do not overlap. For details, see The Periodic Repeats Option.

- Coupled Wall

allows you to specify that the interface acts as a thermally coupled wall.

- Matching

is relevant if only interface internal zones should be created (that is, interior or wall / shadow pairs), since the interface zones on both sides are aligned. With the Matching option, even interface zones that are not perfectly aligned are treated as if they are; however, if the discrepancy between the interface zones on both sides exceeds default thresholds, then warning messages will be displayed. Note that the Matching option is compatible with the Periodic Boundary Condition, Coupled Wall, and Static options. For more information about the recommended uses of this option, see Matching Option.

- Mapped

enables an alternative approach for modeling coupled walls between zones. This approach is more robust than the standard non-conformal interface formulations when the interface zones penetrate each other or have gaps between them. It requires that at least one side of the interface consists of only solid zones.

Note: The Mapped option is not compatible with shell conduction.

- Static

reduces the memory usage and processing time (for interface creation and solution), especially when there are many zones on both sides of the interface. This option will only produce correct results if the interface zones do not move or deform relative to each other at the interface, and it is not compatible with the Periodic Boundary Condition, Periodic Repeats, or Mapped options.

- Non-Overlapping Zones Side 1, Non-Overlapping Zones Side 2

display the names of any wall boundary zones created by Ansys Fluent during the process of creating the selected mesh interface. If the two interface zones overlap each other completely, then the wall boundaries are created but with zero faces.

- Interface Wall Zones Side 1, Interface Wall Zones Side 2

display the names of any wall interface zones created by Ansys Fluent during the process of creating the selected mesh interface.

- Interface Interior Zones

displays the names of any interface interior zones created by Ansys Fluent during the process of creating the selected mesh interface. This is used for embedded LES, when there is a need to be able to convert an interior zone into a RANS-LES interface.

- Periodic Boundary Condition

- Type

allows you to select a periodicity that is either Translational or Rotational.

- Offset

is the offset coordinates or angle, depending on whether Translational or Rotational periodicity is selected. Note that when Auto Compute Offset is enabled, the Offset fields are not editable.

- Auto Compute Offset

will result in Ansys Fluent finding the offset. If this option is disabled, then you will have to provide the offset coordinates or angle in the required fields, depending on whether Translational or Rotational periodicity is selected.

- Mapped

- Enable Local Tolerance

(when enabled) allows you to overwrite any value specified in the Tolerance group box in the Mapped Interface Options Dialog Box, and is used on the selected interface only.

- Local Edge Length Factor

(when enabled) allows you to specify the multiplier that Fluent uses with the smallest edge length of the interface zones to calculate the tolerance for mapping. Disabling Local Edge Length Factor allows you to specify an absolute value for the tolerance.

performs one of the following:

If you have entered a new Mesh Interface name and selected unassigned zones from the Interface Zones Side 1 and Interface Zones Side 2 selection lists, a new mesh interface is created.

If you have made a selection from the Mesh Interface list, the Edit Mesh Interfaces Dialog Box will open so that you can revise the settings of existing mesh interfaces.

deletes the mesh interface selected under Mesh Interface.

allows you to display interface zones or mesh interfaces in the graphics window. Note that you can only select and display an interface zone from Interface Zones Side 1 or Interface Zones Side 2 if it is not yet assigned to an existing mesh interface. After a Mesh Interface is created, you can select the appropriate mesh interface and click the button to display all of the zones under Interface Zones Side 1 and Interface Zones Side 2.

prints information about the selected Mesh Interface in the console. When you click this button, Ansys Fluent will list the two interface boundaries and (if you have initialized the solution) all new zones that were created (that is, wall and/or interior zones).

The Create/Edit Turbo Interfaces dialog box allows you to manually create many-to-many mesh interfaces to connect blades to one another. This dialog box requires you to decide which interface zones make up both sides of each turbo interface and specify the blade row interaction model. For details, see Creating and Editing General Turbo Interfaces.

Controls

- Mesh Interface

contains a text entry box in which you can set the name of the turbo interface, and a list from which you can select an existing mesh interface.

- Interface Zones Side 1, Interface Zones Side 2

contain selectable lists for the interface zones that make up the turbo interface and informational fields that show the names of the zones you selected in each list. (You cannot edit the top fields; the names in these fields will be the names of the zones you selected in the list below it.)

- Interface Options

contains options related to the interface type.

- Periodic Boundary Condition

allows you to create a non-conformal periodic boundary condition interface. Note that the Matching option is enabled by default with such periodic mesh interfaces; for details about the Matching option, see Matching Option.

- General Turbo Interface

(only available when the Turbo Model is enabled) connects two turbo zones. This option is typically used in conjunction with the sliding mesh model, when simulating the interface between a rotor and stator. These models permit for a pitch-change between the modeled blade rows.

- Pitch-Change Types

- Pitch-Scale

stretches or compresses the flow profiles between the cell zones to maintain the interaction between blade row passages. See Blade Row Interaction Modeling for details.

- No Pitch-Scale

maintains the blade row interaction between blade row passages by creating virtual copies of the smaller pitch blade passage. See Blade Row Interaction Modeling for details.

- Mixing Plane

uses a pitchwise averaging procedure to mix out the flow variation between the blade rows. See Blade Row Interaction Modeling for details.

performs one of the following:

If you have entered a new Mesh Interface name and selected unassigned zones from the Interface Zones Side 1 and Interface Zones Side 2 selection lists, a new mesh interface is created.

If you have made a selection from the Mesh Interface list, the Edit Mesh Interfaces Dialog Box will open so that you can revise the settings of existing mesh interfaces.

deletes the mesh interface selected under Mesh Interface.

allows you to display interface zones or mesh interfaces in the graphics window. Note that you can only select and display an interface zone from Interface Zones Side 1 or Interface Zones Side 2 if it is not yet assigned to an existing mesh interface. After a Mesh Interface is created, you can select the appropriate mesh interface and click the button to display all of the zones under Interface Zones Side 1 and Interface Zones Side 2.

prints information about the selected Mesh Interface in the console. When you click this button, Ansys Fluent will list the two interface boundaries and (if you have initialized the solution) all new zones that were created (that is, wall and/or interior zones).

The Curvilinear Coordinate System dialog box allows you to create local coordinate systems that follow the geometry of the model. Refer to Curvilinear Coordinate Systems for additional information.

Controls

- Name

specifies the name of the curvilinear coordinate system.

specifies the cell zone whose geometry will be used to create the curvilinear coordinate system.

- Direction 0 (1)

tabs to specify Direction 0 and 1 of the curvilinear coordinate system. Note that Direction 2 is calculated from the cross product of Direction 0 and 1.

There are 2 options for specifying a direction.

Diffusion - utilizes geometry to specify direction as determined by Boundary Specification.

- Start and End

specifies the direction using a Start Face Zone and an End Face Zone.

- Jump

for closed loop geometries, specifies the direction from Interior Zones (utilizing a coupled wall as a cross section, which is then split into start and end faces).

Base Vector - specifies the direction using an X, Y, Z vector

- Display Face Zones

displays currently selected face zones.

options to visualize the curvilinear coordinate system.

- Direction 0

selects Direction 0 to display in the graphics viewer.

- Direction 1

selects Direction 1 to display in the graphics viewer.

- Direction 2

selects Direction 2 to display in the graphics viewer.

- Auto Scale

scales the vectors to an appropriate size.

- Draw Mesh

opens the Mesh Display dialog box.

- Scale

specifies the size of the vectors for display.

- Skip

Thins the number of vectors displayed to improve visibility.

- Save

Saves the curvilinear coordinate system.

- Display

Displays the curvilinear coordinate system according the settings under .

The Custom Field Function Calculator dialog box allows you to define custom field functions based on existing functions, using simple calculator operators. Any functions that you define will be added to the list of default flow variables and other field functions provided by Ansys Fluent.

Important: Recall that you must enter all constants in the function definition in SI units.

See Creating a Custom Field Function for details about the items below.

User Defined → Field Functions

→ Custom...

Controls

- Definition

displays the function that you are currently defining. As you select each item from the Field Functions list or the calculator keypad, it will appear in the Definition text entry box. You cannot edit the contents of this box directly; if you want to delete part of a function, use the button on the keypad.

- (Calculator Buttons)

are buttons that perform calculator operations. When you select a calculator button (by clicking on it), the appropriate symbol will appear in the Definition text entry box.

- Select Operand Field Functions from

contains the available field functions and the means for selecting them.

- Field Functions

contains a list from which you can select a variable to be used in the definition of a new function.

- Select

enters the variable that is currently selected in the Field Functions list in the Definition field.

- New Function Name

specifies the name of the function you are defining. Should you decide to change the function name after you have defined the function, you can do so in the Field Function Definitions Dialog Box, which you can open by clicking on the Manage... button.

creates the function and adds it to the list of Custom Field Functions within the drop-down list of available field functions. The button is grayed out after you create a new function or if the Definition field is empty.

- Manage...

opens the Field Function Definitions Dialog Box, which enables you to check, rename, save, load, and delete custom field functions.

The Custom Laws dialog box is used to incorporate user-defined functions (see the separate Fluent Customization Manual for details) in place of the default physical laws used in the heat/mass transfer calculations.

The Custom Laws dialog box is opened from the Set Injection Properties Dialog Box.

Controls

- First Law, Second Law, Third Law,...

contain drop-down lists in which you can choose a user-defined particle law to replace the standard law.

- Switching

contains a drop-down list in which you can select a user-defined function that customizes the way Ansys Fluent switches between particle laws.

The Dashboard Definition dialog box allows you create custom embedded window dashboards that are saved with the case file and added to the Outline View tree. See Geometry-Based Adaption with the Hanging Node Method for details.

Results → Graphics

→ Dashboard...

Controls

- Name

is the name for a dashboard definition. You can specify a name or use the default name

dashboard-.id- Base Window

specifies which window will be the background, upon which all other graphics and plot objects are embedded. You can also leave it set to none, allowing you to arrange the child windows without any overlap.

- Pre-defined Layouts

controls how the embedded windows are arranged when they are displayed first displayed. You can manually move and resize the windows once they are displayed.

- Available Objects

lists the available graphics and plot objects that can be included in the dashboard.

- New Object

drop-down list allowing you to create additional graphics objects that can be included in the dashboard.

saves the dashboard to the case file.

saves the dashboard and displays it in the graphics window.

The Deactivate Cell Zones dialog box allows you to deactivate a single cell zone or multiple zones. See Deactivating Zones for details.

Domain → Zones

→ Deactivate...

Controls

- Cell Zones

contains a list of cell zones from which you can select the zone to be deactivated.

- Deactivate

deactivates the selected cell zones.

The Define Control Points dialog box allows you to create, modify, and delete control points for the mesh morpher/optimizer when the unstructured control point distribution is selected. See Using the Mesh Morpher/Optimizer for details about using this dialog box.

The Define Control Points dialog box is opened from the Mesh Morpher/Optimizer Dialog Box.

Controls

- Control Points

lists the control points you have created and allows you to modify and delete them.

- Definition Tools

provides tools for defining the control points.

- Mouse-Probe

allows you to create control points by probing (using the right mouse button, by default) in the graphics window.

- Distribute Throughout Zone

allows you to quickly create a number of control points and distribute them on mesh nodes throughout a specific boundary zone.

- Zones

allows you to select the boundary zone throughout which you want to distribute control points.

- Approximate Number

allows you to specify the approximate number of control points you want to distribute throughout a zone. Note that due to the method by which the control points are distributed, the actual number may exceed the value you enter.

- Distribute

creates a number of control points on mesh nodes throughout the specified zone (within the bounding box) with a distribution that is based on the distribution of the cell faces in that zone.

- Coordinates

allows you to view and modify the coordinates of control points, as well as to create new control points and to delete existing control points.

- X, Y, Z

displays the coordinates of the selected Control Point, and allows you to define new ones and edit existing ones.

- Create

creates a new control point at the currently displayed X, Y, and Z coordinates.

- Modify

revises the X, Y, and Z coordinates of the selected Control Point.

- Delete

deletes the selected Control Point.

The Delete Cell Zones dialog box allows you to delete a single cell zone or multiple zones. See Deleting Zones for details.

Domain → Zones

→ Delete...

Controls

- Cell Zones

contains a list of cell zones from which you can select the zone to be deleted.

- Delete

deletes the selected cell zones.

The Display Options - Adaption dialog box allows you to customize how the cells marked for adaption are displayed.

This dialog box is accessed by clicking in the Manual Mesh Adaption Dialog Box or Automatic Mesh Adaption Dialog Box.

Controls

- Options

contains check boxes that controls the drawing of the mesh.

- Draw Mesh

toggles the ability to draw the mesh with the adaption display. This command opens the Mesh Display Dialog Box, which allows you to select the desired surface or zone meshes to be displayed with the markings.

- Refinement Cells

contains options related to the display of cells marked for refinement.

- Faces

controls whether cell faces are displayed on the cells marked for refinement.

- Edges

controls whether cell edges are displayed on the cells marked for refinement.

- Centroid

controls whether the cell centroid is displayed on the cells marked for refinement.

- Face Color

controls the color of the cell faces on the cells marked for refinement.

- Edge Color

controls the color of the cell edges on the cells marked for refinement.

- Edge Width

controls the thickness of the cell edges on the cells marked for refinement.

- Coarsening Cells

contains options related to the display of cells marked for coarsening.

- Faces

controls whether cell faces are displayed on the cells marked for coarsening.

- Edges

controls whether cell edges are displayed on the cells marked for coarsening.

- Centroid

controls whether the cell centroid is displayed on the cells marked for coarsening.

- Face Color

controls the color of the cell faces on the cells marked for coarsening.

- Edge Color

controls the color of the cell edges on the cells marked for coarsening.

- Edge Width

controls the thickness of the cell edges on the cells marked for coarsening.

- Common Cells

contains options related to the display of cells marked for both refinement and coarsening.

- Faces

controls whether cell faces are displayed on the cells marked for both refinement and coarsening.

- Edges

controls whether cell edges are displayed on the cells marked for both refinement and coarsening.

- Centroid

controls whether the cell centroid is displayed on the cells marked for both refinement and coarsening.

- Face Color

controls the color of the cell faces on the cells marked for both refinement and coarsening.

- Edge Color

controls the color of the cell edges on the cells marked for both refinement and coarsening.

- Edge Width

controls the thickness of the cell edges on the cells marked for both refinement and coarsening.

This dialog box is accessed by clicking in the View ribbon tab.

View → Display

→ Display States...

Controls

- Display States

single selection listing of all defined display states.

create a new display state with the same settings as the active graphics window (or the last active user window if the current active window is displaying a 2D plot).

create a new display state the copies the properties of the selected display state.

save the properties of the selected display state.

delete the selected state.

read in display states from a file.

write display states to a file.

- Name

name of the selected display state.

- Views...

opens the Views Dialog Box.

- Views Drop-down List

list of views that can be associated with this display state.

- General Settings

lists general graphics window settings.

- Front Faces Transparency

controls whether the front faces are transparent.

- Projection

specifies whether the display is in a perspective or orthographic view.

- Axes

controls whether or not the axes triad is displayed.

- Ruler

controls whether or not the ruler is displayed.

- Boundary Markers

controls whether or not boundary markers are displayed. Note that boundary markers are only displayed on mesh, not other graphics objects like contours or vectors.

- Title

controls whether or not the titles bar is displayed.

- Edge Color

controls the color of the cell edges on the cells marked for refinement.

- Lighting Effects

lists lighting settings.

- Light ID

controls which light ID is saved. If more than one light ID is active when you click Use Active from a graphics object dialog box, this option is set to Don't Save.

- Headlights

controls whether the headlight is on or off.

- Lighting

specifies the lighting method that is used for the display.

- Graphic Effects

lists the graphics effects.

- Anti-Aliasing

controls whether or not lines and text are smooth.

- Reflections

controls whether or not a reflection of the model is shown (with the axis of reflection being controlled in Preferences).

- Static Shadows

controls whether or not static shadows are displayed.

- Dynamic Shadows

controls whether or not dynamic shadows are displayed. These shadows move as you rotate your model and are computationally expensive to render.

- Grid Plane

controls whether or not the grid plane is shown (with the axis for the grid being controlled in Preferences).

save the settings of the selected display state and apply these settings to the active graphics window display.

update the currently-selected display state to inherit the display state settings of the active graphics window. This button is not available if the active graphics window is displaying a 2D plot.

resets the selected display state to match the default settings.

Table 52.1: Default Display State Settings

Setting State View isometric Front Faces Transparent Disable Projection Perspective Axes Enable Ruler Disable Boundary Markers Enable Title Disable Light ID 0 Headlights On Lighting Automatic Anti-Aliasing Enable Reflections Enable Static Shadows Enable Dynamic Shadows Disable Grid Plane Enable Note: The default graphics effects settings are dependent on the available graphics driver. If no modern graphics driver is available, graphics effects will be disabled.

Solution → Reports

→ Definitions → New

→ DPM Report

Controls

- Name

specifies the name of the report definition.

- Average Over

(optional) To have Fluent calculate a running average for the DPM Report Definition you can enter a positive integer greater than 1 (the default) for Average Over.

Specifying a number greater than 1 means that Fluent will print, plot, and write the running average value of the selected variable instead of the current value of the same variable.

The value reported is averaged over the last

iterations/time steps, where

is your specified Average Over value. When the iteration/time step number is lower than

, Fluent calculates the average of the available variable values.

- Retain Instantaneous Values

appears when Average Over is set to a value greater than

1. If enabled when you are creating a new report definition, it ensures that all instantaneous values are saved in the new report file that is being created for this report definition. It also results in the Plot Instantaneous Values option being enabled in the newly created report plot.- Report Files

lists all of the report files where you can write the report definition data.

- Report Plots

lists all of the report plots where you can plot the report definition data (assuming this report has the same units as the other report definitions included in the selected report plot).

- Create

options you can choose when creating your report.

- Report File

creates a new report file that includes this report definition.

- Report Plot

creates a new report plot that includes this report definition.

- Frequency

specifies how frequently the report definition is written, plotted, or printed to the console.

- Print to Console

prints the value of the report definition to the console.

- Create Output Parameter

creates an output parameter for this report definition with the name

<report definition name>-op.- Output Quantity

quantities that can be applied to the output parameter.

- Injected Mass

(unsteady particle tracking only) reports the total DPM mass injected into the domain.

- Mass in Domain

(unsteady particle tracking only) reports the total DPM mass present in the domain.

- Mass in Fluid

(unsteady particle tracking only) reports all DPM mass currently residing as free-stream particles in the domain. This option is available only with the wall-film DPM boundary condition.

- Mass in Film

(unsteady particle tracking only) reports all DPM mass currently residing in Lagrangian wall-film. This option is available only with the wall-film DPM boundary condition.

- Escaped Mass

reports the DPM mass that has left the domain through a certain boundary or boundaries.

- Evaporated Mass

reports the total evaporated DPM mass for the selected injection(s). The quantity accounts for fully evaporated particles as well as all mass that has evaporated from any other particles. For unsteady tracking, this includes particles that are still present in the domain.

- Penetration Length

(unsteady particle tracking only) reports the total penetration length in meters.

- Injections

lists the injections that you can select for discrete phase reporting. For the Escaped Mass output quantity, this item is available only if you have enabled the

report/dpm-zone-summaries-per-injectiontext command. Note that for unsteady particle tracking, if you want to report the mass of escaped particles per injection, this text command must be enabled before any particles are injected into the domain.- Boundaries

contains a selectable list of valid boundary zones for escaped mass reporting.

- Show Mass Flow/Change Rate

(unsteady particle tracking only) if enabled, specifies that the mass flow rate will be reported (default). Otherwise the total mass will be reported. This item is not available for the Penetration Length report.

- Particles Mass Fraction