This section contains information about using the soot formation models in Ansys Fluent. For information about the theory behind the soot models in Ansys Fluent, see Soot Formation in the Theory Guide.

When the mass fraction of soot is relatively large (for example, 10%) or if your problem involves the effect of radiation, the soot formation should be computed as part of the main combustion solution and not through postprocessing (as is done for the NOx model). The procedure for setting up and solving a soot formation model is outlined below. Only the steps that are pertinent to soot modeling are shown here. For information about inputs related to other models that you are using in conjunction with the soot formation model, see the appropriate sections for those models.

Set up your combustion problem using Ansys Fluent as usual. Note the following limitations:

None of the soot models are compatible with premixed combustion.

The one-step and two-step soot formation models are only available for turbulent flows.

Enable the desired soot formation model and set the related parameters, as described in this section.

Setup → Models → Species → Soot

Edit...

Define the boundary conditions for soot (and nuclei, if you are not using the one-step model) at flow inlets.

Setup →

Boundary Conditions

Boundary Conditions

In the Solution Controls Task Page, set a suitable value for the soot (and nuclei, if you are not using the one-step model) under-relaxation factor(s). The default value is 0.9. If convergence cannot be obtained with this value, try a lower under-relaxation value.

Solution →

Controls

Controls

Perform calculations until convergence (that is, until the soot / nuclei residual is below 10-6) to ensure that the soot (and nuclei) field is no longer evolving.

Solution →

Run Calculation

Run Calculation

Note that when Soot-Radiation Interaction is enabled in the Soot Model dialog box, soot equations (soot, nuclei, and tar species, if available) must be solved together with the combustion solution to obtain correct radiation coupling. Therefore, when Soot-Radiation Interaction is enabled, the soot equations are not available for pollutant postprocessing, but will be solved together with the combustion solution. However, if other pollutants are to be solved (while soot/radiation interaction is enabled), those pollutant equations can be postprocessed.

Review the mass fraction of soot (and nuclei) by generating graphical plots or alphanumeric reports in the usual way.

Save a new set of case and data files, if desired.

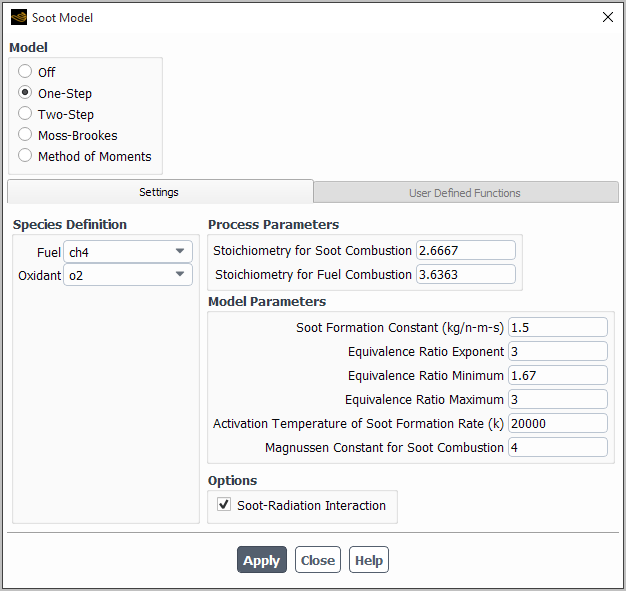

You can enable and set up the one-step soot formation model by using the Soot Model Dialog Box (Figure 22.6: The Soot Model Dialog Box for the One-Step Model).

Setup → Models → Species → Soot

Edit...

Under Model, select One-Step. The dialog box will expand to show the appropriate inputs.

Define the fuel and oxidizer species. Under Species Definition, select the fuel in the Fuel drop-down list and the oxidizer in the Oxidant drop-down list. If you are using the non-premixed model for the combustion calculation and your fuel stream consists of a mixture of components, you should choose the most appropriate species as the Fuel species for the soot formation model. Similarly, the most significant oxidizing component (for example, O2) should be selected as the Oxidant.

If you want to include the effects of soot formation on the radiation absorption coefficient, enable Soot-Radiation Interaction in the Options group box. For more details, see The Effect of Soot on the Absorption Coefficient in the Theory Guide.

Define the following Process Parameters:

- Stoichiometry for Soot Combustion

is the mass stoichiometry,

, in Equation 9–120 in the Theory Guide, which computes the soot combustion rate. The default value of 2.6667 assumes that the soot is pure carbon and the oxidizer is O2.

- Stoichiometry for Fuel Combustion

is the mass stoichiometry,

, in Equation 9–120 in the Theory Guide, which computes the soot combustion rate. The default value supplied by Ansys Fluent (3.6363) is for combustion of propane (C3H8) by oxygen (O2).

Set the Modeling Parameters that are used in Equation 9–117, Equation 9–119, and Equation 9–120 in the Theory Guide:

- Soot Formation Constant

is the parameter

(kg/n-m-s) in Equation 9–117 in the Theory Guide.

- Equivalence Ratio Exponent

is the exponent

in Equation 9–117 in the Theory Guide.

- Equivalence Ratio Minimum

and Equivalence Ratio Maximum are the minimum and maximum values of the fuel equivalence ratio

in Equation 9–117 in the Theory Guide. This equation will be solved only if Equivalence Ratio Minimum

Equivalence Ratio Maximum; if

falls outside of this range, it is assumed that soot does not form.

- Activation Temperature of Soot Formation Rate

is the term

in Equation 9–117 in the Theory Guide.

- Magnussen Constant for Soot Combustion

is the constant

used in the rate expressions governing the soot combustion rate (Equation 9–119 and Equation 9–120 in the Theory Guide).

Note that the default values for these parameters are for propane fuel [32], [167], which are valid for a wide range of hydrocarbon fuels.

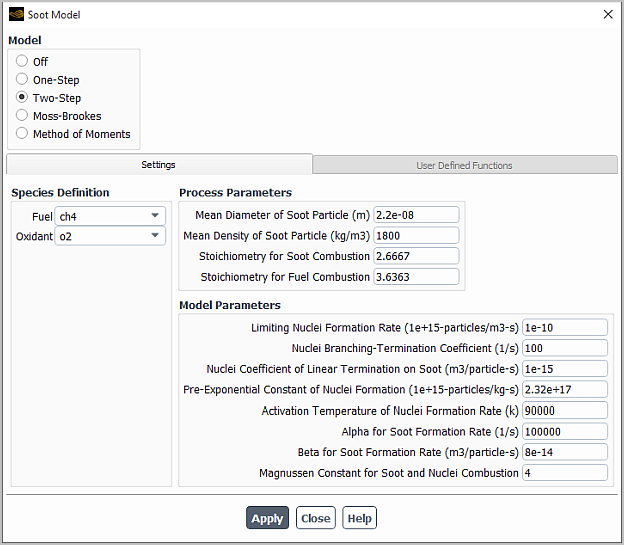

You can enable and set up the two-step soot formation model by using the Soot Model Dialog Box (Figure 22.7: The Soot Model Dialog Box for the Two-Step Model).

Setup → Models → Species → Soot

Edit...

Under Model, select Two-Step. The dialog box will expand to show the appropriate inputs.

Important: Note that the two-step Tesner model should only be used when the eddy-dissipation model is used to define the turbulence-chemistry interaction.

Under Species Definition, select the fuel in the Fuel drop-down list and the oxidizer in the Oxidant drop-down list. If you are using the non-premixed model for the combustion calculation and your fuel stream consists of a mixture of components, you should choose the most appropriate species as the Fuel species for the soot formation model. Similarly, the most significant oxidizing component (for example, O2) should be selected as the Oxidant.

If you want to include the effects of soot formation on the radiation absorption coefficient, enable Soot-Radiation Interaction in the Options group box. For more details, see The Effect of Soot on the Absorption Coefficient in the Theory Guide.

Define the following Process Parameters:

- Mean Diameter of Soot Particle, Mean Density of Soot Particle

are the assumed average diameter and average density of the soot particles in the combustion system, used to compute the soot particle mass

in Equation 9–123 in the Theory Guide. Note that the default values for soot density and diameter are taken from [94].

- Stoichiometry for Soot Combustion

is the mass stoichiometry

in Equation 9–120 in the Theory Guide, which computes the soot combustion rate. The default value of 2.6667 assumes that the soot is pure carbon and the oxidizer is O2.

- Stoichiometry for Fuel Combustion

is the mass stoichiometry,

, in Equation 9–120 in the Theory Guide, which computes the soot combustion rate. The default value supplied by Ansys Fluent (3.6363) is for combustion of propane (

) by oxygen (

).

Set the Modeling Parameters that are used in Equation 9–119, Equation 9–120, Equation 9–123, Equation 9–125, and Equation 9–126 in the Theory Guide:

- Limiting Nuclei Formation Rate

is the limiting value of the kinetic nuclei formation rate,

in Equation 9–126 in the Theory Guide. Below this limiting value, the branching and termination term, (

) in Equation 9–125 in the Theory Guide, is not included.

- Nuclei Branching-Termination Coefficient

is the term

in Equation 9–125 in the Theory Guide.

- Nuclei Coefficient of Linear Termination on Soot

is the term

in Equation 9–125 in the Theory Guide.

- Pre-Exponential Constant of Nuclei Formation

is the pre-exponential term

in the kinetic nuclei formation term, Equation 9–126 in the Theory Guide.

- Activation Temperature of Nuclei Formation Rate

is the term

in the kinetic nuclei formation term, Equation 9–126 in the Theory Guide.

- Alpha for Soot Formation Rate

is

, the constant in the soot formation rate equation, Equation 9–123 in the Theory Guide.

- Beta for Soot Formation Rate

is

, the constant in the soot formation rate equation, Equation 9–123 in the Theory Guide.

- Magnussen Constant for Soot and Nuclei Combustion

is the constant

used in the rate expressions governing the soot combustion rate (Equation 9–119 and Equation 9–120 in the Theory Guide).

The default values for the two-step model are the same as in Magnussen and

Hjertager [94] (for acetylene flame), except for

, which is assumed to have the original value from Tesner et al. [162]. If your model involves propane fuel rather than acetylene,

= 3.5x108 [5] is

recommended. For best results, you should modify both of these parameters using empirically

determined inputs for your specific combustion system.

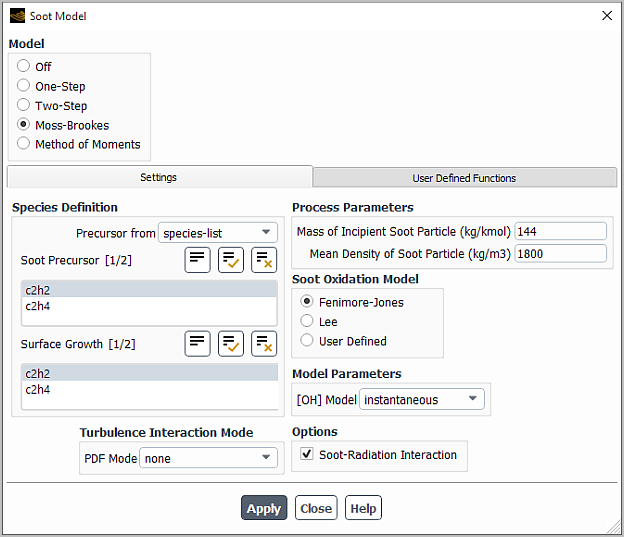

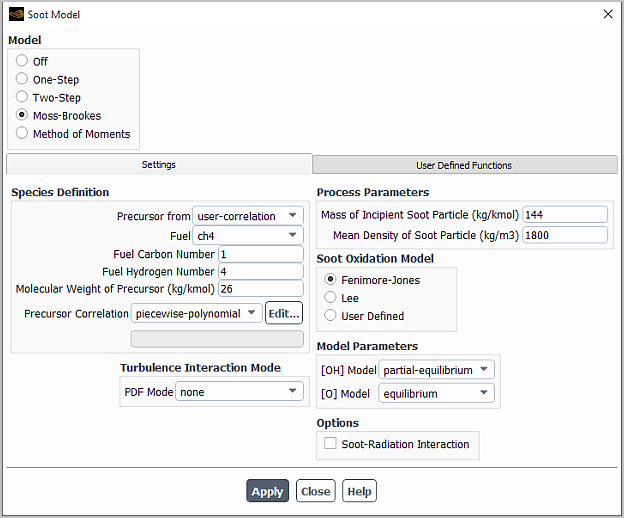

You can enable and set up the Moss-Brookes and Moss-Brookes-Hall soot formation models by using the Soot Model Dialog Box (Figure 22.8: The Soot Model Dialog Box for the Moss-Brookes Model).

Setup → Models → Species → Soot

Edit...

Under Model, select Moss-Brookes or Moss-Brookes-Hall. The dialog box will expand to show the appropriate inputs. Note the following about these models:

The Moss-Brookes model was originally proposed for soot prediction in methane flames. However, it can be equally applicable to higher hydrocarbon species by appropriately modifying the soot precursor and participating surface growth species.

The Moss-Brookes-Hall model is applicable for higher hydrocarbon fuels (for example, kerosene) and will only be available when C2H2, C6H6, C6H5, and H2 are present in the gas phase species list.

Define the precursor species in the Species Definition group box. When suitable precursor species are present in the species list, you can select species-list from the Precursor from drop-down list, and then select the Soot Precursor species and the Surface Growth species from the selection lists. Note that for the Moss-Brookes model, you can select acetylene (c2h2), ethylene (c2h4), and/or benzene (c6h6) for the Soot Precursor; if neither are present or if you would like to specify a different precursor correlation, then curve fitting will be used to determine the precursor and surface growth species mass fractions (see Species Definition for the Moss-Brookes Model with a User-Defined Precursor Correlation for further details regarding curve fitting).

Specify how turbulent fluctuations will be accounted for in the soot formation calculations by defining the turbulence parameters in the Turbulence Interaction Mode group box. Select one of the options in the PDF Mode drop-down list:

Select none to ignore turbulence and use laminar soot rate calculations.

Select temperature to take into account fluctuations of temperature.

Select temperature/species to take into account fluctuations of temperature and mass fraction of the species selected in the Species drop-down list (which appears when you select this option).

(non-premixed and partially premixed combustion calculations only) Select mixture fraction to take into account fluctuation in the mixture fraction(s). This is the recommended approach, as it generally yields the best results and accuracy.

Important: When modeling the formation of other pollutants along with soot, you should compare the selections made in the PDF Mode drop-down lists in the Turbulence Interaction Mode tab of the NOx Model Dialog Box and the Turbulence Interaction Mode group box of the Soot Model dialog box. If mixture fraction is selected in any of these dialog boxes, then it must be selected in all of the others as well.

The mixture fraction option is available only if you are using either the non-premixed or partially premixed combustion model to model the reacting system. If you use the mixture fraction option, the instantaneous temperatures and species concentrations are taken from the PDF look-up table as a function of mixture fraction and enthalpy and the instantaneous soot production rates are calculated at each cell. The PDF used for convoluting the instantaneous soot rates is the same as the one used to compute the mean flow-field properties. For example, for single-mixture fraction models the beta PDF is used, and for two-mixture fraction models, the beta or the double delta PDF can be used. The PDF in terms of mixture fraction is calculated from the values of mean mixture fraction and variance at each cell, and the instantaneous soot rates are convoluted with the mixture fraction PDF to yield the mean rates in turbulent flow.

Note: When mixture fraction is selected as PDF mode, Ansys Fluent calculates and tabulates the soot rates apriori for faster computations of soot rates. The soot rates are tabulated at the first soot iteration and a message

Performing Pollutant PDF integrations...is displayed in the Fluent console.

If you selected temperature or temperature/species for the PDF Mode, you should define the following parameters in the Turbulence Interaction Mode group box:

- PDF Type

allows you to specify the shape of the PDF, which is then integrated to obtain mean rates for the temperature and (if you selected temperature/species for the PDF Mode) the species. If you select beta, the PDF will be modeled using Equation 9–108 in the Theory Guide. If you select gaussian, the PDF will be modeled using Equation 9–111 in the Theory Guide.

- PDF Points

allows you to specify the number of points used to integrate the beta or Gaussian function in Equation 9–105 or Equation 9–106 in the Theory Guide on a histogram basis. The default value of 10 is a minimum value. It is recommended that you run the calculation with this minimum value to convergence, and then keep increasing the value (for example, 20–25) until the pollutants of interest stop changing. Increasing this value may improve accuracy, but will also increase the computation time.

- Temperature Variance

allows you to specify the form of transport equation that is solved to calculate the temperature variance. The default selection is algebraic, which is an approximate form of the transport equation (see Equation 9–114 of the Theory Guide). You have the option of selecting transported to instead solve Equation 9–113 in the Theory Guide. Though the transported form is more exact, it is also more expensive computationally.

- Tmax Option

provides various options for determining the maximum limit of the temperature used for the integration of the PDF (see Equation 8–44 in the Fluent Theory Guide) to calculate mean rates for turbulent fluctuations of soot. The default selection is global-tmax, which sets the limit as the maximum temperature in the flow field. You can select local-tmax if you would rather obtain cell-based maximum temperature limits by multiplying the local cell mean temperature by the value entered in Tmax Factor. You can select specified-tmax to set the limit for each cell to be the value entered in Tmax. Finally, if you have compiled a user-defined function for the soot rate and loaded the library into Ansys Fluent, then you can select user-defined so that the limit is specified by a user-defined function.

- Species

only appears if you have selected temperature/species for the PDF Mode. Your selection in this drop-down menu determines which species’ mass fraction is included in the soot formation calculations.

Important: Note that the species variance will always be calculated using the algebraic form of the transport equation (Equation 9–114 in the Theory Guide).

Under Process Parameters, enter information about the mass and mean density of the soot particles:

- Mass of Incipient Soot Particles

is

in Equation 9–131 and Equation 9–133 in the Theory Guide. Note that this value was assumed to be 144 kg/kmol (12 carbon atoms) in the work of Brookes and Moss, whereas the Hall extension model assumed it to be 1200 kg/kmol (100 carbon atoms).

- Mean Density of Soot Particle

is

in Equation 9–130 and Equation 9–133 in the Theory Guide. Note that this value was assumed to be 1800 kg/m3 in the work of Brookes and Moss [28], whereas Hall et al. [60] assumed it to be 2000 kg/m3.

Select the Soot Oxidation Model. Your choices include the Fenimore-Jones model, as originally used in Brookes and Moss’ work, or the Lee extended model. The Lee model will model soot oxidation due to hydroxyl radicals as in the Fenimore-Jones model, as well as the oxidation due to molecular oxygen.

Set the Modeling Parameters:

- [OH] Model

allows you to specify the method by which the OH radical concentration is calculated. The recommended selection from the drop-down list is instantaneous, although this option is only available when OH is available in the species list and is calculated by the combustion model. The other option is the partial-equilibrium model, which necessitates the availability of O radical concentration within the field.

- [O] Model

must be defined when you have selected partial-equilibrium for the [OH] Model, and specifies the method by which the O radical concentration is calculated. The options include equilibrium, partial-equilibrium, and instantaneous.

If you want to include the effects of soot formation on the radiation absorption coefficient, enable Soot-Radiation Interaction in the Options group box. For more details, see The Effect of Soot on the Absorption Coefficient in the Theory Guide.

Note that in Ansys Fluent, the oxidation rate scaling parameter

( in Equation 9–131 in the Theory Guide) is set

to unity. If you would like to change the value of this parameter,

you can use the

define/models/soot-parameters text command. A lower value will reduce the amount of soot oxidation.

You can choose to specify a user-defined function for the soot

oxidation rate. The compiled UDF hook is available from the User Defined Oxidation Rate drop-down list of the Soot Model dialog box. See

DEFINE_SOOT_OXIDATION_RATE

in the Fluent Customization Manual for details about user-defined functions.

You can choose to specify a user-defined function for the soot

oxidation rate. The compiled UDF hook is available from the User Defined Precursor drop-down list in the Species Definition group box of the Soot Model dialog box. See

DEFINE_SOOT_PRECURSOR

in the Fluent Customization Manual for details about user-defined

functions.

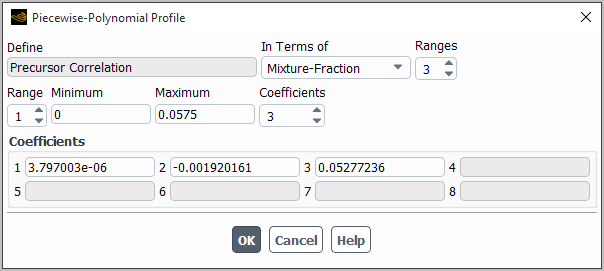

Ansys Fluent accepts the following as possible precursor species for the Moss-Brookes model: C2H2, C6H6, and C2H4. If none of these species are present in the species list (as is often the case when using the eddy-dissipation model) or if you would prefer to specify a different precursor correlation, your setup for the Moss-Brookes model will be different than noted previously. Under such circumstances, you should select user-correlation from the Precursor from drop-down list in the Species Definition group box (note that this is only option possible when the appropriate species are not present). The Soot Model Dialog Box will then be as shown in Figure 22.9: The Soot Model Dialog Box for the Moss-Brookes Model with a User-Defined Precursor Correlation. The parameters you set in the Species Definition group box allow Ansys Fluent to calculate a mixture fraction based on the mass fractions of the oxidant and the carbon/hydrogen contributed by a designated fuel species. The precursor species mass fraction will then be computed as a function (which you will also define) of this mixture fraction.

Figure 22.9: The Soot Model Dialog Box for the Moss-Brookes Model with a User-Defined Precursor Correlation

In the Species Definition group box, select a Fuel species and enter the related Fuel Carbon Number and Fuel Hydrogen Number for use in the mixture fraction calculation.

Enter the Molecular Weight of Precursor (the default value is for acetylene).

Make a selection in the Precursor Correlation drop-down list to indicate how the precursor mass fraction will be related to the mixture fraction. A piecewise-polynomial profile is defined by default.

Important: Note that the default values for the piecewise-polynomial profile are only valid for a methane diffusion flame simulation, in which both the air and fuel initial temperatures are set to 290 K, and acetylene is assumed as the soot precursor.

If you decide not to use the default values for Precursor Correlation, define the correlation between the precursor mass fraction and the mixture fraction. This correlation should be based on a laminar flamelet profile that you have generated. If possible, you should generate the profile using the Species Model dialog box (as described in Setting Up the Steady and Unsteady Diffusion Flamelet Models) with Steady Flamelet selected in the Chemistry tab. If there is no mechanism, you can generate the profile using the equilibrium chemistry model (see Setting Up the Equilibrium Chemistry Model for details). You may also use a third-party software package of your choice. You should then apply a curve-fitting technique to your generated profile, to obtain either a constant value or a piecewise-polynomial function.

In a piecewise-polynomial function, the laminar flamelet profile is divided into a number of mixture fraction ranges. In each range, the precursor species mass fraction

is defined using the following equation:

(22–8)

where

is the number of coefficients

, and

is the mixture fraction. The following piecewise-polynomial function corresponds to the default settings in Ansys Fluent:

(22–9)

To define a piecewise-polynomial profile to relate the precursor mass fraction to the mixture fraction, select piecewise-polynomial from the Precursor Correlation drop-down list and click the button.

In the Piecewise-Polynomial Profile Piecewise-Polynomial Profile Dialog Box, set the following controls:

Enter the number of Ranges. For the example shown in Equation 22–9, three ranges of mixture fraction are defined, which is the maximum allowed.

For the first range (Range = 1), enter the Minimum and Maximum mixture fraction values, and the number of Coefficients. (Up to eight coefficients are available.) The number of coefficients defines the order of the polynomial. An input of

1defines a polynomial of order 0, and the mass fraction will be constant and equal to the single coefficient. An input of2defines a polynomial of order 1, and the mass fraction will vary linearly with mixture fraction, and so on.Define the values for the coefficients in the Coefficients group box. The dialog box in Figure 22.10: The Piecewise-Polynomial Profile Dialog Box shows the inputs for the first range of Equation 22–9.

Increase the value of Range and enter the Minimum and Maximum mixture fractions, number of Coefficients, and the values for the Coefficients for the next range. Repeat if there is a third range.

Important: Note when defining the ranges, you must start with the lowest mixture fraction range, and then proceed in order to the highest range. The solver will not sort them for you.

To define a constant profile to relate the precursor mass fraction to the mixture fraction, select constant from the Precursor Correlation drop-down list and enter a value in the accompanying text entry box.

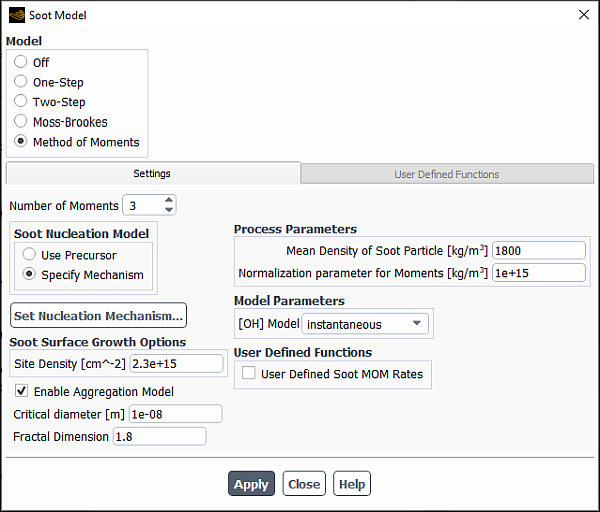

You can enable and set up the Method of Moments model by using the Soot Model dialog box (Figure 22.11: The Soot Model Dialog Box for the Method of Moments Model).

Setup → Models → Species → Soot

Edit...

In the Soot Model dialog box under Model, select Method of Moments. The dialog box will expand to show the appropriate inputs.

Specify Number Of Moments.

Ansys Fluent will solve an equal number of moment transport equations. The default value of 3 moments works reasonably well for a wide range of applications. However, you can specify up to 6 moments to achieve higher accuracy.

From the Soot Nucleation Model group box, select one of the following options:

Use Precursor (default): Enables you to define the precursor species for your soot prediction simulation.

Specify Mechanism: Enables you to provide the nucleation rate and specify nucleation as a reaction between soot precursors. Using this option, you can achieve more accurate results where the nucleation rate data is available.

(if Use Precursor is selected for the soot nucleation model) Under the Species Definition group box, define precursor species.

In the Soot Precursor group list (which is populated with all precursors available in your analysis), select one or more precursors.

The soot precursor species must be a hydrocarbon species. Ansys Fluent uses kinetic theory to calculate the nucleation rates considering coagulation between precursor species.

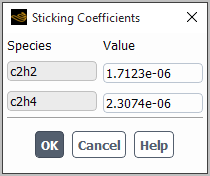

Click Sticking Coefficients... to specify the sticking coefficient for each precursor in the Sticking Coefficients dialog box that will open.

You must specify the sticking coefficient for each precursor because the nucleation rates calculated based on kinetic theory of collision of two soot precursors are generally very large, causing numerical errors.

Important: The default value for a sticking coefficient is calculated based on precursor molecular weight. In general, you can use smaller values for sticking coefficients for smaller precursors. For guidelines on specifying the sticking coefficients for precursor species, see Nucleation in the Fluent Theory Guide.

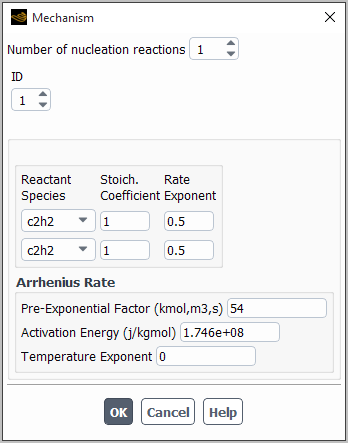

(if Specify Mechanism is selected for the soot nucleation model) Click Set Nucleation Mechanism... and enter the reaction rates inputs in the Mechanism dialog box that will open.

Specify Number of nucleation reactions.

The nucleation reactions can be single or multi-step.

For each reaction, specify the following:

Reactant species and corresponding stoichiometric coefficient and rate exponent

The Arhenius Rate parameters (Pre-Exponential Factor, Activation Energy, and Temperature Exponent)

Note: The inputs in the Mechanism dialog box are required only for reactant species as the main product of specified nucleation reaction is always assumed to be a soot nuclei, and all other products are not considered in calculations of soot nucleation rates.

If you want to account for soot aggregate formation, select Enable Aggregation Model

In addition to the moment transport equations, Ansys Fluent will solve an equal number of the particle moment transport equations.

Once you have enabled the aggregation model, you can specify the following parameters:

Critical diameter: A value of the soot particle diameter above which the coagulation regime is switched from coalescent coagulation to aggregate coagulation.

Fractal Dimension: A parameter that describes the fractal structure of the aggregate. Values between 1.7 and 2.0 work reasonably good for the aggregate coagulation.

Note: When the Enable Aggregation Model option is enabled, the Method of Moments model tends to over-predict the production of soot. This is due, in part, to the linear interpolation of the particle moments. This aspect of the over-prediction can be overcome by employing quadratic interpolation of the particle moments. Another reason for the over-prediction of soot is due to how Ansys Fluent currently ignores the depletion of acetylene during the soot calculations. Acetylene is consumed during the surface growth of soot, and since the gas field stays frozen and has no knowledge of the soot process, thereby producing a higher surface growth of soot, and eventually higher soot yields.

For information about the aggregation model, see Soot Aggregation in the Fluent Theory Guide.

Under Soot Surface Growth Options, specify Soot Density.

The growth of soot due to surface reactions and depletion due to oxidation reactions are modeled using HACA mechanism (see Surface Growth and Oxidation in the separate Theory Guide). For reaction rates and reaction steps, Ansys Fluent uses default values and requires no user inputs except for the soot site density.

Note: You can specify and/or edit the reaction rates of surface reactions using the

define/models/soot-parameterstext command.Important: The soot site density is always provided in units of number of sites per cm2 irrespective of the unit system selected in Ansys Fluent.

Under Process Parameters, specify Mean Density of Soot Particle and Normalization Parameter for Moments.

The normalization parameter is used to minimize numerical errors when solving the normalized soot moment transport equations. The default value for this parameter is sufficient, and you may not need to change it.

Specify the Modeling Parameters:

[OH] Model: Specifies the method by which the [OH] radical concentration is calculated. For OH Model, the following options are available:

instantaneous(recommended where possible)This option is only available when OH is present in the species list and participate in the combustion simulation.

partial-equilibriumThis option necessitates the availability of [O] atom concentration within the field.

[O] Model (available only if

instantaneousis not selected for OH Model): Specifies the method by which the [O] radical concentration is calculated. The following options are available:equilibriumpartial-equilibriuminstantaneous

At flow inlet boundaries, you must specify the Soot

Mass Fraction and (when not using the one-step model) the Nuclei mass concentration. These correspond to in Equation 9–115 and Equation 9–129 and

in Equation 9–121 and Equation 9–129 in

the Theory Guide, respectively.

Setup →

![]() Boundary Conditions

Boundary Conditions

You can retain the default inlet values of zero for both quantities or you can enter nonzero numbers as appropriate for your combustion system.

Ansys Fluent provides additional reporting options when your model includes soot formation. You can generate graphical plots or alphanumeric reports of the following items:

Mass fraction of Soot

Mole fraction of Soot

Soot Density

Soot Volume fraction

Rate of Soot

Normalized Concentration of Nuclei (unavailable for one-step model)

Rate of Nuclei (unavailable for one-step model)

Rate of Soot Mass Nucleation (Moss-Brookes and Moss-Brookes-Hall models only)

Rate of Surface Growth (Moss-Brookes and Moss-Brookes-Hall models only)

Rate of Oxidation (Moss-Brookes and Moss-Brookes-Hall models only)

Rate of Nucleation (Moss-Brookes and Moss-Brookes-Hall models only)

Rate of Coagulation (Moss-Brookes and Moss-Brookes-Hall models only)

Soot Surface Area (Method of Moments model only)

Soot Mean Diameter (Method of Moments model only)

Normalized soot moments (Method of Moments model only)

Normalized Soot Aggregation Moments (Method of Moments model with Aggregation only)

Average Number of Particles in Soot Aggregate (Method of Moments model with Aggregation only)

Primary Particle Diameter (Method of Moments model with Aggregation only)

These parameters are contained in the Soot... category of the variable selection drop-down list that appears in postprocessing dialog boxes.