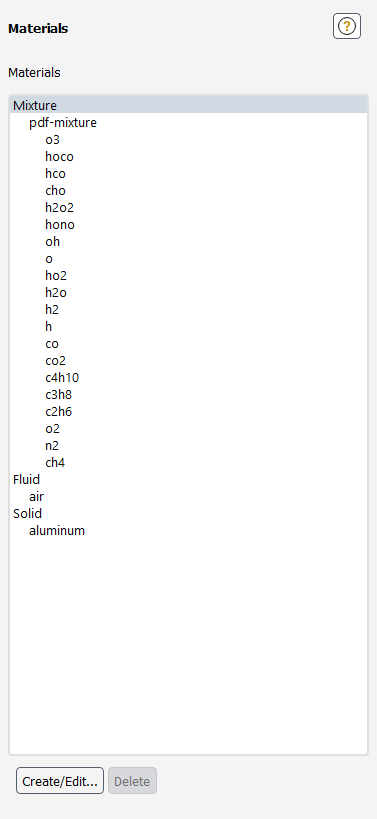

The Materials task page allows you to set properties for any fluid or solid (or mixture, if applicable) materials in your Ansys Fluent simulation.

Controls

- Materials

contains a listing of available fluid or solid (or mixture, if applicable) materials.

- Create/Edit...

displays the Create/Edit Materials Dialog Box for the selected item in the Materials list.

- Delete

removes the selected material from the Materials list,

For additional information, see the following sections:

- 51.5.1. Create/Edit Materials Dialog Box

- 51.5.2. Fluent Database Materials Dialog Box

- 51.5.3. GRANTA MDS Materials Dialog Box

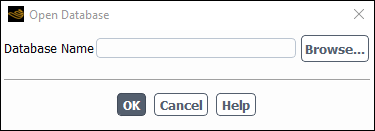

- 51.5.4. Open Database Dialog Box

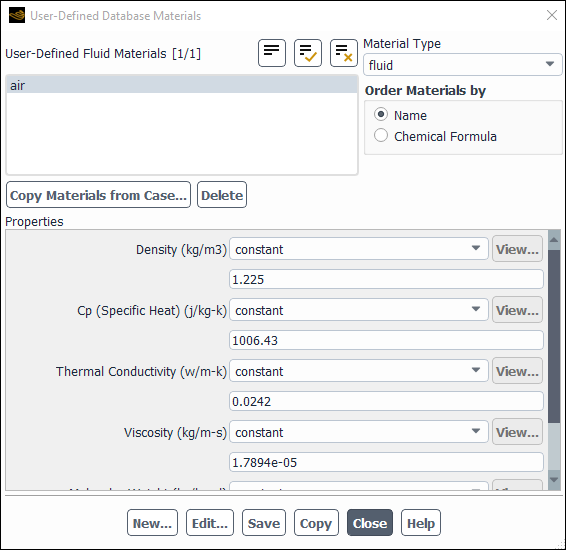

- 51.5.5. User-Defined Database Materials Dialog Box

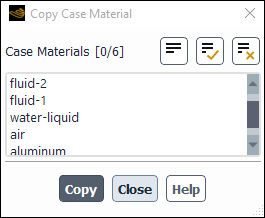

- 51.5.6. Copy Case Material Dialog Box

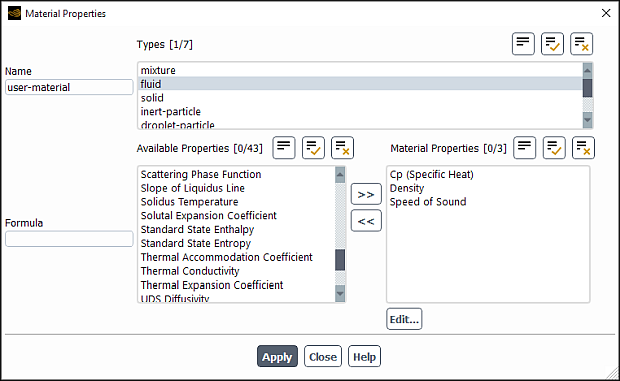

- 51.5.7. Material Properties Dialog Box

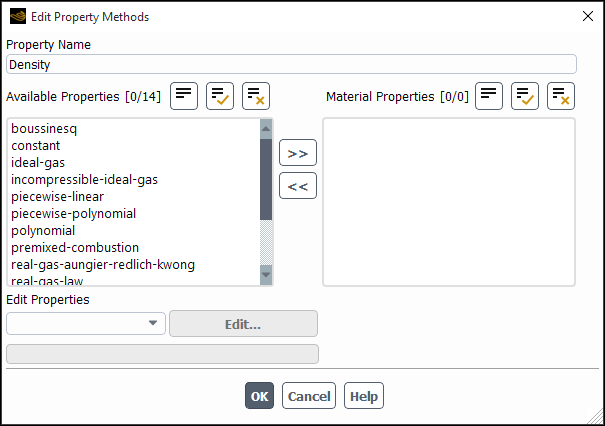

- 51.5.8. Edit Property Methods Dialog Box

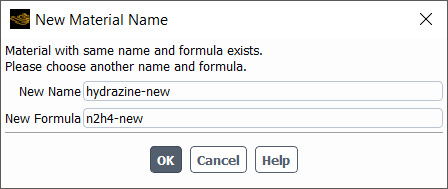

- 51.5.9. New Material Name Dialog Box

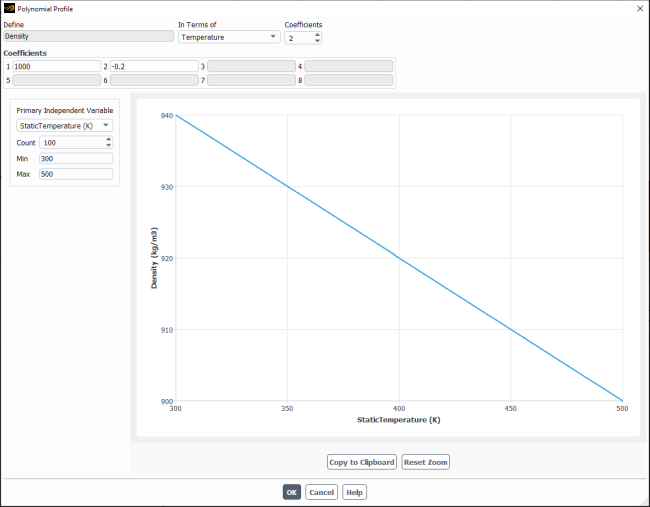

- 51.5.10. Polynomial Profile Dialog Box

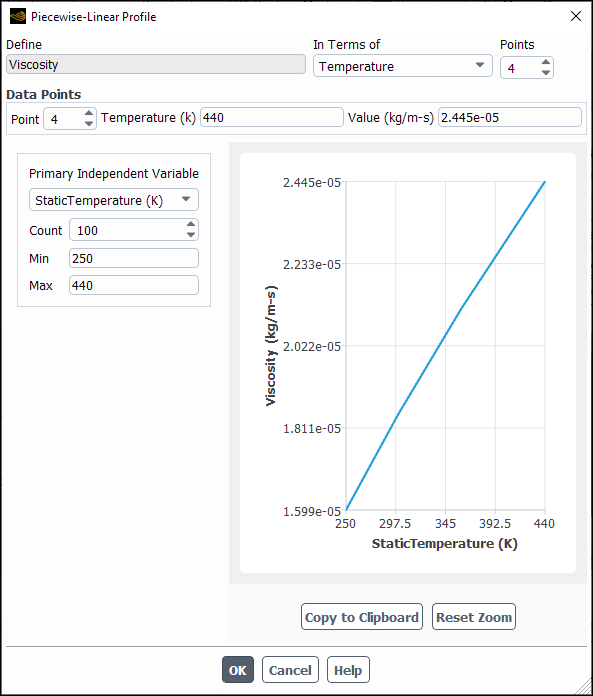

- 51.5.11. Piecewise-Linear Profile Dialog Box

- 51.5.12. Piecewise-Polynomial Profile Dialog Box

- 51.5.13. NASA-9-Coefficient Piecewise-Polynomial Profile Dialog Box

- 51.5.14. Model Options Dialog Box

- 51.5.15. Compressible Liquid Dialog Box

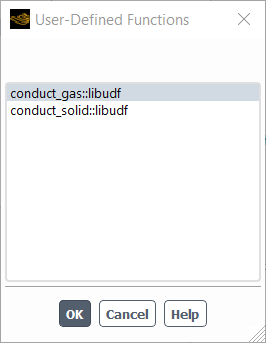

- 51.5.16. User-Defined Functions Dialog Box

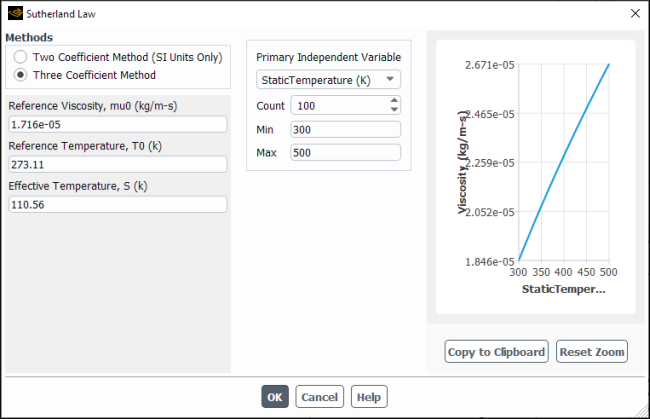

- 51.5.17. Sutherland Law Dialog Box

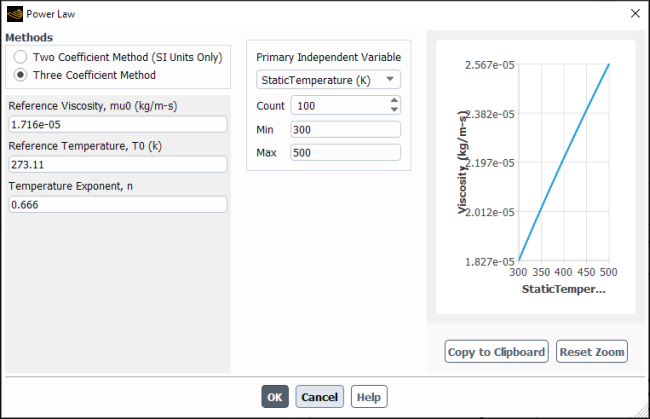

- 51.5.18. Power Law Dialog Box

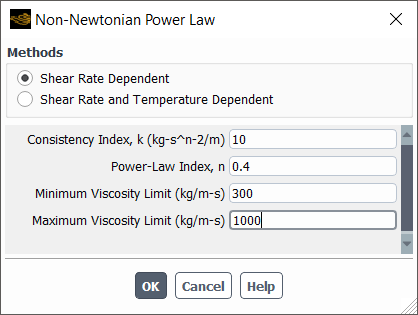

- 51.5.19. Non-Newtonian Power Law Dialog Box

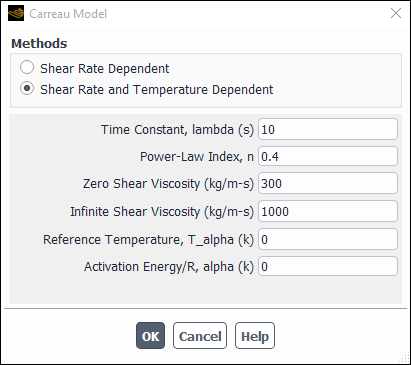

- 51.5.20. Carreau Model Dialog Box

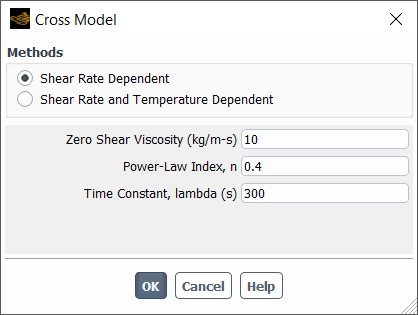

- 51.5.21. Cross Model Dialog Box

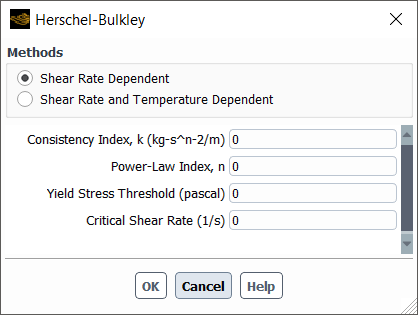

- 51.5.22. Herschel-Bulkley Dialog Box

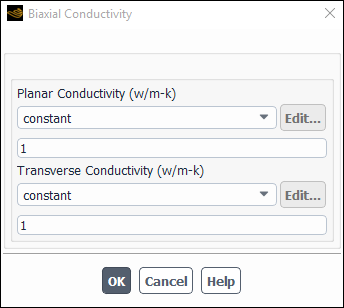

- 51.5.23. Biaxial Conductivity Dialog Box

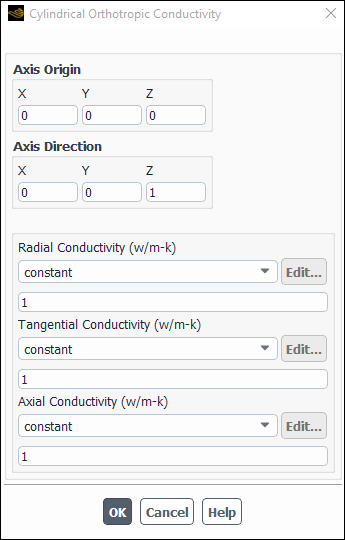

- 51.5.24. Cylindrical Orthotropic Conductivity Dialog Box

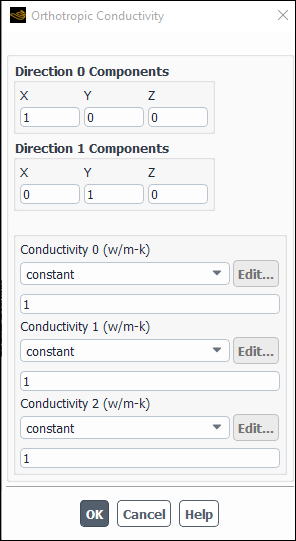

- 51.5.25. Orthotropic Conductivity Dialog Box

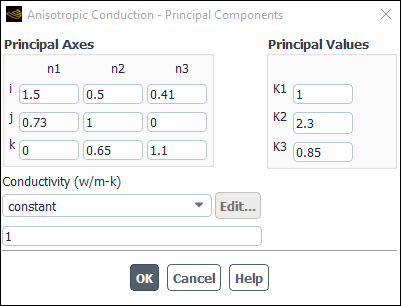

- 51.5.26. Anisotropic Conduction - Principal Components Dialog Box

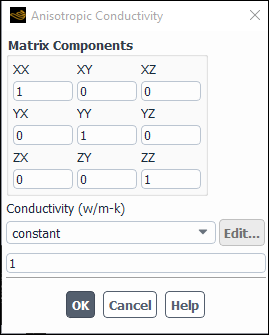

- 51.5.27. Anisotropic Conductivity Dialog Box

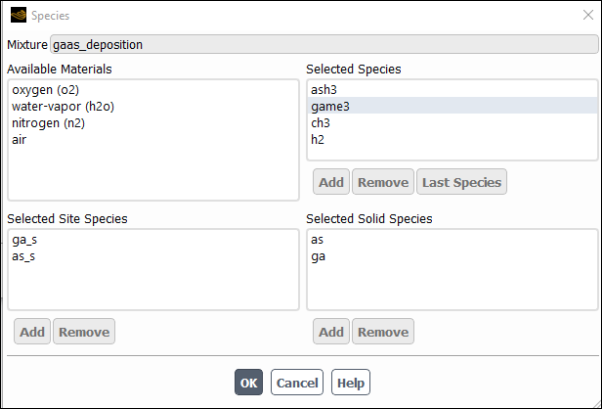

- 51.5.28. Species Dialog Box

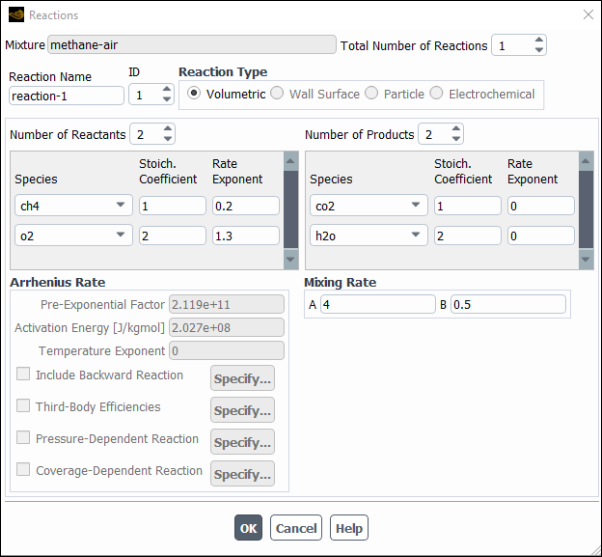

- 51.5.29. Reactions Dialog Box

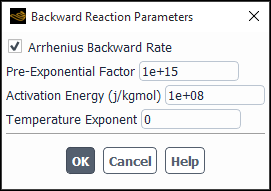

- 51.5.30. Backward Reaction Parameters Dialog Box

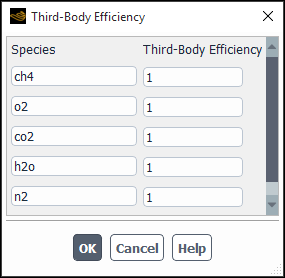

- 51.5.31. Third-Body Efficiency Dialog Box

- 51.5.32. Pressure-Dependent Reaction Dialog Box

- 51.5.33. Coverage-Dependent Reaction Dialog Box

- 51.5.34. Reference Molar Concentrations Dialog Box

- 51.5.35. Reaction Mechanisms Dialog Box

- 51.5.36. Site Parameters Dialog Box

- 51.5.37. Mass Diffusion Coefficients Dialog Box

- 51.5.38. Thermal Diffusion Coefficients Dialog Box

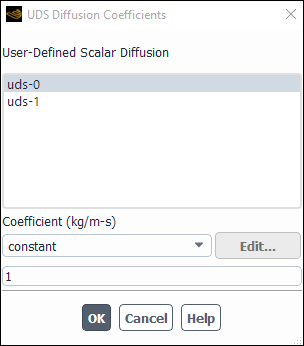

- 51.5.39. UDS Diffusion Coefficients Dialog Box

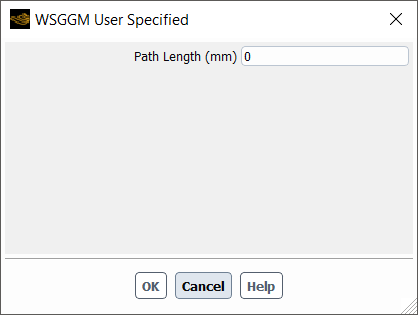

- 51.5.40. WSGGM User Specified Dialog Box

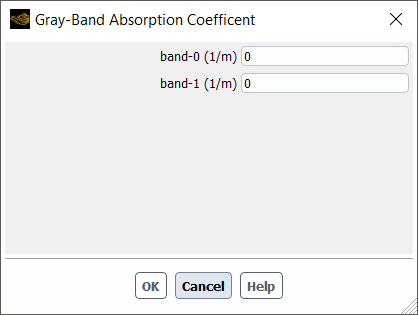

- 51.5.41. Gray-Band Absorption Coefficient Dialog Box

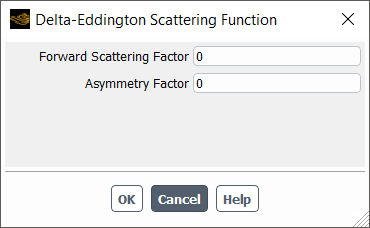

- 51.5.42. Delta-Eddington Scattering Function Dialog Box

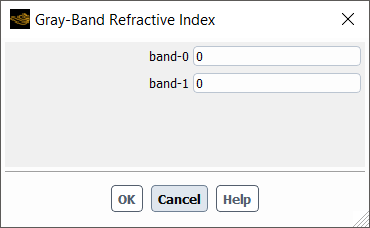

- 51.5.43. Gray-Band Refractive Index Dialog Box

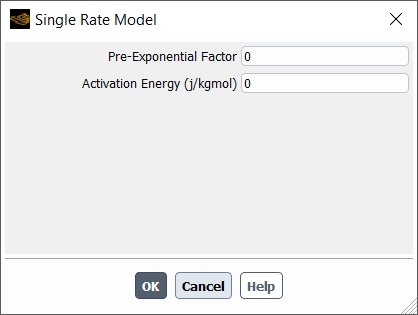

- 51.5.44. Single Rate Model Dialog Box

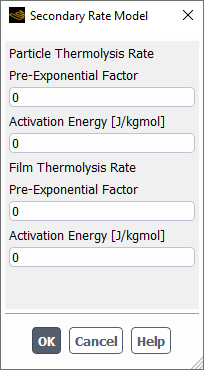

- 51.5.45. Secondary Rate Model Dialog Box

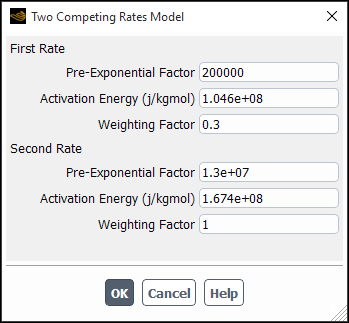

- 51.5.46. Two Competing Rates Model Dialog Box

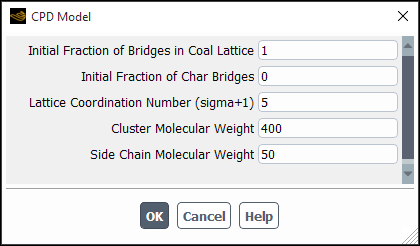

- 51.5.47. CPD Model Dialog Box

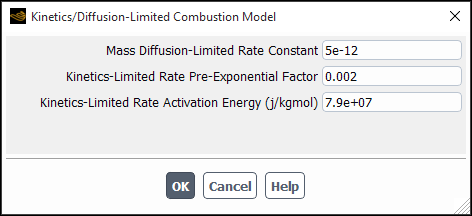

- 51.5.48. Kinetics/Diffusion-Limited Combustion Model Dialog Box

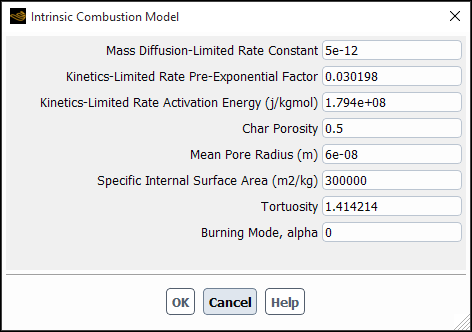

- 51.5.49. Intrinsic Combustion Model Dialog Box

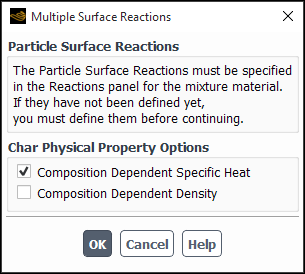

- 51.5.50. Multiple Surface Reactions Dialog Box

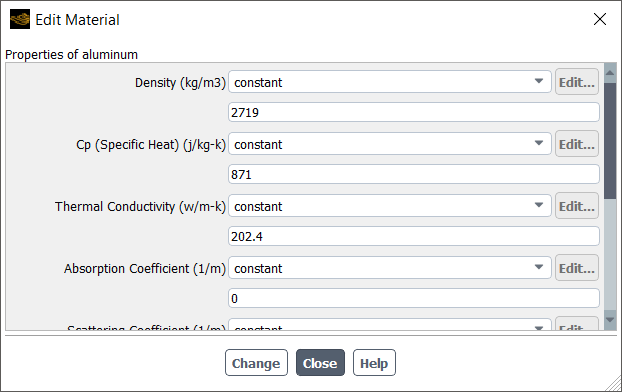

- 51.5.51. Edit Material Dialog Box

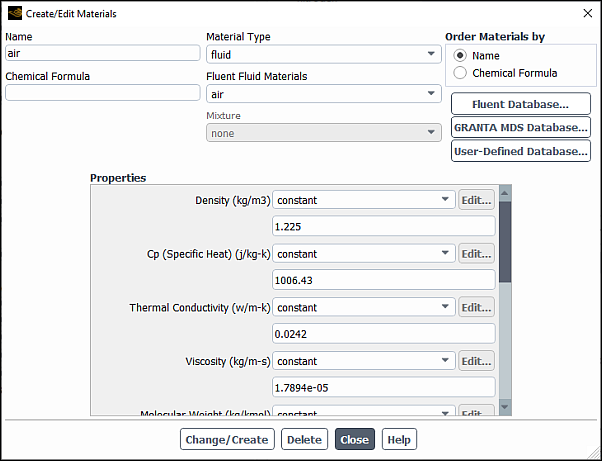

The Create/Edit Materials dialog box is used to create and modify materials. Materials can be downloaded from the global database or defined locally. See Physical Properties for details about defining material properties. Using the Create/Edit Materials Dialog Box describes how to use the dialog box.

Controls

- Name

shows the name of the material. If you edit this field, the new name will take effect when you click Change/Create.

- Chemical Formula

displays the chemical formula for the material. You should generally not edit this field unless you are creating a material from scratch.

- Material Type

is a drop-down list containing all of the available material types. By default, fluid and solid will be the only choices. If you are modeling species transport/combustion, mixture will also be available. For problems in which you have defined discrete-phase injections, inert-particle, droplet-particle, and/or combusting-particle will also appear.

- Fluent Fluid Materials

allows you to choose the fluid material for which you want to modify properties. This option is available when fluid is selected in the Material Type drop-down list.

- Fluent Solid Materials

allows you to choose the solid material for which you want to modify properties. This option is available when solid is selected in the Material Type drop-down list.

- Fluent Mixture Materials

allows you to choose the mixture material for which you want to modify properties. This option is available when mixture is selected in the Material Type drop-down list.

Important: A material may co-exist as a pure substance fluid as well as a species in one or multiple mixture materials. The pure fluid and the species for each mixture are separate objects and may have independent property settings. Therefore, editing the properties of the pure fluid will not modify the same properties for that fluid included in the mixture. If you intend to modify some material properties, you can make a copy of the pure fluid, and rename it. Using the copy in the mixture makes it easier to understand which version of the fluid is being modified.

- Fluent Droplet Particle Materials

allows you to choose the mixture parent when editing species. Choose none to edit the pure substance material. This option is available when droplet-particle is selected in the Material Type drop-down list.

- Order Materials by

allows you to order the materials in the Materials list alphabetically by Name or alphabetically by Chemical Formula.

- GRANTA MDS Database...

opens the GRANTA MDS Materials Dialog Box, from where you can copy materials from the GRANTA MDS database into the current solver.

- Database...

opens the Fluent Database Materials Dialog Box, from where you can copy materials from the global database into the current solver.

- User-Defined Database...

opens the Open Database Dialog Box, where you can specify the user-defined database to be used.

- Properties

contains input fields for the material properties that are required for the active physical models.

- Density

sets the material density. You may set a constant value, or select one of the other methods from the drop-down list above the real number field. See Density for instructions on setting density.

- Cp (Specific Heat)

sets the constant-pressure specific heat of the material. You may set a constant value, or select one of the other methods from the drop-down list above the real number field. See Specific Heat Capacity for instructions on setting specific heat.

- Thermal Conductivity

sets the thermal conductivity of the material. You may set a constant value, or select one of the other methods from the drop-down list above the real number field. See Thermal Conductivity for instructions on setting thermal conductivity.

- Viscosity

sets the viscosity of the material. You may set a constant value, or select one of the other methods from the drop-down list above the real number field. See Viscosity for instructions on setting viscosity.

- Molecular Weight

sets the molecular weight of the material. It is used to derive the gas constant of the material.

- Standard State Enthalpy

specifies the formation enthalpy of a fluid material for a reacting flow. See Standard State Enthalpies for details.

- Standard State Entropy

specifies the standard state entropy of a fluid material for a reacting flow. This input is used only if the fluid material is involved in a reversible reaction. See Standard State Entropies for details.

- Reference Temperature

specifies the reference temperature for the Heat of Formation.

- L-J Characteristic Length

specifies the kinetic theory parameter

for a fluid material. See Kinetic Theory Parameters for details.

- L-J Energy Parameter

specifies the kinetic theory parameter

for a fluid material. See Kinetic Theory Parameters for details.

- Absorption Coefficient

specifies the absorption coefficient

for radiation heat transfer. See Radiation Properties for details. If you choose the wsggm-user-specified option from the drop-down list next to Absorption Coefficient, the WSGGM User Specified Dialog Box will open. If you choose the user-defined-wsggm option from the drop-down list next to Absorption Coefficient, the User-Defined Functions Dialog Box will open.

- Scattering Coefficient

specifies the scattering coefficient

for radiation heat transfer (only for the P-1, Rosseland, DO, or MC radiation models). See Radiation Properties for details.

- Scattering Phase Function

specifies an isotropic (by default) or linear-anisotropic scattering function. If you are using the DO or MC models, delta-eddington and user-defined scattering functions are also available. See Radiation Properties for details. If you choose delta-eddington, the Delta-Eddington Scattering Function Dialog Box will open.

- Refractive Index

specifies the refractive index for the material. It is used only when semi-transparent media are modeled with the DO or MC radiation models.

- Mixture Species

specifies the names of the species that make up a mixture material. To check or modify these names, click the Edit... button to open the Species Dialog Box. This property appears only for mixture materials.

- Reaction

displays the reaction mechanism being used when you are modeling finite-rate reactions. finite-rate appears if LaminarFinite-Rate or Eddy-Dissipation Concept is selected in the Species Model Dialog Box, eddy-dissipation appears if Eddy-Dissipation is selected, and finite-rate/eddy-dissipation appears if Finite-Rate/Eddy-Dissipation is selected.

Click Edit... to open the Reactions Dialog Box.

- Mechanism

allows you to enable different reactions selectively in different geometrical zones. Click the Edit button to open the Reaction Mechanisms Dialog Box. See Defining Zone-Based Reaction Mechanisms for details.

- Mass Diffusivity

contains a drop-down list of available methods for specifying the diffusion coefficients for the species in a mixture material. If you select constant-dilute-appx, you will enter a constant value in the field below. If you select dilute-approx or multicomponent, the Mass Diffusion Coefficients Dialog Box will open, and you can specify the coefficients there. If you select kinetic-theory, you will need to specify the kinetic theory parameters for the individual fluid materials (species) that make up the mixture. See Mass Diffusion Coefficients for details about specifying mass diffusivity.

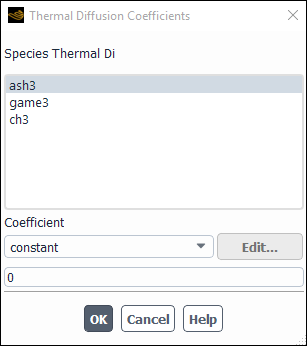

- Thermal Diffusion Coefficient

contains a drop-down list of available methods for specifying the thermal diffusion coefficients for the species in a mixture material. If you select kinetic-theory, you will need to specify the kinetic theory materials (species) that make up the mixture. If you select specified, the Thermal Diffusion Coefficients Dialog Box will open, and you can specify the coefficients there. See Thermal Diffusion Coefficient Inputs for details about specifying thermal diffusion coefficients.

- Density of Unburnt Reactants

sets the density (

in Equation 8–100 in the Theory Guide) of the unburnt products.

- Temperature of Unburnt Reactants

sets the temperature (

in Equation 8–100 in the Theory Guide) of the unburnt products.

- Adiabatic Temperature of Burnt Products

(only for adiabatic premixed combustion models) specifies the value of the burnt products under adiabatic conditions,

in Equation 8–97 in the Theory Guide.

- Unburnt Thermal Diffusivity

specifies the thermal diffusivity (

in Equation 8–77 in the Theory Guide) for use with the premixed combustion model. See Modeling Premixed Combustion for details.

- Laminar Flame Speed

specifies the value of

in Equation 8–77 in the Theory Guide.

- Laminar Flame Thickness

specifies the thickness of the flame for which you have a choice of constant, user-defined, or diffusivity-over-flame-speed.

- Critical Rate of Strain

specifies the value of

in Equation 8–86 in the Theory Guide.

- Heat of Combustion

(only for non-adiabatic premixed combustion models) specifies the value of

in Equation 8–99 in the Theory Guide.

- Unburnt Fuel Mass Fraction

(only for non-adiabatic premixed combustion models) specifies the value of

in Equation 8–99 in the Theory Guide.

- Thermal Expansion Coefficient

specifies the thermal expansion coefficient (

in Equation 7–67) for use with the Boussinesq approximation. See Steps in Solving Buoyancy-Driven Flow Problems for details.

- Droplet Surface Tension

specifies the value of the droplet surface tension (

in Equation 12–371 in the Theory Guide).

- Latent Heat

is the latent heat of vaporization,

, required for phase change from an evaporating liquid droplet or for the evolution of volatiles from a combusting particle. See Setting Material Properties for the Discrete Phase for details.

- Latent Heat at NBP

is the latent heat of vaporization at the normal boiling point, available for droplet-particles. See Using the Cubic Equation of State Models with the Lagrangian Dispersed Phase Models for details.

- Normal Boiling Point (NBP)

is given by Equation 8–104. See Using the Cubic Equation of State Models with the Lagrangian Dispersed Phase Models for details.

- Thermophoretic Coefficient

specifies the thermophoretic coefficient (

in Equation 12–11 in the Theory Guide), and appears when the thermophoretic force is included in the discrete phase calculation.

- Vaporization Temperature

is the temperature,

, at which the calculation of vaporization from a liquid droplet or devolatilization from a combusting particle is initiated by Ansys Fluent. See Setting Material Properties for the Discrete Phase for details.

- Boiling Point

is the temperature,

, at which the calculation of the boiling rate equation is initiated by Ansys Fluent. See Setting Material Properties for the Discrete Phase for details.

- Vapor-Particle-Equilibrium

is the selected approach for the calculation of the vapor concentration of the components at the surface. This can be Raoult’s law (Equation 12–176 in the Theory Guide), the Peng-Robinson real gas model (Equation 12–184 in the Theory Guide), or a user-defined function that provides this value.

- Reaction Model

allows you to select the reaction model for the particle mixture material. You can choose from none and multicomponent-reactions. This item appears only for cases with reacting multicomponent particles. See Multicomponent Particles with Chemical Reactions for details.

- Volatile Component Fraction

(

) is the fraction of a droplet particle that may vaporize via Laws 2 and/or 3 (Droplet Vaporization (Law 2) in the Theory Guide). For combusting particles, it is the fraction of volatiles that may be evolved via Law 4 (Devolatilization (Law 4) in the Theory Guide). See Setting Material Properties for the Discrete Phase for details.

- Binary Diffusivity

is the mass diffusion coefficient,

, used in the vaporization law, Law 2. This input is also used to define the mass diffusion of the oxidizing species to the surface of a combusting particle,

. See Setting Material Properties for the Discrete Phase for details.

- Diffusivity Reference Pressure

is the reference pressure

for the pressure dependent binary diffusivity in Equation 12–91 in the Fluent Theory Guide.

- Saturation Vapor Pressure

is the saturated vapor pressure,

, defined as a function of temperature, which is used in the vaporization law, Law 2. See Setting Material Properties for the Discrete Phase for details.

- Heat of Pyrolysis

is the heat of the instantaneous pyrolysis reaction,

, that the evaporating/boiling species may undergo when released to the continuous phase. The heat of pyrolysis should be entered as a positive number for exothermic reaction and as a negative number for endothermic reaction. The default value of zero implies that the heat of pyrolysis is not considered. See Setting Material Properties for the Discrete Phase for details.

- Composition Averaging Coefficient

is the coefficient

in Equation 12–186 in the Fluent Theory Guide. To assume bulk gas composition for the physical properties in the particle vaporization and heating rates equations, select

nonefrom the Composition Averaging Coefficient drop-down in the Create/Edit Materials dialog box, under Properties. To enable property averaging, selectconstantand enter a value between 0 and 1 for the Composition Averaging Coefficient.= 1 corresponds to bulk gas mixture. For

= 0, the composition reverts to the particle surface composition.

Important: When you define the Composition Averaging Coefficient with a

constantvalue other than 1, you must also specify Specific Heat, Viscosity and Thermal Conductivity for the evaporating species (in the Create/Edit Materials dialog box, under Properties, for the corresponding fluid material of the continuous phase mixture).The default and recommended value for the averaging coefficient is 1/3. However, to improve the simulation results, you must provide accurate temperature-dependent data for the vapor material.

- Temperature Averaging Coefficient

is the coefficient

in Equation 12–185 in the Fluent Theory Guide. To assume bulk gas temperature for the physical properties in the particle vaporization and heating rates equations, select

nonefrom the Temperature Averaging Coefficient drop-down in the Create/Edit Materials dialog box, under Properties. To enable property averaging, selectconstantand enter a value between 0 and 1 for the Temperature Averaging Coefficient.= 1 corresponds to bulk gas conditions. For

= 0, the temperature reverts to the particle surface temperature.

Important: When you define the Temperature Averaging Coefficient with a

constantvalue other than 1, you must also specify Specific Heat, Viscosity and Thermal Conductivity for the evaporating species (in the Create/Edit Materials dialog box, under Properties, for the corresponding fluid material of the continuous phase mixture).The default and recommended value for the averaging coefficient is 1/3. However, to improve the simulation results, you must provide accurate temperature-dependent data for the evaporating vapor material.

- Vaporization/Boiling Model

defines which vaporization/boiling model is used for pure droplets (Law 2) and for multicomponent droplets (Law 7).

If you want to use the default diffusion-controlled model, retain the selection of diffusion-controlled from the drop-down list to the right of Vaporization/Boiling Model. This will apply Equation 12–80 in the Theory Guide.

To use the convection/diffusion-controlled model for vaporization select convection/diffusion-controlled from the drop-down list. Equation 12–85 in the Theory Guide will be applied for the calculation of the vaporization rate, and Equation 12–97 in the Theory Guide will be applied in the particle heat transfer calculations This model is recommended when evaporation rates are high. For slowly evaporating droplets both models are expected to give similar results.

You can select options for the vaporization/boiling model in the Model Options Dialog Box that opens when you click Edit... next to Vaporization/Boiling Model.

- Degrees of Freedom

specifies the kinetic theory parameter

, which is the number of nodes of energy storage. This parameter is required only if you are defining specific heat via kinetic theory. See Kinetic Theory Parameters for details.

- Particle Emissivity

is the emissivity of particles in your model,

, used to compute radiation heat transfer to the particles when the P-1 or DO radiation model is active and particle radiation interaction is enabled in the Discrete Phase Model Dialog Box. See Setting Material Properties for the Discrete Phase for details.

- Particle Scattering Factor

is the scattering factor,

, due to particles in the P-1 or DO radiation model. Note that this property will appear only if particle radiation interaction is enabled in the Discrete Phase Model Dialog Box. See Setting Material Properties for the Discrete Phase for details.

- Swelling Coefficient

is the coefficient,

, which governs the swelling of the coal particle during the devolatilization law, Law 4. A swelling coefficient of unity (the default) implies that the coal particle stays at constant diameter during the devolatilization process. See Setting Material Properties for the Discrete Phase for details.

- Burnout Stoichiometric Ratio

is the stoichiometric requirement,

, for the burnout reaction, in terms of mass of oxidant per mass of char in the particle. See Setting Material Properties for the Discrete Phase for details.

- Combustible Fraction

is the mass fraction of char,

, in the coal particle (the fraction of the initial combusting particle that will react in the surface reaction) Law 5. See Setting Material Properties for the Discrete Phase for details.

- React. Heat Fraction Absorbed by Solid

is the parameter

, which controls the distribution of the heat of reaction between the particle and the continuous phase. The default value of zero implies that the entire heat of reaction is released to the continuous phase. See Setting Material Properties for the Discrete Phase for details.

- Heat of Reaction for Burnout

is the heat released by the surface char combustion reaction, Law 5. This parameter is specified in terms of heat release (for example, Joules) per unit mass of char consumed in the surface reaction. See Setting Material Properties for the Discrete Phase for details.

- Devolatilization Model

defines which version of the devolatilization model, Law 4, is being used. If you want to use the default constant rate devolatilization model, retain the selection of constant in the drop-down list to the right of Devolatilization Model and enter the rate constant

in the field below the list.

Select single-rate, two-competing-rates, or cpd-model in the drop-down list to choose one of the optional devolatilization models (the single kinetic rate model, two kinetic rates model, or CPD model, as described in Devolatilization (Law 4) in the Theory Guide).

When the single kinetic rate model (single-rate) is selected, the Single Rate Model Dialog Box will appear; when the two competing rates model (two-competing-rates) is selected, the Two Competing Rates Model Dialog Box will appear; and when the CPD model (cpd-model) is selected, the CPD Model Dialog Box will appear.

See Setting Material Properties for the Discrete Phase for details.

- Combustion Model

defines which version of the surface char combustion law (Law 5) is being used. If you want to use the default diffusion-limited rate model, retain the selection of diffusion-limited in the drop-down list. No additional inputs are necessary, because the binary diffusivity defined above will be used in Equation 12–146 in the Theory Guide.

To use the kinetics/diffusion-limited rate model for the surface combustion model, select kinetics/diffusion-limited in the drop-down list and enter the parameters in the resulting Kinetics/Diffusion-Limited Combustion Model Dialog Box.

To use the intrinsic model for the surface combustion model, select intrinsic-model in the drop-down list and enter the parameters in the resulting Intrinsic Combustion Model Dialog Box.

To use the multiple surface reactions model, select multiple-surface-reactions in the drop-down list.

See Setting Material Properties for the Discrete Phase for details.

- Pure Solvent Melting Heat

specifies the latent heat for the melting and solidification model (

in Equation 15–3 in the Theory Guide). Note that for solidification to occur, Pure Solvent Melting Heat must be set to a positive non-zero value.

- Solidus Temperature

specifies the solidus temperature for the melting and solidification model (

in Equation 15–3 in the Theory Guide). If you are solving for species transport, the solidus temperature is

in Equation 15–8, and you specify the method by which it is calculated: either according to the mixing-law (which is based on the parameters of the solutes) or a user-defined function.

- Liquidus Temperature

specifies the liquidus temperature for the melting and solidification model (

in Equation 15–3 in the Theory Guide). If you are solving for species transport, the liquidus temperature is

in Equation 15–9, and you specify the method by which it is calculated: either according to the mixing-law (which is based on the parameters of the solutes) or a user-defined function.

- Pure Solvent Melting Temperature

specifies the melting temperature of pure solvent (

in Equation 15–8 and Equation 15–9 in the Theory Guide) for the melting and solidification model when species transport has also been enabled. The solvent is the last species listed under of the mixture material.

- Eutectic Temperature

is the lowest alloy melting temperature, which depends on the relative proportions of the mixture composition of the Eutectic species mass fractions.

- Slope of Liquidus Line

specifies the slope of the liquidus surface with respect to the concentration of the solute (

in Equation 15–8 and Equation 15–9 in the Theory Guide). It is not necessary to specify this value for the solvent. Note that this option is available only for the melting and solidification model when species transport has also been enabled.

- Partition Coefficient

specifies the partition coefficient with respect to the concentration of the solute fluid (

in Equation 15–8 and Equation 15–9 in the Theory Guide). It is not necessary to specify this value for the solvent. Note that this option is available only for the melting and solidification model when species transport has also been enabled.

- Eutectic Mass Fraction

is the mass fraction of a solute in an alloy at which the melting temperature of the alloy is the lowest possible value (

in Equation 15–10 in the Theory Guide). It is not necessary to specify this value for the solvent. Note that this option is available only for the melting and solidification model when species transport has also been enabled.

- Solutal Expansion Coefficient

allows you to specify the coefficient in Equation 15–24 in the Theory Guide for all the species except the last one in the mixture. Note that this option is available only for the melting and solidification model when the Include Solutal Buoyancy option is enabled.

- Diffusion in Solid

specifies the rate of diffusion in the solid. Note that this option is available only for the melting and solidification model when the Lever rule is selected and the species transport is enabled.

- UDS Diffusivity

specifies the diffusion coefficient for a user-defined scalar. This material property is available in the Create/Edit Materials Dialog Box when you specify one or more user-defined scalars in the User-Defined Scalars Dialog Box. If you select defined-per-uds, you will need to specify the diffusion coefficient for each user-defined scalar transport equation in the UDS Diffusion Coefficients Dialog Box.

- Youngs Modulus

specifies the Young's modulus. This material property is only available for solid materials when you have selected a model in the Structural Model Dialog Box.

- Poisson Ratio

specifies the Poisson's ratio. This material property is only available for solid materials when you have selected a model in the Structural Model Dialog Box.

- Electrical Conductivity

sets the material electrical conductivity. You may set a constant value, or select one of the other methods from the drop-down list above the real number field. This material property only becomes available if the electric potential model is enabled.

- Charge Number

specifies the charge number for a fluid material for a flow involving electrochemical reactions. The default setting of 0 means that the fluid species is neutral. This material property only becomes available if the electric potential model is enabled.

When you are viewing the database, additional properties may be displayed. However, after you copy the material to the local area, only the properties with relevance to the current problem will be displayed.

- Change/Create

changes the properties of a locally stored material or creates a new one in the local area. If no material with the specified Name exists locally, Ansys Fluent will create it. If you have modified the material without changing its name, Ansys Fluent will simply update the material with your modifications. If you have assigned a new name to the material and a material with this name already exists locally, an error will be indicated; you must then specify a different name or delete the existing material with that name before trying to save the new material.

- Delete

deletes the currently selected material from the local materials list. It has no effect on the global database.

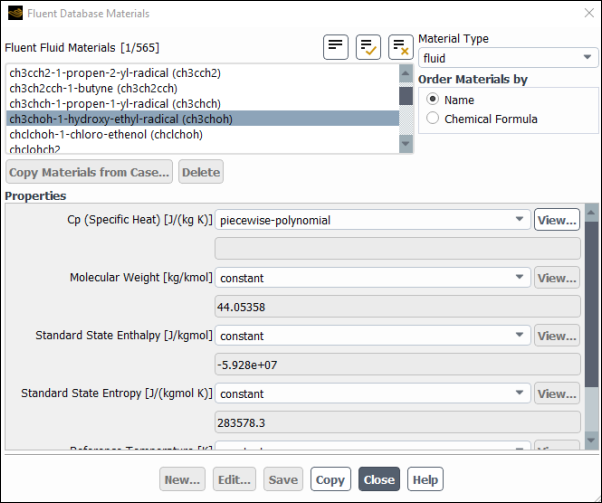

The Fluent Database Materials dialog box is opened by clicking the Fluent Database... button in the Create/Edit Materials Dialog Box. In this dialog box you can view the global (site-wide) material properties database and copy materials list in the solver. See Copying Materials from the Ansys Fluent Database for details.

Controls

- Fluent Fluid Materials

contains a list of all materials of the selected Material Type that are defined in the database. The name of this list will change depending on the selected material type (for example, fluid, solid, and so on). You can select one or more of these materials to be copied to the solver.

- Material Type

is a drop-down list containing all of the available material types. By default, fluid and solid will be the only choices. If you are modeling species transport/combustion, mixture will also be available. For problems in which you have defined discrete-phase injections, inert-particle, droplet-particle, and/or combusting-particle will also appear.

- Order Materials by

allows you to order the materials in the Materials list alphabetically by Name or alphabetically by Chemical Formula.

- Copy Materials from Case...

opens the Copy Case Material Dialog Box.

- Delete

deletes the selected materials from the database.

- Properties

contains fields for the material properties that are defined for the selected material. These fields are for informational purposes only; they cannot be edited.

When you are viewing the database, not all properties displayed are relevant to your Ansys Fluent solution. After you copy the material, only properties with relevance to the current physical models will be displayed.

- Copy

copies the current material from the global database to the local materials list in the solver.

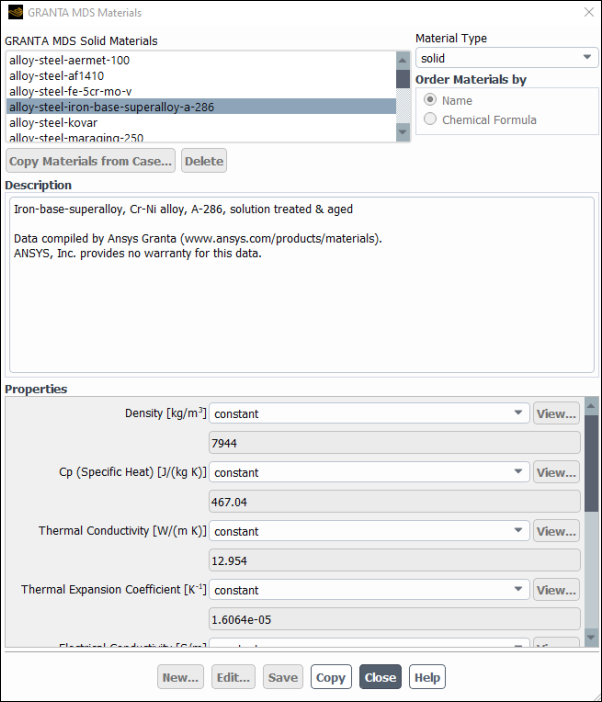

The GRANTA MDS Materials dialog box is opened by clicking the button in the Create/Edit Materials Dialog Box. In this dialog box you can view the global (site-wide) GRANTA MDS material properties database and copy materials list in the solver (available with a separate GRANTA licence). See Copying Materials from the Ansys GRANTA MDS Database for details.

Controls

- GRANTA MDS Solid Materials

contains a list of all materials of the selected Material Type that are defined in the database. You can select one of these materials to be copied to the solver. Note that multi-selection is not supported.

- Material Type

is a drop-down list containing all of the available material types.

- Description

displays a description of the selected material.

- Properties

contains fields for the material properties that are defined for the selected material. These fields are for informational purposes only; they cannot be edited.

When you are viewing the database, not all properties displayed are relevant to your Ansys Fluent solution. After you copy the material, only properties with relevance to the current physical models will be displayed.

A license is required for viewing properties in the GRANTA MDS Materials dialog box. When no license is available, only the Description group box is displayed.

- Copy

copies the current material from the global database to the local materials list in the solver (a GRANTA license is required).

The Open Database dialog box is opened by clicking the User-Defined Database button in the Create/Edit Materials Dialog Box.

Controls

- Browse...

opens The Select File Dialog Box where you can select the user-defined database to be used in the current solver session.

- Database Name

allows you to enter the path and name of a new database. If you select an existing database, this field displays the path and name of the selected database.

The User-Defined Database Materials dialog box is opened by clicking in the Open Database Dialog Box. In this dialog box you can view the user-defined material properties database and copy materials list in the solver. See Viewing Materials in a User-Defined Database for details.

Controls

- User-Defined Materials

contains a list of all materials of the selected Material Type that are defined in the database. The name of this list will change depending on the selected material type (for example, User-Defined Fluid Materials, User-Defined Solid Materials, and so on). You can select one or more of these materials to copy to your local list or edit their properties.

- Material Type

is a drop-down list containing all of the available material types.

- Order Materials By

allows you to order the materials in the User-Defined Materials list alphabetically by Name or alphabetically by Chemical Formula.

- Copy Materials from Case...

opens the Copy Case Material Dialog Box.

- Delete

deletes the selected materials from the database.

- Properties

lists the properties and values of the selected material.

- New...

opens a blank Material Properties Dialog Box where you can define a new material.

- Edit...

opens the Material Properties Dialog Box displaying the properties of the selected material.

- Save

saves the information to the selected database.

- Copy

copies the selected material to your local material list. If the material already exists the New Material Name Dialog Box opens

This dialog box is opened by clicking the Copy Materials from Case... button in the User-Defined Database Materials Dialog Box.

Controls

- Case Materials

lists all the materials present in your local materials list.

- Copy

copies the selected materials to the user-defined database.

This dialog box is opened by clicking New... button in the User-Defined Database Materials Dialog Box. See Creating a New Materials Database and Materials for details.

Controls

- Name

specifies the name of the material that you are creating.

- Formula

(optional) specifies the chemical formula of the material that you are creating.

- Types

allows you to select material type from fluid, solid, inter-particle, droplet-particle, combusting-particle, and mixture materials.

- Available Properties

lists properties applicable to the selected material type.

- Material Properties

lists properties that you have selected from Available Properties list.

- Edit...

opens Edit Property Methods Dialog Box where you can edit the parameters that define a property.

This dialog box is opened by clicking Edit... button in the Material Properties Dialog Box. See Creating a New Materials Database and Materials for details.

Controls

- Property Name

specifies the name of the property that you want to edit.

- Available Properties

specifies the methods that can be used to define the selected property.

- Material Properties

lists properties that you have selected from Available Properties list.

- Edit Properties

allows you to select the property that you want to edit.

This dialog box is opened by clicking the Copy button in the User-Defined Database Materials Dialog Box when a material is already defined with the same name in the Create/Edit Materials Dialog Box.

Controls

- New Name

allows you to enter the new name for the material you need to copy.

- New Formula

allows you to enter the new formula for the material you need to copy.

The Polynomial Profile dialog box allows you to define a physical property as a polynomial function of temperature. This dialog box will open when you select polynomial in the drop-down list next to a physical property in the Create/Edit Materials Dialog Box. See Inputs for Polynomial Functions for details about the items below.

Controls

- Define

shows the property that is being defined as a function of temperature.

- In Terms of

shows the independent variable (Temperature). The property shown in Define will be defined as a polynomial function of temperature.

- Coefficients

is an integer number entry that indicates the number of coefficients to be defined. You can define up to 8 coefficients.

- Coefficient Values

contains real number entries for the number of coefficients set in the Coefficients integer number entry above. The number of entries that are editable will be the same as the number of coefficients you requested.

The Piecewise-Linear Profile dialog box allows you to define a physical property as a piecewise-linear function of temperature. This dialog box will open when you select piecewise-linear in the drop-down list next to a physical property in the Create/Edit Materials Dialog Box. See Inputs for Piecewise-Linear Functions for details about the items below.

Controls

- Define

shows the property that is being defined as a function of temperature.

- In Terms of

shows the independent variable (Temperature). The property shown in Define will be defined as a piecewise-linear function of temperature.

- Points

indicates the number of data pairs that will define the piecewise distribution. You can define up to 50 pairs.

- Data Points

contains entries for defining the data pairs.

- Point

indicates the point for which the data pair (Temperature, Value) is being defined.

- Temperature

is the independent variable.

- Value

is the dependent variable (the property). In the example dialog box above, Viscosity is the variable being defined, as shown in the Define field.

- Primary Independent Variable

allows you to select which variable is the independent variable.

- Count

allows you to specify the number of plot points.

- Min

sets the minimum value for the independent variable.

- Max

sets the maximum value for the independent variable.

- Copy to Clipboard

copies the current plot onto your clipboard.

- Reset Zoom

resets to the default zoom. You can click and drag in the plot to change the zoom level.

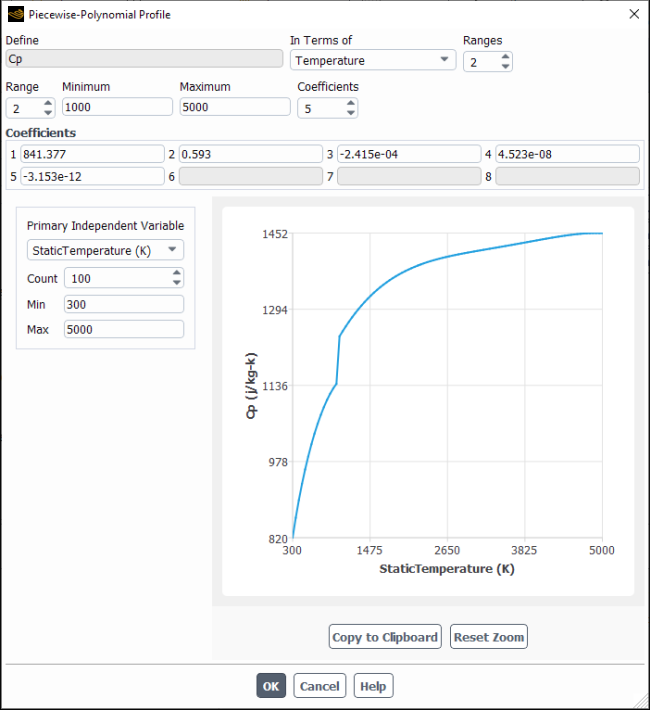

The Piecewise-Polynomial Profile dialog box allows you to define a physical property as a piecewise-polynomial function of temperature. This dialog box will open when you select piecewise-polynomial in the drop-down list next to a physical property in the Create/Edit Materials Dialog Box. See Inputs for Piecewise-Polynomial Functions for details about the items below.

Controls

- Define

shows the property that is being defined as a function of temperature.

- In Terms of

shows the independent variable (Temperature). The property shown in Define will be defined as a polynomial function of temperature.

- Ranges

sets the number of temperature ranges for which you will define polynomial functions. You can define up to 3 ranges.

- Range

indicates the temperature range for which you are defining the polynomial function.

- Minimum, Maximum

set the minimum and maximum temperatures for the specified Range.

- Coefficients

is an integer number entry that indicates the number of coefficients to be defined for the specified Range. You can define up to 8 coefficients.

- Coefficient Values

contains real number entries for the number of coefficients set in the Coefficients integer number entry above. The number of entries that are editable will be the same as the number of coefficients you requested for the specified Range.

- Primary Independent Variable

allows you to select which variable is the independent variable.

- Count

allows you to specify the number of plot points.

- Min

sets the minimum value for the independent variable.

- Max

sets the maximum value for the independent variable.

- Copy to Clipboard

copies the current plot onto your clipboard.

- Reset Zoom

resets to the default zoom. You can click and drag in the plot to change the zoom level.

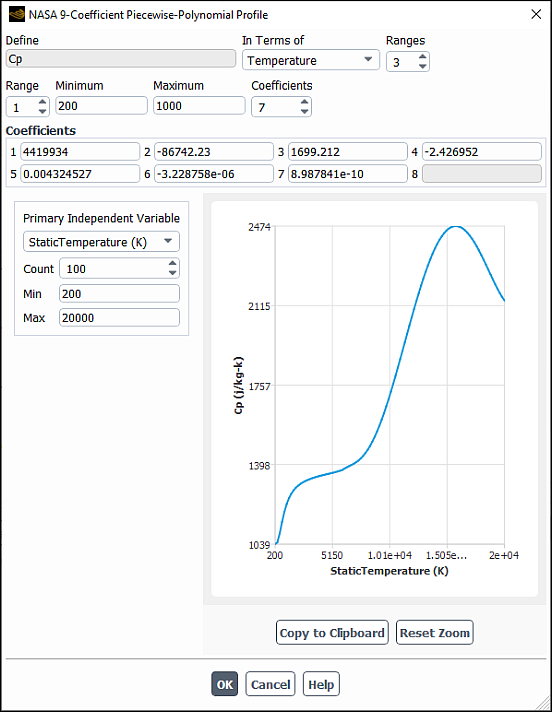

The NASA-9-Coefficient Piecewise-Polynomial Profile dialog box allows you to define specific heat as a piecewise-polynomial function of temperature. The profile can be used for cases with extremely high temperatures (such as hypersonic flows). This dialog box will open when you select nasa-9-piecewise-polynomial from the Cp (Specific Heat) drop-down list in the Create/Edit Materials Dialog Box. See Inputs for NASA-9-Piecewise-Polynomial Functions for details about the items below.

Controls

- Define

shows the property (Cp) that is being defined as a function of temperature.

- In Terms of

shows the independent variable (Temperature). The specific heat (Cp) will be defined as a function of temperature.

- Ranges

sets the number of temperature ranges for which you will define polynomial functions. You can define up to 8 ranges.

- Range

indicates the temperature range for which you are defining the polynomial function.

- Minimum, Maximum

set the minimum and maximum temperatures for the specified Range.

- Coefficients

is an integer number entry that indicates the number of coefficients to be defined for the specified Range. You can define up to 8 coefficients.

- Coefficient Values

is a group box that contains eight real number entry boxes. You can specify values for coefficients 1, 2, 3, and so on, that are used in Equation 8–4. The number of editable boxes is the same as the integer number you entered in Coefficients for the specified Range.

- Primary Independent Variable

is a drop-down box for selecting the independent variable. For the nasa-9-piecewise-polynomial profile, Static Temperature is the only available option.

- Count

allows you to specify the number of plot points.

- Min

sets the minimum value for the independent variable.

- Max

sets the maximum value for the independent variable.

- Copy to Clipboard

copies the current plot onto your clipboard.

- Reset Zoom

resets to the default zoom. You can click and drag in the plot to change the zoom level.

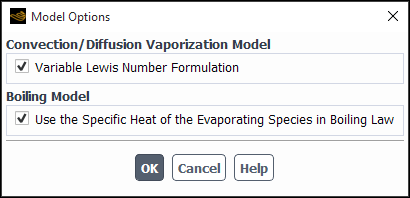

The Model Options dialog box allows you to select boiling model options and to enable the calculation of the Spalding heat number for the convection/diffusion vaporization model. This dialog box opens when you click Edit... next to Vaporization Model in the Create/Edit Materials Dialog Box.

- Convection/Diffusion Vaporization Model

allows you to enable Variable Lewis Number Formulation if you want to compute the Spalding heat number from Equation 12–96 in the Fluent Theory Guide. This group box is available only when you select convection/diffusion-controlled for Vaporization/Boiling Model.

- Boiling Model

is where you can select the Use the Specific Heat of the Evaporating Species in Boiling Law option. This option sets the heat capacity of the gas (

in Equation 12–101 in the Fluent Theory Guide) to the specific heat of the evaporating species selected in the Set Injection Properties dialog box. For the convection/diffusion controlled model with the Variable Lewis Number Formulation, this option is selected by default. This ensures consistency with the convection/diffusion controlled model expression for

in Equation 12–95 in the Fluent Theory Guide.

For more information, see Description of the Properties.

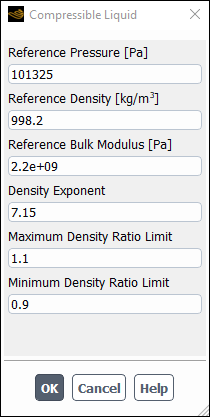

The Compressible Liquid dialog box allows you to model liquid compressibility for high pressure applications using the Tait equation of state. This dialog box will open when you select compressible-liquid in the drop-down list next to one of the Properties in the Create/Edit Materials Dialog Box. See Compressible Liquid Density Method for details about using the items below.

Controls

- Reference Pressure

sets the reference pressure.

- Reference Density

sets the reference density.

- Reference Bulk Modulus

sets the reference bulk modulus.

- Density Exponent

sets the density exponent.

The User-Defined Functions dialog box allows you to choose which user-defined function is to be used to define a material property. This dialog box will open when you select user-defined in the drop-down list next to one of the Properties in the Create/Edit Materials Dialog Box. See the separate Fluent Customization Manual for details about user-defined functions.

The list will contain all available user-defined functions.

The Sutherland Law dialog box allows you to set the coefficients for Sutherland’s law for viscosity. This dialog box will open when you select sutherland in the drop-down list next to Viscosity in the Create/Edit Materials Dialog Box. See Sutherland Viscosity Law for details about the items below.

Controls

- Methods

contains options for selecting the Two Coefficient Method or the Three Coefficient Method.

- C1, C2

set the coefficients

and

in Equation 8–24 in SI units. These inputs will appear if you select the Two Coefficient Method.

- Reference Viscosity

sets the reference viscosity

in Equation 8–25. This input will appear if you select the Three Coefficient Method.

- Reference Temperature

sets the reference temperature

in Equation 8–25. This input will appear if you select the Three Coefficient Method.

- Effective Temperature

sets the effective temperature

in Equation 8–25. This input will appear if you select the Three Coefficient Method.

- Primary Independent Variable

allows you to select which variable is the independent variable.

- Count

allows you to specify the number of plot points.

- Min

sets the minimum value for the independent variable.

- Max

sets the maximum value for the independent variable.

- Copy to Clipboard

copies the current plot onto your clipboard.

- Reset Zoom

resets to the default zoom. You can click and drag in the plot to change the zoom level.

The Power Law dialog box allows you to set the coefficients for the power law for viscosity. This dialog box will open when you select power-law in the drop-down list next to Viscosity in the Create/Edit Materials Dialog Box. See Power-Law Viscosity Law for details about the items below.

Controls

- Methods

contains options for selecting the Two Coefficient Method or the Three Coefficient Method.

- B

sets the coefficient

in Equation 8–26 in SI units. This input will appear if you select the Two Coefficient Method.

- Reference Viscosity

sets the reference viscosity

in Equation 8–27. This input will appear if you select the Three Coefficient Method.

- Reference Temperature

sets the reference temperature

in Equation 8–27. This input will appear if you select the Three Coefficient Method.

- Temperature Exponent

sets the temperature exponent

in Equation 8–26 or Equation 8–27, depending on your Method selection. If you are using the Two Coefficient Method, this input must be in SI units.

- Primary Independent Variable

allows you to select which variable is the independent variable.

- Count

allows you to specify the number of plot points.

- Min

sets the minimum value for the independent variable.

- Max

sets the maximum value for the independent variable.

- Copy to Clipboard

copies the current plot onto your clipboard.

- Reset Zoom

resets to the default zoom. You can click and drag in the plot to change the zoom level.

The Non-Newtonian Power Law dialog box allows you to set the parameters for the non-Newtonian power law for viscosity. This dialog box will open when you select non-newtonian-power-law in the drop-down list next to Viscosity in the Create/Edit Materials Dialog Box. See Power Law for Non-Newtonian Viscosity for details about the items below.

Controls

- Methods

allows you to select the type of dependency on the viscosity.

- Shear Rate Dependent

is where the viscosity is dependent on the shear rate.

- Shear Rate and Temperature Dependent

is where the viscosity is dependent on the shear rate and the temperature.

- Consistency Index

sets the consistency index

in Equation 8–39.

- Power-Law Index

sets the power-law index

in Equation 8–39.

- Minimum Viscosity Limit, Maximum Viscosity Limit

set the minimum and maximum viscosity limits.

- Reference Temperature

sets the reference temperature.

- Activation Energy/R, alpha

is the ratio of the activation energy to the thermodynamic constant

in Equation 8–38.

The Carreau Model dialog box allows you to set the parameters for the non-Newtonian Carreau model for viscosity. This dialog box will open when you select carreau in the drop-down list next to Viscosity in the Create/Edit Materials Dialog Box. See The Carreau Model for Pseudo-Plastics for details about the items below.

Controls

- Methods

allows you to select the type of dependency on the viscosity.

- Shear Rate Dependent

is where the viscosity is dependent on the shear rate.

- Shear Rate and Temperature Dependent

is where the viscosity is dependent on the shear rate and the temperature.

- Time Constant, lambda

sets the time constant

in Equation 8–40.

- Power-Law Index

sets the power-law index

in Equation 8–40.

- Zero Shear Viscosity, Infinite Shear Viscosity

set the zero and infinite shear viscosity limits

and

in Equation 8–40.

- Reference Temperature, T_alpha

sets the reference temperature

in Equation 8–40.

- Activation Energy/R, alpha

is the ratio of the activation energy to the thermodynamic constant

in Equation 8–38.

The Cross Model dialog box allows you to set the parameters for the non-Newtonian Cross model for viscosity. This dialog box will open when you select cross in the drop-down list next to Viscosity in the Create/Edit Materials Dialog Box. See Cross Model for details about the items below.

Controls

- Methods

allows you to select the type of dependency on the viscosity.

- Shear Rate Dependent

is where the viscosity is dependent on the shear rate.

- Shear Rate and Temperature Dependent

is where the viscosity is dependent on the shear rate and the temperature.

- Zero Shear Viscosity

sets the zero shear viscosity limit

in Equation 8–41.

- Power-Law Index

sets the power-law index

in Equation 8–41.

- Time Constant

sets the time constant

in Equation 8–41.

- Reference Temperature, T_alpha

sets the reference temperature

in Equation 8–40.

- Activation Energy/R, alpha

is the ratio of the activation energy to the thermodynamic constant

in Equation 8–38.

The Herschel-Bulkley dialog box allows you to set the parameters for the non-Newtonian Herschel-Bulkley model for viscosity. This dialog box will open when you select herschel-bulkley in the drop-down list next to Viscosity in the Create/Edit Materials Dialog Box. See Herschel-Bulkley Model for Bingham Plastics for details about the items below.

Controls

- Methods

allows you to select the type of dependency on the viscosity.

- Shear Rate Dependent

is where the viscosity is dependent on the shear rate.

- Shear Rate and Temperature Dependent

is where the viscosity is dependent on the shear rate and the temperature.

- Consistency Index

sets the consistency index

in Equation 8–43.

- Power-Law Index

sets the power-law index

in Equation 8–43.

- Yield Stress Threshold

sets the yield stress threshold

in Equation 8–43.

- Critical Shear Rate

set the critical shear rate

in Equation 8–43.

- Reference Temperature, T_alpha

sets the reference temperature

in Equation 8–38.

- Activation Energy/R, alpha

is the ratio of the activation energy to the thermodynamic constant

in Equation 8–38.

The Biaxial Conductivity dialog box allows you to define a biaxial orthotropic thermal conductivity, which is applicable to solid materials used for the wall shell conduction model. This dialog box will open when you select biaxial in the drop-down list next to Thermal Conductivity in the Create/Edit Materials Dialog Box. See Biaxial Thermal Conductivity for details about the items below.

Controls

- Planar Conductivity

specifies the conductivity within the shell (or solid) region.

- Transverse Conductivity

specifies the conductivity normal to the surface of the solid region.

The Cylindrical Orthotropic Conductivity dialog box allows you to define an orthotropic thermal conductivity in cylindrical coordinates. This dialog box will open when you select cyl-orthotropic in the drop-down list next to Thermal Conductivity in the Create/Edit Materials Dialog Box. See Cylindrical Orthotropic Thermal Conductivity for details about the items below.

Controls

- Axis Origin

allows you to specify the origin of the cylindrical coordinate system.

- X, Y, Z

specify the X, Y, and (for 3D cases) Z coordinates.

- Axis Direction

(3D only) allows you to specify the direction of the axis.

- X, Y, Z

specify

1against the direction of the axis.

- Radial Conductivity

specifies the conductivity in the radial direction.

- Tangential Conductivity

specifies the conductivity in the tangential direction.

- Axial Conductivity

(3D only) specifies the conductivity in the axial direction.

The Orthotropic Conductivity dialog box allows you to define an orthotropic thermal conductivity for a solid material, using principal directions that do not have to aligned with the global coordinate system of the simulation. This dialog box will open when you select orthotropic in the drop-down list next to Thermal Conductivity in the Create/Edit Materials Dialog Box. See Orthotropic Thermal Conductivity for details about the items below.

Controls

- Direction 0 Components, Direction 1 Components

specify the directions

and

in Equation 8–54 as X,Y,Z vectors. For 2D cases, only Direction 0 Components will appear.

- Conductivity 0, Conductivity 1, Conductivity 2

specify

,

, and

in Equation 8–54 as constant, polynomial, piecewise-linear, piecewise-polynomial, functions of temperature, user-defined, or expression. For 2D cases, only Conductivity 0 and Conductivity 1 will appear.

- Edit...

opens the appropriate dialog box so you can enter a temperature-dependent conductivity. (This button will be unavailable if you specify a constant conductivity.)

The Anisotropic Conduction - Principal Components dialog box allows you to define an anisotropic thermal conductivity using the components of the principal axes (which do not have to be orthogonal and/or aligned with the global coordinate system) and the associated principal values. This dialog box will open when you select principal-axes-values in the drop-down list next to Thermal Conductivity in the Create/Edit Materials Dialog Box. See Principal Axes and Principal Values for details about the items that follow.

Controls

- Principal Axes

specifies the

,

, and

components of the

,

, and

vectors (in Equation 8–55) that define the principal axes of the anisotropic material. Note that these vectors must be linearly independent.

- Principal Values

specifies the principal values (

,

, and

in Equation 8–58) associated with the principal axes.

- Conductivity

specifies the value of

(in Equation 8–58) as a constant, function of temperature (polynomial, piecewise-linear, piecewise-polynomial), or user-defined function.

- Edit...

opens the appropriate dialog box for the definition of a temperature-dependent or user-defined conductivity. (This button will be unavailable if you specify a constant conductivity.)

The Anisotropic Conductivity dialog box allows you to define a general anisotropic thermal conductivity. This dialog box will open when you select anisotropic in the drop-down list next to Thermal Conductivity in the Create/Edit Materials Dialog Box. See Anisotropic Thermal Conductivity for details about the items below.

Controls

- Matrix Components

specify the components of the matrix

in Equation 8–53.

- Conductivity

specifies the value of

in Equation 8–53 as a constant, function of temperature (polynomial, piecewise-linear, piecewise-polynomial), or user-defined function.

- Edit...

opens the appropriate dialog box so you can enter a temperature-dependent or user-defined conductivity. (This button will be unavailable if you specify a constant conductivity.)

The Species dialog box (opened by clicking the Edit... button next to Mixture Species in the Create/Edit Materials Dialog Box)) allows you to define the species that make up a mixture material. See Defining the Species in the Mixture for details about the items below.

(Note that the Species dialog box is a modal dialog box, which means that you must tend to it immediately before continuing the property definitions.)

Controls

- Mixture

shows the name of the mixture material for which you are defining the species. This field is not editable.

- Available Materials

is a list of all of the materials to be a component in the mixture material by selecting it and clicking the Add button below the Selected Species or Selected Surface Species list. To add a material to the Available Materials list, use the Fluent Database Materials Dialog Box to copy the fluid material to local storage.

- Selected Species

is a list of all the fluid-phase species in the mixture. You can modify the list as follows:

To add a material to the list, select it in the Available Materials list and click the button below the Selected Species list.

To remove a material, select it in the Selected Species list and click .

To move a bulk species to the bottom of the Selected Species list, select the species and click . The transport equation will not be solved for the last species.

See Overview of the Species Dialog Box for more information.

- Selected Solid Species

is a list of all the solid species in the mixture. To add a material to the list, select it in the Available Materials list and click the Add button below the Selected Solid Species list. To remove a material, select it in the Selected Solid Species list and click Remove. See Overview of the Species Dialog Box for more information.

- Selected Site Species

is a list of all the site species in the mixture. To add a material to the list, select it in the Available Materials list and click the Add button below the Selected Site Species list. To remove a material, select it in the Selected Site Species list and click Remove. See Overview of the Species Dialog Box for more information.

The Reactions dialog box (opened by clicking the Edit... button next to Reaction in the Create/Edit Materials Dialog Box) allows you to define the reactions for a mixture material. See Defining Reactions for details about using this dialog box.

(Note that the Reactions dialog box is a modal dialog box, which means that you must tend to it immediately before continuing the property definitions.)

Controls

- Mixture

shows the name of the mixture material for which you are defining the species. This field is not editable.

- Total Number of Reactions

sets the total number of reactions (fluid-phase reactions and surface reactions occurring at wall boundaries). Use the arrows to change the value, or type in the value and press

RETURN.- Reaction Name

contains the name of the reaction.

- ID

sets the number of the reaction you want to define. (Again, if you type in the value be sure to press

RETURN.)- Reaction Type

contains options that allow you to specify the type of reaction.

- Volumetric

indicates that the current reaction is a volumetric reaction.

- Wall Surface

indicates that the current reaction is a wall surface reaction.

- Particle

indicates that the current reaction is a particle reaction. This item is available only when Particle is selected as the Reaction Type in the Species Model dialog box.

- Electrochemical

indicates that the current reaction is an electrochemical reaction. This item is available only when Electrochemical is selected as the Reaction Type in the Species Model dialog box.

- Number of Reactants

specifies the number of reactants in the specified reaction.

- Species

contains drop-down lists of all species in the mixture. (The number of lists will be equal to the Number of Reactants.) Select each reactant in one of these lists.

- Stoich. Coefficient

specifies the stoichiometric coefficient of the reactant species in the reaction.

- Rate Exponent

specifies the rate constant for the reactant species in the reaction.

- Number of Products

indicates the number of products in the specified reaction.

- Species

contains drop-down lists of all species in the mixture. (The number of lists will be equal to the Number of Products.) Select each product in one of these lists.

- Stoich. Coefficient

specifies the stoichiometric coefficient of the product species in the reaction.

- Rate Exponent

specifies the rate constant for the product species in the reaction.

- Arrhenius Rate

contains inputs related to the Arrhenius rate. (If you have chosen Eddy-Dissipation for the Turbulence-Chemistry Interaction in the Species Model Dialog Box, these inputs are not required.)

- Pre-exponential Factor

is the constant

in Equation 7–23 in the Theory Guide. The units of

must be specified such that the units of the molar reaction rate,

(Equation 7–19 in the Theory Guide, are moles/volume-time (for example, kmol/

-s) and the units of the volumetric reaction rate,

in Equation 7–19 in the Theory Guide, are mass/volume-time (for example, kg/

-s).

Important: It is important to note that if you have selected the British units system, the Arrhenius factor should still be specified in SI units. This is because Ansys Fluent applies no conversion factor to the value you enter for

(the conversion factor is 1.0) when you work in British units, as the correct conversion factor depends on your values for

,

, and so on.

- Activation Energy

is the constant

in the forward rate constant expression, Equation 7–23 in the Theory Guide).

- Temperature Exponent

is the value for the constant

in Equation 7–23 in the Theory Guide.

- Include Backward Reaction

specifies that the reaction is reversible. By default, the backward reaction rate constant will be computed from Equation 7–23 in the Fluent Theory Guide. You can specify your own backward reaction rate parameters in the Backward Reaction Parameters Dialog Box. In this case, the backward reaction rate constant will be computed from Equation 7–28 in the Fluent Theory Guide.

- Third-Body Efficiencies

allows you to specify and use third-body efficiencies (

in Equation 7–22 in the Theory Guide). These inputs are optional. (This item is available only if you have selected Volumetric for the Reaction Type.)

- Pressure-Dependent Reaction

enables the modeling of a pressure fall-off reaction. See Inputs for Reaction Definition Finite-Rate/No TCI or Eddy-Dissipation Concept for the Turbulence-Chemistry Interaction in the Species Model Dialog Box and have selected Volumetric for the Reaction Type.)

- Coverage-Dependent Reaction

is used when modeling Wall Surface reactions with site-balancing and reaction rates depend on site coverages.

- Specify...

opens the Backward Reaction Parameters Dialog Box, Third-Body Efficiency Dialog Box, the Pressure-Dependent Reaction Dialog Box, or Coverage-Dependent Reaction Dialog Box in which you can specify the backward rate parameters for the reversible reaction, third-body efficiencies, pressure-dependent reaction parameters, or coverage parameters.

- Mixing Rate

contains inputs related to the mixing rate. (If you have chosen Finite-Rate/No TCI or Eddy-Dissipation Concept for the Turbulence-Chemistry Interaction in the Species Model Dialog Box, these inputs are not required.)

- A

is the constant

in the turbulent mixing rate (Equation 7–39 and Equation 7–40 in the Theory Guide) when it is applied to a species that appears as a reactant in this reaction. The default setting of 4.0 is based on the empirically derived values given by Magnussen and Hjertager [94].

- B

is the constant

in the turbulent mixing rate (Equation 7–40 in the Theory Guide) when it is applied to a species that appears as a product in this reaction. The default setting of 0.5 is based on the empirically derived values given by Magnussen and Hjertager [94].

- Particle Reaction

contains inputs related either to a particle surface reaction or to a multicomponent particle reaction for reacting multicomponent particles. For details, see the following sections:

This group box appears only if you have selected Particle for the Reaction Type.

- Model

(reacting multicomponent particles only) allows you to select between the kinetics/diffusion, surface-kinetics, volume-kinetics, phase-change, thermolysis, and user-defined particle reaction model. See Multicomponent Particles with Chemical Reactions for details.

- Diffusion-Limited Species

is a drop-down list that allows you to select the species for which the concentration gradient between the bulk and the particle surface is the largest when there is more than one gaseous reactant taking part in the particle surface reaction. See User Inputs for Particle Surface Reactions for details.

- Diffusion Rate Constant

is the constant

in Equation 7–104 in the Theory Guide.

- Effectiveness Factor

is the constant

in Equation 7–102 in the Theory Guide.

- Butler-Volmer/Tafel Parameters

contains inputs related to an electrochemical reaction. See User Inputs for Electrochemical Reactions for details. (This group box appears only if Electrochemical is selected for Reaction Type.)

- Tafel Parameters

indicates whether the Bulter-Volmer equation (Equation 7–118 in the Fluent Theory Guide) or the Tafel equation (Equation 7–119 in the Fluent Theory Guide) is used in the kinetics calculation.

- Anodic Transfer Coefficient

is the value of

used in Equation 7–118 in the Fluent Theory Guide. This item appears if the Tafel Parameters check box is cleared.

- Cathodic Transfer Coefficient

is the value of

used in Equation 7–118 in the Fluent Theory Guide. This item appears if the Tafel Parameters check box is cleared.

- Anodic Tafel Slope

is the value of

in Equation 7–119 in the Fluent Theory Guide. This item appears only if the Tafel Parameters check box is selected.

- Cathodic Tafel Slope

is the value of

in Equation 7–119 in the Fluent Theory Guide. This item appears only if the Tafel Parameters check box is selected.

- Exchange Current Density

is the value of

used in Equation 7–118 and Equation 7–119 in the Fluent Theory Guide.

- Reference Temperature

is a value of

used in Equation 7–118 and Equation 7–119 in the Fluent Theory Guide.

- Activation Energy

is a value of

used in Equation 7–118 and Equation 7–119 in the Fluent Theory Guide.

- Equilibrium Potential

is the value of

used in Equation 7–120 in the Fluent Theory Guide

- Specify Reference Molar Concentrations...

opens the Reference Molar Concentrations Dialog Box.

The Backward Reaction Parameters dialog box (opened by clicking Specify... next to Include Backward Reaction in the Reactions Dialog Box) allows you to specify your custom backward rate parameters for a reversible reaction. See Inputs for Reaction Definition for details.

- Arrhenius Backward Rate

allows you to specify backward rate parameters.

- Pre-Exponential Factor

is the constant

in Equation 7–28 in the Fluent Theory Guide.

- Activation Energy

is the constant

in the backward rate constant expression in Equation 7–28 in the Fluent Theory Guide.

- Temperature Exponent

is the constant

in Equation 7–28 in the Fluent Theory Guide.

The Third-Body Efficiency dialog box (opened by clicking Specify... next to the Third-Body Efficiencies button in the Reactions Dialog Box) allows you to specify the third-body efficiencies for each species in the mixture, to be used in Equation 7–22 in the Theory Guide. See Defining Reactions for details.

(Note that the Third-Body Efficiency dialog box is a modal dialog box, which means that you must tend to it immediately before continuing the property definitions.)

Controls

- Species

displays the name of each species in the mixture.

- Third-body Efficiency

specifies the third-body efficiency for each species.

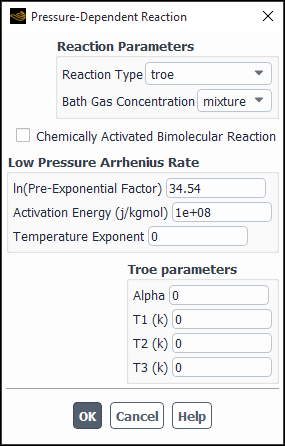

The Pressure-Dependent Reaction dialog box (opened by clicking Specify... under Pressure-Dependent Reaction in the Reactions Dialog Box) allows you to specify parameters for a pressure fall-off reaction. See Inputs for Reaction Definition for details.

(Note that the Pressure-Dependent Reaction dialog box is a modal dialog box, which means that you must tend to it immediately before continuing the property definitions.)

Controls

- Reaction Parameters

contains inputs for specifying the type of pressure fall-off reaction and the reaction parameters. See Pressure-Dependent Reactions in the Theory Guide for details.

- Reaction Type

contains a drop-down list of the available reaction types: lindemann, troe, and sri. See Pressure-Dependent Reactions in the Theory Guide for details.

- Bath Gas Concentration

allows you to specify if the bath gas concentration (

in Equation 7–32 in the Theory Guide) is to be defined as the concentration of the mixture, or as the concentration of one of the mixture’s constituent species.

- Chemically Activated Bimolecular Reaction

results in a net rate constant at any pressure being defined as Equation 7–38 in the Theory Guide.

- Low Pressure Arrhenius Rate

contains inputs for specifying low-pressure Arrhenius parameters.

- ln(Pre-exponential Factor)

is the natural logarithm of the constant

in Equation 7–30 in the Theory Guide. The pre-exponential factor

is often an extremely large number, so you will enter the natural logarithm of this term.

- Activation Energy

is the constant

in Equation 7–30 in the Theory Guide.

- Temperature Exponent

is the constant

in Equation 7–30 in the Theory Guide.

- Troe parameters

contains inputs for specifying parameters for the Troe method. See Pressure-Dependent Reactions in the Theory Guide for details. (This section of the dialog box will appear only if you have selected troe as the Reaction Type.)

- Alpha

is the constant

in Equation 7–35 in the Theory Guide.

- T1

is the constant

in Equation 7–35 in the Theory Guide.

- T2

is the constant

in Equation 7–35 in the Theory Guide.

- T3

is the constant

in Equation 7–35 in the Theory Guide.

- SRI Parameters

contains inputs for specifying parameters for the SRI method. See Pressure-Dependent Reactions in the Theory Guide for details. (This section of the dialog box will appear only if you have selected sri as the Reaction Type.)

- a

is the constant

in Equation 7–36 in the Theory Guide.

- b

is the constant

in Equation 7–36 in the Theory Guide.

- c

is the constant

in Equation 7–36 in the Theory Guide.

- d

is the constant

in Equation 7–36 in the Theory Guide.

- e

is the constant

in Equation 7–36 in the Theory Guide.

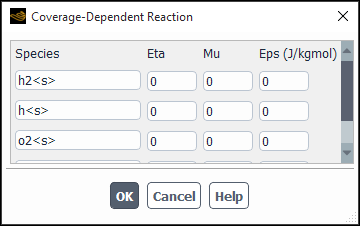

The Coverage-Dependent Reaction dialog box (opened by clicking on Specify... under Coverage-Dependent Reaction in the Reactions Dialog Box) allows you to model Wall Surface reactions with site-balancing.

(Note that the Coverage-Dependent Reaction dialog box is a modal dialog box, which means that you must tend to it immediately before continuing the property definitions.)

Controls

- Species

are the site species of the reaction.

- Eta

is the surface coverage rate modification of the species and is defined in Equation 7–81 in the Theory Guide.

- Mu

is the surface coverage rate modification of the species and is defined in Equation 7–81 in the Theory Guide.

- Eps

is the surface coverage rate modification of the species and is defined in Equation 7–81 in the Theory Guide.

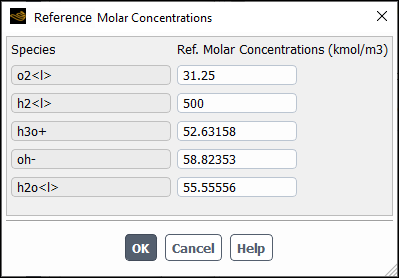

The Reference Molar Concentrations dialog box (opened by clicking Specify Reference Molar Concentrations... under Butler-Volmer/Tafel Parameters in the Reactions Dialog Box) allows you to specify reference species molar concentrations for the electrochemical reaction.

(Note that the Reference Molar Concentrations dialog box is a modal dialog box, which means that you must tend to it immediately before continuing the property definitions.)

Controls

- Species

are the electrochemical reaction species used in the Butler-Volmer equation (Equation 7–118 in the Fluent Theory Guide).

- Reference Molar Concentrations

contains inputs for the reference molar concentrations of electrochemical reaction species (

in Equation 7–118).

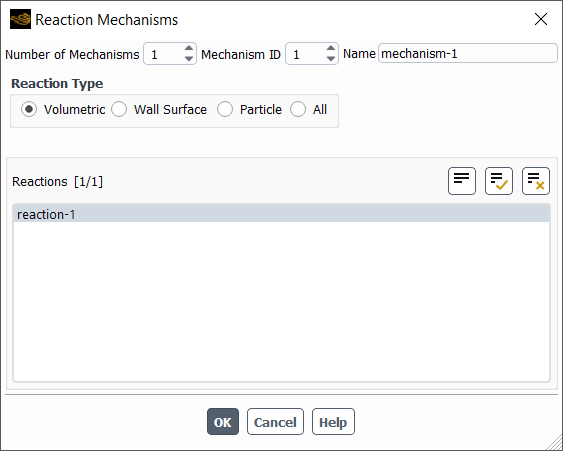

The Reaction Mechanisms dialog box (opened by clicking the Edit... button next to Mechanism in the Create/Edit Materials Dialog Box) allows you to select the reaction mechanism at a particular zone. See Mixture Materials for details about these methods and the related inputs.

(Note that the Reaction Mechanisms dialog box is a modal dialog box, which means that you must tend to it immediately before continuing the property definitions.)

Controls

- Number of Mechanisms

specifies the number of mechanisms present.

- Mechanism ID

is the ID of the mechanism that you specify.

- Name

allows you to enter a name for the mechanism.

- Reaction Type

specifies the type of reaction to be displayed for the mechanism.

- Volumetric

displays all volumetric reactions under the Reactions list.

- Wall Surface

displays all wall surface reactions under the Reactions list.

- Particle

displays all particle reactions under the Reactions list. This item is available only when Particle is selected as the Reaction Type in the Species Model dialog box.

- Electrochemical

displays all electrochemical reactions under the Reactions list.

- All

displays all types of reactions under the Reactions list.

- Reactions

displays the list of reactions of the category specified under Reaction Type.

- Number of Sites

specifies the number of sites at which you can specify the reaction.

- Site Name

contains the name of the site.

- Site Density

allows you to specify the site density of the species

- Define...

opens the Site Parameters Dialog Box.

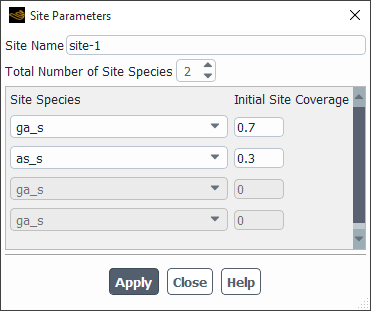

The Site Parameters dialog box (opened by clicking the Define... button next to Site Density in the Reaction Mechanisms Dialog Box) allows you to define the coverage for each site species.

Controls

- Site Name

displays the name of site.

- Total Number of Site Species

specifies the total number of site species.

- Site Species

allows you to select the site species.

- Initial Site Coverage

allows you to specify the initial coverage of the site species.

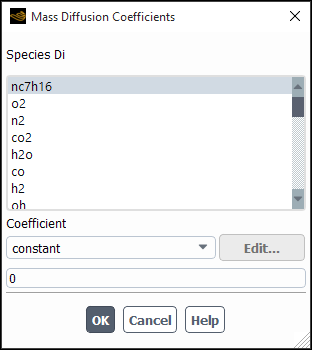

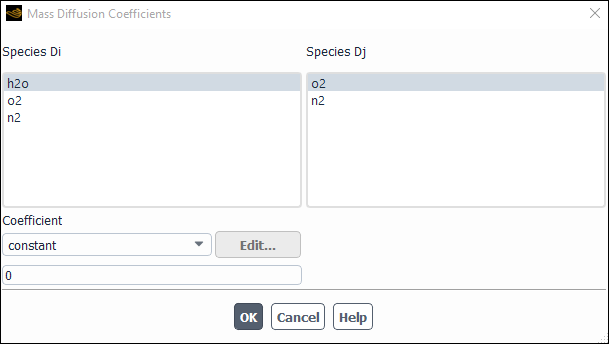

The Mass Diffusion Coefficients dialog box (opened by clicking the Edit... button next to Mass Diffusivity in the Create/Edit Materials Dialog Box allows you to define the diffusion coefficients of the species in the mixture. Its contents will depend on the method you selected for Mass Diffusivity. See Mass Diffusion Coefficient Inputs for details about these methods and the related inputs.

(Note that the Mass Diffusion Coefficients dialog box is a modal dialog box, which means that you must tend to it immediately before continuing the property definitions.)

For the dilute-approx method:

Controls

- Species Di

contains a selectable list of all species in the mixture, from which you can select each species and specify its diffusion coefficient.

- Coefficient

sets the diffusion coefficient for the selected species in the mixture.