GT-POWER users can define time-dependent boundary conditions in Ansys Fluent based on information from GT-POWER. During the Ansys Fluent simulation, Ansys Fluent and GT-POWER are coupled together and information about the boundary conditions at each time step is transferred between them.

Note the following requirements and restrictions for the GT-POWER coupling:

The flow must be unsteady.

The compressible ideal gas law must be used for density.

Each boundary zone for which you plan to define conditions using GT-POWER must be a boundary of one of the following types:

velocity inlet

mass-flow inlet

pressure inlet

pressure outlet

wall (for details, see Torque-Speed Coupling with GT-POWER)

Also, a maximum of 20 boundary zones can be coupled to GT-POWER.

Fluent checks the area of the 1D coupled boundary as calculated by Fluent and GT-POWER to ensure the calculated areas differ by no more than 5%. When the difference is more than 5%, Fluent stops with an error message and displays the two areas.

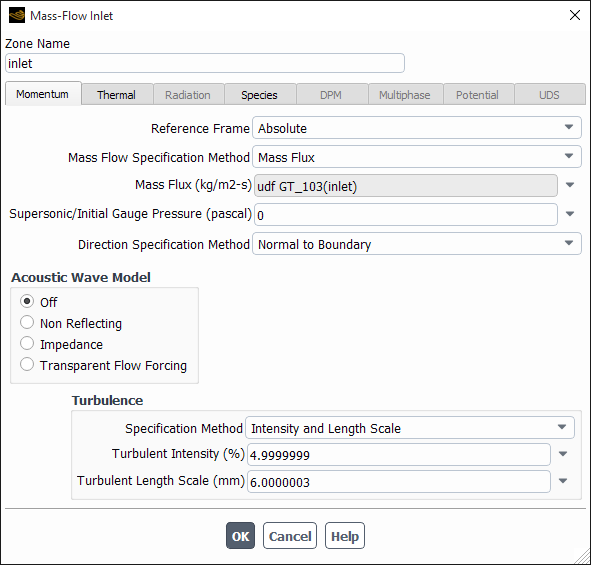

If a mass-flow inlet or pressure inlet is coupled to GT-POWER, you must select Normal to Boundary as the Direction Specification Method in the Mass-Flow Inlet or Pressure Inlet dialog box. For a velocity inlet, you must select Magnitude, Normal to Boundary as the Velocity Specification Method in the Velocity Inlet dialog box.

The mass flow specification method in the Mass-Flow Inlet boundary has to always be Mass Flux and not Mass Flow Rate when coupling with GTPower.

Boundary conditions for the following variables can be obtained from GT-POWER:

velocity

temperature

pressure

density

species mass fractions

and

(Note that it is recommended that you define these conditions in Ansys Fluent yourself, rather than using the data provided by GT-POWER, since the GT-POWER values are based on a 1D model.)

Make sure that the material properties you set in Ansys Fluent are the same as those used in GT-POWER, so that the boundary conditions will be valid for your coupled simulation.

If your model includes species, make sure that the name of each species in GT-POWER corresponds to the Chemical Formula for that species material in the Materials dialog box. Also, recall that Ansys Fluent can handle a maximum of 50 species.

You can install the GT-POWER libraries in a directory other than the default location. If the GT-POWER libraries are loaded into a non-default location, you need to set the following environment variables:

Fluent_GTIHOME— the GTI installation directory where GT-POWER is installedFluent_GTIVERSION— the current version of the GTI installation

Important: GTI is not backwards compatible.

The procedure for setting up the GT-POWER coupling in Ansys Fluent is presented below.

Read in the mesh file and define the models, materials, and boundary zone types (but not the actual boundary conditions), noting the requirements and restrictions listed in Requirements and Restrictions.

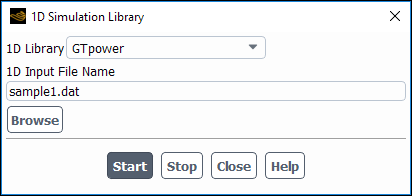

Specify the location of the GT-POWER data and have Ansys Fluent use them to generate user-defined functions for the relevant boundary conditions (using the 1D Simulation Library Dialog Box, shown in Figure 7.107: The 1D Simulation Library Dialog Box).

User Defined → Model Specific → 1D Coupling...

Select GTpower in the 1D Library drop-down list.

Specify the name of the GT-POWER input file in the 1D Input File Name field.

Click the button.

When you click , GT-POWER will start up and Ansys Fluent user-defined functions for each boundary in the input file will be generated.

Set boundary conditions for all zones. For flow boundaries for which you are using GT-POWER data, select the appropriate UDFs as the conditions.

Important: Note that you must select the same UDF for all conditions at a particular boundary zone (as shown, for example, in Figure 7.108: Using GT-POWER Data for Boundary Conditions); this UDF contains all of the conditions at that boundary.

If you plan to continue the simulation at a later time, starting from the final data file of the current simulation, specify how often you want to have the case and data files saved automatically.

Solution →

Calculation Activities

(Autosave Case/Data) → Edit...

Calculation Activities

(Autosave Case/Data) → Edit...To use a GT-POWER restart file to restart an Ansys Fluent calculation, you must edit the GT-POWER input data file. See the GT-POWER User’s Guide for instructions.

Continue the problem setup and calculate a solution in the usual manner.

Torque-speed coupling with GT-POWER is a unique case in which Fluent receives shaft speed from GT-POWER and returns torque. The procedure differs from the typical coupling between GT-Power and Fluent, and is as follows:

Important: You must be using GT-POWER v2017.2 or greater to perform torque-speed coupling with Ansys Fluent.

Complete steps 1 and 2 in the above section on User Inputs. The .dat.h5 file should have at least one turbo-machine exposed to complete the coupling.

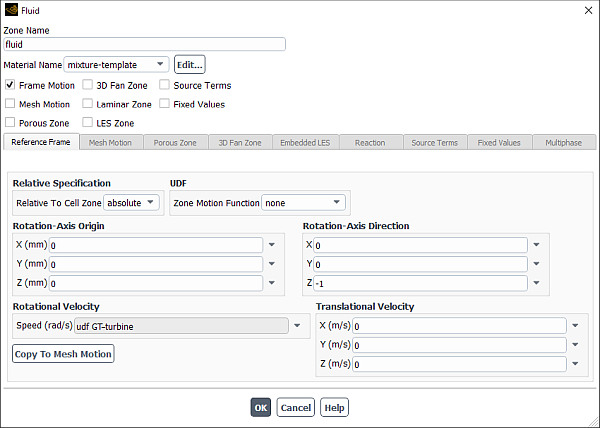

Enable Frame Motion in the cell zone that is receiving shaft speed from GT-Power. You must also select the appropriate UDF for Rotational Velocity. The UDF must correspond to the turbo-machine exposed from GT-POWER ("turbine", in the example shown below).

Specify a Wall boundary on which the torque is calculated and transferred to GT-POWER. The following requirements apply:

The wall boundary must be attached to the rotating cell zone from step 2, to receive the shaft speed from GT-POWER.

The name of the wall boundary must be the same as the turbo-machine it is coupled with ("turbine", in the case presented above).

During the solution, shaft speed is obtained from GT-POWER at every time-step, with Fluent calculating and returning torque within each time-step as well.