Boundary conditions consist of external, internal, and periodic boundaries. Most of the boundary conditions are discussed in the sections that follow.

- 7.4.1. Flow Inlet and Exit Boundary Conditions

- 7.4.2. Using Flow Boundary Conditions

- 7.4.3. Pressure Inlet Boundary Conditions

- 7.4.4. Velocity Inlet Boundary Conditions

- 7.4.5. Mass-Flow Inlet Boundary Conditions

- 7.4.6. Mass-Flow Outlet Boundary Conditions

- 7.4.7. Inlet Vent Boundary Conditions

- 7.4.8. Intake Fan Boundary Conditions

- 7.4.9. Pressure Outlet Boundary Conditions

- 7.4.10. Pressure Far-Field Boundary Conditions

- 7.4.11. Outflow Boundary Conditions

- 7.4.12. Outlet Vent Boundary Conditions

- 7.4.13. Exhaust Fan Boundary Conditions

- 7.4.14. Degassing Boundary Conditions

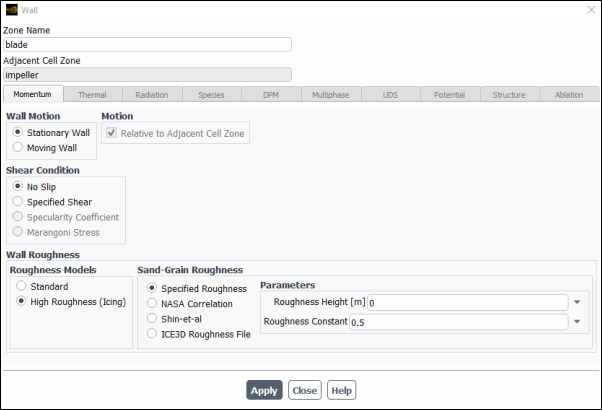

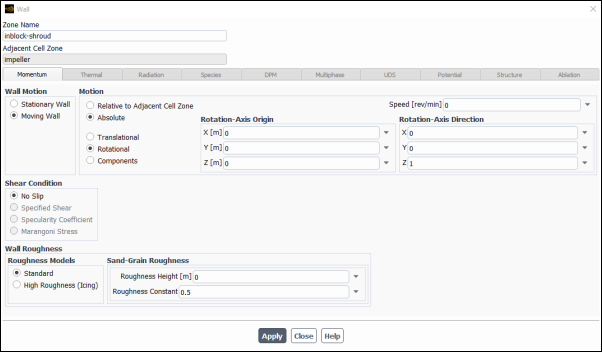

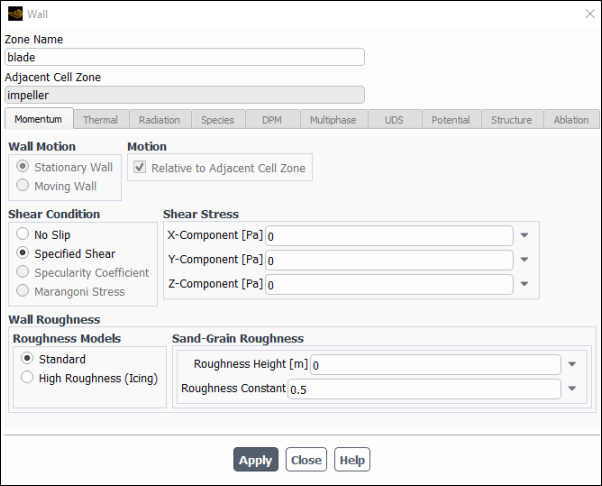

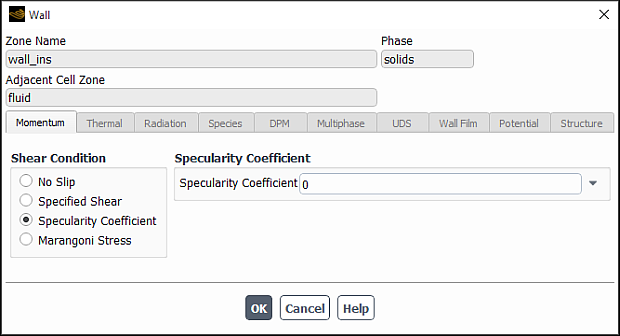

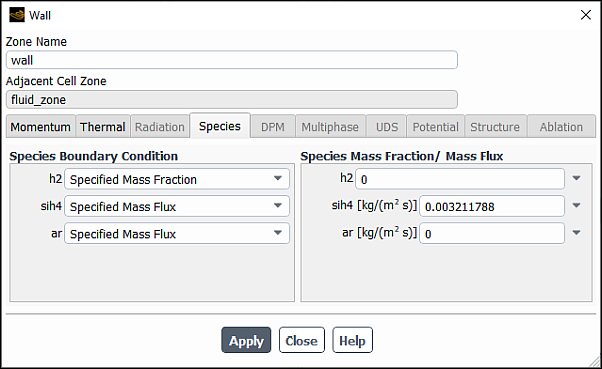

- 7.4.15. Wall Boundary Conditions

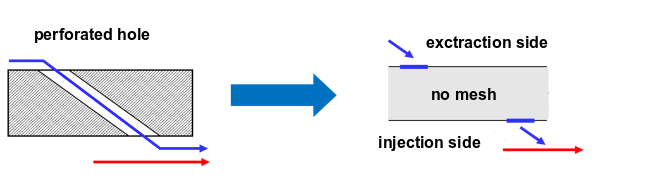

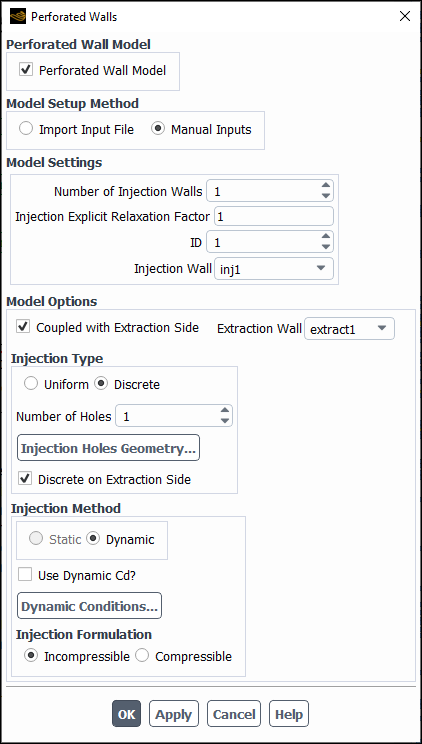

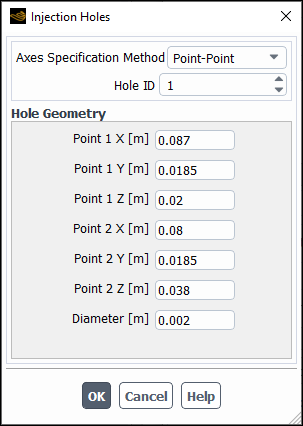

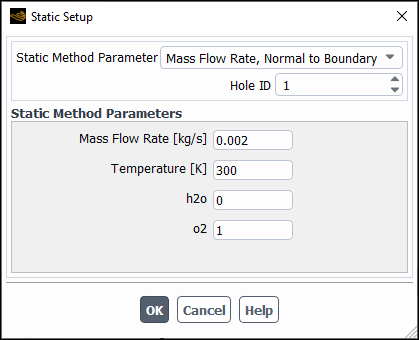

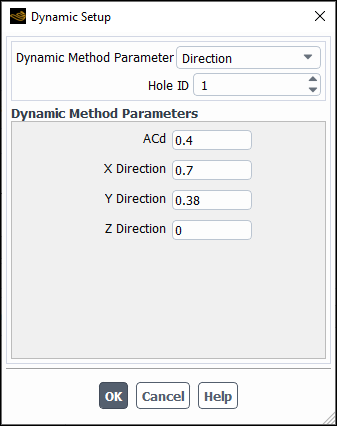

- 7.4.16. Perforated Wall Boundary Conditions

- 7.4.17. Symmetry Boundary Conditions

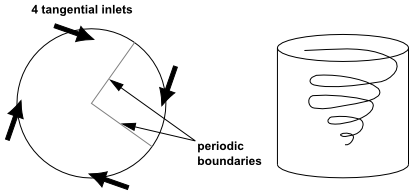

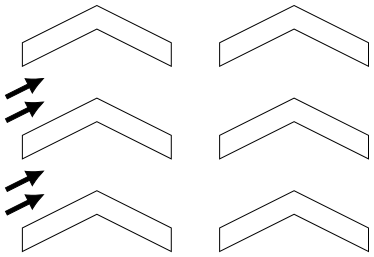

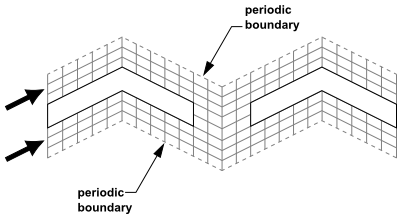

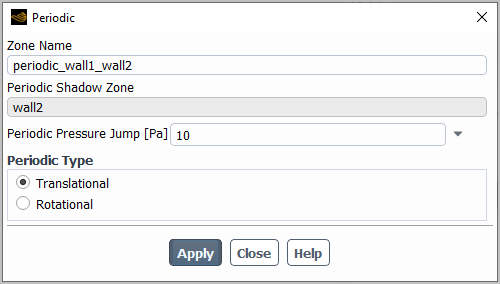

- 7.4.18. Periodic Boundary Conditions

- 7.4.19. Axis Boundary Conditions

- 7.4.20. Fan Boundary Conditions

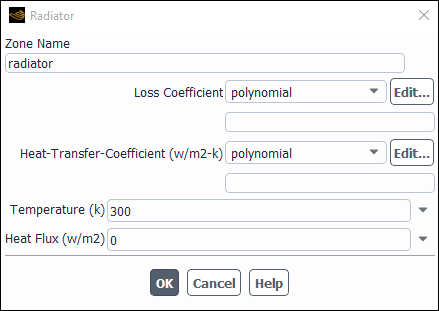

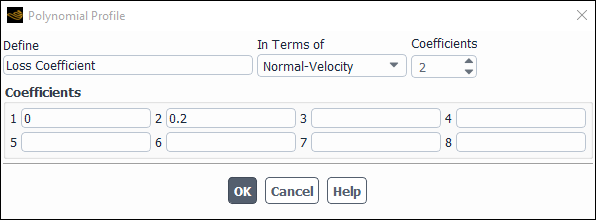

- 7.4.21. Radiator Boundary Conditions

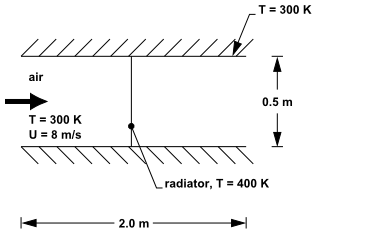

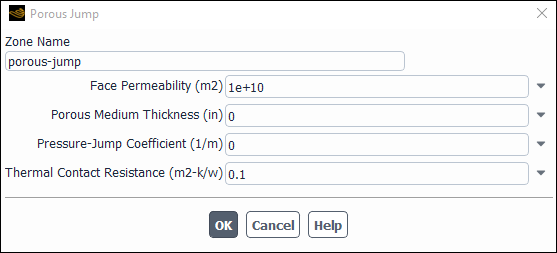

- 7.4.22. Porous Jump Boundary Conditions

You can find details about the following types here:

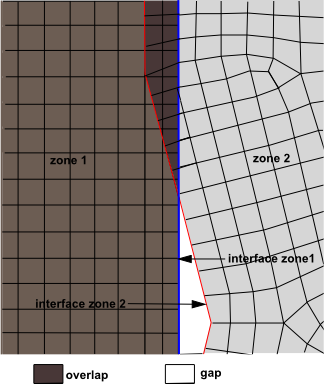

interface zones: Using Sliding Meshes

interior zones: Interior Dialog Box

overset zones: Overset Meshes

RANS/LES interface zones: Setting Up the Embedded Large Eddy Simulation (ELES) Model

Note: By default, boundaries are grouped by type, but you also have the option of grouping them by:

Alphabetical (List View)

Name

Cell Zone (Adjacency)

To change the grouping, right-click the Boundary Conditions branch in the Outline View tree and select Group By/List View or Name or Adjacency.

Setup → Boundary Conditions

Group

By → List View | Name | Adjacency

You can set the default boundary organization method using the Group boundary conditions by drop-down in Preferences (Appearance branch).

File → Preferences

Ansys Fluent has a wide range of boundary conditions that permit flow to enter and exit the solution domain. To help you select the most appropriate boundary condition for your application, this section includes descriptions of how each type of condition is used, and what information is needed for each one. Recommendations for determining inlet values of the turbulence parameters are also provided.

This section provides an overview of flow boundaries in Ansys Fluent and how to use them.

Ansys Fluent provides 12 types of boundary zone types for the specification of flow inlets and exits: velocity inlet, pressure inlet, mass-flow inlet, mass-flow outlet, pressure outlet, pressure far-field, outflow, inlet vent, intake fan, outlet vent, exhaust fan, and degassing.

The inlet and exit boundary condition options in Ansys Fluent are as follows:

Velocity inlet boundary conditions are used to define the velocity and scalar properties of the flow at inlet boundaries.

Pressure inlet boundary conditions are used to define the total pressure and other scalar quantities at flow inlets.

Mass-flow inlet boundary conditions are used in compressible flows to prescribe a mass flow rate at an inlet. It is not necessary to use mass-flow inlets in incompressible flows because when density is constant, velocity inlet boundary conditions will fix the mass flow. Like pressure and velocity inlets, other inlet scalars are also prescribed.

Pressure outlet boundary conditions are used to define the static pressure at flow outlets (and also other scalar variables, in case of backflow). The use of a pressure outlet boundary condition instead of an outflow condition often results in a better rate of convergence when backflow occurs during iteration.

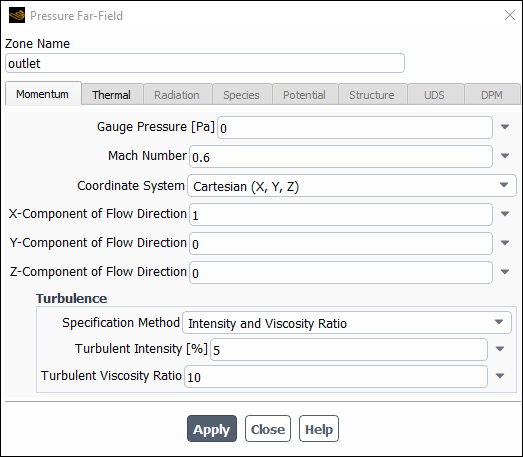

Pressure far-field boundary conditions are used to model a free-stream compressible flow at infinity, with free-stream Mach number and static conditions specified. This boundary type is available only for compressible flows.

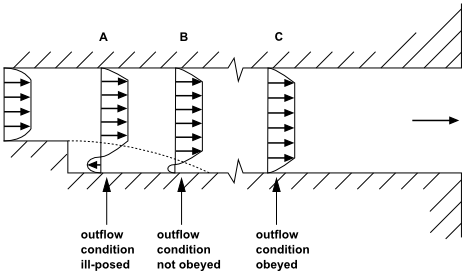

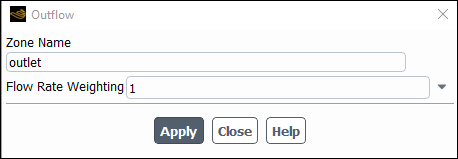

Outflow boundary conditions are used to model flow exits where the details of the flow velocity and pressure are not known prior to solution of the flow problem. They are appropriate where the exit flow is close to a fully developed condition, as the outflow boundary condition assumes a zero streamwise gradient for all flow variables except pressure. They are not appropriate for compressible flow calculations.

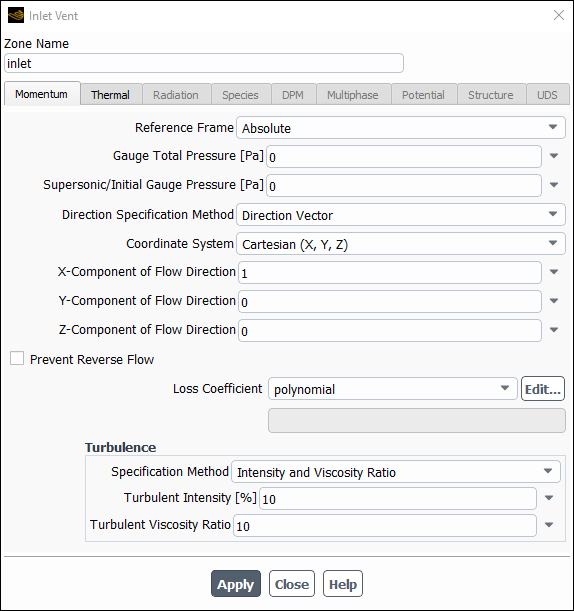

Inlet vent boundary conditions are used to model an inlet vent with a specified loss coefficient, flow direction, and ambient (inlet) total pressure and temperature.

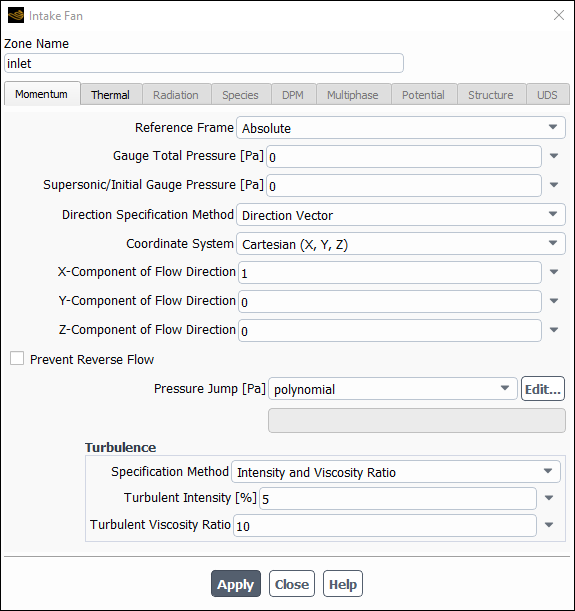

Intake fan boundary conditions are used to model an external intake fan with a specified pressure jump, flow direction, and ambient (intake) total pressure and temperature.

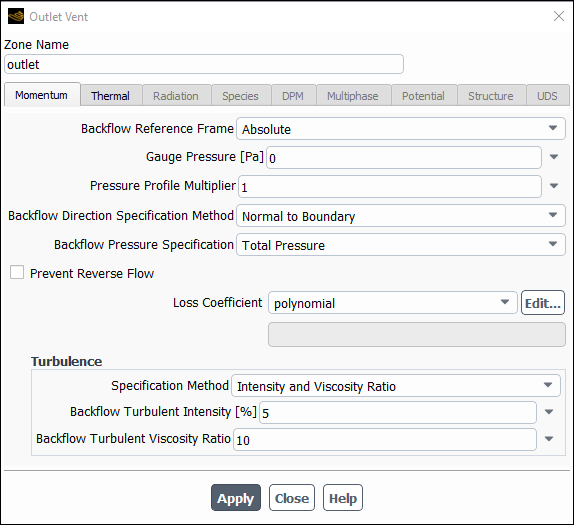

Outlet vent boundary conditions are used to model an outlet vent with a specified loss coefficient and ambient (discharge) static pressure and temperature.

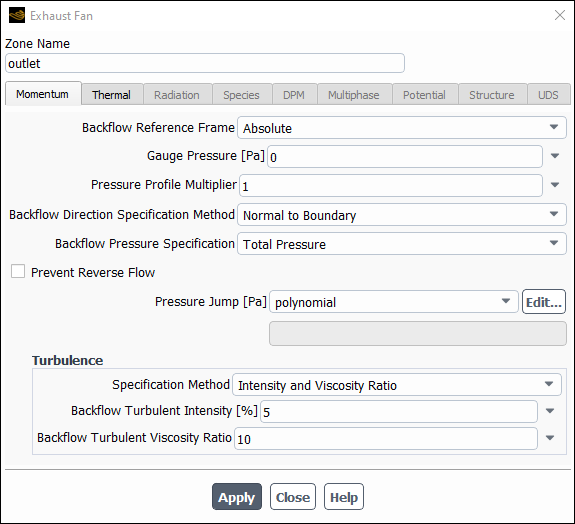

Exhaust fan boundary conditions are used to model an external exhaust fan with a specified pressure jump and ambient (discharge) static pressure.

Degassing boundary conditions are used to model a free surface through which dispersed gas bubbles are allowed to escape, but the continuous liquid phase is not. A typical application is a bubble column in which you want to reduce computational cost by not including the freeboard region in the simulation. The degassing boundary condition is only available for two-phase liquid-gas flows using the Eulerian multiphase model.

When the flow enters the domain at an inlet, outlet, or far-field boundary, Ansys Fluent requires specification of transported turbulence quantities. This section describes which quantities are needed for specific turbulence models and how they must be specified. It also provides guidelines for the most appropriate way of determining the inflow boundary values.

If it is important to accurately represent a boundary layer or fully-developed turbulent flow at the inlet, you should ideally set the turbulence quantities by creating a profile file (see Profiles) from experimental data or empirical formulas. If you have an analytical description of the profile, rather than data points, you can either use this analytical description to create a profile file, or create a user-defined function to provide the inlet boundary information. (See the Fluent Customization Manual for information on user-defined functions.)

Once you have created the profile function, you can use it as described below:

Spalart-Allmaras model: Choose Modified Turbulent Viscosity or Turbulent Viscosity Ratio in the Turbulence Specification Method drop-down list and select the appropriate profile name in the drop-down list next to Turbulent Viscosity or Turbulent Viscosity Ratio. Ansys Fluent computes the boundary value for the modified turbulent viscosity,

, by combining

with the appropriate values of density and molecular viscosity.

-

models: Choose K and Epsilon in the Turbulence Specification Method drop-down list and select the appropriate profile names in the drop-down lists next to Turbulent Kinetic Energy and Turbulent Dissipation Rate.

-

models: Choose K and Omega in the Turbulence Specification Method drop-down list and select the appropriate profile names in the drop-down lists next to Turbulent Kinetic Energy and Specific Dissipation Rate.

-based Reynolds stress models: Choose K and Epsilon in the Turbulence Specification Method drop-down list and select the appropriate profile names in the drop-down lists next to Turbulent Kinetic Energy and Turbulent Dissipation Rate. Choose Reynolds-Stress Components in the Reynolds-Stress Specification Method drop-down list and select the appropriate profile name in the drop-down list next to each of the individual Reynolds-stress components.

-based Reynolds stress models: Choose K and Omega in the Turbulence Specification Method drop-down list and select the appropriate profile names in the drop-down lists next to Specific Dissipation Rate. Choose Reynolds-Stress Components in the Reynolds-Stress Specification Method drop-down list and select the appropriate profile name in the drop-down list next to each of the individual Reynolds-stress components.

In some situations, it is appropriate to specify a uniform value of the turbulence quantity at the boundary where inflow occurs. Examples are fluid entering a duct, far-field boundaries, or even fully-developed duct flows where accurate profiles of turbulence quantities are unknown.

In most turbulent flows, higher levels of turbulence are generated within shear layers than enter the domain at flow boundaries, making the result of the calculation relatively insensitive to the inflow boundary values. Nevertheless, caution must be used to ensure that boundary values are not so unphysical as to contaminate your solution or impede convergence. This is particularly true of external flows where unphysically large values of effective viscosity in the free stream can “swamp” the boundary layers.

You can use the turbulence specification methods described above to enter uniform constant values instead of profiles.

Alternatively, you can specify the turbulence quantities in terms of more convenient quantities such as turbulence intensity,

turbulent viscosity ratio, hydraulic diameter, and turbulence length scale. The default Turbulence Specification Method is set

to Turbulent Viscosity Ratio (for the Spalart-Allmaras model) or Intensity and Viscosity

Ratio (for the -

models, the

-

models, or the RSM). These quantities are discussed further in the following sections.

The turbulence intensity, , is defined as the ratio of the root-mean-square of the velocity fluctuations,

, to the mean flow velocity,

.

A turbulence intensity of 1% or less is generally considered low and turbulence intensities greater than 10% are considered high. Ideally, you will have a good estimate of the turbulence intensity at the inlet boundary from external, measured data. For example, if you are simulating a wind-tunnel experiment, the turbulence intensity in the free stream is usually available from the tunnel characteristics. In modern low-turbulence wind tunnels, the free-stream turbulence intensity may be as low as 0.05%.

For internal flows, the turbulence intensity at the inlets is totally dependent on the upstream history of the flow. If the

flow upstream is under-developed and undisturbed, you can use a low turbulence intensity. If the flow is fully developed, the

turbulence intensity may be as high as a few percent. The turbulence intensity at the core of a fully-developed duct flow can

be derived from an empirical correlation by Blasius for pipe flows (see Chapter 20 Equations (20-4) and (20-5) in [137]), using the additional estimation of the RMS velocity fluctuation at the pipe core :

(7–72) |

At a Reynolds number of 50,000, for example, the turbulence intensity will be 4%, according to this formula.

The default value for turbulence intensity is 5% (medium intensity).

The turbulence length scale, , is a physical quantity related to the size of the large eddies that contain the energy in turbulent

flows.

In fully-developed duct flows, is restricted by the size of the duct, since the turbulent eddies cannot be larger than the duct. An

approximate relationship between

and the physical size of the duct is

(7–73) |

where is the relevant dimension of the duct and

ensures consistency with the definition of the turbulent length scales for one- and two-equation turbulence

models. The factor of 0.07 is based on the maximum value of the mixing length in fully-developed turbulent pipe flow, where

is the diameter of the pipe. In a channel of non-circular cross-section, you can base

on the hydraulic diameter.

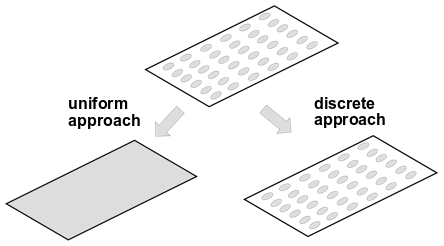

If the turbulence derives its characteristic length from an obstacle in the flow, such as a perforated plate, it is more appropriate to base the turbulence length scale on the characteristic length of the obstacle rather than on the duct size.

It should be noted that the relationship of Equation 7–73, which relates a physical dimension

() to the turbulence length scale (

), is not necessarily applicable to all situations. For most cases, however, it is a suitable

approximation.

Guidelines for choosing the characteristic length or the turbulence length scale

for selected flow types are listed below:

For fully-developed internal flows, choose the Intensity and Hydraulic Diameter specification method and specify the hydraulic diameter

in the Hydraulic Diameter field.

For flows downstream of turning vanes, perforated plates, and so on, choose the Intensity and Length Scale method and specify the characteristic length of the flow opening for

in the Turbulent Length Scale field.

For wall-bounded flows in which the inlets involve a turbulent boundary layer, choose the Intensity and Length Scale method and use the boundary-layer thickness,

, to compute the turbulence length scale,

, from

. Enter this value for

in the Turbulence Length Scale field.

The turbulent viscosity ratio, , is directly proportional to the turbulent Reynolds number (

).

is large (on the order of 100 to 1000) in high-Reynolds-number boundary layers, shear layers, and

fully-developed duct flows. However, at the free-stream boundaries of most external flows,

is fairly small. Typically, the turbulence parameters are set so that

. For internal flows values up to 100 are sensible for the turbulent viscosity ratio,

. The default value for the turbulent viscosity ratio is set to 10.

To specify quantities in terms of the turbulent viscosity ratio, you can choose Turbulent Viscosity

Ratio (for the Spalart-Allmaras model) or Intensity and Viscosity Ratio (for the

-

models, the

-

models, or the RSM). The default value for the turbulence intensity is set to 5% (medium intensity)

and the turbulent viscosity ratio,

, has a default value of 10.

To obtain the values of transported turbulence quantities from more convenient quantities such as ,

, or

, you must typically resort to an empirical relations in addition to the formal definitions of these

quantities. Several formal definitions and useful empirical relations, most of which are used within Ansys Fluent, are presented

below.

To obtain the modified turbulent viscosity, , for the Spalart-Allmaras model from the turbulence intensity,

, and length scale,

, the following equation can be used. Note that this equation assumes that there is no viscous damping, that

is,

(see Modeling the Turbulent Viscosity in the Theory Guide).

(7–74) |

This formula is also used in Ansys Fluent if you select the Intensity and Hydraulic Diameter

specification method with the Spalart-Allmaras model. In this case, is obtained from Equation 7–73.

ensures consistency with the definition of the eddy viscosity for

-

and

-

turbulence models. The value of

is 0.09.

When using a moving reference frame, be aware of the order of the conversion operations applied to the inlet velocity and to

the turbulence quantities, which is explained in the next section. It concerns the values of in Equation 7–74.

The relationship between the turbulent kinetic energy, , and turbulence intensity,

, is

(7–75) |

where is the magnitude of the mean flow velocity.

This relationship is used in Ansys Fluent whenever the Intensity and Hydraulic Diameter,

Intensity and Length Scale, or Intensity and Viscosity Ratio method is used instead

of specifying explicit values for and

or

.

Important: The reference frame for the mean flow velocity in Equation 7–75

corresponds to the Velocity Formulation selected in the General Task Page, see also Choosing the Relative or Absolute Velocity Formulation. When selecting the Reference Frame in any of the inlet boundary condition dialog boxes

(see, for example, Figure 7.37: The Velocity Inlet Dialog Box for the Velocity Inlet Boundary Conditions), be aware

that the specified inlet velocity is first converted to the selected Velocity Formulation and then applied to compute the

turbulent kinetic energy from turbulence intensity using Equation 7–75. If an inlet boundary type does

not require the inlet velocity specification (for example, Pressure Inlet Boundary Conditions), then in Equation 7–75 is the current local solution velocity magnitude, which corresponds

to the selected Velocity Formulation.

If you know the turbulence length scale, , you can determine

from the relationship

(7–76) |

The determination of was discussed previously.

This relationship is used in Ansys Fluent whenever the Intensity and Hydraulic Diameter or

Intensity and Length Scale method is used instead of specifying explicit values for and

.

The value of can be obtained from the turbulent viscosity ratio

and

using the following relationship:

(7–77) |

where is an empirical constant specified in the turbulence model.

This relationship is used in Ansys Fluent whenever the Intensity and Viscosity Ratio method is used

instead of specifying explicit values for and

.

If you are simulating a wind-tunnel situation in which the model is mounted in the test section downstream of a mesh and/or

wire mesh screens, you can choose a value of such that

(7–78) |

where is the approximate decay of

you want to have across the flow domain (say, 10% of the inlet value of

),

is the free-stream velocity, and

is the streamwise length of the flow domain. Equation 7–78 is a linear approximation

to the power-law decay observed in high-Reynolds-number isotropic turbulence. Its basis is the exact equation for

in decaying turbulence,

.

If you use this method to estimate , you should also check the resulting turbulent viscosity ratio

to make sure that it is not too large, using Equation 7–77.

Although this method is not used internally by Ansys Fluent, you can use it to derive a constant free-stream value of

that you can then specify directly by choosing K and Epsilon in the

Turbulence Specification Method drop-down list. In this situation, you will typically determine

from

using Equation 7–75.

If you know the turbulence length scale, , you can determine

from the relationship

(7–79) |

where is an empirical constant specified in the turbulence model. The determination of

was discussed previously.

This relationship is used in Ansys Fluent whenever the Intensity and Hydraulic Diameter or

Intensity and Length Scale method is used instead of specifying explicit values for and

.

The value of can be obtained from the turbulent viscosity ratio

and

using the following relationship:

(7–80) |

This relationship is used in Ansys Fluent whenever the Intensity and Viscosity Ratio method is used

instead of specifying explicit values for and

.

When the RSM is used, if you do not specify the values of the Reynolds stresses explicitly at the inlet using the

Reynolds-Stress Components option in the Reynolds-Stress Specification Method

drop-down list, they are approximately determined from the specified values of . The turbulence is assumed to be isotropic such that

(7–81) |

and

(7–82) |

(no summation over the index ).

Ansys Fluent will use this method if you select K or Turbulence Intensity in the Reynolds-Stress Specification Method drop-down list.

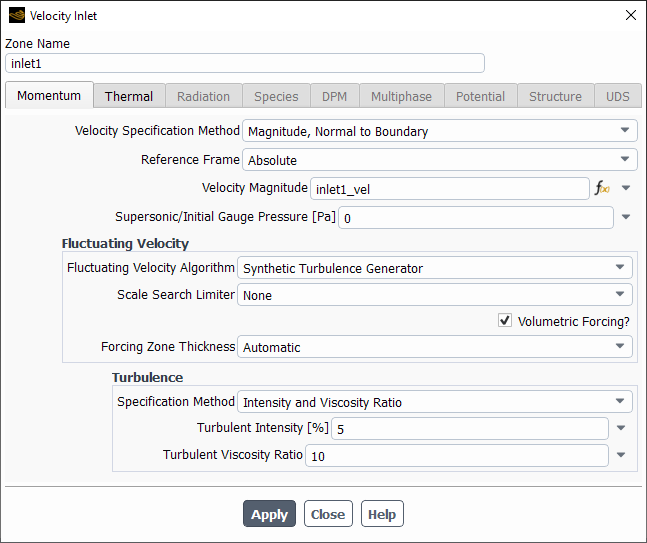

When using Scale Resolving Simulations (SAS, DES, SDES, SBES, and LES models), it is possible to specify unsteady Fluctuating Velocity at velocity and pressure inlets to generate realistic turbulent content. Therefore, additional input is required for velocity and pressure inlets such as the choice of Fluctuating Velocity Algorithm and corresponding parameters (as shown in Figure 7.34: Specifying Inlet Turbulence for Scale Resolving Simulation). The available methods along with their options are described in Inlet Boundary Conditions for Scale Resolving Simulations in the Fluent Theory Guide. Note that even though some LES models do not require specification of the Turbulence parameters at the boundary, it is required when a Fluctuating Velocity Algorithm is selected. Additional parameters available for the Fluctuating Velocity Algorithm are listed in Pressure Inlet Dialog Box and Velocity Inlet Dialog Box.

Pressure inlet boundary conditions are used to define the fluid pressure at flow inlets, along with all other scalar properties of the flow. They are suitable for both incompressible and compressible flow calculations. Pressure inlet boundary conditions can be used when the inlet pressure is known but the flow rate and/or velocity is not known. This situation may arise in many practical situations, including buoyancy-driven flows. Pressure inlet boundary conditions can also be used to define a “free” boundary in an external or unconfined flow.

For an overview of flow boundaries, see Flow Inlet and Exit Boundary Conditions.

You will enter the following information for a pressure inlet boundary:

type of reference frame

total (stagnation) pressure

total (stagnation) temperature

flow direction

static pressure

turbulence parameters (for turbulent calculations)

radiation parameters (for calculations using the P-1, DTRM, DO, surface-to-surface, or MC models)

chemical species mass or mole fractions (for species calculations)

mixture fraction and variance (for non-premixed or partially premixed combustion calculations)

progress variable (for premixed or partially premixed combustion calculations)

discrete phase boundary conditions (for discrete phase calculations)

multiphase boundary conditions (for general multiphase calculations)

open channel flow parameters (for open channel flow calculations using the VOF multiphase model)

acoustic wave model settings

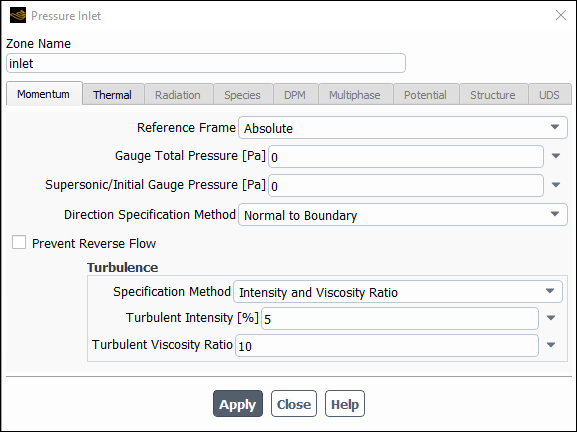

All values are entered in the Pressure Inlet Dialog Box (Figure 7.35: The Pressure Inlet Dialog Box), which is opened from the Boundary Conditions task page (as described in Setting Cell Zone and Boundary Conditions ). Note that open channel boundary condition inputs are described in Modeling Open Channel Flows, and acoustic wave model settings are described in Boundary Acoustic Wave Models.

When gravitational acceleration is activated in the Operating Conditions dialog box (accessed from

the Boundary Conditions task page), the pressure field (including all pressure inputs) will include

the hydrostatic head. This is accomplished by redefining the pressure in terms of a modified pressure that includes the

hydrostatic head (denoted ) as follows:

(7–83) |

where is a constant operating density,

is the gravity vector (also a constant), and

(7–84) |

is the position vector. Noting that

(7–85) |

it follows that

(7–86) |

The substitution of this relation in the momentum equation gives pressure gradient and gravitational body force terms of the form

(7–87) |

where is the fluid density. Therefore, if the fluid density is constant, we can set the operating density

equal to the fluid density, thereby eliminating the body force term. If the fluid density is not

constant (for example, density is given by the ideal gas law), then the operating density should be chosen to be

representative of the average or mean density in the fluid domain, so that the body force term is small.

An important consequence of this treatment of the gravitational body force is that your inputs of pressure (now defined

as ) should not include hydrostatic pressure differences. Moreover, reports of static and total pressure

will not show any influence of the hydrostatic pressure. See Buoyancy-Driven Flows and Natural Convection for additional

information.

Enter the value for total pressure in the Gauge Total Pressure field in the Pressure Inlet dialog box. Total temperature is set in the Thermal tab, in the Total Temperature field.

Remember that the total pressure value is the gauge pressure with respect to the operating pressure defined in the Operating Conditions Dialog Box. Total pressure for an incompressible fluid is defined as

(7–88) |

and for a compressible fluid of constant as

(7–89) |

|

where |

|

|

| |

|

M = Mach number | |

|

|

If you are modeling axisymmetric swirl, in Equation 7–88 will include the swirl component.

The Total Temperature, Gauge Total Pressure, and flow directions are in absolute or relative to the adjacent cell zone reference frames, based on the Reference Frame setting in the Pressure Inlet dialog box.

If the cell zone adjacent to a pressure inlet is defined as a moving reference frame zone, and you are using the pressure-based solver, the velocity in Equation 7–88 (or the Mach number in Equation 7–89) will be absolute or relative to the mesh velocity, depending on whether or not the Absolute velocity formulation is enabled in the General task page. For the density-based solver, the Absolute velocity formulation is always used; hence, the velocity in Equation 7–88 (or the Mach number in Equation 7–89) is always the Absolute velocity.

For the Eulerian multiphase model, the total temperature, and velocity components must be specified for the individual phases. The Reference Frame (Relative to Adjacent Cell Zone or Absolute) for each of the phases is the same as the reference frame selected for the mixture phase. Note that the total pressure values must be specified in the mixture phase.

Important:

If the flow is incompressible, then the temperature assigned in the Pressure Inlet dialog box will be considered the static temperature.

For the mixture multiphase model, if a boundary allows a combination of compressible and incompressible phases to enter the domain, then the temperature assigned in the Pressure Inlet dialog box will be considered the static temperature at that boundary. If a boundary allows only a compressible phase to enter the domain, then the temperature assigned in the Pressure Inlet dialog box will be taken as the total temperature (relative/absolute) at that boundary. The total temperature will depend on the Reference Frame option selected in the Pressure Inlet dialog box.

For the VOF multiphase model, if a boundary allows a compressible phase to enter the domain, then the temperature assigned in the Pressure Inlet dialog box will be considered the total temperature at that boundary. The total temperature (relative/absolute) will depend on the Reference Frame option chosen in the dialog box. Otherwise, the temperature assigned to the boundary will be considered the static temperature at the boundary.

For the Eulerian multiphase model, if a boundary allows a mixture of compressible and incompressible phases in the domain, then the temperature of each of the phases will be the total or static temperature, depending on whether the phase is compressible or incompressible.

Total temperature (relative/absolute) will depend on the Reference Frame option chosen in the Pressure Inlet dialog box.

The flow direction is defined as a unit vector () which is aligned with the local velocity vector,

. This can be expressed simply as

(7–90) |

Important: For the inputs in Ansys Fluent, the flow direction need not be a unit vector, as it will be automatically normalized before it is applied.

Important: For a moving reference frame, the relative flow direction is defined in terms of the relative velocity,

. Thus,

(7–91) |

You can define the flow direction at a pressure inlet explicitly, or you can define the flow to be normal to the

boundary. If you choose to specify the direction vector, you can set either the (Cartesian) ,

, and

components, or the (cylindrical) radial, tangential, and axial components.

For moving zone problems calculated using the pressure-based solver, the flow direction will be absolute or relative to the mesh velocity, depending on whether or not the Absolute velocity formulation is selected in the General task page. For the density-based solver, the flow direction will always be in the absolute frame.

The procedure for defining the flow direction is as follows (refer to Figure 7.35: The Pressure Inlet Dialog Box):

Specify the flow direction by selecting Direction Vector or Normal to Boundary in the Direction Specification Method drop-down list.

If you selected Normal to Boundary in step 1 and you are modeling axisymmetric swirl, enter the appropriate value for the Tangential-Component of Flow Direction. If you chose Normal to Boundary and your geometry is 3D or 2D without axisymmetric swirl, there are no additional inputs for flow direction.

If you selected Direction Vector in step 1, and your geometry is 3D, choose Cartesian (X, Y, Z), Cylindrical(Radial, Tangential, Axial), Local Cylindrical (Radial, Tangential, Axial), or Local Cylindrical Swirl from the Coordinate System drop-down list. Some notes on these selections are provided below:

The Cartesian coordinate option is based on the Cartesian coordinate system used by the geometry. Enter appropriate values for the X, Y, and Z-Component of Flow Direction.

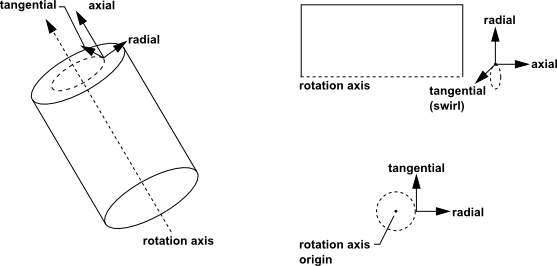

The Cylindrical coordinate system uses the axial, radial, and tangential components based on the following coordinate systems:

For problems involving a single cell zone, the coordinate system is defined by the rotation axis and origin specified in the Fluid Dialog Box.

For problems involving multiple zones (for example, multiple reference frames or sliding meshes), the coordinate system is defined by the rotation axis specified in the Fluid (or Solid) dialog box for the fluid (or solid) zone that is adjacent to the inlet.

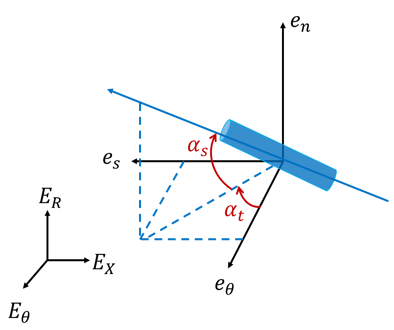

For all of the above definitions of the cylindrical coordinate system, positive radial velocities point radially outward from the rotation axis, positive axial velocities are in the direction of the rotation axis vector, and positive tangential velocities are based on the right-hand rule using the positive rotation axis (see Figure 7.36: Cylindrical Velocity Components in 3D, 2D, and Axisymmetric Domains).

The Local Cylindrical coordinate system allows you to define a coordinate system specifically for the inlet. When you use the local cylindrical option, you will define the coordinate system right here in the Pressure Inlet dialog box. The local cylindrical coordinate system is useful if you have several inlets with different rotation axes. Enter appropriate values for the Axial, Radial, and Tangential-Component of Flow Direction, and then specify the X, Y, and Z components of the Axis Origin and Axis Direction.

The Local Cylindrical Swirl coordinate system option allows you to define a coordinate system specifically for the inlet where the total pressure, swirl velocity, and the components of the velocity in the axial and radial planes are specified. Enter appropriate values for the Axial and Radial-Component of Flow Direction, and the Tangential-Velocity. Specify the X, Y, and Z components of the Axis Origin and Axis Direction. It is recommended that you start your simulation with a smaller swirl velocity and then progressively increase the velocity to obtain a stable solution.

Important: Local Cylindrical Swirl should not be used for open channel boundary conditions and on the mixing plane boundaries while using the mixing plane model.

If you selected Direction Vector in step 1, and your geometry is 2D, define the vector components as follows:

For a 2D planar geometry, enter appropriate values for the X, Y, and Z-Component of Flow Direction.

For a 2D axisymmetric geometry, enter appropriate values for the Axial, Radial-Component of Flow Direction.

For a 2D axisymmetric swirl geometry, enter appropriate values for the Axial, Radial, and Tangential-Component of Flow Direction.

Figure 7.36: Cylindrical Velocity Components in 3D, 2D, and Axisymmetric Domains shows the vector components for these different coordinate systems.

The static pressure (termed the Supersonic/Initial Gauge Pressure) must be specified if the inlet flow is supersonic or if you plan to initialize the solution based on the pressure inlet boundary conditions. Solution initialization is discussed in Initializing the Solution.

Remember that the static pressure value you enter is relative to the operating pressure set in the Operating Conditions Dialog Box. Note the comments in Pressure Inputs and Hydrostatic Head regarding hydrostatic pressure.

The Supersonic/Initial Gauge Pressure is ignored by Ansys Fluent whenever the flow is subsonic, in which case it is calculated from the specified stagnation quantities. If you choose to initialize the solution based on the pressure-inlet conditions, the Supersonic/Initial Gauge Pressure will be used in conjunction with the specified stagnation pressure to compute initial values according to the isentropic relations (for compressible flow) or Bernoulli’s equation (for incompressible flow). Therefore, for a sub-sonic inlet it should generally be set based on a reasonable estimate of the inlet Mach number (for compressible flow) or inlet velocity (for incompressible flow).

When this option is selected, Fluent will erect artificial walls on the boundary mesh faces to prevent flow out of the domain. The artificial walls are removed when the flow is no longer leaving the domain and when a favorable pressure gradient is recovered at the boundary mesh faces.

When artificial walls are created, Fluent will print a message in the console window indicating the number of faces on which artificial walls have been erected and the equivalent area percentage of the boundary it represents.

Note: This feature is not available with multiphase flow.

For turbulent calculations, there are several ways in which you can define the turbulence parameters. Instructions for deciding which method to use and determining appropriate values for these inputs are provided in Determining Turbulence Parameters. Turbulence modeling in general is described in Modeling Turbulence.

The options available depend on which radiation model is active. For details, see Defining Boundary Conditions for Radiation.

If you are modeling species transport, you will set the species mass or mole fractions under Species Mole Fractions or Species Mass Fractions. For details, see Defining Cell Zone and Boundary Conditions for Species.

If you are using the non-premixed or partially premixed combustion model, you will set the Mean Mixture Fraction and Mixture Fraction Variance (and the Secondary Mean Mixture Fraction and Secondary Mixture Fraction Variance, if you are using two mixture fractions), as described in Defining Non-Premixed Boundary Conditions.

If you are using the premixed or partially premixed combustion model, you will set the Progress Variable, as described in Setting Boundary Conditions for the Progress Variable.

If you are modeling a discrete phase of particles, you can set the fate of particle trajectories at the pressure inlet. See Setting Boundary Conditions for the Discrete Phase for details.

If you are using the VOF, mixture, or Eulerian model for multiphase flow, you will need to specify volume fractions for secondary phases and (for some models) additional parameters. See Defining Multiphase Cell Zone and Boundary Conditions for details.

If you are using the VOF model for multiphase flow and modeling open channel flows, you will need to specify the Free Surface Level, Bottom Level, and additional parameters. See Modeling Open Channel Flows for details.

Default settings (in SI) for pressure inlet boundary conditions are as follows:

| Gauge Total Pressure | 0 |

| Supersonic/Initial Gauge Pressure | 0 |

| Total Temperature | 300 |

| Direction Specification Method | Normal to Boundary |

| Turbulent Intensity | 5% |

| Turbulent Viscosity Ratio | 10 |

The treatment of pressure inlet boundary conditions by Ansys Fluent can be described as a loss-free transition from stagnation conditions to the inlet conditions. For incompressible flows, this is accomplished by application of the Bernoulli equation at the inlet boundary. In compressible flows, the equivalent isentropic flow relations for an ideal gas are used.

When flow enters through a pressure inlet boundary, Ansys Fluent uses the boundary condition pressure you input as the

total pressure of the fluid at the inlet plane, . In incompressible flow, the inlet total pressure and the static pressure,

, are related to the inlet velocity via Bernoulli’s equation:

(7–92) |

With the resulting velocity magnitude and the flow direction vector you assigned at the inlet, the velocity components can be computed. The inlet mass flow rate and fluxes of momentum, energy, and species can then be computed as outlined in Calculation Procedure at Velocity Inlet Boundaries.

For incompressible flows, density at the inlet plane is either constant or calculated as a function of temperature and/or species mass/mole fractions, where the mass or mole fractions are the values you entered as an inlet condition.

If flow exits through a pressure inlet, the total pressure specified is used as the static pressure. For incompressible flows, total temperature is equal to static temperature.

In compressible flows, isentropic relations for an ideal gas are applied to relate total pressure, static pressure, and

velocity at a pressure inlet boundary. Your input of total pressure, , at the inlet and the static pressure,

, in the adjacent fluid cell are therefore related as

(7–93) |

where

(7–94) |

= the speed of sound, and

. Note that the operating pressure,

, appears in Equation 7–93 because your boundary condition inputs are in terms of

pressure relative to the operating pressure. Given

and

, Equation 7–93 and Equation 7–94 are used to compute the

velocity magnitude of the fluid at the inlet plane. Individual velocity components at the inlet are then derived using the

direction vector components.

For compressible flow, the density at the inlet plane is defined by the ideal gas law in the form

(7–95) |

For multi-species gas mixtures, the specific gas constant, , is computed from the species mass or mole fractions,

that you defined as boundary conditions at the pressure inlet boundary. The static temperature at the inlet,

, is computed from your input of total temperature,

, as

(7–96) |

Velocity inlet boundary conditions are used to define the flow velocity, along with all relevant scalar properties of the flow, at flow inlets. In this case, the total (or stagnation) pressure is not fixed but will rise (in response to the computed static pressure) to whatever value is necessary to provide the prescribed velocity distribution. This boundary condition is applicable to incompressible and compressible flows.

Important: Use caution when specifying the velocity inlet boundary condition for a compressible fluid in internal flow modeling. If the flow path is completely choked with no secondary flow path for relief, the velocity inlet boundary condition is not recommended, as it can cause numerical instabilities. In this case, you should switch to the pressure inlet boundary condition or refrain from reaching operating conditions that choke the internal flow. The choking condition can happen in high speed supersonic and transonic flow.

In special instances, a velocity inlet may be used in Ansys Fluent to define the flow velocity at flow exits. (The scalar inputs are not used in such cases.) In such cases you must ensure that overall continuity is maintained in the domain.

For an overview of flow boundaries, see Flow Inlet and Exit Boundary Conditions.

You will enter the following information for a velocity inlet boundary:

type of reference frame

velocity magnitude and direction or velocity components

swirl velocity (for 2D axisymmetric problems with swirl)

static pressure

temperature (for energy calculations)

outflow gauge pressure (for calculations with the density-based solver)

turbulence parameters (for turbulent calculations)

radiation parameters (for calculations using the P-1, DTRM, DO, surface-to-surface, or MC models)

chemical species mass or mole fractions (for species calculations)

mixture fraction and variance (for non-premixed or partially premixed combustion calculations)

progress variable (for premixed or partially premixed combustion calculations)

discrete phase boundary conditions (for discrete phase calculations)

multiphase boundary conditions (for general multiphase calculations)

acoustic wave model settings (see Boundary Acoustic Wave Models)

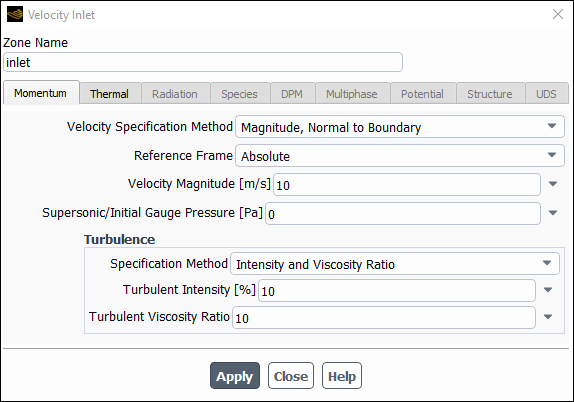

All values are entered in the Velocity Inlet Dialog Box (Figure 7.37: The Velocity Inlet Dialog Box), which is opened from the Boundary Conditions task page (as described in Setting Cell Zone and Boundary Conditions ). Note that acoustic wave model settings are described in Boundary Acoustic Wave Models.

You can define the inflow velocity by specifying the velocity magnitude and direction, the velocity components, or the velocity magnitude normal to the boundary. If the cell zone adjacent to the velocity inlet is moving (that is, if you are using a moving reference frame, multiple reference frames, or sliding meshes), you can specify either relative or absolute velocities. For axisymmetric problems with swirl in Ansys Fluent, you will also specify the swirl velocity.

The procedure for defining the inflow velocity is as follows:

Specify the flow direction by selecting Magnitude and Direction, Components, or Magnitude, Normal to Boundary in the Velocity Specification Method drop-down list.

If the cell zone adjacent to the velocity inlet is moving, you can choose to specify relative or absolute velocities by selecting Relative to Adjacent Cell Zone or Absolute in the Reference Frame drop-down list. If the adjacent cell zone is not moving, Absolute and Relative to Adjacent Cell Zone will be equivalent, so you need not visit the list.

If you are going to set the velocity magnitude and direction or the velocity components, and your geometry is 3D, choose Cartesian (X, Y, Z), Cylindrical (Radial, Tangential, Axial), or Local Cylindrical (Radial, Tangential, Axial) from the Coordinate System drop-down list. See Defining the Flow Direction for information about Cartesian, cylindrical, and local cylindrical coordinate systems.

Set the appropriate velocity parameters, as described below for each specification method.

If you selected Magnitude and Direction as the Velocity Specification Method in step 1 above, you will enter the magnitude of the velocity vector at the inflow boundary (the Velocity Magnitude) and the direction of the vector:

If your geometry is 2D non-axisymmetric, or you chose in step 3 to use the Cartesian coordinate system, you will define the X, Y, and (in 3D) Z-Component of Flow Direction.

If your geometry is 2D axisymmetric, or you chose in step 3 to use a Cylindrical coordinate system, enter the appropriate values of Radial, Axial, and (if you are modeling axisymmetric swirl or using cylindrical coordinates) Tangential-Component of Flow Direction.

If you chose in step 3 to use a Local Cylindrical coordinate system, enter appropriate values for the Axial, Radial, and Tangential-Component of Flow Direction, and then specify the X, Y, and Z components of the Axis Origin and the Axis Direction.

Figure 7.36: Cylindrical Velocity Components in 3D, 2D, and Axisymmetric Domains shows the vector components for these different coordinate systems.

If you selected Magnitude, Normal to Boundary as the Velocity Specification Method in step 1 above, you will enter the magnitude of the velocity vector at the inflow boundary (the Velocity Magnitude).

If you selected Components as the Velocity Specification Method in step 1 above, you will enter the components of the velocity vector at the inflow boundary as follows:

If your geometry is 2D non-axisymmetric, or you chose in step 3 to use the Cartesian coordinate system, you will define the X, Y, and (in 3D) Z-Velocity.

If your geometry is 2D axisymmetric without swirl, you will set the Radial and Axial-Velocity.

If your model is 2D axisymmetric with swirl, you will set the Axial, Radial, and Swirl-Velocity, and (optionally) the Angular Velocity, as described below.

If you chose in step 3 to use a Cylindrical coordinate system, you will set the Radial, Tangential, and Axial-Velocity, and (optionally) the Angular Velocity, as described below.

If you chose in step 3 to use a Local Cylindrical coordinate system, you will set the Radial, Tangential, and Axial-Velocity, and (optionally) the Angular Velocity, as described below, and then specify the X, Y, and Z component of the Axis Origin and the Axis Direction.

Important: Remember that positive values for ,

, and

velocities indicate flow in the positive

,

, and

directions. If flow enters the domain in the negative

direction, for example, you will need to specify a negative value for the

velocity. The same holds true for the radial, tangential, and axial velocities. Positive radial

velocities point radially out from the axis, positive axial velocities are in the direction of the axis vector, and

positive tangential velocities are based on the right-hand rule using the positive axis.

If you chose Components as the Velocity Specification Method in step 1 above, and

you are modeling axisymmetric swirl, you can specify the inlet Angular Velocity in addition to the Swirl-Velocity. Similarly, if you chose

Components as the Velocity Specification Method and you chose in step 3 to use a

Cylindrical or Local Cylindrical coordinate system, you can specify the inlet

Angular Velocity

in addition to the Tangential-Velocity.

If you specify ,

is computed for each face as

, where

is the radial coordinate in the coordinate system defined by the rotation axis and origin. If you specify

both the Swirl-Velocity and the Angular Velocity, or the

Tangential-Velocity and the Angular Velocity, Ansys Fluent will add

and

to get the swirl or tangential velocity at each face.

The static pressure (termed the Supersonic/Initial Gauge Pressure) must be specified if the inlet flow is supersonic or if you plan to initialize the solution based on the velocity inlet boundary conditions. Solution initialization is discussed in Initializing the Solution.

The Supersonic/Initial Gauge Pressure is ignored by Ansys Fluent whenever the flow is subsonic. If you choose to initialize the flow based on the velocity inlet conditions, the Supersonic/Initial Gauge Pressure will be used in conjunction with the specified stagnation quantities to compute initial values according to isentropic relations.

Remember that the static pressure value you enter is relative to the operating pressure set in the Operating Conditions Dialog Box. Note the comments in Pressure Inputs and Hydrostatic Head

For calculations in which the energy equation is being solved, you will set the static temperature of the flow at the velocity inlet boundary in the Thermal tab in the Temperature field.

If you are using the density-based solver, you can specify an Outflow Gauge Pressure for a velocity inlet boundary. If the flow exits the domain at any face on the boundary, that face will be treated as a pressure outlet with the pressure prescribed in the Outflow Gauge Pressure field.

For turbulent calculations, there are several ways in which you can define the turbulence parameters. Instructions for deciding which method to use and determining appropriate values for these inputs are provided in Determining Turbulence Parameters. Turbulence modeling in general is described in Modeling Turbulence.

The options available depend on which radiation model is active. For details, see Defining Boundary Conditions for Radiation.

If you are modeling species transport, you will set the species mass or mole fractions under Species Mole Fractions or Species Mass Fractions. For details, see Defining Cell Zone and Boundary Conditions for Species.

If you are using the non-premixed or partially premixed combustion model, you will set the Mean Mixture Fraction and Mixture Fraction Variance (and the Secondary Mean Mixture Fraction and Secondary Mixture Fraction Variance, if you are using two mixture fractions), as described in Defining Non-Premixed Boundary Conditions.

If you are using the premixed or partially premixed combustion model, you will set the Progress Variable, as described in Setting Boundary Conditions for the Progress Variable.

If you are modeling a discrete phase of particles, you can set the fate of particle trajectories at the velocity inlet. See Setting Boundary Conditions for the Discrete Phase for details.

If you are using the VOF, mixture, or Eulerian model for multiphase flow, you will need to specify volume fractions for secondary phases and (for some models) additional parameters. See Defining Multiphase Cell Zone and Boundary Conditions for details.

Default settings (in SI) for velocity inlet boundary conditions are as follows:

| Temperature | 300 |

| Velocity Magnitude | 0 |

| X-Component of Flow Direction | 1 |

| Y-Component of Flow Direction | 0 |

| Z-Component of Flow Direction | 0 |

| X-Velocity | 0 |

| Y-Velocity | 0 |

|

Z-Velocity | 0 |

| Turbulent Intensity | 5% |

| Turbulent Viscosity Ratio | 10 |

| Outflow Gauge Pressure | 0 |

Ansys Fluent uses your boundary condition inputs at velocity inlets to compute the mass flow into the domain through the inlet and to compute the fluxes of momentum, energy, and species through the inlet. This section describes these calculations for the case of flow entering the domain through the velocity inlet boundary and for the less common case of flow exiting the domain through the velocity inlet boundary.

When your velocity inlet boundary condition defines flow entering the physical domain of the model, Ansys Fluent uses both the velocity components and the scalar quantities that you defined as boundary conditions to compute the inlet mass flow rate, momentum fluxes, and fluxes of energy and chemical species.

The mass flow rate entering a fluid cell adjacent to a velocity inlet boundary is computed as

(7–97) |

Note that only the velocity component normal to the control volume face contributes to the inlet mass flow rate.

Sometimes a velocity inlet boundary is used where flow exits the physical domain. This approach might be used, for example, when the flow rate through one exit of the domain is known or is to be imposed on the model.

Important: In such cases you must ensure that overall continuity is maintained in the domain.

In the pressure-based solver, when flow exits the domain through a velocity inlet boundary condition, Ansys Fluent uses the boundary velocity to compute the flow flux through the exit flow area and the viscous term in the momentum equation. The convection term in all equations including momentum uses upwind discretization and takes the values of the upstream cells.

In the density-based solver, if the flow exits the domain at any face on the boundary, that face will be treated as a pressure outlet with the pressure prescribed in the Outflow Gauge Pressure field.

Mass flow boundary conditions can be used in Ansys Fluent to provide a prescribed mass flow rate or mass flux distribution at an inlet. As with a velocity inlet, specifying the mass flux permits the total pressure to vary in response to the interior solution. This is in contrast to the pressure inlet boundary condition (see Pressure Inlet Boundary Conditions), where the total pressure is fixed while the mass flux varies. The mass-flow inlet is applicable to incompressible and compressible flows.

Important: Use caution when specifying the mass-flow inlet boundary condition for a compressible fluid in internal flow modeling. If the flow path is completely choked with no secondary flow path for relief, the mass-flow inlet boundary condition is not recommended, as it can cause numerical instabilities. In this case, you should switch to the pressure inlet boundary condition or refrain from reaching operating conditions that choke the internal flow. The choking condition can happen in high speed supersonic and transonic flow.

A mass-flow inlet is often used when it is more important to match a prescribed mass flow rate than to match the total pressure of the inflow stream. An example is the case of a small cooling jet that is bled into the main flow at a fixed mass flow rate, while the velocity of the main flow is governed primarily by a (different) pressure inlet/outlet boundary condition pair. A mass-flow inlet boundary condition can also be used as an outflow by specifying the flow direction away from the solution domain.

The adjustment of inlet total pressure might result in a slower convergence, so if both the pressure inlet boundary condition and the mass-flow inlet boundary condition are acceptable choices, you should choose the former.

It is not necessary to use mass-flow inlets in incompressible flows because when density is constant, velocity inlet boundary conditions will fix the mass flow.

For an overview of flow boundaries, see Flow Inlet and Exit Boundary Conditions.

You will enter the following information for a mass-flow inlet boundary:

type of reference frame

mass flow rate, mass flux, or (primarily for the mixing plane model) mass flux with average mass flux

total (stagnation) temperature

static pressure

flow direction

turbulence parameters (for turbulent calculations)

radiation parameters (for calculations using the P-1, DTRM, DO, surface-to-surface, or MC models)

chemical species mass or mole fractions (for species calculations)

mixture fraction and variance (for non-premixed or partially premixed combustion calculations)

progress variable (for premixed or partially premixed combustion calculations)

discrete phase boundary conditions (for discrete phase calculations)

open channel flow parameters (for open channel flow calculations using the VOF multiphase model)

acoustic wave model settings

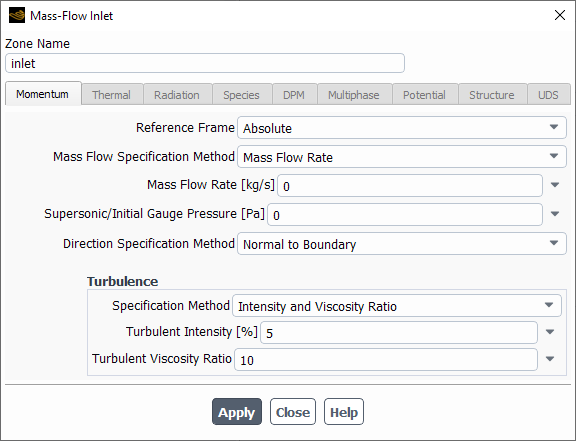

All values are entered in the Mass-Flow Inlet Dialog Box (Figure 7.38: The Mass-Flow Inlet Dialog Box), which is opened from the Boundary Conditions task page (as described in Setting Cell Zone and Boundary Conditions ). Note that open channel boundary condition inputs are described in Modeling Open Channel Flows, and acoustic wave model settings are described in Boundary Acoustic Wave Models.

You will have the option to specify the mass flow boundary conditions either in the absolute or relative reference frame, when the cell zone adjacent to the mass-flow inlet is moving. For such a case, choose Absolute (the default) or Relative to Adjacent Cell Zone in the Reference Frame drop-down list. If the cell zone adjacent to the mass-flow inlet is not moving, both formulations are equivalent.

You can specify the mass flow rate through the inlet zone and have Ansys Fluent convert this value to mass flux, or specify the mass flux directly. For cases where the mass flux varies across the boundary, you can also specify an average mass flux; see below for more information about this specification method.

You can define the mass flux or mass flow rate using a profile or a user-defined function.

The inputs for mass flow rate or flux are as follows:

Make a selection in the Mass Flow Specification Method drop-down list to specify whether you will define a Mass Flow Rate, Mass Flux, or Mass Flux with Average Mass Flux.

If you selected Mass Flow Rate (the default), enter the prescribed Mass Flow Rate when constant is selected from the drop-down list. Otherwise, select your hooked user-defined function (UDF) or transient profile.

Important: The hooked UDF or transient profile can only be used to provide time-varying specification of mass flow rate. Therefore, the transient solver must be used to run the simulation. Note that the variation of profile with position in space is not applicable with this hookup.

See

DEFINE_PROFILEin the Fluent Customization Manual for an example of a mass-flow inlet UDF.Important: Note that for axisymmetric problems, this mass flow rate is the flow rate through the entire (

-radian) domain, not through a 1-radian slice.

If you selected Mass Flux, enter the prescribed Mass Flux, or select your hooked UDF or profile.

If you selected Mass Flux with Average Mass Flux, enter the prescribed Mass Flux and Average Mass Flux.

Important: Note that for axisymmetric problems, the Mass Flux and Average Mass Flux is the flux through a 1-radian slice of the domain.

As noted previously, you can specify an average mass flux with the mass flux. If, for example, you specify a mass flux profile such that the average mass flux integrated over the zone area is 4.7, but you actually want to have a total mass flux of 5, you can keep the profile unchanged, and specify an average mass flux of 5. Ansys Fluent will maintain the profile shape but adjust the values so that the resulting mass flux across the boundary is 5.

The mass flux with average mass flux specification method is also used by the mixing plane model described in Legacy Mixing Plane Model. If the mass-flow inlet boundary is going to represent one of the mixing planes, then you do not need to specify the mass flux or flow rate; you can keep the default Mass Flow Rate of 1. When you create the mixing plane later on in the problem setup, Ansys Fluent will automatically select the Mass Flux with Average Mass Flux method in the Mass-Flow Inlet dialog box and set the Average Mass Flux to the value obtained by integrating the mass flux profile for the upstream zone. This will ensure that mass is conserved between the upstream zone and the downstream (mass-flow inlet) zone.

Enter the value for the total (stagnation) temperature of the inflow stream in the Total Temperature field in the Thermal tab.

The total temperature is specified either in the absolute reference frame or relative to the adjacent cell zone, depending on your setting for the Reference Frame.

For the Eulerian multiphase model, the total temperature, and mass flux components need to be specified for the individual phases. The Reference Frame (Relative to Adjacent Cell Zone or Absolute) for each of the phases is the same as the reference frame selected for the mixture phase.

Important: Note that you can only set the reference frame for the mixture, however, the total temperature can only be set for the individual phases.

Important:

If the flow is incompressible, then the temperature assigned in the Mass-Flow Inlet dialog box is considered to be the static temperature.

For the mixture multiphase model, if a boundary allows a combination of compressible and incompressible phases to enter the domain, then the temperature assigned in the Mass-Flow Inlet dialog box is considered to be the static temperature at that boundary. If a boundary allows only a compressible phase to enter the domain, then the temperature assigned in the Mass-Flow Inlet dialog box is the total temperature (relative/absolute) at that boundary. The total temperature depends on the Reference Frame option selected in the Mass-Flow Inlet dialog box.

For the VOF multiphase model, if a boundary allows a compressible phase to enter the domain, then the temperature assigned in the Mass-Flow Inlet dialog box is considered to be the total temperature at that boundary. The total temperature (relative/absolute) depends on the Reference Frame option chosen in the dialog box. Otherwise, the temperature assigned to the boundary is considered to be the static temperature at the boundary.

For the Eulerian multiphase model, if a boundary allows a mixture of compressible and incompressible phases in the domain, then the temperature of each of the phases is the total or static temperature, depending on whether the phase is compressible or incompressible. Total temperature (relative/absolute) depends on the Reference Frame option chosen in the Mass-Flow Inlet dialog box.

The static pressure (termed the Supersonic/Initial Gauge Pressure) must be specified if the inlet flow is supersonic or if you plan to initialize the solution based on the pressure inlet boundary conditions. Solution initialization is discussed in Initializing the Solution.

The Supersonic/Initial Gauge Pressure is ignored by Ansys Fluent whenever the flow is subsonic. If you choose to initialize the flow based on the mass-flow inlet conditions, the Supersonic/Initial Gauge Pressure will be used in conjunction with the specified stagnation quantities to compute initial values according to isentropic relations.

Remember that the static pressure value you enter is relative to the operating pressure set in the Operating Conditions Dialog Box. Note the comments in Pressure Inputs and Hydrostatic Head regarding hydrostatic pressure.

You can define the flow direction at a mass-flow inlet explicitly, or you can define the flow to be normal to the boundary.

The procedure for defining the flow direction is as follows, referring to Figure 7.38: The Mass-Flow Inlet Dialog Box:

Specify the flow direction by selecting Direction Vector or Normal to Boundary in the Direction Specification Method drop-down list. The default value for this option is Normal to Boundary.

If you selected Direction Vector and your geometry is 2D, go to the next step. If your geometry is 3D, choose Cartesian (X, Y, Z), Cylindrical (Radial, Tangential, Axial), Local Cylindrical (Radial, Tangential, Axial), or Local Cylindrical Swirl in the Coordinate System drop-down list. See Defining the Flow Direction for information about Cartesian, cylindrical, local cylindrical, and local cylindrical swirl coordinate systems.

If you selected Direction Vector, set the vector components as follows:

If your geometry is 2D non-axisymmetric, or you chose to use a 3D Cartesian coordinate system, enter appropriate values for the X-, Y-, and (in 3D) Z-Component of Flow Direction.

If your geometry is 2D axisymmetric, or you chose to use a 3D Cylindrical coordinate system, enter appropriate values for the Axial-, Radial-, and (if you are modeling swirl or using cylindrical coordinates) Tangential-Component of Flow Direction.

If you chose to use a 3D Local Cylindrical coordinate system, enter appropriate values for the Axial-, Radial-, and Tangential-Component of Flow Direction, and then specify the X, Y, and Z components of Axis Origin and the Axis Direction.

If you chose to use a 3D Local Cylindrical Swirl coordinate system, enter appropriate values for the Axial- and Radial-Component of Flow Direction in the axial and radial planes, and the Tangential-Velocity. Specify the X, Y, and Z components of the Axis Origin and the Axis Direction.

Important: Local Cylindrical Swirl should not be used for open channel boundary conditions and on the mixing plane boundaries, while using the mixing plane model.

If you selected Normal to Boundary, there are no additional inputs for flow direction.

Important: Note that if you are modeling axisymmetric swirl, the flow direction will be normal to the boundary; that is, there will be no swirl component at the boundary for axisymmetric swirl.

For turbulent calculations, there are several ways in which you can define the turbulence parameters. Instructions for deciding which method to use and determining appropriate values for these inputs are provided in Determining Turbulence Parameters. Turbulence modeling is described in Modeling Turbulence.

The options available depend on which radiation model is active. For details, see Defining Boundary Conditions for Radiation.

If you are modeling species transport, you will set the species mass or mole fractions under Species Mole Fractions or Species Mass Fractions. For details, see Defining Cell Zone and Boundary Conditions for Species.

If you are using the non-premixed or partially premixed combustion model, you will set the Mean Mixture Fraction and Mixture Fraction Variance (and the Secondary Mean Mixture Fraction and Secondary Mixture Fraction Variance, if you are using two mixture fractions), as described in Defining Non-Premixed Boundary Conditions.

If you are using the premixed or partially premixed combustion model, you will set the Progress Variable, as described in Setting Boundary Conditions for the Progress Variable.

If you are modeling a discrete phase of particles, you can set the fate of particle trajectories at the mass-flow inlet. See Setting Boundary Conditions for the Discrete Phase for details.

If you are using the VOF model for multiphase flow and modeling open channel flows, you will need to specify the Free Surface Level, Bottom Level, and additional parameters. See Modeling Open Channel Flows for details.

Default settings (in SI) for mass-flow inlet boundary conditions are as follows:

| Mass Flow Rate | 1 |

| Total Temperature | 300 |

| Supersonic/Initial Gauge Pressure | 0 |

| X-Component of Flow Direction | 1 |

| Y-Component of Flow Direction | 0 |

| Z-Component of Flow Direction | 0 |

| Turbulent Intensity | 5% |

| Turbulent Viscosity Ratio | 10 |

When mass flow boundary conditions are used for an inlet zone, a velocity is computed for each face in that zone, and this velocity is used to compute the fluxes of all relevant solution variables into the domain. With each iteration, the computed velocity is adjusted so that the correct mass flow value is maintained.

To compute this velocity, your inputs for mass flow rate, flow direction, static pressure, and total temperature are used.

There are two ways to specify the mass flow rate. The first is to specify the total mass flow rate, , for the inlet. The second is to specify the mass flux,

(mass flow rate per unit area). If a total mass flow rate is specified, Ansys Fluent converts it internally to

a uniform mass flux by dividing the mass flow rate by the total inlet area:

(7–98) |

If the direct mass flux specification option is used, the mass flux can be varied over the boundary by using profile files or user-defined functions. If the average mass flux is also specified (either explicitly by you or automatically by Ansys Fluent), it is used to correct the specified mass flux profile, as described earlier in this section.

Once the value of at a given face has been determined, the density,

, at the face must be determined in order to find the normal velocity,

. The manner in which the density is obtained depends upon whether the fluid is modeled as an ideal gas or not.

Each of these cases is examined below.

If the fluid is an ideal gas, the static temperature and static pressure are required to compute the density:

(7–99) |

If the inlet is supersonic, the static pressure used is the value that has been set as a boundary condition. If the inlet is subsonic, the static pressure is extrapolated from the cells inside the inlet face.

The static temperature at the inlet is computed from the total enthalpy, which is determined from the total temperature that has been set as a boundary condition. The total enthalpy is given by

(7–100) |

where the velocity magnitude is related to the mass flow rate given by Equation 7–98 and the known user-specified flow direction vector. Using Equation 7–99 to relate density to the (known) static pressure and (unknown) temperature, Equation 7–100 can be solved to obtain the static temperature.

When you are modeling incompressible flows, the static temperature is equal to the total temperature. The density at the inlet is either constant or readily computed as a function of the temperature and (optionally) the species mass or mole fractions. The velocity is then computed using Equation 7–98.

To compute the fluxes of all variables at the inlet, the flux velocity, , is used along with the inlet value of the variable in question. For example, the flux of mass is

, and the flux of turbulence kinetic energy is

. These fluxes are used as boundary conditions for the corresponding conservation equations during the course

of the solution.

Mass-flow outlet boundaries can be used in Ansys Fluent to pump flow out of the domain at a prescribed mass flow rate or mass flux distribution. A mass-flow outlet is often used when it is more important to match a prescribed mass flow rate than to match the static pressure of the outflow stream. By default, the mass-flow outlet boundary condition is set to 0.

The mass-flow outlet boundary condition is designed to be strictly used only when flow is leaving the domain. It should not be used for mixed flow conditions (where flow is flowing in and out) or when flow is changing directions.

The mass-flow outlet boundary condition has the following limitations:

Mass-flow outlet boundaries are not supported with the Wet Steam model in the density-based solver.

For Eulerian multiphase cases, the mass flow outlet boundary condition should only be used for cases where only one of the phases exits the domain at the boundary. Otherwise, the solution results may be inaccurate.

You will enter the following information for a mass-flow outlet boundary:

mass flow rate, mass flux, mass flux with average mass flux, or exit corrected mass flow rate with reference temperature and gauge pressure

radiation parameters (for calculations using the P-1, DTRM, DO, surface-to-surface, or MC models)

discrete phase boundary conditions (for discrete phase calculations)

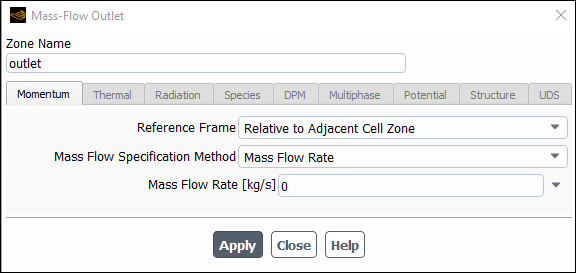

All values are entered in the Mass-Flow Outlet Dialog Box (Figure 7.39: The Mass-Flow Outlet Dialog Box), which is opened from the Boundary Conditions task page (as described in Setting Cell Zone and Boundary Conditions).

Mass-flow outlets only support the Relative to Adjacent Cell Zone specification for the Reference Frame.

You can specify the mass flow rate through the outlet zone and have Ansys Fluent convert this value to mass flux, or specify the mass flux directly. For cases where the mass flux varies across the boundary, you can specify an average mass flux. For compressible problems, you can specify that the mass flow rate is adjusted to total conditions at the outlet, thus maintaining a constant exit corrected mass flow rate.

You can define the mass flow or mass flux rate using a profile or a user-defined function (UDF). For an example of a

mass-flow outlet UDF, see DEFINE_PROFILE in the Fluent Customization Manual.

Important: The hooked UDF or transient profile can only be used to provide time-varying specification of mass flow or mass flux rate. Therefore, the transient solver must be used to run the simulation. Note that the variation of profile with position in space is not applicable with this hookup.

The inputs for mass flow rate or flux are as follows:

Make a selection in the Mass Flow Specification Method drop-down list to specify whether you will define a Mass Flow Rate, Mass Flux, Mass Flux with Average Mass Flux, or (if the density of the material is defined either as an ideal gas or using a real gas model) Exit Corrected Mass Flow Rate.

If you selected Mass Flow Rate (the default), enter the prescribed Mass Flow Rate when constant is selected from the drop-down list. Otherwise, select your hooked user-defined function (UDF) or transient profile.

If you selected Mass Flux, enter the prescribed Mass Flux (or select your hooked UDF or profile).

If you selected Mass Flux with Average Mass Flux, enter the prescribed Mass Flux (or select your hooked UDF or profile) and Average Mass Flux.

Note that if you specify a mass flux profile such that the average mass flux integrated over the zone area is 4.7, but you actually want to have a total mass flux of 5, you can keep the profile unchanged, and specify an average mass flux of 5. Ansys Fluent will maintain the profile shape but adjust the values so that the resulting mass flux across the boundary is 5.

If you selected Exit Corrected Mass Flow Rate, enter the prescribed Exit Corrected Mass Flow Rate (or select your hooked UDF or profile); this corresponds to

in Equation 7–102. Then enter the ECMF Reference Temperature (

) and the ECMF Reference Gauge Pressure (

). For complete details about this method, see Exit Corrected Mass Flow Rate.

Important: Note that for axisymmetric problems:

If you provide a mass flow rate, you must specify the flow rate through the entire (

-radian) domain, not through a 1-radian slice.

If you provide a mass flux rate, you must specify the flux through a 1-radian slice of the domain.

The mass flow boundary will be pumping flow out of the domain normal to the boundary at the prescribed rate or flux. If the mass flow rate is specified, then by default, the fluxes on the boundary will be allowed to vary to preserve the flow profile out of the domain. At convergence, the total mass flow rate should match the specified value.

Important: Note that if constant mass flux is needed rather than the default variable fluxes to preserve the profiles, then you can

do so via the text command define/boundary-conditions/bc-settings/mass-flow. Answer

no when asked to preserve profile while flow leaves.

The options available depend on which radiation model is active. For details, see Defining Boundary Conditions for Radiation.

If you are modeling a discrete phase of particles, you can set the fate of particle trajectories at the mass-flow outlet. See Setting Boundary Conditions for the Discrete Phase for details.

For the Mass Flow Rate specification method, you specify the total mass flow rate, , for the outlet. For the Mass Flux or Mass Flux with Averaged Mass

Flux specification methods, you specify the mass flux,

(mass flow rate per unit area). If a total mass flow rate is specified, Ansys Fluent converts it internally to

a uniform mass flux by dividing the mass flow rate by the total outlet area:

(7–101) |

If the direct mass flux specification option is used, the mass flux can be varied over the boundary by using profile files or user-defined functions. If the average mass flux is also specified, it is used to correct the specified mass flux profile, as described previously in this section.

Once the value of at a given face has been determined, the density,

, at the face must be determined in order to find the normal velocity,

.

Boundary velocities are scaled to achieve the specified value of mass flow rate or mass flux. When the mass-flow outlet is used with the profile preserving feature, a scaling factor of the specified mass flow rate over the computed mass flow rate at the boundary is used to scale the normal face velocities at the boundary. The other velocity components will be extrapolated from the interior. Flow variables such as pressure, temperature, species, or other scalar quantities will be also extrapolated from adjacent cell centers.

The Exit Corrected Mass Flow Rate specification method adjusts the mass flow rate to the total conditions at the outlet, maintaining a constant exit corrected mass flow rate. This boundary option is mainly intended for turbomachinery applications. This method allows you to sweep through the complete machine operational range, including machine operating points from choked flow to stall conditions. When using the Exit Corrected Mass Flow Rate specification method, the boundary operates like a mass-flow outlet on the left side of the speedline curve away from the best efficiency point, and more like a pressure outlet boundary to the right of the best efficiency point all the way beyond the choke point. This method allows you to specify the equivalent mass flow, based on similar criteria, corrected to a specified reference temperature and pressure.

For compressible flows, the exit corrected mass flow rate () is calculated as:

(7–102) |

where and

are mass-averaged values of total pressure and temperature in the absolute frame at the outlet.

and

are the reference conditions, which are constants in the equation. It should be noted that the numerical

behavior of the boundary condition is not affected by the choice of reference conditions; rather, the reference conditions

simply provide a dimensional meaning to the otherwise non-dimensional mass flow rate. It is typical to specify these reference

conditions to be the same as the inflow total pressure and temperature.

In order to maintain a constant exit corrected mass flow, you can observe that the resulting mass flow rate must be proportional to the exit total pressure and inversely proportional to the square root of the exit total temperature (or equivalently, inversely proportional to the stagnation speed of sound). This allows the boundary condition to adapt dynamically to varying operating conditions, while remaining stable as the flow develops from the initial guess.

Note that the Exit Corrected Mass Flow Rate specification method is only available for ideal gas and real gas materials.

You can obtain an initial exit corrected mass flow rate value () from a previously converged case that uses standard inlet and outlet boundaries (for example, a pressure

inlet and a pressure outlet). Use the converged solution to obtain the mass-flow-averaged value of

and

at the outlet boundary, as well as the mass flow rate (

). These values can then be applied to Equation 7–102 along with

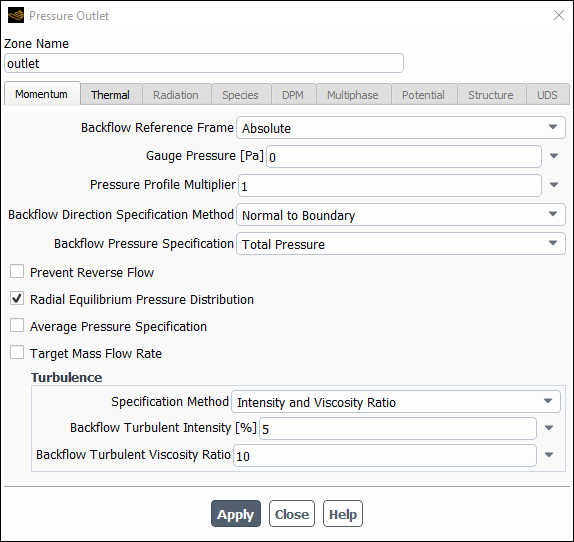

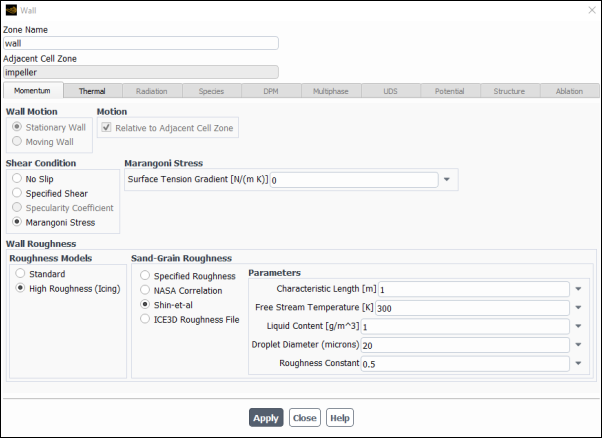

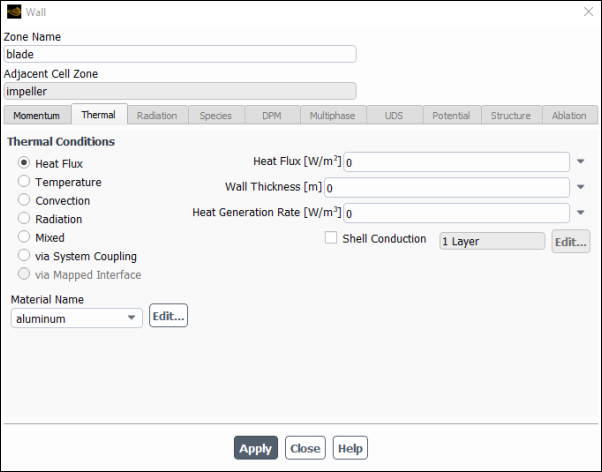

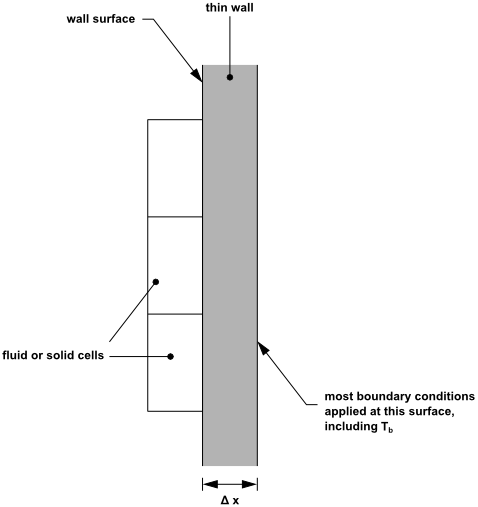

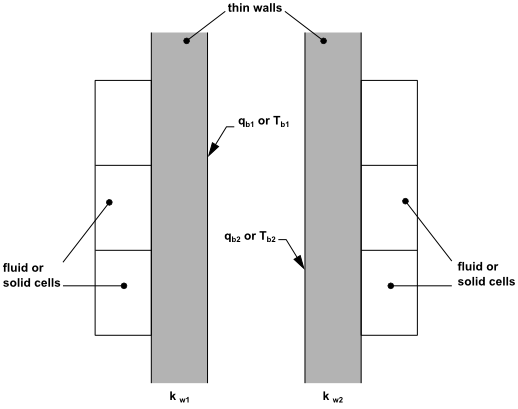

and