The steps for setting up a dynamic mesh problem are listed below. (Note that this procedure includes only those steps necessary for the dynamic mesh model itself; you must set up other models, cell zone conditions, boundary conditions, and so on, as usual.)

Enable the appropriate option for modeling transient or steady flow in the General Task Page.

Setup →

General

General

If your problem involves a steady flow, see Steady-State Dynamic Mesh Applications for important considerations.

Set cell zone conditions and boundary conditions as required in the Cell Zone Conditions Task Page and Boundary Conditions Task Page.

Setup →

Cell Zone

Conditions

Cell Zone

Conditions

Setup →

Boundary

Conditions

Boundary

Conditions

See Cell Zone and Boundary Conditions for information about inputting conditions. The correct wall velocity is set up automatically when a dynamic zone is created for a wall zone and the motion attributes are specified, so you will not specify wall motion in the Wall dialog box. If you create a moving dynamic cell zone, then all wall boundaries adjacent to that cell zone will, by default, impose the correct (moving) boundary conditions, and it is not necessary to declare these wall zones as dynamic zones. Note that if a wall boundary mesh is moving because it belongs to an adjacent moving dynamic cell zone, but the physical boundary conditions are such that the wall is actually not moving, then you will have to declare this boundary as a dynamic zone and specify that the mesh motion is not included in the boundary conditions (see Specifying the Motion of Dynamic Zones).

Enable the dynamic mesh model, and specify related parameters in the Dynamic Mesh Task Page.

Setup →

Dynamic Mesh →

Dynamic Mesh →  Dynamic Mesh

Dynamic Mesh

See Setting Dynamic Mesh Modeling Parameters for details.

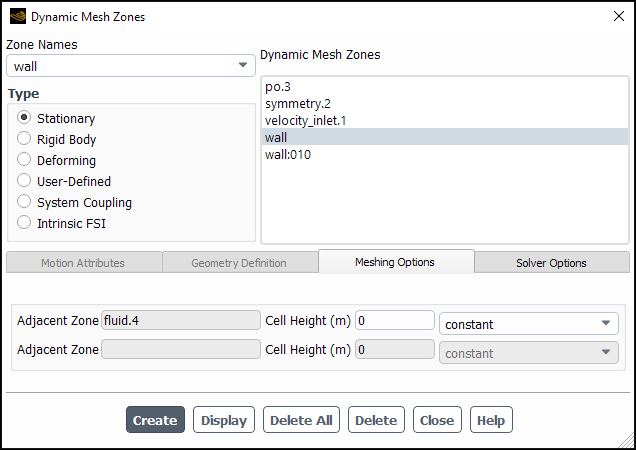

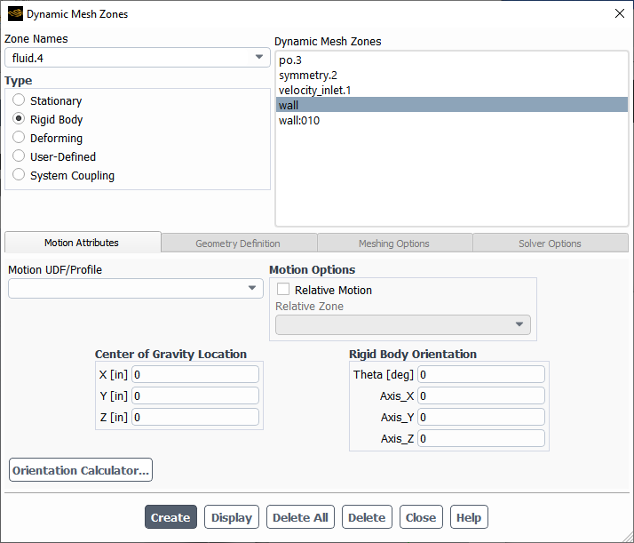

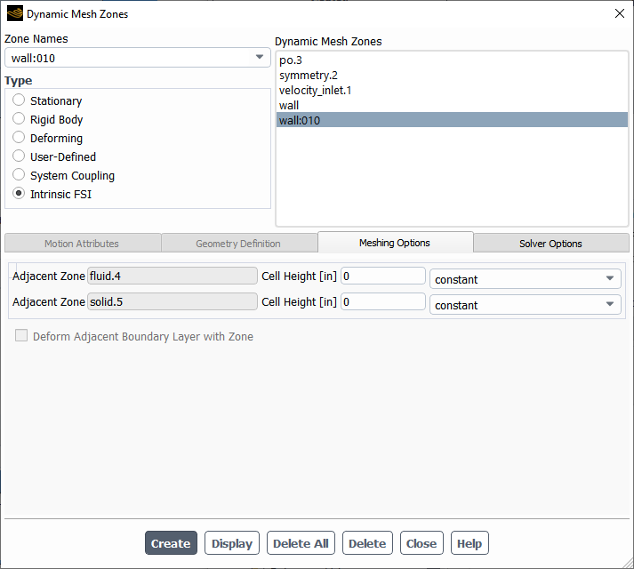

Create the dynamic zones for your model, using the Dynamic Mesh Zones Dialog Box.

Setup →

Dynamic Mesh → Create/Edit...

Dynamic Mesh → Create/Edit...

See Specifying the Motion of Dynamic Zones for details.

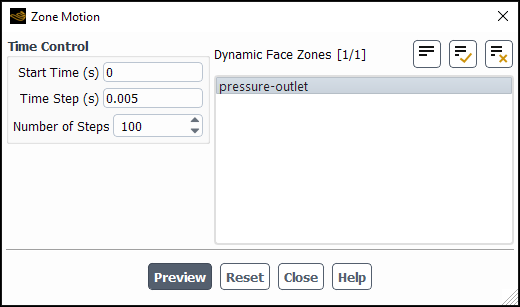

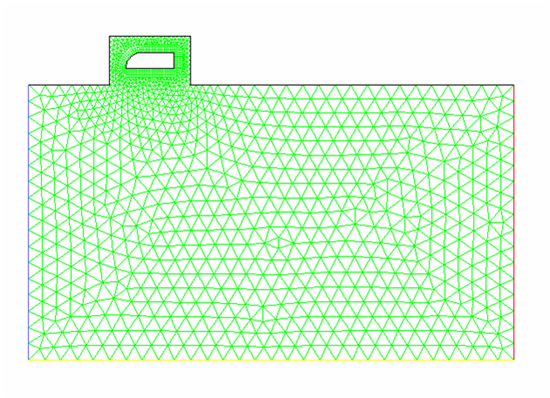

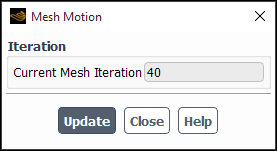

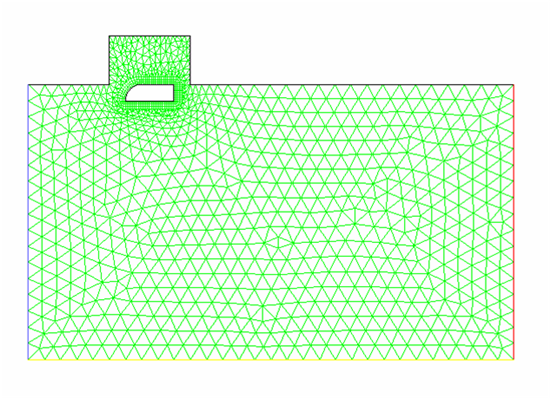

You can display the motion of the moving zones with prescribed motion to verify the simulation setup.

Setup →

Dynamic Mesh → Display Zone Motion...

Dynamic Mesh → Display Zone Motion...

See Previewing the Dynamic Mesh for details.

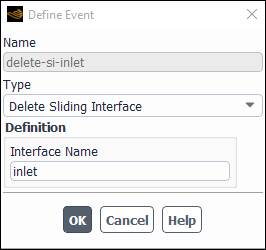

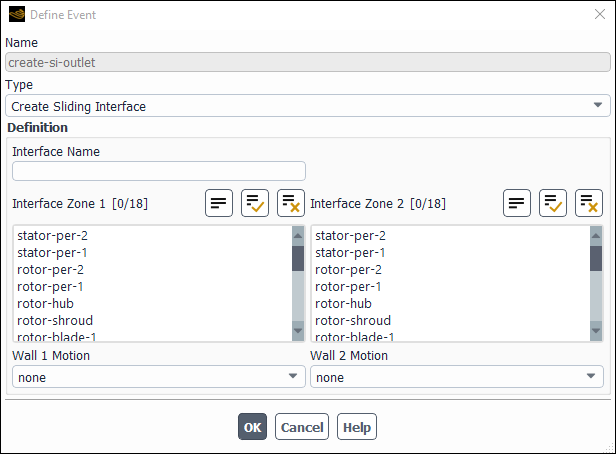

If it is a transient simulation, define the events that will occur during the calculation.

Setup →

Dynamic Mesh → Events...

Dynamic Mesh → Events...

See Defining Dynamic Mesh Events for details.

Save the case and data.

File → Write → Case & Data...

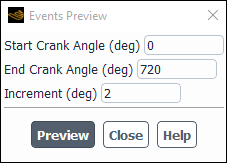

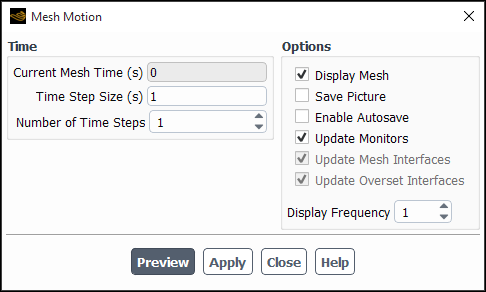

Preview your dynamic mesh setup (when the motion is a prescribed motion). See Steady-State Dynamic Mesh Applications for previewing your steady-state dynamic mesh motion and refer to Previewing the Dynamic Mesh for details.

Setup →

Dynamic Mesh → Preview Mesh Motion...

Dynamic Mesh → Preview Mesh Motion...

Specify the pressure-velocity coupling scheme. For transient flow calculations, the PISO algorithm is recommended, as it is the most efficient for such cases (see PISO for details).

Use the automatic saving feature to specify the file name and frequency with which case and data files should be saved during the solution process.

Solution → Calculation Activities → Autosave (Every) → Edit...

See Automatic Saving of Case and Data Files for details about the use of this feature. This provides a convenient way for you to save results at successive time steps for later postprocessing.

Important: You must save a case file each time you save a data file because the mesh position is stored in the case file. Since the mesh position changes with each time step, reading data for a given time step will require the case file at that time step so that the mesh will be in the proper position. You should also save your initial case file so that you can easily return to the mesh’s original position to restart the solution if desired.

(optional) If you want to create a graphical animation of the mesh over time during the solution procedure, you can use the Calculation Activities Task Page to set up the graphical displays that you want to use in the animation. See Animating the Solution for details.

(optional) For transient cases, after you have initialized or run the calculation you can use the Moving Mesh Courant Number field variable (in the Velocity... category) to guide your solution. This field variable is a non-dimensional value that indicates the number of cells that might be swept in a single time step due to a mesh motion.

For additional information, see the following sections:

- 13.6.1. Setting Dynamic Mesh Modeling Parameters

- 13.6.2. Dynamic Mesh Update Methods

- 13.6.3. Feature Detection

- 13.6.4. In-Cylinder Settings

- 13.6.5. Six DOF Solver Settings

- 13.6.6. Implicit Update Settings

- 13.6.7. Contact Detection Settings

- 13.6.8. Defining Dynamic Mesh Events

- 13.6.9. Specifying the Motion of Dynamic Zones

- 13.6.10. Previewing the Dynamic Mesh

- 13.6.11. Steady-State Dynamic Mesh Applications

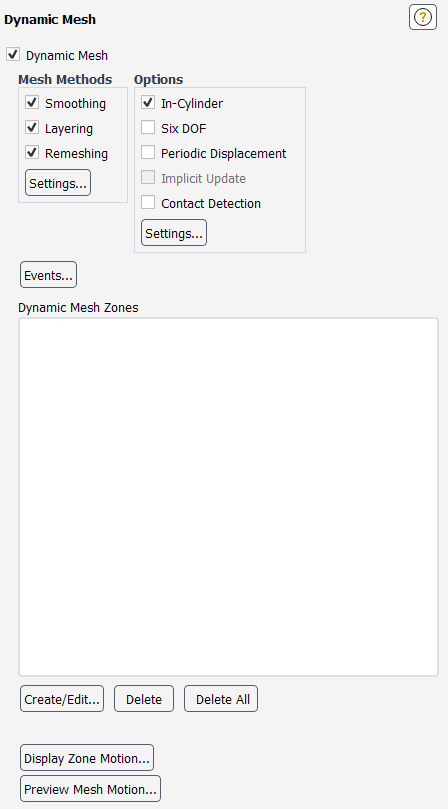

To enable the dynamic mesh model, enable Dynamic Mesh in the Dynamic Mesh Task Page (Figure 13.13: The Dynamic Mesh Task Page).

Setup →

![]() Dynamic

Mesh →

Dynamic

Mesh → ![]() Dynamic Mesh

Dynamic Mesh

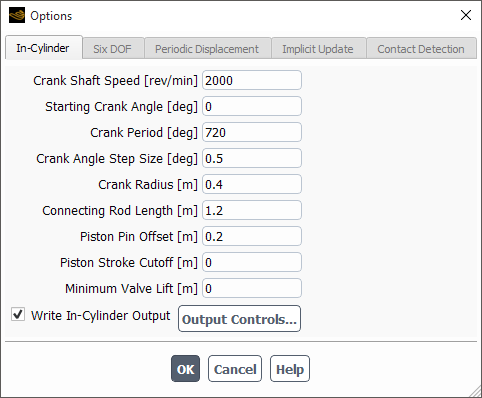

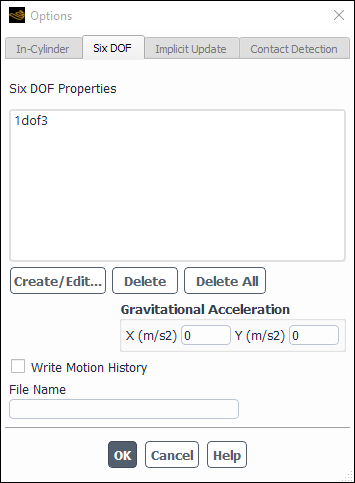

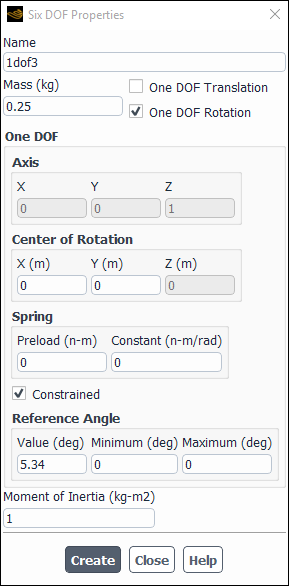

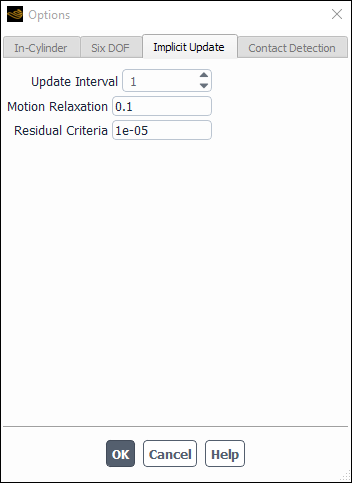

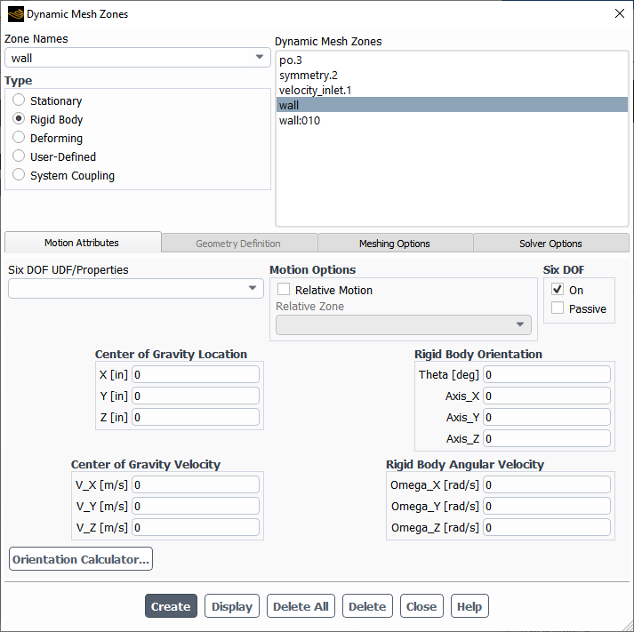

Then, enable the appropriate options in the Options group box. If you are modeling in-cylinder motion, enable the In-Cylinder option. If you are going to use the six degrees of freedom solver, then enable the Six DOF option. If you want to specify periodic displacement based on a mode shape for blade flutter analysis, select Periodic Displacement. If you want to have the dynamic mesh updated during a time step (as opposed to just at the beginning of a time step), then enable the Implicit Update option. More information about these options and the related settings can be found in In-Cylinder Settings, Six DOF Solver Settings, Defining the Periodic Displacement of the Blades, and Implicit Update Settings, respectively.

Next, you must select the appropriate mesh update methods in the Mesh Methods group box, and set the associated parameters, if relevant. See Dynamic Mesh Update Methods for details.

Three groups of mesh motion methods are available in Ansys Fluent to update the volume mesh in the deforming regions subject to the motion defined at the boundaries:

Note: Smoothing, layering, and/or remeshing are incompatible with mesh adaption.

Details on how to set up the various dynamic mesh update methods are provided in the sections that follow.

When smoothing is used to adjust the mesh of a zone with a moving and/or deforming boundary, the interior nodes of the mesh move, but the number of nodes and their connectivity does not change. In this way, the interior nodes “absorb” the movement of the boundary. To enable smoothing, perform the following steps:

Enable the Smoothing option in the Mesh Methods group box of the Dynamic Mesh Task Page.

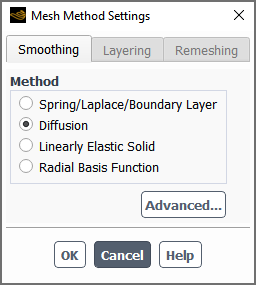

Click the button to open the Mesh Method Settings dialog box.

If you want diffusion-based smoothing, select Diffusion from the Method list. Then click the button and define the settings in the Mesh Smoothing Parameters dialog box. For details, see Diffusion-Based Smoothing.

If you want spring-based smoothing, select Spring/Laplace/Boundary Layer from the Method list. Then click the button and define the settings in the Mesh Smoothing Parameters dialog box. For details, see Spring-Based Smoothing.

If you want smoothing using the linearly elastic solid method, select Linearly Elastic Solid from the Method list. Then click the button and define the settings in the Mesh Smoothing Parameters dialog box. For details, see Linearly Elastic Solid Based Smoothing Method.

If you want smoothing that is based on a radial basis function interpolation, select Radial Basis Function from the Method list. Then click the button and define the settings in the Mesh Smoothing Parameters dialog box. For details, see Radial Basis Function Smoothing.

If you selected Diffusion, Linearly Elastic Solid, or Radial Basis Function smoothing and the simulation involves periodic or quasi-periodic motion, you can specify that the smoothing uses a reference position. This option may improve the mesh quality consistency from cycle to cycle—see Smoothing from a Reference Position for details.

If you plan to apply the 2.5D remeshing method (as described in 2.5D Surface Remeshing Method), perform the following steps to set up Laplacian smoothing (as described in Laplacian Smoothing Method).

Select Spring/Laplace/Boundary Layer from the Method list

Click the button and define only the Laplace Node Relaxation and the Maximum Number of Iterations in the Mesh Smoothing Parameters group box (the other settings are not relevant).

If you plan to apply the boundary layer smoothing method (as described in Boundary Layer Smoothing Method), select Spring/Laplace/Boundary Layer from the Method list.

For diffusion-based smoothing, the mesh motion is governed by the diffusion equation

(13–2) |

where is the mesh displacement velocity. The boundary conditions for Equation 13–2 are obtained from the user-prescribed or computed (six

DOF) boundary motion. On deforming boundaries, the boundary conditions are such that the mesh

motion is tangent to the boundary (that is, the normal velocity component vanishes). The

Laplace equation Equation 13–2 then describes how the prescribed

boundary motion diffuses into the interior of the deforming mesh.

The diffusion coefficient in Equation 13–2 can be used to control how the

boundary motion affects the interior mesh motion. A constant coefficient means that the

boundary motion diffuses uniformly throughout the mesh. With a nonuniform diffusion

coefficient, mesh nodes in regions with high diffusivity tend to move together (that is, with

less relative motion).

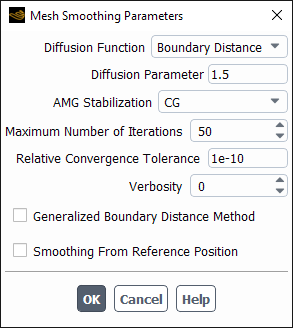

In Fluent, two different formulations for the diffusion coefficient are available for selection from the Diffusion Function

drop-down list in the Mesh Smoothing Parameters Dialog Box. The first

formulation allows you to have the diffusion coefficient be a function of the

Boundary Distance, and is of the form

(13–3) |

where is a normalized boundary distance. The second formulation allows you to have

the diffusion coefficient be a function of the Cell Volume, and is of the

form

(13–4) |

where is the normalized cell volume. In both Equation 13–3 and Equation 13–4,

is a user input parameter. See Diffusivity Based on Boundary Distance and Diffusivity Based on Cell Volume for information about defining the

diffusion coefficient.

Ansys Fluent uses different numerical methods to solve the vector Equation 13–2, depending on the element types present in the mesh. In

the absence of polyhedral elements or elements with hanging nodes (that is, meshes that have

undergone hanging node adaption and some hexcore or CutCell meshes) the equation is solved

using a finite element discretization and the displacement velocity, , is obtained directly at each mesh node. If the mesh contains polyhedral

elements or hanging nodes, the equation is discretized using Ansys Fluent’s standard finite

volume method and the cell-centered solution for the displacement velocity,

, is interpolated onto the nodes using inverse-distance-weighted averaging.

The node positions are then updated according to:

(13–5) |

The finite element discretization is generally superior, as the solution is obtained directly at the nodes and no interpolation step is necessary. The finite volume method can be enforced for meshes of all element types by executing the TUI command:

/define/dynamic-mesh/controls/smoothing-parameters/diffusion-fvm?

yes

With finite element discretization, you can specify the solution method used by the linear solver for the diffusion-based smoothing calculations. By default, the CG (conjugate gradient) method is selected from the AMG Stabilization drop-down list. This method should be faster in this context than the other available methods, as it takes advantage of the symmetry of the matrix used in the linear systems of equations of finite-element-based mesh smoothing. If divergence is detected with CG, then the generalized minimal residual (GMRES) method will be used for an iteration as a fallback, and you will be informed in the console that a finite-element-based mesh smoothing coupled equation is being stabilized to enhance linear solver robustness. In rare cases, the CG method may result in the generation of negative volume cells; you may be able to avoid this by increasing the Maximum Number of Iterations from the default of 50 to a value in the range of 200–500.

If the CG method continues to generate negative volume cells with a higher number of iterations or if you repeatedly see console messages that say the GMRES fallback is being used, it is recommended that you select GMRES from the AMG Stabilization drop-down list. Note that the GMRES method is more robust than the CG method, especially for high-aspect-ratio meshes; but it is also more demanding in terms of memory usage and solver time.

Note that this drop-down list also allows you to select the BCGSTAB (bi-conjugate gradient stabilized) method; like the CG method, BCGSTAB falls back to the GMRES method for an iteration when divergence is detected.

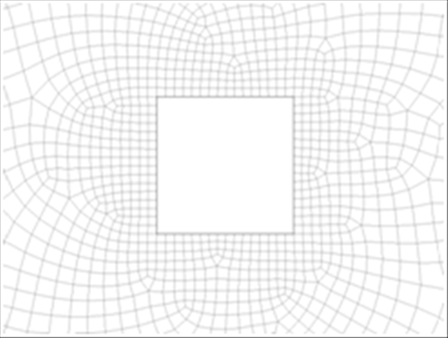

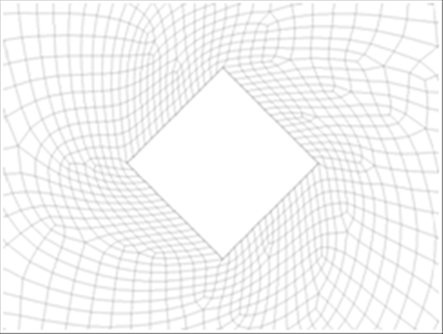

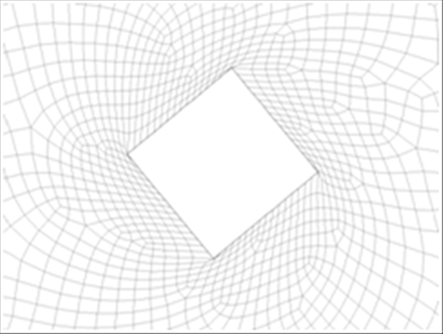

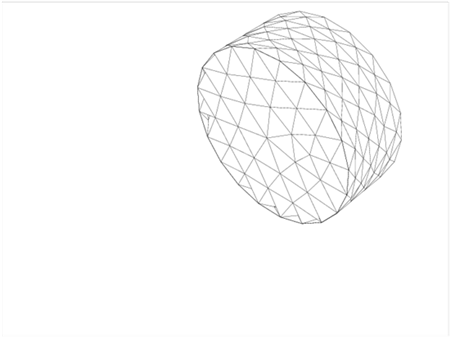

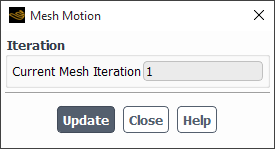

Computationally, solving a PDE for mesh smoothing is generally more costly than spring-based smoothing. But it tends to produce better quality meshes than spring-based smoothing and often allows larger boundary deformations before breaking down. Figure 13.16: The Initial Mesh and Figure 13.17: Valid Mesh After 45 Degree Rotation Using Diffusion-Based Smoothing show a mesh before and after rotating the boundary by 45 degrees, using diffusion-based smoothing. With spring-based smoothing, the same mesh shows degenerated cells after a rotation of 40 degrees (Figure 13.18: Degenerated Mesh After 40 Degree Rotation Using Spring-Based Smoothing). (Note that radial basis function smoothing handles rotation better than both diffusion- and spring-based smoothing.)

It should be noted that with diffusion-based smoothing the interior mesh motion is

governed by the solution to Equation 13–2 and the prescribed

boundary motion, and not by mesh irregularities. Poor quality elements or mesh defects are not

smoothed out by this method, but rather move together with the pre-computed (at the begin of

each mesh update) displacement velocity .

It is also worth noting that the nature of the diffusion equation is such that the

resulting solution (that is, the displacement velocity ) depends on the dimensionality of the problem and the type of boundary

motion prescribed. To illustrate the impact of the type of boundary motion, consider the goal

of boundary-distance-based diffusion (Equation 13–3): to control

which parts of the mesh absorb the boundary motion, so that you can preserve the mesh in the

vicinity of the moving boundary (at the expense of the interior of the mesh). For more

translational (piston-type) boundary motions, you can preserve a reasonably

“thick” region of the mesh adjacent to the boundary (that is, multiple layers of

cells); for rotational boundary motions, the rate of decay for the solution as you move away

from the boundary is such that it can be difficult to preserve even a “thin”

region. For this reason, mesh smoothing can handle translational boundary motions generally

much better than rotational motions.

Although it should in most cases not be necessary, the accuracy of the solution to the diffusion equation governing the mesh motion can be controlled by defining the Maximum Number of Iterations and the Relative Convergence Tolerance.

You can enable printing of smoothing residuals in the console by entering 1 for the Verbosity.

For simulations with periodic or quasi-periodic motion, you can improve the mesh quality consistency by specifying that the diffusion-based smoothing uses a reference position, as described in Smoothing from a Reference Position.

Using boundary-distance-based diffusion (Equation 13–3) allows you to control how the boundary motion diffuses into the interior of the domain as a function of boundary distance. Decreasing the diffusivity away from the moving boundary causes those regions to absorb more of the mesh motion, and better preserves the mesh quality near the moving boundary. This is particularly helpful for a moving boundary that has pronounced geometrical features (such as sharp corners) along with a prescribed motion that is predominantly rotational.

You can manipulate the diffusion coefficient (in Equation 13–3) primarily by adjusting the

Diffusion Parameter in the Mesh Smoothing Parameters Dialog Box (

). A range of 0 to 2 has been shown to be of practical use. A value of 0

(the default value) specifies that

and yields a uniform diffusion of the boundary motion throughout the mesh.

Higher values of

preserve larger regions of the mesh near the moving boundary, and cause the

regions away from the moving boundary to absorb more of the motion.

The following two figures illustrate the effect of the Diffusion

Parameter on the resulting mesh for a translational (piston-type) boundary motion,

when the diffusivity is based on the boundary distance. In this example, an initially

uniformly meshed square domain is deformed by moving the left boundary to the right.

For rotational boundary motions, a value of 1.5 for the Diffusion

Parameter is recommended as a good starting point.

Two different methods are available for the evaluation of the boundary distance

if boundary-distance-based diffusion is used. By default, Fluent uses the

“standard” boundary distance in Equation 13–3,

which is the normalized distance to the nearest wall boundary; note that none of the other

boundary types (for example, inlets, outlets, symmetry, and periodic boundaries) are

considered. This method is the same as that which is used to evaluate the boundary distance

for turbulence models. An example of this method is shown in Figure 13.20: Effect of Diffusion Parameter of 1 on Interior Node Motion, where only the left and right boundaries are walls.

You have the option of enabling the Generalized Boundary Distance Method

option instead, so that

is the normalized distance to the nearest boundary that is not declared as

deforming, regardless of type. Both methods use the largest distance found in all deforming

cell zones to normalize the value.

If the generalized boundary distance is used, an additional scalar equation for the

boundary distance will be solved as part of the solution of Equation 13–2.

Using cell-volume-based diffusion (Equation 13–4) allows you to control how the boundary motion diffuses into the interior of the domain as a function of cell size. Decreasing the diffusivity in larger cells causes those cells to absorb more of mesh motion and therefore better preserves the cell quality of smaller cells.

You can manipulate the diffusion coefficient (in Equation 13–3) by adjusting the

Diffusion Parameter in the Mesh Smoothing Parameters Dialog Box (

). A value of 0 (the default value) specifies that

and yields a uniform diffusion of the boundary motion throughout the mesh.

Higher values of

result in larger cells absorbing more of the motion than smaller

cells.

Note that the cell volume used in Equation 13–4 is the local cell volume, normalized by the average cell volume of all deforming cell zones.

Diffusion-based mesh smoothing can be used to update any cell zone whose boundaries are moving or deforming. It is available for all element types, though it is not as robust for polyhedral elements as radial basis function smoothing.

Diffusion-based smoothing is computationally more expensive than spring-based smoothing, but likely results in better mesh quality (especially for non-tetrahedral / non-triangular cell zones, and for polyhedral cells in particular) and generally allows for larger boundary deformations before breaking down.

Similar to spring-based smoothing, diffusion-based mesh smoothing can handle translational boundary deformations much better than rotational motions. Rotational motions are best handled by radial basis function smoothing.

Diffusion-based smoothing is not compatible with the boundary layer smoothing method or the face region remeshing method. For more information about these methods, see Boundary Layer Smoothing Method and Face Region Remeshing Method.

Unlike the radial basis function smoothing method, the diffusion-based smoothing method is not supported when the smoothing zone contains deforming conformal periodic boundaries and/or is a solid that has a moving wall.

For spring-based smoothing, the edges between any two mesh nodes are idealized as a network of interconnected springs. The initial spacings of the edges before any boundary motion constitute the equilibrium state of the mesh. A displacement at a given boundary node will generate a force proportional to the displacement along all the springs connected to the node. Using Hook’s Law, the force on a mesh node can be written as

(13–6) |

where and

are the displacements of node

and its neighbor

,

is the number of neighboring nodes connected to node

, and

is the spring constant (or stiffness) between node

and its neighbor

. The spring constant for the edge connecting nodes

and

is defined as

(13–7) |

where is the value you enter for Spring Constant Factor in

the Mesh Smoothing Parameters Dialog Box.

At equilibrium, the net force on a node due to all the springs connected to the node must be zero. This condition results in an iterative equation such that

(13–8) |

where is the iteration number.

Since displacements are known at the boundaries (after boundary node positions have been updated), Equation 13–8 is solved using a Jacobi sweep on all interior nodes. At convergence, the positions are updated such that

(13–9) |

where and

are used to denote the positions at the next time step and the current time

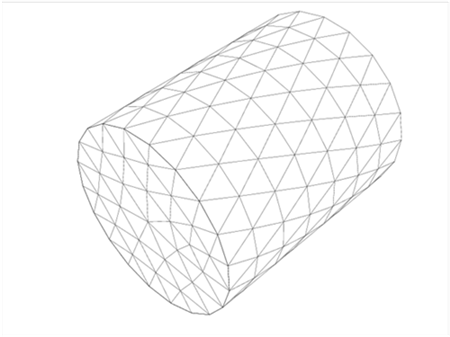

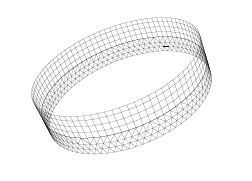

step, respectively. The spring-based smoothing is shown in Figure 13.21: Spring-Based Smoothing on Interior Nodes: Start and Figure 13.22: Spring-Based Smoothing on Interior Nodes: End for a cylindrical

cell zone where one end of the cylinder is moving.

You can control the spring stiffness by adjusting the value of the Spring Constant Factor between 0 and 1. A value of 0 indicates that there is no damping on the springs, and boundary node displacements have more influence on the motion of the interior nodes. A value of 1 imposes the default level of damping on the interior node displacements as determined by solving Equation 13–8.

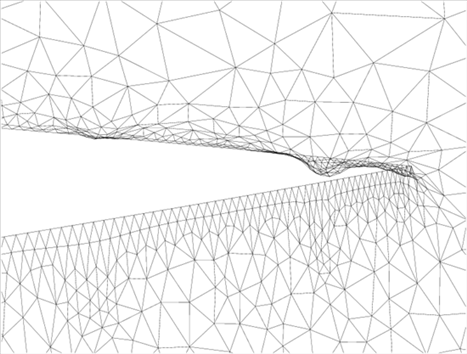

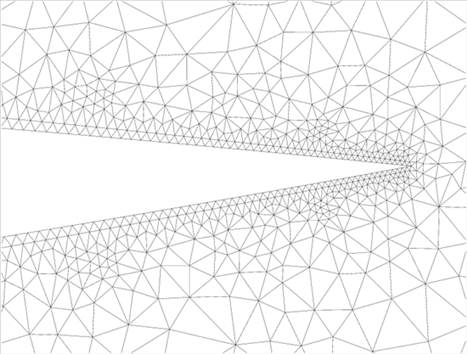

The effect of the Spring Constant Factor is illustrated in Figure 13.23: Interior Nodes Extend Beyond Boundary (Spring Constant Factor = 1) and Figure 13.24: Interior Nodes Remain Within Boundary (Spring Constant Factor = 0), which show the trailing edge of a NACA-0012 airfoil after a counter-clockwise rotation of 2.3° and the mesh is smoothed using the spring-based smoother but limited to 20 iterations. Degenerate cells (Figure 13.23: Interior Nodes Extend Beyond Boundary (Spring Constant Factor = 1)) are created with the default value of 1 for the Spring Constant Factor, as the interior nodes extend beyond the moving boundary. However, the original mesh distribution (Figure 13.24: Interior Nodes Remain Within Boundary (Spring Constant Factor = 0)) is recovered if the Spring Constant Factor is set to 0 (that is, no damping on the displacement of interior nodes near the airfoil surface).

You can control the solution of Equation 13–8 using the values of Convergence Tolerance and Maximum Number of Iterations. Ansys Fluent solves Equation 13–8 iteratively during each time step until one of the following criteria is met:

You can use the spring-based smoothing method to update any cell or face zone whose boundary is moving or deforming.

For non-tetrahedral cell zones (non-triangular in 2D), the spring-based method can be used when the following conditions are met:

The boundary of the cell zone moves predominantly in one direction (that is, no excessive anisotropic stretching or compression of the cell zone).

The motion is predominantly normal to the boundary zone.

If these conditions are not met, the resulting cells may have high skewness values, since not all possible combinations of node pairs in non-tetrahedral cells (or non-triangular in 2D) are idealized as springs. Polyhedral cells are particularly likely to become highly skewed with spring-based smoothing (regardless of whether the previous conditions are met), and so the radial basis function smoothing method is generally recommended for polyhedra (see Radial Basis Function Smoothing).

By default, spring-based smoothing is enabled for all cell zones. This is reflected in the Mesh Smoothing Parameters Dialog Box, where All is selected from the Elements list. If you want to disable spring-based smoothing for cell zones that are not entirely composed of either tetrahedral or triangular cells, you can do that by selecting Tet in Tet Zones in 3D (or Tri in Tri Zones in 2D).

If you have mixed element zones and you do not want spring-based smoothing on all element types, you can enable spring-based smoothing on only the tetrahedral or triangular cells by selecting Tet in Mixed Zones in 3D (or Tri in Mixed Zones in 2D). Selection of smoothing elements in the Mesh Smoothing Parameters Dialog Box applies by default to all cell zones that undergo spring-based smoothing. In order to have more precise control, it is possible to overwrite this global selection on individual dynamic cell zones (see Deforming Motion). This gives, for example, the flexibility to suppress smoothing in zones where dynamic layering (see Dynamic Layering) is used and allows at the same time smoothing of non-simplex (that is not tetrahedral or triangular) elements in other zones.

Unlike the radial basis function smoothing method, the spring-based smoothing method is not supported when the smoothing zone contains deforming conformal periodic boundaries and/or is a solid that has a moving wall.

With mesh smoothing based on the linearly elastic solid model, the mesh motion is governed by the following set of equations.

(13–11) |

where is the stress tensor,

is the strain tensor, and

is the mesh displacement. For the solution of Equation 13–11 only the ratio between the shear modulus,

, and Lamé’s first parameter,

, matters. This ratio is parameterized through Poisson’s ratio

(

):

(13–12) |

You define this property through the Poisson's Ratio field in the Mesh Smoothing Parameters Dialog Box. Note that the linearly elastic solid mesh smoothing model supports constant material properties only. The permissible range for Poisson's Ratio is between -1.0 and 0.5.

The boundary conditions for Equation 13–11 are obtained from the user-prescribed or computed (in the case of six DOF motion) boundary deformations. These imposed deformations are transferred into the interior of the deforming mesh as if the mesh was a linearly elastic solid with the given material properties. On deforming boundaries you can either specify a geometry along which the mesh can slide, or leave the geometry unspecified. If a geometry is specified for the deforming boundary, then the boundary conditions are such that the deformation normal to the boundary vanishes and the stress tangential to the boundary is zero. If the geometry of the deforming boundary is unspecified, then the deforming boundary can also deform in the normal direction and the boundary conditions are such that the traction is zero in all directions. See Deforming Motion for details of how to specify geometry on deforming zones.

The linear system in Equation 13–11 is solved using a finite element discretization and the mesh displacements for the interior and deforming boundary nodes are obtained directly at the nodes. The accuracy to which the linear system is solved can be controlled by the Maximum Number of Iterations and the Relative Convergence Tolerance.

You can specify the solution method used by the linear solver for the linearly elastic solid mesh smoothing calculations. By default, the CG (conjugate gradient) method is selected from the AMG Stabilization drop-down list. This method should be faster in this context than the other available methods, as it takes advantage of the symmetry of the matrix used in the linear systems of equations of finite-element-based mesh smoothing. If divergence is detected with CG, then the generalized minimal residual (GMRES) method will be used for an iteration as a fallback, and you will be informed in the console that a finite-element-based mesh smoothing coupled equation is being stabilized to enhance linear solver robustness. In rare cases, the CG method may result in the generation of negative volume cells; you may be able to avoid this by increasing the Maximum Number of Iterations from the default of 50 to a value in the range of 200–500.

If the CG method continues to generate negative volume cells with a higher number of inner iterations or if you repeatedly see console messages that say the GMRES fallback is being used, it is recommended that you select GMRES from the AMG Stabilization drop-down list. Note that the GMRES method is more robust than the CG method, especially for high-aspect-ratio meshes; but it is also more demanding in terms of memory usage and solver time.

Note that this drop-down list also allows you to select the BCGSTAB (bi-conjugate gradient stabilized) method; like the CG method, BCGSTAB falls back to the GMRES method for an iteration when divergence is detected.

You can enable printing of smoothing residuals in the console by entering 1 for the Verbosity.

For simulations with periodic or quasi-periodic motion, you can improve the mesh quality consistency by specifying that the linearly elastic solid mesh smoothing uses a reference position, as described in Smoothing from a Reference Position.

Most of the properties and limitations discussed for diffusion-based smoothing (Applicability of the Diffusion-Based Smoothing Method) also apply to the linearly elastic solid model, particularly the mesh quality degradation for rotational motions. The linearly elastic solid model is computationally more expensive than diffusion-based smoothing, but for some meshes and mesh motions preserves the mesh quality better.

The current implementation with constant material properties can be a limitation compared with diffusion-based smoothing with non-uniform diffusivity. In cases with rotational boundary motion and sharp corners it may be advantageous to use radial basis function smoothing, or perhaps diffusion-based smoothing with boundary-distance-dependent diffusivity.

The linearly elastic solid smoothing method provides you the option to leave the geometry of deforming face zones unspecified. This option is not available for any other smoothing method except for the radial basis function method.

The linearly elastic solid smoothing method supports triangular and quadrilateral elements in 2D and tetrahedral, hexahedral, wedge, and pyramid cells in 3D. It cannot be applied if the deforming cell zone contains polyhedral cells or hanging nodes. In such cases radial basis function smoothing is recommended.

Linearly elastic solid smoothing is not compatible with the boundary layer smoothing method or the face region remeshing method. For more information about these methods, see Boundary Layer Smoothing Method and Face Region Remeshing Method.

Unlike the radial basis function smoothing method, the linearly elastic solid smoothing method is not supported when the smoothing zone contains deforming conformal periodic boundaries and/or is a solid that has a moving wall.

When the smoothing is based on a radial basis function interpolation, Fluent solves for a displacement field that satisfies the displacements at boundaries with prescribed motion, and then interpolates the displacements onto all other nodes in the interior and at the deforming boundaries. As with the other available smoothing methods, deforming boundaries are boundaries where the nodes are allowed to slide tangentially.

Radial basis function smoothing has the following advantages:

Compared to the other available smoothing methods, it is particularly well suited for motions that undergo rotation. On average, more rotational motion can be absorbed by the mesh with radial basis function smoothing before the mesh quality degenerates.

Unlike linearly elastic solid based smoothing, it is available for adapted meshes with hanging nodes or polyhedra elements.

Unlike diffusion smoothing, it is robust for polyhedral elements.

It is the only smoothing method that is supported when:

the smoothing zone contains deforming conformal periodic boundaries.

the smoothing zone is a solid that has a moving wall, as may be the case in a simulation that models ablation or erosion / accretion (see Thermal Conditions for Two-Sided Walls and Particle Erosion Coupled with Dynamic Meshes, respectively). Note that the ablation or erosion / accretion must be set up on the fluid side of the coupled wall.

On deforming boundaries, you can either specify a geometry (such as a plane, cylinder, and so on) along which the mesh can slide, or leave the geometry unspecified so that the nodes are allowed to move in any direction. See Deforming Motion for details of how to define the geometry for deforming zones. The ability to leave the geometry of deforming face zones unspecified is not available for any other smoothing method except for the radial basis function smoothing method and the linearly elastic solid smoothing method. Note that if you have a non-conformal interface where both of the interface boundaries are defined as deforming dynamic zones with unspecified geometry, then Fluent will ensure that the two interface zones stay connected (by projecting one of the interface zones onto the other); such behavior is only supported with radial basis function smoothing, and then only if the same cell zone is on either side of the non-conformal interface.

Advanced settings are available for radial basis function smoothing in the Mesh Smoothing Parameters Dialog Box. The accuracy to which the displacement field is solved can be controlled by the Relative Convergence Tolerance: if the smoothing produces negative volume cells, you can decrease this value to try to address the problem; if the solution is running well, you can increase the value to speed up the calculation. You can also set the Verbosity to 1 if you want to print the absolute tolerance computed (based on your specified relative tolerance) in the console during the calculation. If you want to limit the amount of the domain that is smoothed to only those cells that are close to the moving boundary zone(s), you can enable the Local Smoothing option (for details, see Local Smoothing with the Radial Basis Function Smoothing Method). Finally, you can specify that the smoothing uses a reference position (as described in Smoothing from a Reference Position), which can improve mesh quality consistency when performing many cycles of periodic or quasi-periodic motion for stationary or moving meshes.

If you want to smooth the entire mesh but would like to take advantage of the boundary layer smoothing that is done as part of the Local Smoothing option (and hence retain the shape of the boundary layers as much as possible), you can make sure that the Local Smoothing option is disabled and use the following text command:

define → dynamic →

controls → smoothing-parameters

→ smooth-boundary-layers-with-adjacent-zone?

Note the following limitations:

The performance of radial basis function smoothing does not scale as well as the other smoothing methods when running distributed memory on a cluster.

Radial basis function smoothing is not compatible with the boundary layer smoothing method. For more information about this method, see Boundary Layer Smoothing Method.

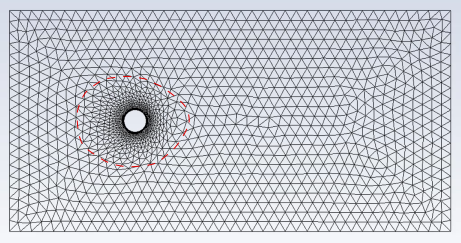

As mentioned in the previous section, you can enable the Local Smoothing option in the Mesh Smoothing Parameters Dialog Box when using the radial basis function smoothing method, so that only the portion of the mesh adjacent to the moving boundary zone is smoothed. This ensures that the mesh away from the moving boundary remains undisturbed by the smoothing, and decreases the computational time required for smoothing. The following figure provides an example of such local smoothing: the circular boundary zone is moving to the right, and only those cells within the red dotted line are smoothed, while the rest of the domain is unaffected.

Note: Depending on the amplitude of motion, it might be necessary to enable remeshing along with the local smoothing, as the motion is now absorbed in a smaller region. For details, see Remeshing.

If there are boundary layers adjacent to the moving zone, they are smoothed before and independently of the local smoothing region, ensuring that they retain their shape as much as possible. The portion of the mesh smoothed by the local smoothing is then evaluated starting from the edge of the boundary layers. When identifying which cells are boundary layers, Fluent searches for prismatic cells (that is, hexahedral cells or wedge or polyhedral cells that have the same number of nodes on the top and bottom faces relative to the boundary normal) that are in layers adjacent to a boundary zone.

When the mesh smoothing is based on diffusion, the linearly elastic solid model, or a radial basis function interpolation, you have the option of specifying that the smoothing uses a reference position. This can be helpful when performing many cycles of periodic or quasi-periodic motion for stationary or moving meshes; for example, turbomachinery rotors with blade flutter. When you ensure that the smoothing is always done from the same reference position, the mesh quality may remain more consistent from cycle to cycle.

To use this feature, enable the Smoothing From Reference Position option in the Mesh Smoothing Parameters Dialog Box. Note this option is enabled by default during the calculation if the case includes a cell zone that has Frame Motion or Mesh Motion enabled with a nonzero rotational velocity and that is also defined as a deforming dynamic mesh zone. This option is not available if the Layering and/or Remeshing options are enabled in the Dynamic Mesh task page, or if automatic adaption criteria is activated in the Manage Adaption Criteria dialog box.

The reference position is saved the first time you perform smoothing after enabling this

option. It is recommended that you do not save your case / data files in the legacy format

(that is, with the file/cff-file? text command set to

no): the reference position is not saved in this format, and so

restarting from a .cas file will imply that a different reference

position is used after restart. This still provides the benefit of consistent quality, but the

resulting meshes might be slightly different from a continuous run. The impact of such slight

mesh changes on the solution results will be small, except for cases with a high degree of

mesh dependence; if you must use a legacy case file, it is recommended that you evaluate the

original mesh to ensure that it is suitable for the problem.

Laplacian smoothing is the most commonly used and the simplest mesh smoothing method. This method adjusts the location of each mesh vertex to the geometric center of its neighboring vertices. This method is computationally inexpensive but it does not guarantee an improvement on mesh quality, since repositioning a vertex by Laplacian smoothing can result in poor quality elements. To overcome this problem, Ansys Fluent only relocates the vertex to the geometric center of its neighboring vertices if and only if there is an improvement in the mesh quality (that is, the skewness has been improved).

This improved Laplacian smoothing can be enabled on deforming boundaries only (that is, the zone with triangular elements in 3D and zones with linear elements in 2D). The computation of the node positions works as follows:

(13–13) |

where is the averaged node position of node

at iteration

,

is the node position of neighbor node of

at iteration

, and

is the number nodes neighboring node

. The new node position

is then computed as follows:

(13–14) |

where is the Laplace node relaxation factor.

This update only happens if the maximum skewness of all faces adjacent to is improved in comparison to

.

For details on applying Laplacian smoothing to either a cell zone (with 2.5D remeshing) or a face zone, see Smoothing Methods or Deforming Motion, respectively.

The boundary layer smoothing method is used to deform the boundary layer mesh during a moving-deforming mesh simulation. For cases that apply mesh motion (either Rigid Body or User-Defined) to a face zone with adjacent boundary layers, the boundary layers can be made to deform accordingly by enabling Deform Adjacent Boundary Layer with Zone for the face zone in the Dynamic Mesh Zones Dialog Box. With boundary layer smoothing enabled, the nodal coordinates of each cell in the boundary layer zone are updated with the same displacement vector as the corresponding nodes on the underlying face zone. The boundary layer smoothing method can be applied to boundary layer zones of all mesh types (that is, wedges and hexahedra in 3D, quadrilaterals in 2D).

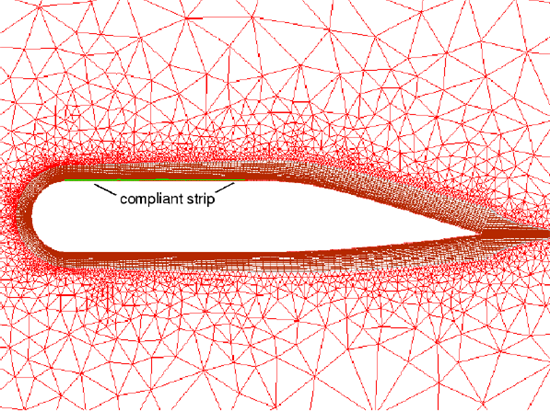

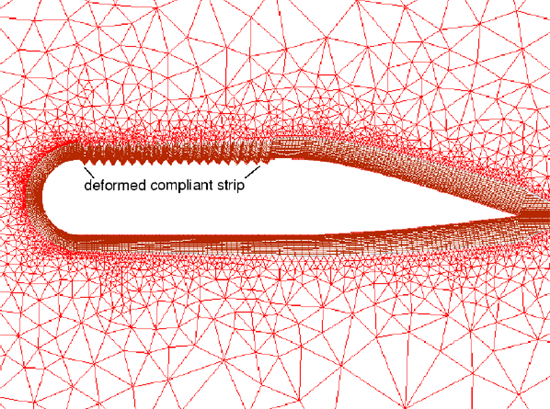

Consider the example below, where a UDF of the form

DEFINE_GRID_MOTION provides the moving-deforming mesh model with the

locations of the nodes located on the compliant strip on an idealized airfoil. The node motion

varies sinusoidally in time and space (compare Figure 13.26: The Undeformed Mesh with Figure 13.27: The Deformed Mesh).

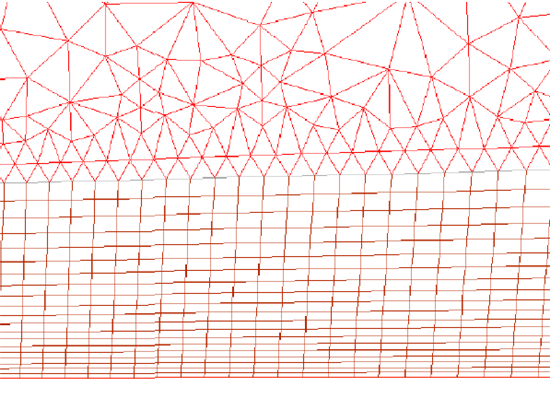

As a result of the boundary layer smoothing, the cells adjacent to the deforming wall are also deformed in order to preserve the quality of boundary layer zone. If you compare Figure 13.28: Zooming into the Undeformed Compliant Strip with Figure 13.29: Zooming into the Deformed Compliant Strip with Boundary Layer Smoothing Applied, you can see how the boundary layer cells have been deformed according to the motion of the nodes on the compliant strip.

Typically, the boundary layer smoothing method preserves the height of the boundary layer cells adjacent to the deformed face zone. However, note that this approach is primarily intended for translational motion. If the faces undergo substantial rotation, the boundary layer cells may become skewed. See Smoothing Methods and Specifying Boundary Layer Deformation Smoothing for details about enabling smoothing and defining a moving and deforming boundary layer, respectively. Note that boundary layer smoothing is compatible with spring-based smoothing only. It cannot be used with diffusion-based smoothing, linearly elastic solid smoothing, or radial basis function smoothing. Also note that the boundary layer smoothing method will work whether or not you have segregated the boundary layer elements into a separate cell zone.

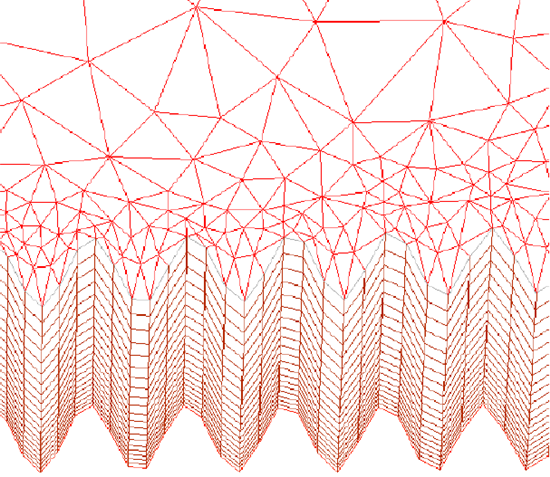

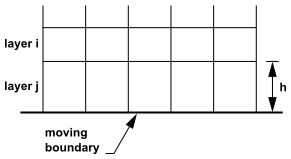

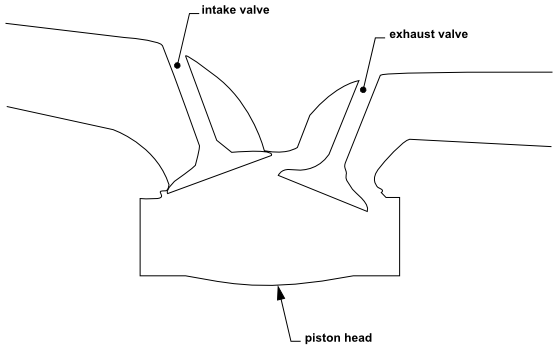

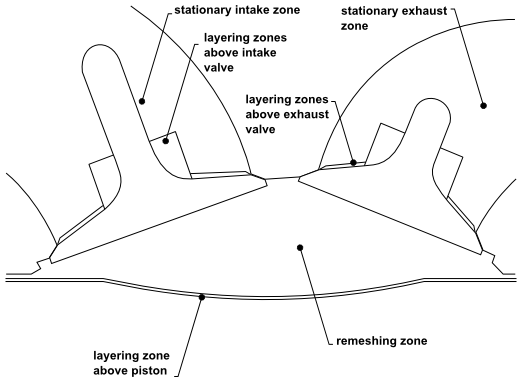

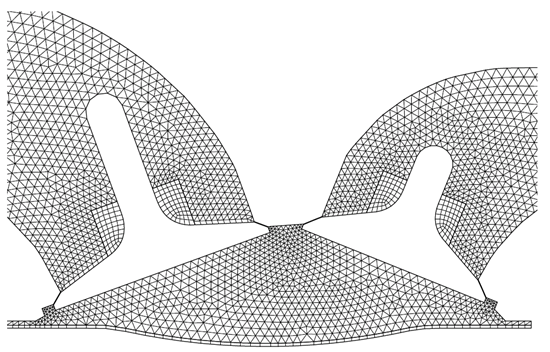

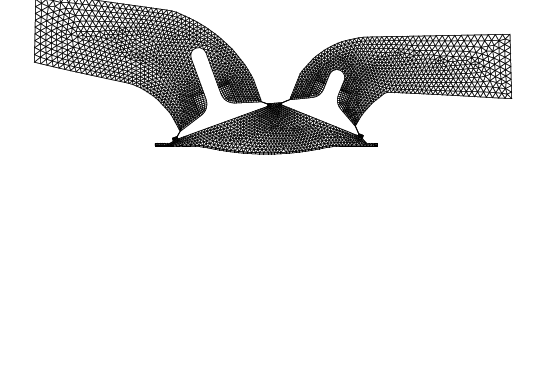

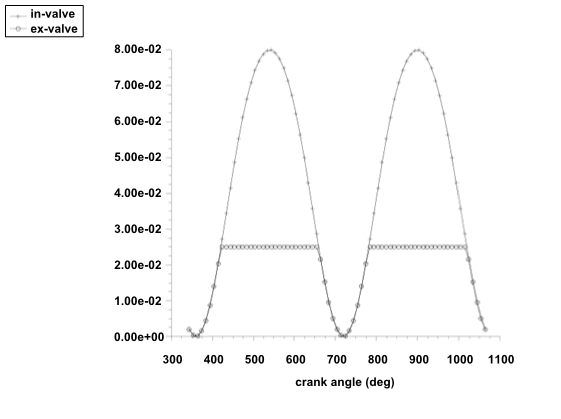

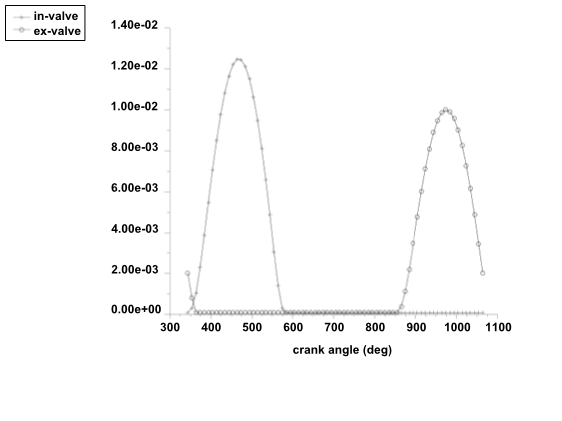

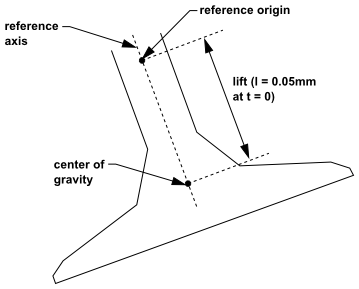

In prismatic (polyhedral, hexahedral, and/or wedge in 3D, or quadrilateral in 2D) mesh

zones, you can use dynamic layering to add or remove layers of cells adjacent to a moving

boundary, based on the height of the layer adjacent to the moving surface. The dynamic mesh

model in Ansys Fluent allows you to specify an ideal layer height on each moving boundary. The

layer of cells adjacent to the moving boundary (layer in Figure 13.30: Dynamic Layering) is split or merged

with the layer of cells next to it (layer

in Figure 13.30: Dynamic Layering) based on the height

(

) of the cells in layer

.

If the cells in layer are expanding, the cell heights are allowed to increase until

(13–15) |

where is the minimum cell height of cell layer

,

is the ideal cell height, and

is the layer split factor. Note that Ansys Fluent allows you to define

as either a constant value or a value that varies as a function of time or

crank angle. When the condition in Equation 13–15 is met,

the cells are split based on the specified layering option. This option can be height based or

ratio based.

With the height-based option, the cells are split to create a layer of cells with constant

height and a layer of cells of height

. With the ratio-based option the cells are split such that, locally, the

ratio of the new cell heights to old cell heights is exactly

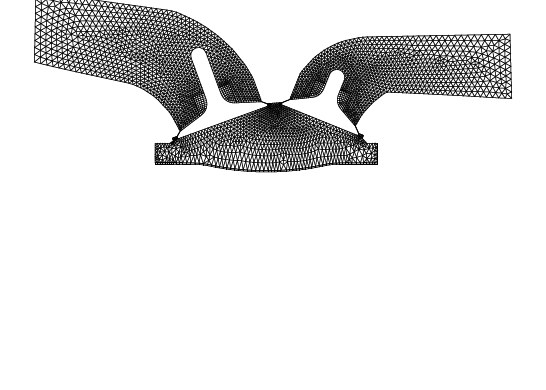

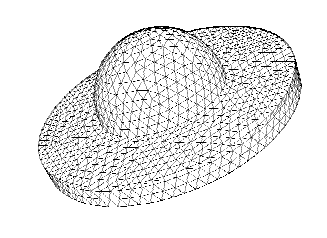

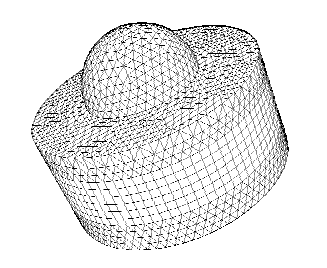

everywhere. Figure 13.31: Results of Splitting Layer with the Height-Based Option and Figure 13.32: Results of Splitting Layer with the Ratio-Based Option show the result of splitting a layer of cells above a

valve geometry using the height-based and ratio-based option.

If the cells in layer are being compressed, they can be compressed until

(13–16) |

where is the layer collapse factor. When this condition is met, the compressed

layer of cells is merged into the layer of cells above the compressed layer in Figure 13.30: Dynamic Layering; that is, the cells in layer

are merged with those in layer

.

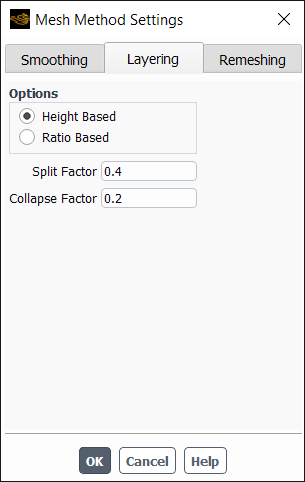

To enable dynamic layering, enable the Layering option under Mesh Methods in the Dynamic Mesh Task Page (Figure 13.33: The Layering Tab in the Mesh Method Settings Dialog Box). The layering control is specified in the Layering tab, which can be displayed by clicking .

You can control how a cell layer is split by specifying either Height Based or Ratio Based under Options. Note that for Height Based, the height of the cells in a particular new layer will be constant, but you can choose to have this height vary from layer to layer as a function of time or crank angle when you specify the Cell Height in the Dynamic Mesh Zones dialog box (see Specifying the Motion of Dynamic Zones for further details).

The Split Factor and Collapse Factor

( in Equation 13–15 and

in Equation 13–16, respectively) are

the factors that determine when a layer of prismatic cells (polyhedra, hexahedra, or wedges in

3D, or quadrilaterals in 2D) that is next to a moving boundary is split or merged with the

adjacent cell layer, respectively.

You can use the dynamic layering method to split or merge cells adjacent to any moving boundary provided the following conditions are met:

All cells adjacent to the moving face zone are prismatic and either polyhedra, hexahedra, or wedges (quadrilaterals in 2D), even though the cell zone may contain mixed cell shapes.

The cell layers must be completely bounded by one-sided face zones, except when sliding interfaces are used (see Applicability of the Face Region Remeshing Method).

Note that you cannot use the dynamic layering method in conjunction with adaption in almost all cases. For more information on the available adaption methods, see Hanging Node Adaption and Polyhedral Unstructured Mesh Adaption in the Theory Guide.

If the moving boundary is an internal zone, cells on both sides (possibly with different ideal cell layer heights) of the internal zone are considered for dynamic layering.

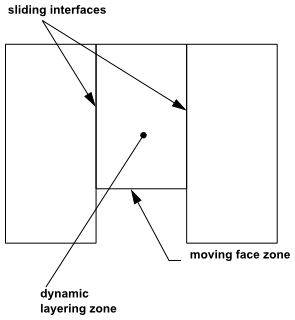

If you want to use dynamic layering on cells adjacent to a moving wall that do not span from boundary to boundary, you must separate those cells that are involved in the dynamic layering and use the sliding interfaces capability in Ansys Fluent to transition from the deforming cells to the adjacent non-deforming cells (see Figure 13.34: Use of Sliding Interfaces to Transition Between Adjacent Cell Zones and the Dynamic Layering Cell Zone). For a moving interior face, the zones must be separated such that they are either expanding or collapsing on the same side. No one zone can consist of both expanding and collapsing layers.

Figure 13.34: Use of Sliding Interfaces to Transition Between Adjacent Cell Zones and the Dynamic Layering Cell Zone

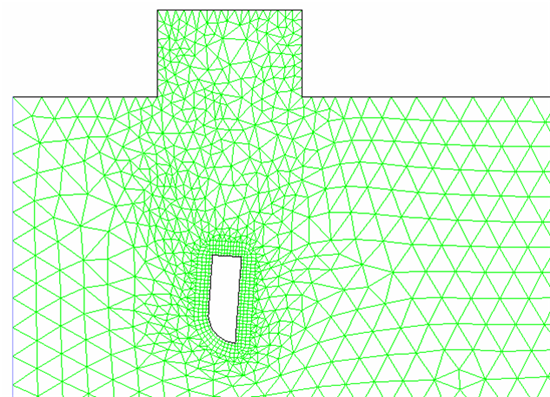

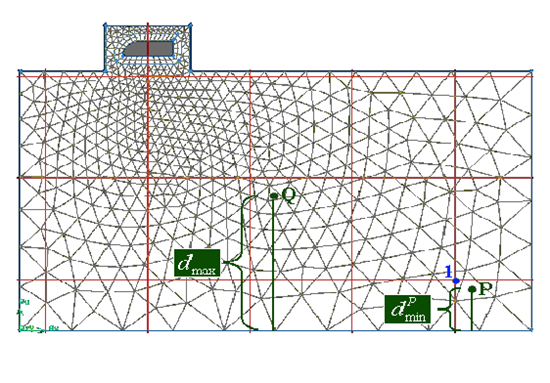

When the boundary displacement is large compared to the local cell sizes, the cell quality can deteriorate or the cells can become degenerate if only mesh smoothing is used. This will invalidate the mesh (for example, result in negative cell volumes) and consequently, will lead to convergence problems when the solution is updated to the next time step.

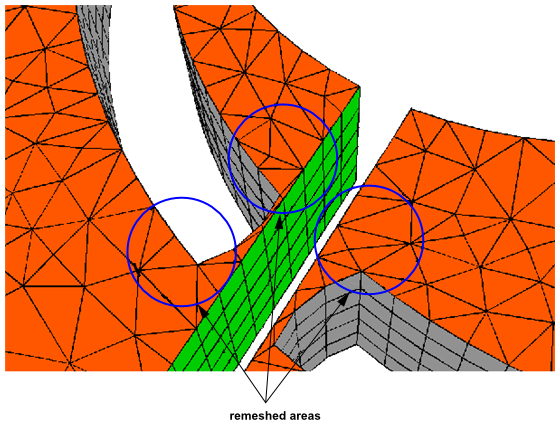

To circumvent this problem, Ansys Fluent can agglomerate cells that violate the skewness or size criteria and locally remesh the agglomerated cells or faces. If the new cells or faces satisfy the skewness criterion, the mesh is locally updated with the new cells (with the solution interpolated from the old cells). Otherwise, the new cells are discarded and the old cells are retained.

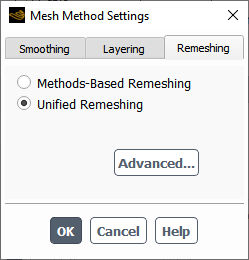

When defining the remeshing settings for your dynamic zones, it is recommended that you use unified remeshing (the default), which applies an algorithm that combines aspects of a variety of remeshing methods and by default attempts to maintain the initial mesh size distribution even as the mesh moves. This simplifies the setup and can provide increased robustness, especially for parallel simulations. It should be noted that such unified remeshing is applied to triangular or tetrahedral cells and can produce wedge cells in 3D boundary layer meshes. As an alternative, you can use methods-based remeshing, which allows you to selectively enable the following options, each of which is suitable for particular kinds of cell types:

The local cell remeshing method only affects triangular and tetrahedral cell types in the mesh (that is, in mixed cell zones the non-triangular/tetrahedral cells are skipped).

The local face remeshing method is available in 3D only and can remesh tetrahedral cells and wedge cells in boundary layer meshes.

The zone remeshing method replaces all cell types with triangular and tetrahedral cells (in 2D and 3D domains, respectively), and can remesh and produce wedge cells in 3D boundary layer meshes.

The face region remeshing method is applied to triangular cells in 2D, and tetrahedral cells in 3D. In 3D domains, the face region remeshing method can also remesh and produce wedge cells in 3D boundary layer meshes.

The 2.5D remeshing method only works on hexagonal meshes or wedge cells extruded from triangular surface elements.

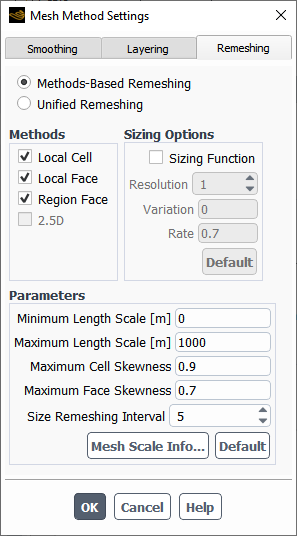

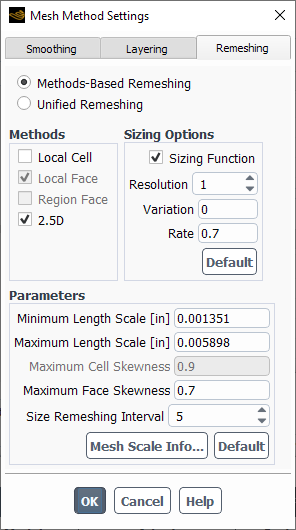

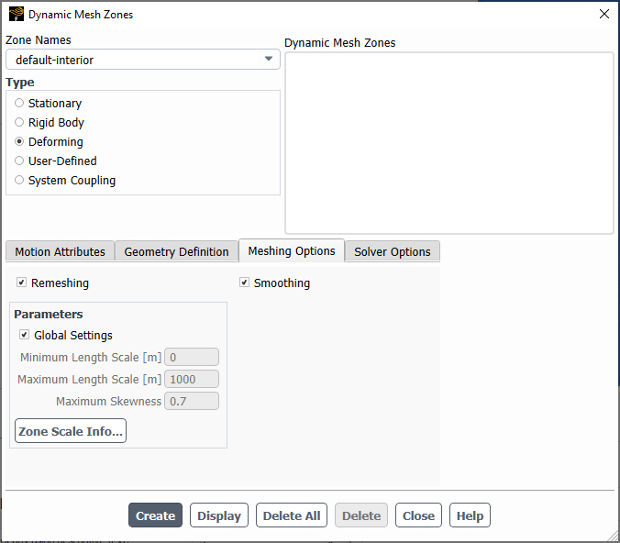

To apply remeshing, enable the Remeshing option under Mesh Methods in the Dynamic Mesh Task Page (Figure 13.13: The Dynamic Mesh Task Page). Click the button to open the Mesh Method Settings dialog box, where you can select either Methods-Based Remeshing or Unified Remeshing in the Remeshing tab (Figure 13.35: The Remeshing Tab in the Mesh Method Settings Dialog Box for Methods-Based Remeshing) and revise the options / parameters or the advanced settings.

For Methods-Based Remeshing, you can view the vital statistics of your mesh by clicking the button at the bottom of the Mesh Method Settings Dialog Box. This button opens the Mesh Scale Info Dialog Box, where you can view the minimum and maximum length scale values, as well as the maximum cell and face skewness values.

For details, see the following sections:

When Methods-Based Remeshing is selected in the Remeshing tab of the Mesh Method Settings dialog box, you can selectively enable the following methods:

Using the local remeshing method (that is, local cell remeshing, with or without local face remeshing), Ansys Fluent marks cells based on cell skewness and minimum and maximum length scales as well as an optional sizing function.

Ansys Fluent evaluates each cell and marks it for remeshing if it meets one or more of the following criteria:

It has a skewness that is greater than a specified maximum skewness.

It is smaller than a specified minimum length scale.

It is larger than a specified maximum length scale.

Its height does not meet the specified length scale (at moving face zones, for example, above a moving piston).

If local remeshing is not able to reduce the maximum cell skewness sufficiently, then the cell zone remeshing method is used to automatically remesh all of the cells in the cell zone, as well as the faces of all adjacent deforming dynamic face zones (see Cell Zone Remeshing Method for details). The maximum allowable cell skewness is set to be 0.98 by default. The cell zone remeshing method gives the mesher more flexibility to create a new mesh of better quality than the local cell remeshing method. The automatic remeshing of cell zones can be disabled using the following text command:

define → dynamic-mesh

→ controls →

remeshing-parameter →

zone-remeshing

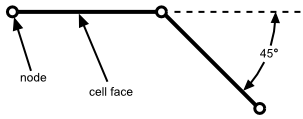

As previously mentioned, in local cell remeshing, Ansys Fluent agglomerates cells based on skewness, size, and height (adjacent moving face zones) prior to the movement of the boundary. The size criteria are specified with Minimum Length Scale and Maximum Length Scale. Cells with length scales below the minimum length scale and above the maximum length scale are marked for remeshing. The value of Maximum Cell Skewness indicates the desired skewness of the mesh. By default, the Maximum Cell Skewness is set to 0.9 for 3D simulations and 0.7 for 2D simulations. Cells with skewness above the maximum skewness are marked for remeshing.

The marking of cells based on skewness is done at every time step when the local remeshing method is enabled. However, marking based on size and height is performed between the specified Size Remeshing Interval since the change in cell size distribution is typically small over one time step.

Note that you should edit the fields in the Parameters group box, as the initial values are unlikely to produce your desired outcome. Clicking will define values that are based on your particular mesh and that should represent a reasonable starting point, and you can then adjust them as needed. After you click the button, it will then change to be a button, which can be used to return to the prior values.

By default, Ansys Fluent replaces the agglomerated cells only if the quality of the remeshed cells has improved.

Note that you cannot use the local cell remeshing method in conjunction with adaption. For more information on the available adaption methods, see Hanging Node Adaption and Polyhedral Unstructured Mesh Adaption in the Theory Guide.

The local face remeshing method only applies to 3D geometries. You can apply this method to the boundaries of deforming or user-defined zone types, so that Ansys Fluent will mark faces (and adjacent cells) based on the face skewness, and then remesh them.

Local face remeshing also allows the remeshing of wedge cells in boundary layers at those boundaries. The detection of boundary layers (as well as the wedge element height distribution and number of layers) is automatic and does not require your input.

To apply local face remeshing, perform the following steps:

Enable the Local Face option in the Remeshing tab of the Mesh Method Settings Dialog Box, and set the Maximum Face Skewness to an appropriate global value.

For each deforming or user-defined boundary zone on which you want local face remeshing applied, enable the Local option in the Meshing Options tab of the Dynamic Mesh Zones Dialog Box. You can also revise the Maximum Skewness in this tab if you don't want to use the global setting for a particular zone. Note that for deforming zones, the Remeshing option must be enabled—which is the default condition—in order to access the Local option, and the Global Settings option must be disabled to revise the Maximum Skewness. For further details on the zone setup, see Deforming Motion and/or User-Defined Motion.

When you enable local face remeshing for a boundary, the faces can be remeshed only if the following conditions are met:

The faces are triangular.

The agglomerated faces do not span multiple zones or feature edges.

Note that you cannot use the local face remeshing method in conjunction with adaption. For more information on the available adaption methods, see Hanging Node Adaption and Polyhedral Unstructured Mesh Adaption in the Theory Guide.

Instead of marking cells based on minimum and maximum length scales, Ansys Fluent also marks cells based on the size distribution generated by the sizing function if the Sizing Function option is enabled.

Cells can be marked using sizing functions only with the following remeshing methods:

local cell remeshing

2.5D surface remeshing (as described in 2.5D Surface Remeshing Method)

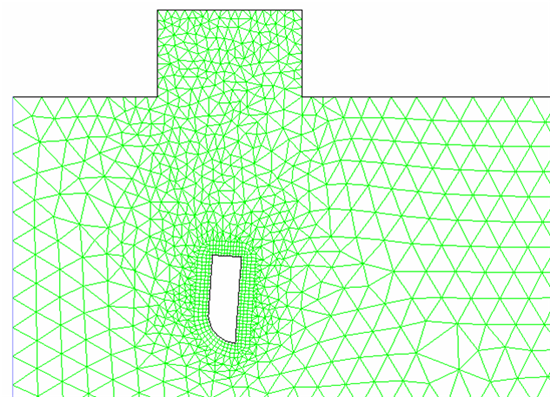

Figure 13.38: Mesh at the End of a Dynamic Mesh Simulation With Sizing Functions demonstrates the advantages of using sizing functions for local remeshing.

In determining the sizing function, Ansys Fluent draws a bounding box around the zone that is approximately twice the size of the zone, and locates the shortest feature length within each fluid zone. Ansys Fluent then subdivides the bounding box based on the shortest feature length and the sizing function Resolution that you specify. This allows Ansys Fluent to create a background mesh.

You control the resolution of the background mesh and a background mesh is created for each fluid zone. The shortest feature length is determined by shrinking a second box around the object, and then selecting the shortest edge on that box. The sizing function is evaluated at the vertex of each individual background mesh.

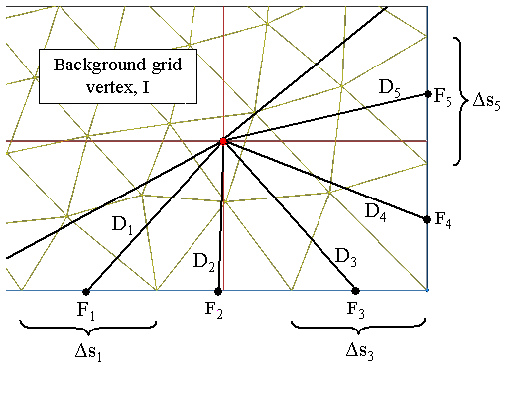

As seen in Figure 13.39: Sizing Function Determination at Background Mesh Vertex I, the local value of the

sizing function is defined by

(13–17) |

where is the distance from vertex

on the background mesh to the centroid of boundary cell

and

is the mesh size (length) of boundary cell

.

The sizing function is then smoothed using Laplacian smoothing. Ansys Fluent then

interpolates the value of the sizing function by calculating the distance from a given cell centroid

to the background mesh vertices that surround the cell (see Figure 13.40: Interpolating the Value of the Sizing Function). The intermediate value of the sizing

function

at the centroid is computed from

(13–18) |

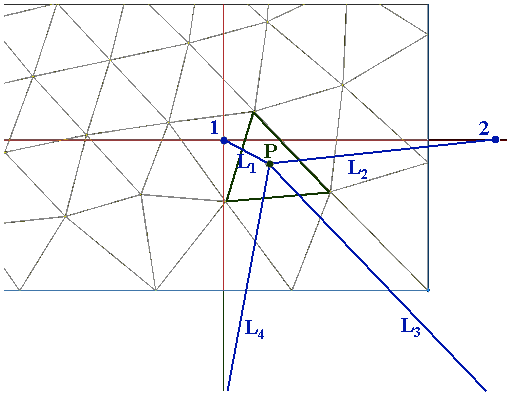

Next, a single point is located within the domain (see Figure 13.41: Determining the Normalized Distance) that has the largest distance

to the nearest boundary to it. The normalized distance

for the given centroid

is given by

(13–19) |

Using the parameters and

(the sizing function Variation and the sizing

function Rate, respectively), you can write the final value

of the sizing function at point

as

(13–20) |

where is the intermediate value of the sizing function at the cell

centroid.

Note that is the sizing function variation. Positive values

mean that the cell size increases as you move away from the boundary. Since the maximum

value of

is one, the maximum cell size becomes

(13–21) |

therefore, is really a measure of the maximum cell size.

The factor is computed from

(13–22) |

(13–23) |

You can use sizing function Variation (or ) to control how large or small an interior cell can be with respect to its

closest boundary cell.

ranges from

to

, an

value of 0.5 indicates that the interior cell size can be, at most, 1.5

the size of the closest boundary cell. Conversely, an

value of

indicates that the cell size interior of the boundary can be half of that

at the closest boundary cell. A value of 0 indicates a constant size distribution away from

the boundary.

You can use the sizing function Rate (or ) to control how rapidly the cell size varies from the boundary. The value

of

should be specified such that

. A positive value indicates a slower transition from the boundary to the

specified sizing function Variation value. Conversely, a negative value

indicates a faster transition from the boundary to the sizing function

Variation value. A value of 0 indicates a linear variation of cell size

away from the boundary.

You can also control the Resolution of the sizing function. This

determines the size of the background bins used to evaluate the size distribution with

respect to the shortest feature length of the current mesh. By default, the sizing function

Resolution is 3 in 2D problems, and

1 in 3D problems.

Note that if you edit the Resolution, Variation, and/or Rate, clicking will return these fields to the default values based on the current mesh. The button will then change to be a button, which can be used to return to the prior values.

In summary, the sizing function is a distance-weighted average of all mesh sizes on all boundary faces (both stationary and moving boundaries). The sizing function is based on the sizes of the boundary cells, with the size computed from the cell volume by assuming a perfect (equilateral) triangle in 2D and a perfect tetrahedron in 3D. You can control the size distribution by specifying the sizing function Variation and the sizing function Rate. If you have enabled the Sizing Function option, Ansys Fluent will agglomerate a cell if

(13–24) |

where is a factor defined by Equation 13–22

and Equation 13–23.

Note that the sizing function is only used for marking cells before remeshing. The sizing function is not used to govern the size of the cell during remeshing.

For steady-state applications (see Steady-State Dynamic Mesh Applications), you can instruct Ansys Fluent to perform a second round of cell marking and agglomeration after the boundary has moved, based on skewness criteria. The intent is to further improve the mesh quality through additional local remeshing. This optional feature works in conjunction with the Mesh Method Settings dialog box (Figure 13.35: The Remeshing Tab in the Mesh Method Settings Dialog Box for Methods-Based Remeshing), and operates according to the skewness parameters you set in this dialog box. The sizing function parameters are not considered during this additional remeshing. Note that enabling this option will increase the time required to update the mesh during the solution.

Note: If you want to employ additional local remeshing, first make sure that you have enabled the Remeshing option in the Dynamic Mesh Task Page.

To enable the additional round of local remeshing, use the following text command:

define → dynamic-mesh

→ controls →

remeshing-parameter →

remeshing-after-moving?

The cell zone remeshing method allows for the remeshing of the complete cell zone, and provides the option to also remesh the faces of all adjacent deforming dynamic face zones. This remeshing method is enabled by default when local cell remeshing is enabled, and is performed automatically if the local cell remeshing does not produce an acceptable mesh (see Local Remeshing Method for the acceptability criteria). Cell zone remeshing can also be manually invoked, using the following text command:

define → dynamic-mesh

→ actions →

remesh-cell-zone

The cell zone remeshing method is available for triangular cells in 2D meshes and

tetrahedral cells in 3D meshes. For 3D meshes, the method also allows the remeshing of wedge

cells in boundary layers. The detection of the boundary layers (as well as the wedge element

height distribution and number of layers) is automatically performed by default, and allows

for different layer parameters on each boundary zone. You can manually specify the parameters

by entering nonzero values for first height, growth rate, and number of layers via the text

commands available in the

define/dynamic-mesh/controls/remeshing-parameters/prism-layer-parameters

menu, although generally it is not necessary to do this. When you enter them manually, the

boundary layer parameters are global: they apply to every prism layer detected in the

remeshing zone.

Note that it is necessary to enable the dynamic mesh model and the remeshing method in order to attain access to the prism layer controls, even if the cell zone is remeshed manually and not as part of a dynamic mesh update.

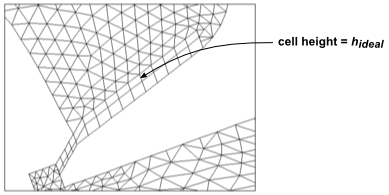

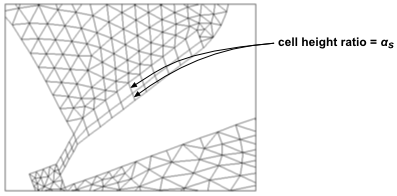

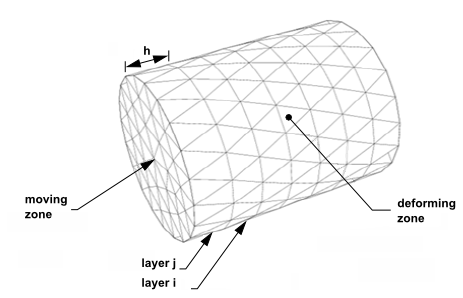

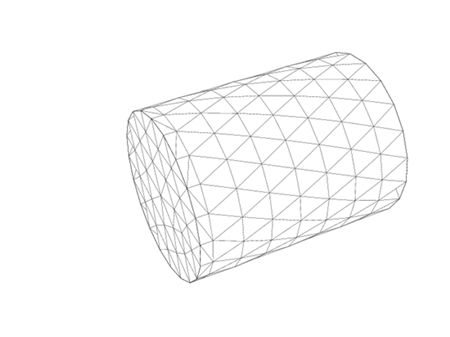

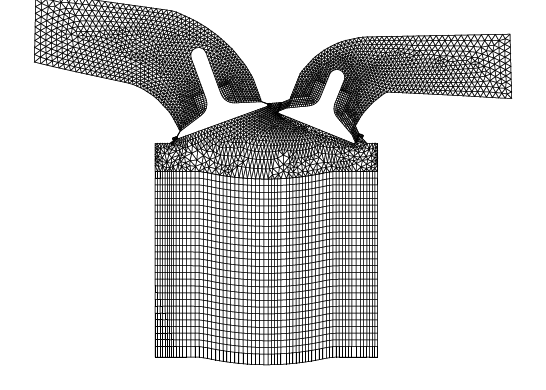

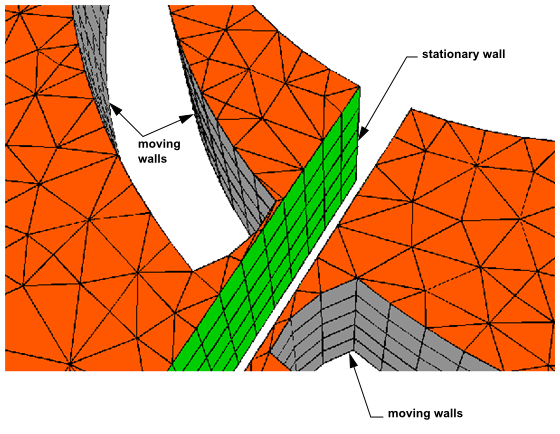

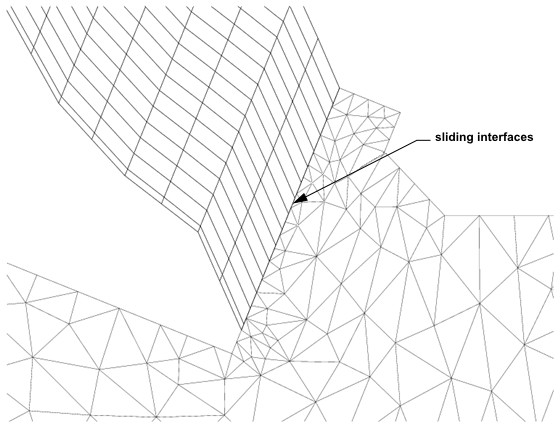

The face region remeshing method allows for the remeshing of those triangular faces (in 3D meshes) and linear faces (in 2D meshes) that are on a deforming face zone and adjacent to a moving face zone (see layer j in Figure 13.42: Expanding Cylinder Before Region Face Remeshing). Ansys Fluent marks the faces based on minimum and maximum length scales, and then remeshes the faces and the associated cells to produce a very regular mesh on the deforming boundary. Although primarily designed for in-cylinder type configurations, where the remeshing region is located where cylinder walls meet the moving piston, face region remeshing can be used for all applications where a moving dynamic zone abuts deforming dynamic face zones.

For 3D simulations, Ansys Fluent allows face region remeshing with symmetric boundary conditions and across multiple face zones. The remeshing can preserve features not only between the different deforming face zones, but also within a face zone. For more information on feature preservation, see Feature Detection. Ansys Fluent also allows face region remeshing of tetrahedral cell zones that contain wedge cells in boundary layers, as described in the section that follows.

To begin marking the faces for face region remeshing, Ansys Fluent identifies the nodes at the intersection of a moving dynamic zone and the adjacent deforming zones. Ansys Fluent then analyzes the height of the faces on the deforming zones that are in the range of the identified nodes, and then remeshes the faces depending on the specified maximum or minimum length scale.

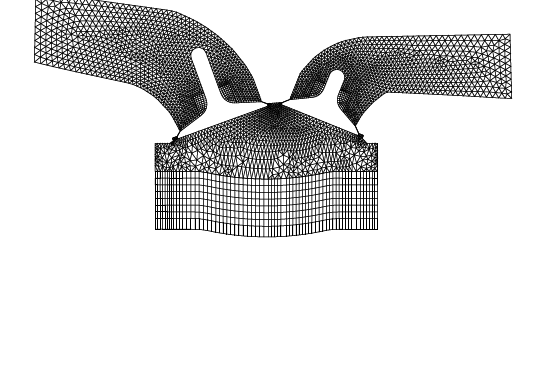

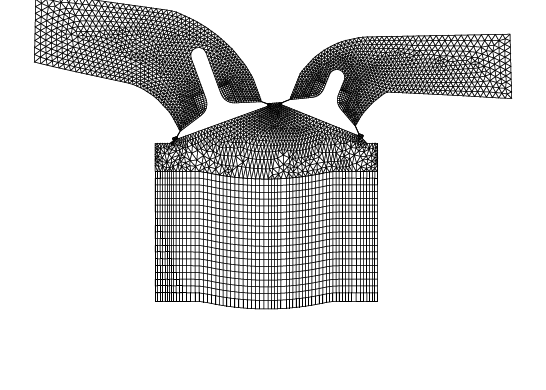

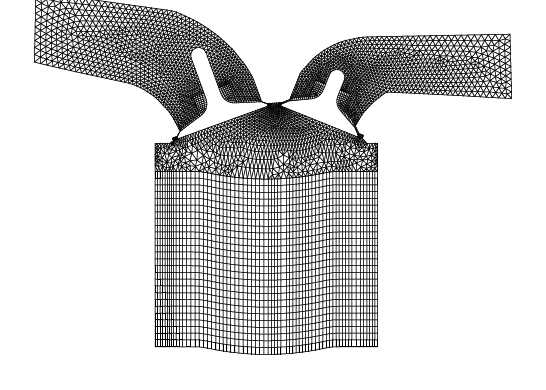

Consider the simple tetrahedral mesh of a cylinder that has a moving end wall (see Figure 13.42: Expanding Cylinder Before Region Face Remeshing). The faces that are subject to remeshing are in layer j of the side wall. If the faces in layer j are expanding, the expansion continues until the height h reaches the maximum length scale, and then the layer is remeshed to form 2 layers of elements (see Figure 13.43: Expanding Cylinder After Region Face Remeshing). Conversely, if the faces of layer j are contracting, the contraction continues until h reaches the minimum length scale, and then layer j and the neighboring layer of faces (layer i) on the deforming zone are remeshed to form a single layer.

In 3D simulations, the face region remeshing method can be applied on meshes that have wedge cells along the deforming face zones. When remeshing the faces on the deforming face zones, the associated wedge cells are remeshed as well. The layer parameters are based on the existing mesh by default; you have the option of manually setting these parameters, as described later in this section.

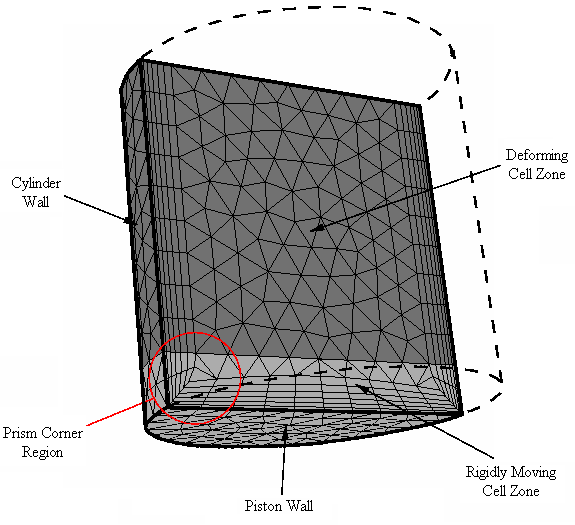

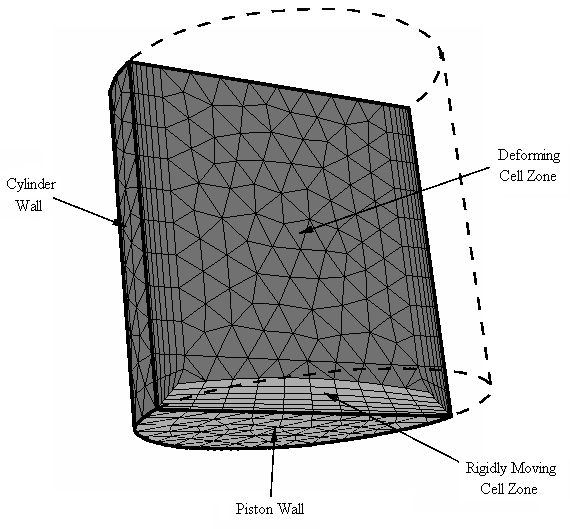

If the motion of the face zone is large compared to the height of the adjacent deforming face zones, it is recommended that you decompose the mesh volume in such a way as to create a dynamic cell zone that moves as a rigid body in between the moving face zone and the deforming dynamic cell zone on which face region remeshing is applied. Consider Figure 13.44: Volume Decomposition for Prism Layers, which displays only half of an in-cylinder mesh. The rigidly moving cell zone encapsulates the prism layers on the moving piston so that the layers are not remeshed, and therefore the risk of generating degenerate cells during the mesh motion update is reduced.

It is preferable (and even mandatory, if the mesh is a half model with a symmetry plane) to decompose the volume such that the “corner” region of the prism layers (shown in the previous figure) exists entirely within the rigidly moving zone. This allows for the largest deformations without risking degenerate elements, because the prism normals of the remeshed cells are uniformly perpendicular to the faces undergoing remeshing.

If the range of motion does not allow you to encapsulate the entire corner region of the prism layers in a rigidly moving zone, it is recommended that you encapsulate the “base” of the prism layers (shown in Figure 13.45: Volume Decomposition for the Base of the Prism Layers) and move these cells with a rigid body motion. Although this is less ideal than encapsulating the corner region, it does reduce the risk of degenerate mesh elements.

For piston-type applications that contain prism layers, a reasonable rule of thumb is that you should decompose the mesh volume if the piston motion is more than half the cylinder height. If you decide not to decompose the volume at all, you must at the very least enable the Deform Adjacent Boundary Layer with Zone option in the Meshing Options tab of the Dynamic Mesh Zone dialog box when setting up the moving face zone (see Rigid Body Motion for details). In any case, it is recommended that you always preview the mesh motion over the complete simulation time, to make sure that you will have a valid mesh at each time step.

The prism layer parameters (that is, element height, growth rate, and number of layers)

are extracted automatically from the mesh and do not generally require your input. To

prevent the prism parameters from drifting due to repeated remeshing, the prism parameters

for first height, growth rate, and number of layers can be entered manually, using the text

commands available in the

define/dynamic-mesh/controls/remeshing-parameters/prism-layer-parameters

menu.

Note the following limitations associated with face region remeshing:

You can use the face region remeshing method only in cell zones that contain triangular cells (in 2D) or tetrahedral cells, with or without prism layers (in 3D). For 3D meshes, the faces on the deforming boundaries that border the moving face must all be triangular.

The face region remeshing method is not compatible with diffusion-based smoothing or linearly elastic solid smoothing.

You cannot use the face region remeshing method in conjunction with adaption. For more information on the available adaption methods, see Hanging Node Adaption and Polyhedral Unstructured Mesh Adaption in the Theory Guide.

The 2.5D surface remeshing method only applies to extruded 3D geometries and is similar to local remeshing in two dimensions on a triangular surface mesh (not a mixed zone). Faces on a deforming boundary are marked for remeshing based on face skewness, minimum and maximum length scale; the 2.5D remeshing method also gives you the option of marking cells using sizing functions, as described in Local Remeshing Based on Sizing Function.

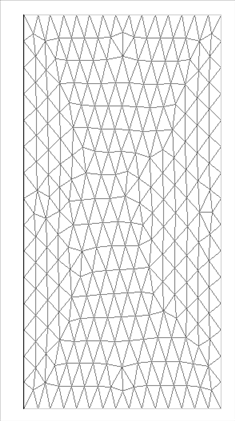

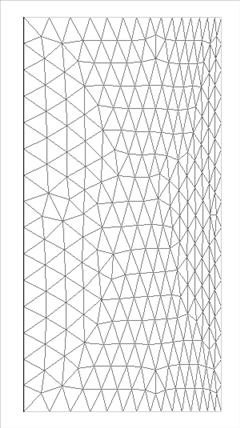

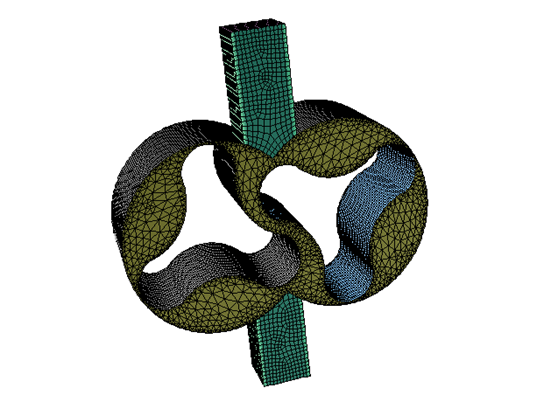

Figure 13.46: Close-Up of 2.5D Extruded Flow Meter Pump Geometry Before Remeshing and Laplacian Smoothing

Figure 13.47: Close-Up of 2.5D Extruded Flow Meter Pump Geometry After Remeshing and Laplacian Smoothing

The following applies to the 2.5D surface remeshing method:

Triangular faces get remeshed based on marking.

Extruded wedges get remeshed based on the remeshing of the triangular face. Only extruded regions get remeshed, not mixed regions.

The 2.5D remeshing method does not support remeshing or moving nodes on the perimeter of the extruded zone(s).

The only smoothing method that is compatible with 2.5D remeshing is Laplacian smoothing.

Note that you cannot use the 2.5D surface remeshing method in conjunction with adaption. For more information on the available adaption methods, see Hanging Node Adaption and Polyhedral Unstructured Mesh Adaption in the Theory Guide.

The extrusion must be along a straight line normal to the deforming zone and the cross-section of the extruded/coopered mesh must be constant along the extrusion direction. For more information about the 2.5D model, see Using the 2.5D Model.

Periodics are not supported at the extruded zones.

For 3D simulations only, you can select the 2.5D model under the Remeshing tab in the Mesh Method Settings Dialog Box. This model allows for a specific subset of remeshing techniques.

The 2.5D mesh essentially is a 2D triangular mesh which is expanded, or extruded, along the normal axis of the specific dynamic zone that you are interested in modeling. The triangular surface mesh is remeshed and smoothed on one side, and the changes are then extruded to the opposite side. Rigid body motion is applied to the moving face zones, while the triangular extrusion surface is assigned to a deforming zone with remeshing and smoothing enabled. The opposite side of the triangular mesh is assigned to be a deforming zone as well, with only smoothing enabled, as in Figure 13.49: 2.5D Extruded Gear Pump Geometry.

For more information on setting smoothing and remeshing parameters, see Dynamic Mesh Update Methods.

The 2.5D model only applies to mappable (that is, extrudable) mesh geometries such as pumps, as in Figure 13.49: 2.5D Extruded Gear Pump Geometry. Only the aspects of the geometry that represent the “moving parts” must be extruded in the mesh.

Important: You must only apply smoothing to the opposite side of the extruded mesh, since Ansys Fluent requires the geometry information for the dynamic zone. Ansys Fluent projects the nodes back to its geometry after the extrusion. Without this geometry information, the dynamic zones tends to lose its integrity.

Important: In parallel, a partition method that partitions perpendicular to the extrusion surface should be used. For example, if the normal of the extrusion surface points in the X-direction then Cartesian-Y or Cartesian-Z would be the perfect partition methods.

The 2.5D model is used in combination with a

DEFINE_GRID_MOTION UDF. (See Hooking DEFINE_GRID_MOTION UDFs in the Fluent Customization Manual for information about hooking this UDF.)

This UDF is associated with the extrusion surface that is adjacent to the cell zone, in turn applying the same deformation to the entire cell zone. This approach is particularly useful when modeling gear pumps that are predominantly extruded hexahedral meshes. For more information about this UDF, contact your support engineer.

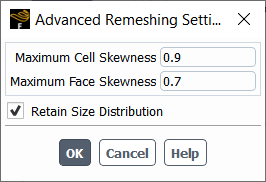

When Unified Remeshing is selected in the Remeshing tab of the Mesh Method Settings dialog box, the mesh quality is improved using an algorithm that combines aspects of a variety of remeshing methods and by default attempts to maintain the initial mesh size distribution even as the mesh moves. Unified Remeshing simplifies the remeshing setup and can provide increased robustness compared to other methods, especially for parallel simulations.

If the default settings of the Unified Remeshing method do not yield a desirable mesh distribution for your simulation, you can attempt to improve it by clicking the button and using the Advanced Remeshing Settings dialog box that opens. The value of the Maximum Cell Skewness sets the threshold for remeshing cells based on skewness, and by default is set to 0.9 for 3D simulations and 0.7 for 2D simulations. For 3D cases, faces (and adjacent cells) on the boundaries of deforming or user-defined zone types are remeshed based on the Maximum Face Skewness.

If necessary, you can disable the Retain Size Distribution option, so that algorithm does not attempt to respect the initial mesh distribution by using local size criteria, but instead marks cells for remeshing when their length scales are outside of the minimum and maximum length scale values of the cell zone in the initial mesh. Should these zonal values be unsuccessful, you can use the following text commands to specify other appropriate length scale values:

define →

dynamic-mesh → controls →

remeshing-parameters → length-min

and

define →

dynamic-mesh → controls →

remeshing-parameters → length-max

The mesh is evaluated at every time step, and the remeshing is applied only if the quality of the cells / faces has improved.

Note:

Unified remeshing is applied to triangular or tetrahedral cells, and can produce wedge cells in 3D boundary layer meshes.

You cannot use unified remeshing in conjunction with adaption. For more information on the available adaption methods, see Hanging Node Adaption and Polyhedral Unstructured Mesh Adaption in the Theory Guide.

You have the option of creating additional controls that can affect the size

distribution of the cells throughout the mesh or just the wedge cells in boundary layers by

using the

define/dynamic-mesh/controls/remeshing-parameters/sizing-controls or

define/dynamic-mesh/controls/remeshing-parameters/prism-controls/

text command menus, respectively. It is generally not necessary to create such controls, but

they may be helpful if you have strict sizing requirements or want more information when

troubleshooting size-related issues. Note that any sizing controls and/or prism controls

created in the meshing mode as part a Watertight Geometry meshing guided

workflow (as described in Using the Watertight Geometry Meshing Guided Workflows) are

automatically imported and used as part the Unified Remeshing. For

further details, see the following sections:

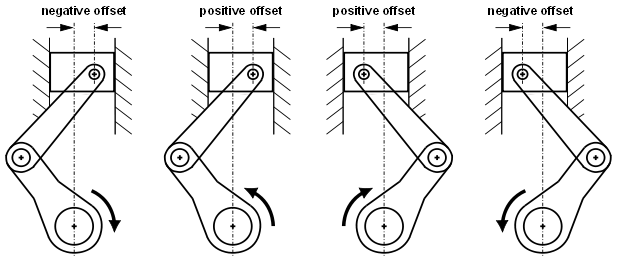

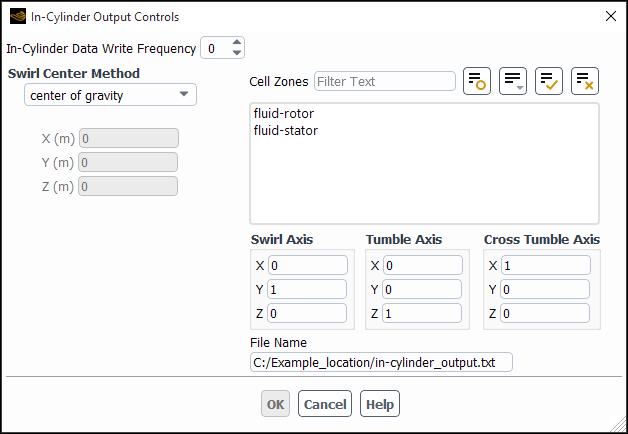

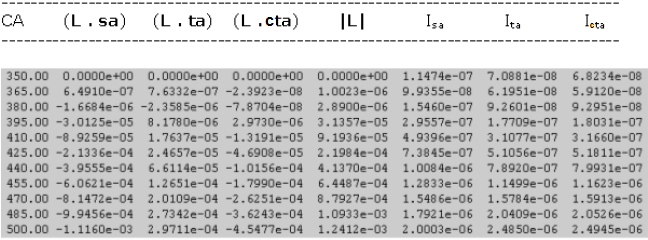

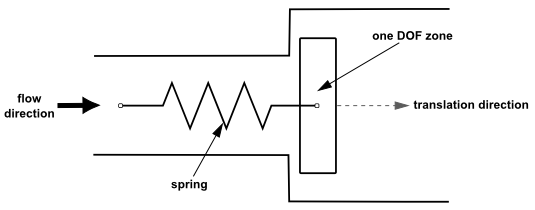

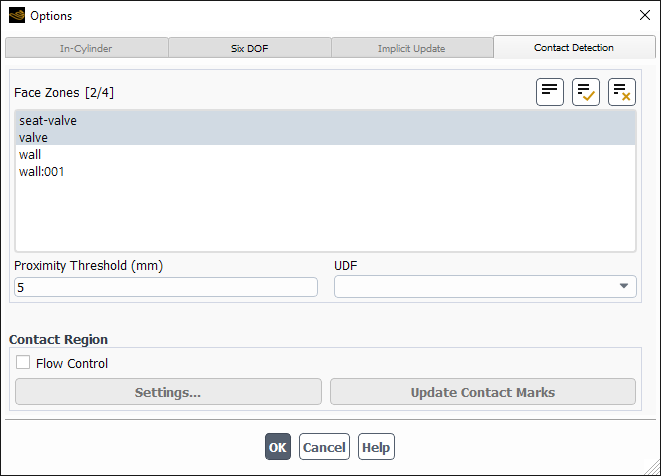

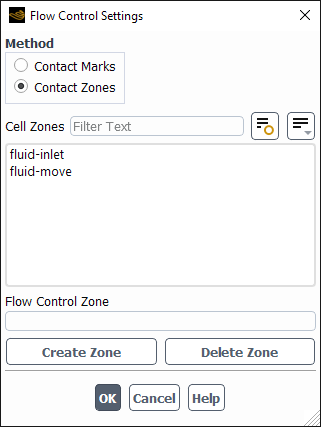

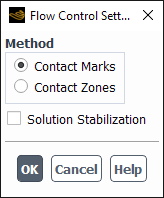

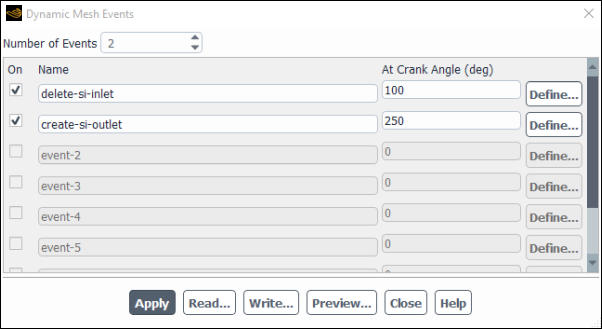

When the Retain Size Distribution option is enabled in the Advanced Remeshing Settings dialog box, you can use one or more sizing controls to modify the algorithm that attempts to respect the initial mesh distribution during unified remeshing. Each sizing control definition is applied to one or more boundary zones, and then affects the size of the cells throughout the mesh based on their distance from those boundary zone(s) and your settings in the definition. Any sizing controls created in the meshing mode as part a Watertight Geometry meshing guided workflow (as described in Using the Watertight Geometry Meshing Guided Workflows) are automatically imported and used; you can choose to edit and/or delete these, and/or create new controls.