Some engineering problems involve fluids that do not behave as ideal gases. For example, at very high-pressure or very low-temperature conditions (for example, the flow of a refrigerant through a compressor) the flow cannot typically be modeled accurately using the ideal-gas assumption. Therefore, the real gas model allows you to solve accurately for the fluid flow and heat transfer problems where the working fluid behavior deviates from the ideal-gas assumption.

Ansys Fluent provides three real gas options for solving these types of flows:

All the models allow you to solve for either a single-species fluid flow or a multiple-species mixture fluid flow.

In addition, real gas property (RGP) table files can be used to incorporate material properties from external sources into an Ansys Fluent simulation.

For additional information, see the following sections:

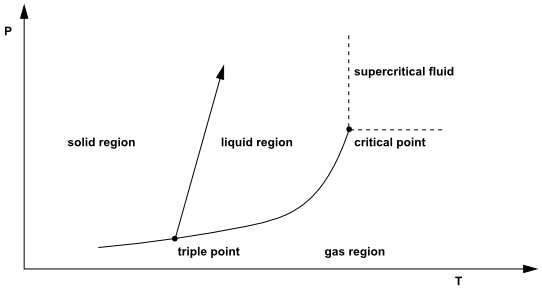

The states at which a pure material can exist can be graphically represented in diagrams of pressure vs. temperature (PT diagrams) and pressure vs. molecular or specific volume (PV diagrams). Homogeneous fluids are normally divided into two classes, liquids and gases. However the distinction cannot always be sharply drawn, because the two phases become indistinguishable at what is called the critical point. A typical pressure-temperature (PT) diagram of a pure material is shown in Figure 8.39: Typical PT Diagram of a Pure Material.

This figure shows the single phase regions, as well as the conditions

of P and T where two phases coexist. Therefore the solid and the gas

region are divided by the sublimation curve, the liquid and gas regions

by the vaporization curve, and the solid and liquid regions by the

fusion curve. The three curves meet at the triple point, where all

three phases coexist in equilibrium. Although the fusion curve continues

upward indefinitely, the vaporization curve terminates at the critical

point. The coordinates of this point are called the critical pressure and critical

temperature

. These represent the highest

temperature and pressure at which a pure material can exist in vapor-liquid

equilibrium. At temperatures and pressures above the critical point,

the physical property differences that differentiate the liquid phase

from the gas phase become less defined. This reflects the fact that,

at extremely high temperatures and pressures, the liquid and gaseous

phases become indistinguishable. This new phase, which has some properties

that are similar to a liquid and some properties that are similar

to a gas, is called a supercritical fluid.

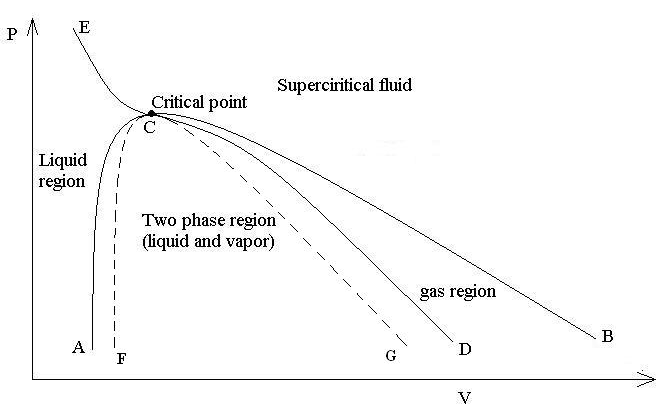

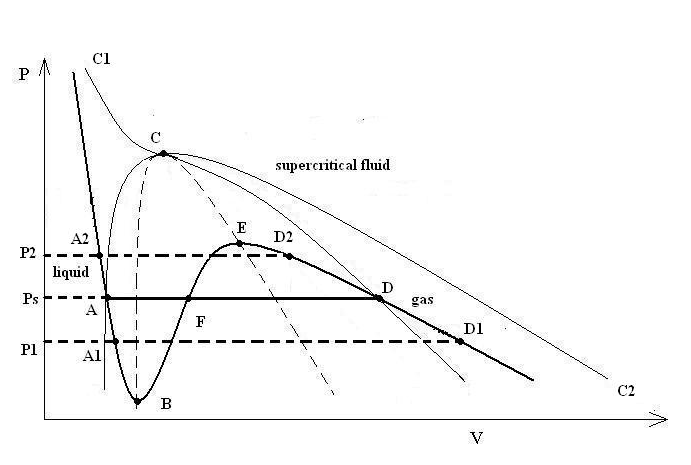

Figure 8.40: Typical PV Diagram of a Pure Material presents a typical

diagram of pressure versus molar or specific volume (PV diagram) of

a pure material. The dome shaped curve ACD is called the saturation

dome and separates the single phase regions in the diagram; curve

AC represents the saturated liquid and curve CD the saturated vapor.

The area under the saturation dome ACD is the two-phase region and

represents all possible mixtures of vapor and liquid in equilibrium.

Curve ECB is the critical isotherm and exhibits a horizontal inflection

at point C at the top of the dome. This is the critical point. The

specific volume corresponding to the critical point, is called the

critical specific volume . The conditions to the right

of the critical isotherm ECB correspond to supercritical fluid. The

dashed lines CF and CG in Figure 8.40: Typical PV Diagram of a Pure Material represent the liquid and the vapor spinodal curves with the regions

ACF and DCG between the saturation and spinodal lines representing

the superheated liquid and supercooled vapor states, respectively.

These states are called "metastable" because they exist temporarily

in small local regions until phase change occurs. As an example, liquid

metastable states may be formed in situations of fast depressurization,

depending on the rate of depressurization and the disturbances that

tend to make the liquid flash into vapor.

The equation of state is the mathematical expression that relates pressure, molar or specific volume, and temperature for any pure homogeneous fluid in equilibrium states.

The simplest equation of state is the ideal gas law, which is approximately valid for the low pressure gas region of the PT and PV diagrams. Ideal gas behavior can be expected when

or

and

If your flow conditions correspond to either of those cases, you may use the ideal gas law in your simulation.

Another idealization, that of the incompressible fluid, can be employed for the low pressure region of the liquid phase. A constant density option is the appropriate selection in that case.

However, both of these approaches are not good approximations for flow conditions close to and beyond the critical point, where the fluid behavior cannot be described by the ideal gas, or the incompressible liquid assumptions. We refer to a fluid under those conditions as a real fluid, or a real gas and more complex relations are used for the determination of its physical and thermodynamic properties.

Ansys Fluent provides the following options for solving real fluid problems:

The cubic equation of state models can be used to solve problems in the gas, liquid, and supercritical fluid regimes. The models are not available for the two-phase region under the phase dome. For further details see Cubic Equation of State Models.

The NIST real gas model can be used to solve problems in the liquid, or gas and supercritical fluid regimes. The model does not allow modeling of the two-phase region. For further details see The NIST Real Gas Models.

The user-defined real gas model allows you to solve problems in all regimes, as long as appropriate relationships are provided through the user-defined real gas functions. For further details see The User-Defined Real Gas Model.

The concepts presented in this section for pure materials are also extended to multicomponent mixtures with the introduction of appropriate composition-dependent parameters in the real gas equations of state and the material property models. All the real-gas modeling options above allow for either single-species or multicomponent flow modeling. In addition, you may solve reacting flow problems with the cubic equations of state models and the user-defined real gas functions.

An equation of state is a thermodynamic equation, which provides a mathematical relationship between two or more state functions associated with the matter, such as its temperature, pressure, volume, or internal energy. One of the simplest equations of state for this purpose is the ideal gas law, which is roughly accurate for gases at low pressures and high temperatures. However, this equation becomes increasingly inaccurate at higher pressures and lower temperatures, and fails to predict condensation from a gas to a liquid.

Introduced in 1949, the Redlich-Kwong equation of state [122] was a considerable improvement over other equations of that time. It is an analytic cubic equation of state and is still of interest primarily due to its relatively simple form. The original form is

(8–75) |

| where | |

| P = absolute pressure (Pa) | |

| R = universal gas constant | |

| V = specific molar volume ( | |

| T = temperature (K) | |

|

| |

|

|

Many investigators have attempted to improve the accuracy of the Redlich-Kwong equation. Ansys Fluent has adopted the original form of the Redlich-Kwong equation, as well as the following modified forms:

The Soave-Redlich-Kwong [152] equation is a three-parameter equation of state, which can be applied for vapor, supercritical, and liquid property predictions. It has found wide acceptance mainly in the oil and gas industry and requires knowledge of the critical temperature, critical pressure, and acentric factor. It was developed by replacing the Redlich-Kwong attractive coefficient defined as

with a two-parameter form

, where

is the acentric factor.

The Peng-Robinson equation [117] is a three-parameter equation of state, also requiring the critical temperature, critical pressure and acentric factor parameters. It is thought to perform as well as the Soave-Redlich-Kwong equation, with an advantage in the prediction of the liquid densities.

The Aungier-Redlich-Kwong [15] equation provides improved predictions for vapor and supercritical fluids near the critical point, as well as for materials with a negative value of the acentric factor. The Aungier modified form is a four parameter equation and requires the critical specific volume in addition to the critical temperature, critical pressure and acentric factor.

The following limitations exist in Ansys Fluent for all cubic equation of state models:

Pressure-inlets, mass flow-inlets, and pressure-outlets are the only inflow and outflow boundaries available for use with the real gas models.

Non-reflecting boundary conditions are not compatible with the real gas models when using the density-based solver. If your model requires NRBC and a real gas model, you must use the pressure-based solver.

The cubic equation of state real gas models are compatible with the Eulerian multiphase models.

The cubic equation of state models are compatible with the Lagrangian Dispersed Phase Models. If you are modeling droplet or multicomponent particles, note that the current formulation does not take into account the near-critical point phenomena, which means that accurate results can be obtained for droplet temperatures below

. See Using the Cubic Equation of State Models with the Lagrangian Dispersed Phase Models for more details.

The real gas models are not available with the premixed, inert, and composition PDF transport combustion models.

The cubic equation of state real gas models can be used with the following species models:

Species transport. Chemical reactions can be modeled with the finite rate and eddy dissipation models. Note that the Dimension Reduction model is not available with the real gas models.

Non-premixed model and partially-premixed model. Note that the Compressibility Effects option must be enabled in the Species Model dialog box in order for the real-gas models to be available. In addition the following restrictions apply when the non-premixed model is used together with a cubic equation of state real-gas model:

The empirical stream options cannot be used, as for the empirical species the critical properties cannot be defined.

Condensed species such as h2o<l> and c<s> are not supported and should be excluded from the PDF table, so ensure that you add all condensed species for your system in the excluded species list prior to the PDF table generation.

The laminar flame speeds for the partially-premixed model are assumed to be the same as for ideal-gases.

When the cubic equation of state models are applied for subcritical conditions near or under the phase dome, the two-phase flow is not modeled and either vapor or liquid state must be selected. Subcritical and supercritical states can co-exist in the same simulation.

The general form of pressure P for the cubic equation of state models is written as [15] :

(8–76) |

| where | |

|

P = absolute pressure (Pa) | |

|

V = specific molar volume ( | |

|

T = temperature (K) | |

|

R = universal gas constant |

The coefficients ,

,

,

, and

are

given for each equation of state as functions of the critical temperature

, critical pressure

, acentric factor

and critical specific volume

. Note that the attractive coefficient

also has a temperature

dependence, which varies for each equation of state model, and is

commonly written as

.

Redlich-Kwong Equation [128]:

(8–77) |

(8–78) |

(8–79) |

The parameter is set equal to

, while

and

are set to 0. The Redlich-Kwong

equation is the simplest of the cubic equations of state in Ansys Fluent and

requires two parameters only, the critical temperature

and the critical pressure

.

Soave-Redlich-Kwong Equation [152]:

(8–80) |

(8–81) |

and

are given by Equation 8–78 and Equation 8–79 respectively. As in the original Redlich-Kwong

equation the parameter

is set equal to

, while

and

are set to 0. The Soave-Redlich-Kwong

requires three parameters, the critical temperature

, the critical pressure

, and the acentric factor

.

Peng-Robinson Equation [117]:

(8–82) |

(8–83) |

The function is given by Equation 8–80,

with n provided in Equation 8–84 as follows:

(8–84) |

In the Peng-Robinson equation is set equal to

,

is equal to

, and

is set to 0.

Similar to the Soave-Redlich-Kwong equation, the Peng-Robinson

equation is a three-parameter equation and requires the critical temperature , the critical pressure

, and the acentric factor

.

Aungier-Redlich-Kwong Equation [15]:

(8–85) |

(8–86) |

and

are given by Equation 8–78 and Equation 8–79, respectively. As in the original Redlich-Kwong

equation, the parameter

is set equal to

and

is set to 0. Parameter

is given by:

(8–87) |

The Aungier-Redlich-Kwong equation requires four parameters,

namely the critical temperature , the critical pressure

, the critical specific volume

, and the acentric factor

.

Enthalpy, entropy, and specific heat are computed in terms of

the relevant ideal gas properties and the departure functions. The

departure function of

any conceptual property

is defined as [122]

(8–88) |

where is the value of the property as computed

from the ideal gas relations. The departure function

can be derived from basic thermodynamic relations

and the equation of state.

Following the above definition, the enthalpy for the equations of state

models is given by the following equations [15]:

(8–89) |

(8–90) |

(8–91) |

| where, | |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

See Equation 8–76 for a description of other coefficients.

Similarly, the departure internal energy can

be shown to be

(8–92) |

| where | |

|

| |

|

| |

|

| |

|

| |

|

|

The specific heat can be computed from the ideal

specific heat

and the departure specific

heat at constant volume

as follows:

(8–93) |

(8–94) |

| where | |

|

| |

|

| |

|

| |

|

| |

|

|

In Equation 8–94 is computed

by differentiating the equation of departure internal energy (Equation 8–92) with respect to

, and the partial derivatives

of the specific volume are computed by differentiating Equation 8–76 appropriately.

The entropy is computed by

(8–95) |

(8–96) |

| where | |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

is given by Equation 8–91 and

,

, and

are computed using Equation 8–77 – Equation 8–87, depending on the equation of state model. Note that the pressure

term in Equation 8–95 cancels out as both

and

are evaluated at the reference pressure.

Equations describing real-gas properties require the knowledge

of the critical constants for pure components and mixtures. These

consist of the critical temperature (), critical

pressure (

), critical specific volume

(

), and the acentric factor (

).

Several critical constants for fluid materials in the Ansys Fluent property

database propdb.scm have been compiled from

a variety of sources available in the open literature [122], [111], [112], [146], [147], [153], [13].

For those fluid materials, for which the critical properties

have not been found in the open literature, these have been estimated

using the commercially available software CRANIUM by Molecular Knowledge

Systems Inc. [1] : http://www.molknow.com/Cranium/cranium.htm

Critical property values for many hydrocarbon and nitrogenous radical species have been obtained from Tang and Brezinsky [159]. Where the critical properties for the radicals were not available in the literature, these were estimated using a modification of the Joback method [122]. This assumes that the radical site constitutes a distinct group with zero group contribution and utilizes the group contribution values for stable species.

The critical properties of coal volatiles have been estimated

assuming that the volatiles can be approximated by a mixture of CO, ,

,

, and

in such

a way, that the atom composition and the net calorific value of the

volatiles is similar to that of the assumed mixture. The critical

properties of the lignite and biomass volatiles have been assumed

equal to those of formaldehyde. The critical properties of diesel

and jet-a fuels have been set equal to those of decane. The critical

properties of kerosene have been set equal to those of dodecane.

For the computation of properties in real-gas mixtures, Ansys Fluent follows

the so-called pseudocritical method. According to this method, the

behavior and properties of a real gas mixture will be the same as

that of a pure component, to which appropriate critical constants

are assigned. These mixture critical constants are functions of the

mixture composition and pure component critical properties, and are

sometimes called pseudocritical constants, because their values are

generally expected to be different from the true mixture critical

constants that may be determined experimentally. However for computational

purposes they are the appropriate critical constant values for the

mixture. According to the pseudocritical method, Ansys Fluent applies Equation 8–76– Equation 8–96 also for mixtures, where the critical

temperature , critical pressure

, critical

specific volume

, and acentric factor

, are replaced by the

corresponding mixture critical constants, critical temperature

, critical pressure

,

critical specific volume

, and acentric

factor

.

The following options are available in Ansys Fluent for the calculation of the mixture pseudocritical constants:

The simplest rule for computing the pseudocritical constants

for a real gas mixture is the mole fraction average [122]. This method is recommended for mixtures where the pure component critical properties for all components are not very different:

(8–97)

where

= mixture pseudocritical constant (temperature, pressure, specific volume or acentric factor)

= critical constant of component i (temperature, pressure, specific volume or acentric factor)

= mole fraction of component i

= number of components in mixture

An alternative approach is based on the one-fluid van der Waals mixing rules as expressed in [128]. According to this approach, in order to apply the equation of state models to mixtures, the coefficients

and

in Equation 8–76 are replaced by composition-dependent expressions as follows:

(8–98)

(8–99)

where

= mole fraction of species i

With the appropriate expressions from Equation 8–77– Equation 8–87 for each equation of state, and assuming a mixture acentric factor

for the evaluation of parameter

in Equation 8–81, Equation 8–84, and Equation 8–86, the mixing rules Equation 8–98 and Equation 8–99 can be rearranged to yield direct expressions of the mixture critical properties as functions of the mole fractions and the component critical properties [15].

The resulting expressions for the mixture critical specific temperature

are as follows:

Soave-Redlich-Kwong and Peng-Robinson models

(8–100)

Redlich-Kwong model and Aungier-Redlich-Kwong model:

(8–101)

where for the Aungier-Redlich-Kwong model

is obtained from Equation 8–86 as function of the mixture acentric factor

. For the Redlich-Kwong model

.

The mixture critical specific pressure

is computed as:

(8–102)

The mixture critical specific volume

is computed as:

(8–103)

The notation for Equation 8–100 to Equation 8–103 is

= mixture pseudocritical temperature (K)

= mixture pseudocritical pressure (Pa)

= mixture pseudocritical molar volume (

/kmol)

= critical temperature for component i (K)

= critical pressure for component i (Pa)

= critical molar volume for component i (

/kmol)

= mole fraction for component i

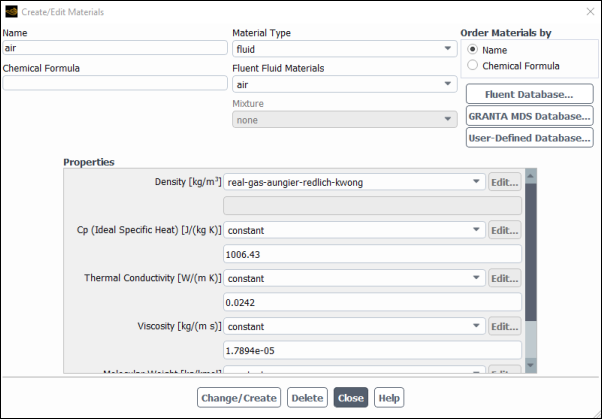

For single or multicomponent flows, you will enable the cubic equation of state real gas models by selecting real-gas-soave-redlich-kwong, real-gas-peng-robinson, real-gas-aungier-redlich-kwong, or real-gas-redlich-kwong from the Density drop-down list in the Create/Edit Materials dialog box.

Setup →

![]() Materials → Create/Edit...

Materials → Create/Edit...

The required inputs for the cubic equation of state real gas models for single component flow and mixtures are described below.

Single Component Flow

When any of the cubic equation of state models is enabled, enter the following material properties in the dialog box:

ideal specific heat

molecular weight

standard state entropy

reference temperature

critical temperature

critical pressure

critical specific volume

acentric factor

Important: Your inputs for the specific heat in the Materials dialog box will now be used to compute the ideal property functions ,

, and

in Equation 8–89, Equation 8–93, and Equation 8–95, respectively. In Ansys Fluent the

departure properties will be computed and added to the ideal part,

to yield the real gas specific heat, enthalpy, and entropy.

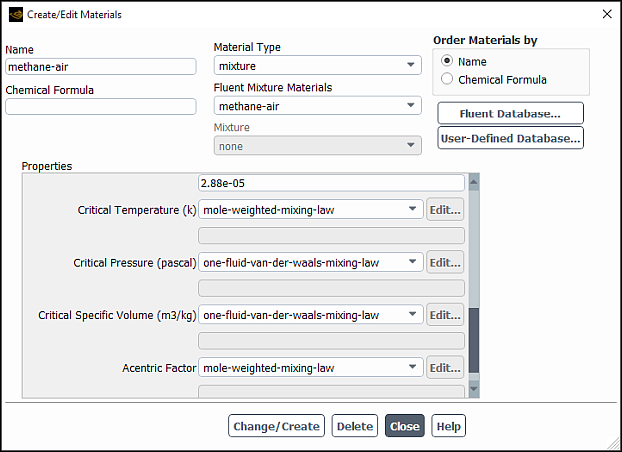

Mixtures

When one of the cubic equation of state models is selected from the Density drop-down list, specify the following material properties for the mixture material in the dialog box:

ideal specific heat

critical temperature

critical pressure

critical specific volume

acentric factor

You also need to enter the following material properties for each of the mixture components in the dialog box:

molecular weight

standard state entropy

reference temperature

When you are modeling a real-gas mixture, the following methods are available for the mixture critical constants:

constant: defines a constant critical temperature, critical pressure, critical specific volume, or acentric factor for the mixture material.

mole-weighted-mixing-law: applies Equation 8–97 for critical temperature, critical pressure, critical specific volume, or acentric factor for the mixture material.

one-fluid-van-der-waals-mixing-law applies Equation 8–100 and Equation 8–101 for the mixture critical temperature (depending on the real-gas model), Equation 8–102 for the mixture critical pressure, and Equation 8–103 for the mixture molar volume.

Important:

Ensure to click the button so that all the above mentioned properties are uploaded and are visible in the interface.

If you have selected mixing-law for the mixture ideal specific heat you will also need to enter the ideal specific heat values for the individual mixture components. If you have not selected constant as the option for any of the critical properties, you must enter the corresponding pure component critical properties for the mixture components.

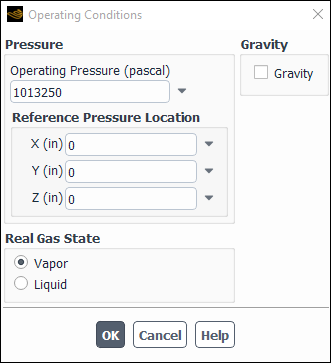

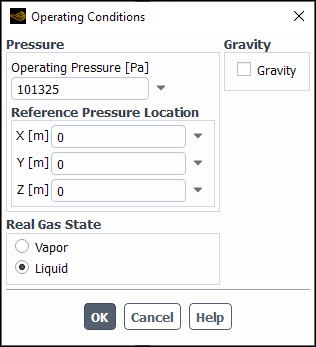

If the operating conditions in your model are in the subcritical regime, select

Vapor or Liquid as the Real Gas

State in the Operating Conditions dialog box (Figure 8.43: The Operating Conditions for a Real Gas State). Alternatively, you can use the

define/operating-conditions/set-state text command. Note that

the default is Vapor and therefore Vapor is

assumed if no changes are made to the Real Gas State settings. If

the operating conditions in your model are entirely in the supercritical regime, this

setting will have no effect.

In addition, you may specify the state for a specific fluid zone or a specific phase (if you are using multiphase modeling) by typing the following text command at the Ansys Fluent console prompt:

>define boundary-conditions modify-zones change-zone-stateSelect a name/id from fluid zones list [(liquid-zone fluid-1)]liquid-zoneSet zone real-gas state: -1:use global setting 0:liquid 1:vapor [-1]0

The flow modeling of real-gas flow is more complex and challenging than simple ideal-gas flow. Therefore, the solution might converge at a slower rate with real-gas flow than when running ideal-gas flow. It is recommended that you first attempt to converge your solution using first-order discretization then switch to second-order discretizations and re-iterate to convergence.

Special considerations apply if the operating regime in your

model is fully or partly subcritical, where the physical state may

be vapor, liquid, or a vapor/liquid mixture. In the cubic EOS real-gas

model, the phase state is determined by the selection of the cubic

root to calculate the molar-volume. This is illustrated in Figure 8.44: The PV Diagram for the Cubic Equation of State Real Gas Model, which shows a pressure versus

molar volume (PV) diagram, with a subcritical isotherm ABFED at temperature

T calculated from a cubic EOS. Curve C1CC2 represents the critical

isotherm and curve ACD the saturation dome. Points A, F, and D represent

the three roots of the EOS at the saturation pressure Ps, where A

corresponds to the molar volume of saturated liquid, D to the molar

volume of saturated vapor and point F does not have a physical significance.

Points A1 and D1 correspond to the liquid and vapor molar volumes

at pressure P1, which is lower than the saturation pressure. The liquid

and vapor molar volumes at pressure P2, which is higher than the saturation

pressure, are marked as A2 and D2 respectively. Points B and E, where

the partial derivatives of pressure with respect to volume are

0, are called spinodal points. The loci of these points for all subcritical

temperatures, the spinodal curve, is shown with the dashed curve BCE

and sets the boundary beyond which the equation of state is no longer

valid, because the local derivative of pressure with respect to volume

becomes positive. State points inside the dome, up to the spinodal

curve, are called “metastable” because normally they

only exist temporarily in small local regions until phase change occurs.

It is important to realize that the current implementation of the cubic equations of state real gas model does not determine the saturation conditions and does not model the two-phase flow where liquid and vapor coexist. In the subcritical regime and for conditions where the cubic EOS has three roots, the phase state selection is controlled by your input of Vapor or Liquid for Real Gas State in the Operating Conditions dialog box (Figure 8.43: The Operating Conditions for a Real Gas State). The default setting is Vapor, which corresponds to the state points to the right of the vapor spinodal. With reference to Figure 8.44: The PV Diagram for the Cubic Equation of State Real Gas Model, for the operating point at temperature T and pressure P1, if the Real Gas State is set to Vapor, the molar volume at point D1, which corresponds to superheated vapor, will be selected in the calculation. On the other hand, if you have selected Liquid, the molar volume of point A1 will be taken, and the corresponding state will be metastable superheated liquid. Similarly for pressure P2, which is higher than the saturation pressure Ps, if you select Liquid for Real Gas State, the liquid molar volume at A2 will be computed, and if you select Vapor the molar volume will correspond to the subcooled vapor state point D2.

In case the calculations fall inside the saturation dome, the solver will not limit the solution, but if conditions are predicted that extend beyond the vapor spinodal curve a warning will be issued:

temperature is below the spinodal point in 12 cells on zone 3.

Cubic equations of state real gas models are not available for

two-phase flows but can be applied to conditions of supercritical

pressure and subcritical temperature

, where the fluid is in the liquid state,

and the supercritical liquid co-exists with gas and supercritical

fluid in the same simulation. In those cases, phase change may take

place, without any of the flow conditions falling inside the saturation

dome.

For multicomponent simulations, when Diffusion Energy

Source is enabled in the Species Model dialog box, the species energy diffusion is by default suppressed

in the supercritical liquid regime and across the gas-liquid boundary.

The diffusion energy source can be included in the liquid regime using

the define/models/species/liquid-energy-diffusion? text command.

If your simulation contains a liquid stream, the appropriate modeling approach in the various operating condition regimes is as follows:

For

a liquid phase does not exist.

In the region

, you can define the flow streams directly in the boundary conditions by setting the appropriate pressure and temperature and the properties will be computed directly by the cubic EOS.

For

or

, a stream can exist in liquid phase when its temperature

. If you would like to model phase change in this regime, the following recommendations apply:

The DPM droplet and multicomponent models are adequate and recommended for the conditions away from the critical point. This regime can be defined as

, where the liquid physical properties can be assumed independent of pressure.

The region

is characterized by near-critical-point phenomena, such as strong liquid density and specific heat dependence on both temperature and pressure. The DPM model can also be used in this regime, but you should be cautious, as it will not take into consideration the near-critical-point behavior. In addition, the applicability of the evaporation and boiling rate equations is questionable in this regime.

If the pressure in your model is above the critical point, it is recommended to use the compressible-liquid method for Density of the droplet material.

The temperature gives an indication of the maximum droplet temperature for applicability of the DPM models for each droplet material. These temperature limits are listed in Table 8.2: Temperature Limits for Droplet Materials in Ansys Fluent Database prodb.scm for many of the droplet materials in Ansys Fluent's

propdb.scm materials database. For supercritical pressures (), the DPM models can still be used provided the droplet temperatures remain below the limit

.

Table 8.2: Temperature Limits for Droplet Materials in Ansys Fluent Database prodb.scm

| Material | Tc (K) | Pc (MPa) | Normal BP (K) | Tlim (K) |

| Argon | 150.86 | 4.89 | 87.30 | 135.77 |

| Benzene | 562.00 | 4.89 | 353.00 | 505.80 |

| Helium | 5.30 | 0.23 | 4.20 | 4.77 |

| Hydrogen | 32.98 | 1.30 | 20.40 | 29.68 |

| Methyl-alcohol | 512.00 | 8.10 | 338.00 | 460.80 |

| Heptanes | 540.00 | 2.74 | 371.00 | 486.80 |

| Hexane | 507.00 | 3.02 | 342.00 | 456.30 |

| Octane | 569.00 | 2.49 | 399.00 | 512.10 |

| Pentane | 470.00 | 3.37 | 309.00 | 423.00 |

| Nitrogen | 126.00 | 3.40 | 77.40 | 113.40 |

| Oxygen | 154.00 | 5.04 | 90.20 | 138.60 |

| Toluene | 592.00 | 4.11 | 384.00 | 532.80 |

| Water | 647.00 | 22.00 | 373.00 | 582.30 |

For high pressure simulations the boiling point will be different from the normal boiling point, and for varying pressure applications the boiling point will vary with the droplet location in the domain.

When a cubic equation of state real gas model is enabled in a simulation that includes evaporating droplet particles, the boiling point is calculated from the vapor pressure data directly, as the temperature where the saturation vapor pressure equals the domain pressure. In addition, the latent heat of the evaporating or boiling droplet will vary with the droplet temperature.

The latent heat at temperature is given by

(8–104) |

where is the normal boiling point and

is the latent heat

at the normal boiling point.

In the Create/Edit Materials dialog box you must enter the Normal Boiling Point (NBP) and the Latent Heat at NBP for the droplet-particle Material Type. These inputs will be used for calculating the Latent Heat at the reference temperature (see Equation 12–509) and the latent heat in the droplet energy balance during vaporization and boiling according to Equation 8–104.

Important: The constant property option is disabled for the Saturation Vapor Pressure property when a real gas model is used in the simulation. Also, ensure to enter the appropriate droplet saturation vapor pressure data to cover the complete pressure/temperature range in your model.

Finally when a cubic equation of state real-gas model is enabled in a simulation with droplet models, the condition for switching from the vaporization to the boiling law will be

(8–105) |

where is the saturation vapor pressure and P is the domain pressure. If

while in the boiling law, the model will switch back to the vaporization law. Under supercritical pressure conditions (

), the vaporization models are applicable at droplet temperatures below the critical point, and the switching condition from vaporization to boiling

is never met because the vapor pressure curve is defined only up to the critical point.

For the multicomponent droplets in the supercritical pressure regime, failure of the saturation temperature calculation algorithm may indicate that the droplet has approached the critical temperature, provided that you have entered accurate vapor pressure data for all components. In such a case, you can use the following text command:

define/models/dpm/options/treat-multicomponent-saturation-temperature-failure?

Dump multicomponent particle mass if the saturation temperature

calculation fails? [no]

y

When this option is enabled, Ansys Fluent dumps the particle mass into the continuous phase if the saturation temperature calculation fails.

All postprocessing functions properly report and display the current thermodynamic and transport properties of the selected real gas model. The thermodynamic and transport properties controlled by the cubic equations of state real gas model include the following:

density

enthalpy

entropy

sound speed

specific heat

any quantities that are derived from the properties listed above (for example, total quantities, ratio of specific heats)

In addition to the properties listed above, you can also report

compressibility factor

reduced temperature

reduced pressure

spinodal temperature

subcritical condition

If you are modeling a real-gas mixture you can report the composition-dependent mixture critical properties

critical temperature

critical pressure

critical specific volume

acentric factor

The NIST real gas models use the National Institute of Standards and Technology (NIST) Thermodynamic and Transport Properties of Refrigerants and Refrigerant Mixtures Database Version 10.0 (REFPROP v10.0) to evaluate thermodynamic and transport properties of approximately 152 fluids or a mixture of these fluids.

The REFPROP v10.0 database is a shared library that is dynamically loaded into the solver when you enable one of the NIST real gas models in an Ansys Fluent session. Once the NIST real gas model is activated, control of relevant property evaluations is relinquished to the REFPROP database. All postprocessing functions will properly report and display the current thermodynamic and transport properties of the real gas.

The following limitations exist for the NIST real gas model:

The NIST real gas model assumes that the fluid you will be using in your Ansys Fluent computation is superheated vapor, supercritical fluid, or liquid. Note that subcritical flow conditions, where vapor coexists with liquid in two-phase flow, are not supported. In addition, all fluid zones must contain the real gas; you cannot include a real gas and another fluid in the same problem.

Pressure-inlet, mass flow-inlet, and pressure-outlet are the only inflow and outflow boundaries available for use with the real gas models.

Non-reflecting boundary conditions are not compatible with the real gas models when using the density-based solver. If your model requires NRBC and a real gas model, you must use the pressure-based solver.

The mixture flow does not permit chemical reactions with the NIST real gas model.

The multicomponent NIST real gas models cannot be used with any of the multiphase models. You can, however, use a NIST material in single-component multiphase flows. The model is compatible with the Lagrangian Dispersed Phase Models only for the massless and inert particle types.

You cannot modify material properties in the REFPROP database libraries, or add custom materials to the NIST real gas model.

Only one pure fluid or one multiple-species mixture in a simulation may use the NIST real gas model. Multiple NIST materials may be created, but those participating in the simulation must all refer to a unique NIST fluid. This is a third-party limitation of the NIST/REFPROP module.

The NIST real gas model supports 152 fluids from the REFPROP database. These include pure

fluids (with the file extension .FLD) and pseudo-fluids (with the

file extension .PPF). The fluids that are supported by REFPROP

v10.0 and used in the NIST real gas model are listed in Table 8.3: v10.0 (the corresponding property file name appears in

parentheses, where it does not coincide with the fluid name).

The REFPROP v10.0 database employs accurate pure-fluid equations of state that are available from NIST. These equations are based on three models:

modified Benedict-Webb-Rubin (MBWR) equation of state

Helmholtz-energy equation of state

extended corresponding states (ECS)

For a fluid that consists of a multispecies-mixture the thermodynamic properties are computed by employing mixing-rules applied to the Helmholtz energy of the mixture components.

Important: The database does not include transport property models for the species marked with * in Table 8.3: v10.0. As a result the NIST real gas model with those species can only be used for modeling inviscid flow.

Table 8.3: v10.0

| Short Name | Full Name | Fluid Data File |

|---|---|---|

| Butene | 1-Butene | 1BUTENE.FLD |

| 1-Butyne | But-1-yne | 1BUTYNE.FLD |

| 1-Pentene | Pent-1-en | 1PENTENE.FLD |

| 3-Methylpentane | 3-Methylpentane | 3METHYLPENTANE.FLD |

| 1,3-Butadiene | Buta-1,3-diene | 13BUTADIENE.FLD |

| 2,2-Dimethylbutan | 2,2-Dimethylbutan | 22DIMETHYLBUTANE.FLD |

| 2,3-Dimethylbutan | 2,3-Dimethylbutan | 23DIMETHYLBUTANE.FLD |

| Acetone | Propanone | ACETONE.FLD |

| Acetylene | Ethyne | ACETYLENE.FLD |

| Ammonia | Ammonia | AMMONIA.FLD |

| Argon | Argon | ARGON.FLD |

| Benzene | Benzene | BENZENE.FLD |

| Butane | n-Butane | BUTANE.FLD |

| Methylcyclohexane | Methylcyclohexane | C1CC6.FLD |

| cis-Butene | cis-2-Butene | C2BUTENE.FLD |

| Propylcyclohexane | n-Propylcyclohexane | C3CC6.FLD |

| Perfluorobutane | Decafluorobutane | C4F10.FLD |

| Perfluoropentane | Dodecafluoropentane | C5F12.FLD |

| Perfluorohexane | Tetradecafluorohexane | C6F14.FLD |

| Undecane | Undecane | C11.FLD |

| Dodecane | Dodecane | C12.FLD |

| Hexadecane | Hexadecane | C16.FLD |

| Docosane | Docosane | C22.FLD |

| R13I1 | Trifluoroiodomethane | CF3I.FLD |

| Chlorine | Chlorine | CHLORINE.FLD |

| Chlorobenzene | Chlorobenzene | CHLOROBENZENE.FLD |

| Carbon monoxide | Carbon monoxide | CO.FLD |

| Carbon dioxide | Carbon dioxide | CO2.FLD |

| Carbonyl sulfide | Carbon oxide sulfide | COS.FLD |

| Cyclobutene | 1-Cyclobutene | CYCLOBUTENE.FLD |

| Cyclohexane | Cyclohexane | CYCLOHEX.FLD |

| Cyclopentane | Cyclopentane | CYCLOPEN.FLD |

| Cyclopropane | Cyclopropane | CYCLOPRO.FLD |

| Deuterium | Deuterium | D2.FLD |

| Heavy water | Deuterium oxide | D2O.FLD |

| D4 | Octamethylcyclotetrasiloxane | D4.FLD |

| D5 | Decamethylcyclopentasiloxane | D5.FLD |

| D6 | Dodecamethylcyclohexasiloxane | D6.FLD |

| Diethanolamine | 2,2'-Iminodiethanol | DEA.FLD |

| Decane | Decane | DECANE.FLD |

| Diethyl ether | Diethyl ether | DEE.FLD |

| Dimethyl carbonate | Dimethyl ester carbonic acid | DMC.FLD |

| Dimethyl ether | Methoxymethane | DME.FLD |

| Ethylbenzene | Phenylethane | EBENZENE.FLD |

| Ethylene glycol | 1,2-Ethandiol | EGLYCOL.FLD |

| Ethane | Ethane | ETHANE.FLD |

| Ethanol | Ethyl alcohol | ETHANOL.FLD |

| Ethylene | Ethene | ETHYLENE.FLD |

| Ethylene oxide | Ethylene oxide | ETHYLENEOXIDE.FLD |

| Ethylene oxide | Fluorine | FLUORINE.FLD |

| Hydrogen sulfide | Hydrogen sulfide | H2S.FLD |

| Hydrogen chloride | Hydrogen chloride | HCL.FLD |

| Helium | Helium-4 | HELIUM.FLD |

| Heptane | Heptane | HEPTANE.FLD |

| Hexane | Hexane | HEXANE.FLD |

| Hydrogen (normal) | Hydrogen (normal) | HYDROGEN.FLD |

| Isobutene | 2-Methyl-1-propene | IBUTENE.FLD |

| Isohexane | 2-Methylpentane | IHEXANE.FLD |

| Isooctane | 2,2,4-Trimethylpentane | IOCTANE.FLD |

| Isopentane | 2-Methylbutane | IPENTANE.FLD |

| Isobutane | 2-Methylpropane | ISOBUTAN.FLD |

| Krypton | Krypton | KRYPTON.FLD |

| MD2M | Decamethyltetrasiloxane | MD2M.FLD |

| MD3M | Dodecamethylpentasiloxane | MD3M.FLD |

| MD4M | Tetradecamethylhexasiloxane | MD4M.FLD |

| MDM | Octamethyltrisiloxane | MDM.FLD |

| Monoethanolamine | Ethanolamine | MEA.FLD |

| Methane | Methane | METHANE.FLD |

| Methanol | Methanol | METHANOL.FLD |

| Methyl linoleate | Methyl (Z,Z)-9,12-octadecadienoate | MLINOLEA.FLD |

| Methyl linolenate | Methyl (Z,Z,Z)-9,12,15-octadecatrienoate | MLINOLEN.FLD |

| MM | Hexamethyldisiloxane | MM.FLD |

| Methyl oleate | Methyl cis-9-octadecenoate | MOLEATE.FLD |

| Methyl palmitate | Methyl hexadecanoate | MPALMITA.FLD |

| Methyl stearate | Methyl octadecanoate | MSTEARAT.FLD |

| m-Xylene | 1,3-Dimethylbenzene | MXYLENE.FLD |

| Nitrous oxide | Dinitrogen monoxide | N2O.FLD |

| Neon | Neon | NEON.FLD |

| Neopentane | 2,2-Dimethylpropane | NEOPENTN.FLD |

| Nitrogen trifluoride | Nitrogen trifluoride | NF3.FLD * |

| Nitrogen | Nitrogen | NITROGEN.FLD |

| Nonane | Nonane | NONANE.FLD |

| Novec 649, 1230 |

1,1,1,2,2,4,5,5,5-Nonafluoro-4-(trifluoromethyl)-3- pentanone | NOVEC649.FLD |

| Octane | Octane | OCTANE.FLD |

| Orthohydrogen | Orthohydrogen | ORTHOHYD.FLD * |

| Oxygen | Oxygen | OXYGEN.FLD |

| o-Xylene | 1,2-Dimethylbenzene | OXYLENE.FLD |

| Parahydrogen | Parahydrogen | PARAHYD.FLD |

| Pentane | Pentane | PENTANE.FLD |

| Propadiene | 1,2-Propadiene | PROPADIENE.FLD |

| Propane | Propane | PROPANE.FLD |

| Propylene | Propene | PROPYLEN.FLD |

| Propylene oxide | 1,2-Epoxypropane | PROPYLENEOXIDE.FLD |

| Propyne | Propyne | PROPYNE.FLD |

| p-Xylene | 1,4-Dimethylbenzene | PXYLENE.FLD |

| R11 | Trichlorofluoromethane | R11.FLD |

| R12 | Dichlorodifluoromethane | R12.FLD |

| R13 | Chlorotrifluoromethane | R13.FLD |

| R14 | Tetrafluoromethane | R14.FLD |

| R21 | Dichlorofluoromethane | R21.FLD |

| R22 | Chlorodifluoromethane | R22.FLD |

| R23 | Trifluoromethane | R23.FLD |

| R32 | Difluoromethane | R32.FLD |

| R40 | Methyl chloride | R40.FLD |

| R41 | Fluoromethane | R41.FLD |

| R113 | 1,1,2-Trichloro-1,2,2-trifluoroethane | R113.FLD |

| R114 | 1,2-Dichloro-1,1,2,2-tetrafluoroethane | R114.FLD |

| R115 | Chloropentafluoroethane | R115.FLD |

| R116 | Hexafluoroethane | R116.FLD |

| R123 | 2,2-Dichloro-1,1,1-trifluoroethane | R123.FLD |

| R124 | 1-Chloro-1,2,2,2-tetrafluoroethane | R124.FLD |

| R125 | Pentafluoroethane | R125.FLD |

| R134a | 1,1,1,2-Tetrafluoroethane | R134A.FLD |

| R141b | 1,1-Dichloro-1-fluoroethane | R141B.FLD |

| R142b | 1-Chloro-1,1-difluoroethane | R142B.FLD |

| R143a | 1,1,1-Trifluoroethane | R143A.FLD |

| Dichloroethane | 1,2-Dichloroethane | R150.FLD |

| R152a | 1,1-Difluoroethane | R152A.FLD |

| R161 | Fluoroethane | R161.FLD |

| R218 | Octafluoropropane | R218.FLD |

| R227ea | 1,1,1,2,3,3,3-Heptafluoropropane | R227EA.FLD |

| R236ea | 1,1,1,2,3,3-Hexafluoropropane | R236EA.FLD |

| R236fa | 1,1,1,3,3,3-Hexafluoropropane | R236FA.FLD |

| R245ca | 1,1,2,2,3-Pentafluoropropane | R245CA.FLD |

| R245fa | 1,1,1,3,3-Pentafluoropropane | R245FA.FLD |

| R365mfc | 1,1,1,3,3-Pentafluorobutane | R365MFC.FLD |

| R1123 | Trifluoroethylene | R1123.FLD |

| R1216 | Hexafluoropropene | R1216.FLD |

| R1224yd(Z) | (Z)-1-Chloro-2,3,3,3-tetrafluoropropene | R1224YDZ.FLD |

| R1233zd(E) | trans-1-Chloro-3,3,3-trifluoro-1-propene | R1233ZDE.FLD |

| R1234yf | 2,3,3,3-Tetrafluoroprop-1-ene | R1234YF.FLD |

| R1234ze(E | trans-1,3,3,3-Tetrafluoropropene | R1234ZEE.FLD |

| R1234ze(Z) | cis-1,3,3,3-Tetrafluoropropene | R1234ZEZ.FLD |

| R1243zf | 3,3,3-Trifluoropropene | R1243ZF.FLD |

| R1336mzz(Z) | (Z)-1,1,1,4,4,4-Hexafluoro-2-butene | R1336MZZZ.FLD |

| RC318 | Octafluorocyclobutane | RC318.FLD |

| RE143a | Methyl trifluoromethyl ether | RE143A.FLD |

| RE245cb2 | Methyl-pentafluoroethyl-ether | RE245CB2.FLD |

| RE245fa2 | 2,2,2-Trifluoroethyl-difluoromethyl-ether | RE245FA2.FLD |

| RE347mcc (HFE-7000) | 1,1,1,2,2,3,3-Heptafluoro-3-methoxypropane | RE347MCC.FLD |

| Sulfur hexafluoride | Sulfur hexafluoride | SF6.FLD |

| Sulfur dioxide | Sulfur dioxide | SO2.FLD |

| trans-Butene | trans-2-Butene | T2BUTENE.FLD |

| Toluene | Methylbenzene | TOLUENE.FLD |

| Vinyl chloride | Chloroethylene | VINYLCHLORIDE.FLD |

| Water | Water | WATER.FLD |

| Xenon | Xenon | XENON.FLD |

| Air (dry) | Nitrogen + oxygen + argon (0.7812/0.2096/0.0092) | AIR.PPF |

| R404A | 44% R125/4% R134a/52% R143a | R404A.PPF * |

| R407C | 23% R32/25% R125/52% R134a | R407C.PPF * |

| R410A | 50% R32/50% R125 | R410A.PPF * |

| R507A | 50% R125/50% R143a | R507A.PPF * |

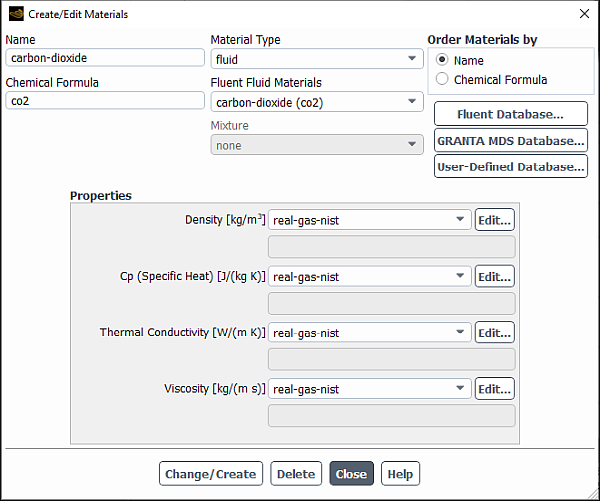

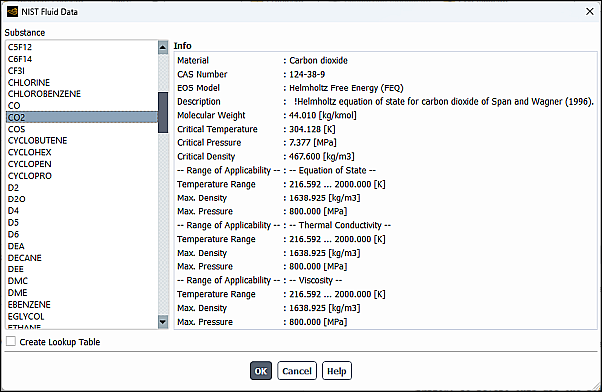

The NIST real gas model can be enabled for pure fluids by selecting

real-gas-nist for Density on the

Create/Edit Materials dialog box.

Physics →

Materials → Create/Edit...

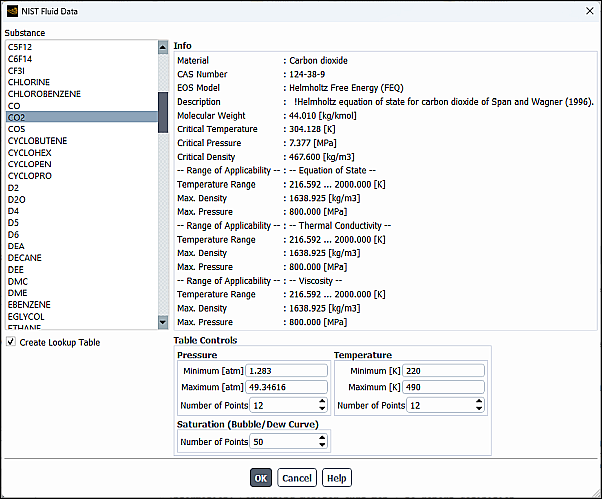

When you select Edit… for Density, you will be prompted to select the appropriate NIST data from the NIST Fluid Data dialog box. After selecting a valid fluid, properties for the specified material, including its applicable pressure and temperature ranges, will be displayed.

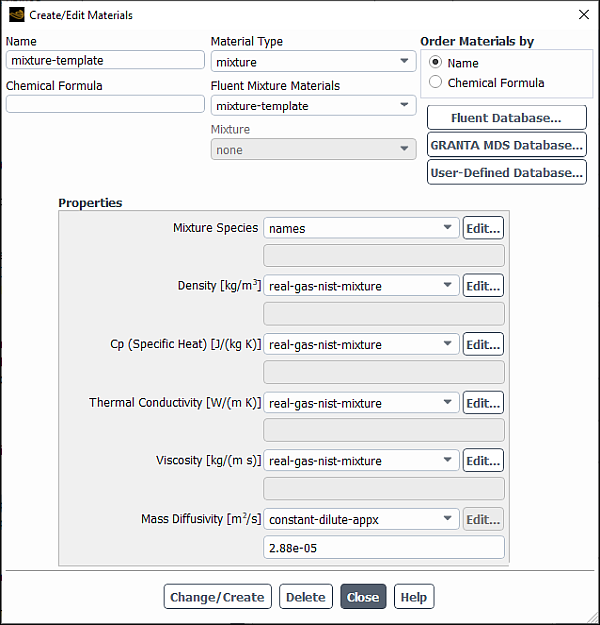

For multiple-species mixtures, enable the Species Transport model and specify the number and names of species, as described in Enabling Species Transport and Reactions and Choosing the Mixture Material. Then on the Create/Edit Materials dialog box, select real-gas-nist-mixture for Density.

Afterwards, you must select the appropriate NIST fluid data for each species as you would for a pure fluid.

Important:

For mixture flows, not all combinations of species mixtures are allowed. This could be due to lack of data for one or more binary pairs. In such situations an error message generated by NIST will be returned and displayed on the Ansys Fluent console, and no real gas material is allowed to be created. In some combinations the mixing data will be estimated, a warning message will be displayed on the Ansys Fluent console and the mixture material allowed to be created.

Transport property calculations are not supported for mixtures that include water with molar concentration over 5%. If this limit is exceeded in your calculation, Ansys Fluent will issue a warning message. Transport equations are not available for the ammonia/water mixture and for mixtures with alcohols. As a result, the NIST real gas model with those mixtures can only be used for modeling inviscid flow.

Cp (Specific Heat), Thermal Conductivity, and Viscosity will be automatically set respectively to real-gas-nist (pure fluid) or real-gas-nist-mixture (multiple species mixture).

If you want to use NIST lookup tables in your simulation, you can create them as described in Creating NIST Look-up Tables.

If your case contains no NIST tables, and you would like to model flow in the liquid state, you can set the Real Gas State to liquid in the Operating Conditions dialog box.

In addition, you may specify the state for specific fluid zones or a specific phase (if you are using the multiphase model) by typing the following text command in the Ansys Fluent console prompt:

>define boundary-conditions modify-zones change-zone-stateSelect a name/id from fluid zones list [(liquid-zone fluid-1)]liquid-zoneSet zone real-gas state: -1:use global setting 0:liquid 1:vapor [-1]0

By default, the NIST functions are called directly each time the thermal properties are updated during an iteration. Alternatively, you can use NIST look-up tables in your simulation as described below. Computing the look-up table reduces the computation time because the NIST functions do not need to be called each time the thermal properties are updated.

To create a full NIST look-up table, first enable the NIST real gas model as described in Using the NIST Real Gas Models, and then select Create Lookup Table.

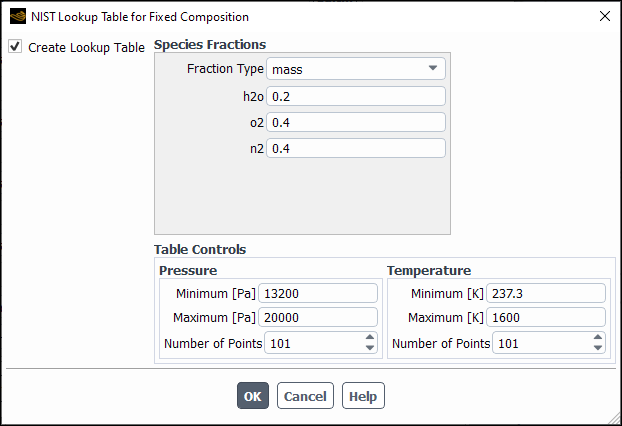

For both single and multi-species real gas models, you need to specify:

Pressure and Temperature bounds for the table.

You must ensure that the temperature and pressure bounds you specify are strictly within the stated limits of applicability that are displayed when selecting the NIST fluid data.

Number of pressure and temperature points.

The minimum number of pressure and temperature points is 12 and there is no upper limit. However, the larger the table, the greater the memory and computing time requirements. It is advised to perform test runs to balance the costs (memory and computing time) and accuracy.

For single-species, you also need to specify the number of points for Saturation (Bubble/Dew Curve) properties.

For multi-species, you also need to specify the mixture composition on a mass or mole basis. You must ensure that the sum of all constituent fractions add up to 1 when specifying mass/molar fractions for the components. The maximum number of species is 20.

If properties are needed at conditions outside the limits you have specified for the table, Fluent automatically calls the original NIST model functions to calculate the thermal properties. If more than 10% of the property evaluations require computation outside the look-up table, Fluent prints a message indicating the percentage of calculations using direct computation. This can be used as an indicator to adjust the temperature and pressure ranges for the table to minimize the computational cost.

For computation of saturation properties for the bubble and dew points for a single- or multiple-species, Fluent provides macros that you can use in UDFs. See NIST Real Gas Saturation Properties for more information.

Look-up tables apply for compressible fluids with material properties that are a function of local pressure and temperature. The material properties covered by the table include fluids in the liquid and vapor phases. Flashing applications between liquid and vapor phases can be conducted using saturation conditions established for the fluid(s) using mass transfer models.

Look-up tables and saturation tables are created for fixed fluid compositions. This means the look-up tables are based on the following assumptions:

Mixture composition is constant.

No chemical reactions are involved.

No mixing of fluids of different compositions, including no mixing between phases.

Look-up tables only apply to single-species/multi-species in single-phase flows

The temperature and pressure bounds must be specified within the stated limits of applicability that are displayed when the NIST model is loaded.

When specifying the look-up table size, it is important to pick temperature and pressure ranges that are large enough to satisfy the current flow conditions.

If the temperature and pressure ranges you specify are too narrow, Fluent uses the NIST model to calculate thermal properties. The time saved by creating the table will be negated if the percentage of calculations performed outside of the table is greater than 10%. This percentage is printed, so you can use it as an indicator for adjusting the temperature and pressure range of the table.

The look-up table is a structured table and may not be suitable for simulating flow behaviors near the critical point when higher resolution is required.

When you enable one of the NIST real gas models (pure fluid or multiple-species mixture) using the legacy TUI and select a valid material, Ansys Fluent’s functionality remains the same as when you model fluid flow and heat transfer using an ideal gas, with the exception of the Create/Edit Materials Dialog Box.

When you enable one of the NIST real gas models (pure fluid or multiple-species mixture) through the legacy TUI, the following limitations apply in addition to those listed in Limitations of the NIST Real Gas Models:

When you are using the NIST real gas models, the NIST materials defined in your simulation will appear in the Create/Edit Materials Dialog Box either with the name real-gas-

_name, where_nameis the NIST material selected for the single species model, or with the name real-gas-mixture for the multiple species model. The inputs for the properties calculated by the NIST functions are disabled. You can use the Create/Edit Materials Dialog Box to define or modify:Mass diffusivity property in the real-gas-mixture material if you are using the multiple-species NIST real gas model (note that the kinetic-theory option is not available)

Radiation properties if you are modeling radiation

Properties of materials other than the NIST real-gas-mixture or real-gas-fluid materials

Activating one of the NIST real gas models is a two-step process. First you enable either the single- or multi-species NIST real gas model, and then you select the fluid material from the REFPROP database.

Enable the appropriate NIST real gas model by typing the following text command at the Ansys Fluent console prompt:

Pure fluid real gas model:

>

define/user-defined/real-gas-models/nist-real-gas-modeluse NIST real gas? [no]yesMulti-species real gas model:

>

define/user-defined/real-gas-models/nist-multispecies-real-gas-modeluse multispecies NIST real gas? [no]yes

The list of available pure fluid materials you can select from will be displayed.

Select material from the REFPROP database list:

Pure fluid real gas model:

Enter the name of a single pure fluid that you want to investigate as follows:

select real-gas data file [""]

methane.fldMulti-species real gas model:

Enter the number of desired species in the mixture:

Number of species []

3followed by the name of each fluid in quotation marks selected from the list printed in the console:

select real-gas data file [""]

nitrogen.fldselect real-gas data file [""]co2.fldselect real-gas data file [""]methane.fldUpon selection of a valid pure or multi-species fluids, Ansys Fluent will load the relevant material data from a library of pure fluids supported by the REFPROP database, and report that it is opening the shared library (

librealgas.so) where the compiled REFPROP database source code is located. A list of properties for the specified material, including its applicable pressure and temperature ranges, will also be reported in the console.

Important:For mixture flows, not all combinations of species mixtures are allowed. This could be due to lack of data for one or more binary pairs. In such situations an error message generated by NIST will be returned and displayed on the Ansys Fluent console, and no real gas material is allowed to be created. In some combinations the mixing data will be estimated, a warning message will be displayed on the Ansys Fluent console and the mixture material allowed to be created.

Transport property calculations are not supported for mixtures that include water with molar concentration over 5%. If this limit is exceeded in your calculation, Ansys Fluent will issue a warning message. Transport equations are not available for the ammonia/water mixture and for mixtures with alcohols. As a result, the NIST real gas model with those mixtures can only be used for modeling inviscid flow.

If you want to use NIST lookup tables in your simulation, you can create them as described in the following sections:

Creating Full NIST Look-up Tables (single and multi-species materials with thermal properties as well as saturation data for a fixed multi-species composition)

Creating Binary Mixture Saturation Tables for Binary Mixtures (binary mixtures only)

(cases with no NIST tables only) If you would like to model flow in the liquid state, you can use the

set-stateTUI command. Note that the default state is vapor, so if you do not go through this step, vapor is assumed. Also, if the flow conditions do not permit liquid to exist, a vapor calculation will be performed instead.>

define/user-defined/real-gas-models/set-stateSelect vapor state (else liquid)?[yes]In addition, you may specify the state for a specific fluid zone or a specific phase (if you are using the multiphase model) by typing the following text command at the Ansys Fluent console prompt:

>

define boundary-conditions modify-zones change-zone-stateSelect a name/id from fluid zones list [(liquid-zone fluid-1)]liquid-zoneSet zone real-gas state: -1:use global setting 0:liquid 1:vapor [-1]0

By default, the NIST functions are called directly each time the thermal properties are updated during iteration. Alternatively, you can use the NIST look-up tables in your simulation as described below. Computing the look-up table offers two advantages:

Reduction in computation time because the NIST functions do not need to be called each time the thermal properties are updated

The look-up table created is applicable to both liquid and vapor phases

To create a full NIST look-up table, first enable the NIST real gas model as described in Activating the NIST Real Gas Model, and then follow these steps:

When prompted with

Create Full NIST LookUp Tables for multi components? [no], answeryes.Specify parameters for the look-up table generation.

For both single- and multi-species real gas models, you need to specify:

Pressure and temperature bounds for the table

You must ensure that the temperature and pressure bounds you specify are strictly within the stated limits of applicability that are displayed when the NIST model is loaded.

Number of pressure, temperature, and saturation points, which determines the resolution of the property look-up table

The minimum number of pressure and temperature points is 12 and there is no upper limit. However, the larger the table, the greater the memory and computing time requirements. Use a few test runs to strike the best balance of costs (memory and computing time) and accuracy.

For multi-species, you will also need to specify:

Upper and lower molar density bounds for bubble and dew point calculations

Molar density is used to build the saturation table. The default values work well for most compositions.

The mixture composition on a mass or mole basis

You must ensure that the sum of all constituent fractions adds up to 1 when specifying mass/molar fractions for the components. The maximum number of species is 20.

The bubble points and dew points filenames and the directory where you want to store the files.

Examples of inputs for the NIST look-up tables:

Pure fluid real gas model:

Min Pressure Value For NIST Table (pa) [13200] Max Pressure Value For NIST Table (pa) [20000]

1000000Min Temperature Value For NIST Table (k) [237.3] Max Temperature Value For NIST Table (k) [500]400Number of Pressure Points For NIST Table [101] Number of Temperature Points For NIST Table [101] Number of Saturation Points For Bubble/Dew Curve [300] NIST table created! Properties for both liquid and vapor phases included! Tcrit = 3.391730e+02 pcrit = 3.617700e+06 Dcrit = 5.735823e+02 Ttrp = 1.725200e+02Multi-species real gas model:

Min Pressure Value For NIST Table (pa) [130000] Max Pressure Value For NIST Table (pa) [5000000] Min Temperature Value For NIST Table (k) [220] 180 Max Temperature Value For NIST Table (k) [490] 600 Number of Pressure Points For NIST Table [101] Number of Temperature Points For NIST Table [101] Please Select Mass Fractions [Y] or Molar Fractions [N] for Composition of Fluid [yes] Composition of Fluid will be set in Mass Fractions! co2.fld [0.4] methane.fld [0.4] 0.6 Create NIST Saturation Curves for the same multi components? [no] y Number of Saturation Points For Bubble/Dew Curve [300] 22 Min Molar Density For Bubble and Dew Points Calculations (mol/l) [0.1] Max Molar Density For Bubble and Dew Points Calculations (mol/l) [25] Bubble Points File Name ["Bubble_PT.xy"] Dew Points File Name ["Dew_PT.xy"] Directory to store Saturation Files [""] Start NIST Look-Up Table Calculations ... Property Table... 83.3 percent completed! NIST table for 2-components created! Properties for both liquid and vapor phases included! End NIST Look-Up Table Calculations Use the created NIST Lookup Table for thermal property calculations? [no] y

Once the table is created, you must confirm that you want to use the look-up table for thermal properties calculations when prompted.

Use the created NIST Lookup Table for thermal property calculations? [no]

yesThe created NIST Lookup Table will be used to calculate the thermal properties!If properties are needed at conditions outside the limits you have specified for the table, Fluent will automatically call the original NIST model functions to calculate the thermal properties. If more than 10% of the property evaluations require computation outside the look-up table, Fluent will print a message indicating the percentage of calculations using direct computation. This can be used as an indicator to adjust the temperature and pressure ranges for the table to minimize the computational cost.

For multi-species real gas properties, the following tables will be created:

fluid properties

saturation conditions

Capabilities and Limitations on Using Multi-Species Full NIST look-up Tables

The look-up table is not saved with the case file. If you restart Fluent or re-read case and data files into the current Fluent session, the table will be cleared and you must go through the steps above to re-create it before running a simulation.

For computation of saturation properties for the bubble and dew points for a single- or multiple-species, Fluent provides macros that you can use in UDFs. See NIST Real Gas Saturation Properties in the Fluent Customization Manual for more information.

The tables apply for compressible fluids with material properties that are a function of local pressure and temperature. The material properties covered by the table include fluids in the liquid and vapor phases. The flashing applications between liquid and vapor phases can be conducted using saturation conditions established for the fluid(s) using mass transfer models.

The property look-up tables and saturation tables are created for fixed fluid compositions. This means the look-up tables are based on the following assumptions:

Mixture composition is constant

No chemical reactions are involved

No mixing of fluids of different compositions, including no mixing between phases

The look-up table only applies to single-species/multi-species in single-phase flows.

The temperature and pressure bounds must be specified within the stated limits of applicability that are displayed when the NIST model is loaded.

When specifying the table size, it is important to pick temperature and pressure ranges that are large enough to satisfy the current flow conditions.

If the temperature and pressure ranges you specify are too narrow, Fluent uses the NIST model to calculate the thermal properties. The time saved by creating the table will be negated if the percentage of calculations performed outside of the table is greater than 10%. This percentage is printed, so you can use it as an indicator for adjusting the temperature and pressure range of the table.

For multi-species table, the bubble and dew points are saved into files(Fluent plot file format) called

Bubble_PT.xyandDew_PT.xyin the working directory.The look-up table is a structured table and may not be suitable for simulating flow behaviors near the critical point when higher resolution is required.

To create a saturation data look-up table for binary species mixtures (mixtures of two species only), first enable the NIST real gas model as described in Activating the NIST Real Gas Model and then follow these steps:

When prompted with

Create Full NIST LookUp Tables for multi components? [no], answerno.When prompted with

Create Saturation Table For Binary Mixture Only? [no], answeryes.Important: Not all binary mixtures can be computed from the Fluent built-in NIST model. The allowed combination of materials is determined by the current database of NIST that can be found in hmx.bnc in the Ansys Fluent installation directory.

Specify parameters for the binary saturation data look-up table generation:

The number of saturation curves

The number of points for each saturation curve

The default number is 12. The actual number of points for each bubble and dew curve may be different than specified because the NIST model may not yield valid computation results for every density point for a given mass fraction.

Upper and lower molar density bounds for bubble and dew point calculations

The molar density is used to build the saturation table. You should provide reasonable values for the minimum and maximum molar densities corresponding to gas phase at low pressure and high temperature, and liquid phase at high pressure and low temperature. The default values (as shown in the example below) are a good starting point. You may need to adjust these values if there is not enough data in the selected range.

The filenames for bubble points and dew points and the existing directory where you want to store the files.

An example of inputs for the NIST binary look-up table:

Number of Mass Fraction Points For Binary Mixture [12] Number of Saturation Points For Bubble/Dew Curve [12] Min Molar Density For Bubble and Dew Points Calculations (mol/l) [0.1] Max Molar Density For Bubble and Dew Points Calculations (mol/l) [25] Bubble Points File Name ["Bubble_PT.xy"] Dew Points File Name ["Dew_PT.xy"] Directory to store Saturation Files [""] out

The lookup table builds multiple sets of the bubble and dew points for the binary mixture with mass fractions for the first component between 0 and 1. The second component mass fraction is equal to the first component mass fraction subtracted from unity. The number of saturation curves is determined by the number of mass fraction points that you specified.

Once the lookup table is created, Fluent saves the bubble and dew points data into files and directory you specified.

NIST Binary Saturation Files

NIST binary saturation files store saturation data lookup table for bubble and dew points for a binary mixture with mass fractions between 0 and 1. They can be used for mass and heat transfer modeling involving phase changes.

The binary saturation file structure is as follows. The file contains several data sets for bubble/dew point curves for a series of mass fractions. Each data set consists of the following three parts:

Line 1: The mass fraction of the first species (a single float number between 0 and 1).

Line 2: The number of data pairs for saturation pressure and temperature.

The specified number of lines that follow line 2: Data pairs of saturation pressure and temperature. The last pressure-temperature pair corresponds to the critical condition.

The example below shows the saturation dew point data for the first two curves, both with 12 pressure-temperature pairs. The first data set is for 0 and the second is for a 0.083333 mass fraction of the first species. The pressure-temperature critical condition is (4.872200e+06, 3.053220e+02) for the first curve and (5.547305e+06, 2.947561e+02) for the second curve.

0.000000 12 1.142108e+00 9.036800e+01 7.314020e+01 1.099093e+02 1.202771e+03 1.294505e+02 8.833626e+03 1.489918e+02 3.890130e+04 1.685331e+02 1.219542e+05 1.880744e+02 3.025174e+05 2.076156e+02 6.354397e+05 2.271569e+02 1.182515e+06 2.466982e+02 2.011733e+06 2.662395e+02 3.201942e+06 2.857807e+02 4.872200e+06 3.053220e+02 0.083333 12 1.509489e+05 1.891238e+02 1.257388e+06 2.428513e+02 2.252097e+06 2.631615e+02 3.090473e+06 2.752623e+02 3.775539e+06 2.831498e+02 4.318958e+06 2.883822e+02 4.735586e+06 2.917723e+02 5.042345e+06 2.938262e+02 5.258091e+06 2.949048e+02 5.402834e+06 2.952901e+02 5.495209e+06 2.951982e+02 5.547305e+06 2.947561e+02 ..... .....

The flow modeling of NIST real-gas flow is much more complex and challenging than simple ideal-gas flow. Therefore, you should expect the solution to converge at much slower rate with real-gas flow than when running ideal-gas flow. Also due to the complexity of the equations used in property evaluations, converging a solution with the real-gas model is in general done at much lower Courant values when you are using the density-based solver, or at much lower under-relaxation values if you are using the pressure-based solver. It is recommended that you first attempt to converge your solution using first-order discretization, then switch to second-order discretizations and re-iterate to convergence.

The real-gas properties in NIST are defined within a limited/bounded range. It is important that the flow conditions you are prescribing fall within the range of the database. It is possible that you specify flow at a state that is physically valid but otherwise not defined in the database. In this situation the solution will diverge or immediately generate an error message on the Ansys Fluent console as soon as the state crosses the limit of the database. In some instances, the actual converged state is just within the bounded defined database but only transitory outside the range. In this situation the divergence can be avoided by lowering the Courant value or under-relaxation factors so a less aggressive convergence rate is adapted.

Finally, if you attempt to initialize the flow from an inlet flow conditions and an error message is generated from one of the property routines, then this is an indicator that the flow conditions you have specified is not defined within the range of the database.

When you save your completed real gas model to a case file, the linkage to the shared library

containing real gas properties will be saved to the case file (along with property data

for the material you selected in the NIST real gas model). This information can be

reported to the console by listing the material properties (using the command

/define/materials/list-properties <material-name>) and

viewed in the Create/Edit Materials dialog box by selecting

Edit… for density.

All postprocessing functions properly report and display the current thermodynamic and transport properties of the selected real gas model. The thermodynamic and transport properties controlled by the NIST real gas model include the following:

density

enthalpy

entropy

molecular weight

molecular viscosity

sound speed

specific heat

thermal conductivity In addition to the properties listed above, you can also report

compressibility factor

any quantities that are derived from the properties listed above (for example, total quantities, ratio of specific heats)

The user-defined real gas model (UDRGM) has been developed to allow you to write your own custom real gas model to fit your particular modeling needs. It also allows you to simulate a single-species flow, multiple-species mixture flow, multiphase flow, or volumetric reactions.

The following limitations exist for the UDRGM:

You cannot include more than one user-defined real gas material (fluid or mixture) in the same problem. However, you can use other materials together with real gas in your simulation.

When you are using the UDRGM, the materials defined in your real gas UDF will appear in the Create/Edit Materials Dialog Box with the name real-gas-fluid or real-gas-mixture and all physical and thermodynamic property inputs disabled. Use the Create/Edit Materials Dialog Box to define or modify:

Mass diffusivity property in the real-gas-mixture material if you are modeling multicomponent flow.

Chemical reactions in the real-gas-mixture if you are modeling reacting flow.

Radiation properties for the real-gas-mixture or the real-gas-fluid materials if you are modeling radiation.

Properties of materials other than the user-defined real-gas-mixture or real-gas-fluid materials.

Note: If you are using the UDRGM together with other materials from Ansys Fluent's property database in dispersed phase or multiphase calculations, take care to use the same reference temperature as in Ansys Fluent in your real-gas UDF. The reference temperature in Ansys Fluent is 298.15 K.

Pressure-inlets, mass flow-inlets, and pressure-outlets are the only inflow and outflow boundaries available for use with the real gas models.

Non-reflecting boundary conditions are not compatible with the real gas models when using the density-based solver. If your model requires NRBC and a real gas model, you must use the pressure-based solver.

The UDRGM can be used with the Eulerian multiphase models.

The UDRGM is compatible with the Lagrangian Dispersed Phase Models. Refer to Using the Cubic Equation of State Models with the Lagrangian Dispersed Phase Models for guidelines and restrictions of this approach.

The real gas models cannot be used with the non-premixed, partially premixed, and composition PDF transport combustion models. Chemical reactions can however be modeled with the finite rate and eddy dissipation models. Note that the Dimension Reduction model is not available with the real gas models.

The UDRGM does not allow specification of site or solid species and consequently cannot be used with wall surface reactions.

The UDRGM requires a library of functions written in the C programming language. Moreover, there are certain coding requirements that need to be followed when writing these functions. Sample real gas function libraries are provided to assist you in writing your own UDRGM. When UDRGM functions are compiled, they will be grouped in a shared library that later will be loaded and linked with the Ansys Fluent executable. The procedure for using the UDRGM is defined as follows:

Define the real gas equation of state and all related thermodynamic and transport property equations.

Create a C source code file that conforms to the format defined in this section.

Start Ansys Fluent and set up your case file in the usual way.

Compile your UDRGM C library and build a shared library file (you can use the available compiled UDF utilities in either the graphical user interface or the text command interface).

Load your newly created UDRGM library via the text command menu:

If a single-species UDRGM to be used, then the text command menu is:

> define/user-defined/real-gas-models/user-defined-real-gas-modeluse user defined real gas? [no]yesOn the other hand, if you are simulating multiple-species UDRGM flow, then the text command menu to use is:

> define/user-defined/real-gas-models/user-defined-multispecies-real-gas-modeluse user multispecies defined real gas? [no]yesUpon activating the UDRGM, the function library will now supply the fluid material properties for your case.

You can simulate volumetric reactions with your real gas model using the Species Model Dialog Box, or the text interface (

define/models/species/volumetric-reactions?).You can access the Species Model from the tree by going to Setup/Models/Species and double-clicking Species.

In the Species Model Dialog Box

Enable Species Transport under Model.

Enable Volumetric under Reactions.

Select the appropriate Turbulence-Chemistry Interaction option.

Set up the reaction by clicking the button for the real-gas-mixture Mixture Material.