The program uses real constants and KEYOPTs to control contact behavior using surface-to-surface contact elements. For more information in addition to what is presented here, refer to the individual contact element descriptions in the Element Reference.

If you decide the real constant and KEYOPT settings you have specified for a particular contact pair are not appropriate, you can use the CNCHECK,RESET command to reset all values back to their default settings. Some real constants and key options are not affected by this command. See CNCHECK for details.

In many cases, certain default settings may not be appropriate for your specific model. You can issue the CNCHECK,AUTO command to obtain optimized KEYOPT and real constant settings in terms of robustness and efficiency. Usually, only the undefined or default KEYOPT settings and real constants are changed. Refer to the CNCHECK command description for details of which settings are typically changed. You should always verify these changes by issuing the CNCHECK,DETAIL command to list current contact pair properties. If necessary, you can overwrite the optimized settings by redefining specific KEYOPTs (KEYOPT command) and real constants (RMODIF command).

The following related topics are available:

- 3.9.1. Real Constants

- 3.9.2. Element KEYOPTS

- 3.9.3. Selecting a Contact Algorithm (KEYOPT(2))

- 3.9.4. Determining Contact Stiffness and Allowable Penetration

- 3.9.5. Choosing a Friction Model

- 3.9.6. Selecting Location of Contact Detection

- 3.9.7. Selecting a Sliding Behavior

- 3.9.8. Adjusting Initial Contact Conditions

- 3.9.9. Modeling Interference Fit

- 3.9.10. Physically Moving Contact Nodes Toward the Target Surface

- 3.9.11. Physically Moving the Target Body Toward the Contact Surface

- 3.9.12. Determining Contact Status and the Pinball Region

- 3.9.13. Avoiding Spurious Contact in Self Contact Problems

- 3.9.14. Selecting Surface Interaction Models

- 3.9.15. Using KEYOPT(3) to Control Units of Contact Stiffness and Stress State

- 3.9.16. Modeling Contact with Superelements

- 3.9.17. Modeling Contact for 2D Axisymmetric Elements with Torsion

- 3.9.18. Applying Contact Stabilization Damping

- 3.9.19. Modeling Interface Damping in Assembled Structures

- 3.9.20. Accounting for Thickness Effect

- 3.9.21. Using Time Step Control and Impact Constraints

- 3.9.22. Using the Birth and Death Options

Use the R and RMORE commands to define real constants. The first two real constants, R1 and R2, are used to define the geometry of the target surface elements. The remaining are used by the contact surface elements.

R1 and R2 define the target element geometry.

FTOLN is a factor based on the thickness of the element which is used to calculate allowable penetration. [2]

ICONT defines an initial closure factor (or adjustment band).

PINB defines a "pinball" region.

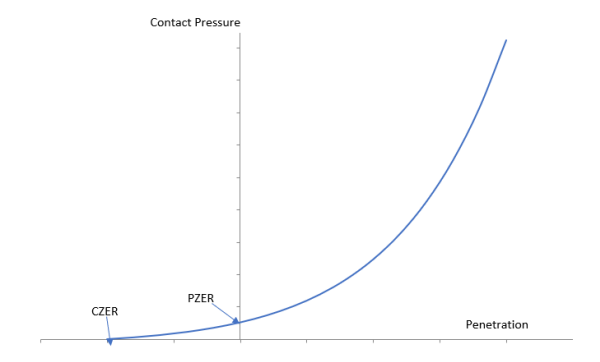

PZER defines pressure at zero penetration.

CZER defines initial clearance.

TAUMAX specifies the maximum contact friction.

CNOF specifies the positive or negative offset value applied to the contact surface.

FKOP specifies the stiffness factor applied when contact opens.

COHE specifies the cohesion sliding resistance.

TCC specifies the thermal contact conductance coefficient.

FHTG specifies the fraction of frictional dissipated energy converted into heat.

SBCT specifies the Stefan-Boltzmann constant.

RDVF specifies the radiation view factor.

FWGT specifies the weight factor for the distribution of heat between the contact and target surfaces for thermal contact or for electric contact.

ECC specifies the electric contact conductance or capacitance per unit area.

FHEG specifies the fraction of electric dissipated energy converted into heat.

FACT specifies the ratio of static to dynamic coefficients of friction.

DC specifies the decay coefficient for static/dynamic friction.

SLTO controls maximum sliding distance when MU is nonzero and the tangent contact stiffness (FKT) is updated at each iteration (KEYOPT(10) = 0 or 2) or when KEYOPT(2) = 3.

TNOP specifies the maximum allowable tensile contact pressure. [2]

TOLS adds a small tolerance that extends the edge of the target surface.

MCC specifies the magnetic contact permeance (3D only).

PPCN specifies the pressure-penetration criterion (surface contact elements only).

FPAT specifies the fluid penetration acting time (surface contact elements only).

COR specifies the coefficient of restitution for impact between rigid bodies using impact constraints (KEYOPT(7) = 4).

STRM specifies load step number for ramping penetration, or starting time for ramping contact stiffness.

FDMN specifies the stabilization damping factor in the normal direction.

FDMT specifies the stabilization damping factor in the tangential direction.

FDMD specifies the destabilizing squeal damping factor (3D only).

FDMS specifies the stabilizing squeal damping factor (3D only).

TBND specifies the critical bonding temperature.

WBID is an internal contact pair ID (used only by the Results Tracker in Workbench Mechanical)

PCC specifies the pore fluid contact permeability coefficient.

PSEE specifies the pore fluid seepage.

ABPP specifies the ambient pore pressure.

FPFT specifies the gap pore fluid flow participation factor.

FPWT specifies the gap pore fluid flow distribution weighting factor.

DCC specifies the diffusivity coefficient.

DCON specifies the diffusive convection coefficient.

ABDC specifies the ambient concentration.

BSRL identifies the real constant set ID of the original (base) contact pair after a spitting operation.

KSYM identifies the real constant set ID of the companion pair for a symmetric pair or self contact (determined by the splitting logic).

TFOR specifies the pair-based force convergence tolerance.

TEND defines the ending time for ramping contact stiffness.

When the contact element is used as part of a forced-distributed constraint and KEYOPT(7) = 2 on the target element, FKN is used to define weighting factors in tabular format with node number as the primary variable.

When the relaxation option is enabled (KEYOPT(11) = 1 on the target element) for a surface-based constraint or a rigid body, FKN and FKT are translational relaxation coefficient and rotational relaxation coefficient, respectively, and tabular input is not supported. In addition, FTOLN and TNOP are translational tolerance and rotational tolerance, respectively.

Real constant defaults can vary depending on the environment you are working in. The following table compares the program default values with those of the Ansys Workbench product.

Table 3.1: Summary of Real Constant Defaults in Different Environments

| Real Constants | Description | Ansys Mechanical APDL Default | Ansys Workbench Default | |

|---|---|---|---|---|

| No. | Name | |||

| 1 | R1 [4] | Radius associated with target geometry |

0 | n/a |

|

Target radius (CONTA177) |

Calculated by program | |||

| 2 | R2 [4] |

Radius associated with target geometry |

0 | n/a |

|

Superelement thickness |

1 | |||

|

Contact radius (CONTA177) |

Calculated by program | |||

| 3 | FKN | Normal penalty stiffness factor | 1 | [1] |

| 4 | FTOLN | Penetration tolerance factor | 0.1 | 0.1 |

| 5 | ICONT | Initial contact closure | 0 | 0 |

| 6 | PINB | Pinball region | [2] | [2] |

| 7 | PZER | Pressure at zero penetration | [7] | [7] |

| 8 | CZER | Initial contact clearance factor | 0.01 | 0.01 |

| 9 | TAUMAX | Maximum friction stress | 1.00E+20 | 1.00E+20 |

| 10 | CNOF | Contact surface offset | 0 | 0 |

| 11 | FKOP | Contact opening stiffness | 1 | 1 |

| 12 | FKT | Tangent penalty stiffness factor | 1 | 1 |

| 13 | COHE | Contact cohesion | 0 | 0 |

| 14 | TCC | Thermal contact conductance | 0 | [3] |

| 15 | FHTG | Frictional heating factor | 1 | 1 |

| 16 | SBCT | Stefan-Boltzmann constant | 0 | n/a |

| 17 | RDVF | Radiation view factor | 1 | n/a |

| 18 | FWGT | Heat distribution weighing factor | 0.5 | 0.5 |

| 19 | ECC | Electric contact conductance | 0 | [6] |

| 20 | FHEG | Joule dissipation weighting factor | 1 | n/a |

| 21 | FACT | Static/dynamic ratio | 1 | 1 |

| 22 | DC | Exponential decay coefficient | 0 | 0 |

| 23 | SLTO | Allowable elastic slip | 1% | 1% |

| 24 | TNOP | Maximum allowable tensile contact pressure | [5] | [5] |

| 25 | TOLS | Target edge extension factor | 2 | 2 |

| 26 | MCC | Magnetic contact permeance | 0 | n/a |

| 27 | PPCN | Pressure-penetration criterion | 0 | n/a |

| 28 | FPAT | Fluid penetration acting time | 0.01 | n/a |

| 29 | COR | Coefficient of restitution | 1 | 1 |

| 30 | STRM | Load step number for ramping penetration | 1 [8] | 1 [8] |

| 31 | FDMN | Normal stabilization damping factor | 1 | n/a |

| 32 | FDMT | Tangential stabilization damping factor | 0.001 | n/a |

| 33 | FDMD | Destabilizing squeal damping factor | 1 | n/a |

| 34 | FDMS | Stabilizing squeal damping factor | 0 | n/a |

| 35 | TBND | Critical bonding temperature | n/a | n/a |

| 36 | WBID | Internal contact pair ID (used only by the Results Tracker in Workbench Mechanical) | n/a | Internal pair ID |

| 37 | PCC | Pore fluid contact permeability coefficient | 0 | n/a |

| 38 | PSEE | Pore fluid seepage coefficient | 0 | n/a |

| 39 | ABPP | Ambient pore pressure | 0 | n/a |

| 40 | FPFT | Gap pore fluid flow participation factor | 0 | n/a |

| 41 | FPWT | Gap pore fluid flow distribution weighting factor | 0.5 | n/a |

| 42 | DCC | Contact diffusivity coefficient | 0 | n/a |

| 43 | DCON | Diffusive convection coefficient | 0 | n/a |

| 44 | ABDC | Ambient concentration | 0 | n/a |

| 45 | BSRL | Real ID of base contact pair (after splitting) | 0 | n/a |

| 46 | KSYM | Real ID of companion pair (determined by the splitting logic) | 0 | n/a |

| 47 | TFOR | Pair-based force convergence tolerance | n/a | n/a |

| 48 | TEND | Ending time for ramping contact stiffness | 0 | 0 |

FKN = 10 for bonded. For all other, FKN = 1.0, but if bonded and other contact behavior exists, FKN = 1 for all.

Depends on contact behavior (rigid vs. flex target), NLGEOM,ON or OFF, KEYOPT(9) setting, KEYOPT(12) setting, and the value of CNOF (see Defining the Pinball Region (PINB)).

Calculated as a function of highest conductivity and overall model size.

R1 and R2 are used to define the contact or target element geometry for pair-based contact. See Defining Target Element Geometry and the target element descriptions (TARGE169 and TARGE170) for details on how they are used for different geometries.

TNOP defaults to the force convergence tolerance divided by contact area at contact nodes.

Calculated as a function of lowest resistivity and overall model size.

If TEND is specified as a positive value, STRM defaults to zero.

For the real constants FKN, FTOLN, ICONT, PINB, PZER, CZER, FKOP, FKT, SLTO, TNOP, FDMN, and FDMT, you can specify either a positive or negative value. The program interprets a positive value as a scaling factor and interprets a negative value as the absolute value. The program uses the depth of the underlying element as the reference value for ICONT, FTOLN, PINB, and CZER. For example, a positive value of 0.1 for ICONT indicates an initial closure factor of 0.1 x depth of the underlying element. However, a negative value of 0.1 indicates an actual adjustment band of 0.1 units. Contact related settings (ICONT, FTOLN, PINB, FKN, FKT, SLTO) are always averaged across all contact elements in a contact pair.

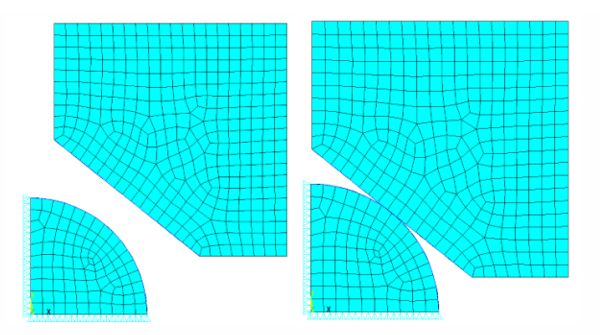

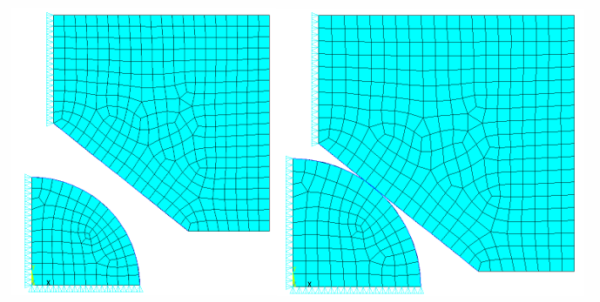

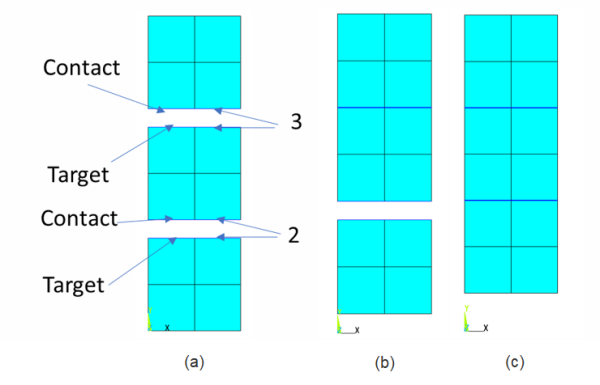

Figure 3.12: Depth of the Underlying Element shows the depth of the underlying element for a solid element. If the underlying elements are shell or beam elements, the depth will usually be 4 times the element thickness. The final contact depth may also be adjusted based on the average contact length when the shape of the underlying element is relatively thin.

Each contact pair has a pair-based depth which is obtained by averaging the depth of each contact element across all the contact elements in a contact pair. This can avoid the problem of very different element-based depths when there are meshes with large variations in element sizes.

Note: When the contact pair depth is too small (for example, 10-5), the machine precision may not guarantee the accuracy of penetration to be calculated. You should scale the length unit in the model.

For certain real constants, you can define the real constant as a function of primary variables by using tabular input. Table 3.2: Real Constants and Corresponding Primary Variables for CONTA172, CONTA174, CONTA175, CONTA177 lists real constants that allow tabular input and their associated primary variables.

You should follow the positive and negative convention for the real constant values. Use all positive or all negative values. Do not mix positive and negative values.

Use the *DIM command to dimension the table and identify the variables. The possible primary variables used in tabular input are:

Time (TIME)

X location (X) in local/global coordinates

Y location (Y) in local/global coordinates

Z location (Z) in local/global coordinates

Temperature (TEMP) degree of freedom

Contact pressure (PRESSURE):

Specify positive index values for compression, negative index values for tension.

Geometric contact gap/penetration (GAP):

Numerical offsets are not included.

Specify positive index values for penetration, negative index values for an open gap.

Node number (NODE)

Note that the primary variables X, Y, and Z represent the coordinates of the contact detection points at the beginning of solution (undeformed configuration). Coordinate system applicability is determined by the *DIM command.

When defining the tables, the primary variables must be in ascending order in the table indices (as in any table array).

When defining real constants via the R,

RMORE, or RMODIF command, enclose the

table name in % signs (that is, %tabname%). For

example, given a table named CNREAL3 that contains normal contact stiffness

(FKN) values, you would issue a command similar to the following:

RMODIF,NSET,3,%CNREAL3% !NSETis the real constant set ID associated with the contact pair

For more information and examples of using table inputs, see Tabular Input via Table Array Parameters in the Ansys Parametric Design Language Guide, Applying Loads Using Tabular Input in the Basic Analysis Guide, and the *DIM command.

Table 3.2: Real Constants and Corresponding Primary Variables for CONTA172, CONTA174, CONTA175, CONTA177

| Real Constants | TIME | Location (X,Y,Z) [1] | TEMP | PRESSURE [2] | GAP [3] | NODE | %_CNPROP% [6] | |

|---|---|---|---|---|---|---|---|---|

| Number | Name | |||||||

| 3 | FKN | x | x | x | x [4] | x | x [8] | x |

| 7 | PZER | x [7] | x [7] | |||||

| 9 | TAUMAX | x | x | x | x | x | x | |

| 10 | CNOF | x | x | x | ||||

| 11 | FKOP | x | x | x | x | x | ||

| 12 | FKT | x | x | x | x | x | x | |

| 14 | TCC | x | x | x | x [5] | x | x | |

| 17 | RDVF | x | x | x | x | x | ||

| 19 | ECC | x | x | x | x [5] | x | x | |

| 26 | MCC | x | x | x | x | x | ||

| 27 | PPCN | x | x | x | x | x | x | |

| 31 | FDMN | x | x | x | x | x | ||

| 32 | FDMT | x | x | x | x | x | ||

| 35 | TBND | x | x | x | x | x | x | |

| 37 | PCC | x | x | x | x [5] | x | x | |

| 38 | PSEE | x | x | x | x [5] | x | x | |

| 39 | ABPP | x | x | x | x [5] | x | x | |

| 40 | FPFT | x | x | x | x | x | x | |

| 42 | DCC | x | x | x | x [5] | x | x | |

| 43 | DCON | x | x | x | x [5] | x | x | |

| 44 | ABDC | x | x | x | x [5] | x | x | |

Coordinates of the contact detection points at the beginning of solution (undeformed configuration).

Contact normal pressure via the primary variable PRESSURE. For PRESSURE index values, specify positive values for compression or negative value for tension.

Geometric contact gap/penetration via the primary variable GAP. For GAP index values, specify positive values for penetration or negative values for an open gap.

Contact pressure at the end of the previous iteration, if it exists.

When the contact element type does not contain any structural degrees of freedom, the real constants TCC, ECC, PCC, PSEE, ABPP, DCC, DCON, and ABDC should not be defined as a function of the contact pressure.

When defined by tabular input or by the

USERCNPROP.Fuser subroutine, PZER must be a positive value, and it represents an absolute pressure (not a factor). This differs from its typical usage.When the contact element is used as part of a forced-distributed constraint and KEYOPT(7) = 2 on the target element, FKN is used to define weighting factors in tabular format with node number as the primary variable.

You can write a USERCNPROP.F subroutine to define your

own real constants. The real constants that can be defined via this user

subroutine are noted in the real constant table found in each contact element

description.

When defining real constants with the R,

RMORE, or RMODIF command, you must use

the reserved table name _CNPROP and enclose it in % signs (%_CNPROP%). When a

value field on one of these commands is set to %_CNPROP%, the program internally

calls the user-defined subroutine USERCNPROP. For example,

to specify your own normal contact stiffness, FKN, you would issue a command

similar to the following:

RMODIF,NSET,3,%_CNPROP% !NSETis the real constant set ID associated with the contact pair

If several real constant values are defined via %_CNPROP% for a given contact

pair, the subroutine will be called for each of these real constant entries.

Therefore, you can use a single USERCNPROP subroutine to

modify multiple real constant values. For details, see Defining Your Own Real Constant (USERCNPROP).

Each contact element includes several KEYOPTS. Ansys recommends using the default settings, which are suitable for most contact problems. For some specific applications, you can override the defaults. The element KEYOPTS allow you to control several aspects of contact behavior.

KEYOPT defaults can vary depending on the environment you are working in. The following table compares the default values between the various contact creation tools, for both Ansys Mechanical APDL and Ansys Workbench.

Table 3.3: Summary of KEYOPT Defaults in Different Environments

| KEYOPT | Description | Ansys Mechanical APDL | Contact Wizard | General Contact (GCGEN command) | Ansys Workbench Default Linear (bonded, no sep) | Ansys Workbench, Default Nonlinear (standard, rough) |

|---|---|---|---|---|---|---|

| 1 | Selects DOF [1] | Manual | Auto | Auto | Auto | Auto |

| 2 | Contact Algorithm | Aug. Lagr. | Aug. Lagr. | Penalty | Aug. Lagr. | Aug. Lagr. |

| 3 | Unit control for normal contact stiffness or 2D stress state for underlying superelements | No unit control | No unit control | Not supported | n/a | n/a |

| 4 | Location of contact detection point | gauss | gauss | gauss | gauss | gauss |

| 5 | CNOF/ICONT adjustment | No adjust | No adjust | Not supported | No adjust | No adjust |

| 6 | Contact stiffnes variation | Use default range | Use default range | Use default range | Use default range | Use default range |

| 7 | Element level time increment control | No control | No control | No control | No control | No control |

| 8 | Symmetric contact behavior | No action | No action | GCDEF option | No action | No action |

| 9 | Effect of initial penetration or gap | Include all | Include all | TBDATA,,C1 | Exclude all | Include all |

| 10 | Contact stiffness update | Between iterations | Between iterations | Between iterations | Between iterations | Between iterations |

| 11 | Beam/shell thickness effect | Exclude | Exclude | Include | Exclude | Exclude |

| 12 | Behavior of contact surface | Standard | Standard |

TB,INTER,,,TBOPT | Bonded | n/a |

| 13 | Degree-of-freedom control for contact involving thermal shells | TEMP degree of freedom | n/a | Not supported | n/a | n/a |

| 14 | Behavior of fluid penetration load | Iteration- based | Iteration- based | Not supported | n/a | n/a |

| 15 | Effect of stabilization damping | Active only in first load step | n/a | Active only in first load step | n/a | n/a |

| 16 | Squeal damping controls | Damping scaling factor | n/a | Not supported | n/a | n/a |

| 18 | Sliding behavior | Finite sliding | Finite sliding | Finite sliding | Small sliding [2] | Finite sliding [3] |

For surface-to-surface contact elements, the program offers several different contact algorithms:

Penalty method (KEYOPT(2) = 1)

Augmented Lagrangian (default) (KEYOPT(2) = 0)

Lagrange multiplier on contact normal and penalty on tangent (KEYOPT(2) = 3)

Pure Lagrange multiplier on contact normal and tangent (KEYOPT(2) = 4)

Internal multipoint constraint (MPC) (KEYOPT(2) = 2)

The penalty method uses a contact spring to establish a relationship between the two contact surfaces. The spring stiffness is called the contact stiffness. This method uses the following real constants: FKN and FKT for all values of KEYOPT(10), plus FTOLN and SLTO if KEYOPT(10) = 0 or 2.

The augmented Lagrangian method (which is the default) is an iterative series of penalty methods. The contact tractions (pressure and frictional stresses) are augmented during equilibrium iterations so that the final penetration is smaller than the allowable tolerance (FTOLN). Compared to the penalty method, the augmented Lagrangian method usually leads to better conditioning and is less sensitive to the magnitude of the contact stiffness. However, in some analyses, the augmented Lagrangian method may require additional iterations, especially if the deformed mesh becomes too distorted.

The pure Lagrange multiplier method enforces zero penetration when contact is closed and "zero slip" when sticking contact occurs. The pure Lagrange multiplier method does not require contact stiffness, FKN and FKT. Instead it requires chattering control parameters, FTOLN and TNOP. This method adds contact traction to the model as additional degrees of freedom and requires additional iterations to stabilize contact conditions. It often increases the computational cost compared to the augmented Lagrangian method.

An alternative algorithm is the Lagrange multiplier method applied on the contact normal and the penalty method (tangential contact stiffness) on the frictional plane. This method enforces zero penetration and allows a small amount of slip for the sticking contact condition. It requires chattering control parameters, FTOLN and TNOP, as well as the maximum allowable elastic slip parameter SLTO.

The internal multipoint constraint (MPC) algorithm is used in conjunction with bonded contact (KEYOPT(12) = 5 or 6) and no separation contact (KEYOPT(12) = 4) to model several types of contact assemblies and kinematic constraints. See Multipoint Constraints and Assemblies for more information about how to use this feature.

Keep the following points in mind when using the Lagrange multiplier methods.

The Lagrange multiplier methods (KEYOPT(2) = 3, 4) do not support the Gauss point detection option (KEYOPT(4) = 0) for surface-to-surface contact. They support the nodal detection options for surface-to-surface contact and node-to-surface contact. When using these options, be careful not to overconstrain the model. The model is overconstrained when a contact node has prescribed boundary conditions, CE equations, or CP equations. The program first attempts to detect all potential overconstraints, and then eliminates the overconstraints by switching to the penalty method internally. However, there is no guarantee that the program will eliminate all cases of overconstraint. You should always verify your model carefully to address this issue.

For 3D higher-order contact elements (CONTA174) using nodal detection (KEYOPT(4)=1,2), the Lagrange multiplier method is applied at each contact node (including midside nodes), but the penalty method is applied on the center of the contact elements, even when KEYOPT(2) = 3 or 4 is set. For Normal Lagrange formulation (KEYOPT(2)=3,4), with 3D higher-order contact elements (with midside nodes), use of surface projection-based contacts (KEYOPT(4)=3,4) is strongly recommended.

In general, normal contact stiffness (FKN) has very little influence on the contact results when a Lagrange multiplier method is used. You should not overwrite the default FKN in most cases.

The Lagrange multiplier methods also introduce more degrees of freedom, which may result in spurious modes for modal and linear eigenvalue buckling analyses. The augmented Lagrangian method (KEYOPT(2) = 0) would be a better choice for these analysis types.

The Lagrange multiplier methods introduce zero diagonal terms in the stiffness matrix. Any iterative solver (for example, the PCG solver) will encounter a preconditioning matrix singularity with these methods. Therefore, you should switch to the sparse solver.

The following topics related to determining contact stiffness and allowable penetration are available.

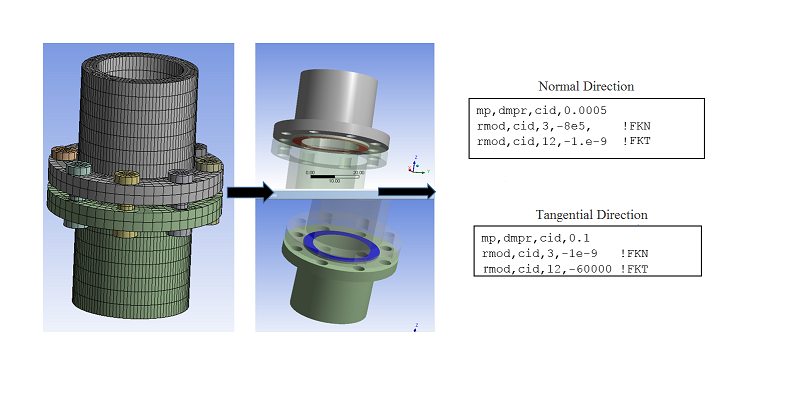

For the augmented Lagrangian method and penalty method, normal and tangential contact stiffnesses are required. The amount of penetration between contact and target surfaces depends on the normal stiffness. The amount of slip in sticking contact depends on the tangential stiffness.

Higher stiffness values decrease the amount of penetration/slip, but can lead to ill-conditioning of the global stiffness matrix and to convergence difficulties. Lower stiffness values can lead to a certain amount of penetration/slip and produce an inaccurate solution. Ideally, you want a high enough stiffness that the penetration/slip is acceptably small, but a low enough stiffness that the problem will be well-behaved in terms of convergence.

The program provides default values for contact stiffnesses (FKN, FKT), allowable penetration (FTOLN), and allowable slip (SLTO). Material properties of underlying elements can affect the calculation of default values of contact stiffnesses, as follows:

If the underlying solid material is an anisotropic elastic material, all elastic moduli may affect the contact stiffness.

The initial contact stiffness of contact elements overlaid on layered structural solid elements (SOLID185 or SOLID186) is influenced by the material properties of each layer weighted by the respective layer thickness.

In most cases, you do not need to define the contact stiffness. In addition, Ansys recommends that you use KEYOPT(10) = 0 or 2 to allow the program to update the contact stiffness automatically.

For certain contact problems, you may choose to use the real constant FKN to define a normal contact stiffness factor. The usual factor range is from 0.1 - 10.0, with a default of 1.0. The default value should work in most cases. You can also define an absolute normal contact stiffness by specifying a negative value for FKN.

In addition, FKN can be defined as a function of primary variables by using

tabular input (%tabname%). The possible primary

variables include time, temperature, initial contact detection point location

(at the beginning of solution), contact pressure of the previous iteration

(positive PRESSURE index values indicate compression, negative PRESSURE index

values indicate tension), and current geometric penetration (positive GAP index

values indicate penetration, negative GAP index values indicate an open gap).

For more information, see Defining Real Constants in Tabular Format.

The user subroutine USERCNPROP.F is also available for

defining FKN. To use this subroutine, you must specify the table name %_CNPROP%

as the real constant value. For more information, see Defining Real Constants via a User Subroutine.

If you input an absolute normal contact stiffness by specifying a negative value for FKN, you can control the units by using KEYOPT(3). By default, the units of the user-specified absolute normal contact stiffness is FORCE/LENGTH3. You can change the units to FORCE/LENGTH by setting KEYOPT(3) = 1. This KEYOPT(3) = 1 setting is valid only when a penalty-based algorithm is used (KEYOPT(2) = 0 or 1) and the absolute normal contact stiffness is explicitly specified. Using KEYOPT(3) = 1 is not recommended in conjunction with nodal detection options (KEYOPT(4) = 1 or 2) if any midside nodes exist for the CONTA174 3D contact element. (KEYOPT(3) has different meanings in other situations. For more information, see Using KEYOPT(3) to Control Units of Contact Stiffness and Stress State.)

Note: The default contact normal stiffness is affected by defined material properties, element size, and the user-defined penetration tolerance (FTOLN). Many factors may be applied to the actual contact normal stiffness during the solution. The default contact stiffness listed in the Contact Manager or by the CNCHECK command may be different from the actual contact stiffness reported by the ETABLE command. You should check the value reported by ETABLE to confirm that the appropriate contact normal stiffness is used.

Use real constant FTOLN in conjunction with the augmented Lagrangian method. FTOLN is a tolerance factor to be applied in the direction of the surface normal. The range for this factor is less than 1.0 (usually less than 0.2), with a default of 0.1, and is based on the depth of the underlying solid, shell, or beam element (see Figure 3.12: Depth of the Underlying Element). This factor is used to determine if penetration compatibility is satisfied.

Contact compatibility is satisfied if penetration is within an allowable tolerance (FTOLN times the depth of underlying elements). The depth is defined by the average depth of each individual contact element in the pair. If the program detects any penetration larger than this tolerance, the global solution is still considered unconverged, even though the residual forces and displacement increments have met convergence criteria. You can also define an absolute allowable penetration by specifying a negative value for FTOLN. In general, the default contact normal stiffness is inversely proportional to the final penetration tolerance. The tighter the tolerance, the higher the contact normal stiffness.

When you use real constant FTOLN in conjunction with KEYOPT(10) = 0 or 2, the normal contact stiffness (used for the penalty method and the augmented Lagrange method) is updated at each iteration based on the current mean stress of the underlying elements and the allowable tolerance (FTOLN times the depth of the underlying elements). See also Using KEYOPT(10).

Note: When the contact stiffness is too large (for example, 1016), the machine precision may not guarantee good conditioning of the global stiffness matrix. In this case, you should scale the force unit in the model if possible.

Note: FTOLN is also used in the Lagrange multiplier methods (KEYOPT(2) = 3, 4) as a chattering control parameter.

The program automatically defines a default tangential contact stiffness that is proportional to MU and the normal stiffness FKN. The default tangential stiffness corresponds to a default value of FKT = 1.0. A positive value for FKT is a factor. A negative value indicates an absolute value of tangential stiffness.

For KEYOPT(10) = 0 or 2, or when the Lagrange multiplier on normal and penalty on tangent option is used (KEYOPT(2) = 3), the program updates tangential contact stiffness based on current contact normal pressure, PRES, and maximum allowable elastic slip, SLTO (KT = FKT*MU* PRES/SLTO). In addition, other adjustments may be applied to the tangential contact stiffness.

By default, the allowed tangential contact stiffness variation is intended to enhance stiffness updating (when KEYOPT(13) = 0) by calculating an optimal allowable range in stiffness for use in the updating scheme. To increase the tangential stiffness variational range for the frictional contact, set KEYOPT(13) = 1 to make an aggressive refinement to the allowable stiffness range. Use of KEYOPT(13) = 1 is not recommended when contact convergence is relatively easy as it might produce a large amount of elastic slip for sticking contact.

The real constant SLTO is used to control maximum sliding distance when FKT is updated at each iteration. The program provides default tolerance values which work well in most cases.

The default value for SLTO is 1 percent of the average contact length in a pair. However, for a steady-state rolling analysis, the default value is 0.1(ω*R), where ω is the spin velocity specified by the SSTATE command and R is the distance of the contact detection point from the center of rotation.

You can override the default value for SLTO by defining a scaling factor (positive value when using command input) or an absolute value (negative value when using command input). A larger value will enhance convergence but compromise accuracy. Based on the tolerance, current normal pressure, and friction coefficient, the tangential contact stiffness FKT can be obtained automatically. In certain cases users can override FKT by defining a scaling factor (positive input value) or absolute value (negative input value) (see Positive and Negative Real Constants for more information).

In addition, FKT can be defined as a function of primary variables by using

tabular input (that is, %tabname%). The possible

primary variables include time, temperature, initial contact detection point

location (at the beginning of solution), current contact pressure (positive

PRESSURE index values indicate compression, negative PRESSURE index values

indicate tension), and current geometric penetration (positive GAP index values

indicate penetration, negative GAP index values indicate an open gap). For more

information, see Defining Real Constants in Tabular Format.

The user subroutine USERCNPROP.F is also available for

defining FKT. To use this subroutine, you must specify the table name %_CNPROP%

as the real constant value. For more information, see Defining Real Constants via a User Subroutine.

FKN, FTOLN, FKT, and SLTO can be modified from one load step to another. They can also be adjusted in a restart run.

Determining a good stiffness value may require some experimentation on your part. To arrive at a good stiffness value, you can try the following procedure as a "trial run":

Use a low value for the contact stiffness to start. In general, it is better to underestimate this value rather than overestimate it. Penetration problems resulting from a low stiffness are easier to fix than convergence difficulties that arise from a high stiffness.

Run the analysis up to a fraction of the final load (just enough to get the contact fully established).

Check the penetration and the number of equilibrium iterations used in each substep. If the global convergence difficulty is caused by too much penetration (rather than by residual forces and displacement increments), FKN may be underestimated or FTOLN may be too small. If the global convergence requires many equilibrium iterations for achieving convergence tolerances of residual forces and displacements rather than the resulting penetration, FKN or FKT may be overestimated.

Adjust FKN, FKT, FTOLN, or SLTO as necessary and run the full analysis. If the penetration control becomes dominant in the global equilibrium iterations (that is, if more iterations were used to converge the problem to within the penetration tolerance than to converge the residual forces), you may increase FTOLN to permit more allowable penetration or increase FKN.

In addition, keep these points in mind when specifying contact stiffness:

For bonded contact and rough contact, the program uses MU = 1.0 to calculate tangential contact stiffness. The default tangential contact stiffness is proportional to the normal stiffness when the contact status is closed or open (near-field). When an absolute value of tangential stiffness is specified (a negative value input for FKT), the tangential stiffness remains unchanged regardless of the contact status.

Generally, the contact stiffness, FKN and FKT, has units of FORCE/LENGTH3. However, for contact force-based models the contact stiffness has units FORCE/LENGTH. This applies to CONTA175 with KEYOPT(3) = 0 and CONTA177 with KEYOPT(3) = 0 or 4. In addition, the absolute normal contact stiffness (that is, a negative value input for FKN) can have units of FORCE/LENGTH under some circumstances. See Using FKN and FTOLN for more information.

In general, if the underlying solid element has material properties defined by both TB and MP commands, the properties defined by TB take precedence over the properties defined by MP in the calculation of initial contact stiffness. However, for TB,EXPE (experimental data) and TB,USER (user-defined material model), MP,EX takes precedence. Ansys, Inc. recommends you define MP,EX when using TB,EXPE or TB,USER so that the initial contact stiffness is calculated using a realistic value for EX as defined by the MP command rather than a heuristic contact stiffness that is not influenced by the material property.

The normal and tangential contact stiffness can be updated during the course of an analysis, either automatically (due to large strain effects that change the underlying element's stiffness) or explicitly (by user-specified FKN or FKT values). KEYOPT(10) governs how the normal and tangential contact stiffness is updated when the augmented Lagrangian or penalty method is used. In most cases Ansys, Inc. recommends that you use KEYOPT(10) = 0 to allow the program to update contact stiffnesses automatically. The possible settings for KEYOPT(10) are:

KEYOPT(10) = 0: the normal contact stiffness is updated at each iteration based on the current mean stress of the underlying elements and the allowable penetration, FTOLN, except in the very first iteration. The default normal contact stiffness for the first iteration is determined by underlying element depth, material properties, and FTOLN. In addition, if bisections occur in the beginning of the analysis, the normal contact stiffness is reduced by a factor of 0.2 for each bisection. The tangential contact stiffness is updated at each iteration based on the current contact pressure, MU, and allowable slip (SLTO). The actual elastic slip never exceeds the maximum allowable limit (SLTO) during the entire solution.

KEYOPT(10) = 1: the contact stiffness is updated at each load step if FKN or FKT is redefined by the user. Stiffness and other settings (ICONT, FTOLN, SLTO, and PINB) are averaged across contact elements in a contact pair. The default contact stiffness is determined by underlying element depth and material properties.

KEYOPT(10) = 2: the behavior is similar to KEYOPT(10) = 0 (updating contact stiffness at each iteration), except that the actual elastic slip during the solution is guaranteed not to exceed the maximum allowable limit (SLTO) within a substep. In general, this option results in fewer iterations than the KEYOPT(10) = 0 option.

Note: When a Lagrange multiplier method (KEYOPT(2) = 4) or MPC algorithm (KEYOPT(2) = 2) is used, KEYOPT(10) is ignored.

The default method of updating normal contact stiffness (KEYOPT(10) = 0 or 2) is suitable for most applications. However, the variational range of the normal contact stiffness may not be wide enough to handle certain contact situations. For example:

In the case of a very small penetration tolerance (FTOLN), a larger normal contact stiffness is often needed.

If convergence difficulties are encountered (due to nonlinear materials, localized contact, etc.), a downward adjustment to stiffness may be helpful.

To stabilize the initial contact condition and to prevent rigid body motion, a smaller normal contact stiffness is required.

The allowed normal contact stiffness variation is intended to enhance stiffness updating when KEYOPT(10) = 0 or 2 by calculating an optimal allowable range in stiffness for use in the updating scheme. To increase the stiffness variational range, set KEYOPT(6) = 1 to make a nominal refinement to the allowable stiffness range, or KEYOPT(6) = 2 to make an aggressive refinement to the allowable stiffness range.

Use of KEYOPT(6) = 1 or 2 is not recommended when contact convergence is relatively easy as it might produce an unnecessary drop in contact stiffness.

Set KEYOPT(6) = 3 to define the pressure-penetration relationship. The augmented Lagrangian method (KEYOPT(2) = 0) with KEYOPT(6) = 3 behaves the same as the penalty algorithm (KEYOPT(2) = 1): no augmentation and penetration tolerance checks are applied. See Pressure-Penetration Relationship (KEYOPT(6) = 3) for more information.

When KEYOPT(6) = 0, 1, or 2, the program uses a uniform normal contact stiffness for each contact pair. This can cause convergence issues when the mesh size across contact elements within a pair varies greatly.

With the exponential pressure-penetration relationship (KEYOPT(6) = 3), the resulting contact stiffness is no longer uniform within a pair. This is a contact-detection-based law that can make contact behavior smoother in the following situations: self contact, contact involving soft materials like rubber, models having a large initial gap, non-uniform contact surface meshes, and contact interface chattering.

When KEYOPT(6) = 3, the contact pressure-penetration relationship follows an exponential law based on default values of real constants PZER (pressure at zero penetration) and CZER (initial contact clearance). PZER is calculated based on underlying element properties. A small contact pressure starts developing as the initial clearance is detected and increases exponentially as the gap reduces and penetration increases.

A positive value for CZER indicates a scaling factor associated with the depth of the underlying elements. A negative value indicates an absolute initial contact clearance value. CZER defaults to 0.01.

A positive value for PZER indicates a scaling factor, with the typical range being from 0.1 - 10.0. PZER default to 1.0. A negative value for PZER indicates an absolute contact pressure at zero penetration. When PZER is negative (an absolute value) and CZER is positive (a scaling factor), the program computes the actual contact pressure internally based on the penetration tolerance FTOLN and the initial contact clearance CZER.

The default values are adequate for most contact models. However, you can specify PZER and/or CZER to define the contact pressure-penetration exponential relationship.

You can also set a maximum cutoff stiffness by inputting real constant FKN. The computed contact stiffness from the exponential relationship will not exceed the cutoff value. If FKN is not specified, the program uses the default value of penalty contact stiffness to calculate the cutoff value. The actual cutoff stiffness is 1000 times the penalty stiffness input by you or computed by the program. For example, if FKN is not input and the program calculates an initial contact stiffness of 42265, the cutoff contact stiffness used is 0.42265E+08.

The following equation is used to define the contact stiffness vs. gap relationship (FKN as a function of gap, g):

where:

| c0 = initial gap |

| p = p0 when g = 0 |

Contact pressure can be defined as a function of gap by using tabular input (that

is, %tabname%) for real constant PZER with GAP as the

primary variable. GAP represents current geometric gap/penetration (positive GAP index

values indicate penetration, negative GAP index values indicate an open gap). For more

information, see Defining Real Constants in Tabular Format. Pressure will be 0 for gap greater

than CZER. Ansys recommends defining the table according to CZER.

Alternatively, you can use the user subroutine

USERCNPROP.F to define the pressure-gap

relationship. See Defining Your Own Real Constant (USERCNPROP) for details. To properly

define the relationship, be sure to return the following two output

arguments:

| cnprop(1) = user defined contact pressure at the given penetration |

| cnprop(2) = normal contact stiffness at the given penetration (derivative of the contact stiffness with respect to the penetration) |

When defined by tabular input or by the

USERCNPROP.F user subroutine, PZER must be a

positive value, and it represents an absolute pressure (not a factor). This

differs from its typical usage.

The pressure-penetration feature (KEYOPT(6) = 3):

Cannot be used with bonded and no-separation behaviors (KEYOPT(12) > 1).

Does not support the Lagrange methods and MPC contact (KEYOPT(2) > 1).

If the above settings are used, the program assumes aggressive-variation of contact stiffness (KEYOPT(6) = 2).

KEYOPT(6) = 3 does not support the Augmented Lagrange method (KEYOPT(2) = 0). If these settings are used together, the program switches to the penalty method (KEYOPT(2) = 1) internally.

When the automatic stiffness ramp-up option is defined (see 3. Automatically ramp up the contact stiffness under Modeling Interference Fit) the program internally actives the aggressive-variation of contact stiffness (KEYOPT(6) = 2) only for the specified load step or time period.

KEYOPT(6) = 3 is not recommended with the settings listed below since it may not behave as expected:

Impact constraints (KEYOPT(7) = 4)

Fluid penetration (SFE,,,PRES and KEYOPT(14))

In general, the Lagrange multiplier methods (KEYOPT(2) = 3, 4) do not require normal contact stiffness, FKN, unless overconstraints are detected. Instead they require chattering control parameters, FTOLN and TNOP, by which the program assumes that the contact status remains unchanged. FTOLN is the maximum allowable penetration and TNOP is the maximum allowable tensile contact pressure.

Note: A negative contact pressure occurs when the contact status is closed. A tensile contact pressure (positive) refers to a separation between the contact surfaces, but not necessarily an open contact status. However, the sign of the contact pressure is switched during postprocessing.

Note: For contact force-based models, TNOP is the maximum allowable tensile contact force. This applies to CONTA175 with KEYOPT(3) = 0 and CONTA177 with KEYOPT(3) = 0 or 4.

The behavior can be described as follows:

If the contact status from the previous iteration is open and the current calculated penetration is smaller than FTOLN, then contact remains open. Otherwise the contact status switches to closed and another iteration is processed.

If the contact status from the previous iteration is closed and the current calculated contact pressure is positive but smaller than TNOP, then contact remains closed. If the tensile contact pressure is larger than TNOP, then the contact status changes from closed to open and the program continues to the next iteration.

The program provides reasonable defaults for FTOLN and TNOP. FTOLN defaults to the displacement convergence tolerance. TNOP defaults to 1% of the force convergence tolerance divided by the contact area at contact nodes.

When providing values for FTOLN and TNOP:

A positive value is a scaling factor applied to the default values.

A negative value is used as an absolute value (which overrides the default).

The objective of FTOLN and TNOP is to provide stability to models which exhibit contact chattering due to changing contact status. If the values you use for these tolerances are too small, the solution will require more iterations. If the values are too large, however, the accuracy of the solution will be affected as a certain amount of penetration or tensile contact force is allowed.

The following topics related to choosing a friction model are available:

In the basic Coulomb friction model, two contacting surfaces can carry shear stresses up to a certain magnitude across their interface before they start sliding relative to each other. This state is known as sticking. The Coulomb friction model defines an equivalent shear stress τ, at which sliding on the surface begins as a fraction of the contact pressure p (τ = µp + COHE, where µ is the friction coefficient and COHE specifies the cohesion sliding resistance). Once the shear stress is exceeded, the two surfaces will slide relative to each other. This state is known as sliding. The sticking/sliding calculations determine when a point transitions from sticking to sliding or vice versa.

As an alternative to the program-supplied friction model, you can define your

own friction model with the USERFRIC subroutine (see Writing Your Own Friction Law (USERFRIC)). Furthermore, you can define your own contact

interaction behavior with the USERINTER subroutine (see

Defining Your Own Contact Interaction (USERINTER)).

For frictionless, rough, and bonded contact, the contact element stiffness matrices are symmetric. Contact problems involving friction produce unsymmetric stiffnesses. Using an unsymmetric solver is more computationally expensive than a symmetric solver for each iteration. For this reason, the program uses a symmetrization algorithm by which most frictional contact problems can be solved using solvers for symmetric systems. If frictional stresses have a substantial influence on the overall displacement field and the magnitude of the frictional stresses is highly solution dependent, the symmetric approximation to the stiffness matrix may provide a low rate of convergence. In such cases, choose the unsymmetric solution option (NROPT,UNSYM) to improve convergence.

The interface coefficient of friction, MU, is used for the Coulomb friction model. Input MU as a material property for the contact elements. The Coulomb friction can be isotropic or orthotropic.

Use MU = 0 for frictionless contact. For rough or bonded contact (KEYOPT(12) = 1, 3, 5, or 6. See Selecting Surface Interaction Models), the program assumes infinite frictional resistance regardless of the specified value of MU.

MU can have dependence on temperature, time, normal pressure, sliding distance, or sliding relative velocity. Suitable combinations of up to two fields can be used to define dependency (for example, temperature only, temperature and sliding distance, or sliding relative velocity and normal pressure). If the underlying element is a superelement (MATRIX50), the material property set must be the same as the one used for the original elements that were assembled into the superelement.

Note that if the coefficient of friction is defined as a function of temperature, the program always uses the contact surface temperature as the primary variable (not the average temperature from the contact and target surfaces).

If you want to change the friction coefficient between load steps, it is recommended you change it in a ramped fashion. This is especially important when changing the surface behavior from frictionless to frictional contact. A sudden change in friction can result in a discontinuous frictional force leading to convergence issues. To avoid this, define friction as a function of time (TB,FRIC and TBFIELD with TIME specified as the field variable) to slowly ramp the change in friction coefficient.

Defining Isotropic Friction

Isotropic Friction (TB,FRIC,,,ISO) is available for 2D and 3D contact elements. The isotropic friction model is based on a single coefficient of friction, MU. Contacting surfaces experience the same friction in all directions. You can use either TB command input (recommended method) or the MP command to specify MU. For more information, see Isotropic Friction in the Material Reference.

Defining Orthotropic Friction

Orthotropic friction is available only for the 3D contact elements (CONTA174, CONTA175, CONTA176, and CONTA177). The orthotropic friction model is based on two coefficients of friction, MU1 and MU2, defined in the two principle directions for the element.

See the individual element descriptions to understand the principle directions for each element type. The two principal directions and the direction normal to these two principal directions constitute the friction coordinate system.

See Orthotropic Friction in the Material Reference for details on how to specify the coefficients of friction. Three different orthotropic friction options are available:

TB,FRIC,,,ORTHO: For this case, the friction coordinate system is always attached to the contact element and rotates with the contact element. Physically, this represents a case where the surface of the body meshed with contact elements is the source of the orthotropic friction.

TB,FRIC,,,FORTHO: For this case, the friction coordinate system is essentially fixed in space and does not rotate as the contact element rotates. Physically, this represents a case where a fixed surface that is meshed with target elements is the source of the orthotropic friction.

TB,FRIC,,,EORTHO. This option is similar to the ORTHO option and only differs when the frictional coefficients are defined as a function of sliding distance or sliding velocity. The difference occurs in the way the coefficients are interpolated. For

TBOPT= ORTHO, the friction coefficient in each direction is a function of sliding distance or velocity in that direction only. ForTBOPT= EORTHO, the friction coefficient in each direction depends upon the magnitude of total sliding or total velocity, therefore causing sliding in one direction to affect the friction coefficients in both directions. The total sliding or velocity is calculated as the vector sum of sliding or velocity in each direction.

Example 3.1: Using TBOPT = ORTHO versus

TBOPT = FORTHO

To illustrate the difference between the ORTHO and FORTHO options, consider the example of a flexible rectangular block meshed with contact elements which is pressed down on a rigid target surface on the global X-Z plane. Orthotropic friction can be defined as:

TB,FRIC,,,ORTHO ! TBOPT = ORTHO TBDATA,,0.2,0.001 ! MU1 = 0.2, MU2 = 0.001

or

TB,FRIC,,,FORTHO TBDATA,,0.2,0.001

The friction coordinate system is parallel to the global coordinate system, with the two principal directions initially parallel to the global X and global Z directions.

First, the block slides in the +X direction and then slides back to the starting position. During this sliding motion, the block experiences a friction coefficient of 0.2 for both the ORTHO and FORTHO options.

Next, the block is rotated 90° and made to slide along the Z direction. For the ORTHO option, the block experiences the same friction coefficient of 0.2 in the Z direction since the friction coordinate system has also rotated with the block and contact elements. However, for the FORTHO option, the block experiences a friction coefficient of 0.001 in the Z direction after the rotation since the friction coordinate system is fixed.

The animations below show contour plots of frictional force experienced by the block when the ORTHO and FORTHO options are used. Note the almost zero frictional force after the rotation in the FORTHO case.

The program provides one extension of classical Coulomb friction: real

constant TAUMAX is maximum contact friction with units of stress. This maximum

contact friction stress can be introduced so that, regardless of the magnitude

of normal contact pressure, sliding will occur if the friction stress reaches

this value. You typically use TAUMAX when the contact pressure becomes very

large (such as in bulk metal forming processes). TAUMAX defaults to 1.0e20.

Empirical data is often the best source for TAUMAX. Its value may be close to

, where σy is the yield stress of

the material being deformed.

You have an option to define TAUMAX as a function of primary variables by

using tabular input (that is, %tabname%). The

possible primary variables include time, temperature, initial contact detection

point location (at the beginning of solution), current contact pressure

(positive PRESSURE index values indicate compression, negative PRESSURE index

values indicate tension), and current geometric penetration (positive GAP index

values indicate penetration, negative GAP index values indicate an open gap).

For more information, see Defining Real Constants in Tabular Format.

The user subroutine USERCNPROP.F is also available for

defining TAUMAX. To use this subroutine, you must specify the table name

%_CNPROP% as the real constant value. For more information, see Defining Real Constants via a User Subroutine.

Another real constant used for the friction law is the cohesion, COHE (default COHE = 0), which has units of stress. It provides sliding resistance, even with zero normal pressure (see Figure 3.17: Sliding Contact Resistance).

Two other real constants, FACT and DC are involved in specifying static and dynamic friction coefficients, as described in the next section.

The coefficient of friction can depend on the relative velocity of the surfaces in contact. Typically, the static coefficient of friction is higher than the dynamic coefficient of friction.

The program provides the following exponential decay friction model:

where:

| μ = coefficient of friction. |

| MU = dynamic coefficient of friction. |

| FACT = ratio of static to dynamic coefficients of friction. It defaults to the minimum value of 1.0 |

| DC = decay coefficient, which has units of time/length. Therefore, time has some meaning in a static analysis. DC defaults to zero. When DC is zero, the equation is rewritten to be μ = MU for the case of sliding and μ = FACT*MU for the case of sticking. |

| Vrel = slip rate calculated by the program. |

For the isotropic friction model, MU is input using the MP command or the TB command as explained above. For orthotropic friction, MU is the equivalent coefficient of friction computed from MU1 and MU2 which are specified with TB command input:

Figure 3.18: Friction Decay shows the exponential decay curve where the static coefficient of friction is given by:

You can determine the decay coefficient if you know the static and dynamic coefficients of friction and at least one data point (μ1 ; Vrel1). The equation for friction decay can be rearranged to give:

If you do not specify a decay coefficient and FACT is greater than 1.0, the coefficient of friction will change suddenly from the static to the dynamic value as soon as contact reaches the sliding state. This behavior is not recommended because the discontinuity may lead to convergence difficulties.

In a static analysis, you can model steady-state frictional sliding between two flexible bodies or between a flexible and a rigid body with different velocities. In this case the sliding velocities no longer follow the nodal displacements, and they are predefined through the CMROTATE command. This command sets the velocities on the nodes of the element component as an initial condition at the start of a load step. The program determines the sliding direction based on the direction of the sliding velocities.

This feature is applicable to 3D contact (CONTA174, CONTA175) and is primarily used for generating sliding contact at frictional contact interfaces in a brake squeal analysis. In this case, the contact pair elements (either the contact elements or the target elements) on the brake rotor need to be included in the rotating element component (CM command) that is specified on the CMROTATE command. Ansys recommends that you include only the contact elements or only the target elements in the element component.

Velocities defined by CMROTATE will be ignored for the following contact definitions:

| Frictionless contact |

| Rough contact (KEYOPT(12) = 1) |

| Bonded contact (KEYOPT(12) = 3, 5, 6) |

| MPC contact (KEYOPT(2) = 2) |

Note: You should always verify the sliding direction when the velocities defined by CMROTATE are applied on nodes that are shared by more than one frictional contact pair. In this situation, you can redefine any contact elements that have a potentially incorrect sliding direction as frictionless contact.

The amplitude of the sliding velocity defined by CMROTATE will affect the solution when the friction coefficient is specified as a function of sliding velocity via the command TB,FRIC, or when static and dynamic friction is defined via the real constants FACT and DC.

In a complex eigenvalue extraction analysis using the QRDAMP or DAMP methods (see MODOPT), the effects of squeal damping will contribute to the damping matrix. The squeal damping can be identified as two parts: destabilizing damping and stabilizing damping.

You can activate destabilizing squeal damping by one of the following methods:

Define friction as a function of sliding velocity via the TB,FRIC command.

Define static/dynamic friction via real constants FACT and DC.

Define a constant friction-sliding velocity gradient via real constant FDMD in conjunction with KEYOPT(16) = 1.

Specify the destabilizing squeal damping coefficient directly (either a positive or negative value) in conjunction with KEYOPT(16) = 2.

When the destabilizing squeal damping is included by method (1) or (2), you can study its effects by using FDMD as a scaling factor (KEYOPT(16) = 0). FDMD defaults to 1.0. The program multiplies the internally calculated destabilizing damping by this factor.

You can specify a constant friction-sliding velocity gradient directly via FDMD by setting KEYOPT(16) = 1. The defined gradient has units of TIME/LENGTH and it is negative in general.

You can also specify the destabilizing squeal damping coefficient directly via FDMD by setting KEYOPT(16) = 2. The defined damping coefficient has units of MASS/(AREA*TIME) and it is negative in general. In a linear non-prestressed modal analysis, this is the only way to take the destabilizing squeal damping effects into account.

The stabilizing squeal damping is deactivated by default. To activate it, you must specify the scaling factor via the real constant FDMS. FDMS defaults to 0.0. The program multiplies the internally calculated stabilizing damping by this factor. By setting KEYOPT(16) = 1 or KEYOPT(16) = 2 you can specify the stabilizing squeal damping coefficient directly via FDMS. The defined damping coefficient has units of MASS/(AREA*TIME) and it is positive in general. In a linear non-prestressed modal analysis, this is the only way to take the stabilizing squeal damping effects into account.

If squeal damping is included in a brake squeal modal analysis that uses the QR Damp eigensolver (MODOPT,QRDAMP command), care should be taken not to generate a damping matrix with large values (coefficients) relative to the values of the stiffness matrix. The accuracy of the QRDAMP eigensolver is based on the assumption that the values in the damping matrix are at least an order of magnitude smaller than the stiffness matrix values. If large squeal damping matrix values are generated in conjunction with a QRDAMP modal solution, then the QRDAMP eigensolver could produce spurious zero modes, which can generally be ignored. In this case, the non-zero eigenvalues from the QRDAMP modal solution are still accurate. Ansys recommends that you use the DAMP eigensolver (MODOPT,DAMP) to check the final solution.

As a special case, when contact friction is used in a steady-state rolling analysis, the frictional stress calculation is changed to a viscous formulation. For details, see Contact Algorithm in the Theory Reference.

The following topics related to selecting the location of contact detection are available:

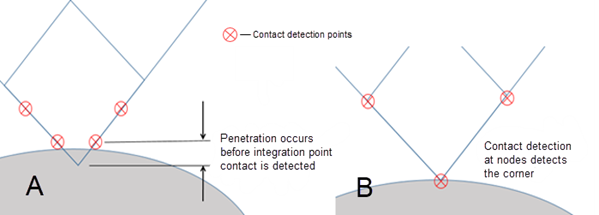

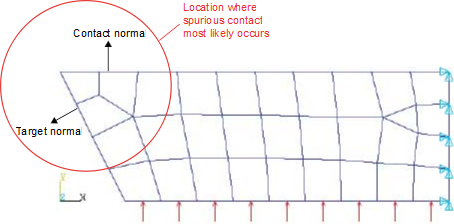

Contact detection points are located at the integration points of the contact elements which are interior to the element surface. The contact element is constrained against penetration into the target surface at its integration points. However, the target surface can, in principle, penetrate through into the contact surface, see Figure 3.19: Contact Detection Located at Gauss Point.

Surface-to-surface contact elements use Gauss integration points as a default, which generally provide more accurate results than the nodal detection scheme, which uses the nodes themselves as the integration points. The node-to-surface contact element, CONTA175, and the line-to-surface contact element, CONTA177, always use the nodal detection scheme.

The nodal detection algorithms require the smoothing of the contact surface (KEYOPT(4) = 1) or the smoothing of the target surface (KEYOPT(4) = 2), which is quite time consuming. You should use this option only to deal with corner, point-to-surface, or edge-to-surface contact (see Figure 3.20: Contact Detection Point Location at Nodal Point). KEYOPT(4) = 1 specifies that the contact normal be perpendicular to the contact surface. KEYOPT(4) = 2 specifies that the contact normal be perpendicular to the target surface. Use KEYOPT(4) = 2 when the target surface is smoother than the contact surface.

Be aware, however, that using nodes as the contact detection points can lead to other convergence difficulties, such as node slippage, where the node slips off the edge of the target surface, see Figure 3.21: Node Slippage Using Nodal Detection KEYOPT(4) = 1 or 2. In order to prevent node slippage, you can use real constant TOLS to extend the target surface when the default setting still cannot avoid the problem. For most point-to-surface contact problems, Ansys recommends using CONTA175. See Node-to-Surface Contact later in this guide.

Smoothing is required for nodal detection algorithms, and it is performed by averaging surface normals connected to the node. As a result, the variation of the surface normal is continuous over the surface, which leads to a better calculation of friction behavior and a better convergence.

Real constant TOLS is used to add a small tolerance that will internally extend the edge of the target surface when you define the contact detection at the nodal point (KEYOPT(4) = 1 or 2). TOLS is useful for problems where contact nodes are likely to lie on the edge of targets (as at symmetry planes or for models generated in a node-to-node contact pattern). In these situations, the contact node may repeatedly slip off the target surface and go completely out of contact, resulting in convergence difficulties from oscillations. Units for TOLS are percent (1.0 implies a 1.0% increase in the target edge length). A small value of TOLS will usually prevent this situation from occurring. The default value is 2 for both small deflection (NLGEOM,OFF) and large deflection (NLGEOM,ON).

Note: For Normal Lagrange formulation (KEYOPT(2)=3,4), with 3D higher-order contact elements (with midside nodes), use of surface projection-based contacts (KEYOPT(4)=3,4) is strongly recommended.

The definition of KEYOPT(4) in node-to-surface contact element CONTA175 is different. KEYOPT(4) = 1 for surface-to-surface contact is equivalent to KEYOPT(4) = 1 for node-to-surface contact. However, KEYOPT(4) = 2 for surface-to-surface contact is equivalent to KEYOPT(4) = 0 for node-to surface contact. See KEYOPT(4).

You can define the surface projection contact method by setting KEYOPT(4) = 3 or 4 for the surface-to-surface contact elements (CONTA172 and CONTA174) and the line-to-surface contact element (CONTA177):

KEYOPT(4) = 3 – Standard surface projection

KEYOPT(4) = 4 – Dual shape function projection

For CONTA172 and CONTA174, a unified contact detection approach is also available:

KEYOPT(4) = 5 – Unified approach which combines the standard surface projection with Gauss and the normal-to-target-surface nodal detection method

Standard Surface Projection and Dual Shape Function Projection Options (KEYOPT(4) = 3 or 4)

For the standard surface projection (KEYOPT(4) = 3) and dual shape function projection (KEYOPT(4) = 4) options, the contact detection remains at contact nodal points. These options enforce a contact constraint on an overlapping region of the contact and target surfaces (see Figure 3.22: Surface Projection Based Contact) rather than on individual contact nodes (KEYOPT(4) = 1, 2) or Gauss points (KEYOPT(4) = 0). The contact penetration/gap is computed over the overlapping region in an average sense. Advantages of the surface projection based method are:

In general, it provides more accurate contact tractions and stresses of underlying elements compared with other KEYOPT(4) settings.

The results are less sensitive to the designation of the contact and target surface.

It satisfies moment equilibrium when an offset exists between contact and target surfaces with friction.

Contact forces do not jump when contact nodes slide off the edge of target surfaces. The real constant TOLS is not used with this option.

There are certain disadvantages to using surface projection based contact, as follows:

This method is computationally more expensive since more nodes are included in each contact constraint condition, especially if 3D higher order contact/target elements are used in the model. This effect will be more obvious when a modal has a large percentage of contact/target elements, or when the target elements are much more refined than the contact elements.

When the target elements are extremely refined, the program may issue an error message stating that the data points for a particular node exceed the limit. To resolve this, you should switch to another contact detection option or flip the contact and target surfaces.

This method calculates the penetration/gap over the contacting area in an average sense. When a model has corner or edge contact, the averaged penetration/gap could be quite different than the real geometric penetration observed at contact nodes. In this situation, mesh refinement is usually required in order to achieve an accurate solution.

Comparison of the Standard Projection Option and the Dual Shape Function Option

Compared to the standard surface projection option (KEYOPT(4) = 3), the dual shape function projection option (KEYOPT(4) = 4) uses a special interpolation function for the discretization of contact traction. This option reduces dependent terms for each contact constraint. The resulting gap function and slip increments are closer to the local geometric gap/slip at contact nodes. It is more efficient in terms of solution performance and memory usage and generally remedies potential overconstraint due to MPC equations.

The dual shape function option is recommended for Lagrange multiplier contact (KEYOPT(2) = 3 or 4), MPC bonded contact (KEYOPT(2) = 2), and small sliding behavior (KEYOPT(18) = 1 or 2). For MPC bonded contact, the program internally switches to the dual shape function option if the standard projection option is defined.

Be aware that the dual shape function option is not as accurate as the standard projection option when the contact surface mesh is very coarse.

Unified Contact Detection Approach (KEYOPT(4) = 5)

Selecting the best contact detection is problem dependent and can have a significant impact on the solution. Each detection method has advantages and disadvantages:

For standard surface projection (KEYOPT(4) = 3) and dual shape function projection (KEYOPT(4) = 4), the penetration or gap at each contact node is an average value from the projected area. Thus, for corner and edge contact, the nodes on the corner or edge will penetrate the target surface which could result in large penetrations.

The same drawback applies to Gauss point detection (KEYOPT(4) = 0). If the contact surface has significant curvature or a corner, the contact surface can penetrate into the target surface (see A in the figure below).

Nodal point detection with normal to target (KEYOPT(4) = 2) is better suited for edge or corner contact (see B in the figure below). However, the contact node can easily drop off the edges of the target surface, causing a sudden jump in internal contact forces.

No detection method works best for all problems. One detection method may be obviously better for the early stage of the deformation, while another method may work better for the later stages.

To overcome this problem, the unified contact detection option (KEYOPT(4) = 5) combines three individual contact detection methods: Gauss point, nodal point with normal to target, and standard surface projection. This approach generally overcomes drawbacks of each individual method. The main advantages are:

More contact constraint points for the contact interface

Lower residual penetration

Less sensitivity to mesh sizing at the contact interface

Lower number of equilibrium iterations

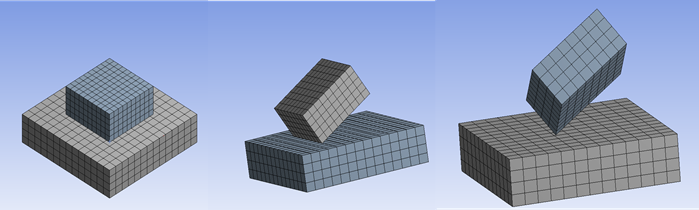

Furthermore, the unified detection approach in conjunction with a symmetric contact definition works robustly for non-smoothing contact. Interference fit, press fit, snap fit, and snap-through are typical applications that can benefit from the unified contact approach.

The figure below shows a contact pair with mixed surfaces, edges, and corners under large deformations and displacements.

Keep in mind that the unified approach is the most expensive option. Use of additional features such as adaptive small sliding (KEYOPT(18) = 2) and contact pair-splitting logic (CNCHECK,DMP) often improve the performance.

Limitations for Surface Projection Based Contact (KEYOPT(4) = 3, 4, or 5)

The surface projection contact method currently does not support the following:

Thermal contact modeled via a “free thermal surface” definition.

Pore fluid flow modeled by quadratic contact/target elements (with midside nodes).

Rigid surfaces defined by primitive target segments. (This type of rigid surface is supported for the unified approach (KEYOPT(4) = 5) when only the Guass and nodal detection methods are used.)

3D contact/target elements with partially dropped midside nodes (dropping all midside nodes is supported).

The unified approach (KEYOPT(4) = 5) does not support:

The MPC formulation (KEYOPT(2) = 2).

Nonlinear mesh adaptivity (NLADAPTIVE)

The following sliding behavior topics are available:

Three different sliding behavior options are available: finite sliding (default), small sliding, and adaptive small sliding. The sliding behavior you choose will have an influence on solution robustness, performance, and accuracy. Select the appropriate sliding behavior based on the relative motion of the contact interfaces in your model.

The finite-sliding option is used by default (KEYOPT(18) = 0). This option allows for arbitrary separation, sliding, and rotation of the contact interfaces. In general, each contact detection point can interact with different target elements, depending on the contact status (open, closed, or sliding). The program re-forms nodal connectivity of the contact element based on the current configuration at each equilibrium iteration. The finite-sliding logic is computationally expensive, but guarantees solution accuracy.

Activate the small-sliding option (KEYOPT(18) = 1) when the contact interface will have relatively-small sliding motion (less than 20% of the contact length) during the entire analysis. For large deflection analysis, this option still permits arbitrary large rotation.

For small sliding, each contact detection point always interacts with the same target element, which is determined from the initial configuration. The nodal connectivity of the contact element remains unchanged throughout the analysis. Contact searching is performed only once in the beginning of the analysis, which is cost-effective.

The small-sliding logic also improves solution robustness. It can easily solve certain complex contact models for which the finite-sliding logic would have difficulties or find no solution. This is especially true for models having a bad quality geometry or mesh and non-smooth contact interfaces. (See this white paper for more discussion of this behavior.)

The small-sliding logic can cause nonphysical results if the relative sliding motion does not remain small. Therefore, if you choose this option it is your responsibility to ensure that the small-sliding assumption is not violated. Use the NLHIST or NLDIAG command to monitor the number of contact points having too much sliding (that is, the SLID value is greater than 50% of the contact length or 50% of the associated target element length).

Use the finite-sliding option if you are not absolutely sure that the small-sliding logic is appropriate.

Use the small-sliding option with great caution for the following cases:

The EKILL command applied to target elements of contact pairs using the projection-based contact option (KEYOPT(4) = 3, 4, or 5)

A general contact definition

Activate the adaptive small-sliding option (KEYOPT(18) = 2) when the contact interface will have relatively-small sliding motion (less than 20% of the contact length) during each sub-step of the analysis. The contact interface can undergo either small sliding or finite sliding within each substep based on the contact status at the beginning of the substep. If the contact status is closed at the beginning of a substep, small sliding is used during that substep.

For this option, each contact detection point interacts with the same target element, which is determined from the beginning configuration of each substep. The nodal connectivity of the contact element remains unchanged during the substep.

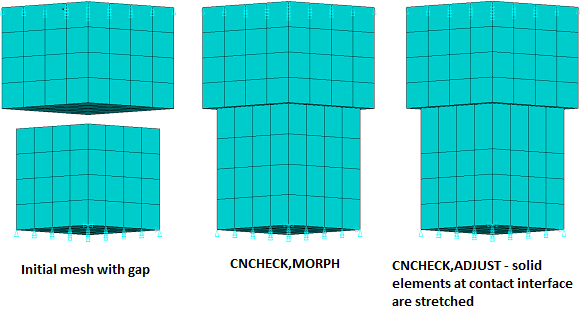

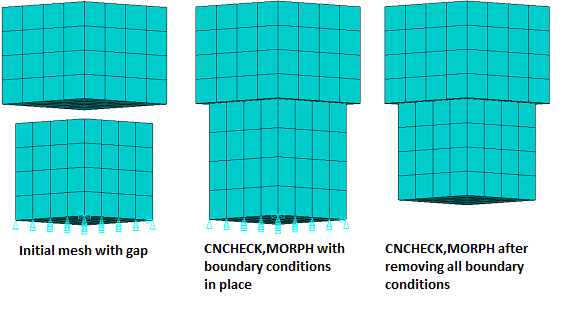

The adaptive small-sliding logic often improves robustness compared to the finite sliding logic and can also improve solution accuracy compared to the small sliding logic. It can handle situations when contact pairs are initially in far-field and then come into contact.