CONTA174

3D 8-Node

Surface-to-Surface Contact

CONTA174 Element Description

CONTA174 is used to represent contact and sliding between 3D target surfaces and a deformable surface defined by this element. The element is applicable to 3D structural and coupled-field contact analyses. It can be used for both pair-based contact and general contact.

In the case of pair-based contact, the target surface is defined by the 3D target element type, TARGE170. In the case of general contact, the target surface can be defined by CONTA174 elements (for deformable surfaces) or TARGE170 elements (for rigid bodies only).

The element is located on the surfaces of 3D solid or shell elements with or without midside nodes (for example, SOLID185, SOLID186, SOLID187, SHELL281, SOLID225, SOLID226, SOLID279, SOLID285, CPT216, MATRIX50).

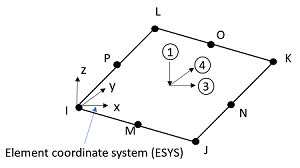

The element has the same geometric characteristics as the solid or shell element face with which it is connected (see Figure 174.1: CONTA174 Geometry). Contact occurs when the element surface penetrates an associated target surface.

Coulomb friction, shear stress friction, user-defined friction

with the USERFRIC subroutine, and user-defined

contact interaction with the USERINTER subroutine

are allowed. The element also allows separation of bonded contact

to simulate interface delamination.

See CONTA174 in the Mechanical APDL Theory Reference for more details about this element. A 2D surface-to-surface contact element (CONTA172) is also available.

CONTA174 Input Data

The geometry and node locations are shown in Figure 174.1: CONTA174 Geometry. The element is defined by eight nodes (if the underlying solid or shell element has midside nodes). It can degenerate to a six node element depending on the shape of the underlying solid or shell elements. If the underlying solid or shell elements do not have midside nodes, you may still use CONTA174 but the midside nodes will be dropped. See Quadratic Elements (Midside Nodes) in the Modeling and Meshing Guide for more information on the use of midside nodes.

The node ordering is consistent with the node ordering for the underlying solid or shell element. The positive normal is given by the right-hand rule going around the nodes of the element and is identical to the external normal direction of the underlying solid or shell element surface. For shell elements, the same nodal ordering between shell and contact elements defines upper surface contact; otherwise, it represents bottom surface contact. The contact surface's outward normal should point toward the target surface.

Pair-Based Contact versus General Contact

There are two methods to define a contact interaction: the pair-based contact definition and the general contact definition. Both contact definitions can exist in the same model. CONTA174 can be used in either type of contact definition.

The pair-based contact definition is usually more efficient and more robust than the general contact definition; it supports more options and specific contact features.

Pair-Based Contact

In a pair-based contact definition, the 3D contact surface elements (CONTA174) are associated with 3D target segment elements (TARGE170) via a shared real constant set. The program looks for contact interaction only between surfaces with the same real constant set ID (which is greater than zero). The material ID associated with the contact element is used to specify interaction properties (such as friction coefficient) defined by MP or TB commands.

If more than one target surface will make contact with the same boundary of solid elements, you must define several contact elements that share the same geometry but relate to separate targets (targets which have different real constant numbers). Alternatively, you can combine several target surfaces into one (that is, multiple targets sharing the same real constant numbers). See Identifying Contact Pairs in the Contact Technology Guide for more information.

For rigid-flexible and flexible-flexible contact, one of the deformable surfaces must be represented by a contact surface. See Designating Contact and Target Surfaces in the Contact Technology Guide for more information.

See Generating Contact Elements in the Contact Technology Guide for information on generating elements automatically using the ESURF command.

General Contact

In a general contact definition, the general contact surfaces are generated automatically by the GCGEN command based on physical parts and geometric shapes in the model. The program overlays contact surface elements (CONTA174) on 3D deformable bodies (on both lower- and higher-order elements); 3D contact line elements (CONTA177) on 3D beams, on feature edges of 3D deformable bodies, and on perimeter edges of shell structures; and vertex-to-surface elements (CONTA175) on convex corners of 3D solid bodies and/or shell structures. The general contact definition may also contain target elements (TARGE170) overlaid on the surfaces of standalone rigid bodies.

The GCGEN command automatically assigns section IDs and element type IDs for each general contact surface. As a result, each general contact surface consists of contact or target elements that are easily identified by a unique section ID number. The real constant ID and material ID are always set to zero for contact and target elements in the general contact definition.

The program looks for contact interaction among all surfaces and within each surface. You can further control contact interactions between specific surfaces that could potentially be in contact by using the GCDEF command. The material ID and real constant ID input on GCDEF identify interface properties (defined by MP or TB commands) and contact control parameters (defined by the R command) for a specific contact interaction. Unlike a pair-based contact definition, the contact and target elements in the general contact definition are not associated with these material and real constant ID numbers.

If both pair-based contact and general contact are defined in a model, the pair-based contact definitions are preserved, and the general contact definition automatically excludes overlapping interactions wherever pair-based contact exists.

Some element key options are not used or are set automatically for general contact. See the individual KEYOPT descriptions in "CONTA174 Input Summary" for details.

Friction

CONTA174 supports isotropic and orthotropic Coulomb friction. For isotropic friction, specify a single coefficient of friction, MU, using either TB command input (recommended) or the MP command. For orthotropic friction, specify two coefficients of friction, MU1 and MU2, in two principal directions using TB command input. (See Contact Friction in the Material Reference for more information.)

For isotropic friction, the applicable coordinate system is the default element coordinate system (noted by the R and S axes in the above figure).

For orthotropic friction, the principal directions are determined as follows. The global coordinate system is used by default, or you may define a local element coordinate system with the ESYS command. (These are depicted by the xo and x axes in the above figure.) The first principal direction is defined by projecting the first direction of the chosen coordinate system onto the contact surface. The second principal direction is defined by taking a cross product of the first principal direction and the contact normal. These directions also follow the rigid body rotation of the contact element to correctly model the directional dependence of friction. Be careful to choose the coordinate system (global or local) so that only the z-direction parallels (or is nearly parallel to) the surface normal.

If you want to set the coordinate directions for isotropic friction (to the global Cartesian system or another system via ESYS), you can define orthotropic friction and set MU1 = MU2.

To define a coefficient of friction for isotropic or orthotropic friction that is dependent on temperature, time, normal pressure, sliding distance, or sliding relative velocity, use the TBFIELD command along with TB,FRIC. See Contact Friction in the Material Reference for more information.

To implement a user-defined friction model, use the TB,FRIC command with

TBOPT = USER to specify friction properties and write a

USERFRIC subroutine to compute friction forces. See Writing Your Own Friction Law (USERFRIC) in the Contact Technology Guide for

more information on how to use this feature. See also the Guide to User-Programmable Features in the Programmer's Reference for a detailed description

of the USERFRIC subroutine.

Other Input

The contact interaction subroutine USERINTER is available for

user-defined interface interactions, including interactions in the normal and tangential

directions as well as coupled-field interactions. See Defining Your Own Contact Interaction (USERINTER) in the Contact Technology Guide for more information on

how to use this feature. See also the Guide to User-Programmable Features in the Programmer's Reference for a detailed description of the

USERINTER subroutine.

To model the fluid penetration loads shown in Figure 174.2: Fluid Penetration Pressure Directions, use the SFE command to specify

the fluid pressure values in the normal (LKEY = 1) and

tangential directions (LKEY = 3 and 4) in the element

coordinate system (ESYS) and the fluid penetration starting points

(LKEY = 2). For more information, see Applying Fluid-Pressure-Penetration Loads in the Contact Technology Guide.

To model proper momentum transfer and energy balance between contact and target surfaces, impact constraints should be used in transient dynamic analysis. See the description of KEYOPT(7) below and the contact element discussion in the Mechanical APDL Theory Reference for details.

To model separation of bonded contact with KEYOPT(12) = 2, 3, 4, 5, or 6, use the TB command with the CZM label. See Debonding in the Contact Technology Guide for more information.

To model wear at the contact surface, use the TB command with the WEAR label. See Contact Surface Wear in the Contact Technology Guide for more information.

Two types of geometry correction are available for this element: surface smoothing and bolt thread modeling. Surface smoothing is a geometry correction technique that eliminates inaccuracies introduced by faceted elements on a curved (spherical or revolute) contact surface. Bolt thread modeling provides a method for simulating contact between a threaded bolt and bolt hole without having to model the detailed thread geometry. Both of these geometry correction techniques are implemented through section definitions (SECTYPE, SECDATA, and SECNUM commands). For more information, see Geometry Correction for Contact and Target Surfaces in the Contact Technology Guide.

A summary of the element input is given in "CONTA174 Input Summary". A general description of element input is given in Element Input. For axisymmetric applications see Harmonic Axisymmetric Elements.

Using CONTA174 to Define a Result Section

A result section is a user-defined surface comprised of CONTA174 elements that is used to output and monitor section forces, moments, and other output quantities. See Monitoring Result Section Data During Solution in the Structural Analysis Guide for more information. When this element is used to define a result section, KEYOPT(4) = 1 and 2 are the only applicable key option settings, and no real constants are used. For this special case, the CONTA174 element does not represent contact interaction.

CONTA174 Input Summary

- Nodes

I, J, K, L, M, N, O, P

- Degrees of Freedom

Set by KEYOPT(1)

- Real Constants

R1, R2, FKN, FTOLN, ICONT, PINB, PZER, CZER, TAUMAX, CNOF, FKOP, FKT, COHE, TCC, FHTG, SBCT, RDVF, FWGT, ECC, FHEG, FACT, DC, SLTO, TNOP, TOLS, MCC, PPCN, FPAT, COR, STRM, FDMN, FDMT, FDMD, FDMS, TBND, WBID, PCC, PSEE, ABPP, FPFT, FPWT, DCC, DCON, ABDC, BSRL, KSYM, TFOR, TEND See Table 174.1: CONTA174 Real Constants for descriptions of the real constants. - Material Properties

TB command: See Element Support for Material Models for this element. MP command: MU, EMIS, DMPR, DMPS - Surface Loads

Pressure, Face 1 (I-J-K-L) (opposite to contact normal direction); used for fluid pressure penetration loading. On the SFE command use LKEY= 1 to specify the normal pressure values, and useLKEY= 2 to specify starting points and penetrating points. UseLKEY= 3, 4 to specify the tangential pressure values along the x and y direction of the element coordinate system (ESYS)Convection, Face 1 (I-J-K-L) Heat Flux, Face 1 (I-J-K-L) - Special Features

- KEYOPTs

Presented below is a list of KEYOPTS available for this element. Included are links to sections in the Contact Technology Guide where more information is available on a particular topic.

- KEYOPT(1)

Selects degrees of freedom:

- 0 --

UX, UY, UZ

- 1 --

UX, UY, UZ, TEMP

- 2 --

TEMP (or a combination of TBOT, TTOP, and TEMP set by KEYOPT(13))

- 3 --

UX, UY, UZ, TEMP, VOLT

- 4 --

TEMP, VOLT

- 5 --

UX, UY, UZ, VOLT

- 6 --

VOLT

- 7 --

MAG

- 8 --

UX, UY, UZ, PRES

- 9 --

UX, UY, UZ, PRES, TEMP

- 10 --

PRES

- 11 --

UX, UY, UZ, CONC, TEMP

- 12 --

UX, UY, UZ, CONC, TEMP, VOLT

- 13 --

UX, UY, UZ, CONC

- 14 --

CONC

Note: For KEYOPT(1) = 8, 9, and 10, the pore pressure (PRES) degree of freedom is ignored at midside nodes if the underlying element is a higher-order 3D coupled pore-pressure mechanical solid (CPT216, CPT217).

Note: For general contact, the GCGEN command automatically sets KEYOPT(1) based on the degrees of freedom of the underlying solid or shell elements.

- KEYOPT(2)

Contact algorithm:

- 0 --

Augmented Lagrangian (default)

- 1 --

Penalty function

- 2 --

Multipoint constraint (MPC); see Multipoint Constraints and Assemblies in the Contact Technology Guide for more information

- 3 --

Lagrange multiplier on contact normal and penalty on tangent

- 4 --

Pure Lagrange multiplier on contact normal and tangent

- KEYOPT(3)

Units of normal contact stiffness:

- 0 --

FORCE/LENGTH3 (default)

- 1 --

FORCE/LENGTH

Note: KEYOPT(3) = 1 is valid only when a penalty-based algorithm is used (KEYOPT(2) = 0 or 1) and the absolute normal contact stiffness value is explicitly specified (that is, a negative value input for real constant FKN). It is not recommended in conjunction with using nodal detection options (KEYOPT(4) = 1 or 2) if any midside nodes exist for the contact element.

Note: KEYOPT(3) is not supported for contact elements used in a general contact definition.

- KEYOPT(4)

Standard KEYOPT(4) Usage

Location of contact detection point:

- 0 --

On Gauss point (for general cases)

- 1 --

On nodal point - normal from contact surface

- 2 --

On nodal point - normal to target surface

- 3 --

On nodal point - normal from contact surface (standard projection-based method)

- 4 --

On nodal point - normal from contact surface (dual shape function projection-based method)

- 5 --

Unified approach that combines Gauss point, normal to target surface, and standard projection methods

Note: Certain restrictions apply when the surface projection-based method (KEYOPT(4) = 3, 4, or 5) is defined. For more information, see Using the Surface Projection-Based Contact Method in the Contact Technology Guide.

Alternate KEYOPT(4) Usage with Surface-Based Constraints

To define a surface-based constraint, set KEYOPT(4) as follows:

- 1 --

Defines a force-distributed constraint. The force-distributed constraint can be based on either the MPC approach (KEYOPT(2) = 2) or the Lagrange multiplier method (KEYOPT(2) = 3).

- 2 --

Defines a rigid surface constraint. The rigid surface constraint can be based on either the MPC approach (KEYOPT(2) = 2) or the Lagrange multiplier method (KEYOPT(2) = 3).

- 3 --

Defines a coupling constraint. The MPC approach (KEYOPT(2) = 2) must be used.

For more information, see Surface-Based Constraints in the Contact Technology Guide.

Alternate KEYOPT(4) Usage with Result Sections

When CONTA174 is used to define a result section, KEYOPT(4) determines how motion of the result section is accounted for in a large deflection analysis:

- 1 --

The anchor point moves and the local coordinate system rotates with the average rigid body motion of the contact elements used to define the result section.

- 2 --

The anchor point moves and the local coordinate system rotates with the average rigid body motion of the underlying elements.

For more information, see Monitoring Result Section Data During Solution in the Structural Analysis Guide.

- KEYOPT(5)

CNOF/ICONT Automated adjustment:

- 0 --

No automated adjustment

- 1 --

Close gap with auto CNOF

- 2 --

Reduce penetration with auto CNOF

- 3 --

Close gap/reduce penetration with auto CNOF

- 4 --

Auto ICONT

- KEYOPT(6)

Normal contact stiffness variation (used to enhance stiffness updating when KEYOPT(10) ≠ 1):

- 0 --

Use default range for stiffness updating

- 1 --

Make a nominal refinement to the allowable stiffness range

- 2 --

Make an aggressive refinement to the allowable stiffness range

- 3 --

Use an exponential pressure-penetration relationship

- KEYOPT(7)

Element level time incrementation control / impact constraints:

- 0 --

No control

- 1 --

Automatic bisection of increment

- 2 --

Change in contact predictions made to maintain a reasonable time/load increment

- 3 --

Change in contact predictions made to achieve the minimum time/load increment whenever a change in contact status occurs

- 4 --

Use impact constraints for standard or rough contact (KEYOPT(12) = 0 or 1) in a transient dynamic analysis with automatic adjustment of time increment

Note: KEYOPT(7) = 4 is not supported for contact elements used in a general contact definition.

- KEYOPT(8)

Symmetric contact behavior:

- 0 --

Both symmetric pairs are active. However, each pair has its own contact characteristics.

- 1 --

Both symmetric pairs are active and have the same contact characteristics.

- 2 --

The program internally selects which asymmetric contact pair is used at the solution stage (used only when symmetric contact is defined). However, the contact stiffness of the active contact pair is influenced by the underlying element stiffness of the inactive pair.

- 3 --

The program internally selects which asymmetric contact pair is used at the solution stage (used only when symmetric contact is defined). The contact characteristics of the active contact pair are completely independent of the inactive pair.

Note: KEYOPT(8) settings are ignored for asymmetric contact pairs and rigid-to-rigid contact pairs.

Note: KEYOPT(8) is ignored for contact elements used in a general contact definition. Instead, use the command GCDEF,AUTO to enable auto-asymmetric pairing logic.

- KEYOPT(9)

Effect of initial penetration or gap:

- 0 --

Include both initial geometrical penetration or gap and offset - 1 --

Exclude both initial geometrical penetration or gap and offset

- 2 --

Include both initial geometrical penetration or gap and offset, but with ramped effects

- 3 --

Include offset only (exclude initial geometrical penetration or gap)

- 4 --

Include offset only (exclude initial geometrical penetration or gap), but with ramped effects

- 5 --

Include offset only (exclude initial geometrical penetration or gap) regardless of the initial contact status (near-field or closed)

- 6 --

Include offset only (exclude initial geometrical penetration or gap), but with ramped effects regardless of the initial contact status (near-field or closed)

Note: The effects of KEYOPT(9) are dependent on settings for other KEYOPTs. The indicated initial gap effect is considered only if KEYOPT(12) = 4 or 5. See the discussion on using KEYOPT(9) in the Contact Technology Guide for more information.

Note: KEYOPT(9) is not supported for contact elements used in a general contact definition. Instead, use the command TBDATA,,

C1in conjunction with TB,INTER to specify the effect of initial penetration or gap. If TBDATA,,C1is not specified, the default for general contact is to exclude initial penetration/gap and offset. For more information, see Interaction Options for General Contact Definitions in the Material Reference.- KEYOPT(10)

Contact stiffness update:

- 0 --

Each iteration based on the current mean stress of underlying elements. The actual elastic slip never exceeds the maximum allowable limit (SLTO) during the entire solution.

- 1 --

Each load step if FKN is redefined during the load step.

- 2 --

Each iteration based on the current mean stress of underlying elements. The actual elastic slip does not exceed the maximum allowable limit (SLTO) within a substep.

- KEYOPT(11)

Shell thickness effect:

- 0 --

Exclude

- 1 --

Include

Note: KEYOPT(11) = 1 is not valid when the underlying elements are part of a pre-integrated shell section (SECTYPE,,GENS).

Note: If the base element is SHELL294, then the shell thickness effect is always included for CONTA174, regardless of the value of KEYOPT(11).

- KEYOPT(12)

Behavior of contact surface:

- 0 --

Standard

- 1 --

Rough

- 2 --

No separation (sliding permitted)

- 3 --

Bonded

- 4 --

No separation (always)

- 5 --

Bonded (always)

- 6 --

Bonded (initial contact)

Note: When KEYOPT(12) = 5 or 6 is used with the MPC algorithm to model surface-based constraints, the KEYOPT(12) setting will have an impact on the local coordinate system of the contact element nodes. See Specifying a Local Coordinate System in the Contact Technology Guide for more information.

Note: KEYOPT(12) is not supported for contact elements used in a general contact definition. Instead, use the command TB,INTER with the appropriate

TBOPTlabel to specify the behavior at the contact surface. For more information, see Interaction Options for General Contact Definitions in the Material Reference.- KEYOPT(13)

Use Alternate KEYOPT(13) to set tangential contact stiffness variation only for frictional contact.

- 0 --

Use the default range for stiffness updating.

- 1 --

Make an aggressive refinement to the allowable stiffness range.

Alternate KEYOPT(13) may be used when the pure thermal contact option is set (KEYOPT(1) = 2) and the element is being used to model thermal transfer between thermal shells (SHELL131, SHELL132) or between thermal shells and thermal solids.

Degree-of-freedom control for contact involving thermal shells SHELL131 and SHELL132:

- 0 --

TEMP for contact surface TEMP for target surface - 1 --

TBOT for contact surface TBOT for target surface - 2 --

TTOP for contact surface TTOP for target surface - 3 --

TBOT for contact surface TEMP for target surface - 4 --

TEMP for contact surface TBOT for target surface - 5 --

TTOP for contact surface TEMP for target surface - 6 --

TEMP for contact surface TTOP for target surface - 7 --

TBOT for contact surface TTOP for target surface - 8 --

TTOP for contact surface TBOT for target surface

Note: When KEYOPT(13) is used for contact involving thermal shells, it is not supported for contact elements used in a general contact definition.

- KEYOPT(14)

Behavior of fluid pressure penetration load. KEYOPT(14) is valid only if a fluid pressure penetration load (SFE,,,PRES) is applied to the contact element:

- 0 --

Fluid pressure penetration load is applied based on the contact status of the current iteration. Any contact detection point which was previously exposed to the fluid pressure remains in the condition of "penetrating" (default).

- 1 --

Fluid pressure penetration load is applied based on the contact status of the last converged substep. Any contact detection point which was previously exposed to the fluid pressure remains in the condition of "penetrating".

- 2 --

Fluid pressure penetration load is applied based on the contact status of the current iteration. At each iteration, the fluid pressure penetration load is newly applied from the initial starting points.

- 3 --

Fluid pressure penetration load is applied based on the contact status of the last converged substep. At each iteration, the fluid pressure penetration load is newly applied from the initial starting points.

Note: KEYOPT(14) is not supported for contact elements used in a general contact definition.

- KEYOPT(15)

Effect of contact stabilization damping:

- 0 --

Damping is activated only in the first load step (default).

- 1 --

Deactivate automatic damping.

- 2 --

Damping is activated for all load steps.

- 3 --

Damping is activated at all times regardless of the contact status of previous substeps.

Note: Normal stabilization damping is only applied to the contact element when the current contact status of the contact detection point is near-field. When KEYOPT(15) = 0, 1, or 2, normal stabilization damping is not applied in the current substep if any contact detection point has a closed status. However, when KEYOPT(15) = 3, normal stabilization damping is always applied as long as the current contact status of the contact detection point is near-field. Tangential stabilization damping is automatically activated when normal damping is activated. Tangential damping can also be applied independent of normal damping for sliding contact. See Applying Contact Stabilization Damping in the Contact Technology Guide for more information.

- KEYOPT(16)

Squeal damping controls for interpretation of real constants FDMD and FDMS:

- 0 --

FDMD and FDMS are scaling factors for destabilizing and stabilizing damping (default).

- 1 --

FDMD is a constant friction-sliding velocity gradient. FDMS is the stabilization damping coefficient.

- 2 --

FDMD and FDMS are the destabilizing and stabilization damping coefficients.

Note: KEYOPT(16) is not supported for contact elements used in a general contact definition.

- KEYOPT(18)

Sliding behavior:

- 0 --

Finite sliding (default). The contacting interface can undergo separation, relative large sliding, and arbitrary rotation.

- 1 --

Small sliding. The contacting interface can undergo only small sliding during the entire solution; arbitrary rotation is permitted.

- 2 --

Adaptive small sliding. The contact interface can undergo either small sliding or finite sliding within each substep based on the contact status at the beginning of the substep. If the contact status is closed, small sliding is used.

Table 174.1: CONTA174 Real Constants

| No. | Name | Description | For more information, see this section in the Contact Technology Guide . . . |

|---|---|---|---|

| 1 | R1 |

Target radius for cylinder, cone, or sphere | |

| 2 | R2 |

Target radius at second node of cone | |

| 3 | FKN | ||

| 4 | FTOLN |

Penetration tolerance factor [5] | |

| 5 | ICONT |

Initial contact closure | |

| 6 | PINB |

Pinball region | or |

| 7 | PZER | Pressure at zero penetration [1] [2] | Pressure-Penetration Relationship (KEYOPT(6) = 3) |

| 8 | CZER | Initial contact clearance | Pressure-Penetration Relationship (KEYOPT(6) = 3) |

| 9 | TAUMAX | ||

| 10 | CNOF | ||

| 11 | FKOP | ||

| 12 | FKT | ||

| 13 | COHE |

Contact cohesion | |

| 14 | TCC | ||

| 15 | FHTG |

Frictional heating factor | |

| 16 | SBCT |

Stefan-Boltzmann constant | |

| 17 | RDVF | ||

| 18 | FWGT |

Heat distribution weighing factor | Modeling Heat Generation Due to Friction (thermal) orHeat Generation Due to Electric Current (electric) |

| 19 | ECC |

Electric contact conductance or electric contact capacitance [1] [2] [4] | |

| 20 | FHEG |

Joule dissipation weight factor | |

| 21 | FACT |

Static/dynamic ratio | |

| 22 | DC |

Exponential decay coefficient | |

| 23 | SLTO |

Allowable elastic slip | |

| 24 | TNOP |

Maximum allowable tensile contact pressure [5] | |

| 25 | TOLS |

Target edge extension factor | |

| 26 | MCC | ||

| 27 | PPCN | ||

| 28 | FPAT |

Fluid penetration acting time | |

| 29 | COR |

Coefficient of restitution | |

| 30 | STRM |

Load step number for ramping penetration or Starting time for contact stiffness ramping | |

| 31 | FDMN | Normal stabilization damping factor [1] [2] | |

| 32 | FDMT | Tangential stabilization damping factor [1] [2] | |

| 33 | FDMD | Destabilization squeal damping factor | |

| 34 | FDMS | Stabilization squeal damping factor | |

| 35 | TBND | Critical bonding temperature [1] [2] | |

| 36 | WBID | Internal contact pair ID (used by Ansys Workbench) | |

| 37 | PCC | Pore fluid contact permeability coefficient [1] [2] | |

| 38 | PSEE | Pore fluid seepage coefficient [1] [2] | |

| 39 | ABPP | Ambient pore pressure [1] [2] | |

| 40 | FPFT | Gap pore fluid flow participation factor [1] [2] | |

| 41 | FPWT | Gap pore fluid flow distribution weighting factor | |

| 42 | DCC | Contact diffusivity coefficient [1] [2] | |

| 43 | DCON | Diffusive convection coefficient [1] [2] | |

| 44 | ABDC | Ambient concentration [1] [2] | |

| 45 | BSRL | Original contact pair real constant ID (after contact splitting) | Real Constant Set IDs for Split Pairs |

| 46 | KSYM | Real constant ID of the associated companion pair for symmetric contact or self contact (after contact splitting) | Real Constant Set IDs for Split Pairs |

| 47 | TFOR | Pair-based force tolerance | Checking Contact Pair-Based Force Convergence |

| 48 | TEND | Ending time for ramping contact stiffness | Modeling Interference Fit |

This real constant can be defined as a function of certain primary variables.

This real constant can be defined by the user subroutine USERCNPROP.F.

When CONTA174 is used as part of a forced-distributed constraint and KEYOPT(7) = 2 on the TARGE170 element, FKN is used to define weighting factors in tabular format with node number as the primary variable.

ECC is electric contact conductance per unit area in a current-based electric analysis, or electric contact capacitance per unit area in a charge-based electric analysis (see Modeling Surface Interaction).

When the relaxation option is enabled (KEYOPT(11) = 1 on the TARGE170 element), FKN and FKT are translational relaxation coefficient and rotational relaxation coefficient, respectively, and tabular input is not supported. In addition, FTOLN and TNOP are translational tolerance and rotational tolerance, respectively.

CONTA174 Output Data

The solution output associated with the element is in two forms:

Nodal displacements included in the overall nodal solution

Additional element output as shown in Table 174.2: CONTA174 Element Output Definitions

A general description of solution output is given in Solution Output. See the Basic Analysis Guide for ways to view results.

The Element Output Definitions table uses the following notation:

A colon (:) in the Name column indicates that the item can be accessed by the Component Name method (ETABLE, ESOL). The O column indicates the availability of the items in the file jobname.out. The R column indicates the availability of the items in the results file.

In either the O or R columns, “Y” indicates that the item is always available, a letter or number refers to a table footnote that describes when the item is conditionally available, and “-” indicates that the item is not available.

Table 174.2: CONTA174 Element Output Definitions gives element output. In the results file, the nodal results are obtained from its closest integration point.

Table 174.2: CONTA174 Element Output Definitions

| Name | Definition | O | R |

|---|---|---|---|

| EL | Element Number | Y | Y |

| NODES | Nodes I, J, K, L, M, N, O, P | Y | Y |

| XC, YC, ZC | Location where results are reported | Y | 5 |

| TEMP | Temperatures T(I), T(J), T(K), T(L), T(M), T(N), T(O), T(P) | Y | Y |

| VOLU | AREA | Y | Y |

| NPI | Number of integration points | Y | - |

| ITRGET | Target surface number (assigned by the program) | Y | - |

| ISOLID [15] | Underlying solid or shell element number | Y | - |

| CONT:STAT | Current contact statuses | 1 | 1 |

| OLDST | Old contact statuses | 1 | 1 |

| ISEG | Current contacting target element number | Y | Y |

| OLDSEG | Underlying old target number | Y | - |

| CONT:PENE | Current penetration (gap = 0; penetration = positive value) | Y | Y |

| CONT:GAP | Current gap (gap = negative value; penetration = 0) | Y | Y |

| NGAP | New or current gap at current converged substep (gap = negative value; penetration = positive value) | Y | - |

| OGAP | Old gap from previously converged substep (gap = negative value; penetration = positive value) | Y | - |

| IGAP | Initial gap at start of current substep (gap = negative value; penetration = positive value) | Y | Y |

| GGAP | Geometric gap at current converged substep (gap = negative value; penetration = positive value) | - | Y |

| CONT:PRES | Normal contact pressure | Y | Y |

| TAUR/TAUS [7] | Tangential contact stresses | Y | Y |

| KN | Current normal contact stiffness (Force/Length3) | Y | Y |

| KT | Current tangent contact stiffness (Force/Length3) | Y | Y |

| MU [8] | Friction coefficient | Y | Y |

| TASS/TASR [7] | Total (algebraic sum) sliding in S and R directions | 3 | 3 |

| AASS/AASR [7] | Total (absolute sum) sliding in S and R directions | 3 | 3 |

| TOLN | Penetration tolerance | Y | Y |

| CONT:SFRIC | Frictional stress, SQRT (TAUR**2+TAUS**2) | Y | Y |

| CONT:STOTAL | Total stress, SQRT (PRES**2+TAUR**2+TAUS**2) | Y | Y |

| CONT:SLIDE | Amplitude of total accumulated sliding, SQRT (TASS**2 + TASR**2) | 3 | 3 |

| FDDIS | Frictional energy dissipation rate | 6 | 6 |

| ELSI | Total equivalent elastic slip distance | - | Y |

| PLSI | Total (accumulated) equivalent plastic slip due to frictional sliding | - | Y |

| GSLID | Amplitude of total accumulated sliding (including near-field) | - | 9 |

| VREL | Equivalent sliding velocity (slip rate) | - | Y |

| DBA | Penetration variation | Y | Y |

| PINB | Pinball Region | - | Y |

| CONT:CNOS | Total number of contact status changes during substep | Y | Y |

| TNOP | Maximum allowable tensile contact pressure | Y | Y |

| SLTO | Allowable elastic slip | Y | Y |

| CAREA | Contacting area | - | Y |

| CONT:FPRS | Actual applied fluid penetration pressure (magnitude of normal and tangential) | - | Y |

| FPRSN | Actual applied fluid penetration normal pressure | - | Y |

| FPTR, FPTS | Actual applied fluid penetration tangential pressure in R and S directions (x and y directions of ESYS) | - | Y |

| FSTART | Fluid penetration starting time | - | Y |

| DTSTART | Load step time during debonding | Y | Y |

| DPARAM | Debonding parameter | Y | Y |

| DENERI [12] | Energy released due to separation in normal direction - mode I debonding | Y | Y |

| DENERII [12] | Energy released due to separation in tangential direction - mode II debonding | Y | Y |

| DENER [13] | Total energy released due to debonding | Y | Y |

| CNFX [10] | Contact element force-X component | - | 4 |

| CNFY [10] | Contact element force-Y component | - | 4 |

| CNFZ [10] | Contact element force-Z component | - | 4 |

| CNTX [11] | Contact element force due to tangential stresses - X component | - | 4 |

| CNTY [11] | Contact element force due to tangential stresses - Y component | - | 4 |

| CNTZ [11] | Contact element force due to tangential stresses - Z component | - | 4 |

| SDAMP | Squeal damping coefficient / Stabilization damping coefficient | - | Y |

| WEARX, WEARY, WEARZ | Wear correction - X, Y, and Z components | - | Y |

| VWEAR [14] | Volume lost due to wear | - | Y |

| CONV | Convection coefficient | Y | Y |

| RAC | Radiation coefficient | Y | Y |

| TCC | Conductance coefficient | Y | Y |

| TEMPS | Temperature at contact point | Y | Y |

| TEMPT | Temperature at target surface | Y | Y |

| FXCV | Heat flux due to convection | Y | Y |

| FXRD | Heat flux due to radiation | Y | Y |

| FXCD | Heat flux due to conductance | Y | Y |

| CONT:FLUX | Total heat flux at contact surface | Y | Y |

| FXNP | Flux input | - | Y |

| CNFH | Contact element heat flow | - | Y |

| JCONT | Contact current density (Current/Unit Area) | Y | Y |

| CCONT | Contact charge density (Charge/Unit Area) | Y | Y |

| HJOU | Contact power/area | Y | Y |

| ECURT | Current per contact element | - | Y |

| ECHAR | Charge per contact element | - | Y |

| ECC | Electric contact conductance (for electric current DOF), or electric contact capacitance per unit area (for piezoelectric or electrostatic DOFs) | Y | Y |

| VOLTS | Voltage on contact nodes | Y | Y |

| VOLTT | Voltage on associated target | Y | Y |

| MCC | Magnetic contact permeance | Y | Y |

| MFLUX | Magnetic flux density | Y | Y |

| MAGS | Magnetic potential on contact node | Y | Y |

| MAGT | Magnetic potential on associated target | Y | Y |

| PCC | Pore fluid contact permeability coefficient | Y | Y |

| PSEE | Pore fluid seepage coefficient | Y | Y |

| PRESS | Pore pressure on contact nodes | Y | Y |

| PREST | Pore pressure on associated target | Y | Y |

| PFLUX | Pore volume flux density per unit area flow into contact surface | Y | Y |

| EPELX | Pore volume flux per contact element | - | Y |

| DCC | Contact diffusivity coefficient | Y | Y |

| DCON | Diffusive convection coefficient | Y | Y |

| CONCS | Concentration on contact nodes | Y | Y |

| CONCT | Concentration on associated target | Y | Y |

| DFLUX | Diffusion flux density per unit area flow into contact surface | Y | Y |

| EDELX | Diffusion flux per contact element | - | Y |

The possible values of STAT and OLDST are:

0 = Open and not near contact 1 = Open but near contact 2 = Closed and sliding 3 = Closed and sticking The program will evaluate model to detect initial conditions.

Only accumulates the sliding for sliding and closed contact (STAT = 2,3).

Contact element forces are defined in the global Cartesian system.

Available only at centroid as a *GET item.

FDDIS = (contact friction stress)*(sliding distance of substep)/(time increment of substep)

For the case of orthotropic friction, components are defined in the global Cartesian system (default) or in the local element coordinate system specified by ESYS.

For orthotropic friction, an equivalent coefficient of friction is output.

Accumulated sliding distance for near-field, sliding, and closed contact (STAT = 1,2,3).

The contact element force values (CNFX, CNFY, CNFZ) are calculated based on the individual contact element plus the surrounding contact elements. Therefore, the contact force values may not equal the contact element area times the contact pressure (CAREA * PRES).

CNTX, CNTY, and CNTZ report the total contact element forces due to tangential stresses. Since CNFX, CNFY, and CNFZ report the total contact element forces, the contact element forces due to normal pressure are (CNFX-CNTX), (CNFY-CNTY), and (CNFZ-CNTZ).

DENERI and DENERII are available only when one of the following material models is used: TB,CZM,,,,CBDD or TB,CZM,,,,CBDE.

DENER is available only when one of the following material models is used: TB,CZM,,,,BILI or TB,CZM,,,,EXPO.

The wear volume lost (VWEAR) is calculated based on the individual contact element plus the surrounding contact elements. Therefore, the wear volume may not equal the contact element area times the wear amount in the contact normal direction (CAREA * Wear).

The underlying element (ISOLID) can be obtained by a *GET command following a CNCHECK command. See Designating Contact and Target Surfaces for detail.

Note: Contact results (including all element results) are generally not reported for elements that have a status of "open and not near contact" (far-field).

Table 174.3: CONTA174 Item and Sequence Numbers lists output available through the ETABLE command using the Sequence Number method. See Creating an Element Table in the Basic Analysis Guide and The Item and Sequence Number Table in this reference for more information. The following notation is used:

- Name

output quantity as defined in the Table 174.2: CONTA174 Element Output Definitions

- Item

predetermined Item label for ETABLE command

- E

sequence number for single-valued or constant element data

- I, J, K, L

sequence number for data at nodes I, J, K, L

Table 174.3: CONTA174 Item and Sequence Numbers

| Output Quantity Name | ETABLE and ESOL Command Input | |||||

|---|---|---|---|---|---|---|

| Item | E | I | J | K | L | |

| PRES | SMISC | 13 | 1 | 2 | 3 | 4 |

| TAUR | SMISC | - | 5 | 6 | 7 | 8 |

| TAUS | SMISC | - | 9 | 10 | 11 | 12 |

| FLUX [3] | SMISC | - | 14 | 15 | 16 | 17 |

| FDDIS [3] | SMISC | - | 18 | 19 | 20 | 21 |

| FXCV [3] | SMISC | 22 | 23 | 24 | 25 | |

| FXRD [3] | SMISC | - | 26 | 27 | 28 | 29 |

| FXCD [3] | SMISC | - | 30 | 31 | 32 | 33 |

| FXNP | SMISC | - | 34 | 35 | 36 | 37 |

| JCONT/CCONT/PFLUX [3] | SMISC | - | 38 | 39 | 40 | 41 |

| HJOU | SMISC | - | 42 | 43 | 44 | 45 |

| MFLUX/DFLUX [3] | SMISC | - | 46 | 47 | 48 | 49 |

| STAT [1] | NMISC | 41 | 1 | 2 | 3 | 4 |

| OLDST | NMISC | - | 5 | 6 | 7 | 8 |

| PENE [2] | NMISC | - | 9 | 10 | 11 | 12 |

| DBA | NMISC | - | 13 | 14 | 15 | 16 |

| TASR | NMISC | - | 17 | 18 | 19 | 20 |

| TASS | NMISC | - | 21 | 22 | 23 | 24 |

| KN | NMISC | - | 25 | 26 | 27 | 28 |

| KT | NMISC | - | 29 | 30 | 31 | 32 |

| TOLN | NMISC | - | 33 | 34 | 35 | 36 |

| IGAP | NMISC | - | 37 | 38 | 39 | 40 |

| PINB | NMISC | 42 | - | - | - | - |

| CNFX | NMISC | 43 | - | - | - | - |

| CNFY | NMISC | 44 | - | - | - | - |

| CNFZ | NMISC | 45 | - | - | - | - |

| CNTX | NMISC | 186 | - | - | - | - |

| CNTY | NMISC | 187 | - | - | - | - |

| CNTZ | NMISC | 188 | - | - | - | - |

| ISEG [4] | NMISC | - | 46 | 47 | 48 | 49 |

| AASR | NMISC | - | 50 | 51 | 52 | 53 |

| AASS | NMISC | - | 54 | 55 | 56 | 57 |

| CAREA | NMISC | 58 | 59 | 60 | 61 | 184 |

| MU | NMISC | - | 62 | 63 | 64 | 65 |

| DTSTART | NMISC | - | 66 | 67 | 68 | 69 |

| DPARAM | NMISC | - | 70 | 71 | 72 | 73 |

| FPRSN | NMISC | - | 74 | 75 | 76 | 77 |

| TEMPS | NMISC | - | 78 | 79 | 80 | 81 |

| TEMPT | NMISC | - | 82 | 83 | 84 | 85 |

| CONV | NMISC | - | 86 | 87 | 88 | 89 |

| RAC | NMISC | - | 90 | 91 | 92 | 93 |

| TCC | NMISC | - | 94 | 95 | 96 | 97 |

| CNFH | NMISC | 98 | - | - | - | - |

| ECURT/ECHAR/EPELX | NMISC | 99 | - | - | - | - |

| ECC/PCC/PSEE | NMISC | - | 100 | 101 | 102 | 103 |

| VOLTS/PRESS | NMISC | - | 104 | 105 | 106 | 107 |

| VOLTT/PREST | NMISC | - | 108 | 109 | 110 | 111 |

| CNOS | NMISC | - | 112 | 113 | 114 | 115 |

| TNOP | NMISC | - | 116 | 117 | 118 | 119 |

| SLTO | NMISC | - | 120 | 121 | 122 | 123 |

| MCC/DCC | NMISC | - | 124 | 125 | 126 | 127 |

| MAGS/CONCS | NMISC | - | 128 | 129 | 130 | 131 |

| MAGT/CONCT | NMISC | - | 132 | 133 | 134 | 135 |

| ELSI | NMISC | - | 136 | 137 | 138 | 139 |

| DENERI or DENER | NMISC | - | 140 | 141 | 142 | 143 |

| DENERII | NMISC | - | 144 | 145 | 146 | 147 |

| FSTART | NMISC | - | 148 | 149 | 150 | 151 |

| GGAP | NMISC | - | 152 | 153 | 154 | 155 |

| VREL | NMISC | - | 156 | 157 | 158 | 159 |

| SDAMP | NMISC | - | 160 | 161 | 162 | 163 |

| PLSI | NMISC | - | 164 | 165 | 166 | 167 |

| GSLID | NMISC | - | 168 | 169 | 170 | 171 |

| WEARX | NMISC | - | 172 | 173 | 174 | 175 |

| WEARY | NMISC | - | 176 | 177 | 178 | 179 |

| WEARZ | NMISC | - | 180 | 181 | 182 | 183 |

| VWEAR | NMISC | 189 | - | - | - | - |

| EDELX | NMISC | 185 | - | - | - | - |

| FPTR | NMISC | - | 190 | 191 | 192 | 193 |

| FPTS | NMISC | - | 194 | 195 | 196 | 197 |

Element Status = highest value of status of integration points within the element

A positive value of flux corresponds to flow into the contact surface.

The floating point output format for large integers may lead to incorrect ISEG values. You should verify the NMISC values via the *GET command. For example, *GET,

Par,ELEM,N,NMISC,46 returns the ISEG value for node I of elementN.

You can display or list contact results through several POST1 postprocessor commands. The contact specific items for the PLNSOL, PLESOL, PRNSOL, and PRESOL commands are listed below:

| STAT | Contact status |

| PENE | Contact penetration |

| PRES | Contact pressure |

| SFRIC | Contact friction stress |

| STOT | Contact total stress (pressure plus friction) |

| SLIDE | Contact sliding distance |

| GAP | Contact gap distance |

| FLUX | Total heat flux at contact surface |

| CNOS | Total number of contact status changes during substep |

| FPRS | Actual applied fluid penetration pressure |

CONTA174 Assumptions and Restrictions

The 3D contact element must coincide with the external surface of the underlying solid or shell element.

This element is nonlinear and requires a full Newton iterative solution, regardless of whether large or small deflections are specified. An exception to this is when MPC bonded contact is specified (KEYOPT(2) = 2 and KEYOPT(12) = 5 or 6).

The normal contact stiffness factor (FKN) must not be so large as to cause numerical instability.

FTOLN, PINB, and FKOP can be changed between load steps or during restart stages.

You can use this element in nonlinear static or nonlinear full transient analyses.

In addition, you can use it in modal analyses, eigenvalue buckling analyses, and harmonic analyses. For these analysis types, the program assumes that the initial status of the element (that is, the status at the completion of the static prestress analysis, if any) does not change.

It is possible for at least one midside node of the contact element to be in contact while the corner nodes are not in contact. Because the program reports contact results only for the corner nodes, the element may have a closed contact status even though the reported contact pressure is zero. To verify the contact status for contact elements in this situation, list the following ETABLE quantities: SMISC,13 (PRES); NMISC,41 (STAT); NMISC,43 (CNFX); NMISC,44 (CNFY); and NIMSC,45 (CNFZ).

Only damping defined via KEYOPT(15) is supported. All other damping specifications (Rayleigh damping, DMPSTR, and so on) are not supported.

Certain contact features are not supported when this element is used in a general contact definition. For details, see General Contact in the Contact Technology Guide.

CONTA174 Product Restrictions

When used in the product(s) listed below, the stated product-specific restrictions apply to this element in addition to the general assumptions and restrictions given in the previous section.

Ansys Mechanical Pro —

The MAG DOF (KEYOPT(1) = 7) is not available.

Birth and death is not available.

Debonding is not available.

User-defined contact is not available.

User-defined friction is not available.

Ansys Mechanical Premium —

The MAG DOF (KEYOPT(1) = 7) is not available.

Debonding is not available.

User-defined contact is not available.

User-defined friction is not available.