Whether you are beginning a new simulation or modifying an existing one, it is a good idea to ensure that your simulation parameters are set exactly the way you want before you start processing. Once you Start a Simulation and begin processing, you cannot go back and change the settings without losing the simulation results that have been created.

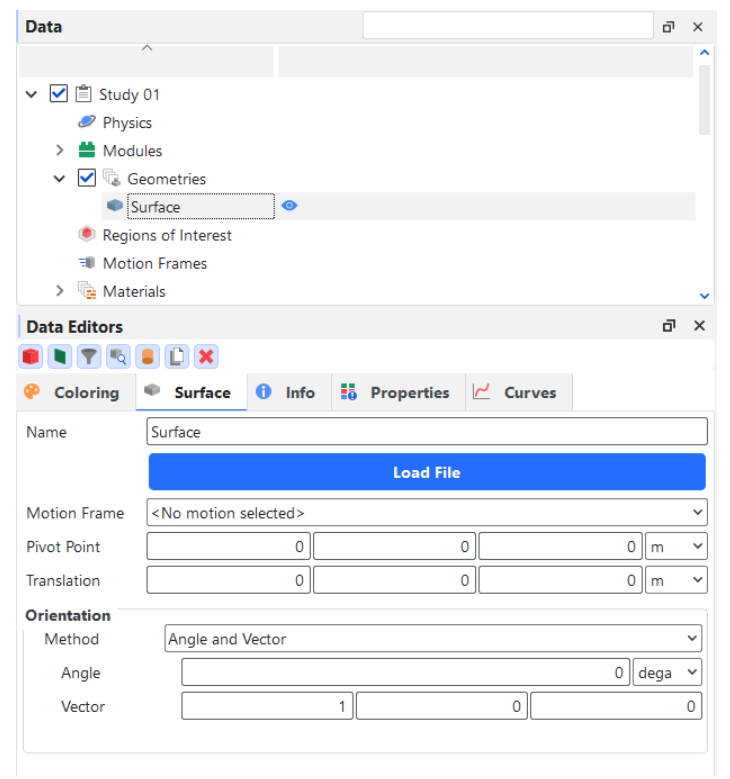

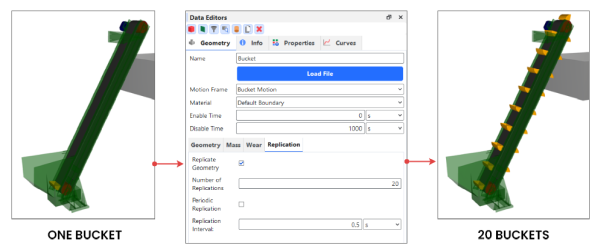

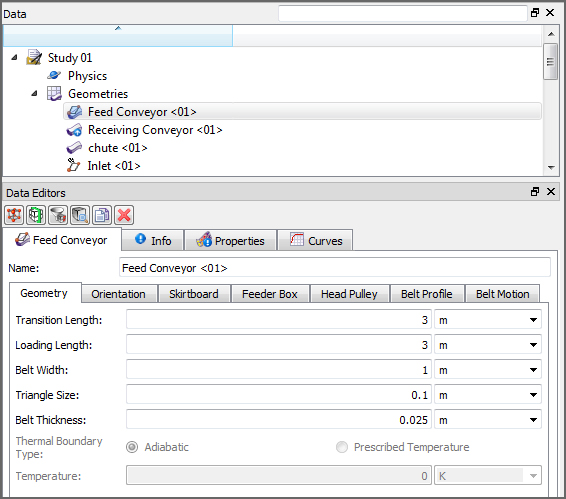

Setting simulation parameters involves setting simulation-wide values as well as parameters specific to particles, geometries, materials, interactions, inputs, and more. To make the setup of multiple similar items quicker, you many also choose to duplicate already-setup items, or remove many similar items at one time.

What would you like to do?

See Also:

You set simulation-wide parameters when you want to change the default values provided by Rocky to affect your whole simulation. Simulation-wide parameters are settings that can include:

Study items, which include setting the simulation title and customer name.

Physics items, which include setting how you want gravity applied; and setting simulation-wide models such as adhesion, rolling resistance, heat transfer, and coarse graining.

Modules items, which include collision and particle statistics collection.

Domain Settings items, which include defining the simulation coordinate limits and setting an optional periodic domain.

Solver items, which include setting simulation time length, and certain data collection times.

Simulation-wide parameters are set by first selecting the Study, Physics, Modules, Domain Settings, and Solver sections in the Data panel and then editing the results in the Data Editors panel. These values can be set at any time before you begin processing your simulation. However, it is recommended that at least the Physics and Modules settings be made first as your selections there may affect other settings later on.

What would you like to do?

Learn more About Study Parameters

Learn more About Physics Parameters

Learn more About Modules Parameters

Learn more About SPH Parameters

Learn more About Domain Settings Parameters

Learn more About Solver Parameters

Set Study, Physics, Modules, Domain Settings, and Solver Parameters

See Also:

Note: Unlike most other setup parameters, you are able to change your Study parameters at any time-even during active processing. (See also I cannot change my setup parameters during processing.)

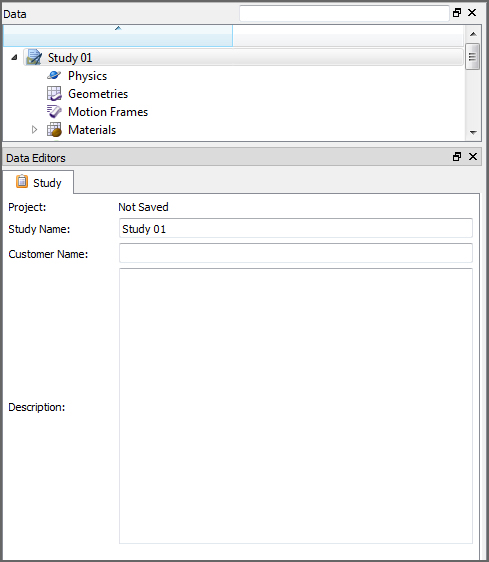

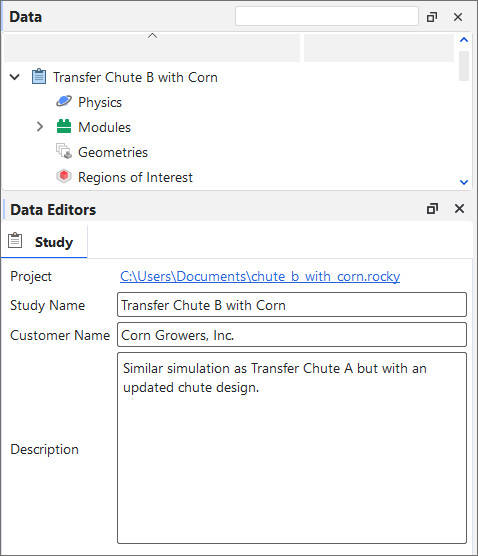

Use the figures and table below to help you understand the various Study parameters you can set for a simulation project.

Table 1: Study parameter options

Setting | Description | Range |

|---|---|---|

Project | When the project is saved, this lists the full path for the .rocky project file in hyperlink form (Figure 2). If the project has not yet been saved, "Not Saved" will be displayed (Figure 1). | Path automatically provided |

Study Name | Name of the simulation you are working on. For example, "Transfer Chute B with corn." Note: The Study entity on the Data panel will be renamed with what you enter here (Figure 2). | No limit |

Customer Name | Name of the customer for whom you are doing the simulation. | No limit |

Description | Description of the simulation. | No limit |

What would you like to do?

See Also:

The Rocky Physics parameters include simulation-wide settings that affect how the components are calculated. These include settings affecting gravity; the rolling resistance and force models used for calculating momentum; and the separate settings that enable Thermal Modeling and Coarse-Graining.

The rolling resistance and force models used for calculating momentum have specific combinations that are unsupported in this version of Rocky. Refer to the compatibility table in Physics and Force Limitations for details.

To learn more about how these models are calculated, refer to the DEM Technical Manual. (From the Rocky Help menu, point to Manuals and then click DEM Technical Manual.)

To learn more about setting up and using Thermal in Rocky, refer to the Enable Thermal Modeling Calculations topic.

To learn more about how this model is calculated, refer to the DEM Technical Manual. (From the Rocky Help menu, point to Manuals and then click DEM Technical Manual.)

To learn more about the Coarse-Graining used in Rocky, and see examples for its usage, refer to the following resources:

DEM Technical Manual. (From the Rocky Help menu, point to Manuals and then click DEM Technical Manual.)

CFD Coupling Technical Manual. (From the Rocky Help menu, point to Manuals and then click CFD Coupling Technical Manual.)

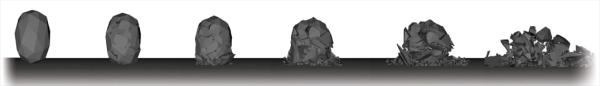

In this version of Rocky, Coarse-Graining and Particle Breakage are incompatible. This means if any Particle sets within an Enable Coarse-Graining (previously named Coarse Grain Modeling (CGM)) simulation has breakage parameters enabled, the entire simulation-including any Particle sets without breakage-will be unable to be processed.

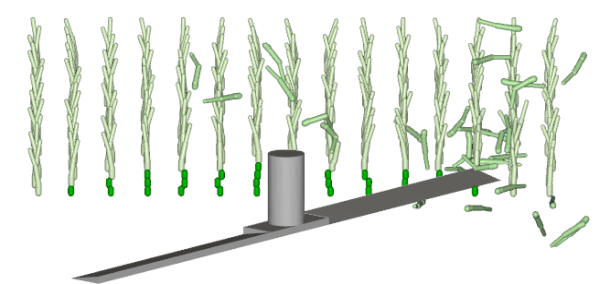

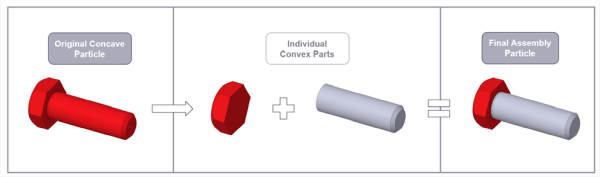

In addition, CGM works only with single-element particle shapes. This means that Coarse Grain Models are incompatible with Particle sets composed of multiple elements (also known as Meshed particles), including flexible Fibers, flexible Shells, and flexible Solids.

In terms of momentum settings, CGM can be used only with these two Adhesive Forces: Constant and Linear. All other types of Adhesive Forces-including JKR-are incompatible with Coarse Grain Modeling in this version. Also note that the Velocity Dependent restitution model (an Experimental (Beta) Feature) is also incompatible with CGM.

In terms of CFD coupling, Coarse Graining is incompatible with 1-Way LBM. While other types of coupling is allowed, only drag forces will be considered. This means that fluid forces such as torque, virtual mass, and lift are not compatible with Coarse Graining. (See also the CFD Coupling Technical Manual. (From the Rocky Help menu, point to Manuals and then click CFD Coupling Technical Manual.))

Also note that the Radl et al. Coarse Grain Model is currently incompatible with Multi GPU processing. (It is compatible with both Single GPU and CPU processing, however.)

(See also Physics and Force Limitations.)

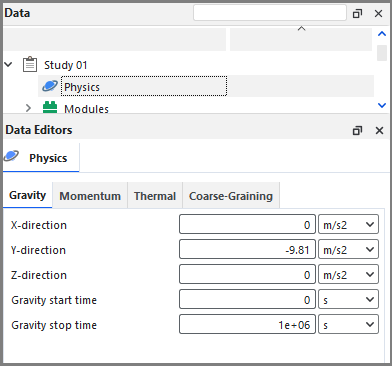

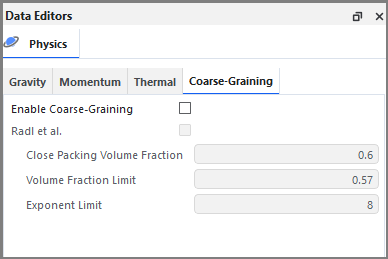

Use the figures and table below to help you understand the various Physics parameters you can set for a simulation project.

Table 1: Physics parameter options (all tabs)

Setting | Description | Range |

|---|---|---|

Gravity | ||

X-direction | Used to change the direction that gravity affects particles and free boundaries, this is the amount of acceleration applied in the X direction during the simulation. Tip: When prescribing movements, it can be easier to align geometries with the global axes and then simulate gravity in the plane that represents downward forces. For example, if you had your equipment horizontally aligned with the X direction, you could then modify the Y and X components of gravity to simulate it as if it were inclined in the YX plane. | No limit |

Y-direction | Used to change the direction that gravity affects particles and free boundaries, this is the amount of acceleration applied in the Y direction during the simulation. Note: The default value is -9.81 m/s2, which accounts for the effect of gravity pointing in the downward Y direction only. | No limit |

Z-direction | Used to change the direction that gravity affects particles and free boundaries, this is the amount of acceleration applied in the Z direction during the simulation. | No limit |

Gravity Start Time | The duration you want to wait before gravity components are activated. | Positive values |

Gravity Stop Time | The duration you want to wait before gravity components are deactivated. | Positive values |

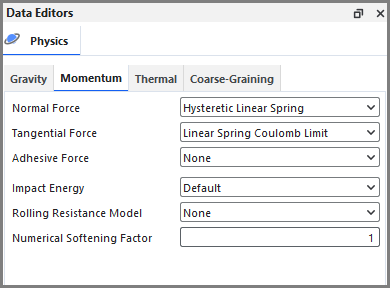

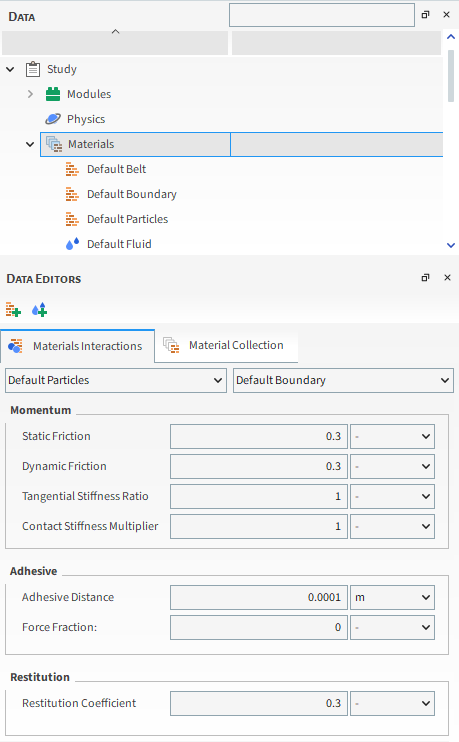

Momentum | ||

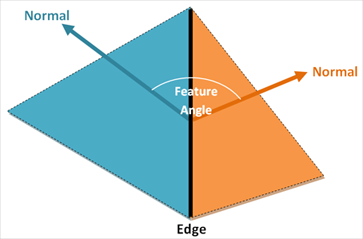

Normal Force | The type of model used to calculate the normal components of the contact forces. The model you select here determines what Adhesive Force and Tangential Force options are available. For additional details about these models, see the Rocky DEM Technical Manual. (From the Rocky program Help ** menu, point to **Manuals, and then click DEM Technical Manual.) | Hysteretic Linear Spring; Linear Spring Dashpot; Hertzian Spring Dashpot Note: This setting is considered to be exclusive so if you have one or more external Modules that are able to override this model, you must have only one such Module enabled within your simulation project. Refer to the Module's documentation (if provided) for more information. (See also Rocky Simulation Entities that can be Affected by Modules.) |

Tangential Force | The type of model used to calculate the tangential components of the contact forces. The models available are dependent upon the Normal Force you selected. Specifically:

For additional details about these models, see the Rocky DEM Technical Manual. (From the Rocky program Help ** menu, point to **Manuals, and then click DEM Technical Manual.) | Linear Spring Coulomb Limit; Coulomb Limit; Mindlin-Deresiewicz Note: This setting is considered to be exclusive so if you have one or more external Modules that are able to override this model, you must have only one such Module enabled within your simulation project. Refer to the Module's documentation (if provided) for more information. (See also Rocky Simulation Entities that can be Affected by Modules.) |

Adhesive Force | Defines how adhesion between materials is calculated. Material-to- Material interactions are then defined in the Modify Material Interaction and Adhesion Values step. (See also About Modifying Materials Interactions and Adhesion Values.) The models available are dependent upon the Normal Force you selected. Specifically:

For additional details about these models, see the Rocky DEM Technical Manual. (From the Rocky program Help ** menu, point to **Manuals, and then click DEM Technical Manual.) | None; Constant; Linear; JKR Note: This setting is considered to be exclusive so if you have one or more external Modules that are able to override this model, you must have only one such Module enabled within your simulation project. Refer to the Module's documentation (if provided) for more information. (See also Rocky Simulation Entities that can be Affected by Modules.) |

Restitution Model | When the Experimental (Beta) Features checkbox is enabled on the Options | Preferences dialog (see also About Setting Global Preferences), this enables you to select the type of model used to calculate restitution. Note: The Velocity Dependent model is incompatible with Enable Coarse-Graining. (See also the Coarse-Graining section below.) | Constant; Velocity Dependent |

Impact Energy | The type of model used to calculate the impact energy of a contact. Unless you have enabled a custom external Module that defines a different Impact Energy model, the only option listed will be Default. Impact energy is used in Rocky as the main input parameter for the built-in instantaneous breakage models. You will need to implement a custom impact energy calculation only if you intend to use a custom contact force model along with such breakage models. If in that case, you choose not to implement the impact energy calculation, Rocky will use a standard calculation based on the impact work, as defined in equation (4.10) of the DEM Technical Manual. | Default Note: This setting is considered to be exclusive so if you have one or more external Modules that are able to override this model, you must have only one such Module enabled within your simulation project. Refer to the Module's documentation (if provided) for more information. (See also Rocky Simulation Entities that can be Affected by Modules.) |

Rolling Resistance Model | Defines how rolling resistance for particles are calculated. After a model is selected, Rolling Resistance values are then set per Particle sets on its Movement tab. (See also About Adding and Editing Particle Sets). Specifically:

Note: Both types of Rolling Resistance Models are incompatible with concave Custom Polyhedron particle shapes (see also Physics and Force Limitations.) For more information on the calculations used to form these models, see the Rocky DEM Technical Manual. (From the Rocky program Help ** menu, point to **Manuals, and then click DEM Technical Manual.) | None; Type A: Constant Moment; Type C: Linear Spring Rolling Limit |

Numerical Softening Factor | Factor applied to the materials (includes both particles and boundaries) stiffnesses values that are used to calculate both timesteps and contact forces. This enables you increase the size of your timesteps, and speed up your processing time, without having to change the material properties themselves. This is especially useful in long or particularly complex cases, or for those with Thermal Modeling enabled. Tips:

See also About Modifying Material Compositions and and Enable Thermal Modeling Calculations. | Positive values Note: Typical values will range between 0.001 and 1.0 |

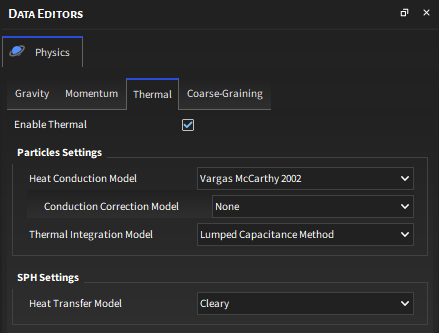

Thermal | ||

Enable Thermal | Makes possible the simulation of conductive heat transfer between particles and other particles, and particles and boundaries. Enables convective heat transfer between particles and fluids when coupled with Ansys Fluent (see also Set or Modify Fluid and/or Air Flow Properties). See also Enable Thermal Modeling Calculations. | Turns on or off |

| Particle Settings | ||

Heat Conduction Model | When Enable Thermal is selected, this is the type of model used to calculate heat conduction. Unless you have enabled a custom external Module that defines a different Heat Conduction Model, only the default Vargas McCarthy 2002 model will be used. | Vargas McCarthy 2002 Note: This setting is considered to be exclusive so if you have one or more external Modules that are able to override this model, you must have only one such Module enabled within your simulation project. Refer to the Module's documentation (if provided) for more information. (See also Rocky Simulation Entities that can be Affected by Modules.) |

Conduction Correction Model | When Thermal is enabled, this allows you to select a strategy to counteract the adverse effects that can occur when you use the Numerical Softening Factor to speed up a simulation. (See also the definition in the Momentum tab section above.) Specifically:

Tip: To learn more about these models, refer to the DEM Technical Manual. (From the Rocky Help menu, point to Manuals and then click DEM Technical Manual.) | None; Morris et al. Area; Morris et al. Area+Time |

Thermal Integration Model | When Enable Thermal is selected, this is the type of model used to integrate heat conduction calculations. Unless you have enabled a custom external Module that defines a different Thermal Integration Model, only the default Lumped Capacitance Method will be used, which ignores any conduction inside the particle and assumes only that the entire particle has a single temperature. | Lumped Note: This setting is considered to be exclusive so if you have one or more external Modules that are able to override this model, you must have only one such Module enabled within your simulation project. Refer to the Module's documentation (if provided) for more information. (See also Rocky Simulation Entities that can be Affected by Modules.) |

| SPH Settings | ||

| Heat transfer Model |

When Enable Thermal is selected, this is the type of model used to calculate heat transfer for SPH elements. Unless you have enabled a custom external module that defines a different Heat transfer Model, only the default, Cleary model, will be used. | Cleary Note: This setting is considered to be exclusive so if you have one or more external Modules that are able to override this model, you must have only one such Module enabled within your simulation project. Refer to the Module’s documentation (if provided) for more information. |

Coarse-Graining | ||

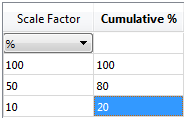

Enable Coarse-Graining | Enables a coarse grain model (CGM) to be used in the simulation. Tip: Turning on Enable Coarse-Graining allows you to increase the original particle size and reproduce the system behavior using a reduced number of particles via use of the CGM Scale Factor. (See also the Size Tab section of About Adding and Editing Particle Sets.) Notes: In this version of Rocky, Enable Coarse-Graining is incompatible with:

| Turns on or off |

Radl et al. | When Enable Coarse-Graining is selected, this determines whether or not the Radl et al. model will be enabled, which helps describe additional physical processes on particle flows by determining the amount of energy dissipated based upon the velocities of the surrounding particles. Specifically:

Note: In this version of Rocky, the Radl et al. model is incompatible with Multi GPU processing. (See also About Starting a Simulation.) Tip: To learn more about these models, refer to the DEM Technical Manual. (From the Rocky Help menu, point to Manuals and then click DEM Technical Manual.) | Turns on or off |

Close Packing Volume Fraction | When Radl et al. is enabled, this defines the maximum volume fraction that particles are allowed to reach, which is one of three parameters that together determine what characteristics turn off the Radl et al. model and how quickly that shutoff happens. The shutoff function is especially important for cases with closely packed particles in constant contact as the Radl et al. model is not optimized for this scenario and applying it in those situations result in too much energy being removed from the system. Tip: This parameter is represented by Note: This text field does not support parametric variables. (See also I cannot enter an input variable or mathematical function into a text field.) | 0-1 |

Volume Fraction Limit | When Radl et al. is enabled, this defines the particle volume fraction value above which the shutoff function will not affect the particles' relaxation time. This parameter is one of three that together determines what characteristics turn off the Radl et al. model and how quickly that shutoff happens. The default value of 0.57 represents 95% of the default Close Packing Volume Fraction of 0.6. Tip: This parameter is represented by | 0-1 |

Exponent Limit | When Radl et al. is enabled, this defines the exponent value (default is 8) used in the shutoff function. The exponent is used to control how sensitive the shutoff function is regarding volume fraction variations, and is one of three parameters that together determines what characteristics turn off the Radl et al. model and how quickly that shutoff happens. Tip: Refer to equation 2.101 in the Rocky DEM Technical Manual for details. | 0-100 |

Search Distance Multiplier | When the Advanced Features checkbox is enabled on the Options | Preferences dialog (see also About Setting Global Preferences), and the Radl et al. checkbox is also enabled, this value will be multiplied by the biggest particle size to achieve the estimation radius used by the Radl et al. model to determine which particles are close enough to be used for energy dissipation calculations. Specifically:

| Positive values Note: This value must be greater than Update Distance Multiplier |

Updated Distance Multiplier | When the Advanced Features checkbox is enabled on the Options | Preferences dialog (see also About Setting Global Preferences), and the Radl et al. checkbox is also enabled, this value will be multiplied by the biggest particle size to define the distance a particle has to move before Rocky will update the neighbor list used by the Radl et al. model to compute the average neighbor velocity. Specifically:

| Positive values Note: This value must be less than Search Distance Multiplier |

What would you like to do?

See Also:

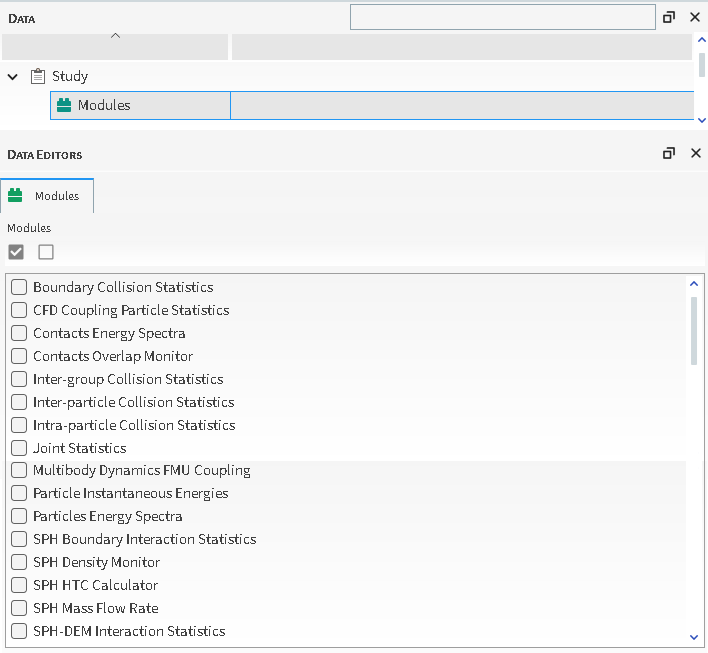

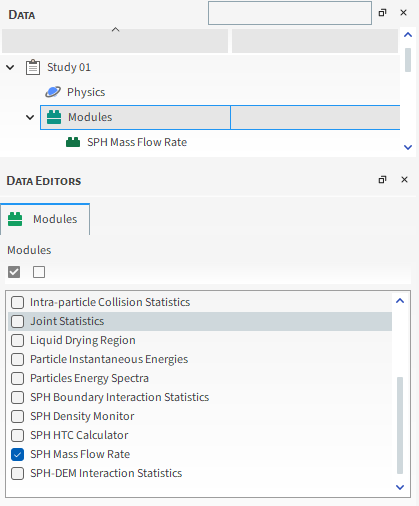

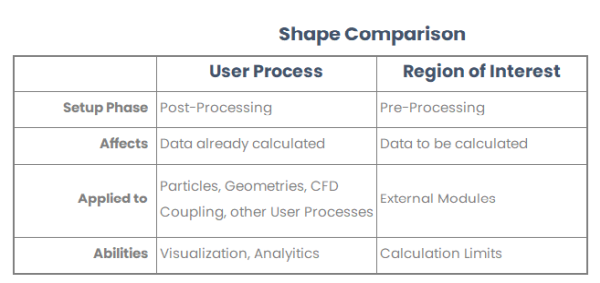

When you enable a Module in Rocky, you are choosing to add in custom, discrete features and/or functionality within your project. Depending upon the type of Module you enable and what it does, there may be additional settings that affect other areas of your Rocky project setup.

Use this topic to understand more about Module parameters and how setting them affect your project.

Tip: To learn more about the different types of Rocky Modules and where you obtain them, refer to the topic Understand Rocky Modules.

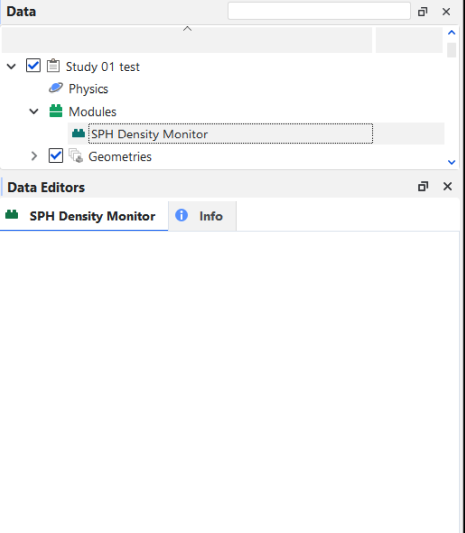

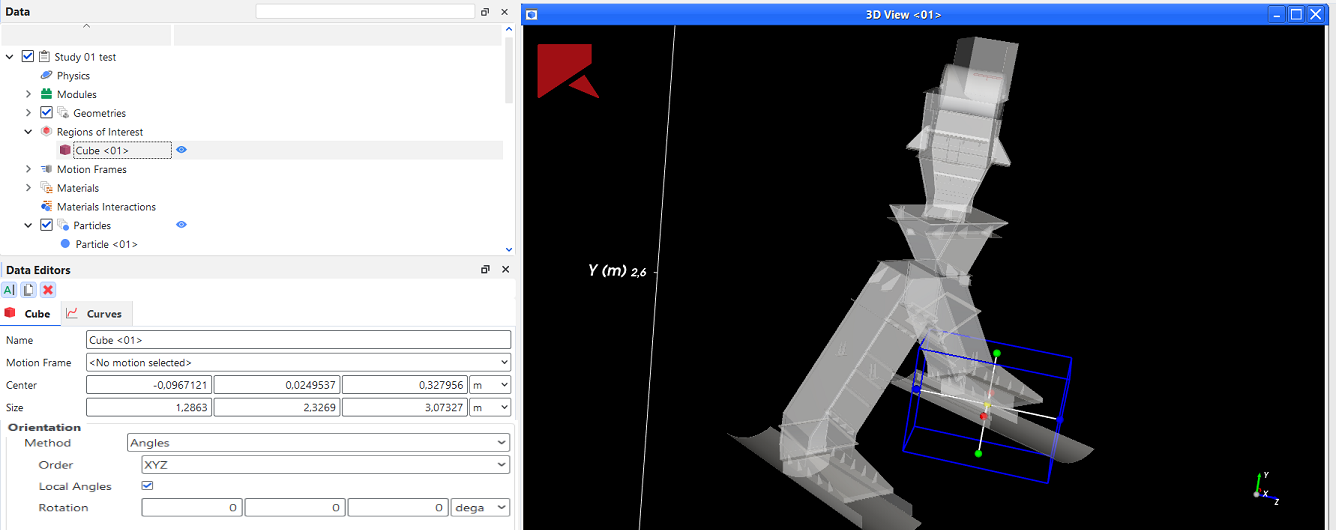

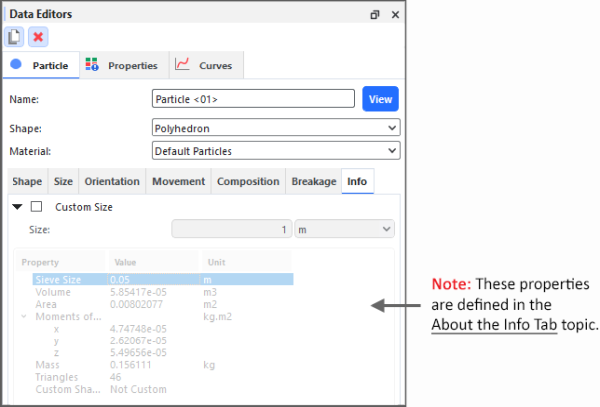

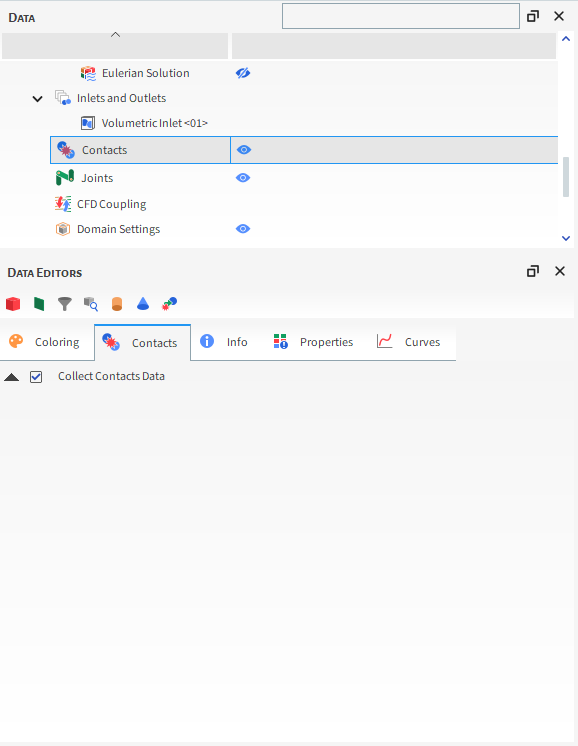

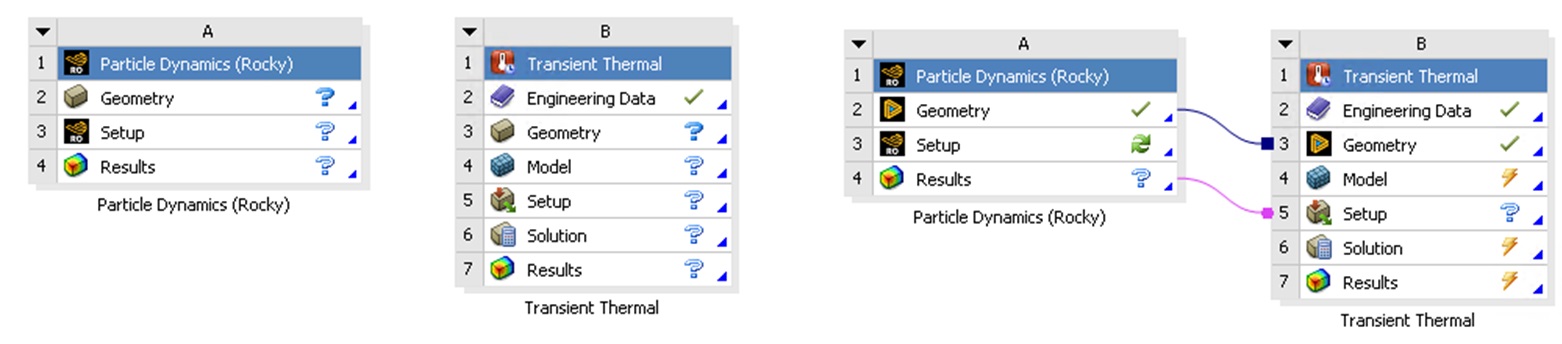

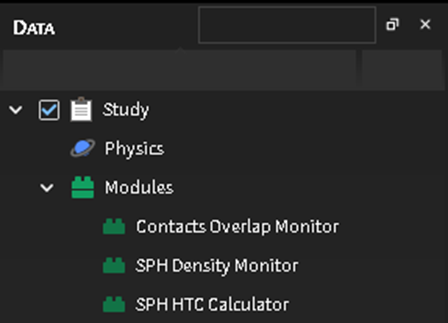

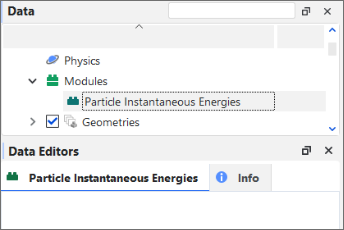

Because the default state for most Modules is disabled, it becomes very important for you to ensure that you have enabled the Modules and options you want prior to setting up the rest your simulation. This is done by selecting the main Modules entity in the Data panel and then enabling the checkbox for the module you want to use in the Data Editors panel (Figure 1).

Important: Only embedded Modules and external Modules that you have already installed will appear in on the list. (See also Install an External Module.)

In addition, because it is possible that turning on a Module will add or change options presented in other parts of the Rocky setup, it is recommended that turning on the Modules and options you want is one of the very first steps you take when setting up your project.

Tip: If you have similar projects that you set up regularly, using a script to record and then play back your Module configuration steps can save you from having to repeat these steps on future projects. (See also About Creating and Using PrePost Scripts.)

Note: Enabling more than one Module at once can cause some parameters to be shared across Modules. (See also Recognize Shared Parameters with Asterisks (*).)

Once enabled, many types of Modules have parameters that you can define. Depending upon the type of Module and what it does, the settings can be in any of the following combinations.

For these types of Modules, once you enable the Module itself, the functionality will be applied without any additional actions from you.

Tip: You will know that a Module has no additional settings when you select it from the Data panel, and find no settings on the Module's Data Editors panel, and its Info tab says "Module does not affect any simulation entity."

An example of this kind of Module is the Particle Instantaneous Energies Module. (See also About the Particle Instantaneous Energies Module.)

For these types of Modules, once you enable the Module itself, there are one or more additional settings in one or both of the following locations:

On the Module's Data Editors panel

For these types of Modules, there are one or more additional settings to be made on the Data Editors panel for the Module.

An example of this kind of Module is the Boundary Collision Statistics Module. (See also About the Boundary Collision Statistics Module.)

Elsewhere in the Rocky setup

For these types of Modules, there are one or more additional settings to be made in (or have otherwise been affected by) other locations of the Rocky UI. These may require additional setup steps for the Module in those other locations.

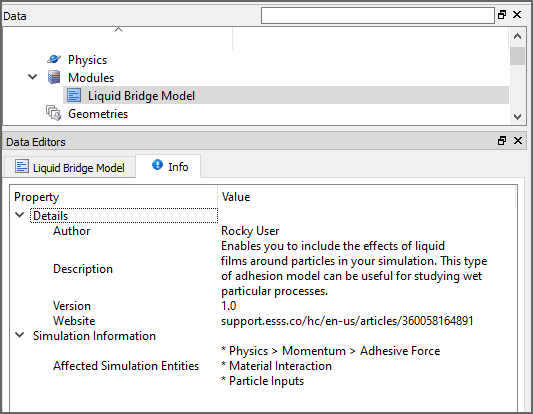

Tip: You will know that a Module has other settings in (or is otherwise affecting) other parts of the Rocky setup when you select it from the Data panel and then from the Data Editors panel, see that its Info tab has information next to the Affected Simulation Entities label. You can then use that information to discover where else in the Rocky setup Module-specific settings might need to be applied.

An example of this kind of Module is the Liquid Bridge Model Module, which has Module-specific settings in three other areas of the Rocky setup.

Note: In this version of Rocky, the Liquid Bridge Model Module is provided as an *external* module. Refer to the Install an External Module topic for details.

Use this section to learn more about where and when you might define parameters for your Modules.

Once enabled, some types of Modules will have additional settings on the Module's main tab in the Data Editors panel. To learn if there are additional, Module-specific settings that affect other parts of your Rocky project setup, you can view the information on the Info tab.

The Info tab on individual Modules (see also About the Info Tabs) describe the Author and Version details for the Module, and lists what other entities in the Rocky UI are affected by enabling that particular Module.

For example, the Info tab for the Liquid Bridge Model Module (Figure 2) describes three places in the Rocky UI affected by that module.

This information can help you verify that the parameters in those locations are set correctly for the feature enabled by the module.

Note: In this version of Rocky, the Liquid Bridge Model Module is provided as an *external* module. Refer to the Install an External Module topic for details.

Once enabled, some Modules will cause other areas of the Rocky UI to have additional settings specific to that Module, or will cause other changes, such as model overrides. These kinds of changes and additional settings are unique to each Module, so the best way to determine what other settings might be required for your Module is to view the Affected Simulation Entities information on the Info tab. (See the "About the Info Tab for Modules" section above.)

Once you understand what other parts of the UI are affected, you can then be sure to verify the Module-specific settings in those areas when setting up the rest of your project.

Tip: To learn more about what specific Rocky UI settings and options Modules can affect, refer to the Rocky Simulation Entities that can be Affected by Modules topic.

What would you like to do?

Learn more About Rocky Modules

Learn more About the Contacts Energy Spectra Module

Learn more About the Contacts Overlap Monitor Module

Learn more About the CFD Coupling Particle Statistics Module

Learn more About the Inter-group Collision Statistics Module

Learn more About the Inter-particle Collision Statistics Module

Learn more About the Intra-particle Collision Statistics Module

Learn more About Joint Statistics Module

Learn more About the Particles Energy Spectra Module

Set Study, Physics, Module, Domain Settings, and Solver Parameters

See Also:

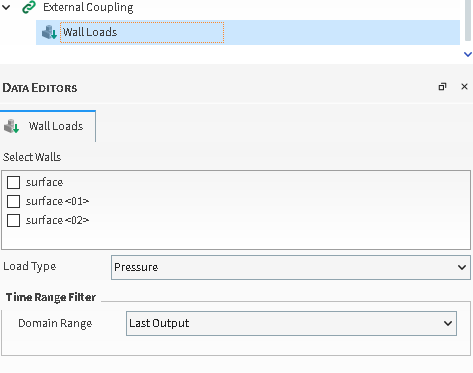

The Boundary Collision Statistics module enables the collection of boundary-related collision data, such as collision frequency, intensities, and impact velocities.

Figure 3.11: Options in the Data Editors panel when the Boundary Collision Statistics Module is enabled

When the Boundary Collision Statistics Module is enabled (Figure 1), you are able to select any of the following Properties:

Duration

Forces for FEM Analysis

Frequency

Intensities

Normal Impact Velocity

Sliding Distance

Stresses

Tangential Impact Velocity

After processing your simulation, specific Properties and Curves for the options you enabled will be available for the boundaries in your simulation.

What would you like to do next?

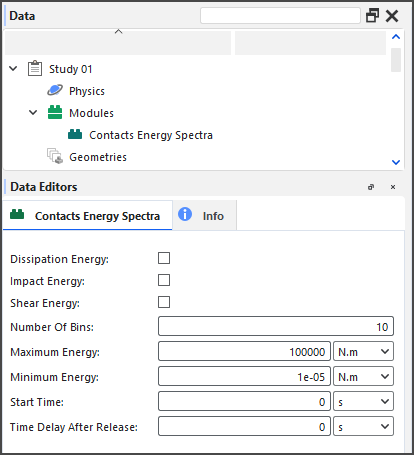

The Contacts Energy Spectra module enables the collection of different kinds of energy statistics per contact pair (particle group and/or geometry) and size, which can help you predict breakage and attrition rates for continuous processes such as grinding mills.

When the Contacts Energy Spectra Module is enabled (Figure 1), you can choose to collect one or more of three different types of collision energy-Dissipation Energy, Impact Energy, and/or Shear Energy-and define the limits for how the energy data is collected.

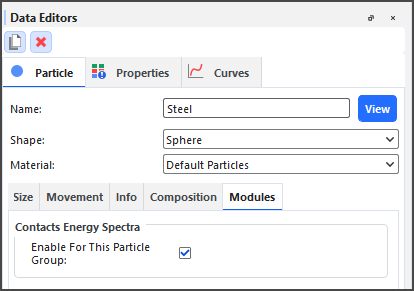

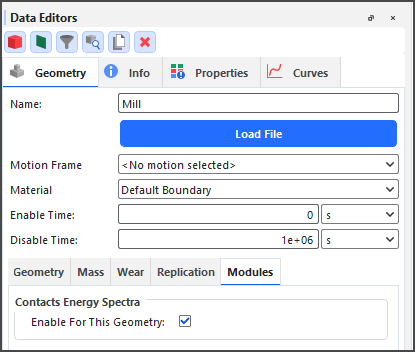

In this version of Rocky, you can also choose which particle group (Figure 2) and geometry component Figure 3.13: Additional module options for Particle groups when the Contacts Energy Spectra module is enabled you want to participate in energy spectra collection.

Figure 3.13: Additional module options for Particle groups when the Contacts Energy Spectra module is enabled

Figure 3.14: Additional module options for a geometry component when the Contacts Energy Spectra module is enabled

After processing your simulation, you can plot the resulting energy curves (Dissipation, Impact, and/or Shear) for each pair of particle-to-particle or particle-to-geometry contact types, each generated by the power, cumulative power, and collisions rate.

What would you like to do next?

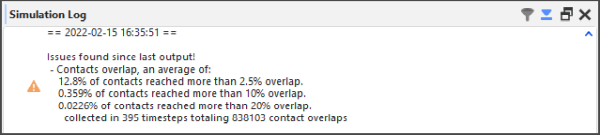

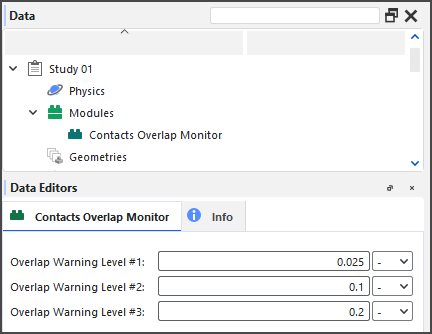

When enabled, the Contacts Overlap Monitor module checks each contact pair (particle-particle or particle-boundary) for the amount that they overlapped-the percentage of which is determined by the size of the smallest particle in the contact pair-and then raises a warning in the Simulation Log panel (Figure 1) if an overlap exceeds any of the three warning levels you define (Figure 2).

Monitoring your contacts for overlaps is important because Rocky uses the overlap value in order to compute collision forces. Therefore, large overlap values can lead to serious stability and accuracy issues in a simulation.

What would you like to do next?

Learn more About Monitoring Overlaps

Learn more About Collecting Data in Rocky

See Also:

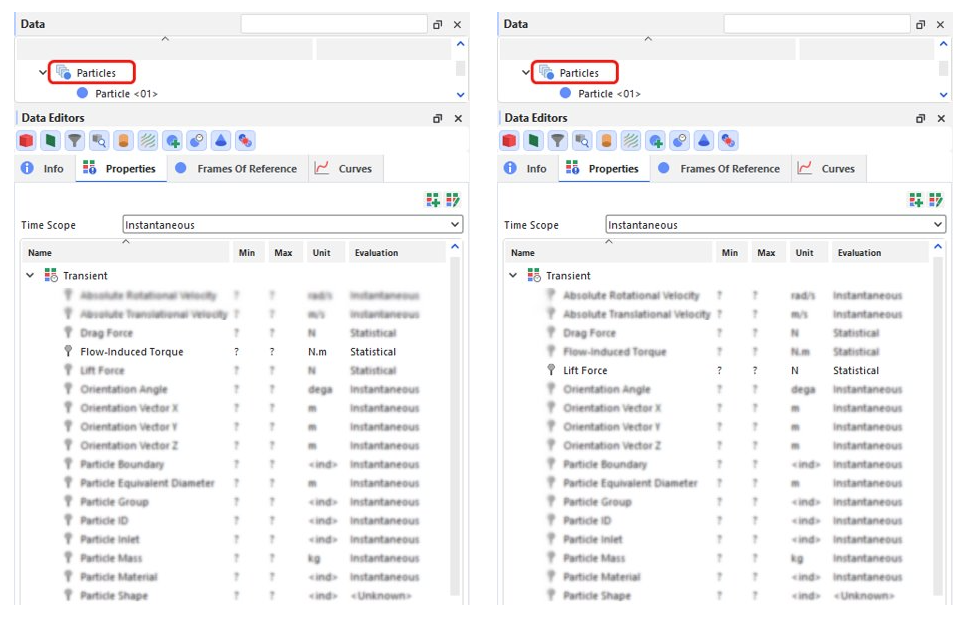

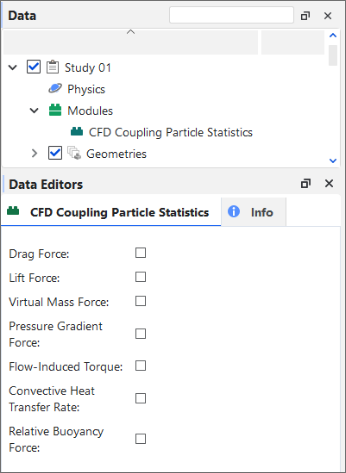

The CFD Coupling Particle Statistics Module enables the collection of particle-fluid interactions, such as drag, lift, and virtual mass forces.

Figure 3.17: Options in the Data Editors panel when the CFD Coupling Particle Statistics Module is enabled

When the CFD Coupling Particle Statistics Module is enabled (Figure 1), you are able to select any of the following Properties:

Convective Heat Transfer Rate

Drag Force

Flow-Induced Torque

Lift Force

Pressure Gradient Force

Virtual Mass Force

After processing your simulation, specific Properties for the options you enabled will be available for the particles in your CFD Coupling simulation.

What would you like to do next?

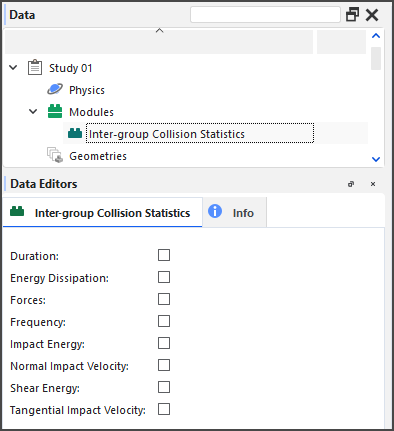

The Inter-group Collision Statistics module enables the collection of collisions data for each particle-particle and particle-boundary pair group.

Figure 3.18: Options in the Data Editors panel when the Inter-group Collision Statistics Module is enabled

When the Inter-group Collision Statistics Module is enabled, you are able to select the following Properties:

Duration

Energy Dissipation

Forces

Frequency

Impact Energy

Normal Impact Velocity

Shear Energy

Tangential Impact Velocity

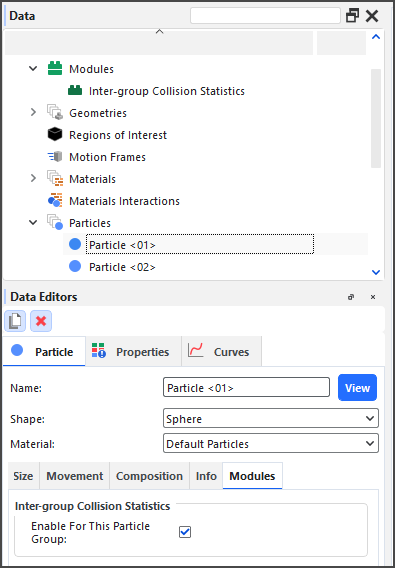

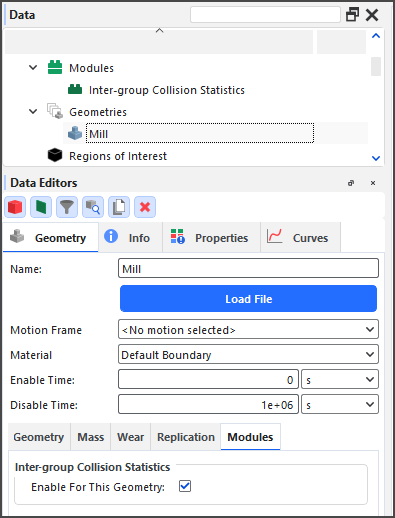

In this version of Rocky, you can also choose which particle group (Figure 2) and geometry component (Figure 3) you want to participate in these collections.

Figure 3.19: Additional module options for Particle groups when the Inter-group Collision Statistics module is enabled

Figure 3.20: Additional module options for a geometry component when the Inter-group Collision Statistics module is enabled

After processing your simulation, specific Curves for the options you enabled will be available for the main Particles entity.

What would you like to do next?

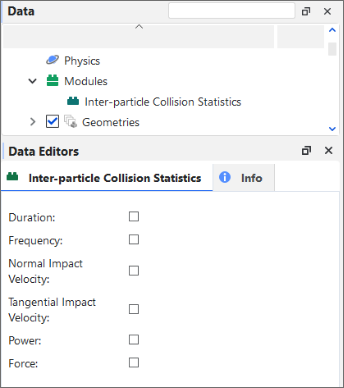

The Inter-particle Collision Statistics module enables the collection of collisions effects upon individual particles resulting from interactions with other particles and boundaries.

Figure 3.21: Options in the Data Editors panel when the Inter-particle Collision Statistics Module is enabled

When the Inter-particle Collision Statistics Module is enabled, you are able to select any of the following Properties:

Duration

Force

Frequency

Normal Impact Velocity

Power

Tangential Impact Velocity

After processing your simulation, specific Properties and Curves for the options you enabled will be available for the main Particles entity.

What would you like to do next?

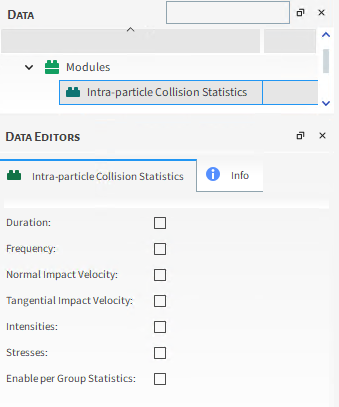

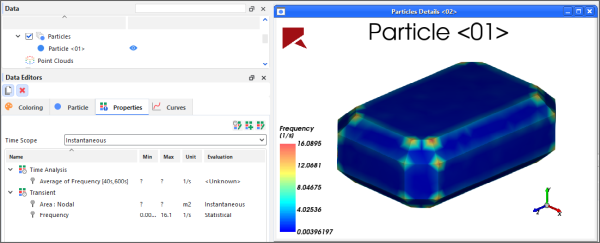

The Intra-particle Collision Statistics module enables the particle-related collision data affecting the surfaces of a Particle set.

Figure 3.22: Options in the Data Editors panel when the Intra-particle Collision Statistics Module is enabled

When the Intra-particle Collision Statistics Module is enabled, you are able to select any of the following Properties:

Duration

Frequency

Normal Impact Velocity

Tangential Impact Velocity

Intensities

Stresses

Enable per Group Statistics

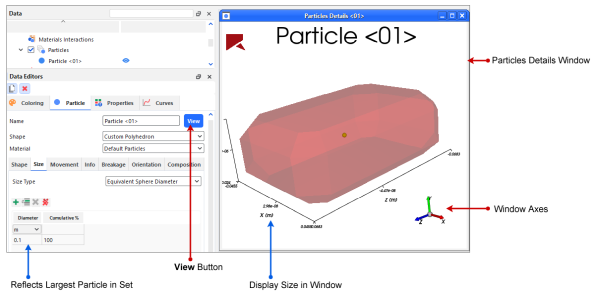

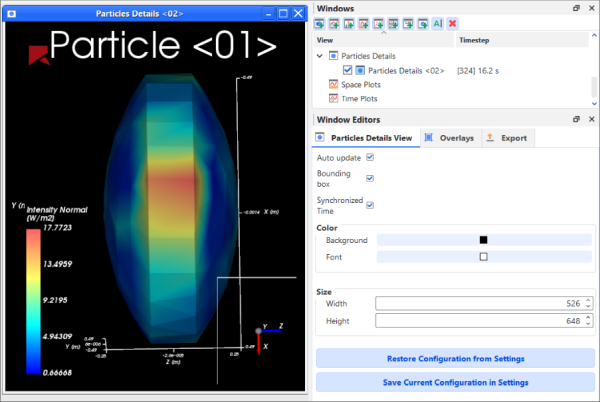

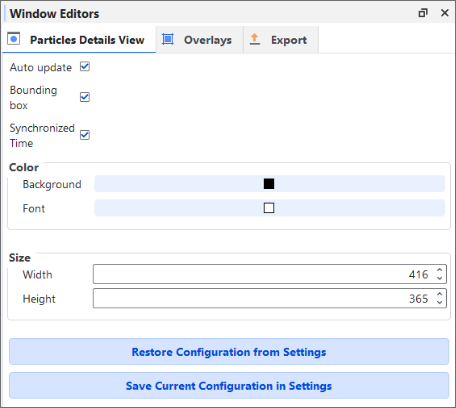

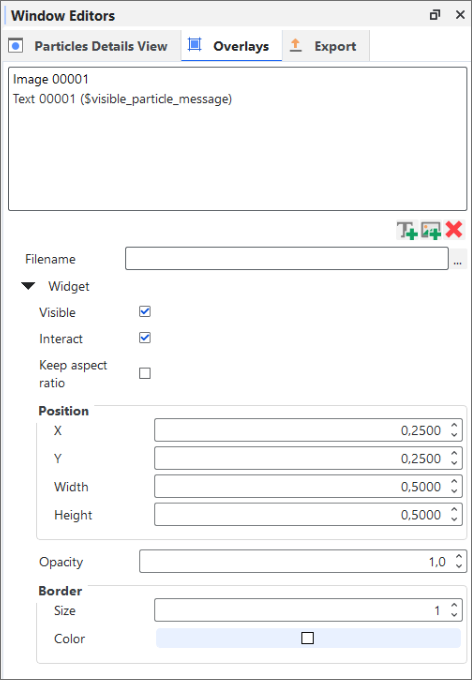

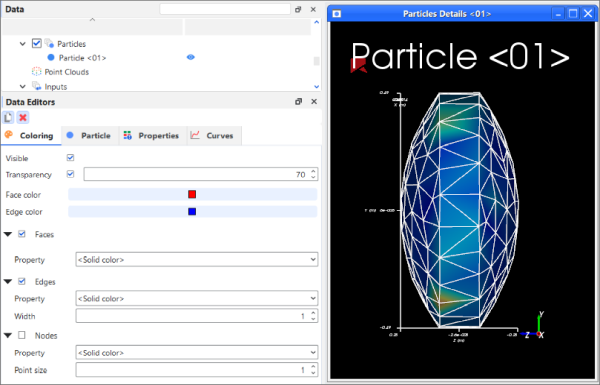

After processing your simulation, specific Properties for the options you enabled will be available for each individual Particle set. You can then choose to display this information graphically on the surface of a representative particle in the Particles Details window

What would you like to do next?

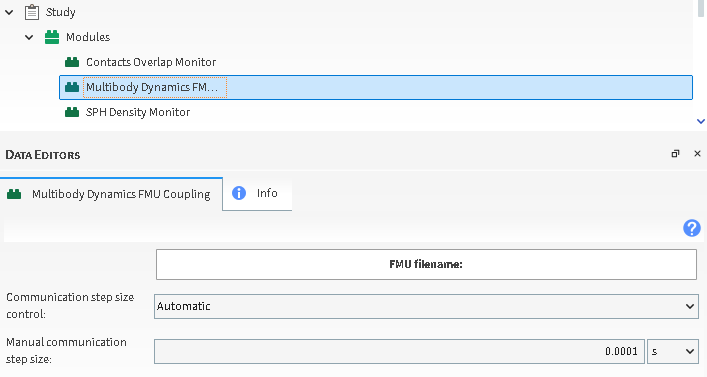

The Multibody Dynamics FMU Coupling Module enables you to import FMU files into Rocky without needing to install external Rocky modules into compatible softwares.

Note: For Ansys Motion software and Adams, modules for these software are still needed to export the FMU files.

When the Multibody Dynamics FMU Coupling Module is enabled, you are able to import a FMU file through the FMU filename: button, and select the following properties:

Communication step size control: configures the step size method for the communication between Rocky and the FMU file. Three different options can be selected:

Automatic: this method allows Rocky to automatically calculate a communication step size control.

Manual: this method requires a manual input from you. If the manual input value is smaller than Rocky's timestep, it will be overruled by the one calculated by Rocky.

Rocky timestep: this method considers the simulation timestep calculated by Rocky to be the communication step size control.

Manual communication step size: configures the step size of the manual communication method.

Rage: [Positive Values]

Note: This option is only used when the Manual communication step size control is selected.

See Also

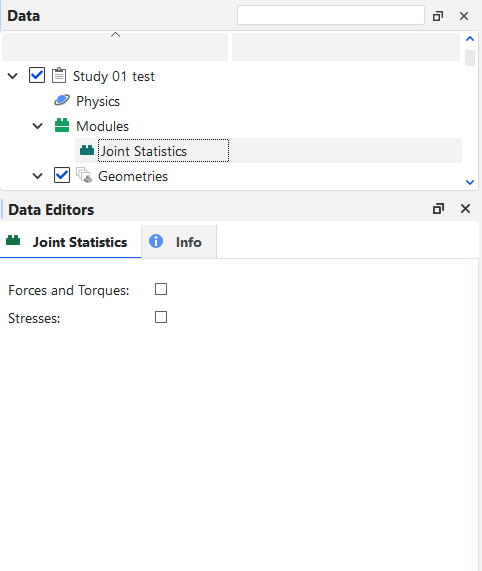

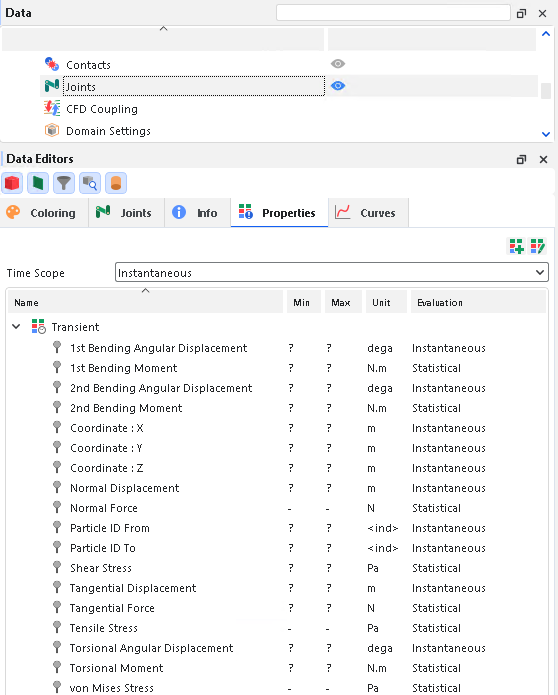

The Joint Statistics module enables new joint properties, with the purpose of generating new statistics data for analysis, such as Stresses and Forces and Torques calculations.

When the Joint Statistics Module is enabled (Figure 1), you are able to select any of the following Properties:

Forces and Torques

Stresses

This way, in the post-processing phase, it is possible to visualize the results of the parameters selected in Joints properties.

See Also

The Particle Instantaneous Energies module enables the collection of energies data related to the velocities and positions of each particle in the simulation. This data can then be used to calculate the kinetic and potential energies of each individual particle, which can be useful when performing global or partial energy balances in a simulation.

Figure 3.26: There are no options in the Data Editors panel when the Particle Instantaneous Energies Module is enabled

When the Particle Instantaneous Energies Module is enabled, there are no properties or settings to enable.

After processing your simulation, specific Properties for the options you enabled will be available for the main Particles entity.

What would you like to do next?

The Joint Statistics module enables new joint properties, with the purpose of generating new statistics data for analysis, such as Stresses and Forces and Torques calculations.

When the Joint Statistics Module is enabled (Figure 1), you are able to select any of the following Properties:

Forces and Torques

Stresses

This way, in the post-processing phase, it is possible to visualize the results of the parameters selected in Joints properties.

See Also

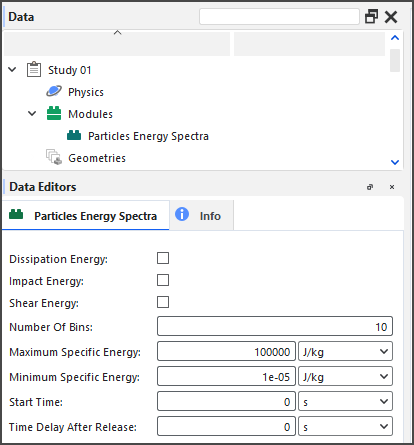

The Particles Energy Spectra module enables the collection of different kinds of energy statistics per particle type and size category, which can help predict breakage and attrition rates for continuous processes such as grinding mills.

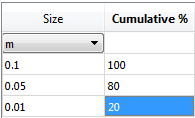

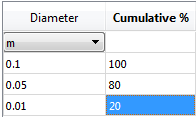

When the Particles Energy Spectra module is enabled (Figure 1), you can choose to collect one or more of three different types of collision energy-Dissipation Energy, Impact Energy, and/or Shear Energy-and define the limits for how the energy data is collected.

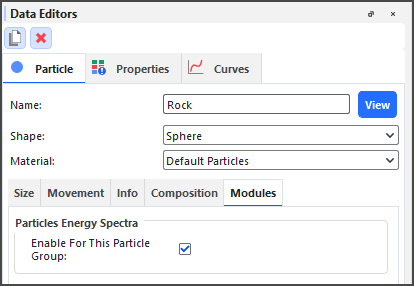

In this version of Rocky, you can also choose which particle group (Figure 2) you want to participate in energy spectra collection.

Figure 3.30: Additional module options for Particle groups when the Particles Energy Spectra module is enabled

After processing your simulation, you can plot the resulting Cumulative Specific Power curves for the type of energy you collected (Dissipation, Impact, and/or Shear) for each particle set, generated by each size of the particle size distribution, and separated by Specific Energy.

What would you like to do next?

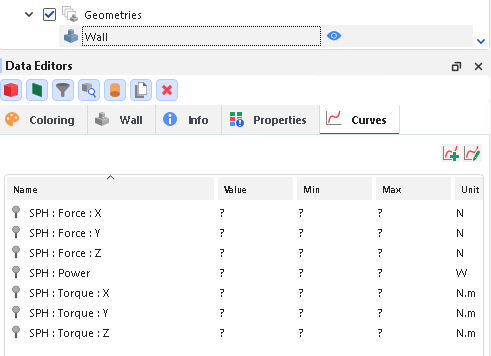

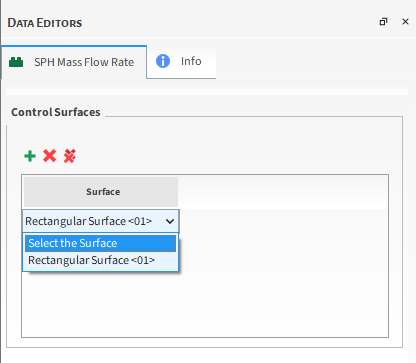

The SPH Mass Flow Rate module is a flow meter that acts by calculating the SPH mass flow rate through a surface, enabling you to choose where you want to measure the mass flow rate.

When the SPH Mass flow Rate Module is enabled (Figure 1), you are able to select one or more surfaces present in the simulation and measure the mass flow rate through them.

Figure 3.32: Geometries options in the Data Editors panel when the SPH Mass Flow Rate Module is enabled

After processing your simulation, specific mass flow rate curves will be available for the surfaces you selected through the module.

What would you like to do next?

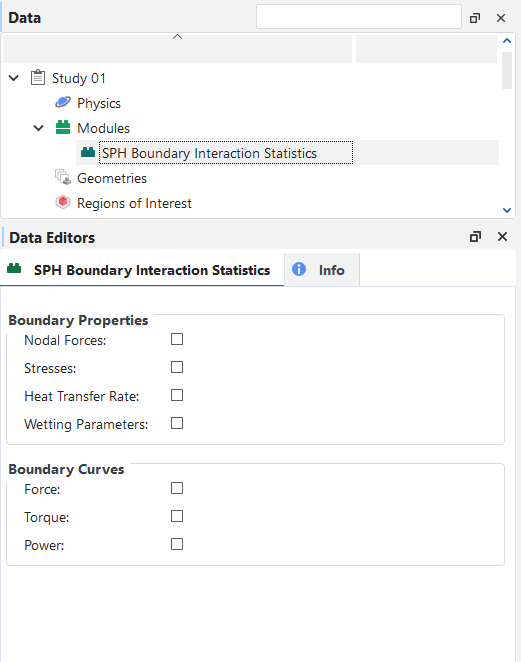

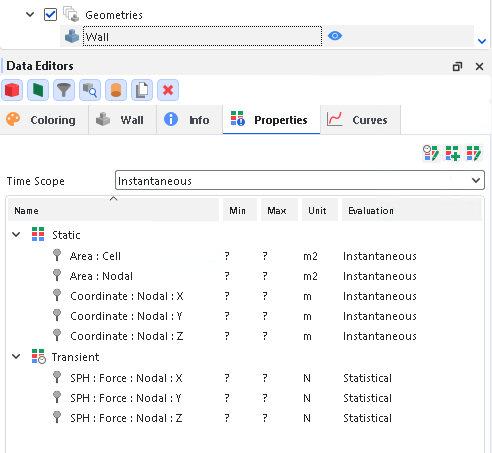

The SPH Boundary Interaction Statistics Module enables a collection of SPH boundary-related data, separated into Boundary Properties, where SPH forces are divided into triangles and the nodal force is collected, and Boundary Curves where the collected value refers to the entire geometry.

Figure 3.33: Options in the Data Editors panel when the SPH Boundary Interaction Statistics Module is enabled

When the SPH Boundary Interaction Statistics Module is enabled (Figure 1), you are able to select any of the following parameters:

Boundary Properties

Nodal Forces

Stresses;

Heat Transfer Rate;

Wetting Parameters.

The Stresses parameter calculates the time average of the stresses on the triangle. If there is no motion and the Cartesian forces are already stored, stresses are calculated with them, otherwise, normal and tangential components of the forces are stored.

The Heat transfer rate parameter calculates the time average of the heat transferred between the fluid and the triangle (positive if the transfer is triangle->fluid, negative otherwise). The Wetting parameters calculates the time average of the ratio between the wet area (approximate) and the triangle area.

Note: Due the use of a kernel function for approximating the wet area, SPH elements located within a distance equal to the kernel radius from a boundary triangle will contribute to that area. This means that if a moving wall approaches an SPH free surface, for instance, it may show wet fractions above zero before actually touching the SPH elements.

Boundary Curves

Force;

Torque;

Power.

After processing your simulation, specific data based on the options you enabled will be available in Walls Properties or Curves. As you can see in the figures below:

Walls-Properties

Figure 3.34: Results in Walls Properties when the SPH Boundary Interaction Statistics Module is enabled

Walls-Curves

What would you like to do next?

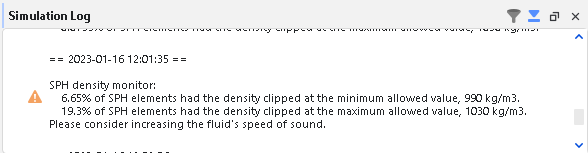

The SPH Density Monitor Module enables the monitoring of density values of the SPH elements during a simulation.

During the simulation, if the module detects that the density values were clipped due the existence of positive or negative deviations that exceeded the maximum allowed values, it will issue a warning, indicating the percentage of SPH elements that had density values clipped. These Warnings are registered in the log file and can be consulted later.

See the example in the figure below:

What would you like to do next?

Learn more Understand Rocky Modules

Learn more About Modules Parameters

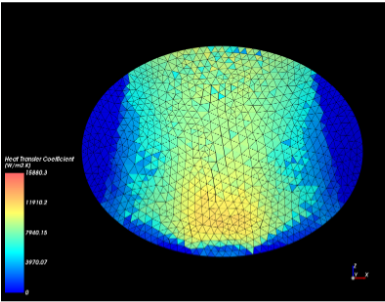

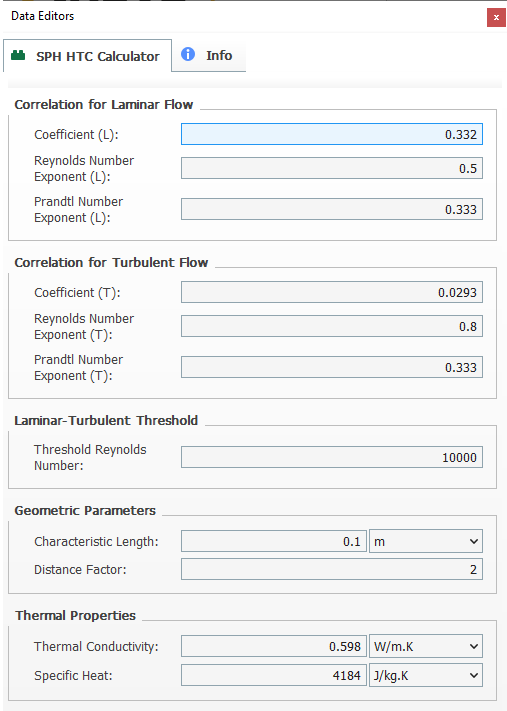

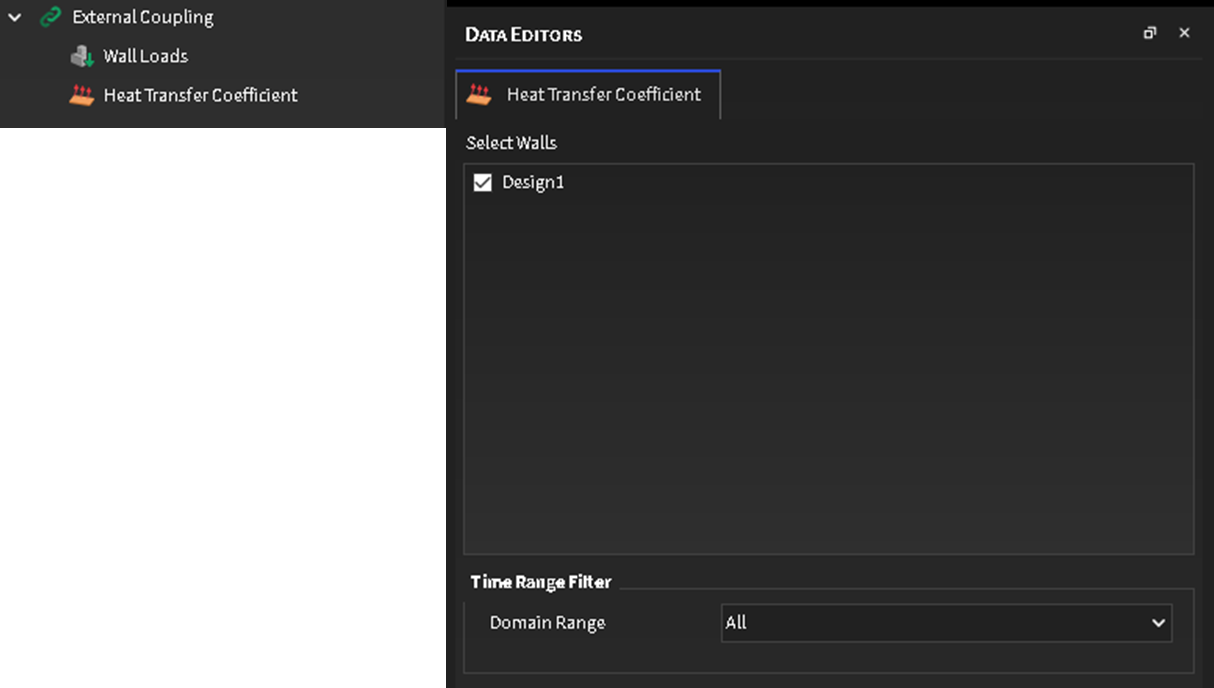

The SPH HTC Calculator module calculates the heat transfer coefficient (HTC) through forced convection for each wall triangle. It provides an estimation of heat exchange without requiring a thermal solution.

The heat transfer coefficient is calculated using simple correlations based on local Reynolds and Prandtl numbers. The correlations used for computing the Nusselt number depend on whether the flow is laminar or turbulent, as determined by the user-defined threshold.

Limitations

Listed below are known limitations of the SPH HTC Calculator module:

User input is required for fluid thermal conductivity and specific heat.

The module ignores the internal values of these properties in the fluid material; however, fluid viscosity is still extracted from the fluid material data.

The heat transfer coefficient is computed based on the local Nusselt number, which utilizes the fluid velocity at a specific distance from the wall, as determined by the Distance Factor.

The user has the ability to modify the parameters utilized for calculating the Nusselt number in accordance with the flow characteristics.

Module Options

Refer to Figure 3.39: SPH HTC Calculator module options. and the parameter definitions below to understand how to enable and configure the SPH HTC Calculator module. These parameters are explained below:

Coefficient (L): Coefficient used to compute the Nusselt number for a laminar flow. Range: [Positive values]

Reynolds Number Exponent (L): Exponent that raises the Reynolds number to compute the Nusselt number for a laminar flow. Range: [Positive values]

Prandtl Number Exponent (L): Exponent that raises the Prandtl number to compute the Nusselt number for a laminar flow. Range: [Positive values]

Coefficient (T): Coefficient used to compute the Nusselt number for a turbulent flow. Range: [Positive values]

Reynolds Number Exponent (T): Exponent that raises the Reynolds number to compute the Nusselt number for a turbulent flow. Range: [Positive values]

Prandtl Number Exponent (T): Exponent that raises the Prandtl number to compute the Nusselt number for a turbulent flow. Range: [Positive values]

Threshold Reynolds Number: This defines the laminar-turbulent transition. Above this Reynolds number, the flow is considered turbulent. Range: [Positive values]

Characteristic Length: Length used to compute the Reynolds number and the heat transfer coefficient. Range: [Positive values]

Distance Factor: Factor that multiplies the SPH element spacing for computing the distance from the wall at which the velocity is obtained. Range: [Positive values]

Thermal Conductivity: This defines the fluid thermal conductivity, which is used to compute the Prandtl number and the heat transfer coefficient. Range: [Positive values]

Specific Heat: This defines the specific heat used to compute the Prandtl number. Range: [Positive values]

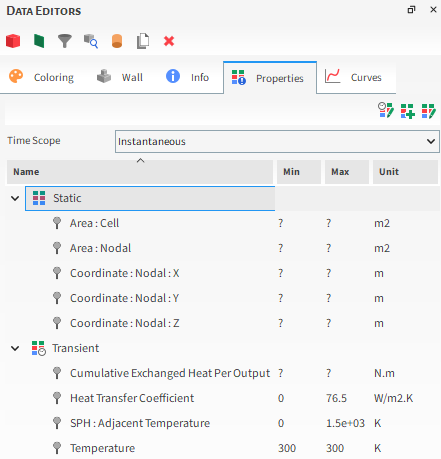

Post-processing abilities

After simulating, a new Heat Transfer Coefficient property becomes available for wall entities. This property aids in visualizing heat exchange between the SPH fluid and each wall.

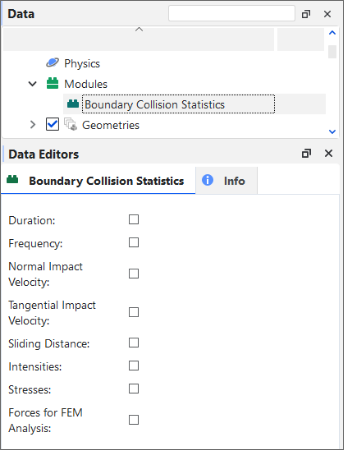

Figure 3.40: New wall properties are shown in the Data Editors panel when the SPH HTC Calculator module is enabled.

These new properties are explained below:

Heat Transfer Coefficient: This provides the heat transfer coefficient for each wall triangle.

SPH: Adjacent Temperature This provides the SPH adjacent temperature for each wall triangle. When coupling with mechanical this average adjacent temperature is sent to mechanical.

You can analyze these properties in a plot or histogram window. Alternatively, you can graphically display these properties in a 3D View window.

Setting up and using the module

Ensure that the module is enabled. (From the Data panel, select Modules and then from the Data Editors panel, ensure the SPH HTC Calculator checkbox is enabled.)

From the Data panel, under Modules , select the new SPH HTC Calculator entry.

From the Data Editors panel, on the SPH HTC Calculator tab, enter the values you want.

Continue setting up the simulation as you normally would.

Process the simulation as you normally would.

When you are ready to post-process your simulation results, you can make use of the new parameter on the Properties tab for the main Particles entity.

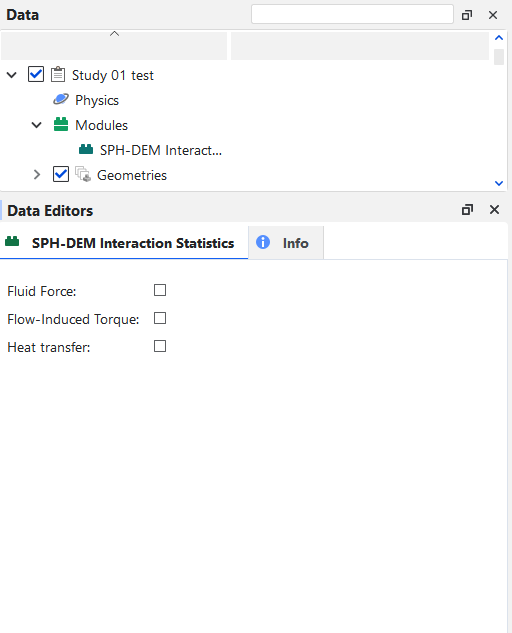

The SPH-DEM Interaction Statistics Module enables the calculation of interaction between particles and fluids within the simulation.

Figure 3.41: Options in the Data Editors panel when the SPH DEM Interaction Statistics Module is enabled

When the SPH-DEM Interaction Statistics Module is enabled (Figure 1), you are able to select any of the following Properties:

Fluid Force

Flow-Induced torque

Heat Transfers

Important: To Heat Transfers option works, it's necessary that the Enable Thermal checkbox in Physics is selected. Otherwise, an error message will appear.

After processing your simulation, specific SPH Properties will appear along with the Particle parameters for the options you enabled before starting your simulation. You can see some of this properties below:

SPH:Flow-Induced Torque

SPH:Flow-Induced Torque: X

SPH:Flow-Induced Torque: Y

SPH:Flow-Induced Torque: Z

SPH:Fluid Force

SPH:Fluid Force: X

SPH:Fluid Force: Y

SPH:Fluid Force: Z

SPH:Heat Transfer Rate

What would you like to do next?

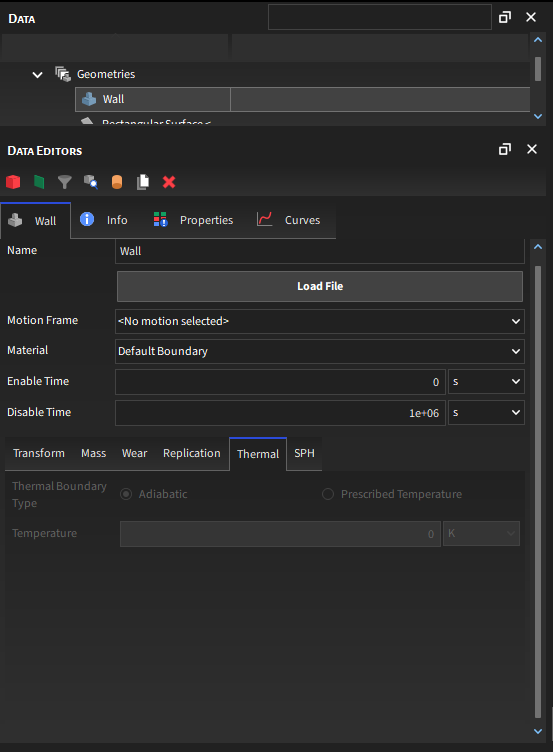

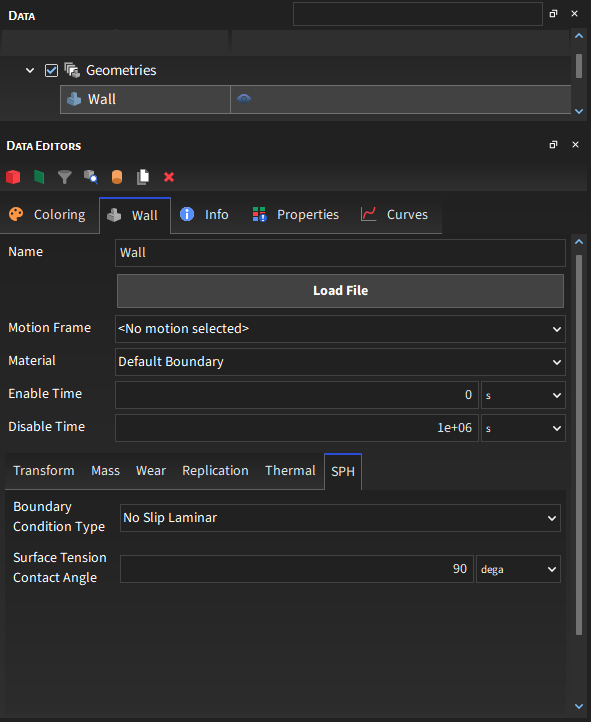

The SPH parameters available define how the simulation of fluid flow is going to be calculated inside Rocky.

Rocky uses an SPH (Smoothed-Particle Hydrodynamics) technique to perform fluid flow simulations. To ensure that the simulation is a good representation of the physics involved, you have control of several parameters that set how the SPH method is going to work in a Rocky simulation. Below you can learn more about these parameters.

Note: Simulation files from previous versions of Rocky that included SPH as a module are not compatible with new versions from 23R1 onwards.

To learn more about how this model is calculated, refer to the SPH Technical Manual. (From the Rocky Help menu, point to Manuals and then click SPH Technical Manual).

Rocky includes an option for thermal modeling in an SPH simulation. To learn more about setting up and using SPH Thermal model in Rocky, refer to the Enable Thermal Modeling Calculations topic.

When setting up an SPH simulation, you have the option of using the Eulerian Solution feature. By default it is enabled. This option allows you to obtain interpolated results for SPH properties (see more About Properties ). This option may result in more use of computational resources. If you want to disable it, you can do so by unchecking the checkbox Eulerian Solution under the SPH item on the data panel). To learn more about setting up and using Eulerian Solution in Rocky, refer to the About SPH Eulerian Solution topic.

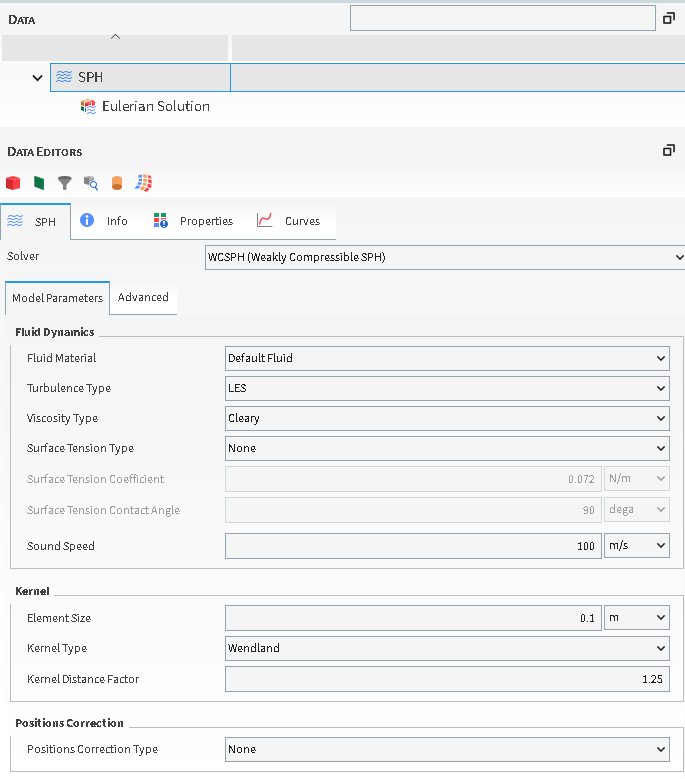

The SPH parameters in Rocky can be edited from the SPH entity on the data panel. They are divided into two categories: the SPH Model Parameters with the basic setup needed to perform an SPH simulation, and an Advanced tab, with parameters that allow a fine-tuning of the simulation.

Use the figure and table below to help you understand the various SPH parameters you can set for a simulation project in the SPH Model Parameters tab.

Table 1: SPH Solver Settings

|

Setting |

Description |

|---|---|

|

WCSPH (Weakly Compresible SPH) |

The Weakly Compressible SPH solver is suitable for simulating incompressible fluids, by using an artificial equation of state to compute the relation between pressure and density. |

|

ISPH (Implicit Incompressible SPH) BETA |

The Implicit Incompressible SPH solver is also suitable for simulating incompressible fluids. In this formulation, the fluid incompressibility constraint is enforced by solving a system of linear equations at each simulation time, to compute pressure values that lead to element velocities and displacements that satisfy the constraint. This treatment allows to solve the flow equations with larger timesteps than the ones needed for the Weakly Compressible SPH (WCSPH) formulation. Note: The ISPH can only be used if the Experimental (Beta) Features checkbox is enabled on the Options | Preferences | Additional Features dialog. Important: Note that beta features have not been fully tested and validated. Ansys, Inc. makes no commitment to resolve defects reported against these prototype features. However, your feedback will help us improve the overall quality of the product. We will not guarantee that the projects using this beta feature will run successfully when the feature is finally released so you may, therefore, need to modify the projects. |

|

DFSPH (Divergence-Free SPH) BETA |

The Divergence Free SPH solver is also suitable for simulating incompressible fluids. This solver can be considered an extension of the IISPH formulation, because both enforce a constant density value through the solution of a Poisson pressure equation. However, DFSPH introduces an additional step in which the divergence-free condition is enforced on the velocity field. Note: The DFSPH can only be used if the Experimental (Beta) Features checkbox is enabled on the Options | Preferences | Additional Features dialog. Important: Note that beta features have not been fully tested and validated. Ansys, Inc. makes no commitment to resolve defects reported against these prototype features. However, your feedback will help us improve the overall quality of the product. We will not guarantee that the projects using this beta feature will run successfully when the feature is finally released so you may, therefore, need to modify the projects. |

Note: Simulations with parameters defined in ISPH as a module must be set again, as they will not be compatible with ISPH integrated in the Rocky UI from release 2024 R2 onwards.

Table 2: SPH Model Parameters Tab

Setting | Description | Range |

|---|---|---|

Fluid Dynamics | ||

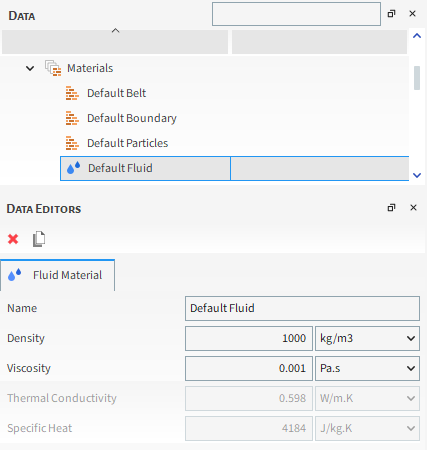

Fluid Material | Allows you to choose the fluid material that will be used in the simulation. (see also About Modifying Fluid Material Compositions). | Automatically Determined |

Turbulence Type | Defines the turbulence modeling approach.

For additional details about these models, see the SPH Technical Manual. (From the Rocky program Help menu, point to Manuals, and then click SPH Technical Manual.) | Laminar; LES |

Viscosity Type | Defines the viscosity model used in the calculation of SPH element acceleration due viscous forces flow.

For additional details about these models, see the SPH Technical Manual. (From the Rocky program Help menu, point to Manuals, and then click SPH Technical Manual.) Important: It is also important to mention that the Viscosity Type can be overruled by the SPH Turbulent Viscosity Limiter module, which defines a ratio between the set viscosity from the UI and the maximum viscosity that can be achieved. More information about how modules affect simulations can be found at Rocky Simulation Entities that can be Affected by Modules. Also, information about this module can be found in its respective manual. | Cleary; Morris |

Surface Tension Type | Defines the surface tension model used to model free surfaces.

Note: The Pairwise Potential can only be used if the Experimental (Beta) Features checkbox is enabled on the Options | Preferences | Additional Features dialog.

If CSF or Pairwise Potential model are enabled, a new parameter will be required:

Important: When the Pairwise Surface Tension type is selected, the Surface Tension Boundary Angle will be available for the specified geometry, located in the geometry tab (See Imported wall, SPH parameters in the Data Editors panel). | None; CSF; CSS; Pairwise Potential |

Sound Speed / Maximum Expected Velocity | For WCSPH, the Sound Speed, which is about 10x the maximum expected velocity for the simulation must be set here. For IISPH and DFSPH, the value is the Maximum Expected Velocity for the simulation. | Positive Numbers [m/s] |

Kernel | ||

Element Size | Defines the size of an SPH element. For coupled DEM-SPH simulations, an element size at least 3 times smaller than the smallest particle size in the simulation is necessary. | Positive Values |

Kernel Type | Defines the type of kernel function used for SPH calculations

For additional details about these models, see the SPH Technical Manual. (From the Rocky program Help menu, point to Manuals, and then click SPH Technical Manual.) | Cubic; Quintic; Wendland |

Kernel Distance Factor | Defines the kernel distance factor, which affects the size of the kernel support. | Positive Values |

Positions Correction | ||

Positions Correction Type | Defines the formulation applied to prevent SPH elements from clumping together and distribute them more evenly in space.

For additional details about these models, see the SPH Technical Manual. (From the Rocky program Help menu, point to Manuals, and then click SPH Technical Manual.) | None; XSPH; Shift |

Use the figure and table below to help you understand the various SPH parameters you can set for a simulation project in the Advanced tab.

Table 3: SPH Advanced Parameters Tab

Setting | Description | Range |

|---|---|---|

Kernel | ||

Minimum Distance Factor | Defines the factor used to calculate the minimum distance between SPH elements in order to avoid singularities. | Positive Values |

Numerics | ||

User Neighbors List | Allows Rocky to use a neighbors list which is stored in memory. This will speed up the simulation, but if the number of elements in the list exceeds the system memory available, an allocation error may occur. | On or Off |

Timestep Factor | Defines the coefficient used to compute the SPH solver time step. | Positive Values |

Number of Search Cell Sub-Steps | Defines the coefficient that is used to define the search cell size. | Positive Values |

Turbulence Modelling | ||

Cleary Viscosity Factor | Defines the coefficient used in the Cleary formulation of the acceleration due to viscous forces. | Positive Values |

LES Distance Factor | Defines the characteristic length used to compute the turbulent viscosity term. | Positive Values |

LES Smagorinsky Constant | Defines the Smagorinsky constant used to compute the turbulent viscosity term. | Positive Values |

|

Limit Turbulent Viscosity |

The Limit Turbulent Viscosity is used for clipping the viscosity at SPH simulations for turbulent flows. This features aims at preventing the SPH turbulent viscosity from becoming too large and,therefore, possibly destabilizing the simulation. |

On or Off |

|

Maximum Turbulent/Molecular Viscosity Ratio |

This parameter is used for the viscosity clipping, being the maximum viscosity ratio allowed for the current simulation. |

Positive Values |

Positions Correction | ||

Shifting Factor | Defines the shifting factor for the Shift approach. | Positive Values |

XSPH Factor | Defines the XSPH factor used for the XSPH position correction model. | Positive Values |

Free Surface Divergence Limit | Defines the concentration gradient reference used to avoid SPH elements placed near the free surface to be shifted in the normal direction for the Shifting particle correction algorithm. | Positive Values |

Density Correction | Only for WCSPH | |

Update Coupled Density | Defines if the density of the fluid will be updated with the calculations. | On or Off |

Number of Density Correction Steps | Defines the frequency for the density correction calculation. Note: To turn off SPH Density Correction for SPH-only simulations, change the Number of Density Correction Steps to 0. | Positive Values |

Negative Density Deviation | Defines the maximum negative pressure deviation allowed from the initial density value for an SPH element. Note: Another way to turn off SPH Density Correction for SPH-only simulations is to set Negative an Positive Density Deviation to 0. | Positive Values |

Positive Density Deviation | Defines the maximum positive pressure deviation allowed from the initial density value for an SPH element. Note: Another way to turn off SPH Density Correction for SPH-only simulations is to set Negative and Positive Density Deviation to 0. | Positive Values |

Tensile Instability Correction | Only for WCSPH | |

Stability Degree | Defines the degree of the tensile instability correction. | Positive Values |

Stability Negative Factor | Defines the coefficient that multiplies the pressure, if negative, for computing the tensile instability correction term. Default value is zero as the tensile instability correction was found unnecessary for most simulations with the current formulation. | Positive Values |

Stability Positive Factor | Defines the coefficient that multiplies the pressure, if positive, for computing the tensile instability correction term. Default value is zero as the tensile instability correction was found unnecessary for most simulations with the current formulation. | Positive Values |

Wall Boundary Conditions | ||

Boundary Damping Factor | Defines the viscous damping coefficient used in the calculation of the normal force acting on the SPH element due to the wall interaction. | Positive Values |

Boundary Stiffness Factor | Defines the elastic coefficient used in the calculation of the normal force acting on the SPH element due to the wall interaction. | Positive Values |

Boundary Distance Normal Factor | Defines a multiplier used to evaluate the interaction distance between SPH elements and boundaries for the normal force. | Positive Values |

Boundary Distance Tangential Factor | Defines a multiplier used to evaluate the interaction distance between SPH elements and boundaries for the tangential force. | Positive Values |

Surface Tension | ||

Surface Tension Boundary Fraction | Defines a factor used to calculate the surface tension. | Positive Values |

Pressure Calculation | Only for WCSPH | |

Pressure Degree | Coefficient of the equation of state used to compute the relation between pressure and density | Positive Values |

|

Pressure Solution | Only for IISPH and DFSPH | |

| Density Relative Error Tolerance | Defines the tolerance for the relative error in the density calculation. | Positive Values |

| Maximum Number of Iterations | The maximum number of iterations for convergence of the pressure. | Positive Values |

| Pressure Under-Relaxation Factor | Defines a factor introduced to ensure stability of the process, by reducing the amount of changes between iterations. | Positive Values |

| Negative Pressure Factor | Defines the factor that multiplies negative pressures during the iterative solution process. | Positive Values |

What would you like to do?

See Also:

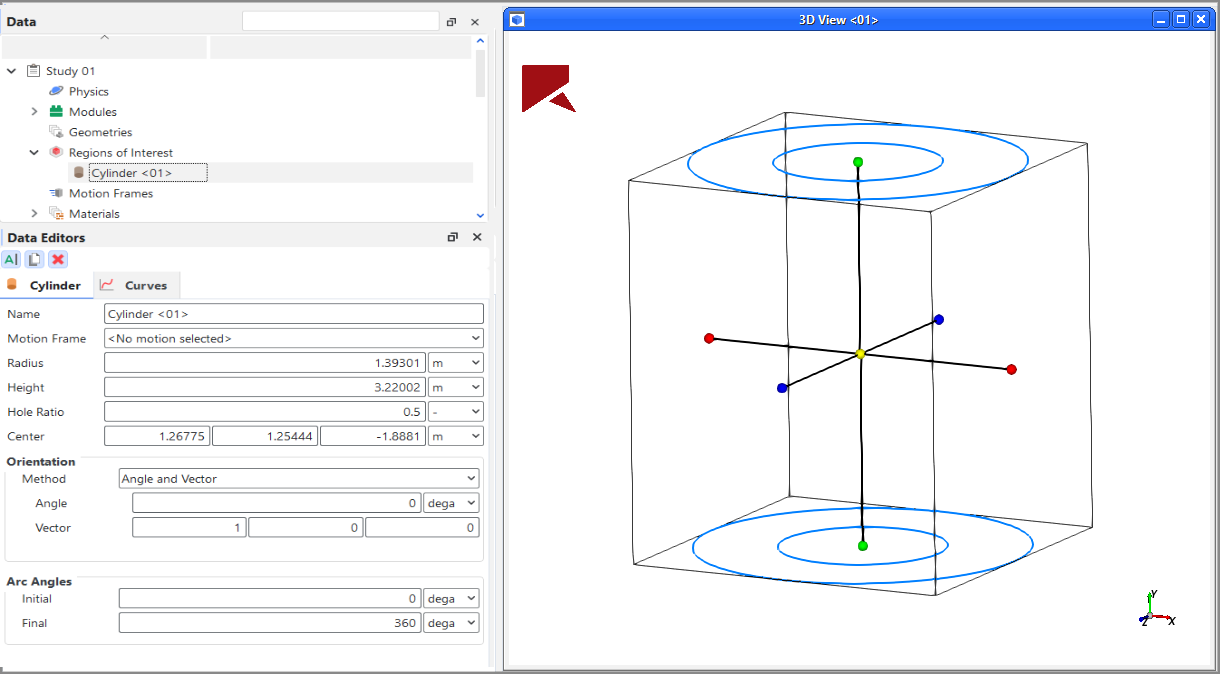

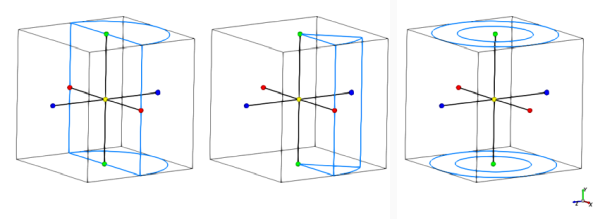

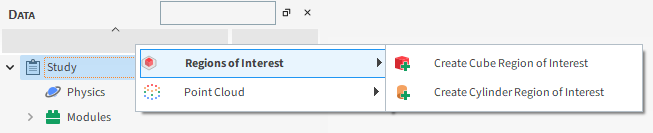

The current SPH feature also has a support for Region of Interest (ROI). This means that it is capable of freezing and disabling SPH-SPH interactions outside a given region. With this feature, there can be a simulation speed increase.

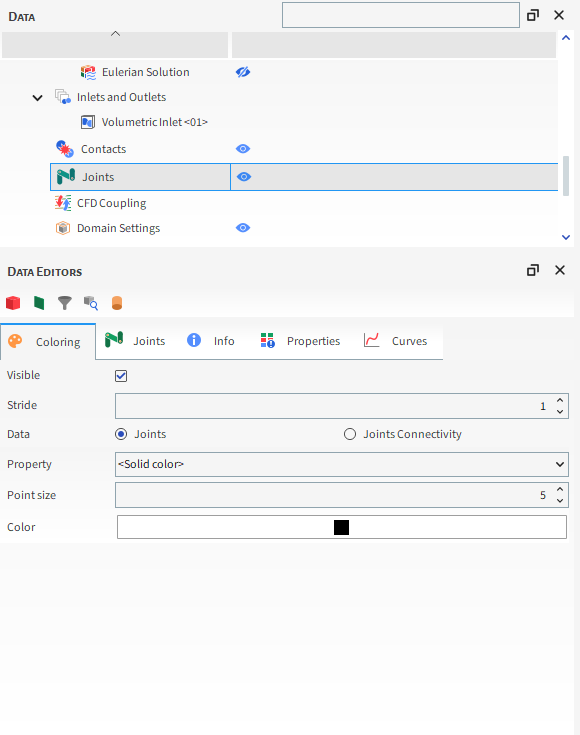

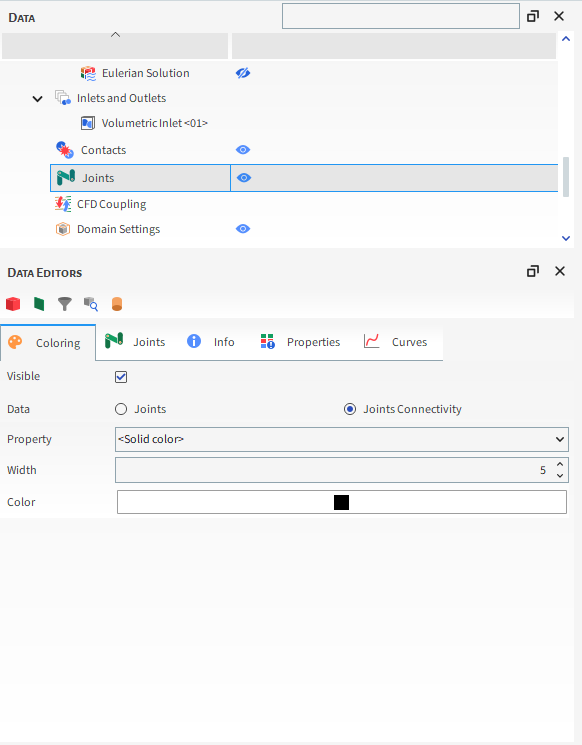

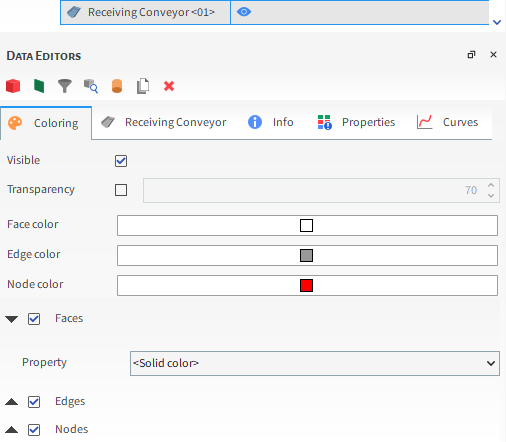

Use the figure below to help you understand the Joints parameters you can set for a simulation project.

Table 3.1: Joints Parameters - Coloring

|

Setting |

Description |

Range |

|---|---|---|

|

Visible |

When enabled, shows the selected entity in the active view window. |

Turns on or off. |

|

Stride |

One out of this number of data points will be shown when displaying Joints. The lower the number, the more data points will be displayed. |

Whole numbers 1 or greater. |

|

Data |

Joints: Enables the selected joints to be colored in the 3D View. Joints Connectivity:Enables the selected joint connectors to be colored in the 3D View. |

Options limited by the selected Data. |

|

Property |

Provide properties and other color options that apply to the display Data type within which the list is contained.

|

<Solid color>; List of properties automatically generated from the Properties tab. |

|

Point size |

When Joints is selected, this changes the size of the dots used to draw the Joints. |

Positive Values. |

|

Width |

When Joints Connectivity is selected, this changes the thickness of Positive values the lines used to draw the borders. |

Positive Values. |

|

Color |

When Joints or Joints Connectivity are selected and the Property is <Solid Color>, this enables the selected display Data type to be colored in the one solid color chosen. |

Options limited by the selected Color. |

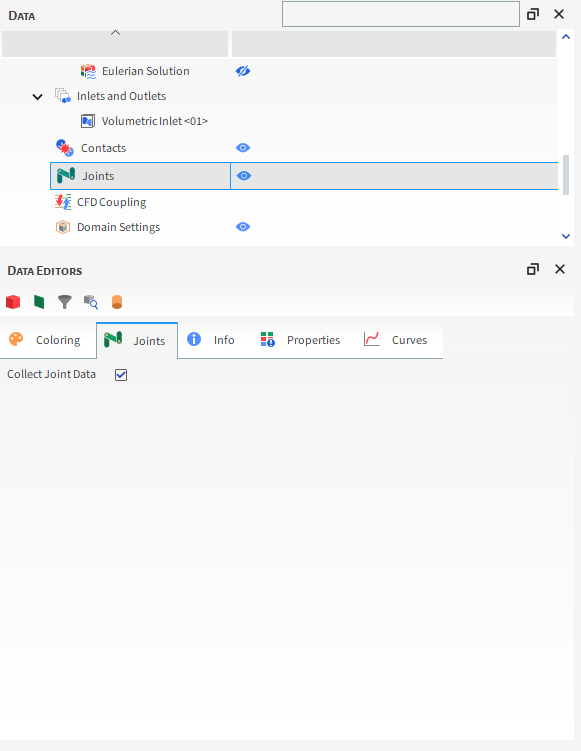

Select Collect Joint Data checkbox for joint data to be collected. This way, after simulation, it's possible to analyze joints positions and displacements in properties tab.

Important: To visualize Joints parameters, it's necessary to clear the Meshed Particles Upscaling checkbox.

What would you like to do?

See Also:

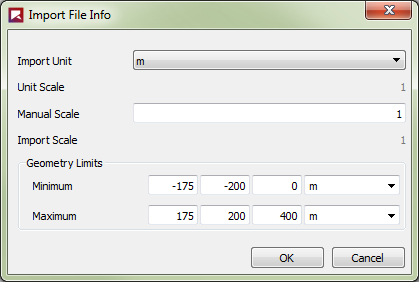

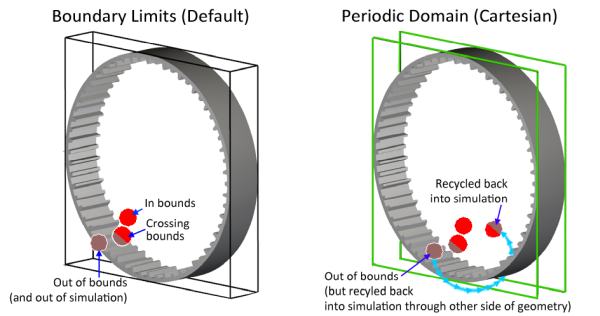

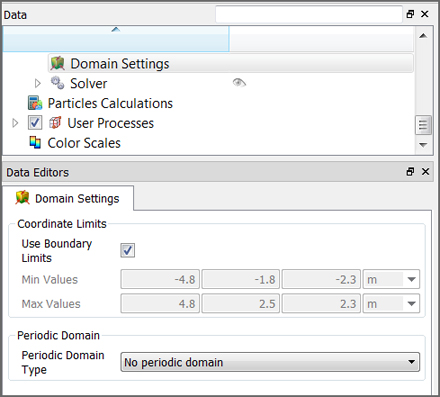

Domain settings enable you to define Coordinate Limits and, if desired, an additional Periodic Domain for your simulation project.

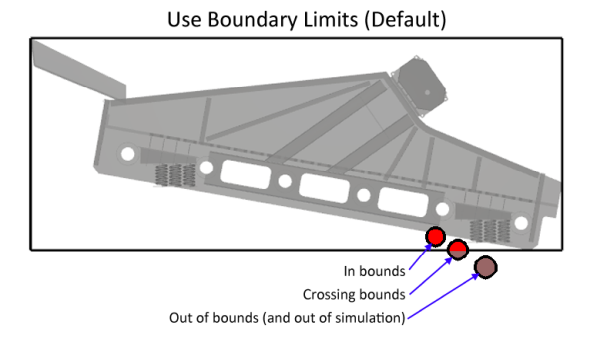

Coordinate Limits determine where in the simulation calculations may occur. This means that any items that fall outside the limits you have defined-including particles and geometries-will not be included in the simulation calculations.

For particles, falling outside the coordinate limits also means they will not be visualized. For particles that are set to be released outside the coordinate limits, this means they will not appear in the simulation at all. For particles that were within the limits but then exited out of them, this means those particles will disappear immediately upon leaving the limits (Figure 1).

Note: Rocky uses a particle's center point to determine whether it is inside or outside the domain.

For geometries, falling outside the coordinate limits means only that they are not included in calculations. Geometries will still be visualized regardless of whether or not they are within the coordinate limits.

Because of these reasons, it is important that you set your coordinate limits appropriately for the type of simulation you are setting up. For closed systems, such as mixers and mills, where particles are not expected to fall outside of the geometry limits, choosing to use the Use Boundary Limits checkbox might be the best option.

For open systems, such as crushers or vibrating screens, where particles are expected to reach beyond the limits of the geometries, setting your own custom coordinate limits might be a better option.

Tip: To see a walk-through example of setting custom coordinate limits, refer to Tutorial - Vibrating Screen in the Rocky Tutorial Guide.

Periodic Domains enable you to include an additional domain within your simulation Coordinate Limits within which particles that are exiting out one side of the periodic domain area are recycled back into the domain from the opposite side.

In this version of Rocky, periodic domains can either be Cartesian, which are based upon two parallel planes (box-shaped domain), or Cylindrical, which are based upon two intersecting planes rotated by an angle to create a cylindrical sector (wedge-shaped domain).

Both types of periodic domains do not allow the injection of particles outside the bounds of the periodic domain. This means that when setting up your Particle Inputs, ensure that your Continuous Injection Inlet, Volume Fill box bounds, or Custom Input definitions are located well within your periodic domain. (See also About Adding and Editing Particle Inputs.)

Cartesian Periodic Domains are the original type of what used to be known as "periodic boundaries" and whose functionality has been included with Rocky since its earliest releases. When choosing to use Cartesian Periodic Domains, two parallel planes are created along the axis (or combination of axes) you specify. Particles that exit the simulation through one plane will reappear in the simulation through the opposite plane (Figure 2).

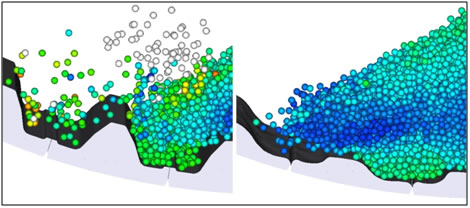

Figure 3.49: Particle behavior when exiting only the coordinate limits (left) and then with a periodic cartesian domain set (right)

This is especially useful for simulating cross sections or slices of mills; particles flung out of one side of the mill cross section can be recycled back into the simulation from the other side.

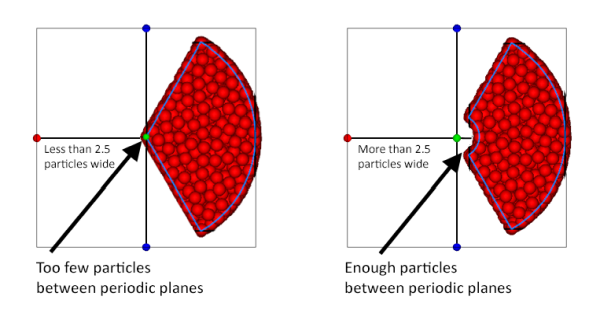

Tip: If you choose to set Cartesian periodic domains, ensure that your periodic domain width (the distance between the Min Coordinate and Max Coordinate values) is at least 2.5 times wider than your largest particle size. Or, alternatively, ensure that your largest particle size is less than 0.4 times the width of your periodic domain.

For example, a 0.1 m particle can work in a 0.25 m or wider periodic domain. Alternatively, a 1 m periodic domain can support a 0.4 m or smaller particle size. (See also My particle size is too large for my periodic domain.)

Note: Rocky's Cartesian Periodic Domain functionality was originally designed to be located at the extreme ends of the geometry in question; for example, at the limits of a Mill slice. Sometimes, however, it is desirable to make your periodic domain smaller than the geometry and/or coordinate limits of the domain. Rocky will support you doing this, but be aware that depending on the configuration of the geometries and the periodic limits, it is possible that during the simulation, some particles might go through the walls of your geometries in an unexpected manner. (See also Particles are going through the walls of my geometry.)

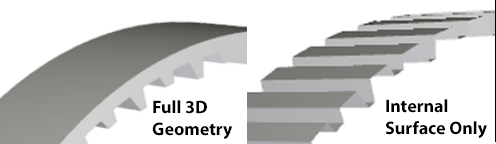

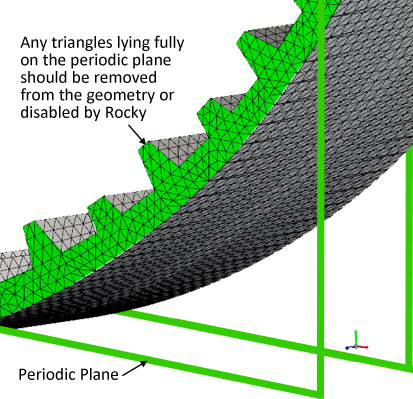

Important: As shown in Figure 3 below, for simulations where the geometry motion is in the periodic plane (i.e., if the periodic direction is Z then the periodic plane is X-Y; if the periodic direction is Y then the periodic plane is X-Z; and if the periodic direction is X then the periodic plane is Y-Z), any triangles whose all 3 vertices exactly lie on the periodic plane should either be removed from the geometry design in a CAD tool prior to being imported into Rocky, or be disabled by Rocky to ensure proper simulation results. In this version of Rocky, these triangles are disabled for you by default. (See also About Solver Parameters.)

Figure 3.50: Geometry triangles lying fully on the periodic plane (in green) should be removed or disabled

It is recommended that you import only the geometry's internal surface (Figure 4) instead of using the automatic triangle disabling from Rocky. When disabled only, the triangles can be deformed due to wear, and it can cause instabilities in the process — particles could enter into the geometry, for example.

Tip: To see a walk-through example using Cartesian Periodic Domains, refer to the following Workshop:

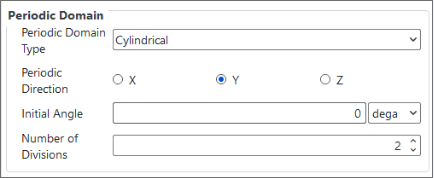

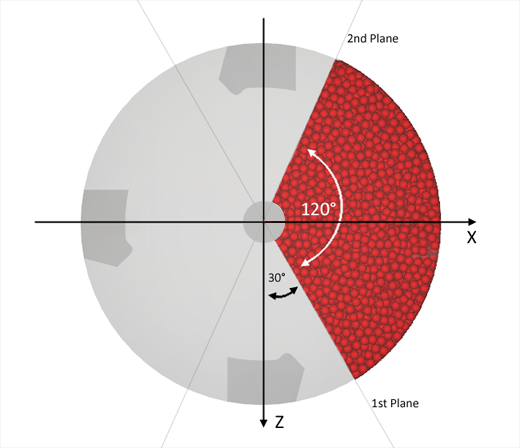

Similar to Cartesian Periodic Domains, Cylindrical Periodic Domains enable you to specify the locations of two planes between which particles are recycled. But rather than being parallel, the two planes in a Cylindrical Periodic Domain are intersecting and rotated by an angle, creating a cylindrical sector, which can look similar in shape to a "wedge" or "slice" of pie.

This can be useful in cylindrical mixing devices, for example, where simulating only a slice of the device would have similar particle properties as simulating the full device, but with many fewer particles and calculations.

The size of the wedge is determined by the number of (evenly spaced) radial divisions you specify for the cylinder. So a division of 2 would create a wedge half the size of the cylinder; a division of 3 would create a wedge a third the size of the cylinder, and so on.

The placement of the wedge is determined both by the location of the cylinder, which is orientated along the X, Y, or Z Periodic Direction you specify, and the Initial Angle value you specify for the first plane, which will be measured in the positive plane perpendicular to the Periodic Direction.

Tip: The positive angular direction is always counterclockwise when the Periodic Direction is set to point towards outside the screen (top view). This means:

For a Periodic Direction of Y, the Initial Angle is measured from the positive Z axis

For a Periodic Direction of X, the Initial Angle is measured from the positive Y axis

For a Periodic Direction of Z, the Initial Angle is measured from the positive X axis

In the mixing drum example shown in Figure 5, the Periodic Direction is Y, the

Initial Angle is 30 degrees, and the Number of Divisions is 3. These settings result

in a periodic, wedge-shaped domain (area in red) that begins 30 degrees counterclockwise in the positive Z direction, and ends 120 degrees (360/3 divisions)

later.

Figure 3.52: Illustration of how the size and location of a Cylindrical Periodic Domain is determined

Limitations and Best Practices

When setting a Cylindrical Periodic Domain, keep in mind the following requirements, limitations, and best practices:

The Periodic Direction must be aligned with one of the three main axes (X, Y, or Z) and must also be parallel to the gravity direction you have set for the simulation.

Because the size of the wedge is determined by how many (evenly spaced) radial divisions you specify, the Number of Divisions value must be a whole integer equal to 2 or greater.

Your Continuous Injection Inlet, Volume Fill box bounds, or Custom Input definitions must be located within the limits of the periodic domain. (See also About Adding and Editing Particle Inputs.)

Using a Particle Trajectory User Process with a Cylindrical Periodic Domain might result in incorrect results. (See also My trajectory lines are outside my periodic domain.)

It is recommended that you design your geometries, define your particle sizes, and set your Cylindrical Periodic Domain limits such that your periodic domain width (the distance between the periodic planes) at any radial distance from the origin is at least 2.5 times wider than your largest particle size. As illustrated on the left side of Figure 6, in most cases, particles at the narrowest part of the wedge will not meet these requirements, which is likely to cause instabilities and affect the accuracy of the results. It is therefore recommended that you apply Cylindrical Periodic Domains only to particles that are simulated in a ring shape, similar to when you specify a Cylinder User Process with the Hole defined (right side of Figure 7).

Figure 6: Cylindrical Periodic Domain with full wedge (left) and with center removed (right)

Figure 6: Cylindrical Periodic Domain with full wedge (left) and with center removed (right) To reduce the chance of simulation errors, ensure that your geometry triangles fall inside the selected domain and that the periodic planes do not cross the triangle surfaces. The ideal situation is to have the periodic planes crossing along the exact edges of the triangles, as shown on the right side of Figure 6.

Figure 7: Periodic planes intersecting boundary triangles (left) and aligning on the edges (right)

Figure 7: Periodic planes intersecting boundary triangles (left) and aligning on the edges (right)

Use the figures and table below to help you understand the various Domain Settings parameters you can set for a simulation project.

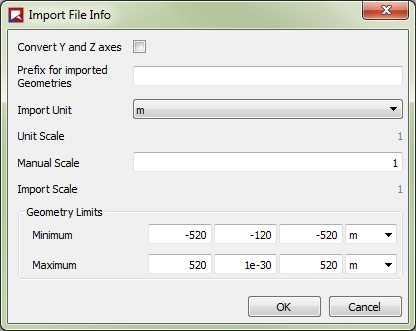

Figure 3.53: Domain Settings, Coordinate Limits parameters in the Data Editors panel (No periodic domain)

Table 1: Domain Settings parameter options

Setting | Description | Range |

|---|---|---|

Coordinate Limits | ||

Use Boundary Limits | When selected, automatically sets the coordinate limits of the simulation at the extreme ends of the existing geometries. When geometries change or move, the limits will be changed also. Notes:

| Turns on or off |

Min Values | When Use Boundary Limits is cleared, this enables you to set the minimum values for the simulation coordinate limits in the following format: X Y Z These custom limits will be visible in the 3D View. | No limit for X, Y, and Z values but must be lower than Max Values |

Max Values | When Use Boundary Limits is cleared, this enables you to set the maximum values for the simulation coordinate limits in the following format: X Y Z These custom limits will be visible in the 3D View. | No limit for X, Y, and Z values but must be higher than Min Values |

Periodic Domain | ||

Periodic Domain Type | Enables you to choose whether or not to include a periodic domain, and if so, what type of domain you want to include. Specifically:

| No periodic domain; Cartesian; Cylindrical |

Periodic Direction | When either Cartesian or Cylindrical is selected as Periodic Domain Type, this determines the direction periodic domains are enabled. Specifically:

| Turns on or off |

Periodic at Geometry Limits | When Cartesian is set for Periodic Domain Type, enabling this checkbox locates the periodic domain at the farthest edge of the simulation geometries. When cleared, the Min. Coordinate and Max. Coordinate values will be used to define the periodic domain limits. | Turns on or off |

Min Coordinate | Location along the axis specified for Periodic Direction to place the first of two planes that define the box-like shape of the cartesian periodic domain limits. Tip: Ensure the distance from this coordinate to the Max Coordinate is at least 2.5 times wider than the largest particle size. | No limit |

Max Coordinate | Location along the axis specified for Periodic Direction to place the second of two planes that define the box-like shape of the cartesian periodic domain limits. Tip: Ensure the distance from this coordinate to the Min Coordinate is at least 2.5 times wider than the largest particle size. | No limit |

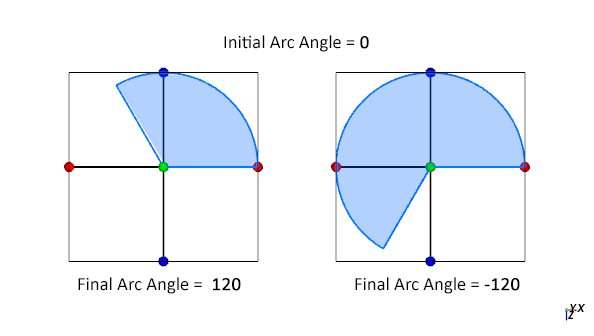

Initial Angle | When Cylindrical is set for Periodic Domain Type, this determines the location of the first of two intersecting planes that define the wedge-like shape of the cylindrical periodic domain limits. How this value is measured depends upon the Periodic Direction specified. Specifically:

Entering a 0 (zero) value will align the first plane with the axis of measure; entering any other value will offset the plane by that angle amount. | No limit |

Number of Divisions | When Cylindrical is set for Periodic Domain Type, this defines how the cylinder will be divided to determine the final size of the wedge. Specifically:

| Whole numbers greater than or equal to 2 |

What would you like to do?

See Also:

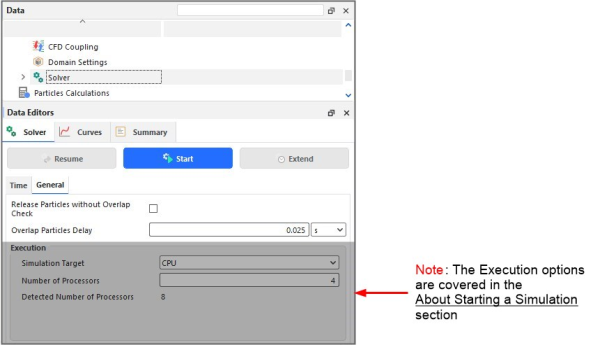

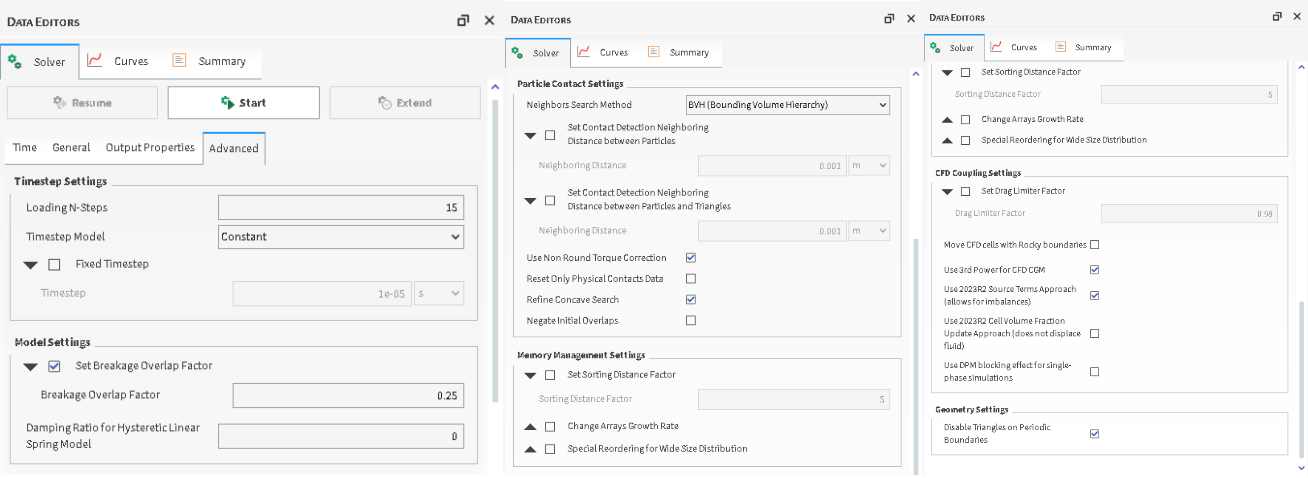

Unlike most setup parameters, which you can define only prior to processing, you are able to change the parameters under Execution on the Solver | General tab, or any of the options on the Solver | Advanced tab after processing has started without invalidating your results. You must first Stop processing, change the parameters you want, and then Resume processing again in this scenario. (See also I cannot change my setup parameters during processing.)

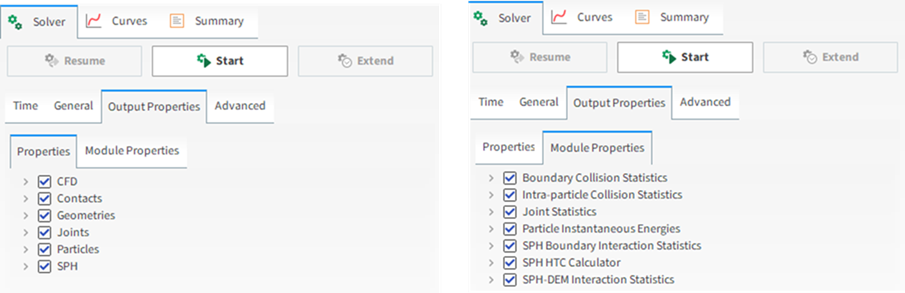

Important: In this version of Rocky, Particles Energy Spectra and Contacts Energy Spectra are defined in their own respective modules. (See also About Particles Energy Spectra and About Contacts Energy Spectra.)

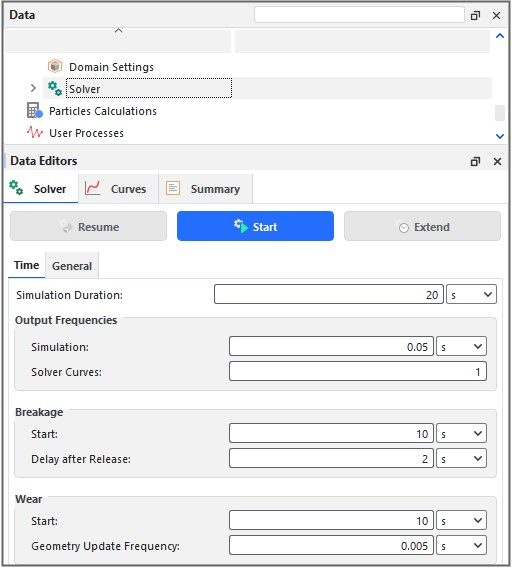

Use the figures and tables below to help you understand the various Solver parameters you can set for a simulation project.

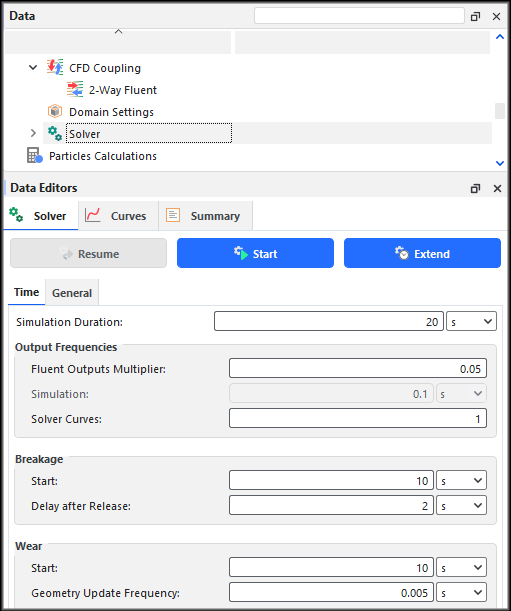

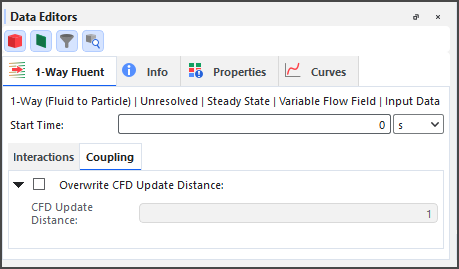

Figure 3.57: Solver | Time parameters for 2-Way Fluent CFD Coupling simulations in the Data Editors panel

Table 1: Solver | Time parameter options

Setting | Description | Range |

|---|---|---|

Simulation Duration | The total amount of real time that you want the simulation to run. Tip: When calculating the Simulation Duration value, be sure to account for the length and speed of your conveyors, the mass flow rate of your particles, steady-state, and so on. | Positive values |

Output Settings Fluent Outputs Multiplier | For 2-Way Fluent CFD Coupling simulations only, this value determines how many Fluent time steps must occur before simulation files from both Rocky and Fluent are saved. For example, a value of 1 means files will be saved at every Fluent time step; a value of 10 means that files will be saved for every ten Fluent time steps, and so on. (See also About Using the 2-Way Fluent Method.) | Positive, whole values |

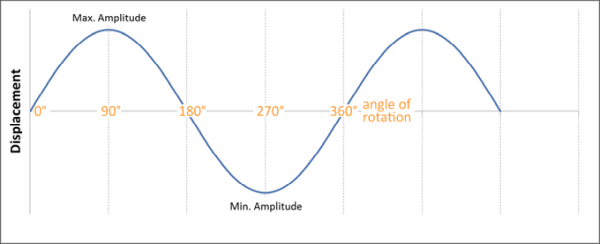

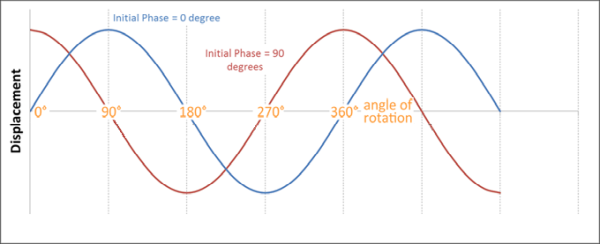

Output Settings Simulation | The time intervals at which you want your output files to be saved. Note: This parameter is disabled in 2-Way Fluent CFD Coupling simulations and is instead calculated based upon the Fluent time step and the Fluent Outputs Multiplier. (See also About Using the 2-Way Fluent Method.) Tip: To prevent rotating or vibrating boundaries from appearing like they are moving backwards, divide the rotational velocity (for rotating boundaries) or frequency (for vibrating boundaries) by 2 and then set your simulation output frequency as slightly lower than that value. Tip: Rocky also has a feature to select multiple output frequencies during the simulation, which is useful to increase or reduce the output data after some time, so that specific phenomena can be evaluated with more or less detail. (See also I cannot find the Output Frequency parameter.) | Value must be positive but less than Simulation Duration |

Output Settings Solver Curves | Controls the frequency at which the Solver Curves are updated while the simulation is being processed. The value entered here represents the number of times the Solver Curves will be updated between two consecutive outputs. For example, if the Simulation Output Settings is set to 1 [s] and the Solver Curves Output Frequency is set to 100, it means that the Solver Curves will be updated at every 0.01 [s]. Note: Rocky will limit the time interval for updating the Solver Curves Frequency to be larger than 100 simulation time steps. | Whole values greater than zero |

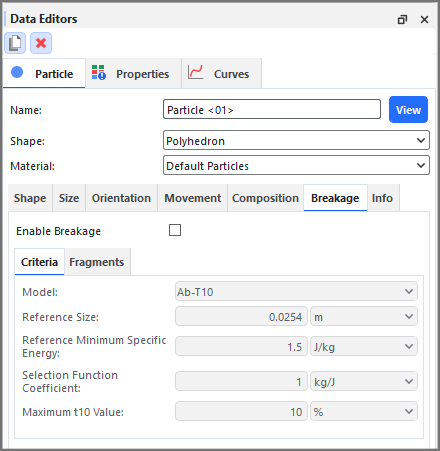

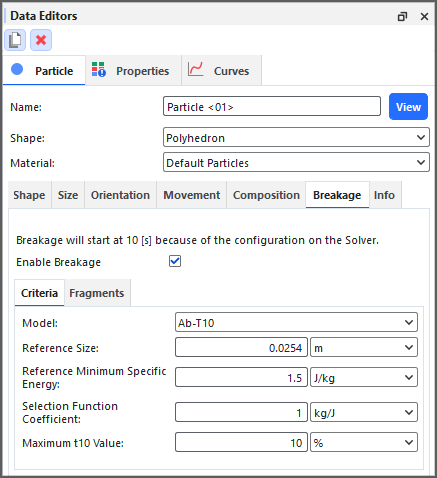

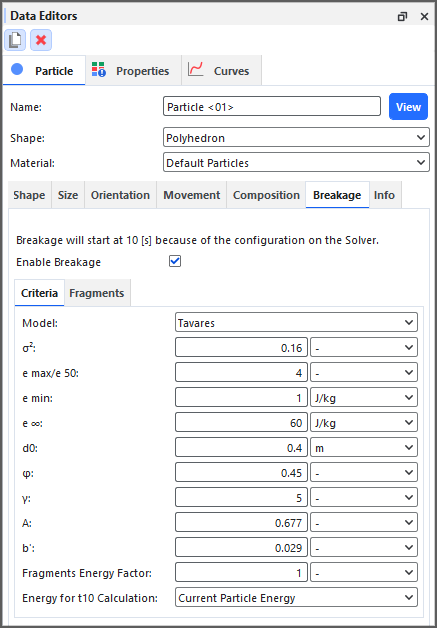

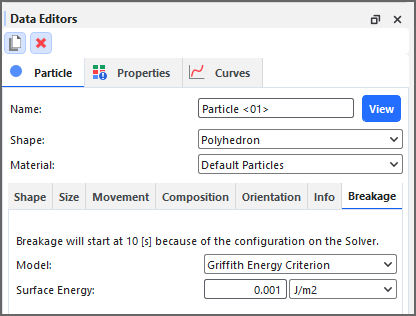

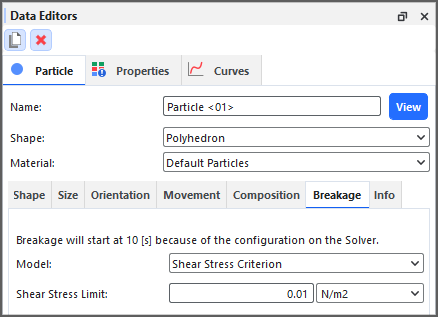

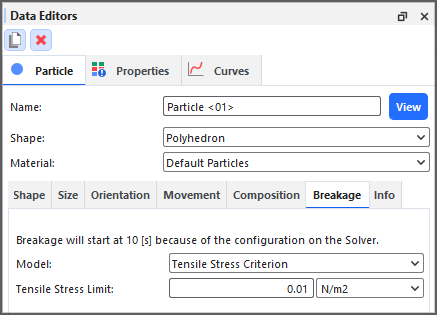

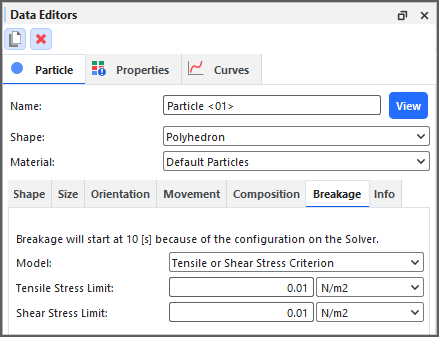

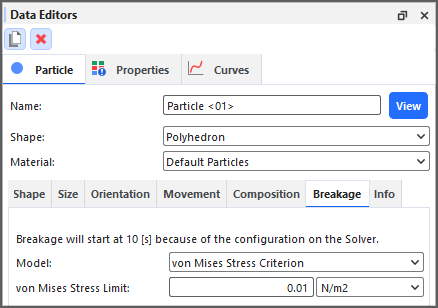

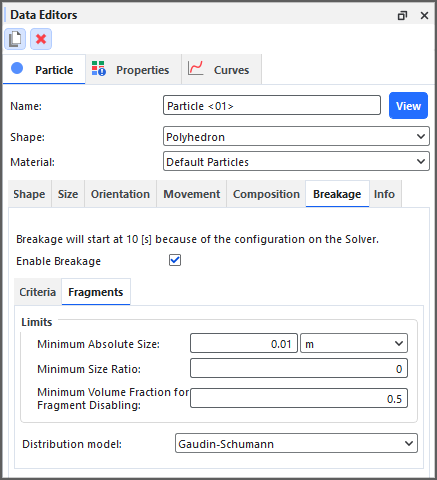

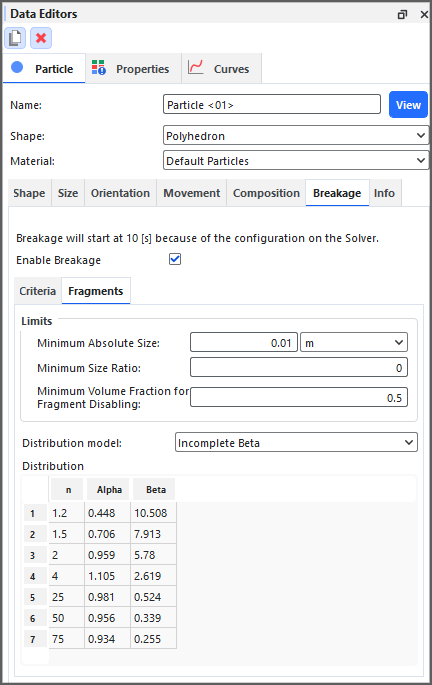

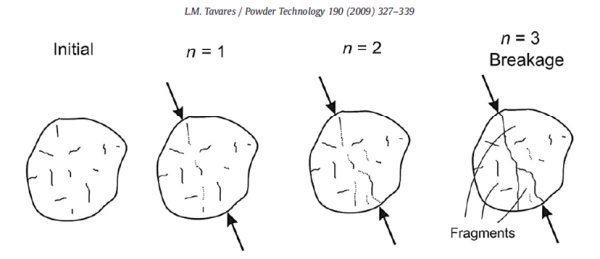

Breakage Start | The amount of time you want to wait before starting to calculate particle breakage. Tip: It is best practice to set your Breakage Start time to begin after a steady state has been reached in your particle flow. | Value must be positive but less than Simulation Duration |

Breakage Delay after Release | The amount of time you want to wait after a particle has been released before starting to calculate particle breakage. | Value must be positive but less than Simulation Duration |

Wear Start | The amount of time you want to wait before starting to calculate belt and boundary wear. Tip: It is best practice to set your Wear Start time to begin after a steady state has been reached in your particle flow. | Value must be positive but less than Simulation Duration |