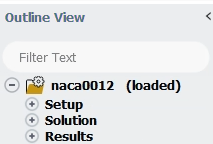

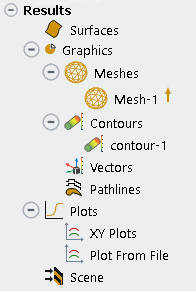

Once a simulation is loaded, a simulation tree appears in the Outline View. The name of the simulation you have loaded appears at the top of the tree along with the text (loaded). Underneath the name of the simulation, the tree is composed of three main branches.

Setup, Solution and Results.

Setup

Defines the type of simulation, the in-flight icing conditions, the physical models and the boundary conditions to use in your simulation.

Solution

Defines the solver settings of your in-flight icing simulation including monitoring, initialization and output files.

Results

Allows post-processing of your in-flight icing results.

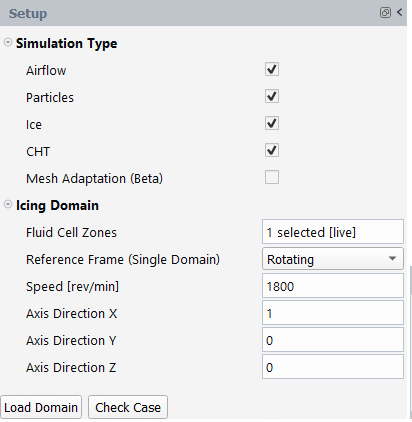

Simulation Type

To start your simulation, you must define its type. Three types are provided when selecting the Setup branch.

Airflow

The airflow solver. Two solvers are supported ( and ).

The particle impingement solver, in this case DROP3D. Vapor transport can also be enabled as part of the Particles solution. An airflow solution is required to conduct this simulation.

Ice

The ice accretion solver, in this case ICE3D. An airflow and particles solution are required to conduct this simulation.

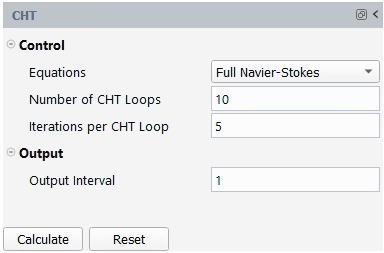

CHT

Conjugate heat transfer (CHT) module that couples Fluent’s intrinsic CHT with the icing solver. A converged dry air CHT, particle and initial ice solution are required to conduct this simulation.

Therefore, five combinations of simulation types are supported:

Stand-alone Airflow simulation

Stand-alone Particles simulation, with an airflow solution already loaded.

Stand-alone Ice simulation, an Airflow and Particles solution already loaded.

An Airflow + Particles simulation. Each simulation is run in sequence.

An Airflow + Particles + Ice simulation. Each simulation is run in sequence. This combination allows the simulation of single and multiple quasi-steady (multi-shot) ice accretion calculations.

Stand-alone CHT simulation, with an Airflow, Particles, and Ice solution already loaded.

Disabling a Simulation Type from the Setup window will hide its relevant settings from the Outline View.

Airflow conditions are used by all four simulation types and Particles conditions are required for Ice.

Icing Domain

A Fluent case might contain multiple cell zones (fluid or solid) or domains. By default, Fluent Icing will consider all cell zones as the icing domain. To specify the correct fluid cell zones in the multiple cell zones scenario, enable the checkbox and select the desired ones from the zone list.

For simulations with rotating components like propellers and engine rotors, the Reference Frame should be set to . This will activate the rotational frame formulation for the equations of motion in all solvers, applying a rotation vector defined as revolutions per minute (rpm) along the axis specified in this panel. If there are static walls in the domain (shrouds, splitters, etc.), they will have to be given the opposite rotation speed in their respective boundary condition section.

Once the domain is selected, use the button to properly set the domain.

The list of Boundary Conditions is restricted to the zones enclosing the selected domains

Mesh and nodal solutions used by the Icing solvers will be restricted to the selected domains.

The Icing Domain selection does not affect a Fluent airflow calculation launched from Fluent Icing.

Post-processing of particles and icing solutions using Viewmerical or CFD-Post will only be done on the selected domains.

Note: Solutions obtained on a different subset of domains cannot be loaded.

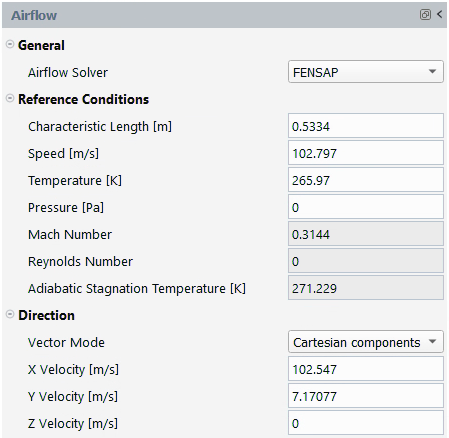

The Airflow window defines the airflow solver, the airflow conditions and the direction of the icing simulation.

General

Choose between and as the Airflow solver. Your choice will appear in the Outline View as an Airflow branch under Setup. Clicking this branch will allow the set-up of the air properties and physical models of either Fluent or FENSAP.

Conditions

These are the reference airflow conditions used by all simulation types. By default, its values are copied from the Reference Conditions of the case file.

The table below connects these variables to FENSAP-ICE or Fluent variables.

| Fluent Icing | FENSAP-ICE | Fluent |

|---|---|---|

| Characteristic Length [m] | Characteristic length | Length |

| Speed [m/s] | Air velocity | Velocity |

| Temperature [K] | Air static temperature | Temperature |

|

Pressure [Pa] (Corresponds to the absolute air static pressure of FENSAP and is the sum of the Operating Pressure and the Reference Pressure in Fluent. | Air static pressure (FENSAP only supports absolute pressure quantities). | Reference Pressure |

| Operating Pressure | Operating Pressure |

Note: When modifying the Pressure [Pa] in Fluent Icing you are modifying the Reference Pressure in Fluent while the Operating Pressure remains equal to the original value from the case file. If you wish to modify the Operating Pressure, you will need to update the other pressure values at the boundaries or in the Initialization section at the same time within the Fluent workspace.

Direction

Two approaches to specify the orientation of the reference airflow are supported.

Cartesian components

The direction is specified by assigning velocity components in X, Y and Z.

Angle of attack

The direction of the flow is specified via two angles, AoA [deg.] and Yaw [deg.] and its velocity magnitude by Velocity magnitude [m/s]. The planes on which these two angles are defined are obtained by selecting the coordinate axis of lift (Lift Direction) and drag (Drag Direction) for a zero degree AoA. The AoA is defined on the plane consisting of the Drag Direction as the primary axis and the Lift Direction as the secondary axis, while the Yaw angle is defined on the plane consisting of the Drag Direction as the primary axis and the result of the cross product of Drag Direction x Lift Direction as the secondary axis.

For instance, if the Drag Direction is set to X+ and the Lift Direction is set to Y+, the flow direction will be defined by the X+ axis if you set the AoA [deg.] and Yaw [deg.] to 0 degree. If the AoA [deg.] is set to

90degrees and the Yaw [deg.] is set to0degree, the flow will be entirely in the Y+ direction. If the AoA [deg.] is set to0degree and the Yaw [deg.] is set to90degrees, the flow will be entirely in the Z+ direction.

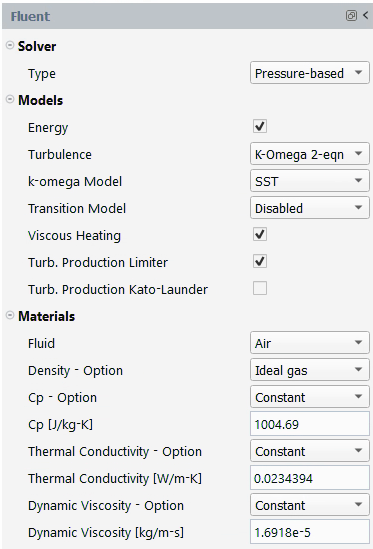

Fluent Airflow Solver

If Fluent has been selected as the Airflow solver in the Airflow window, the Fluent window appears if you click Setup → Airflow → Fluent. In this window, you can specify the material properties of air and the most common physical models of air used for icing simulations.

For more information regarding recommendations on how to set-up air properties and physical models in Fluent, consult Recommended Settings.

Materials

Set the same air properties as the ones coming from the loaded case file (Fluid set to Case settings) or set new air properties (Fluid set to Air).

The parameters shown below Fluid are the Fluent parameters and they only appear if Fluid is set to . For icing simulations, you should set Density to and the remaining properties using the Recommended Settings. Alternatively, this could be done by right-clicking Fluent in the Outline View and then by selecting .

Models

The parameters shown in Models are the Fluent parameters under Setup → Models. Only the physical models recommended in Recommendations to Set up a Fluent Calculation are provided. Follow Recommended Settings to select the appropriate models for icing calculations.

The Other flag is displayed next to Turbulence when the case file contains a viscous model that is different than the ones supported by Fluent Icing (k-Omega 2-eqn and Transition SST 4-eqn).

Although viscous heating and energy appear as options here to be compatible with standard Fluent setup, they must be enabled for icing simulations otherwise heat transfer coefficients used in the ice accretion model will not be calculated correctly.

Solver

Select which Fluent solver type to use: or . Refer to Overview of Using the Solver in the Fluent User's Guide for more information about these solver types.

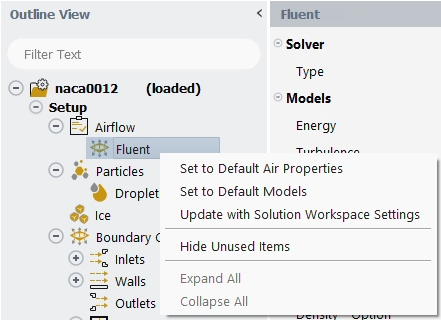

Commands

Access the following commands by right-clicking Fluent, located in Setup → Airflow → Fluent.

Set to Default Air Properties

Changes the current material to Air and will set the air material properties to the Recommended settings for icing simulations, see Recommended Settings.

Set to Default Models

Enable the Recommended settings for models. See Recommended Settings.

Update with Solution Workspace Settings

Use this option to synchronize your Solution workspace or background solver session changes with Fluent Icing.

Note: Changes made to Fluent Icing are automatically synchronized with simulation workspace.

Recommended Settings

When performing icing simulations using Fluent as the airflow solver, the following Material settings for Air are recommended. These can be automatically set by right-clicking the Fluent node under Airflow and choosing .

Set the Density - Option to ideal-gas

Set Cp [J/kg-K] to

1004.688. This value is equal to γ/(γ-1)*R, where γ = 1.4 and the gas constant R = 287.05376 J/kg-K.Set the Thermal Conductivity - Option to Constant and set Thermal Conductivity [W/m-K] to an appropriate value for the condition. To compute its value, refer to the thermal conductivity equation below.

Set the Dynamic Viscosity - Option to Constant, and set Dynamic Viscosity [kg/m-s] to an appropriate value for the condition. To compute its value, refer to the viscosity equation below.

Use the following equations to compute the thermal conductivity and dynamic viscosity, respectively.

Furthermore, the following Model settings are recommended.

Energy must be enabled for icing simulations.

The Turbulence model with is recommended for icing simulations.

and must be enabled for icing simulations.

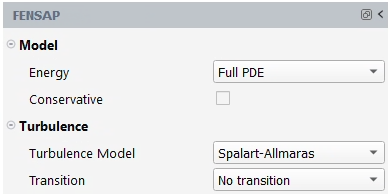

FENSAP Airflow Solver

If is selected as the airflow solver in the Airflow window, the following FENSAP window appears when selecting → → .

In this new window, you can specify the most common physical models of air used in icing simulations.

The most common airflow properties of FENSAP for icing simulations are the ideal gas properties with constant thermal conductivity and dynamic viscosity as specified in the Recommended Settings.

Model

In Fluent Icing, the momentum equations are always set to Navier-Stokes and three options are available for Energy.

Full PDE, Constant enthalpy and Energy only. Full PDE is the most common option for icing applications. By default, FENSAP solves the energy equation in non-conservative form which results in robust convergence especially when the momentum and energy systems are uncoupled. To solve the energy equation in conservative form, enable Conservative. The conservative formulation improves heat flux accuracy for transonic speeds and above, but may require a lower CFL number to converge.

For more information regarding these settings, consult The Energy Equation.

Turbulence

All turbulence and transition models of FENSAP are supported in Fluent Icing. The default settings (SA with no transition) are the most common for ice accretion simulations. For more information regarding these models, consult section Turbulent Flows and Transition to Turbulence.

Note: Default numerical convergence settings are applied to all turbulence models of FENSAP.

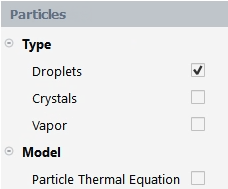

The Particles window defines the type of particles to simulate and the activation of the particle thermal equation that models the temperature and phase change of particles. The particle thermal equation would be important when solving flows with hot exhausts, and internal flows in turbomachinery components.

Note: Air/particle momentum coupling is modeled 1-way where air is not affected by particles. In general, icing cloud particle volume fraction is in the order of 1e-6, making this a dilute particle flow problem. Therefore, in in-flight icing simulations particle flow computations are done segregated from the air flow. This simplifies the modeling process and makes it more cost efficient.

The thermal coupling between air and particles can be significant, and requires 2-way coupling of the energy equations plus vapor transport. In FENSAP-ICE, this is done by solving in mode with the energy-only mode for airflow. This option is currently not available in Fluent Icing.

Type

Three particle types are supported:

Droplets

Supercooled water droplets that are still in liquid form at lower ambient temperatures. They typically accrete ice on external aircraft surfaces.

Crystals

Ice crystals are solid ice particles of various shapes and sizes that are suspended in air. They bounce off cold external aircraft surfaces but typically accrete on warm internal surfaces (engine components) where they can melt and stick.

Vapor

Water vapor pressure determines the evaporation rate on icing surfaces, which is a strong thermal flux that leads to ice formation. Water vapor also acts as a mode of energy transport where warm droplets can shed heat in the form of evaporated mass which can be recovered later in the form of condensation onto particles. For external icing problems inclusion of vapor transport in the modeling process makes very little difference in the results.

Vapor transport model features a simplified nucleation model where any vapor mass greater than local saturation point is considered to have nucleated. This limits the maximum observable relative humidity to 100% in the solution domain, and clips the maximum vapor pressure to local saturation pressure. In FENSAP-ICE, thermal coupling with the airflow solver transfers the released latent heat of evaporation to the air. Since Air+Droplets mode is currently not available in Fluent Icing, this energy source is ignored.

These particle types can be selected concurrently and therefore can all be simulated simultaneously within the same Particle simulation.

Enabling a particle Type from the Particles window will create its corresponding branch under Particles as well as any other relevant setting related to this particle type in Boundary Conditions and Solution.

Model

By default, continuity and momentum equations of droplets and crystals, and continuity equations of vapor are always solved when these particles are selected in Type. These are the typical equations needed to study external in-flight icing physics. For more information regarding these equations, consult The Particle Transport System and Supercooled Large Droplets (SLD).

To activate the energy transfer between particles as well as their respective phase change, the Particle Thermal Equation must be enabled. You should enable this option when studying internal in-flight icing physics, for example, inside engines.

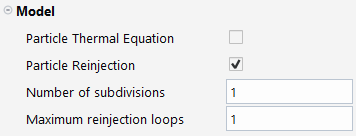

Reinjection

When either Droplets or Crystals particle types are selected, external reinjection can be solved. The primary solution will be used to evaluate the mass of particles which splashes (droplets) or bounces (crystals) at the walls.

Number of Subdivisions

When is enabled, the wall conditions are split into a Number of subdivisions. A new independent particle run will be solved for each of these subdivisions to account for the crossing of reinjected particles trajectories.

Maximum Reinjection Loops

When is enabled, reinjected particles can hit the wall several times before exiting the domain. The particle wall interaction will be solved until no reinjected particle hits the wall or the specified Maximum reinjection loops is reached.

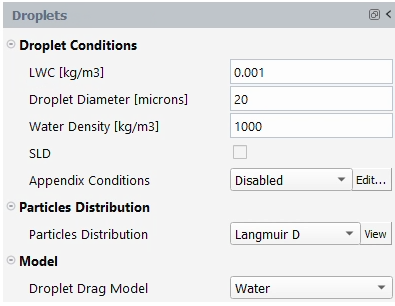

Droplets

If Droplets is selected as a particle Type in the Particles window, the following Droplets window appears when you click Setup → Particles → Droplets.

In this window, you can specify the ambient/reference conditions of water droplets, the type and size distribution, and the drag model.

Droplet Conditions

The main physical parameters describing the droplets are:

LWC [kg/m3]

The Liquid Water Content (LWC) is the concentration of water droplets in the air.

Droplet Diameter [microns]

Spherical droplets are assumed to be of a single, uniform size, usually equal to the median volume diameter (MVD) of the sample size distribution. In Particles, the droplet diameter is the MVD.

Water Density [kg/m3]

This is the density of the water droplets. By default, its value is set to 1,000 kg/m3.

SLD

Supercooled Large Droplets (SLD) options allow the set-up of extra physical models when water droplets exceed a MVD of ~40 microns.

Note: When particle reinjection is enabled, SLD is automatically selected.

Appendix Conditions

Appendix conditions are recognized droplet cloud environments that linked ambient conditions to average droplet sizes and concentrations. Select the appropriate Appendix Conditions drop-down, then use the button located to the right of the Appendix Conditions menu. This will automatically set LWC [kg/m3] and Droplet Diameter [microns] to use in your simulation.

Note: The altitude in the Appendix Conditions panel is computed from the absolute pressure defined under Setup → Airflow → Conditions. If the altitude is modified, a new Pressure [Pa] value is automatically computed and imposed under Setup → Airflow → Conditions. However, this is not the case for the boundary conditions. It is therefore recommended to manually update Pressure [Pa] at the inlet and outlets of your farfield domain by first setting the boundary under Setup → Airflow → Conditions to . You can then either copy the new reference pressure inside Pressure [Pa] at the boundary, or by click the button located at the bottom of your boundary condition panel.

The following droplet appendices are supported:

Appendix C

In general, valid for droplet sizes below 40 microns.

Appendix O (SLD)

In general, valid for droplet sizes that exceed 40 microns. To use , SLD must be enabled.

Inside each Appendix panel, ambient conditions such as air temperature and altitude are taken from the submenu inside the Airflow panel. In this case, altitude and absolute pressure follow the U.S. Standard Atmosphere (1976).

Note: Only one Appendix can be activated at a time. For more information regarding these appendices, consult Appendix C and Appendix O - Supercooled Large Droplets.

Only built-in droplet size distributions are currently supported by Fluent Icing. These distributions can be selected in the Droplet Distribution pull-down menu.

Monodispersed

Indicates that a calculation is performed using a single diameter. This diameter is specified in the Droplet diameter box and corresponds to the MVD.

Langmuir B to E

If one of these is selected, water droplets are simulated by computing the droplet concentration and speed for each individual diameter of the discrete distribution, which are subsequently automatically weight-averaged at the end of the simulation. Fluent Icing always uses 7 droplet diameters to represent a Langmuir B to E distribution. The various Langmuir diameter distributions and their corresponding weights are pre-defined in FENSAP-ICE. To learn more about these distributions and their respective weights, consult Droplets Reference Conditions. The distribution can be viewed by using the button on the right side of the distribution menu.

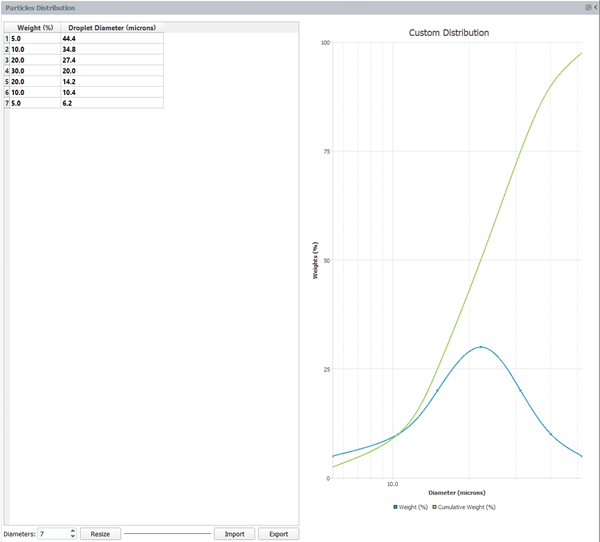

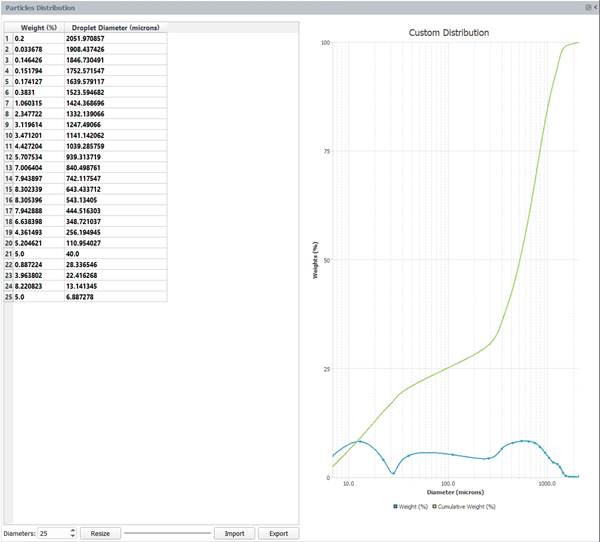

An arbitrary droplet diameter distribution can be set by using the button on the right side of the distribution menu.

The Particles Distribution panel allows you to edit the weight/diameter distribution table.

: The button is for read-only distributions ( or ) and permit to toggle the distribution in Edit mode, the distribution setting is then set to Custom.

: Change the number of rows in the particles distribution table.

/ : Reads or writes a .csv file with the following format, for example for the equivalent distribution of a with a MVD of 20 microns:

Weight,Diameter 0.05,44.4 0.1,34.8 0.2,27.4 0.3,20 0.2,14.2 0.1,10.4 0.05,6.2

The Particles Distribution must be defined as following:

Droplet Diameter (microns): Diameters ordered in increasing or decreasing order.

Weight (%): Sum of weights adding up to 100%.

If an individual value or a whole column is invalid, it will be highlighted in yellow.

If the Appendix Conditions is set to , the Droplet Distribution can be either or . See Appendix O - Supercooled Large Droplets in the Ansys FENSAP-ICE User Manual for more details.

The selected distribution can be viewed using the button, right side of the distribution menu. The Appendix O (SLD) distribution depends on the environment (freezing drizzle, freezing rain) or diameter range (larger or lower than 40 microns) selected in its Particles Distribution panel.

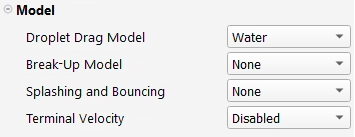

Model

In this submenu, different water droplet physical models can be enabled to better represent their behavior for higher Weber numbers. Some of these models are only available when the SLD option is enabled under Droplet Conditions.

General Models

Droplet Drag Model

These models correspond to drag correlations. Four choices are available (Water, Water -Stokes law, Water – extended Reynolds, Snowflakes). The default drag model is set to Water, which is the drag model used in almost all our water droplet validation cases. For more information regarding these models, consult Particle Drag Correlations.

SLD-Only Models

Break-up Model

Models the process by which a large droplet is broken up into smaller droplets due to aerodynamic forces. To enable this model, select Pilch & Erdman, the only break model supported in FENSAP-ICE. If selected, an extra governing equation is solved for droplet diameter. For more information regarding this model, consult Droplet Break-Up. This option is automatically selected when external reinjection is enabled.

Splashing and Bouncing

Only the By post-processing with three splashing models (Mundo, Honsek and Wright) are supported in Fluent Icing. These are the most validated models used in SLD splashing & bouncing simulations, with a preference for Mundo, default Splashing Model setting. They modify the droplet collection efficiency on the surface by predicting if water droplets bounce or splash. Droplets that bounce or splash are not re-introduced into the computational domain. For more information regarding these models, consult Splashing and Bouncing by Post-Processing, Mundo Model, Honsek-Habashi Model and Wright-Potapczuk Model in the Ansys FENSAP-ICE User Manual. If reinjection is enabled, the selected splashing model is used to evaluate the mass of reinjected droplets.

Terminal Velocity

This option enables supercooled large droplets to fall without exceeding their terminal velocity. This option will alter the transport of droplets and therefore its impingement. The direction and the magnitude of the gravity vector must be specified in the case file. For more information regarding this model, consult Terminal Velocity. Pay attention to the gravity direction specification with respect to the mesh coordinate system. An aircraft at level flight usually has a small positive angle of attack which has to be factored into the gravity direction. An aircraft during climb has a positive vertical speed component in addition to a significant angle of attack with respect to that flight direction, both of which should be considered when specifying the gravity vector.

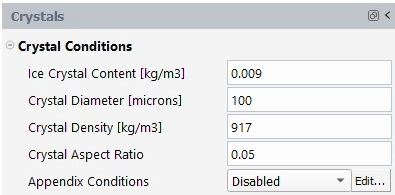

Crystals

If Crystals has been selected as a particle Type in the Particles window, the following Crystals window appears when you click Setup → Particles → Crystals.

In this window, you can specify the ambient/reference conditions of crystals.

Note: Only one drag model of crystals has been implemented and it follows the oblate spheroidal drag correlation formulated by Pitter. For more information regarding this model, consult Ice Crystal Drag Correlations.

Crystal Conditions

The main physical parameters describing the ice crystals are:

Ice Crystal Content [kg/m3]

The Ice Crystal Content (ICC) is the concentration of crystals in the air.

Crystal Diameter [microns]

Ice crystals are assumed to be of a single, uniform size. In this case, the crystal diameter corresponds of the semi-major axis length of a thin oblate spheroid.

Crystal Density [kg/m3]

This is the density of the ice that forms the ice crystal. By default, its value is set to 917 kg/m3.

Crystal Aspect Ratio

This is the aspect ratio (E=b/a) of an oblate spheroid, where b is the semi-major axis length and a is the semi-minor axis length.

Note: Icing wind tunnel experiments with glaciated droplets usually lead to aspect ratios around 1. Increasing the aspect ratio increases the drag of the crystals and make them follow the air more closely, decreasing their collection efficiency.

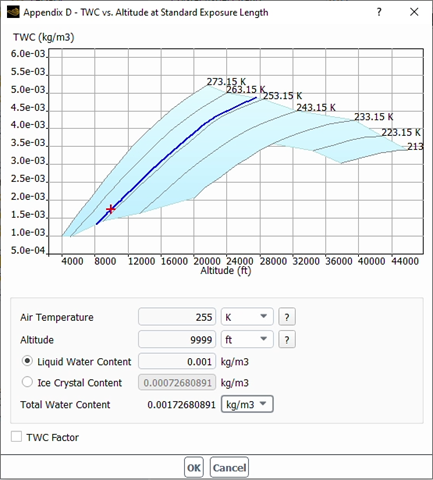

Appendix Conditions

Only one recognized cloud environment type condition for crystals is supported in Fluent Icing, it is . If this option is enabled, use the button located at the bottom of the property panel. This will automatically set the ICC and the LWC to use in your simulation since Appendix D defines the Total Water Content (TWC).

Inside the Appendix D panel, ambient conditions such as air temperature and altitude are taken from the Conditions submenu inside the Airflow panel. In this case, altitude and absolute pressure follow the U.S. Standard Atmosphere (1976).

Note: Only one Appendix can be activated at a time. For more information regarding Appendix D, consult Appendix D - Ice Crystals.

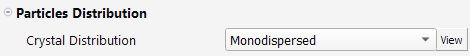

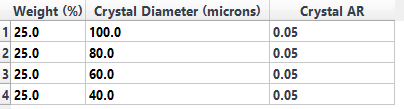

Crystal Distributions

If are the only particles type enabled ( are not enabled), the Particles Distribution panel is available and allows you to configure a diameter distribution.

Indicates that a calculation is performed using a single diameter. This diameter is specified in the Crystal Diameter (microns) box and corresponds to the MVD.

An arbitrary crystal diameter distribution can be set by using the button on the right side of the distribution menu. Similar to under Particles Distribution.

A custom crystal distribution allows you to define both Crystal Diameter (microns), and Crystal AR (Aspect Ratio).

The .csv file format for / contains that extra aspect ratio column, such as:

Weight,Diameter,Aspect Ratio 25,100,5.0e-02 25,80,5.0e-02 25,60,5.0e-02 25,40,5.0e-02

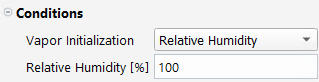

Vapor

If Vapor has been selected as a particle Type in the Particles window, the following Vapor window appears when you click Setup → Particles → Vapor. In this window, you can specify the ambient/reference conditions of vapor.

Conditions

The main physical parameters describing vapor are:

Relative Humidity [%]

This option is enabled if selected under Vapor Initialization. This option corresponds to the ambient relative humidity and ranges from 0 to 100 %. It is defined as the ratio of partial vapor pressure to the saturation vapor pressure.

Vapor Concentration [kg/m3]

This option is enabled if selected under Vapor Initialization. This option corresponds to the ambient vapor concentration.

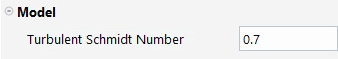

Turbulent Schmidt Number

If are enabled through → → Icing, Turbulent Schmidt Number can also be specified. The default value is 0.7.

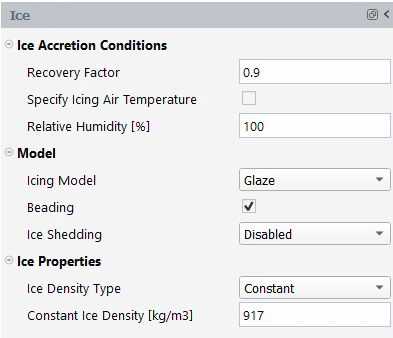

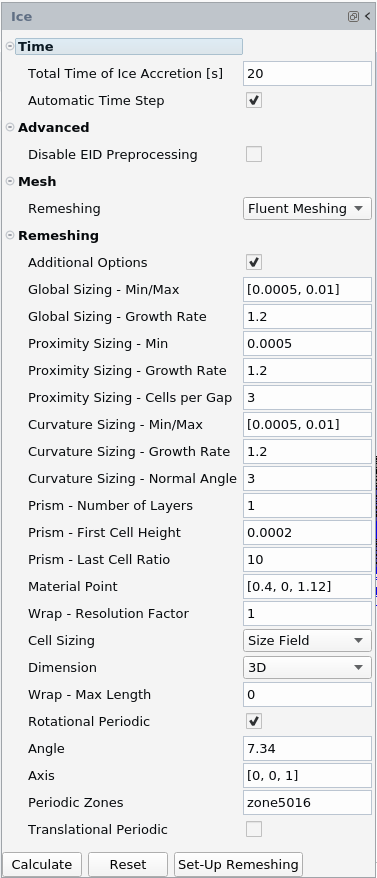

The Ice window defines the icing conditions and the icing physical models to use during the ice accretion simulation.

Ice Accretion Conditions

The main physical parameters describing the ice accretion process are:

Recovery Factor

The recovery factor is used to introduce the effect of the energy losses due to friction when computing the adiabatic/recovery temperature at the wall. This is a factor that is used to compute the convective heat transfer coefficients in FENSAP-ICE for ambient/reference or icing temperatures. Its default value is 0.9 (~Pr1/3) is observed on flat plate experiments. This is the value used in FENSAP-ICE ice shape validation cases. On wing and airfoil stagnation points, the value of the recovery factor is closer to 1. Using 1 instead of 0.9 will increase the amount of water film runback.

Specify Icing Air Temperature

The Icing Air Temperature [K] is the static temperature at which ice accretion is computed. This temperature can therefore be different than the ambient air temperature specified in the Airflow window or inside your inlet boundary conditions. If the energy equation of particles is enabled, the icing air temperature must be the ambient air temperature specified in the Airflow window. This option cannot be used in multi-shot computations. It is automatically disabled for multi-shot ice accretion.

Relative Humidity [%]

This is the relative humidity expressed in percentage value. For atmospheric clouds, this value should be set to 100%. If is enabled in Particles, this parameter is disabled, and ignored. The vapor pressure field computed in the vapor transport model is used on walls when calculating the rate of water film evaporation.

For more information regarding these parameters, consult Icing Conditions.

Model

The main physical models describing the ice accretion process are:

Icing Model

The icing models solve the surface water film continuity and energy equations using an explicit unsteady 3D finite volume scheme (see Governing Equations) in different forms.

Glaze

Glaze icing model is meant for glaze and mixed type ice shapes including water runback and evaporation. This is the most comprehensive model that can operate above and below freezing temperatures and produce rime ice with no water film, glaze ice with water film at 0° C, and all water above freezing temperature that can form in anti-icing and de-icing scenarios.

Water film

This model engages the pure water film mode where the energy equation is used to calculate water temperature instead of ice accretion rate. It is meant for water film runback simulations at above freezing conditions.

Rime

In rime mode, no runback is assumed, and the continuity equation simply dictates the rate of icing. The energy equation is used to compute the below freezing ice temperature.

Beading

When enabled, the beading model calculates variable surface roughness evolution on iced walls. The resultant roughness is expressed as equivalent sand-grain roughness. During a multi-shot simulation this sand-grain roughness affects the convective heat fluxes and therefore the local cooling effects over iced surfaces. Most importantly, it eliminates the guess work of choosing a constant wall roughness which would be applied to the entire wall uniformly. You should activate this model to obtain accurate multi-shot results.

Heat Flux

This option is only visible if the Airflow Solver is set to , and are enabled through → → Icing. This option allows the selection of two types of convective heat flux produced by FENSAP to conduct an ice accretion simulation.

Convective heat fluxes computed using temperature gradients on the walls. This method is 2nd order accurate and is the default option when is disabled.

Convective heat fluxes computed based on Gresho’s Consistent Galerkin formulation. Gresho fluxes tend to exhibit oscillations when the surface grid is uneven or coarse and therefore it is less robust than .

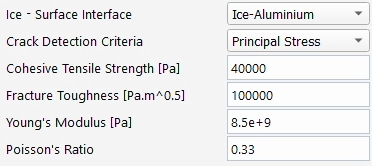

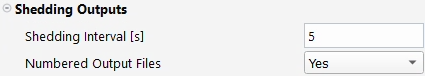

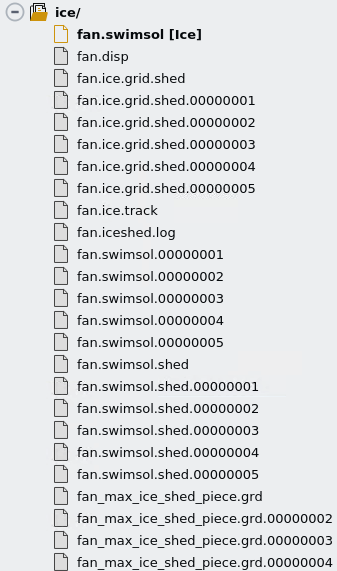

Ice Shedding

This option enables ice stress and crack propagation analysis in single-shot icing simulations. Currently, it is only meant for rotating components where loads on the ice are primarily due to the centrifugal forces. With this feature, you can simulate the natural ice shedding phenomenon on aircraft components like propellers and engine fans. For more information on the model, see Ice Shedding on Rotating Components.

When enabled, additional ice properties will be listed below that are required for the ice stress and crack propagation analysis.

Crystals

appears in the Ice window if Crystals has been selected in the Particles window. enables the contribution of crystals to the icing calculation, otherwise, Ice assumes that all crystals bounce off the surface, . Two bouncing models are available.

NTI Bouncing Model

This model determines the amount of crystals that stick based on local surface conditions, such as impact velocity, crystal size and film height. The model also includes an optional feature to account for crystal Erosion effects on ice accreting surfaces.

NRC Bouncing Model

This model calculates the sticking faction based on the LWC to TWC ratio hitting the surface.

Ice Properties

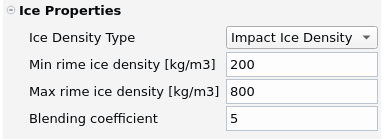

Ice Density Type

There are five models to specify the ice density in Fluent Icing Constant, Macklin, Jones Glaze, Jones Rime and Impact Ice Density: By default, a constant value of 917 kg/m3 is set. The other density types are correlations that uses the local ice surface temperature and other icing conditions. For more information regarding these ice density correlations, consult Ice Density. The other density types are correlations that uses the local ice surface temperature and other icing conditions. For more information regarding these ice density correlations, consult Ice Density.

Impact Ice Density Model

The Impact Ice Density model is created by Ansys especially for swept wing icing simulations, inspired by the void density model in NASA’s LEWICE3D. It is meant to be used as part of multishot icing with remeshing workflow, to help generate realistic ice shapes with feathers and scallops. The studies for the AIAA Ice Prediction Workshops showed that this density model is essential in capturing accurate scallop formations that produce valid Maximum Combined Cross Sections (MCCS) both for glaze and rime conditions. It uses local droplet impact angle and freezing fraction to vary the density from 917 kg/m3 to 200 kg/m3. Perpendicular impact and low freezing fraction increase the density of ice which is closer to glaze ice, and the opposite reduces the density resembling feathery ice observed near the impingement limits of aircraft surfaces.

The model is controlled by three parameters: minimum rime ice density, maximum rime ice density, and blending coefficient:

For glaze ice conditions where the freezing fraction is closer to 0, the ice density will be closer to 917 kg/m3. In rime ice conditions, the ice density will be set between min and max rime ice density values entered in this panel. The maximum rime ice density value is used when the impact angle of droplets is 90O (perpendicular) to the surface. The minimum ice density value is set for impact angle = 0O (tangent), which is a theoretical value that droplets will get close to at impingement limits. The change from maximum to minimum rime ice density based on the impact angle value is done with a non-linear blending function, which is controlled by the blending coefficient. The range for this coefficient is 2 – 10. Higher blending coefficient values keep the ice density high for a wider range of impact angles. Currently the recommended value is 5, which is determined based on the swept wing ice accretion results from 1st and 2nd AIAA Ice Prediction Workshops. More details are provided in Ansys FENSAP-ICE User Manual for this model.

Partial differential equations are solved for each Fluent Icing module. Therefore, each module requires a set of suitable boundary conditions. The options shown in each boundary condition type reflect the simulation type, conditions and physical models selected/enabled in Airflow, Particles and Ice.

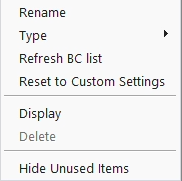

Note: Fluent Icing offers the option to modify boundary condition types to those supported by Fluent Icing. Only a couple of boundary condition types are currently supported by Fluent Icing. Boundary condition types can also be modified from the background solver session that is connected to Fluent Icing (by using ). These changes can be viewed in Fluent Icing by right-clicking any boundary condition type inside the Outline View and selecting Refresh BC List. Only supported boundary condition types are shown in Fluent Icing.

The right-click menu for each boundary offers options to rename, refresh, change type, and reset to custom settings if needed.

Only a couple of Fluent boundary condition types are currently supported by Fluent Icing.

Inlets

Pressure-far-field

Velocity Inlet

Mass-flow Inlet

Pressure Inlet

Walls

Outlets

Pressure Outlet

Symmetry

Periodic

In the next sections, a brief description of the content of Inlets, Outlets and Walls is provided. Symmetry and periodic types do not require a specific set-up for icing applications and therefore are not describe here.

Ice accretion simulations require inlet airflow and particles boundary conditions. Four types of Fluent boundary conditions are supported to simulate the Airflow module of Fluent Icing. Since the Particles module only supports Dirichlet boundary conditions, particle concentration and velocity conditions are specified on all Fluent boundary types.

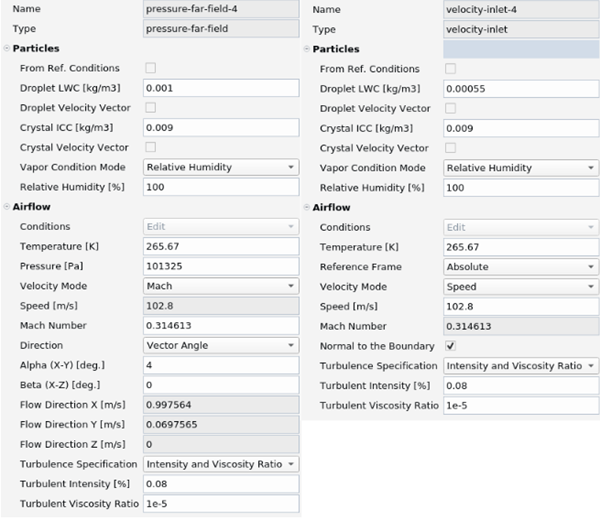

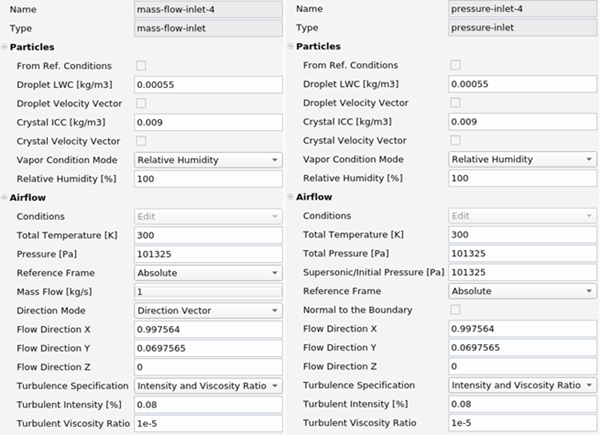

The following figures show each Inlet boundary type supported by Fluent Icing when all particles type are enabled.

Airflow

To simplify set-up of the Airflow solver, it is possible to automatically define the boundary conditions for all the Inlet types by selecting one of the two options under Conditions.

Case settings

With this option, inlet boundary conditions are automatically taken from your case file. Therefore, this is only available if a case file has been set up beforehand with the Fluent Solution workspace.

Edit

With this option, you can define boundary conditions that are different than those contained in the original case file or in the Airflow settings.

The following tables map the Fluent Icing airflow boundary conditions to Fluent and FENSAP airflow boundary conditions when Edit is selected.

Table 2.1: Pressure Far-Field, Mapping of Airflow Fluent Icing Boundary Condition into Fluent & FENSAP Boundary Conditions

| Fluent Icing | Fluent | FENSAP | ||

|---|---|---|---|---|

| Type: Pressure-far-field | Type: Pressure-far-field | Type: Supersonic or Far-field | ||

| Temperature [K] | Temperature (k) | Temperature | ||

| Pressure [Pa] (Absolute) | Gauge Pressure (pascal) | Pressure | ||

| Velocity mode | ||||

| Speed [m/s] | --------- | --------- | ||

| Mach number | Mach number | --------- | ||

| Direction mode | --------- | |||

| Vector Components | --------- | |||

| Flow direction X | X-Component of Flow Direction | Velocity X | ||

| Flow direction Y | Y-Component of Flow Direction | Velocity Y | ||

| Flow direction Z | Z-Component of Flow Direction | Velocity Z | ||

| Vector Angle | ||||

| Alpha (X-Y) [deg] | --------- | --------- | ||

| Beta (X-Z) [deg] | --------- | --------- | ||

Table 2.2: Velocity Inlet, Mapping of Airflow Fluent Icing Boundary Condition into Fluent & FENSAP Boundary Conditions

| Fluent Icing | Fluent | FENSAP | |||

|---|---|---|---|---|---|

| Type: Velocity Inlet | Type: Velocity Inlet | Type: Subsonic | |||

| Temperature [K] | Temperature (k) | Temperature | |||

| Pressure [Pa] (Absolute) | Supersonic / Initial Gauge Pressure (pascal) | --------- | |||

| Velocity Mode | |||||

| Speed [m/s] | Velocity Magnitude (m/s) | --------- | |||

| Mach number | --------- | --------- | |||

| Normal to the boundary | Magnitude, Normal to Boundary | --------- | |||

| Direction | |||||

| Vector Components | |||||

| Flow direction X | X-Component of Flow Direction | Velocity X | |||

| Flow direction Y | Y-Component of Flow Direction | Velocity Y | |||

| Flow direction Z | Z-Component of Flow Direction | Velocity Z | |||

| Vector Angle | |||||

| Alpha (X-Y) [deg] | --------- | --------- | |||

| Beta (X-Z) [deg] | --------- | --------- | |||

Table 2.3: Mass Flow Inlet, Mapping of Airflow Fluent Icing Boundary Condition into Fluent & FENSAP Boundary Conditions

| Fluent Icing | Fluent | FENSAP | ||

|---|---|---|---|---|

| Type: Mass Flow Inlet | Type: Mass Flow Inlet | Type: Mass Flow | ||

| Temperature [K] | Total Temperature (k) | Static Temperature | ||

| Pressure [Pa] (Absolute) | Supersonic / Initial Gauge Pressure (pascal) | -------- | ||

| Direction mode | --------- | -------- | ||

| Direction Vector | ||||

| Mass Flow [kg/s] | Mass Flow Rate (kg/s) | Mass Flow | ||

| Flow direction X | X-Component of Flow Direction | Alpha & Beta | ||

| Flow direction Y | Y-Component of Flow Direction | |||

| Flow direction Z | Z-Component of Flow Direction | |||

| Normal to Boundary | ||||

| Mass Flow [kg/s] | Mass Flow Rate (kg/s) | -------- | ||

Table 2.4: Pressure Inlet, Mapping of Airflow Fluent Icing Boundary Condition Into Fluent Boundary Conditions

| Fluent Icing | Fluent | |

|---|---|---|

| Type: Pressure Inlet | Type: Pressure Inlet | |

| Temperature [K] | Total Temperature (k) | |

| Total Pressure [Pa] (Absolute) | Supersonic / Initial Gauge Pressure (pascal) | |

| Normal to the boundary | Normal to Boundary | |

| Flow direction X | X-Component of Flow Direction | |

| Flow direction Y | Y-Component of Flow Direction | |

| Flow direction Z | Z-Component of Flow Direction | |

Note: Reference Frame allows the inlets to be defined relative to a cell zone motion or in absolute reference frame. This does not apply to fixed cell zones. However, if a rotating domain is defined, the inlet properties (for example, Flow Direction) can be defined relative to the domain motion.

Velocity Mode allows the use of Speed [m/s] or Mach Number as a boundary condition when the Inlet is a or a .

Normal to the Boundary defines the flow direction using the normal vectors of the boundary surface. If selected, the Direction options do not appear. This option only appears when the inlet is a .

Direction allows the specification of three types of flow direction at the inlet of a or .

Vector Components

If selected, the orientation of the inlet flow is defined by the following unit vector components, Flow Direction X, Flow Direction Y and Flow Direction Z.

Vector Angle

If selected, the orientation of the inlet flow is defined by the following angles, Alpha (X-Y) [deg] and Beta (X-Z) [deg].

Case settings

If selected, the orientation of the inlet flow is defined by the orientation used in the case file.

Direction Mode allows the definition of two types of flow direction at the inlet of a Mass Flow Inlet.

Direction Vector

If selected, the orientation of the inlet flow is defined by the following normalized flow components, Flow Direction X, Flow Direction Y and Flow Direction Z.

Normal to Boundary

If selected, the orientation of the inlet flow is defined by the normal vectors of the boundary surface.

Italic Fluent and FENSAP boundary conditions shown in the mapping tables highlight conditions that do not have a perfect counterpart in Fluent Icing.

Fluent

X/Y/Z-Component of Flow Direction

The Flow orientation in Fluent can be defined by a non-unitary vector. However, when using Fluent Icing, this orientation must be provided as a normalized vector.

Total Temperature [K]

When using Fluent as the Airflow solver in Fluent Icing, write the total temperature of a mass flow or pressure inlet boundary condition type inside Temperature.

FENSAP

Alpha and Beta angles

These angles are not supported by Fluent Icing. In FENSAP, Alpha is the angle in the X-Y plane and Beta is the angle in the X-Z plane. Transform these angles to normalized vector components and impose them as boundary conditions inside Direction Mode → Direction Vector.

Currently, the Fluent Icing user interface only supports turbulence boundary conditions when using Fluent as the airflow solver.

There are two options available in the current implementation: and . When loading a case file, Fluent Icing will automatically set the Turbulence Specification method to and use the constant values associated with the turbulent intensity and viscosity ratio if they are specified in the case file. Only these turbulence models are currently supported during the import: , , and . For , only the intermittency parameter constant value is imported.

If any of the above-mentioned conditions are not satisfied, Fluent Icing will set the Turbulence Specification method to . The turbulence settings in the case file will be used. You can verify them from the Solution workspace. If you change to within Fluent Icing, the turbulence settings that appear in the Fluent Icing properties panel of will be applied to the Solution workspace.

Note: Only constant values can be set from the Boundary Conditions properties panel in Fluent Icing.

If is selected as the Airflow solver, it is not possible to specify turbulence parameters at the boundary condition; default turbulence boundary conditions are imposed.

SA

Eddy/laminar viscosity ratio of 1e-5

kw-SST

Eddy/laminar viscosity ratio of 1 and Turbulence intensity of 0.01.

To change these default values, use the text commands, Fluent Journal Commands, in the Fluent Console window. For instance, to change the Eddy/laminar viscosity ratio to 1e-3 and the turbulence intensity to 1e-4, type the following commands:

/icing/settings/set flow/turb_eddy_lam_ratio 1e-3/icing/settings/set flow/turb_intensity 1e-4

A zero value to these settings will revert them to their default value. Such text commands can also be sent from Fluent Icing by using the

Send Commandaction, in the contextual menu of the case file.

Note: To learn more about these Fluent Inlet boundary conditions, consult Pressure Far-Field Boundary Conditions, Velocity Inlet Boundary Conditions, Mass-Flow Inlet Boundary Conditions and Pressure Inlet Boundary Conditions under Boundary Conditions in the Fluent User's Guide. To learn more about FENSAP Inlet boundary conditions supported in Fluent Icing, consult Inlets and Far-fields – 1000-BCs.

Particles

To simplify set up of the Particles solver, it is possible to automatically define the boundary conditions at the Inlet by checking . In this case, the Particles window settings are applied as boundary conditions and it is assumed that particles and airflow share the same inlet velocity.

The following lists the boundary conditions of all types of Particles when the option is unchecked.

Droplet Boundary Conditions

Droplet boundary conditions are available if Droplets has been selected in Setup → Particles

Droplet LWC [kg/m3]

Set the water droplet concentration at the Inlet.

Droplet Diameter

Set the MVD of the spherical particle that represents a cloud of water droplets at the Inlet. This option is available when the Break-up model has been activated inside Setup → Particles → Droplets.

Droplet Temperature [K]

Set the temperature of the cloud of water droplets at the inlet. This option is available when the Particle Thermal Equation is enabled in Setup → Particles.

Droplet Velocity Vector

When enabled, this option allows the specification of an inlet droplet velocity that is different than the airflow velocity at the inlet. In this case, set the velocity components (Droplet X Velocity [m/s], Droplet Y Velocity [m/s], Droplet Z Velocity [m/s]) of the water droplet cloud.

Crystal Boundary Conditions

Crystal boundary conditions are available if Crystals has been selected in Setup → Particles.

Crystal ICC [kg/m3]

Set the ice crystal concentration at the Inlet.

Crystal Temperature [K]

Set the temperature of the cloud of ice crystals at the inlet. This option is available when the Particle thermal equation is enabled in Setup → Particles.

Crystal Melt Fraction

Set the crystal melt fraction at the inlet if the crystal temperature is equal to the freezing temperature (273.15 K). The crystal melt fraction is automatically set to 0 or 1 if the crystal temperature is lower or higher than 273.15K respectively. This option is available when the is enabled in Setup → Particles.

Crystal Velocity Vector

When enabled, this option allows the specification of an inlet ice crystal velocity that is different than the airflow velocity at the inlet. In this case, set the velocity components (Crystal X Velocity [m/s], Crystal Y Velocity [m/s], Crystal Z Velocity [m/s]) of the ice crystal cloud.

Vapor Boundary Conditions

Vapor boundary conditions are available if Vapor has been selected in Setup → Particles.

Vapor Condition Mode

Set the type of vapor boundary condition to impose at the inlet.

Relative Humidity [%]

Set the relative humidity at the inlet. This value is defined as the ratio of partial vapor pressure to the saturation vapor pressure.

Vapor Concentration [kg/m3]

Set the vapor concentration at the inlet.

Note: In the case of Inlet boundaries that share inlet and outlet cells, the Particles solver will identify the cells that are inlets based on the velocity components of droplets and crystals that have been specified under Particles.

Built-in Inlet type commands are available by right-clicking the inlet type icon in the Outline View or by pressing on the buttons located at the bottom of the Inlet properties window. Two commands are currently supported.

Copies the Airflow settings into the Airflow submenu of the Inlet window when Edit is selected in Conditions.

Display

Displays the surface mesh of the Inlet type selected in the Graphics window.

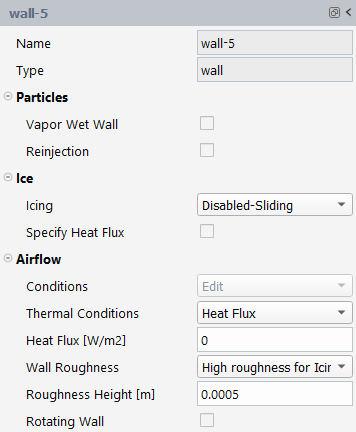

Ice accretion simulations require appropriate airflow, vapor and icing wall boundary conditions. The following figure shows each Wall boundary type supported by Fluent Icing.

Airflow

In the current version of Fluent Icing, all walls with no slip condition unless otherwise specified in the original case file. The no slip condition is a requirement for computing heat transfer coefficients on walls that are to be enabled for ice accretion.

The following table maps the Fluent Icing airflow wall boundary conditions to Fluent wall boundary conditions.

Mapping of Airflow Fluent Icing Wall Boundary Conditions into Fluent & FENSAP Boundary Conditions.

| Fluent Icing | Fluent | FENSAP |

|---|---|---|

| Thermal Conditions | --------- | |

| Temperature [K] | Temperature (k) | Temperature |

| Heat Flux [W/m2] | Heat Flux (w/m2) | Heat Flux |

| Wall Roughness | --------- | |

| High roughness for Icing | High Roughness (Icing) / Specified Roughness | Sand-grain roughness |

Thermal Conditions allows the specification of three types of energy equation boundary conditions at the wall.

Temperature [K]

If selected, specify a temperature at the wall. For ice accretion simulations over a wall, set a temperature that is equal to the adiabatic stagnation temperature + 10K. This temperature is used to compute convective heat transfer coefficients in the Ice module. Therefore, the Ice module will provide the actual temperature profile over the wall.

Heat Flux [W/m2]

If selected, specify a heat flux at the wall. If all walls of your computational domain are set to adiabatic conditions (zero heat flux), Fluent Icing will automatically activate EID. EID is a feature that improves the accuracy of icing calculations for high Mach number flows, important to accurately predict beak ice phenomenon. For more information regarding this model, consult Compute EID (Extended Icing Data) .

Case Settings

If selected, the thermal condition specified in the Fluent case file is used. For more information, consult Thermal Boundary Conditions at Walls within the Fluent User's Guide.

Wall Roughness allows you to specify two types of roughness properties at the wall.

High Roughness for Icing

If selected, specify a Roughness Height (m) at the wall. By default, Fluent Icing sets a Roughness Constant of 0.5 in Fluent. This value describes a uniform sand-grain roughness distribution. In FENSAP, the Roughness height (m) parameter always applies a constant roughness distribution and therefore the Roughness Constant parameter is not required. For ice accretion simulations over a specific wall, you should set the roughness height to

0.0005m which is a value commonly used during validation exercises. When running a multi-shot calculation, this value will either be replaced by the roughness distribution computed by the beading model at the previous shot, if selected in Setup → Ice, or remain constant during the entire multi-shot calculation. For more information regarding the High Roughness model, consult Additional Roughness Models for Icing Simulations in the Fluent User's Guide.Case Settings

If selected, the wall roughness condition specified in the Fluent case file is used. For more information, consult Setting the Roughness Parameters in the Fluent User's Guide.

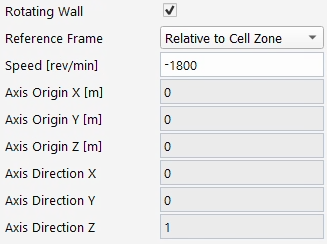

can be used to assign a rotation rate. Enabling this option will display the following rotation settings.

If the rotating domain contains static walls such as engine shrouds and bypass

splitters, these walls should be configured to have zero velocity in the

absolute reference frame. This can be done by setting Reference

Frame as and setting Speed

[rev/min] to 0 or with speed being the exact opposite of the domain

rotation rate. This is equivalent to setting walls as counter rotating in

FENSAP-ICE.

If the domain is rotating, then the walls can only have the same rotation axis and origin as the domain. Otherwise if the domain is fixed, it is possible to apply rotation to walls that are aligned with any axis and position.

For the steady state physics to be valid, walls set as must be axisymmetric.

Particles

Among all Particles type, the vapor model provides a wall boundary condition option that allows the walls to stay at 100% relative humidity and enables evaporation at these walls. To set this boundary condition check the Vapor Wet wall condition. This condition is usually not used in icing calculations. It is a useful feature to observe rates of evaporation and consequent vapor trail computed by the vapor transport PDE.

When the external reinjection model is enabled, the wall conditions involved in the reinjection process must be selected.

Note: It is required to select at least one wall for crystal bouncing.

Ice

Ice is computed over the walls of the computational domain. Two options are provided under Ice. The first Icing can be used to disable certain walls and exclude them from the computations. This could be used to enable an aircraft surface like the wing and/or the tail, while excluding the fuselage. The other option, , allows setting a heat flux on a wall to examine its impact on the ice accretion process. The latter could be used to quickly assess the amount of heat required to prevent ice formation, for instance.

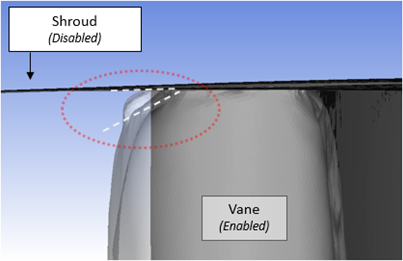

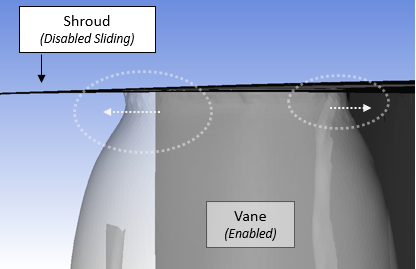

Icing, just under Ice, is divided into five options:

This is the default setting under Icing and it allows the wall to be part of the computational domain for icing.

If selected, it will exclude the wall from icing calculations.

If selected, the wall will be included in the solution of surface water film continuity and energy equations, but ice displacement will be deactivated. The wall will act as a sliding support surface for adjoining surfaces that could displace and slide against it following a contact boundary condition.

If selected, it will remove this wall from the continuity and energy system while using it as a sliding support surface for adjoining ice accreting walls to slide against. A typical use of this option is the handling of hub and shroud walls of an engine stator while the blade accretes ice.

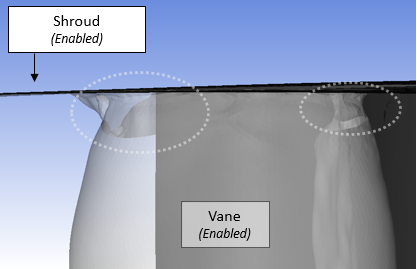

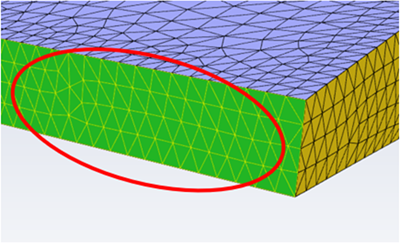

Note: The examples below illustrate how the options of , , and are affecting the results of icing calculations at the corner of the shroud and a guide vane attached to it. Figure 2.5: Wall Disabled shows the case where the shroud is disabled, and ice is only allowed to grow on the blade. This anchors the blade/shroud intersection nodes in place, and forces a tight concave space to form between the ice and the shroud. This can become a problem for multi-shot icing simulations if the remeshing algorithm cannot establish a good quality mesh at this region. Figure 2.6: Wall Disabled-Sliding shows the case where the shroud is set to , which allows the blade/shroud intersection nodes to slide across the shroud surface. This method has better success in remeshing during multi-shot icing simulations. Figure 2.7: Wall Enabled for Icing shows case where both the shroud and the blade are for icing calculations.

Sink

If selected, liquid water film will not be allowed to enter the wall and will act as an exit.

Built-in wall commands are available by right-clicking the Wall icon in the Outline View or by pressing on the buttons located at the bottom of the Wall properties window. Two commands are currently supported.

Temp. Adiabatic+10

Sets a temperature to the wall that is equal to the adiabatic stagnation temperature inside the Airflow settings panel, plus 10 K. In this manner, inside the Airflow submenu of the Wall properties panel, the Thermal Conditions will automatically switch to Temperature and the appropriate temperature will be shown next to Temperature [K].

Display

Displays the surface mesh of the wall selected in the Graphics window.

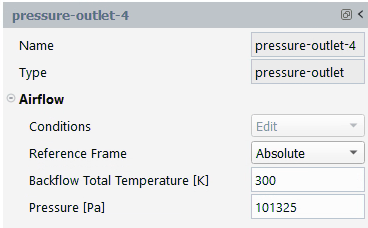

Pressure Outlet is currently the only outlet type supported by Fluent Icing.

Three fields can be modified through the properties window of that boundary condition. The Reference Frame, Backflow Total Temperature [K] and Pressure [Pa]. Reference Frame allows the outlets to be defined relative to a cell zone motion or in absolute reference frame. This does not apply to fixed cell zones. However, if a rotating domain is defined, the outlet properties can be defined relative to the domain motion. Temperature then controls the backflow air properties when reversed flow occurs and pressure corresponds to the absolute pressure at the outlet, the absolute pressure is the result of adding the operating pressure to the gauge pressure in Fluent. The absolute pressure is equal to the static pressure variable used in FENSAP to specify a subsonic outlet.

Note: If more Pressure Outlet settings are required, for instance more settings are needed to define flow reversal conditions at the outlet, you can add them inside the original case file or through the Fluent session connected to Fluent Icing.

If turbomachinery domains such as fan and compressor rows are being simulated, Radial Equilibrium option is recommended for more realistic physics. This can be enabled in the Fluent workspace for that particular boundary, and in Fluent Icing the boundary condition should be set to . If Conditions is set to , it can be reverted to through the right-click menu.

Built-in outlet type commands are available by right-clicking the outlet type icon in the Outline View or by pressing on the buttons located at the bottom of the Outlet properties window. Two commands are currently supported.

Copies the Airflow settings into the Airflow submenu of the Outlet.

Displays the surface mesh of the Inlet type selected in the Graphics window.

In Solution, you will define the solver settings of your Fluent Icing simulation including monitoring, initialization and output files for each of its Fluent Icing modules (Airflow, Particles and Ice). These solver settings will allow you to conduct the five simulation scenarios mentioned in Setup as long as they have been properly selected in the Setup window.

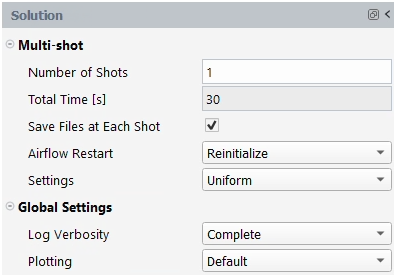

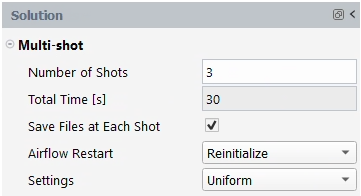

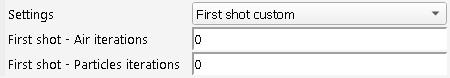

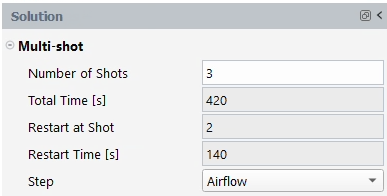

The Solution window provides the multi-shot and general settings for all Fluent Icing modules.

Multi-shot

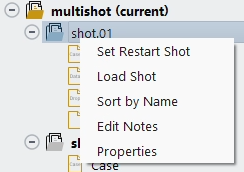

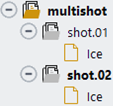

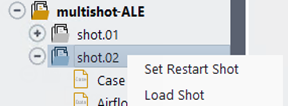

The Multi-shot menu under Solution is only available when all three solver types have been selected in the Setup window. See Multi-Shot. The total time of icing will be the sum of individual icing times set for each shot. By default, this is a uniform distribution and the per-shot time is entered in Solution → Ice. The shot time distribution can be modified by updating Settings from to . It is possible to restart from a step of a shot, by right-clicking an already partly or fully completed shot on the project panel and choosing :

Global Settings

This submenu sets the common output and monitoring settings of all Fluent Icing modules.

Log Verbosity

Controls the amount of convergence and execution information displayed (Minimal, Complete, Detailed) inside the Console window. Its content varies for each Fluent Icing module. Minimal is the default and will display a simplified convergence log (one line per iteration).

Plotting

Controls plotting of the residuals and any report set in the case file. Three options are supported.

Default will display the residual curves and any reports in the Plot window at every iteration.

Disabled will disable all plotting.

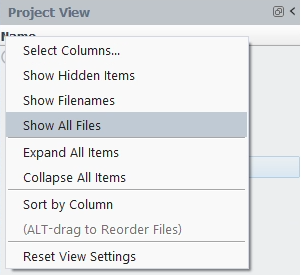

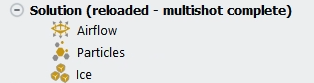

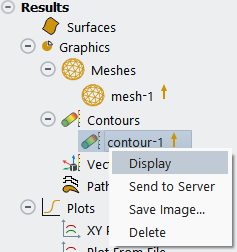

Fluent Icing components shown under Solution in the Outline View window are accompanied by an icon to their left. This icon reports if a solution file has been loaded or computed. The following table shows these icons.

| Airflow | Particles | Ice | |

|---|---|---|---|

| Solution not loaded or computed |

|

|

|

| Solution loaded or computed |

|  |

|

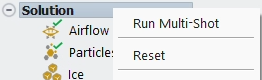

To run a multi-shot calculation, first complete the set-up of all the Fluent Icing modules under Solution, then right-click the Solution icon in the Outline View and select .

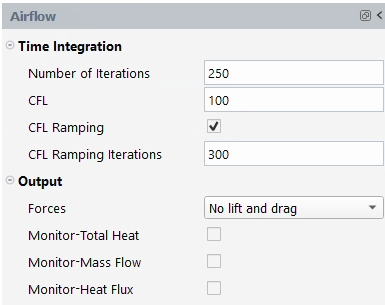

The Airflow window under Solution allows the configuration of the airflow solver, monitor and output parameters. Depending on the Airflow solver selected in Setup, the Airflow window will show either Fluent or FENSAP parameters. Only steady-state airflow simulations are supported in Fluent Icing.

Fluent Airflow

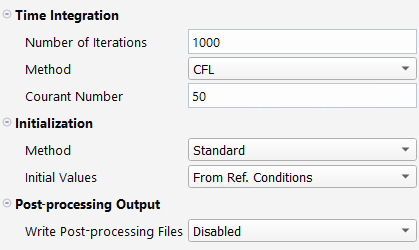

In this window, the Number of Iterations to run a steady calculation is supported.

Time Integration

Select the solution control method used by Fluent:

: Uses the current settings from the case file.

: Sets the solution control to method with the option to set the time scale factor.

: Sets the solution control to method with the option to set the Courant Number.

: Sets the solution control to method with the option to set the Initial Courant Number, the Maximum Courant Number, First to High Order Blending [%] and the Explicit Under-Relaxation Factor. ( is only supported for the solver)

Note: is the recommended time integration scheme, with a time scale factor of 0.001 – 0.01. If using , it is recommended to not exceed a of 10.

Initialization

Select the initialization method to be used by Fluent:

: Uses the current initialization settings from the case file.

: Performs the standard initialization by setting the Initial Values to the options below.

: The reference conditions defined in Setup → Airflow → Conditions.

: Values coming from an inlet boundary condition.

: User-defined initial values.

: Performs hybrid initialization.

Standard hybrid initialization of Fluent which computes an area weighted average of surface temperatures and applies it to the whole domain.

In Fluent Icing, this behavior is modified by patching the volume with the reference temperature after hybrid initialization is complete.

: Performs the FMG initialization with the specified FMG Courant Number.

Note: If FMG residuals are not decreasing, the initial solution will not be ideal to begin with. You can try lower values for the FMG Courant Number such as 0.2 to improve convergence.

See Fluent User's Guide in the Fluent User's Guide for more information about different initialization methods.

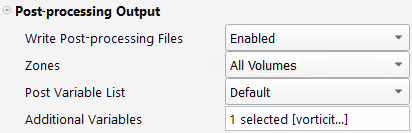

Moreover, it is also possible to specify the type solution output by selecting one of the three options inside Post-processing Output.

Default option. A Fluent solution (.dat, .dat.h5) is written and can be used to restart subsequent computations.

A Fluent solution and Post solution (.dat.post) are written.

Only a Post solution is written. No restart solution is written.

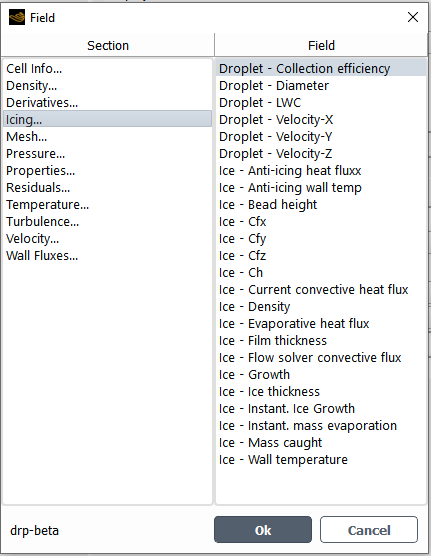

The Post solution file is used for post-processing purposes only. It can be read by the module, EnSight and CFD-Post. It does not contain all the information that it is necessary to resume a calculation and therefore it is considered to be lightweight to load when compared to a .dat or .dat.h5 file. When selecting or in Write Post-processing Files, several options are provided in order to define the content of the Post solution.

Zones

The post solution file is written using the full 3D domain.

Only selected surfaces (in the Surface Selection option below) are written to the file, leading to smaller file sizes but with no volumetric information.

Post Variable List

Select the list of variables written to the post file. Three options are available.

Velocity, Density, Temperature, Pressure, Heat Flux and Shear Stress fields are written.

Adds Mach Number, Viscosity, Thermal Conductivity, Cp, Wall Distance, Total Pressure, Total Temperature, Effective Viscosity and Pressure Coefficient to the post file.

Select the variables to be written to the post file from the list of variables that are available in Fluent post processing dataset.

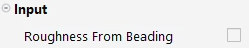

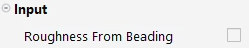

An additional option, Roughness from Beading, is available in this window when an Ice solution with beads has been previously run and loaded to your Fluent Icing simulation.

By enabling this option, the roughness distribution computed by the beads model will be applied as a boundary profile on all walls where the High roughness for Icing model has been enabled. The Roughness Height [m] of these walls will be updated to ICE3D Roughness file, which uses the ROUGHNESS boundary profile, the sand-grain beads profile, computed by Ice.

FENSAP Airflow Window

In this case, the Airflow window contains the most common steady-state solver and monitoring settings of the FENSAP airflow solver.

The Time Integration submenu allows the set-up of the

pseudo time step number, CFL, as well as the

Number of Iterations to use during the simulation. If

convergence problems are encountered, reduce the CFL or

activate the CFL Ramping Iterations option and specify a

number of CFL Ramping Iterations. This option gives access

to a mechanism that linearly increases the CFL number from

1, at the start of the simulation, to its full value

at the end of the CFL Ramping Iterations.

The Output submenu allows the creation of numbered solution files and of the most common monitoring variables to track in order to guarantee full convergence of the FENSAP solver.

Forces

By default, No lift and drag coefficients are outputted during the simulation. However, if Forces is set to Drag-Custom direction, the resultant lift, drag and moment coefficients (on all walls) will be monitored during the simulation. These aerodynamic coefficients are computed using the Conditions defined in Setup → Airflow and the following parameters.

Lift Axis

Provide the positive orientation of lift along the positive or negative X, Y and Z axis. FENSAP will obtain its true direction based on this information and the drag direction.

Drag – X, Drag – Y, Drag – Z

Provide the non-dimensional direction of drag in Cartesian coordinates.

Reference Area

Specify a reference area in m2 that is used to compute the aerodynamic coefficients.

Moment – X, Moment – Y, Moment – Z

Specify a point in the computational domain that will act as the moment center to compute the aerodynamic moment coefficient.

Monitor - Total Heat

If selected, monitors the total convective heat flux using all the walls of the computational domain.

Monitor -Mass Flow

If selected, monitors the mass inflow, outflow and deficit of air inside the computational domain.

Monitor -Heat Flux

If selected, monitors the total enthalpy inflow, outflow and deficit of the computational domain.

The Roughness from Beading is an additional option is available in this window when an Ice solution with beads has been previously run and loaded to your Fluent Icing simulation.

By enabling this option, the roughness distribution computed by the beads model will be applied as a boundary profile on all walls where the High roughness – Icing model has been enabled. The Roughness Height (m) of these walls will be updated to ICE3D Roughness file, which uses the ROUGHNESS boundary profile, sand-grain beads profile computed by Ice.

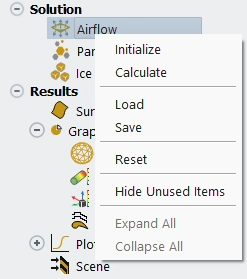

Airflow Commands

Built-in airflow commands are available by right-clicking the Airflow icon under Solution in the Outline View. The following commands are currently supported.

Executes an initialization of the airflow solver using the Initialization settings of Fluent. Initialize is not available for FENSAP. will also remove the green check mark next to the Airflow module icon and unbold the current airflow solution in the Project View.

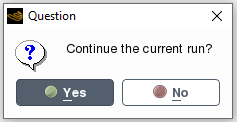

Launches the simulation of the Airflow module. If a solution is loaded, the simulation will continue from that loaded solution. Otherwise, Calculate will first Initialize and then use this solution to solve the PDEs of the Airflow module.

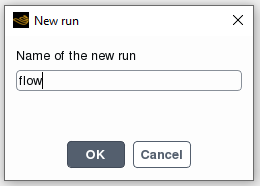

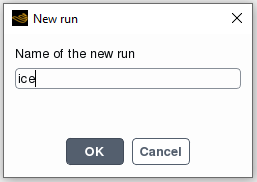

If a run has already been performed in the simulation, a window will appear asking if you would like to continue the current run. If , the calculation will continue in the current run folder. Once complete, a new solution file will overwrite the previous solution.

If is selected, a window appears asking for a Name of the new run. If is selected, a new run folder is created inside the simulation folder. This new folder contains a run settings file and all future solution files will be written in it.

If a solution is loaded in memory, the simulation will use it as an initial solution. Otherwise, will first Initialize and then compute the Airflow module.

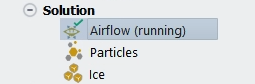

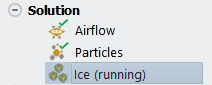

Once the Airflow module begins to run, (running) will be displayed next to the Airflow module in the object tree. This state will change to (ended) if the Airflow module completes properly, or (interrupted) if the run is interrupted.

Interrupt

Stops the execution of the airflow solver at the end of the next iteration. The solution is kept in memory. This option is only available if Airflow is currently running.

Load

Loads an airflow solution file into memory.

Save

Saves the airflow solution that’s in memory to a file.

Reset

Removes the airflow solution from memory. will also remove the green check mark next to the Airflow icon and unbold the current Airflow solution in the Project View.

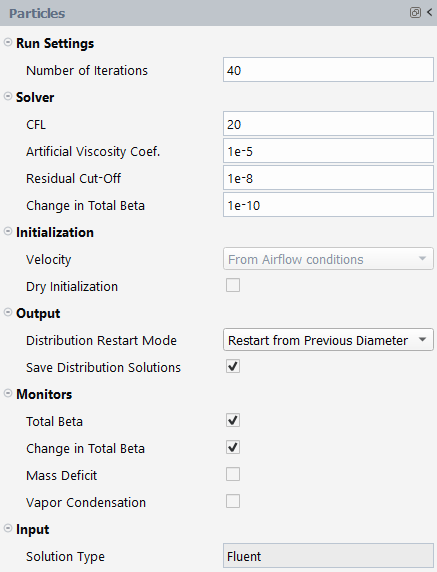

The Particles panel contains the most common steady-state solver, initialization and monitoring settings of the Fluent Icing Particles solver, DROP3D.

The Run Settings submenu allows the set-up of the Number of Iterations to conduct during the iterative simulation. A different Reinj. Number of Iterations is used to solve the reinjection loops.

The Solver submenu is divided into three points, the pseudo time step, the artificial viscosity and the convergence criteria.

CFL

The recommended values for the CFL range between

10and20. If convergence problems are encountered, reducing the CFL might help.Artificial Viscosity Coef.

The Particles module uses the Streamline upwind (SU) technique to stabilize the PDEs. This scheme is complemented with a user-set crosswind diffusion. Its default value is 1e-5 and has been extensively used in a large number of validation cases. In the case of structured grids, you can increase this value to 1e-4 if you experience oscillations of LWC within the shadow zone. Its impact to collection efficiency is generally minimal. Crosswind dissipation scales with mesh size, similar to the upwind scheme, and is lower with finer grids.

Residual Cut-Off

The Residual cut-off is the stopping criterion of the overall residual of the Particles governing equations. Lower the default value of 1e-8, especially if you are interested in capturing shadow zones.

Change in Total Beta

This parameter is the difference in total collection efficiency of all walls between two consecutive iterations. It is therefore a measure of convergence of the number of particles (droplets or crystals) that hit the walls of the computational domain. Lower the default value of 1e-10 if you see differences in collection efficiency between printouts.

Note: Both the Residual Cut-Off and Change in Total Beta thresholds can be increased a few orders to let DROP3D complete its runs quicker. Using 1e-6 and 1e-8 respectively can reduce the overall runtime significantly, while producing similar collection efficiency results. This is especially effective when running particle size distributions with large number of bins. You should verify the difference at least on a few sample cases before incorporating higher thresholds in your workflow.

The Initialization submenu allows the initialization of the particle concentration and particle velocity fields.

Velocity

Two initialization choices are offered for the velocity field.

From Airflow Conditions

If selected, the Speed and Direction inside of Setup → Airflow are used as the initial velocity of all types of particles at all nodes in the computational domain.

Cartesian components

If selected, specify the velocity components (X velocity [m/s], Y velocity [m/s] and Z velocity [m/s]) that will be assigned as the initial velocity for all particles inside the computational domain.

Dry Initialization

If selected, sets the particle concentration (LWC, ICC or Vapor Humidity) to zero everywhere inside the computational domain except at the inlet, where Particles boundary conditions are defined. Otherwise, the Particles concentration specified in Setup → Particles will be used to initialize the computational domain.

The Output submenu contains the following options:

Distribution Restart Mode

Select this option to initialize the solution fields of a droplet size with the results from the previously solved size. Depending on the case, this can decrease or increase the number of iterations needed to converge the droplet equations. For purely external flows, restarting from the previous diameter can be beneficial in reaching total beta convergence quicker. For flows with internal cavities, restarting from a previous solution may lead to some incorrect LWC that would have to be cleared with many iterations before reaching convergence. This is a case specific setting that should be studied before incorporating into the workflow of an analysis.

Save Distribution Solutions

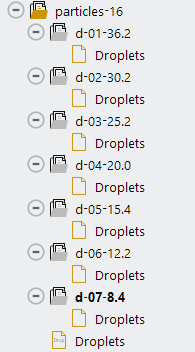

Select this option if you would like to save all the solutions of a distribution simulation. The solutions will be numbered from 1 to the total number of particles sizes that define this distribution. The number 1 will be assigned to the largest particle size and the last number to the smallest particle size.

Note: This option is only available when a Particles or Crystal Distribution is selected under Setup → Particles → Droplets → Droplet Distribution, or Particles → Crystals → Crystal Distribution.

The folder structure for a particles distribution run will contain one result per diameter. The last result, not within a folder, is the combined solution obtained by mass-averaging the results of individual droplet size solutions.

The Monitors submenu allows the tracking of convergence of surface integral quantities such as collection efficiency, mass deficit and vapor condensation.

Total Beta

If selected, monitors the total collection efficiency computed on all walls of the computational domain.

Change in Total Beta

If selected, monitors the difference in total collection efficiency of all walls between two consecutive iterations.

Mass Deficit

If selected, monitors the mass inflow, outflow and deficit of particles inside the computational domain.

Vapor Condensation

If selected, monitors the total vapor condensation on all the walls of the computational domain.

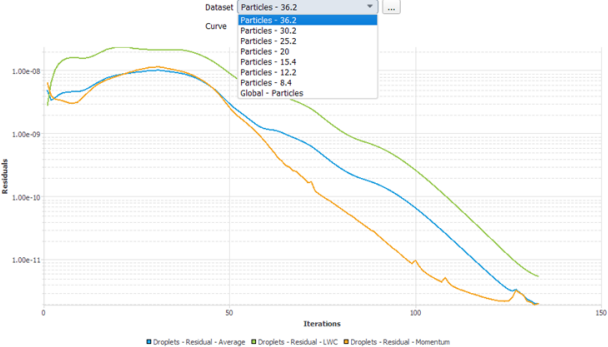

Note: In a particle distribution simulation, each particle size simulation is executed in sequence. The residuals graph is displayed at the end of the execution and will present a summary of the convergence of each calculation.

The residual graph is a combined plot of all the residual plots in a single sequence.

Particles Commands

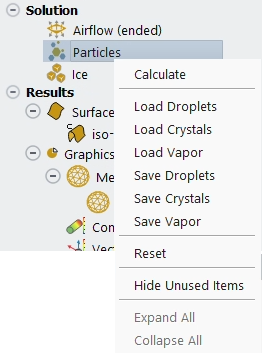

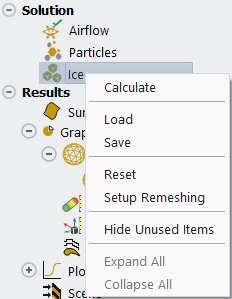

Built-in particles commands are available by right-clicking the Particles icon under Solution in the Outline View. The following commands are currently supported.

Calculate

Executes the Particles module.

If a run has already been performed in the simulation, a window will appear asking if should continue in the current run folder. If is selected, the calculation will continue in the current run folder, and once complete, a new solution file will overwrite the previous solution.

If is selected, a window appears asking for a Name of the new run. If is selected, a new run folder is created inside the simulation folder. This new folder contains a run settings file and all future solution files will be written in it.

If a solution is loaded before is selected, the simulation will continue from that loaded solution. Otherwise, will first initialize and then solve Particles.

Once the Particles module begins to run, (running) will be displayed next to the Particles in the object tree. This state will change to (ended) if the Particles module completes properly, or (interrupted) if the run is interrupted.

Interrupt

Stops the execution of the particles solver at the end of the next iteration. The solution is kept in memory.

Load Droplets

Loads a particles droplets solution, with suffix .droplet, in memory.

Load Crystals

Loads a particles crystals solution, with suffix .crystal, in memory.

Load Vapor

Loads a particles vapor solution, with suffix .vapor, in memory.

Save Droplets

Saves only the water droplet solution files of your Particles simulation. This droplet solution file will contain the suffix .droplet.

Save Crystals