PIPE288

3D 2-Node

Pipe

PIPE288 Element Description

The PIPE288 element is suitable for analyzing slender to moderately stubby pipe structures. The element is based on Timoshenko beam theory. Shear-deformation effects are included.

PIPE288 is a linear, quadratic, or cubic two-node pipe element in 3D. The element has six degrees of freedom at each node (the translations in the x, y, and z directions and rotations about the x, y, and z directions). The element is well-suited for linear, large rotation, and/or large strain nonlinear applications.

PIPE288 includes stress stiffness terms, by default, in any analysis with NLGEOM,ON. The provided stress-stiffness terms enable the elements to analyze flexural, lateral, and torsional stability problems (using eigenvalue buckling, or collapse studies with arc length methods or nonlinear stabilization).

Elasticity, hyperelasticity, plasticity, creep, and other nonlinear material models are supported. Internal fluid and external insulation are supported. Added mass, hydrodynamic added mass and loading, and buoyant loading are available.

PIPE288 Element Technology and Usage Recommendations

PIPE288 is based on Timoshenko beam theory, a first-order shear-deformation theory. Transverse-shear strain is constant through the cross-section; that is, cross-sections remain plane and undistorted after deformation.

The element can be used for slender or stout pipes. Due to the limitations of first-order shear-deformation theory, only moderately "thick" pipes can be analyzed. The slenderness ratio of a pipe structure (GAL2 / (EI) ) can be used to judge the applicability of the element, where:

- G

Shear modulus

- A

Area of the cross-section

- L

Length of the member (not the element length)

- EI

Flexural rigidity

For pipes, (GAL2 / EI) can be reduced to: 2L2 / ((1 + ν) (Ro2 + Ri2)), or for thin-walled pipes: L2 / ((1 + ν) R2), where ν = Poisson's ratio, Ro = outer radius, Ri = inner radius, and R = average radius.

The following illustration provides an estimate of transverse-shear deformation in a cantilever pipe subjected to a tip load. Although the results cannot be extrapolated to other applications, the example serves generally. Ansys, Inc. recommends a slenderness ratio greater than 30.

| Slenderness Ratio (GAL2/(EI)) | δ Timoshenko / δ Euler-Bernoulli |

|---|---|

| 25 | 1.120 |

| 50 | 1.060 |

| 100 | 1.030 |

| 1000 | 1.003 |

The PIPE288 element supports an elastic relationship between transverse-shear forces and transverse-shear strains.

When KEYOPT(3) = 0 (linear, default), PIPE288 is based on linear shape functions. It uses one point of integration along the length; therefore, all element solution quantities are constant along the length. For example, when SMISC quantities are requested at nodes I and J, the centroidal values are reported for both end nodes. This option is recommended if the element is used as stiffener and it is necessary to maintain compatibility with a first-order shell element (such as SHELL181). Only constant bending moments can be represented exactly with this option. Mesh refinement is generally required in typical applications.

When KEYOPT(3) = 2 (quadratic), PIPE288 has an internal node in the interpolation scheme, effectively making this a beam element based on quadratic shape functions. Two points of integration are used, resulting in linear variation of element solution quantities along the length. Linearly varying bending moments are represented exactly.

When KEYOPT(3) = 3 (cubic), PIPE288 has two internal nodes and adopts cubic shape functions. Quadratically varying bending moments are represented exactly. Three points of integration along the length are used, resulting in quadratic variation of element solution quantities along the length. Unlike typical cubic (Hermitian) formulations, cubic interpolation is used for all displacements and rotations.

In general, the more complex the element, the fewer elements are needed. Quadratic and cubic options are recommended when higher-order element interpolations are desired in situations where:

Nonuniform loads (including tapered distributed loads) exist within the element; in this case, the cubic option gives superior results over the quadratic option.

(For partially distributed loads and non-nodal point loads, only the cubic option is valid.)

The element may undergo highly nonuniform deformation (for example, when individual frame members in civil engineering structures are modeled with single elements).

PIPE288 supports both thin-pipe (KEYOPT(4) = 1) and thick-pipe (KEYOPT(4) = 2) options. The thin-pipe option assumes a plane stress state in the pipe wall and ignore the stress in the wall thickness direction. The thick-pipe option accounts for the full 3D stress state and generally leads to more accurate results in thick-walled pipes where through-the-thickness stress can be significant. The element allows change in cross-sectional area in large-deflection analysis. While the thick-pipe option can accurately determine the cross-section area change from the actual material constitutive properties, the thin-pipe option calculates the approximate area change based on a simple material incompressibility assumption. The thin pipe option runs slightly faster than the thick pipe option. The thick pipe option should generally be avoided for very thin-walled pipes (for example, Do/Tw > 200.0), and the thin pipe option should generally be avoided for somewhat thick-walled pipes (for example, Do/Tw < 100.0). The thick pipe option is required for a “solid” pipe section (Do/Tw = 2.0). For more information, see SECDATA.

Two limitations are associated with the quadratic and cubic options in PIPE288:

Although the elements employ higher-order interpolations, the initial geometry of PIPE288 is treated as straight.

Because the internal nodes are inaccessible, no boundary/loading/initial conditions are allowed on these internal nodes.

As a result of the limitations associated with the quadratic and cubic options, you will notice discrepancies in the results between PIPE289 and the quadratic option of PIPE288 if the midside nodes of the PIPE289 model have specified boundary/loading/initial conditions and/or the midside nodes are not located exactly at the element midpoint. Similarly, the cubic option of PIPE288 may not be identical to a traditional cubic (Hermitian) beam element.

For the mass matrix and load vectors, a higher order integration rule than that used for

stiffness matrix is employed. The elements support both consistent and lumped mass matrices.

LUMPM,ON activates lumped mass matrix. Consistent mass matrix is the default

behavior. You can add mass per unit length via the SECCONTROL

ADDMAS values. See "PIPE288 Input Summary".

When ocean loading is applied, the loading is nonlinear (that is, based on the square of the relative velocity between the structure and the water). Accordingly, the full Newton-Raphson option (NROPT,FULL) may be necessary to achieve optimal results. (Full Newton-Raphson is applied automatically in an analysis involving large-deflection effects (NLGEOM,ON).)

When KEYOPT(5) = 1, PIPE288 deforms in the XY plane only. It has three degrees of freedom at each node (translations in the x and y directions, and rotation about the z direction).

PIPE288 Input Data

The geometry, node locations, coordinate system, and pressure directions for this element are shown in Figure 288.1: PIPE288 Geometry. PIPE288 is defined by nodes I and J in the global coordinate system.

If ocean

loading is present, the global origin is normally at the mean sea level, with the global

Z axis pointing away from the center of the earth; however, the vertical location can be adjusted

via Zmsl (Val6) on

OCDATA (following OCTYPE,BASIC). Ocean loading is not supported for

PIPE288 in the XY plane (KEYOPT(5) = 1).

Because the section is round, the element orientation is important only for defining offsets and temperatures, and interpreting bending moment directions and stress locations.

Node K is the preferred method for defining the orientation of PIPE288 in 3D space (KEYOPT(5) = 0). For information about orientation nodes and beam meshing, see Generating a Beam Mesh With Orientation Nodes in the Modeling and Meshing Guide. See LMESH and LATT descriptions for information about generating the K node automatically.

PIPE288 in 3D space can also be defined without the orientation node. The element x axis is oriented from node I toward node J. When no orientation node is used, the default orientation of the element y axis is automatically calculated to be parallel to the global X-Y plane. If the element is parallel to the global Z axis (or within a 0.01 percent slope of it), the element y axis is oriented parallel to the global Y axis. To control the element orientation about the element x axis, use the orientation-node option. If both are defined, the orientation-node option takes precedence. The orientation node K, if used, defines a plane (with I and J) containing the element x and z-axes (as shown). If this element is used in a large-deflection analysis, the location of the orientation node K only initially orients the element.

The orientation of PIPE288 in the XY plane is determined by the location of nodes I and J. The element x axis is oriented from node I (end 1) toward node J (end 2). The element y axis is along the negative global Z axis. Orientation node K is not needed.

The pipe element is a one-dimensional line element in space. The cross-section details are provided separately (SECTYPE and SECDATA). A section is associated with the pipe elements by specifying the section ID number (SECNUM). A section number is an independent element attribute.

PIPE288 Cross-Sections

PIPE288 can be associated only with the pipe cross-section (SECTYPE,,PIPE). The material of the pipe is defined as an element attribute (MAT).

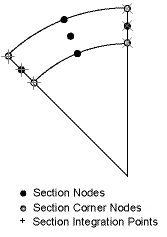

PIPE288 is provided with section-relevant quantities (area of integration, position, etc.) automatically at a number of section points (SECDATA). Each section is assumed to be an assembly of a predetermined number of cells and is numerically integrated.

Section Flexibility

You can apply section-flexibility factors (SFLEX), valid only for linear material properties and small strain analyses. Offsets, temperature loading, and initial-state loading are not supported. Stress output is based on the section forces, including axial force, bending moments, torsional moment, transverse shear forces, and pressures; strain output is based on the nodal displacements.

PIPE288 Loads

Element loads are described in Element Loading. Internal fluid and external insulation are supported. Added mass (including for ocean loading), hydrodynamic added mass, and hydrodynamic and buoyant loading, are available (OCDATA and OCTABLE). Ocean loading is not supported for PIPE289 in the XY plane (KEYOPT(5) = 1).

Forces are applied at the nodes I and J. If the centroidal axis is not colinear with the

element x axis because of offsets, applied axial forces will cause bending. The nodes should

therefore be located at the desired points where you want to apply the forces. Use the

OFFSETY and OFFSETZ arguments

(SECOFFSET) appropriately. By default, the program uses the centroid as the

reference axis for the pipe elements.

Pressure Input

Internal and external pressures are input on an average basis over the element. Lateral pressures are input as force per unit length. End "pressures" are input as forces.

To input surface-load information on the element faces, issue SFE

On faces 1 and 2, internal and external pressures are input, respectively, on an average basis over the element.

On face 3, the input (VAL1) is the global Z coordinate of the free

surface of the internal fluid of the pipe. Specify this value with

ACEL,0,0,ACEL_Z, where

ACEL_Z is a positive number. The free surface coordinate is used for

the internal mass and pressure effects. If VAL1 on

SFE is zero, no fluid inside of the pipe is considered. If the internal

fluid free surface should be at Z = 0, use a very small number instead. The pressure calculation

presumes that the fluid density above an element to the free surface is constant. For cases

where the internal fluid consists of more than one type of fluid (such as oil over water), the

free surface coordinate of the elements in the fluids below the top fluid need to be adjusted

(lowered) to account for the less dense fluid(s) above them. VAL1

does not update with large deflections (NLGEOM,ON); if changes are necessary,

you can reissue SFE at later load steps.

The internal fluid mass is assumed to be lumped along the centerline of the pipe, so as the centerline of a horizontal pipe moves across the free surface, the mass changes in step-function fashion. The free surface location is stepped, even if you specify ramped loading (KBC,0).

On face 4 and face 5, lateral pressures are input as force-per-unit-length.

On face 6 and face 7, end "pressures" are input as forces.

Faces 4 through 8 are shown by the circled numbers in Figure 288.1: PIPE288 Geometry.

Temperature Input

When KEYOPT(1) = 0, temperatures can be input as element body loads at the inner and outer surfaces at both ends of the pipe element so that the temperature varies linearly through the wall thickness. If only two temperatures are specified, those two temperatures are used at both ends of the pipe element (that is, there is no gradient along the length). If only the first temperature is specified, all others default to the first. The following graphic illustrates temperature input at a node when KEYOPT(1) = 0:

When KEYOPT(1) = 1, temperatures can be input as element body loads at three locations at both nodes of the pipe element so that the temperature varies linearly in the element y and z directions. At either end of the element, temperatures can be input at these locations:

At the element x axis (T(0,0))

At the outer radius from the x axis in the element y direction (T(Ro,0)) (not supported for (KEYOPT(5) = 1)

At the outer radius from the x axis in the element z direction (T(0,Ro))

The following graphic illustrates temperature input at a node when KEYOPT(1) = 1:

Element locations (T(Y,Z)) are given according to the convention used in Figure 288.1: PIPE288 Geometry.

For pipe elements, element body-load commands (BFE) accept an element number and a list of values, 1 through 6 for temperatures TI(0,0), TI(1,0), TI(0,1), TJ(0,0), TJ(1,0), and TJ(0,1). This input can be used to specify temperature gradients that vary linearly both over the cross section and along the length of the element. Values of TI(1,0) and TJ(1,0) are ignored for PIPE288 in the XY plane (KEYOPT(5) = 1).

The following defaults apply to element temperature input:

If all temperatures after the first are unspecified, they default to the first. This pattern applies a uniform temperature over the entire element. (The first coordinate temperature, if unspecified, defaults to TUNIF.)

If all three temperatures at node I are input, and all temperatures at node J are unspecified, the node J temperatures default to the corresponding node I temperatures. This pattern applies a temperature gradient that varies linearly over the cross section but remains constant along the length of the element.

For any other input pattern, unspecified temperatures default to TUNIF.

Alternatively, temperatures at nodes I and J can be defined

using nodal body loads (BF,NODE,TEMP,VAL1). This specifies a uniform

temperature over the cross section at the specified node.

Other Input

The effects of pressure load stiffness are automatically included for this element. If an unsymmetric matrix is needed for pressure load stiffness effects, issue NROPT,UNSYM.

PIPE288 Input Summary

- Nodes

I, J, K (an optional but recommended orientation node) if KEYOPT(5) = 0 I, J if KEYOPT(5) = 1 - Degrees of Freedom

UX, UY, UZ, ROTX, ROTY, ROTZ if KEYOPT(5) = 0 UX, UY, ROTZ if KEYOPT(5) = 1 - Section Information

- Material Properties

TB command: See Element Support for Material Models for this element. MP command: EX, EY, EZ, PRXY, PRYZ, PRXZ (or NUXY, NUYZ, NUXZ), ALPX, ALPY, ALPZ (or CTEX, CTEY, CTEZ or THSX, THSY, THSZ), DENS, GXY, GYZ, GXZ, ALPD, BETD, DMPR, DMPS - Surface Loads

- Pressure --

face 1 – Internal pressure face 2 – External pressure face 3 – Z coordinate of free surface of fluid on inside of pipe (not applicable if KEYOPT(5) = 1) face 4 – (I-J) (-z normal direction) face 5 – (I-J) (-y normal direction) (not applicable if KEYOPT(5) = 1) face 6 – (I-J) (+x tangential direction) face 7 – (I) (+x axial direction) face 8 – (J) (-x axial direction) --- I and J denote end nodes. Use a negative value for loading in the opposite direction. Input pressure values for faces 1, 2, and 3 via SFE. Input pressure values for faces 4 through 8 via SFBEAM. For faces 4, 5, and 6, offsets apply only for the cubic option (KEYOPT(3) = 3).

- Body Loads

- Temperatures --

TOUT(I), TIN(I), TOUT(J), TIN(J) if KEYOPT(1) = 0.

TAVG(I), Ty(I), Tz(I), TAVG(J), Ty(J), Tz(J) if KEYOPT(1) = 1.

- Special Features

- KEYOPT(1)

Temperature input

- 0 --

Through wall gradient

- 1 --

Diametral gradient

- KEYOPT(3)

Shape functions along the length:

- 0 --

Linear

- 2 --

Quadratic

- 3 --

Cubic

- KEYOPT(4)

Hoop strain treatment

- 1 --

Thin pipe theory

- 2 --

Thick pipe theory

- KEYOPT(5)

Deformation occurs in 3D space or XY plane:

- 0 --

3D space (default)

- 1 --

XY plane

- KEYOPT(6)

End cap loads

- 0 --

Internal and external pressures cause loads on end caps

- 1 --

Internal and external pressures do not cause loads on end caps

- KEYOPT(7), KEYOPT(9), KEYOPT(11), and KEYOPT(12)

Active only when OUTPR,ESOL is active:

- KEYOPT(7)

Output control for section forces/moments and strains/curvatures:

- 0 --

Output section forces/moments, strains/curvatures, internal and external pressures, and effective tension(default)

- 1 --

Same as KEYOPT(7) = 0 plus current section area

- 2 --

Same as KEYOPT(7) = 1 plus element basis directions (X,Y,Z)

- 3 --

Output section forces/moments, strains/curvatures, internal and external pressures, and effective tension

- KEYOPT(8)

Shear stress output:

- 0 --

Output a combined state of the following two types (default)

- 1 --

Output only torsion-related shear stresses

- 2 --

Output only flexure-related transverse-shear stresses

- KEYOPT(9)

Output control at integration points:

- 0 --

None (default)

- 1 --

Maximum and minimum stresses/strains

- 2 --

Same as KEYOPT(9) = 1 plus stresses and strains at each section node

- KEYOPT(11)

Output control for values extrapolated to the element and section nodes:

- 0 --

None (default)

- 1 --

Maximum and minimum stresses/strains

- 2 --

Same as KEYOPT(11) = 1 plus stresses and strains along the exterior boundary of the cross-section

- 3 --

Same as KEYOPT(11) = 1 plus stresses and strains at all section nodes

- KEYOPT(12)

Hydrodynamic output (not available in harmonic analyses that include ocean wave effects (HROCEAN)):

- 0 --

None (default)

- 1 --

Additional hydrodynamic printout

- KEYOPT(15)

Results file format:

- 0 --

Store averaged results at each section corner node (default).

- 1 --

Store non-averaged results at each section integration point. (The volume of data may be excessive.)

PIPE288 Output Data

The solution output associated with these elements is in two forms:

Nodal displacements and reactions included in the overall nodal solution

Additional element output as described in Table 288.1: PIPE288 Element Output Definitions

For ways to view results, see the Basic Analysis Guide.

To view 3D deformed shapes for PIPE288, issue

OUTRES,MISC or OUTRES,ALL for static or transient

analyses. To view 3D mode shapes for a modal or eigenvalue buckling analysis, expand the modes

with element results calculation active (via Elcalc = YES on

MXPAND).

Linearized Stress

It is customary in pipe design to employ components of axial stress that contribute to axial loads and bending in each direction separately; therefore, PIPE288 provides a linearized stress output as part of its SMISC output record, as indicated in the following definitions:

SDIR is the stress component due to axial load.

SDIR = Fx/A, where Fx is the axial load (SMISC quantities 1 and 14) and A is the area of the cross-section.

SByT and SByB are bending stress components.

| SByT = -Mz * R0 / I |

| SByB = Mz * R0 / I |

| SBzT = My * R0 / I |

| SBzB = -My * R0 / I |

where My, Mz are bending moments in the beam coordinate system (SMISC quantities 2,15,3,16) as shown in Figure 288.1: PIPE288 Geometry, R0 is the outside radius, and I is the moment of inertia of the cross-section. The program uses the maximum and minimum cross-section dimensions.

Corresponding definitions for the component strains are:

| EPELDIR = Ex |

| EPELByT = -Kz * R0 |

| EPELByB = Kz * R0 |

| EPELBzT = Ky * R0 |

| EPELBzB = -Ky * R0 |

where Ex, Ky, and Kz are generalized strains and curvatures (SMISC quantities 7,8,9, 20,21 and 22).

The reported stresses are strictly valid only for elastic behavior of members. PIPE288 always employs combined stresses in order to support nonlinear material behavior. When the elements are associated with nonlinear materials, the component stresses can at best be regarded as linearized approximations and should be interpreted with caution.

When using KEYOPT(9) with the cubic option (KEYOPT(3) = 3), the integration point at the middle of the element is reported last in the integration-point printout.

PIPE288 Element Output Definitions

In the table below, the O column indicates the availability of the items in the file Jobname.out. The R column indicates the availability of the items in the results file.

In either the O or R columns, “Y” indicates that the item is always available, a number refers to a table footnote that describes when the item is conditionally available, and “-” indicates that the item is not available.

For the stress and strain components, x refers to axial, y refers to hoop, and z refers to radial.

Table 288.1: PIPE288 Element Output Definitions

| Name | Definition | O | R |

|---|---|---|---|

| EL | Element number | Y | Y |

| NODES | Element connectivity | Y | Y |

| MAT | Material number | Y | Y |

| C.G.:X, Y, Z | Element center of gravity | Y | 1 |

| Area | Area of cross-section | 2 | Y |

| S:x, y, z, xy, yz, xz | Section point stresses | 3 | Y |

| EPEL:x, y, z, xy, yz, xz | Elastic strains | 3 | Y |

| EPTO:x,y,z xy, yz, xz | Section point total mechanical strains (EPEL + EPPL + EPCR) | 3 | Y |

| EPTT:x,y,z xy, yz, xz | Section point total strains (EPEL + EPPL + EPCR + EPTH) | 3 | Y |

| EPPL:x, y, z, xy, yz, xz | Section point plastic strains | 3 | Y |

| EPCR:x, y, z, xy, yz, xz | Section point creep strains | 3 | Y |

| EPTH:x, y, z, xy, yz, xz | Section point thermal strains | 3 | Y |

| NL:SEPL | Plastic yield stress | - | 4 |

| NL:SRAT | Plastic yielding (1 = actively yielding, 0 = not yielding) | - | 4 |

| NL:HPRES | Hydrostatic pressure | - | 4 |

| NL:EPEQ | Accumulated equivalent plastic strain | - | 4 |

| NL:CREQ | Accumulated equivalent creep strain | - | 4 |

| NL:PLWK | Plastic work/volume | - | 4 |

| SEND:ELASTIC, PLASTIC, CREEP | Strain energy densities | - | 4 |

| TQ | Torsional moment | Y | Y |

| TE | Torsional strain | Y | Y |

| SFy, SFz | Section shear forces | 2 | Y |

| SEy, SEz | Section shear strains | 2 | Y |

| Ky, Kz | Curvature | Y | Y |

| Ex | Axial strain | Y | Y |

| Fx | Axial force (excluding insulation) | Y | Y |

| My, Mz | Bending moments | Y | Y |

| INT PRESS | Internal pressure at integration point | 5 | 5 |

| EXT PRESS | External pressure at integration point | 5 | 5 |

| EFFECTIVE TENS | Effective tension at integration point | 5 | 5 |

| SDIR | Axial direct stress | - | 2 |

| SByT | Bending stress on the element +Y side of the pipe | - | 2 |

| SByB | Bending stress on the element -Y side of the pipe | - | 2 |

| SBzT | Bending stress on the element +Z side of the pipe | - | 2 |

| SBzB | Bending stress on the element -Z side of the pipe | - | 2 |

| EPELDIR | Axial strain at the end | - | Y |

| EPELByT | Bending strain on the element +Y side of the pipe | - | Y |

| EPELByB | Bending strain on the element -Y side of the pipe | - | Y |

| EPELBzT | Bending strain on the element +Z side of the pipe | - | Y |

| EPELBzB | Bending strain on the element -Z side of the pipe | - | Y |

| TEMP | Temperatures at all section corner nodes | - | Y |

| LOCI:X, Y, Z | Integration point locations | - | 6 |

| SVAR:1, 2, ... , N | State variables | - | 7 |

| The following values apply to ocean loading only and are averaged values for the element: [8] | |||

| GLOBAL COORD | Element centroid location | 9 | Y |

| VXY, VZ | Horizontal and vertical fluid particle velocities (VXY is always > 0) | 9, 10 | Y |

| AR, AZ | Radial and vertical fluid particle accelerations | 9 | Y |

| PHDYN | Dynamic fluid pressure head | 9 | Y |

| ETA | Wave amplitude over center of element | 9 | Y |

| TFLUID | Fluid temperature (printed if VISC is nonzero) | 9 | Y |

| VISC | Viscosity (output if VISC is nonzero) | 9 | Y |

| REN, RET | Normal and tangential Reynolds numbers (if VISC is nonzero) | 9 | Y |

| CT | Input tangential drag coefficients evaluated at Reynolds numbers | 9 | Y |

| CDY, CDZ | Input normal drag coefficients evaluated at Reynolds numbers | 9 | Y |

| CMY, CMZ | Input inertia coefficients evaluated at Reynolds numbers | 9 | Y |

| URT, URN | Tangential (parallel to element axis) and normal relative velocities | 9 | Y |

| ABURN | Vector sum of normal (URN) velocities | 9 | Y |

| ARN | Relative accelerations normal to element | 9 | Y |

| FX, FY, FZ | Hydrodynamic tangential and normal forces per unit length in element coordinates | 9 | Y |

| ARGU | Effective position of wave (radians) | 9 | Y |

Available only at the centroid as a *GET item, or on the NMISC record for ocean loading.

Available if the element has a nonlinear material, or if large-deflection effects are enabled (NLGEOM,ON) for SEND.

Available only if ocean loading is present.

Available only if OUTRES,LOCI is used.

Available only if the UserMat subroutine and TB,STATE are used.

Values are given as the average of the hydrodynamic integration points, which are distributed along the wetted portion of the element.

Applies to ocean loading only.

More output is described via the PRESOL and *GET,,SECR in POST1.

PIPE288 Item and Sequence Numbers

Table 288.2: PIPE288 Item and Sequence Numbers lists output available for ETABLE and ESOLusing the Sequence Number method. See Creating an Element Table and The Item and Sequence Number Table in this reference for more information. The table uses the following notation:

- Name

output quantity as defined in Table 288.1: PIPE288 Element Output Definitions

- Item

predetermined Item label for ETABLE

- E,I,J

sequence number for data at nodes E, I and J

Table 288.2: PIPE288 Item and Sequence Numbers

| Output Quantity Name | ETABLE and ESOL Command Input | |||

|---|---|---|---|---|

| Item | E | I | J | |

| Fx | SMISC | -- | 1 | 14 |

| My | SMISC | -- | 2 | 15 |

| Mz | SMISC | -- | 3 | 16 |

| TQ | SMISC | -- | 4 | 17 |

| SFz | SMISC | -- | 5 | 18 |

| SFy | SMISC | -- | 6 | 19 |

| Ex | SMISC | -- | 7 | 20 |

| Ky | SMISC | -- | 8 | 21 |

| Kz | SMISC | -- | 9 | 22 |

| TE | SMISC | -- | 10 | 23 |

| SEz | SMISC | -- | 11 | 24 |

| SEy | SMISC | -- | 12 | 25 |

| BM | SMISC | -- | 27 | 29 |

| BK | SMISC | -- | 28 | 30 |

| SDIR | SMISC | -- | 31 | 36 |

| SByT | SMISC | -- | 32 | 37 |

| SByB | SMISC | -- | 33 | 38 |

| SBzT | SMISC | -- | 34 | 39 |

| SBzB | SMISC | -- | 35 | 40 |

| EPELDIR | SMISC | -- | 41 | 46 |

| EPELByT | SMISC | -- | 42 | 47 |

| EPELByB | SMISC | -- | 43 | 48 |

| EPELBzT | SMISC | -- | 44 | 49 |

| EPELBzB | SMISC | -- | 45 | 50 |

| TEMP | SMISC | -- | 51-53 | 54-56 |

| INT PRESS [1] | SMISC | -- | 61 | 65 |

| EXT PRESS [1] | SMISC | -- | 62 | 66 |

| EFFECTIVE TENS [1] | SMISC | -- | 63 | 67 |

| S:x, y, z, xy, yz, xz | LS | -- | CI[2], DI[3] | CJ[2], DJ[3] |

| EPEL:x, y, z, xy, yz, xz | LEPEL | -- | CI[2], DI[3] | CJ[2], DJ[3] |

| EPTH:x, y, z, xy, yz, xz | LEPTH | -- | CI[2], DI[3] | CJ[2], DJI[3] |

| EPPL:x, y, z, xy, yz, xz | LEPPL | -- | CI[2], DI[3] | CJ[2], DJ[3] |

| EPCR:x, y, z, xy, yz, xz | LEPCR | -- | CI[2], DI[3] | CJ[2], DJ[3] |

| EPTO:x, y, z, xy, yz, xz | LEPTO | -- | CI[2], DI[3] | CJ[2], DJ[3] |

| EPTT:x, y, z, xy, yz, xz | LEPTT | -- | CI[2], DI[3] | CJ[2], DJ[3] |

| NL: SEPL, SRAT, HPRES, EPEQ, CREQ, PLWK | NLIN | -- | EI[4], FI[5] | EJ[4], FJ[5] |

| Area | NMISC | -- | 29 | 30 |

| The following output quantities are valid for ocean loading only: [8] | ||||

| GLOBAL COORD | NMISC | 1, 2, 3 | -- | -- |

| VXY, VZ | NMISC | 4, 5 | -- | -- |

| AR, AZ | NMISC | 6, 7 [6] | -- | -- |

| PHDYN | NMISC | 8 [6] | -- | -- |

| ETA | NMISC | 9 [6] | -- | -- |

| TFLUID | NMISC | 10 | -- | -- |

| VISC | NMISC | 11 | -- | -- |

| REN, RET | NMISC | 12, 13 [7] | -- | -- |

| CT | NMISC | 14 | -- | -- |

| CDY, CDZ | NMISC | 15, 16 | -- | -- |

| CMY, CMZ | NMISC | 17, 18 [6] | -- | -- |

| URT, URN | NMISC | 19, 20, 21 | -- | -- |

| ABURN | NMISC | 22 [6] | -- | -- |

| ARN | NMISC | 23, 24 [6] | -- | -- |

| FX, FY, FZ | NMISC | 25, 26, 27 | -- | -- |

| ARGU | NMISC | 28 [6] | -- | -- |

Internal pressure (INT PRESS), external pressure (EXT PRESS), and effective tension (EFFECTIVE TENS) occur at integration points, and not at end nodes.

CI and CJ are the sequence numbers for accessing the averaged line element solution quantities (LS, LEPEL, LEPTH, LEPPL, LEPCR, LEPTO, and LEPTT) at RST section nodes (section corner nodes where results are available), at element Node I and J respectively. CI and CJ are applicable only when KEYOPT(15) = 0. For a given section corner node

nn, CI and CJ are given as follows:CI = (

nn- 1) * 6 + COMPCJ = (

nnMax+nn- 1) * 6 + COMPWhere

nnMaxis the total number of RST section nodes, and COMP is the stress or strain component (1 - x, 2 - y, 3 - z, 4 - xy, 5 - yz, 6 - xz). Locations of RST section nodes can be visualized with SECPLOT,,6.DI and DJ are the sequence numbers for accessing the non-averaged line element solution quantities (LS, LEPEL, LEPTH, LEPPL, LEPCR, LEPTO, and LEPTT) at RST section integration points (section integration points where results are available), at element Node I and J respectively. DI and DJ are applicable only when KEYOPT(15) = 1. For the

ith integration point (i= 1, 2, 3, or 4) in section cellnc, DI and DJ are given as follows:DI = (

nc- 1) * 24 + (i- 1) * 6 + COMPDJ = (

ncMax+nc- 1) * 24 + (i- 1) * 6 + COMPWhere

ncMaxis the total number of RST section cells, and COMP is the stress or strain component (1 - x, 2 - x, 3 - z, 4 - xy, 5 - yz, 6 - xz). Locations of RST section cells can be visualized with SECPLOT,,7.EI and EJ are the sequence numbers for accessing the averaged line element nonlinear solution quantities (NLIN) at RST section nodes (section corner nodes where results are available), at element Node I and J, respectively. EI and EJ are applicable only when KEYOPT(15) = 0. For a given section corner node

nn, EI and EJ are given as follows:EI = (

nn- 1) * 10 + COMPEJ = (

nnMax+nn- 1) * 10 + COMPwhere

nnMaxis the total number of RST section nodes, and COMP is the nonlinear element solution component (1 - SEPL, 2 - SRAT, 3 - HPRES, 4 -EPEQ, 5 - CREQ, 6 - PLWK). Locations of RST section nodes can be visualized via SECPLOT,,6.FI and FJ are the sequence numbers for accessing the nonaveraged line element nonlinear solution quantities (NLIN) at RST section integration points (section integration points where results are available), at element Node I and J, respectively. FI and FJ are applicable only when KEYOPT(15) = 1. For a given section integration point (

i= 1, 2, 3, or 4) in section cellnc, FI and FJ are given as follows:FI = (

nc- 1) * 40 + (i- 1) * 10 + COMPFJ = (

ncMax+nc- 1) * 40 + (i- 1) * 10 + COMPwhere

ncMaxis the total number of RST section cells and COMP is the nonlinear element solution component (1 - SEPL, 2 - SRAT, 3 - HPRES, 4 - EPEQ, 5 - CREQ, 6 - PLWK). Locations of RST section cells can be visualized via SECPLOT,,7.These quantities are output only if a Reynold's number dependency is used.

Values are given as the average of the hydrodynamic integration points, which are distributed along the wetted portion of the element.

For more usage details, see Plot and Review the Section Results in the Structural Analysis Guide and Example: Problem with Cantilever Beams in the Structural Analysis Guide.

Transverse-Shear Stress Output

The shear stresses are caused by torsional and transverse loads. PIPE288 is based on first-order shear-deformation theory, also popularly known as Timoshenko beam theory. The transverse-shear strain is constant for the cross-section; therefore, the shear energy is based on a transverse-shear force. This shear force is redistributed by predetermined shear stress distribution coefficients across the pipe cross-section, and made available for output purposes. Use KEYOPT(8) to activate output of shear stresses caused by flexure or transverse loading.

By default, the program uses a mesh density (for cross-section modeling) that provides accurate results for torsional rigidity, warping rigidity, inertia properties, and shear center determination. The default mesh employed is also appropriate for nonlinear material calculations; however, more refined cross-section models may be necessary if the shear stress distribution due to transverse loads must be captured very accurately. Issue SECDATA to adjust cross-section mesh density.

The traction-free state at the edges of the cross-section is met only in a well-refined model of the cross-section.

The transverse-shear distribution calculation ignores the effects of Poisson's ratio. The Poisson's ratio affects the shear correction factor and shear stress distribution slightly, and this effect is ignored.

PIPE288 Assumptions and Restrictions

The pipe cannot have zero length.

Cross-section distortion or collapse is not considered.

The element works best with the full Newton-Raphson solution scheme (the default option in solution control).

Only moderately "thick" pipes can be analyzed. See "PIPE288 Element Technology and Usage Recommendations" for more information.

The element supports an elastic relationship between transverse-shear forces and transverse-shear strains.

Stress stiffening is always included in geometrically nonlinear analyses (NLGEOM,ON). Prestress effects can be activated via PSTRES.

Hydrodynamic output via KEYOPT(12) is not available in harmonic analyses that include ocean wave effects (HROCEAN).

For a random vibration (PSD) analysis, equivalent stress is not calculated.

Temperature-dependent density of the internal fluid is evaluated at an average temperature of the element. Temperature-dependent density of the insulation is evaluated at an average temperature at each integration point along the length.

PIPE288 Product Restrictions

When used in the product(s) listed below, the stated product-specific restrictions apply to this element in addition to the general assumptions and restrictions given in the previous section.

Ansys Mechanical Pro —

Birth-and-death is not available.

Initial state is not available.

Ocean loading is not available.