Use NLAD-ETCHG to change the element type (according to specified criteria) during solution, either to simulate some problems which otherwise cannot be simulated or to improve the accuracy of simulation results. Nonlinear mesh adaptivity on the tetrahedral mesh is enabled automatically after the element-type change.

NLAD-ETCHG is available for 3D analyses only, and for models with hex-dom meshes using SOLID185 or SOLID186. After the program converts the hex-dom mesh, the new tetrahedral mesh type is SOLID187.

NLAD-ETCHG applies to both large-deformation (NLGEOM,ON) and small-deformation (NLGEOM,OFF) analyses:

The mesh-quality-based criterion applies only to large-deformation problems.

Refinement-type criteria (energy-based (NLADAPTIVE,,,ENERGY) and position-based (NLADAPTIVE,,,BOX)) apply to both large- and small-deformation problems.

To determine how best to apply NLAD-ETCHG, consider the following:

Refinement-driven NLAD-ETCHG is ideally suited to small-deformation (NLGEOM,OFF) analysis or elastoplastic problems with large deformation (NLGEOM,ON).

A mechanistically consistent higher-order tetrahedral-element mesh generated via NLAD-ETCHG provides a high-quality base tetrahedral mesh for subsequent refinement (via conventional mesh adaptivity). A quality tetrahedral mesh helps to capture local deformations in more detail, useful in applications such as rubber sealing for small cavities, local necking, or local buckling with solution progress. Refinement via general remeshing refines the mesh when used with an energy-based (NLADAPTIVE,,,ENERGY) or position-based (NLADAPTIVE,,,BOX) criterion.

At the first refinement of the SOLID185 or SOLID186 component to a SOLID187 component (via NLAD-ETCHG), the program maintains the tetrahedral element edge length so that it remains the same as that of the hex-dom original element edge length (guaranteeing element volume reduction). This procedure creates a high-quality base tetrahedral mesh, enabling the solution to capture local stress/strain effects accurately. Subsequent refinement of the SOLID187 component by the same criteria driving the NLAD-ETCHG operation reduces the element edge to approximately 75 percent of the original, and may also create transition layers to connect the refined regions to the unrefined regions. NLAD-ETCHG via general remeshing can remove mesh-distortion problems when used with the mesh-quality-based criterion.

The mesh-quality-based criterion typically applies to large-deformation (NLGEOM,ON) problems. As with conventional nonlinear adaptivity, using this criterion for small-deformation (NLGEOM,OFF) problems is not meaningful because the remeshing occurs on the initial mesh only, as the reference coordinates are unchanged during a small-deformation analysis. Because hex-dom meshes can usually model large deformation better than small deformation, NLAD-ETCHG can occur at a later point in the load history. The later conversion generally leads to a more efficient solution with a quality higher-order tetrahedral mesh, as the tetrahedral remeshings need not occur in the early stages of the solution. At the first general remeshing of the SOLID185 or SOLID186 component to a SOLID187 component (via NLAD-ETCHG), the program uses mesh-distortion criteria for hex-dom elements to trigger the mesh type conversion to tetrahedral. Mesh gradation and density are maintained in the same way as for tetrahedral remeshing. This operation provides a quality base tetrahedral mesh for subsequent remeshing as more loading is applied.

Subsequent remeshing of the SOLID187 component uses mesh-distortion criteria for higher-order tetrahedral elements. The remeshings occurs automatically as additional loading causes more element distortion in the model.

Note: The NLAD-ETCHG substep at which the hex-dom mesh is converted to the tetrahedral mesh cannot occur at the same substep where a conventional tetrahedral element NLAD is requested from other parts of the model.

Following are the supported analysis types, elements, materials, loads, boundary conditions, and other NLAD-ETCHG requirements:

| Support Category | Support Details | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Solid elements | |||||||||||||||

|

Contact elements |

| ||||||||||||||

|

Contact pair behavior |

| ||||||||||||||

|

Surface-effect elements | |||||||||||||||

|

Materials | |||||||||||||||

| Analysis types |

| ||||||||||||||

| |||||||||||||||

| Region to be remeshed[n] |

|

[a] KEYOPT 2 = 0, full integration with B-bar method.

[b] Pure displacement formulation (KEYOPT(6) = 0) and mixed u-P (KEYOPT(6) = 1).

KEYOPT(6) values are maintained while remeshing from hex-dom (SOLID185, SOLID186) to tetrahedral (SOLID187).

Material-type IDs are maintained while remeshing from hex-dom (SOLID185, SOLID186) to tetrahedral (SOLID187).

[c] KEYOPT 2 = 0, (Uniform Reduced Integration), KEYOPT 2 = 1 (full integration).

[d] NLADAPTIVE does not support elements with dropped mid-side nodes in element.

[e] General contact is not supported.

[f] For flexible-to-flexible contact pairs, any large initial penetration approaching or exceeding a single-element depth may cause remeshing to fail. In such cases, Ansys, Inc. recommends assigning different material and/or element types to the contacting bodies.

[g] The newly generated contact elements and flexible target elements conform to the quadratic triangular face of the newly generated SOLID187 elements.

[i] For linear analyses with linear elastic

materials and small-deflection effects

(NLGEOM,OFF), the iterative

Newton-Raphson solution procedure is set

automatically. The smallest possible number of

substeps must also be set (either directly via

NSUBST or indirectly via

DELTIM) to a value that ensures

remeshing. Guidance for setting the number of

substeps can be taken from the

NLADAPTIVE,,ON,VAL1

value specifying the remeshing frequency.

[j] Do not remove nodal constraints (DDELE, FDELE, BFDELE, SFDELE) during solution before remeshing.

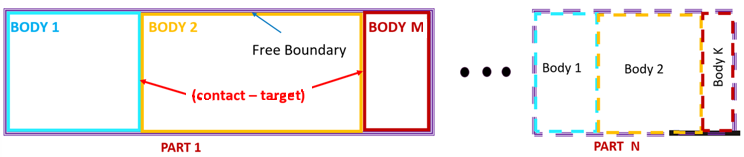

[k] Remeshable components for NLAD-ETCHG can only be defined on bodies that do not have compatible mesh boundaries with other bodies. By definition, bodies are bound by free surfaces and/or by contact-target interfaces where mesh compatibility is not enforced on neighboring bodies. For example, see Figure 4.1: Multipart Multibody Schematic. Components for NLAD-ETCHG can only be defined on full bodies (1, 2, M, etc.).

[n] Initial state, element birth and death, and cyclic symmetry analysis are not supported.

[o] For initially coarse meshes on curved surfaces, the Euler rotation angles of the nodes may be improperly interpolated onto the newly meshed region of the same curved surfaces. If applied nodal boundary conditions (such as displacement) exist on those nodes, they are mapped incorrectly, as the boundary conditions are specified on the local nodal coordinate system (defined by the Euler angles). Curved surfaces should therefore have a reasonably fine mesh. Adjacent nodes on a boundary cannot have different nodal coordinate systems, if this boundary is selected for remeshing.

As shown in Figure 4.1: Multipart Multibody Schematic, NLAD-ETCHG criteria are applied on element components. Those components must be defined and selected before issuing the first SOLVE.

NLAD-ETCHG does not require restart files (unless the analysis is run using distributed-memory parallel processing). Issuing RESCONTROL,,NONE, however, is neither necessary nor allowed.

Restarting from a given substep in a nonlinear mesh adaptivity analysis require the .rdnn and .rnnn files (in addition to other restart files). For information about how to write those files, see RESCONTROL.

Simultaneous remeshing of a SOLID185 component (via NLAD-ETCHG) and another SOLID187 component (via standard nonlinear mesh adaptivity) is not allowed.

During the NLAD-ETCHG solution procedure, only components defined with nonlinear adaptive criteria are preserved.

Elements in the region are not remeshed if:

the elements in the same region have more than one component name, and

a nonlinear adaptive criterion associated with one of the component names is disabled.

NLAD-ETCHG remeshes the entire component, as shown:

For problems with multiple load steps, operations referencing node numbers (such as applying body-force loads (BF) or defining degrees of freedom at nodes (D)) on the initial mesh but scoped across the load steps are not allowed.

NLAD-ETCHG does not support nonlinear stabilization, initial-mesh loading and constraint, or mesh-coarsening options.

NLAD-ETCHG components have the following additional properties, in addition to being scoped on a whole body:

All hex-dom elements in the component must have the same material type.

All hex-dom elements in the component must have the same KEYOPT(6) value.

All hex-dom elements in the component must have the same real number.

All hex-dom SOLID186 elements in a component must have the same KEYOPT(2) value.

The component cannot have these combinations of element types:

A mixture of components, each with a separate element topology, is generally not allowed.

The coordinate-truncation defaults for nodal locations of meshes during remeshing (NLMESH,TCOR) work well in most cases. Modify them with caution.

If coordinate truncation is disabled (NLMESH,TCOR,OFF), solution repeatability is affected due to the finite-precision arithmetic used by Mechanical APDL.

In cases where coordinate truncation is enabled (NLMESH,TCOR,ON) but the target, contact, or surface elements are not generating properly, or the loads and boundary conditions are not being mapped properly, try disabling coordinate truncation to improve the solution.

The character string "_NLAD" is invalid. When using general remeshing for refinement or for removing distortion, the character string "_NLAD" cannot appear in component names, in the job name, or in the main title of input defined via /TITLE.

External constraint equations and coupling constraint equations (CE and CP) are not supported.

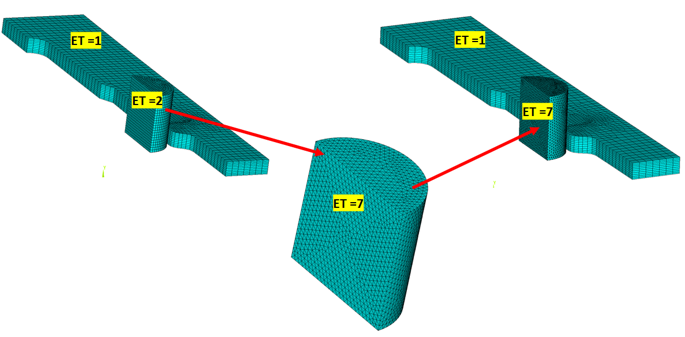

After using NLAD-ETCHG to convert the elements in the component (as in Figure 4.2: SOLID185 Component (ET = 2) Remeshed with SOLID187 (ET = 7), for example), you can use standard nonlinear mesh adaptivity on the component.

The NLAD-ETCHG process closely mirrors the standard nonlinear mesh adaptivity process.

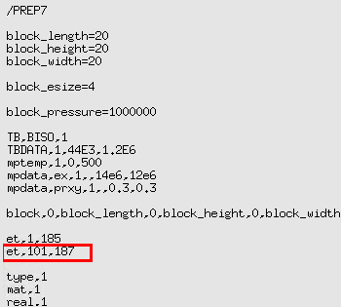

A newly defined SOLID187 element type, and input commands (NLADAPTIVE) on hex-dom components (one with an additional argument), suffice for enabling NLAD-ETCHG:

When the solution begins, the NLAD-ETCHG process is automatic and requires no further input.

4.2.2.1. Specify the Replacement (SOLID187) Element Type

Specify the desired new (tetrahedral) element type, SOLID187, that will replace the SOLID185 or SOLID186 element types in the nonlinear adaptive component during the NLAD-ETCHG process.

Specify the desired replacement SOLID187 element type

(ET_NEW) as a new NLADAPTIVE

argument:

NLADAPTIVE,,ON,,,,,,ET_NEW |

As shown in the example input, the second NLADAPTIVE

command differs from the first by the addition of a

VAL4 argument, as shown:

NLADAPTIVE, Component,

Action, Criterion,

Option, VAL1,

VAL2, VAL3,

VAL4 |

VAL4 identifies a

SOLID185/SOLID186

component as a candidate for remeshing. If VAL4 is

unspecified, remeshing does not occur on the component.

In this example, the nonlinear adaptivity component

comp1 is comprised of a hex-dom

SOLID185 mesh. The first NLADAPTIVE

command checks for the remeshing criteria (energy in this case) at the specified

frequencies. If any SOLID185 element in the component

is flagged by the criteria, the entire comp1 component is

remeshed with a SOLID187 mesh (element type

(ET) 101 in the example).

The remeshed SOLID187 component is subsequently checked against the same criteria at the same frequency for the remainder of the analysis. Standard remeshing rules apply for SOLID187, implying that partial remeshing is now possible after this step.

A hex-dom component is scoped to the whole body and cannot share a nodally compatible interface with any other mesh (as shown in Figure 4.1: Multipart Multibody Schematic). A hex-dom component can be bounded only by surfaces that are free, have boundary conditions or loads, or contact and target elements.

As shown in Figure 4.2: SOLID185 Component (ET = 2) Remeshed with SOLID187 (ET = 7), the remeshed component (ET = 7) is a body that does not share a nodally compatible interface with the rest of the bodies and is bounded by contact/target elements and free surfaces.

NLAD-ETCHG criteria-checking is performed at the end of each specified

substep (according to the specified checking frequency) after it converges.

(The frequency of criteria-checking is set via

VAL1 and Action =

ON on NLADAPTIVE.) After generating a new mesh, the

program moves to the next substep and conventional tetrahedral-element-based

criteria-checking commences at the same frequency for further tetrahedral

remeshing. If a given substep is the last of a load step, the mesh remains

unchanged.

The following topics about criteria-checking in NLAD-ETCHG are available:

This part of the nonlinear mesh adaptivity process defines regions of the model for which nonlinear adaptivity is to be applied.

Components (with SOLID185 or SOLID186) are defined as shown in Figure 4.1: Multipart Multibody Schematic. The same component cannot have both SOLID185 and SOLID186 elements. You can define multiple NLAD-ETCHG criteria on the same component as in standard nonlinear mesh adaptivity. If all criteria are activated (NLADAPTIVE,ON) at the same substep, mesh-quality-based criteria take precedence and others are ignored.

If an element has unsupported nonlinear adaptive criteria, or the analysis type is not supported, the criteria or the element's contribution to nonlinear adaptivity are ignored.

Elements in the same region can have different component names so that the same type of criteria with the same options but different values (NLADAPTIVE) can be applied. The components must be defined and selected before issuing the first SOLVE.

During solution, the NLAD-ETCHG criteria are checked for each component to determine if elements should be remeshed from SOLID185/SOLID186 to SOLID187, or if the SOLID187 elements should be remeshed after the component no longer has hex-dom elements.

Based on the criteria, the program first remeshes the hex-dom elements to tetrahedral elements on the first remesh attempt. In subsequent substeps, at the specified frequency, either refinement or remesh happens on the tet elements generated in the first remesh. Surface, target, and contact elements are regenerated automatically when solid elements underneath remeshed.

NLAD-ETCHG criteria remain active until overwritten by a new command. The criteria can be modified between load steps and upon restart. Defined criteria can also be deleted or listed. For more information, see NLADAPTIVE.

This part of the NLAD-ETCHG process defines the frequency at which nonlinear mesh adaptivity criteria are checked during solution.

The frequency is problem- and criterion-dependent. Too-frequent checking can slow the simulation and cause premature conversion of the hex-dom meshes to tetrahedral meshes, eliminating the advantage of NLAD-ETCHG to better model hex-dom mesh deformation.

Checking too infrequently (especially in analyses with large-deformation) can cause the hex-dom mesh to be too distorted. In such cases, creating a mechanistically consistent tetrahedral mesh is difficult, as solution and contact-element result-mapping becomes inaccurate.

For more information, see Specifying Criteria-Checking Frequency.