Use nonlinear mesh adaptivity to control the mesh quality during a nonlinear solution. The process is defined by nonlinear adaptivity criteria in three additional inputs before the solution. When the solution begins, the process is automatic and requires no further input.

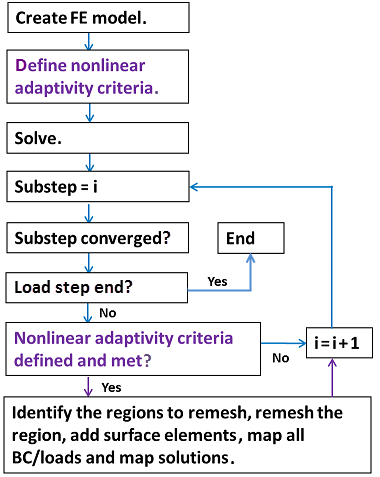

The following flowchart shows the general process during solution when nonlinear mesh adaptivity is activated:

Nonlinear adaptivity criteria-checking is performed at the end of each specified

substep (according to the specified checking frequency) after it converges. (The

frequency of criteria-checking is set via VAL1 and

Action = ON on NLADAPTIVE.) After

generating a new mesh, the program moves to the next substep. If a given substep is

the last of a load step, the mesh remains unchanged.

The following topics about checking nonlinear adaptivity criteria are available:

This part of the nonlinear mesh adaptivity process defines regions of the model for which nonlinear adaptivity is to be applied.

Contact and target element components can have only contact-based criteria applied. Solid elements can have all other criteria applied; mesh-quality-based criteria can be combined with them. If all criteria are activated (NLADAPTIVE,ON) at the same substep, mesh-quality-based criteria take precedence and others are ignored.

If an element has unsupported nonlinear adaptive criteria, or the analysis type is not supported, the criteria or the element’s contribution to nonlinear adaptivity are ignored.

Elements in the same region can have different component names so that the same type of criteria with the same options but different values (NLADAPTIVE) can be applied. The components must be defined and selected before issuing the first SOLVE.

During solution, the nonlinear mesh adaptivity criteria are checked for each component to determine if elements should be split or remeshed.

Based on the criteria, the program splits or remeshes solid elements. Surface, target, and contact elements are regenerated when solid elements underneath are split or remeshed.

Nonlinear adaptivity criteria remain active until overwritten by a new command. The criteria can be modified between load steps and upon restart. Defined criteria can also be deleted or listed. For more information, see NLADAPTIVE.

This part of the nonlinear mesh adaptivity process defines the frequency at which nonlinear mesh adaptivity criteria are checked during solution.

The frequency is problem- and criterion-dependent. Too-frequent checking can slow the simulation, but checking too infrequently can result in local deformations being missed during solution or remeshing to occur later than needed to solve the problem.

For more information, see Specifying Criteria-Checking Frequency.