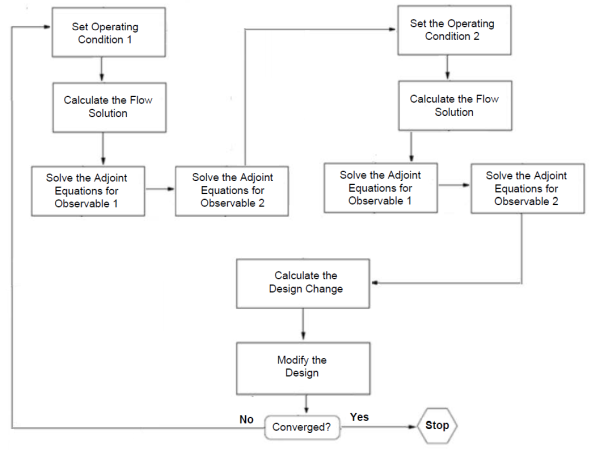

This section describes the process for loading the adjoint solver module, as well as setting up, running, and postprocessing the adjoint solutions. This section also demonstrates how the adjoint solution can guide the modification of the boundary shapes or turbulence model parameters.

The typical use of the adjoint solver involves the following steps (though not all of these may be necessary for every workflow):

Load or compute a conventional flow solution.

Specify the observable(s) of interest.

Set the adjoint solver controls.

Set the adjoint solver monitors and convergence criteria.

Initialize the adjoint solution and iterate to convergence.

For shape optimization:

Postprocess the adjoint solution to extract the sensitivity of the observable with respect to the boundary condition settings and the shape of the geometry.

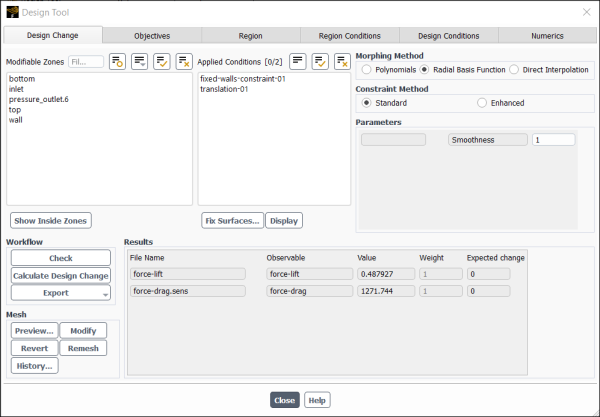

Set up the Design Tool and calculate the optimal design change.

Modify the boundary shapes based on shape-sensitivity data and recompute the flow solution. The former can be done through the Design Tool, whereas multiple iterations of both the former and the latter can be performed by the Gradient-Based Optimizer.

For turbulence model optimization:

Postprocess the adjoint solution to extract the sensitivity of the observable with respect to the turbulence model settings and the shape of the geometry.

Use the Gradient-Based Optimizer and Turbulence Model Design Tool to modify the turbulence model parameters based on flow-sensitivity data and construct an augmented turbulence model.

This section provides information about using the Ansys Fluent adjoint solver in the following sections:

In addition, see the Fluent Tutorials for more information about using the adjoint solver. (To access tutorials and their input files, go to the tutorials area of the customer site.)

The current adjoint solver implementation provides basic adjoint solutions that accompany a conventionally-computed flow solution provided certain criteria are met.

The adjoint solver is implemented on the following basis:

The flow state is for a steady single-phase flow, or ideal gas, that is either laminar or turbulent.

For turbulent flows, the k-ε and k-ω models are supported. When the adjoint turbulence equation is not enabled, a frozen turbulence assumption is made, in which the effect of changes to the state of the turbulence is not taken into account when computing sensitivities. When the adjoint turbulence equation is enabled with the GEKO turbulence model, the effect of changes to the state of the turbulence will be taken into account when computing sensitivities.

The adjoint solver supports both user-defined scalar (UDS) and species transport equations, up to 50 adjoint UDS/adjoint species equations can be specified. When the adjoint UDS/adjoint species equations are not enabled, a frozen UDS/frozen species assumption is made, where the effect of changes to the state of the UDS/species are not taken into account when computing sensitivities. When the adjoint UDS/adjoint species equations are enabled, the effect of changes to the state of the UDS/species will be taken into account when computing sensitivities.

Adjoint species is supported for the following species models and species settings:

Species Transport model

Chemistry Solver

None - Direct Source

Stiff Chemistry Solver

Volumetric reactions

Diffusion Energy Source species transport options

All Turbulence-Chemistry Interaction options.

For details on these settings see Species Model Dialog Box.

The adjoint solver does not support 2d axisymmetric cases.

For moving (that is, non-inertial) reference frame problems, the single reference frame (SRF) and multiple reference frame (MRF) approaches are supported (as long as the absolute velocity formulation is used), while the mixing plane model (MPM) is not. Note that for the MRF approach, the adjoint solver does not support having a zone with a frame of motion that is relative to an already moving reference frame.

Solid zones are supported, as long as they do not use a moving reference frame approach.

By default, the adjoint solver uses spatial discretization methods that are chosen for stability. If desired, you can select more accurate methods, as described in Using the Adjoint Solution Methods Dialog Box.

The adjoint solver supports constant values for all material properties; non-constant functions are only supported for the following. If you are using a non-constant function not included in this list, the sensitivity accuracy may be reduced; even so, for most cases the sensitivity results will still provide useful information.

Density :

ideal-gas

incompressible-ideal-gas

piecewise-linear

piecewise-polynomial

polynomial

expression (as a function of temperature only)

Cp (Specific Heat) :

piecewise-linear

piecewise-polynomial

polynomial

nasa-9-piecewise-polynomial

kinetic-theory

Thermal Conductivity :

piecewise-linear

piecewise-polynomial

polynomial

expression (as a function of temperature only)

kinetic-theory

Viscosity

piecewise-linear

piecewise-polynomial

polynomial

expression

power-law

sutherland

kinetic-theory

Mass Diffusivity

constant-dilute-appx

dilute-approx

unity-lewis-number

UDS Diffusivity

polynomial

expression (as a function of temperature or pressure)

The boundary conditions are only of the following types:

Wall boundaries are supported with the following limitations:

Thin walls and shells are not supported.

Only Heat Flux, Temperature, and via System Coupling are supported for Thermal walls.

Only No Slip is supported for the Shear Condition.

Velocity inlet

Mass-flow inlet

Mass-flow outlet

Pressure inlet

Pressure outlet

Note that the Prevent Reverse Flow option is not considered in the adjoint calculation.

Pressure far-field

Symmetry

Rotational and translation periodic

Most of the boundary conditions in the above list can be defined using profiles, however, ensure that there are no warnings as described below upon initializing the adjoint solver.

Constant and user-defined sources defined by either an expression or UDF are supported for the momentum equation and for scalar transport equations such as the energy equation, turbulence equations, and UDS/species transport equations. See User-Defined Sources for details.

It is important to note that these requirements are not strict conditions for the conventional flow solver, but rather modeling limitations for the adjoint solver.

When the adjoint solver is initialized or an observable is evaluated, and before iterations are performed, a series of checks is performed to determine the suitability of the existing flow solution for analysis with the adjoint solver. Two types of message may appear:

Warning message: There are certain physics models and boundary condition types that are not explicitly modeled in the adjoint solver, but their absence does not disallow you from proceeding with the calculation. In this case, a warning message will be printed that explains the nature of the inconsistency.

Checking adjoint setup... -- Warning: Model is active but not included in adjoint calculation: P1 radiation model Done

The adjoint solver will still run in this case but the quality of the adjoint solution data can be expected to be poorer as a result of the inconsistency. This is because in such cases the unsupported settings will revert to corresponding supported settings for the adjoint solver. Though the calculation will proceed, it is important to note that the results produced should be considered on this basis. When reverting back to the fluid calculation, the original settings will be preserved and the modified settings are not migrated onto the original case. The warning indicates that the setting change will be made automatically and specifically for the adjoint solution.

Error message: There are some model and boundary conditions that are incompatible with the computation of an adjoint solution with the current adjoint solver implementation. In this case, an explanatory error message will be printed in the console window.

Checking adjoint setup... ** Unable to proceed: Model is active but not compatible with adjoint calculation: Transition SST turbulence model Done

The adjoint solver will not run in this case and changes must be made manually to the settings identified in the console before the solver can be run.

User-defined sources can be created for the momentum equation or for scalar

transport equations such as the energy equation, turbulence equations, species

transport equations, and user-defined scalar (UDS) transport equations.

User-defined sources that are defined in compiled UDFs can be accounted for in

the application of the adjoint solver, provided that the source derivatives with

respect to flow variables and cell centroid coordinates are provided. This is

achieved by creating the source term UDF definition in the usual fashion, with

the exception that a special UDF macro is used,

DEFINE_SOURCE_AE (The suffix

_AE denotes Adjoint Enabled).

DEFINE_SOURCE_AE (name ,

c, t ,

dS, eqn)

|

Argument Type |

Description |

|---|---|

|

|

UDF name |

|

|

Index that identifies cell on which the source term is to be applied |

|

|

Pointer to cell thread |

|

|

Array that contains the derivative of the source term with respect to the dependent variable of the transport equation, as well as the flow variables and cell centroid position |

|

|

Equation number |

Function returns

real

Consider a source that may depend on velocity, pressure, cell-centroid coordinates, temperature, tke coefficient, omega equation, uds equations, and species equations:

Where,

,

, and

are the Cartesian velocity components in the cell.

is the pressure in the cell.

are the cell centroid coordinates as defined by the

C_CENTROIDmacro.is the temperature in the cell.

is the value of the turbulence kinetic energy in the cell.

is the specific dissipation rate in the cell.

is the (n)th user defined scalar in the cell.

is the (n)th species mass fraction in the cell.

If the source strength depends on one or more of these quantities, then the

derivatives of the source strength with respect to those variables must be

computed and filled in as entries to the dS[] array. In

particular,

|

|

|

|

|

|

|

|

|

|

|

|

|

|

must be defined in the UDF if there is a dependency of the source upon them. The specification of this derivative information is essential for sensitivities, including shape sensitivity, to be computed correctly by the adjoint solver.

Defining an observable is a key initial step that must be performed for any adjoint calculation. The observable is the quantity for which sensitivities are sought. Observables can be defined based on flow variables, or as operations on other observables. For a list of the types of observables you can define refer to General Observables and General Operations. You can define multiple observables, but only one observable at a time can be selected for the adjoint sensitivity calculation.

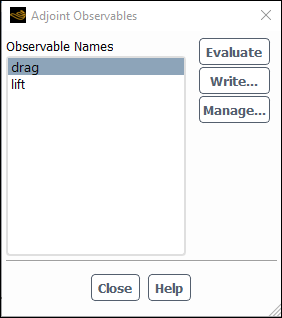

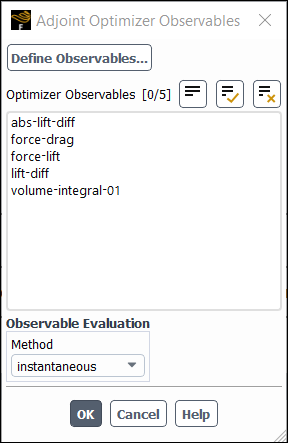

Observables are created and selected in the Adjoint Observables dialog box, which is accessed by clicking in the Design ribbon tab (Gradient-Based group box). (Figure 48.1: Adjoint Observables Dialog Box).

Design →

Gradient-Based →

Observable...

For more information, see the following sections:

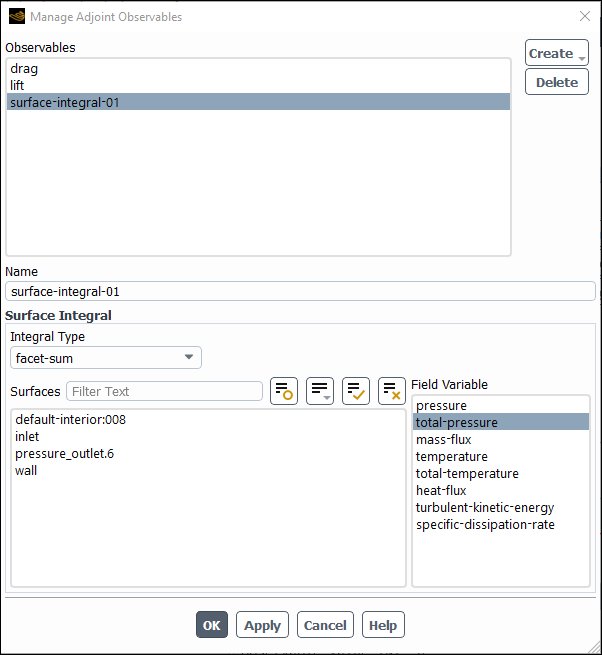

You can create a new observable by defining a single valued expession or by clicking Manage... in the Adjoint Observables dialog box and then Create... in the Manage Adjoint Observables dialog box.

From the Create... drop-down list you can choose from several observable types and operation types. Various types of observable quantities can be defined and the available types of observables are described in General Observables.

From the Observable types drop-down you can pick an observable from the list. Similarly, you can select an operation from the Operation types drop-down list. You can also select an observable to combine existing observables in various ways or apply unary operations to create a wide variety of compound observables. The operations that you can apply to existing observables are described in General Operations.

Once selected, you must edit the definition of the new observable within the Manage Adjoint Observables dialog box( Editing Observable Definitions).

Once an observable is created, it appears in the Observables list. When you select an observable in the Observables list, the Manage Adjoint Observables dialog box changes to expose various properties that can be assigned for the selected observable.

Once the observable properties are defined (Inputs for Observable Types), click Apply to apply the settings and proceed to define other observables, or click in the Manage Adjoint Observables dialog box to apply the settings and close the dialog box. Available observables are described in General Observables.

Note: It is permissible to leave observable definitions incomplete. The Manage Adjoint Observables dialog box can be considered as a workspace for the definition and manipulation of observables. Only those operations with complete definitions will appear in the Adjoint Observables dialog box. Operations with undefined fields, or operations that depend on themselves, will be excluded from the list of usable observables.

Inputs for Observable Types

The inputs for each type of observable are summarized below:

Select the walls that are to contribute to the force of interest in the Wall Zones list.

Define the direction in which the force is to be computed by entering the components of this direction in the X Component, Y Component, and Z Component (for 3D) fields.

For a moment of force observable:

Enter the X, Y , and Z (for 3D) components of the Moment Center.

Enter the X, Y, and Z (for 3D) components of the Moment Axis.

Select a wall in the Wall Zones list.

Enter the X, Y, and Z (for 3D) components of the Swirl Center.

Enter the X, Y, and Z (for 3D) components of the Swirl Axis.

Select a fluid in the Fluid Zones list.

For a pressure-drop observable:

Select the inlets and outlets between which the total pressure drop is to be computed using the Inlets and Outlets lists.

For a fixed value observable, perform the following:

Enter the Value of the Constant.

For a surface-integral observable:

Select the type of integral from the Integral Type drop-down list. Available integral types are described in General Observables.

Select a Surface and the corresponding Field Variable.

For a volume-integral observable:

Select the type of integral from the Volume Integral Type drop-down list. Available integral types are described in General Observables.

Select the Field Variable of interest. If the chosen field variable is a vector quantity, you will need to specify a Direction along which the field variable will be evaluated.

If using the Target-volume-integral as the Volume Integral Type, specify the user-defined memory location of your target field variable data from the Target Field (User Define Memory) drop-down list.

Under Integration Domain, select whether to integrate over selected Zones, a Box Region, or a Cell Register.

Select the Zones for integration, enter the coordinates of the rectangular (in 2D) or hexahedral (in 3D) integration region under Box Settings, or make a selection from the Cell Register drop-down list.

Select an observable from the Numerator drop-down list to represent the numerator of the ratio.

Select an observable from the Denominator drop-down list to represent the denominator of the ratio.

Select two observables from the corresponding drop-down list that will be used to compute their product.

For a linear combination observable:

Under Linear Combination of powers , enter a Constant value.

Enter the number of Components .

Make a selection from the Combination Type drop-down list. For details, see General Operations.

For each component, enter a corresponding Coefficient, an Observable, and a Power.

For an arithmetic average observable:

Enter the number of Components .

Select observables from the corresponding Observable lists.

For a mean-variance observable:

Enter the number of Components .

Select observables from the corresponding Observable lists.

For a unary operation observable:

Select an operation from the drop-down list (see General Observables for a list of available operators).

Select an observable from the corresponding drop-down list upon which the unary operation is to be applied.

Expressions can be used as adjoint observables or as field variables for Surface Integral and Volume Integral observables. Single-valued expressions can be used as observables and can be selected from the list of Observable Names within the Adjoint Observables dialog box. For Surface Integral and Volume Integral observables, field expressions can be selected from the Field Variable drop-down list within the Manage Adjoint Observables dialog box.

For both expression observables and surface/volume integral observables defined with an expression, the expression can be a combination of single-valued and field expressions within a binary operator, for example:

VolumeAve((P - VolumeAve(P, ['fluid:011']))^2,

['fluid:011'])

where P is a field expression and

VolumeAve(P, ['fluid:011'])

is a single-valued expression.

Note: Apart from combined single-valued and field expressions, only single-valued scalar expressions can be used as observables and only field expressions can be used to define surface/volume integral observables.

Single-valued or field expressions can not be combined with vector expressions. For example, the following expression is not supported:

Average(Velocity.x,['wall'],Weight=None)*Force(['wall'])

Where Average(Velocity.x,['wall'],Weight

=None)is a scalar single-valued

expression and Force(['wall']) is a

vector single-valued expression.

However, the above expression is supported by using the

component of the vector

Force(['wall']) and written

as:

Average(Velocity.x,['wall'],Weight =None)*Force(['wall']).x

Observables can not be created for expressions containing Flux functions, Report Definitions, and cannot contain the following Mathematical functions:

gradient

normalize

Note that when defining an expression for use in an adjoint observable, it is recommended to not use discontinuous functions (e. g. floor, min, or max) due to a possibly invalid differentiation. However you can use a similar continuous function to mimic the behavior, such as using the softmax function to minic the max function.

If an adjoint observable is not fully supported, a warning message similar to the following will be printed in the console when the observable is selected, or before running the adjoint solver:

Warning: the adjoint observable does not support the expression: DensityAll.

Note: When using an expression that contains angles as an

adjoint observable, all angles must be divided by

1[rad] to make the angles

dimensionless. For example,

sin(aoa) must be written as

sin(aoa/1[rad]).

Expressions containing the following Variables can be used as observables:

Pressure...

Static Pressure

Pressure Coefficient

Dynamic Pressure

Absolute Pressure

Total Pressure

Sensitivities...

Adjoint GEKO CSEP

Adjoint GEKO CNW

Adjoint GEKO CMIX

Adjoint GEKO BF

Mesh...

Face Area Magnitude

X Face Area

Y Face Area

Z Face Area

Cell Volume

X-Coordinate

Y-Coordinate

Z-Coordinate

Position.mag

Turbulence...

Turbulent Kinetic Energy (k)

Turbulent Viscosity

Effective Viscosity

Turbulent Dissipation Rate (Epsilon)

Specific Dissipation Rate (Omega)

Turbulent Intensity

Turbulent Viscosity Ratio

Production of k

Turbulent Reynolds Number (Re_y)

Blending Function for GEKO

Curvature Correction Function fr

Density...

Density

Properties...

Sound Speed

Thermal Conductivity

Specific Heat (Cp)

Species...

Eff Diff Coef of

species-nLam Diff Coef of

species-nEnthalpy of

species-nMass fraction of

species-nMolar Concentration of

species-nMole fraction of

species-n

Velocity...

Velocity Magnitude

X Velocity

Y Velocity

Z Velocity

Axial Velocity

Radial Velocity

Tangential Velocity

Velocity Angle

Vorticity Magnitude

X-Vorticity

Y-Vorticity

Z-Vorticity

Mach Number

Cell Reynolds Number

Q Criterion Normalized

Q Criterion Raw

Lambda 2 Criterion

Derivatives...

Strain Rate

dX-Velocity/dx

dY-Velocity/dx

dZ-Velocity/dx

dVelocitydx.mag

dX-Velocity/dy

dY-Velocity/dy

dZ-Velocity/dy

dVelocitydy.mag

dX-Velocity/dz

dY-Velocity/dz

dZ-Velocity/dz

dVelocitydz.mag

dp-dX

dp-dY

dp-dZ

dpd.mag

Temperature...

Static Temperature

Total Temperature

Entropy

For more information on Fluent expressions see Expression Operations and Functions.

You can select which observable to use for the sensitivity calculation in the list of Observable Names.

Note:

Only one observable can be used in any one adjoint calculation. In the Adjoint Observables dialog box, the observable that is currently highlighted is the observable that will be used in the sensitivity calculation.

Any observables that have been created but which are missing required inputs will not appear in the list of Observable Names.

Clicking the Evaluate button computes the current value of the selected observable quantity and prints the result in the console window. Clicking the Write... button provides the option to write the result to a named file.

The Sensitivity Orientation determines the sign of the postprocessed sensitivities. For instance, if you select Maximize then changes in the direction of positive sensitivities will increase the value of the observable. A standard rule of thumb can be applied: if you want to improve the solution, then follow the direction of the sensitivity vectors. Another standard rule of thumb can also be applied for postprocessed scalars: if you want to improve the solution, then increase values where the sensitivity is positive and/or decrease values where the sensitivity is negative.

For turbulence model optimization (see Using the Turbulence Model Design Tool), optimization observables should be defined as the difference between the results computed from your RANS simulation and experimental data or data from a high-fidelity simulation. Optimization observables can be specified to target a constant quantity (such as lift or drag) or target field data (such as a velocity or pressure field). Note that targeted field data must either be from experimental data or exported into user-defined memory (UDM) from a high-resolution RANS simulation or time-averaged flow solution of an SBES simulation.

Target field data can be written to user-defined memory using the following text command:

/adjoint/utilities/interpolate/write-data

To import target field data into user-defined memory for the case being optimized enter the following text command:

/adjoint/utilities/interpolate/read-data

For more information on creating and editing the following observables see Creating New Observables and Editing Observable Definitions.

For targeting field data, create a Volume Integral observable and configure the following settings:

From the Volume Integral Type drop-down list, select Target-volume-integral which is the norm of the difference between the field computed from your RANS simulation and the target field data.

Specify the Volume Integral settings for your optimization problem, including selecting the appropriate User-Defined Memory location of your imported target data.

For targeting a constant quantity (e.g force), the observable should be defined as the absolute value of the sum of the quantity computed by your RANS simulation and the target quantity.

The general procedure for defining an observable to target a constant quantity is as follows:

Create a new Observable for the quantity of interest (e.g force).

Create a linear combination operation to define the difference between the computed quantity and the target quantity.

Within the Linear Combination of powers group box, select Sum from the Combination Type drop-down list and retain the value of

1for the Coefficient , Components, and Power settings.Select the observable you created for your quantity of interest from the Observable drop-down list.

Enter the negation of the value of your target quantity under Constant. For example if your target quantity is

5000for lift, enter-5000.

Create a unary operation for the absolute value of the linear combination operation defined in the previous step.

Once an observable is defined as described in Defining Observables, the solution of the adjoint for that observable can be computed based on the current flow solution. The steps for solving the adjoint are similar to those for solving the flow and are detailed in the following sections:

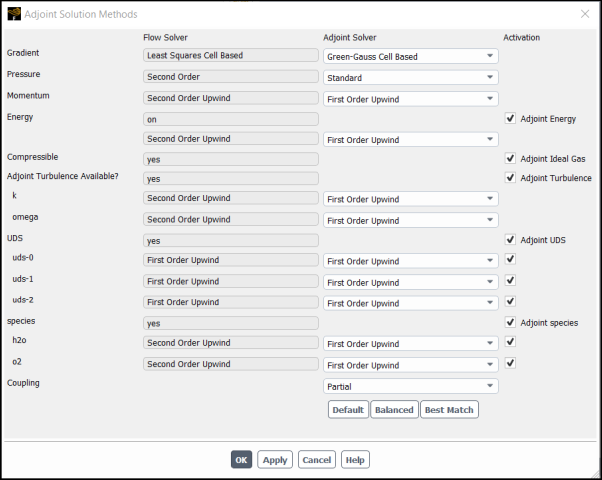

You can specify the methods used for computing the adjoint solutions in the Adjoint Solution Methods dialog box. To open the Adjoint Solution Methods dialog box, click in the Design ribbon tab (Gradient-Based group box).

Design →

Gradient-Based →

Methods...

The Adjoint Solution Methods dialog box shows a side-by-side comparison of the schemes used for the flow solver and for the adjoint solver. Using the same scheme for the adjoint solution and the flow solution yields the most accurate discrete derivative calculation when the adjoint solution is converged. However, not all schemes used for the flow solver are supported for the adjoint solver. In these cases an alternate adjoint scheme must be used. This does not typically lead to severe deterioration of the adjoint results quality. Even if the same scheme is available for the adjoint solver this is not always practical because stability may be reduced with some schemes. Therefore, you can use the drop-down lists under Adjoint Solver to select alternate schemes as needed.

In some cases it may not be desirable to solve the energy adjoint even if energy is solved in the flow solver. For example, consider an incompressible flow where the specified observable does not involve thermal quantities. In this case the adjoint for the energy equation is identically zero, but its inclusion would add an unnecessary numerical burden. You can disable the Adjoint Energy option to avoid solving the energy adjoint.

If the primary flow is a compressible ideal gas, you can specify that the physics of the compressible flow are modeled in the adjoint solver by enabling the Adjoint Ideal Gas option. Enabling this option automatically enables the Adjoint Energy option as well. If the flow is not a compressible ideal gas, it will be treated as being incompressible for the purposes of the adjoint calculation.

When the flow solver uses the generalized -

(GEKO) turbulence model (for details, see

Setting up the Generalized k-ω (GEKO) Model), you can

enable the Adjoint Turbulence option in

order to take the effect of changes to the state of the

turbulence into account when computing sensitivities for the

adjoint calculations, rather than using a frozen turbulence

assumption. This has the following advantages:

The shape sensitivity will be more accurate. This is helpful when high accurate shape sensitivity is needed, such as:

when the design is close to optimal design

when the turbulence state can change significantly with respect to the design changes

when performing optimization with multiple objectives

Sensitivities for GEKO parameters and the curvature correction parameter (CCURV) can be can be calculated at each cell, which can help you to tune the GEKO model.

Including turbulence in the adjoint calculations can make it harder to reach convergence, and will increase the computational and memory cost. For this reason, it is suggested that you only enable turbulence adjoint equations when it is necessary; in most cases, the frozen turbulence assumption should be fine.

Note: You must make sure that the Intermittency Transition Model option was disabled for the flow solution, as it is not supported with adjoint turbulence. However, the Algebraic Transition Model is supported with adjoint turbulence.

When one or multiple user-defined scalar (UDS) transport equations are defined, you can specify the adjoint solver to compute the adjoint for the UDS equations by enabling the Adjoint UDS option. Additionally, when species transport is defined, the adjoint for species transport equations can be computed by enabling the Adjoint species option. After enabling Adjoint UDS or Adjoint species, you can enable the desired UDS or species transport equations to be computed by the adjoint solver. Up to 50 adjoint UDS/adjoint species equations can be enabled.

If the UDS or species transport equations are not necessary for optimization, it is recommended to disable Adjoint UDS and Adjoint species to save time and memory and improve convergence. For example, disabling Adjoint UDS and Adjoint species is recommended for the following scenarios:

When a specific observable is not significantly influenced by UDS or species transport equations.

When the state of UDS or species transport equations do not change significantly with respect to the design changes.

During the early stages of optimization, where achieving sensitivity accuracy is less important.

The adjoint solver utilizes the algebraic multigrid (AMG)

algorithm to solve the correction equations (adjoint

equations) and each AMG block consists of an

N x

N matrix, where

N is the number of adjoint

equations (for more information on the algebraic multigrid

in Ansys Fluent see Algebraic Multigrid (AMG) in the

Fluent theory guide). The adjoint solver can be specified

to be fully coupled or partially coupled by selecting

Full or

Partial respectively in the

Coupled drop-down list. When

Full is selected, all adjoint

equations are coupled within a single AMG block. The adjoint

solver is set to partially coupled by default, and with

Partial selected the adjoint

continuity equation and adjoint momentum equations are

coupled within one AMG block while all other adjoint

equations are solved individually in segregated AMG blocks.

For example, the adjoint solver must solve the following

seven adjoint equations for a 3D turbulence case:

adjoint x-momentum

adjoint y-momentum

adjoint z-momentum

adjoint continuity

adjoint flow rate

adjoint k

adjoint omega

When the adjoint solver is fully coupled,

all of the adjoint equations will be solved within a single

7 x 7 = 49 AMG block. For

the partially coupled adjoint solver, the AMG block for the

adjoint continuity and adjoint momentum equations will be

4 x 4 = 16, while all other

adjoint equations are solved seperately in individual

1 x 1 = 1 AMG blocks.

The significant reduction in the size of the AMG blocks for the partially coupled solver both reduces memory requirements and improves speed per iteration significantly as well, especially when Adjoint Turbulence and/or Adjoint Energy are enabled. Note that while the partially coupled adjoint solver significantly improves performance, the outer convergence may be slightly reduced.

Clicking the button will disable the Adjoint Turbulence equation and set the spatial discretization methods as follows:

Green-Gauss Cell Based for Gradient.

Standard for Pressure .

First Order Upwind for Momentum and Energy (chosen due to their stability).

Partial for Coupling .

Clicking the button will attempt to match the adjoint schemes to the schemes used for the flow solver which should in general provide more accurate calculations at convergence. Where the schemes cannot be matched, the settings will be used.

Clicking the button will provide a balance between stability and accuracy settings. Due to momentum discretization and adjoint turbulence having the largest affect on convergence, the Balanced setting will disable Adjoint Turbulence, set Momentum to First Order Upwind, and use Best Match settings for all other methods.

By default the Rhie-Chow: momentum based flux type is used for the adjoint solver. However, the adjoint solver can be specified to use the same flux type as that of the flow solver using the following text command:

adjoint/expert/match-fluent-flux-type?

By default, the adjoint solver will incorporate 1st order poor mesh numerics used by the conventional flow solver as outlined in Robustness with Meshes of Poor Quality. Poor mesh numerics can be disabled using the following command:

/adjoint/expert/undo-2024r1-default-changes?

The advancement of the adjoint solution to reach a converged solution is an essential part of the analysis. The solution algorithm for the adjoint solver is similar to the coupled pressure-based solver that is available for conventional flow computations in Ansys Fluent.

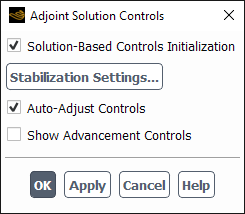

By default, the adjoint solver advancement settings will be automatically adjusted during calculation to encourage convergence, with initial values determined by the state of the flow solution. If needed, you can adjust the advancement controls in the Adjoint Solution Controls dialog box.

To open the Adjoint Solution Controls dialog box, click in the Design ribbon tab (Gradient-Based group box).

Design →

Gradient-Based →

Solver Controls...

Controls

- Solution-Based Controls Initialization

When enabled, the advancement controls are selected automatically when the adjoint solution is initialized based on the state of the flow.

This button opens the Stabilized Strategy and Scheme Settings dialog box, which you can use to define the stabilization strategy, scheme(s), and settings for the adjoint solution. For details, see Stabilization Strategies, Schemes, and Settings.

- Auto-Adjust Controls

When enabled, the convergence of the AMG solver and the adjoint residuals are monitored during solution advancement. Based on the trends observed, the Courant number is automatically adjusted to encourage reliable solution advancement and convergence. This is especially useful when a new type of problem is being solved for which appropriate settings are not initially clear. You can enable or disable Auto-Adjust Controls at any time during the solution.

The Courant number starts at the value you defined in the Advancement Controls group box or the value determined by the Solution-Based Controls Initialization option. When the residual minimization scheme is used, over the first two iterations the Courant number will be increased as high as possible (while still allowing the AMG solver to converge), and will then remain unchanged; for all other setups, the Courant number will be adjusted to ensure the AMG solver converges, with the goal of reducing the AMG residuals at the rate of 1 order of magnitude over 6-8 iterations. Messages will appear as the calculation progresses indicating the adjustments that are being made.

- Show Advancement Controls

This option toggles the visibility of the various advancement controls for direct user specification.

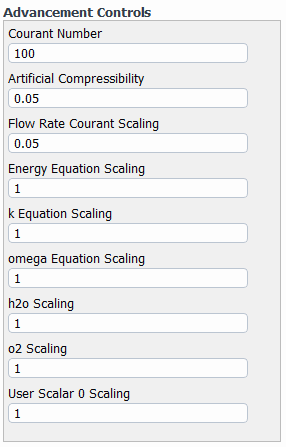

- Advancement Controls

contains the advancement controls.

- Apply Preconditioning

Enables solution preconditioning. This is needed for most cases involving turbulent flow. If preconditioning is enabled, additional controls are available.

- Courant Number

A higher number corresponds to a more aggressive advancement of the computation at the risk of instability. Disabling preconditioning corresponds to an infinite Courant number.

- Artificial Compressibility

A nonzero value introduces artificial compressibility into the computation of the adjoint continuity equation. A value of

1.0or less is reasonable.-

Flow Rate Courant Scaling ,

Energy Equation Scaling ,

k Equation Scaling ,

omega Equation Scaling,

species-nScaling, User Scalar n Scaling These values should be larger than zero (default value is

0.05for flow rate and1for all other equations). A smaller value implies a less aggressive algorithm that encourages stability of the AMG linear solver.

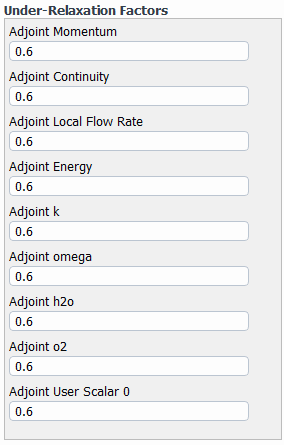

- Under-Relaxation Factors

contains the under-relaxation factors.

-

Adjoint Momentum,

Adjoint Continuity,

Adjoint Local Flow Rate,

Adjoint Energy ,

Adjoint k, Adjoint

omega, Adjoint

species-n, Adjoint User Scalar n Each of these can be set to a value between

0.0to1.0. A higher value leads to a more aggressive algorithm that is less likely to be stable. A value of1.0for each can be used for some simple cases without difficulty.

-

Adjoint Momentum,

Adjoint Continuity,

Adjoint Local Flow Rate,

Adjoint Energy ,

Adjoint k, Adjoint

omega, Adjoint

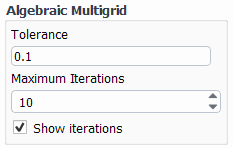

- Algebraic Multigrid

contains the algebraic multigrid controls.

- Tolerance

The tolerance used for judging convergence.

- Maximum Iterations

The maximum number of inner iterations of the AMG solver.

- Show Iterations

If enabled, a more verbose iteration history is printed in the text console during iterations. The details of the inner iteration can be useful when deciding on appropriate Courant Number, Artificial Compressibility, and Flow Rate Courant Scaling. If many inner iterations are needed, or if the inner iterations diverge, this signals that a reduction in Courant Number may be needed. Alternatively, an increase in Artificial Compressibility or a reduction in the Flow Rate Courant Scaling may be sufficient for the AMG iterations to converge.

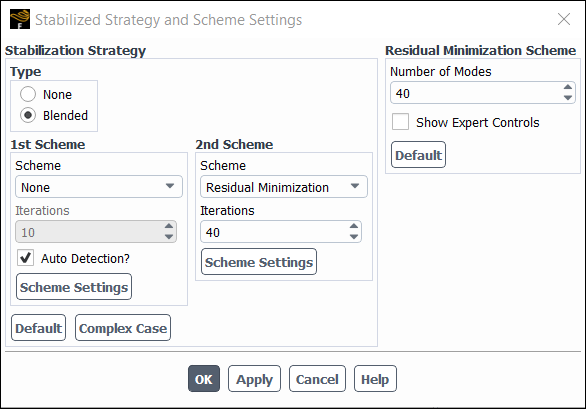

For an overview of when stabilization is needed and descriptions of the available schemes, see Adjoint Solver Stabilization. You can define a stabilization strategy in the Stabilized Strategy and Scheme Settings dialog box, which is opened by clicking the button in the Adjoint Solution Controls dialog box.

Selecting None from the Type list in the Stabilization Strategy group box on the left allows you to select a single stabilization method to be used throughout the calculation, or none at all. You specify your preference using the Scheme drop-down list in the Current Scheme group box, then click the button to define the scheme settings on the right.

Alternatively, you can select Blended from the Type list in the Stabilization Strategy group box on the left, so that either no scheme (None) or the Dissipation scheme is applied at the beginning of the calculation, depending on your selection from the Scheme drop-down list in the 1st Scheme group box; then a second scheme (the Residual Minimization scheme) is used for the remainder of the calculation. If you enable the Auto Detection? option, the first scheme will be used until divergence or slow convergence in the adjoint residual is detected; otherwise, you specify an explicit number of Iterations to be run before switching to the second scheme. The latter can be useful for cases that take a long time to diverge or show signs of slow convergence with the first scheme, as you can force an early switch to the residual minimization scheme (which generally converges quickly). You can also specify the maximum number of Iterations to allow for the 2nd Scheme, as the residual minimization scheme can be expensive on a per iteration basis. Note that settings used for the dissipation and residual minimization schemes are defined within the Dissipation Scheme and Residual Minimization Scheme group boxes on the right, which will appear after clicking the button in the 1st Scheme and 2nd Scheme group boxes, respectively. The controls for each scheme are described in the sections that follow.

Note: After your first calculation is complete, the second stabilization scheme will be used at the start of all subsequent calculations, unless you click the button in the Run Adjoint Calculation dialog box prior to calculating. Initializing the strategy is recommended when there is an operation that will cause a residual jump (such as morphing the mesh), as the first scheme can resolve some of the modes more efficiently.

When using the Blended strategy,

note that you can use the

button to revert

any changes you have made to the settings. You can

also use the

button to use settings that are more appropriate for

complex cases that would benefit from the initial

use of the dissipation scheme to damp local

diverging modes, before switching to the residual

minimization scheme; note that for some cases, you

may need to increase the

Iterations for the

dissipation scheme or increase the damping factor in

the Dissipation Scheme group

box (for example, to 100)

to allow the scheme to fully damp the modes.

The stabilization settings for each scheme are described in the following sections:

The dissipation scheme operates by introducing nonlinear damping strategically into the calculation domain. The strategy is intended to provide minimal intervention in order to damp the growth of instabilities that lead to adjoint solution divergence. A marker is tracked, based on the state of the adjoint solution, and the damping is applied directly to the adjoint solution in regions where the marker becomes large.

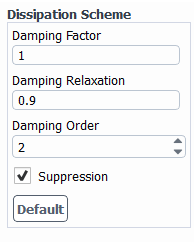

When Dissipation is selected from the Scheme drop-down list within the Current Scheme or 1st Scheme group box (depending on the specified Stabilization Strategy), you can then click the button to open the Dissipation Scheme group box on the right and define the following settings:

- Damping Factor

The overall level of dissipation is proportional to this value although the damping level is determined ultimately through a nonlinear process.

- Damping Relaxation

The damping relaxation can be used to control the rate at which the dissipation is updated as the adjoint solution progresses. As you decrease the value from 1, the rate at which the dissipation is updated is decreased.

- Damping Order

The spatial order of the dissipation. A higher order leads to more intense and localized damping. This can typically be set to be one order larger than the adjoint calculation spatial order.

- Suppression

As part of the dissipation scheme, the growth of instabilities is stopped by the effect of the dissipation; enabling the Suppression option ensures that these undesirable patterns will then also decay as the calculation progresses.

Since the order of discretization of the dissipation scheme is usually set higher than the adjoint, the formal order of accuracy of the adjoint solution is unaffected by the addition of dissipation. However, regions of intense dissipation can appear for some cases when using this scheme. This can sometimes appear as isolated spots and streaks in the adjoint solution on surfaces. The scale of these features is such that they are often easily smoothed during postprocessing to generated design changes.

The residual minimization scheme operates by building a Krylov subspace and using it to build a solution with minimum residual.

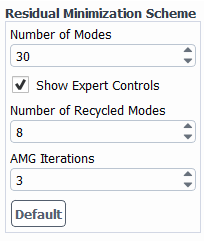

When Residual Minimization is selected from the Scheme drop-down list within the Current Scheme or 2nd Scheme group box (depending on the specified Stabilization Strategy), you can then click the button to open the Residual Minimization Scheme group box on the right and define the following settings:

- Number of Modes

This specifies the number of modes in the Krylov subspace used to approximate the solution. Increasing the number of modes will increase the convergence and reduce the final residual. The convergence rate may increase sharply when the number of modes is larger than a certain threshold. Note that the memory needed for this scheme is proportional to (number of adjoint equations) * (number of modes + number of recycled modes). You should ensure that you have enough memory for the value you enter here; an estimation of the additional memory needed at the peak is printed in the console when you click .

- Show Expert Controls

Enabling this option reveals the expert controls described below, so that you can adjust them from the default values.

- Number of Recycled Modes

This specifies the number of modes that are selected, stored, and used for the next iteration to speed up the convergence. The default value is a quarter of the number of modes.

For the initial step of the residual minimization scheme, the number of sub-iterations is equal to the number of modes; for later steps, it is the difference of the number of modes and the number of recycled modes. Therefore, increasing the number of recycled modes will reduce the number of sub-iterations for each main iteration; while this relation is straightforward, the effect on the overall convergence ratio is not, as it is case dependent.

- AMG Iterations

This specifies the fixed number of AMG iterations in each sub-iteration. Increasing the number may improve the overall convergence, but it also increases the time for each sub-iteration.The residual minimization scheme is unique in that it does not require the AMG solver to reduce the inner residual by at least one order; it only requires that the AMG solver not be diverging. In fact, a more aggressive setting of preconditioning may slow down the inner AMG convergence, but improve the overall outer loop convergence. Such an improvement can be significant.

Note: The following tips can be helpful when using the residual minimization scheme:

It is highly recommended that you first run the adjoint solver without a stabilization scheme until the adjoint residual starts to diverge, and then enable the residual minimization scheme. The first run damps out many stable modes in the adjoint residual and reduces the number of modes required in the residual minimization scheme. Note that this can easily be done by selecting the Blended strategy in the Stabilization Strategy group box.

The overall adjoint residual will be printed in the console. The residual should either decrease monotonically or stall within each main iteration or between main iterations. If you do not see such behavior, click the button in the Run Adjoint Calculation dialog box to initialize the scheme.

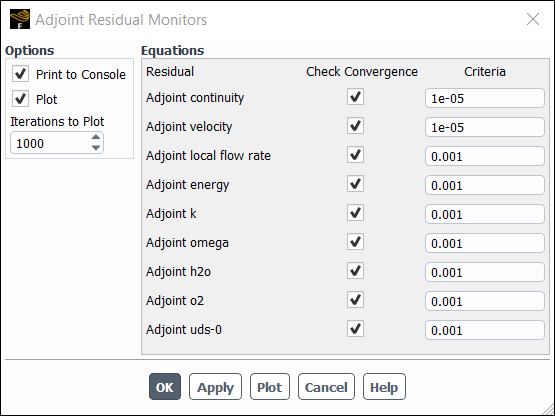

The progress of the iterations of the adjoint solver and the monitoring of the convergence is controlled in the Adjoint Residual Monitors dialog box. This dialog box is accessed by clicking in the Design ribbon tab (Gradient-Based group box).

Design →

Gradient-Based →

Monitors...

The steps to define the monitor behavior are as follows:

Decide whether or not the residuals are to be printed in the console by setting the Print to Console check box as desired.

Decide whether or not the residuals are to be plotted in the main window by setting the Plot check box as desired.

Set how many iterations are to be shown in the residual curves that are plotted in the Iterations to Plot field.

Enable and/or disable those values that are to be used as criteria for convergence, and set the Criteria in each case. The options are to test the residuals for the following equations: Adjoint continuity, Adjoint velocity, Adjoint local flow rate , Adjoint energy, Adjoint k, Adjoint omega, Adjoint

species-n, and/or Adjoint uds-n.

Click the or buttons to confirm that the settings are acceptable. Clicking will cause existing adjoint residuals to be plotted in the main graphics window.

If the adjoint calculation does not converge properly, you can print and/or postprocess the adjoint equation residuals, as this can provide useful information for the diagnosis of convergence issues. Convergence issues can be caused by:

Flow instability such as high shear flow, flow separation, or reverse flow

Poor mesh quality

A specific boundary condition

Unsupported models in Fluent, as mentioned in the warning message

To help understand the cause of your particular convergence issue, you can enable the following text commands prior to running the adjoint calculation:

adjoint→expert→diagnosis→print-residuals-by-zoneThis text command specifies that the residuals are printed in the console during the calculation in a format that allows you to see if the high residual is located at a specific boundary zone.

adjoint→expert→diagnosis→retain-cell-residualsThis text command saves the residuals as field variables that can be postprocessed, so that you can visualize the high residual region to check if any of the previously mentioned reasons are the cause of convergence issues. Occasionally, the divergence only occurs locally, and most of the residual is located at a small region. In this case, even though the adjoint residual value is not low, the adjoint solution can still be used to improve your design if you can avoid morphing that region.

adjoint→expert→diagnosis→print-residuals-by-distributionThis text command specifies that the distribution of the residuals is printed in the console during the calculation, so that you can see if a high percentage of the residuals is located in a small number or percentage of cells.

Note: After setting up the text user command, you need to run at least 1 adjoint iteration to print / save the residual or receive a message.

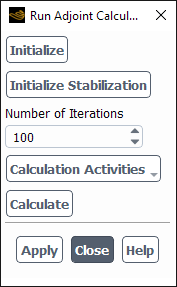

Initialization and execution of the adjoint solver is accomplished in the Run Adjoint Calculation dialog box. This dialog box is accessed by clicking in the Design ribbon tab (Gradient-Based group box).

Design →

Gradient-Based →

Calculate...

The function of this dialog box is as follows:

sets the value of the adjoint velocity and pressure to zero everywhere in the problem domain.

initializes the stabilization strategy, such that the first stabilization scheme is used at the start of the next calculation rather than continuing to use the second stabilization scheme. This button is only available when the blended stabilization strategy is used. For details, see Stabilization Strategies, Schemes, and Settings.

clears all of the unstable modes that have been identified in calculations using the stabilization scheme, but leaves the adjoint solution unchanged. This button is only available when the residual minimization scheme is enabled.

sets the number of iterations for the calculation. Note that if you are using a blended stabilization strategy, the calculation may end sooner if the total of the iterations you specified in the Stabilized Strategy and Scheme Settings dialog box (described in Stabilization Strategies, Schemes, and Settings) is less than the value you enter here.

allows you to access dialog boxes so you can set up various tasks that can be performed during the adjoint calculation. This drop-down list provides the following selections:

- Autosave...

opens the Adjoint Autosave dialog box. For details, see Automatic Saving of Case and Data Files During an Adjoint Calculation.

- Execute Commands...

opens the Execute Commands Dialog Box , which you can use to set up commands to be executed during the adjoint calculation (such as postprocessing commands that export fields). For details, see Executing Commands During the Calculation. Note that once you have opened this dialog box from Run Adjoint Calculation dialog box, the following selections become available in the When drop-down list:

- Adjoint Iteration

This specifies that execution of the command is based on the adjoint iteration. It is executed immediately before each adjoint advancement step.

- Design Iteration

This specifies that execution of the command is based on the design iteration. It is executed after the design calculation and before any animation recording, both of which are before the morphing of the mesh.

Note that unexpected behavior may result if the executed command changes settings for the adjoint calculation.

advances the adjoint solver by the Number of Iterations specified in the adjacent field.

Depending on the monitor settings, the residuals may be printed in the console and/or plotted in the main graphics window.

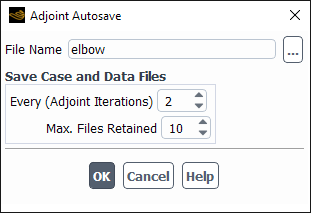

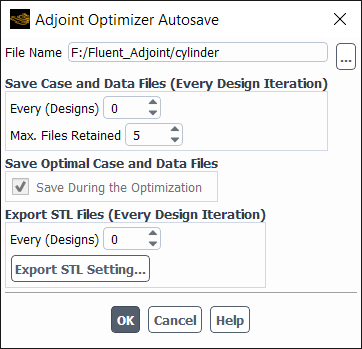

The Adjoint Autosave dialog box allows you to specify automatic saving of case and data files at specified intervals during an adjoint calculation. This dialog box is accessed by selecting from the Calculation Activities drop-down list in the Run Adjoint Calculation dialog box (described in Running the Adjoint Calculation).

The function of this dialog box is as follows:

- File Name

specifies the root name for the files that are saved. The adjoint iteration and an appropriate suffix will be added to the specified root name; by default, the suffix will be

.cas.h5or.dat.h5.- Save Case and Data Files

provides the following controls:

- Every (Adjoint Iterations)

specifies the frequency (in adjoint iterations) with which case and data files are saved. The default value is set to

0, indicating that no automatic saving is performed.- Max. Files Retained

specifies the maximum number of case and data files that can be retained. If you have constraints on the disk space, you can restrict the number of files to be saved using this field. After saving the specified number of files, Ansys Fluent will overwrite the earliest existing files. The default value for this field is

5. Entering a value of0ensures that all of the files are retained.

Adjoint solution data can be postprocessed so that it provides both qualitative and quantitative views of the effect of many types of change that may be imposed on a system. While shape changes are often of particular interest there is a very rich data set, one as large as the original flow field, available for exploration. Postprocessing tools are provided with the intention of permitting the adjoint data to be mined in such a way that it provides useful supporting information for an engineer who is making design decisions for a system, or has questions about the reliability of the original flow calculation.

Since the Ansys Fluent adjoint solver is a discrete adjoint solver, the primitive adjoint solution data provides sensitivity to changes cell-wise for the computational mesh. Normalization of these results by the cell volume provides a mesh-independent view into the data set.

Information regarding postprocessing the adjoint solutions can be found in the following sections:

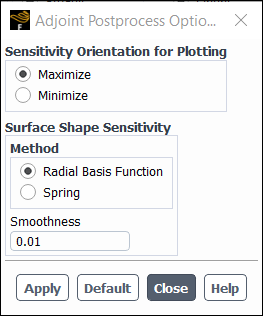

Settings for postprocessing adjoint sensitivity data is accomplished in the Adjoint Postprocess Options dialog box. This dialog box is accessed by clicking in the Design ribbon tab (Gradient-Based group box).

Design →

Gradient-Based → Postprocess

Options...

The function of this dialog box is as follows:

- Sensitivity Orientation for Plotting

provides the following controls:

- Maximize

specifies changes in the direction of positive sensitivities to increase the value of the observable.

- Minimize

specifies changes in the direction of negative sensitivities to decrease the value of the observable.

When defining Sensitivity Orientation for Plotting, a standard rule of thumb can be applied: if you want to improve the solution using the Maximize or Minimize settings, then follow the direction of the sensitivity vectors. Another standard rule of thumb can also be applied for postprocessed scalars: if you want to improve the solution, then increase values where the sensitivity is positive and/or decrease values where the sensitivity is negative.

- Method

By default the Radial Basis Function is used to calculate and smooth the surface shape sensitivity. However, you can enable the Spring option to reduce memory and computational cost. The spring method assumes that the interior mesh motion is governed by the surface mesh motion, using the spring analogy equation. The adjoint of the spring equation is then solved to back propagate the interior shape sensitivity onto the surface, resulting in a physical shape sensitivty that is not smoothed. To smooth the shape sensitivty, Laplace surface smoothing is used based on the defined smoothness settings to achieve a smoothed surface shape sensitivity.

- Smoothness

Specifies the smoothness of the Sensitivity to Surface Shape field, which is smoothed using either the radial basis function (when Radial Basis Function is enabled), or by solving an adjoint spring equation (when Spring is enabled). Decreasing this value will accentuate the effect of local geometric features on the Sensitivity to Surface Shape field.

Adjoint solution data can be postprocessed using standard Ansys Fluent postprocessing tools including contours, vectors, xy-plots, histograms, and surface and volume integrals.

Under Sensitivities... (for example, in the Contours dialog box), you can find the following fields:

- Magnitude of Sensitivity to Body Forces (Cell Values)

This field is the magnitude of the adjoint velocity primitive field. This field can be interpreted as the magnitude of the sensitivity of the observable to body force per unit volume. It can be used to identify regions in the domain where small changes to the momentum balance in the flow can have a large or small effect on the observable. This field is often observed to be large, for example, upstream of a body for which drag sensitivity is of interest, with the field diminishing in the upstream direction. This indicates the interference effect for an object positioned at various locations upstream of the object of interest.

- Sensitivity to Body Force X-Component (Cell Values), Sensitivity to Body Force Y-Component (Cell Values), and Sensitivity to Body Force Z-Component (Cell Values)

These are the components of the adjoint velocity primitive field. These fields can be interpreted as the magnitude of the sensitivity of the observable to components of a body force per unit volume. Consider a body force distribution, expressed as a force per unit volume. The volume integral of the vector product of that distribution with the components of this field gives a first-order estimate of the net effect of the body force on the observation.

- Sensitivity to Mass Sources (Cell Values)

This field is the primitive adjoint pressure field. This field can be interpreted as the sensitivity of the observable with respect to mass sources or sinks in the domain. Consider a mass source / sink distribution, expressed as mass flow rate per unit volume. The volume integral of that distribution, weighted by the local value of this field, gives the effect of the sources / sinks on the observation. When plotted on a boundary, this field indicates the effect of the addition or removal of fluid from the domain upon the quantity of interest. It is important to note that in this scenario the effect of the momentum of the fluid that is added or removed is not taken into account. The boundary velocity sensitivity should be plotted if that effect is also of interest.

- Sensitivity to Energy Sources (Cell Values)

This field is available when the energy adjoint equation is solved and is the primitive adjoint temperature field. It can be interpreted as the sensitivity of the observable with respect to the thermal energy sources or sinks per unit volume in the domain.

- Sensitivity to Turbulent Kinetic Energy Sources (Cell Values)

This field is available when the turbulence adjoint equations are solved and is the sensitivity of the observable with respect to the turbulent kinetic energy (

) sources per unit volume in the domain.

- Sensitivity to Specific Dissipation Rate Sources (Cell Values)

This field is available when the turbulence adjoint equations are solved and is the sensitivity of the observable with respect to the specific dissipation rate (

) sources per unit volume in the domain.

- Sensitivity to Scalar-n Sources (Cell Values)

This field is available when the specified UDS adjoint equations are solved and is the sensitivity of the observable with respect to the user-defined scalar sources per unit volume in the domain.

- Sensitivity to

species-nSources (Cell Values) This field is available when the specified species adjoint equations are solved and is the sensitivity of the observable with respect to the species sources per unit volume in the domain.

- Artificial Dissipation

This field is available when the adjoint dissipation stabilization scheme is enabled and shows the location and amount of the nonlinear damping that has been introduced to damp the growth of instabilities that lead to adjoint solution divergence.

- Sensitivity to Viscosity

This field shows the sensitivity of the quantity of interest to variations in the turbulent effective viscosity for a turbulent problem, or the laminar viscosity in a laminar case. The sensitivity is normalized by the cell volume to account for cell size variations in the mesh.

- Shape Sensitivity Magnitude

This field is the magnitude of the sensitivity of the observable with respect to a deformation applied to the mesh (both boundary and interior mesh). When plotted on the surface of a body the locations where this quantity is large indicates where small changes to the surface shape can have a large effect on the observable of interest. If the shape sensitivity magnitude is small then the effect of shape changes in this region can be expected to have a small effect on the observable of interest. When viewing this field, it is often observed that the magnitude varies by many orders of magnitude. Contour plots will clearly draw attention to regions with the highest sensitivity (often sharp edges and corners). However, it should be remembered that a relatively small surface movement that is distributed over a large area can have a cumulative effect that is large.

- Normal Shape Sensitivity

This field shows the normal component of the shape sensitivity. A positive value indicates an orientation directed into the domain, while a negative value indicates that the shape sensitivity is oriented outwards from the domain. This field eliminates the component of the vector shape sensitivity field that lies in the plane of the wall.

- Normal Surface Shape Sensitivity

This field shows the normal component of the surface shape sensitivity, which is an accumulation of surrounding nodal sensitivities to the surface. A positive value indicates an orientation directed into the domain, while a negative value indicates that the surface shape sensitivity is oriented outwards from the domain. The accumulation of surrounding nodal sensitivities produces a more accurate representation of the physical surface sensitivity when compared to the Normal Shape Sensitivity field which uses raw nodal sensitivity data. The normal surface shape sensitivity field is smoothed using the radial basis function and smoothness settings can be adjusted within the Adjoint Postprocess Options dialog box.

- Normal Optimal Displacement

This field shows the normal component of the optimal displacement computed from the adjoint design tool calculation. This field is defined only for portions of walls lying within the control-volume specified for morphing. A positive value of displacement indicates that the surface will be displaced into the flow domain, whereas a negative value of displacement corresponds to wall movement outwards from the flow domain. This field eliminates the component of the optimal displacement vector that lies in the plane of the wall.

- Optimal Displacement X-Component , Optimal Displacement Y-Component , Optimal Displacement Z-Component (in 3D)

These fields are the individual components of the optimal displacement computed from the adjoint design tool calculation. These fields are defined only for portions of walls lying within the control-volume specified for morphing.

- log10(Shape Sensitivity Magnitude)

In view of the large range of values possible for the shape sensitivity magnitude, a convenience function that plots

of the magnitude is provided. This allows the importance of the surfaces in a domain to be ranked more easily based on how they affect the observation of interest when they are reshaped.

- Shape Sensitivity X-Component, Shape Sensitivity Y-Component, and Shape Sensitivity Z-Component (in 3D)

These fields are the individual components of the sensitivity of the observable of interest with respect to the mesh node locations. It is plotted as cell data and is computed as the average of the nodal sensitivities for a given cell, divided by the cell volume. Note that for this discrete adjoint solver the sensitivity of the result with respect to node locations both on and off boundaries is computed. The normalization by cell volume indicates that the fields that are plotted are the weighting factors for a continuous spatial deformation field. (Note that the nodal sensitivity data itself is used when mesh morphing is performed, and predictions about the effect of shape changes are made.)

- Sensitivity to Boundary X-Velocity , Sensitivity to Boundary Y-Velocity, and Sensitivity to Boundary Z-Velocity (in 3D)

These fields are defined on those boundaries where a user-specification of a boundary velocity is made for the original flow calculation. This includes no-slip walls. The field shows how sensitive the observable of interest is to changes in the boundary velocity at any point. It is interesting to note that even though the original boundary condition specification may be for a uniform velocity on the domain boundary, the effect of a non-uniform velocity perturbation is available. The effect of any specific boundary velocity change can be estimated as an integral of the vector product of the change to the velocity with the plotted sensitivity field. A plot of this quantity on a velocity inlet, for example, can be very useful for assessing whether or not the inlet is positioned too close to key parts of the system. That is, it addresses the question of whether or not the flow domain is too small to achieve a successful computation of the performance measure of interest. Viewing this field will also indicate whether or not the assumption of a uniform inflow is adequate.

- Sensitivity to Boundary Pressure

This field is defined on boundaries where there is a user-specified pressure as part of a boundary condition, such as on a pressure outlet. The field shows the sensitivity of the observation of interest to variations in the boundary pressure across the flow boundary. It is interesting to note that even though the original boundary condition specification may be for a uniform pressure on the domain boundary, the effect of a non-uniform pressure perturbation is available, The effect of any specific boundary pressure change can be estimated as an integral of the product of the change to the pressure with the plotted sensitivity field. Viewing this field will also indicate whether or not the assumption of a uniform pressure is adequate for the simulation.

- Sensitivity to Boundary Temperature

This field is available when the energy adjoint equation is solved and is defined on boundaries where a temperature boundary condition is applied. This includes walls, velocity inlets, mass-flow inlets, pressure inlets, pressure far-field boundaries, and pressure outlets where a backflow temperature may be specified. The field shows the sensitivity of the observation of interest to variations in the boundary temperature across the boundaries. Note that even if the original boundary condition specification is for a uniform temperature on the boundary, the effect of a non-uniform temperature perturbation is available. The effect of any specific boundary temperature change can be estimated as an integral of the product of the change to the temperature with the plotted sensitivity field. This field can be used to indicate whether or not the assumption of a uniform temperature is adequate for the simulation.

- Sensitivity to Boundary Heat Flux

This field is available when the adjoint energy equation is solved and is defined on walls where a heat flux boundary condition is imposed. The field shows the sensitivity of the observation of interest to variations in the boundary heat flux through the wall. Its properties are analogous to those of Sensitivity to Boundary Temperature.

- Sensitivity to Scalar-n Boundary Value

This field is available when the specified UDS adjoint equations are solved and is defined on boundaries where a user-defined scalar boundary condition with specified value is imposed. The field shows the sensitivity of the observation of interest to variations in the user-defined scalar boundary value across the flow boundary.

- Sensitivity to Scalar-n Boundary Flux

This field is available when the specified UDS adjoint equations are solved and is defined on boundaries where a user-defined scalar boundary condition with specified flux is imposed. The field shows the sensitivity of the observation of interest to variations in the user-defined scalar boundary flux across the flow boundary.

- Sensitivity to

species-nBoundary Value This field is available when the species adjoint equations are solved and is defined on boundaries where a species boundary condition with a specified mass fraction is imposed. The field shows the sensitivity of the observation of interest to variations in the species mass fraction across the flow boundary.

- Sensitivity to

species-nBoundary Flux This field is available when the species adjoint equations are solved and is defined on boundaries where a species boundary condition with specified flux (mass) is imposed. The field shows the sensitivity of the observation of interest to variations in the species boundary flux (mass) across the flow boundary.

- Sensitivity to Flow Blockage

This field is provided as a convenient tool for identifying portions of the flow domain where the introduction of blockages or obstructions in the flow can affect the observation of interest. Consider a blockage in the flow that generates a reaction force on the flow that is proportional to the local flow speed, and acting in the opposite direction to the local flow:

where

is a local coefficient for the reaction force. The local contribution of this force on the observation of interest is determined by the vector product of this force with the adjoint velocity field. The flow blockage field that is plotted is

, namely the negative of the vector product of the flow velocity and the adjoint velocity (Cell Value).

- Sensitivity to GEKO CSEP

This field is available when the turbulence adjoint equations are solved and is the sensitivity of the observable with respect to the

parameter, which is used to optimize flow separation from smooth surfaces.

- Sensitivity to GEKO CNW

This field is available when the turbulence adjoint equations are solved and is the sensitivity of the observable with respect to the

parameter, which is used to optimize flow in non-equilibrium near wall regions (such as heat transfer or

).

- Sensitivity to GEKO CMIX

This field is available when the turbulence adjoint equations are solved and is the sensitivity of the observable with respect to the

parameter, which is used to optimize strength of mixing in free shear flows.

- Sensitivity to GEKO Blending Function

This field is available when the turbulence adjoint equations are solved and is the sensitivity of the observable with respect to the blending function,

, which is used to deactivate GEKO parameters inside boundary layers.

- Sensitivity to CCURV

This field is available when the turbulence adjoint equations are solved for a case in which the Curvature Correction option is enabled in the Viscous Model dialog box. It is the sensitivity of the observable with respect to the curvature correction parameter, CCURV , which is used to optimize the strength of the curvature correction if needed for a specific flow.

- Adjoint GEKO CSEP

This field is available after performing gradient-based turbulence model optimization within the Gradient-Based Optimizer and is the optimized

parameter, which is used to optimize flow separation from smooth surfaces.

- Adjoint GEKO CNW

This field is available after performing gradient-based turbulence model optimization within the Gradient-Based Optimizer and is the optimized

parameter, which is used to optimize flow in non-equilibrium near wall regions (such as heat transfer or

).

- Adjoint GEKO CMIX

This field is available after performing gradient-based turbulence model optimization within the Gradient-Based Optimizer and is the optimized

parameter, which is used to optimize strength of mixing in free shear flows.

- Adjoint GEKO BF

This field is available after performing gradient-based turbulence model optimization within the Gradient-Based Optimizer and is the optimized blending function (

), which is used to deactivate GEKO parameters inside boundary layers..

- Adjoint GEKO CSEP (Trained)

This field is available after performing Offline training of the neural network turbulence model within the Optimizer Design Variables dialog box, and is the trained

parameter.

- Adjoint GEKO CNW (Trained)

This field is available after performing Offline training of the neural network turbulence model within the Optimizer Design Variables dialog box, and is the trained

parameter.

- Adjoint GEKO CMIX (Trained)

This field is available after performing Offline training of the neural network turbulence model within the Optimizer Design Variables dialog box, and is the trained

parameter.

- Adjoint GEKO BF (Trained)

This field is available after performing Offline training of the neural network turbulence model within the Optimizer Design Variables dialog box, and is the trained blending function parameter (

).

- Non-Equilibrium Parameter

This field is available when the Neural Network Model has been applied for turbulence model optimization within the Optimizer Design Variables dialog box, and is the Non-Equilibrium Parameter flow feature.

- Second Invariant

This field is available when the Neural Network Model has been applied for turbulence model optimization within the Optimizer Design Variables dialog box, and is the Second Invariant flow feature.

- Third Invariant

This field is available when the Neural Network Model has been applied for turbulence model optimization within the Optimizer Design Variables dialog box, and is the Third Invariant flow feature.

- Fourth Invariant

This field is available when the Neural Network Model has been applied for turbulence model optimization within the Optimizer Design Variables dialog box, and is the Fourth Invariant flow feature.

- Fifth Invariant

This field is available when the Neural Network Model has been applied for turbulence model optimization within the Optimizer Design Variables dialog box, and is the Fifth Invariant flow feature.

- Length Ratio

This field is available when the Neural Network Model has been applied for turbulence model optimization within the Optimizer Design Variables dialog box, and is the length ratio flow feature.

- Turbulent Reynolds Number (Scaled)

This field is available when the Neural Network Model has been applied for turbulence model optimization within the Optimizer Design Variables dialog box, and is the scaled turbulent reynolds number flow feature.

- Turbulent Viscosity Ratio (Scaled)

This field is available when the Neural Network Model has been applied for turbulence model optimization within the Optimizer Design Variables dialog box, and is the scaled turbulent viscosity ratio flow feature.

- Mahalanobis distance

This field is available when the Neural Network Model is selected for turbulence model optimization within the Optimizer Design Variables dialog box. Large values for the Mahalanobis distance suggest large deviations in flow features compared to the training data results.

- Adjoint Local Solution Marker

This field intended for expert users, can be plotted to identify those portions of the flow domain where the stabilized adjoint solution advancement scheme is applied. It is preferable to plot this with the Node Values disabled in the Contours dialog box. In this case, the Adjoint Local Solution Marker will take a value between 0 and 1. The

Mode Amplitude Cutoffdefined through theadjoint/controls/stabilizationtext command defines the lower bound for cells where the stabilized scheme is applied.- Adjoint X-Velocity Residual

This field is available for users using the adjoint diagnosis and is the x-component of the residual of the adjoint momentum equation in each cell.

- Adjoint Y-Velocity Residual

This field is available for users using the adjoint diagnosis and is the y-component of the residual of the adjoint momentum equation in each cell.

- Adjoint Z-Velocity Residual

This field is available for users using the adjoint diagnosis and is the z-component of the residual of the adjoint momentum equation in each cell.

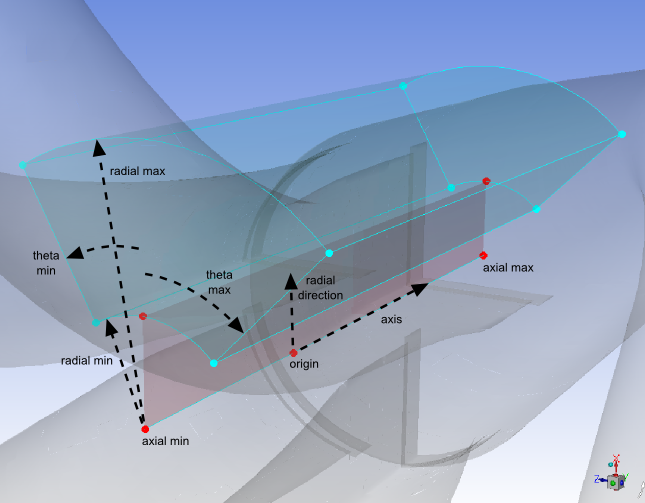

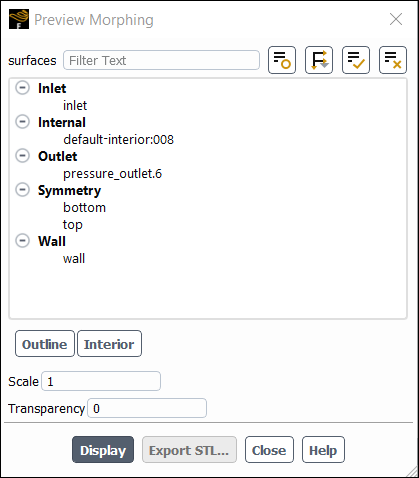

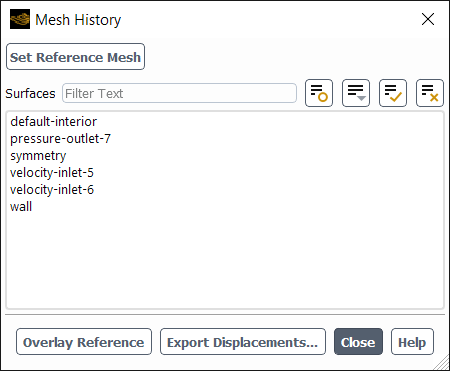

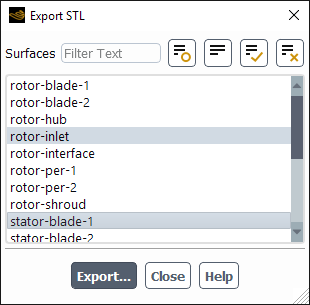

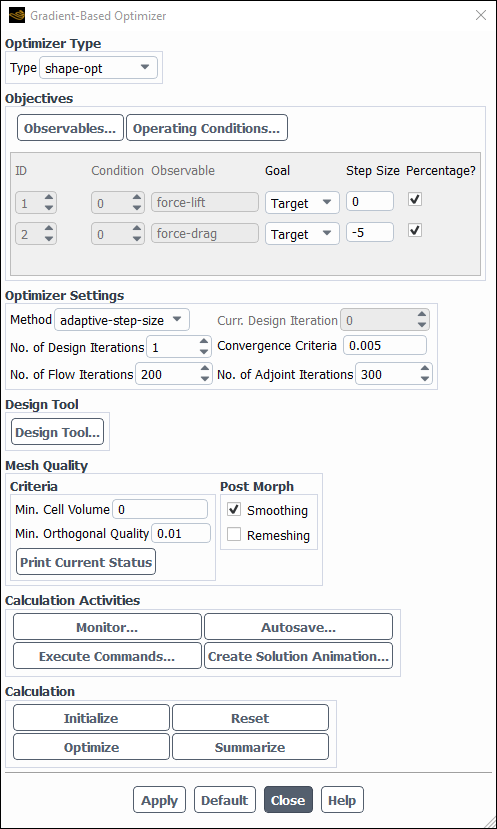

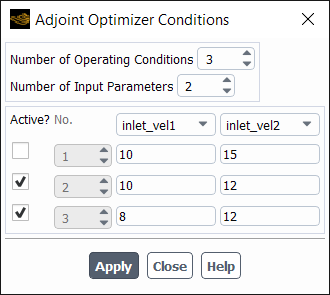

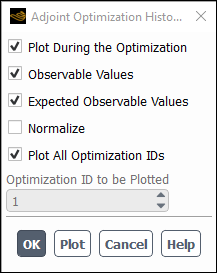

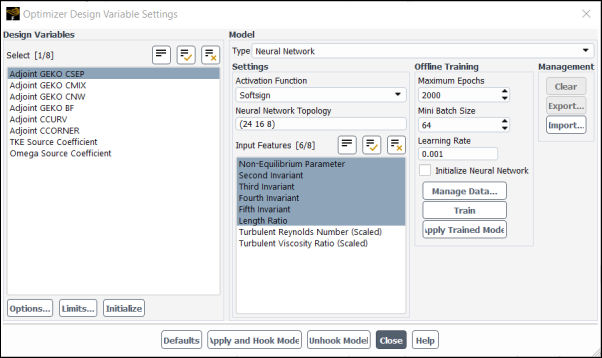

- Adjoint Continuity Residual