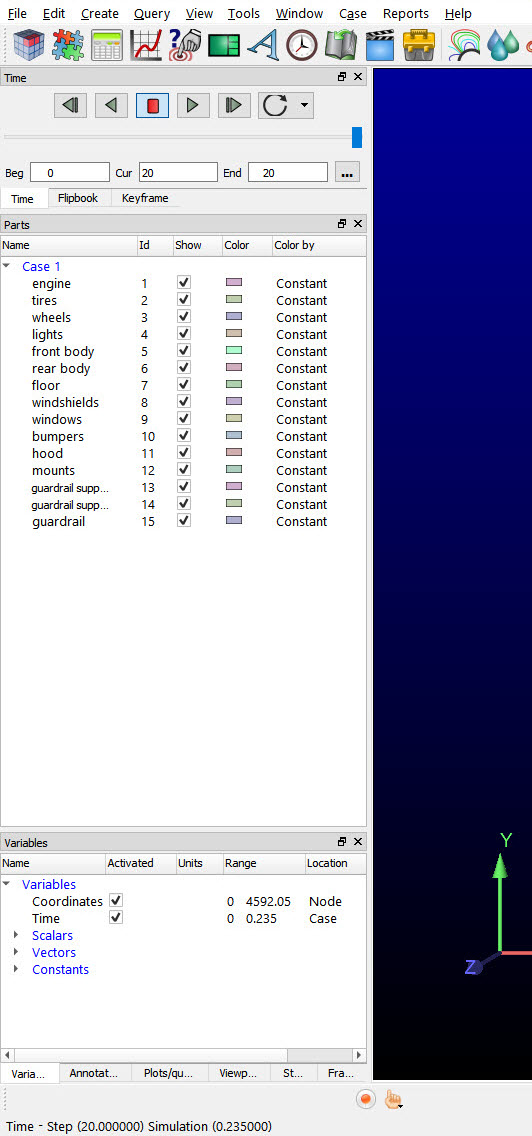

By default, the first icon on the Feature Icon Bar is the major feature entitled Parts.

When model parts are loaded from data files, or created parts are produced through the use of part features, they appear in the Parts list and are displayed in the graphics window.

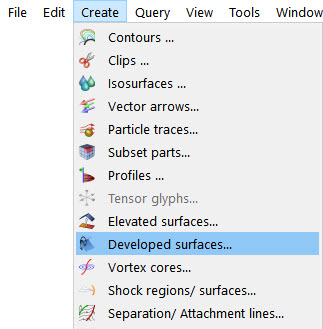

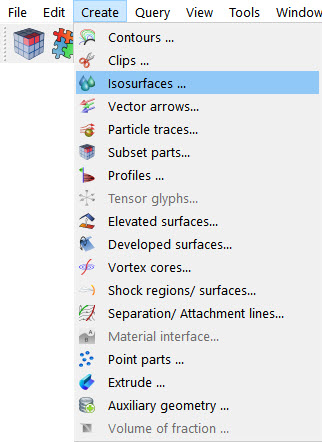

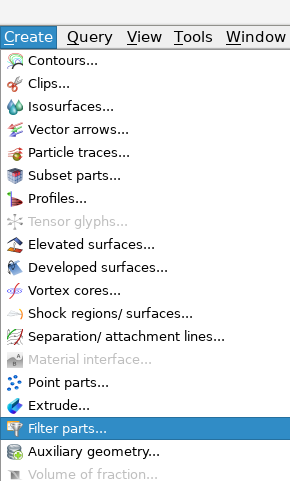

The secondary feature icons appear after the first separator. By default the ones shown are those associated with parts and include contours, isosurfaces, clips, vector arrows, and particle traces. But as discussed above, these can be customized. And the entire list is always available through the menu.

The attributes of selected parts can be edited via the Quick Action Icon Bar, which appears after the second separator. Or in the Feature Panel dialog, which can be opened by double-clicking on the parts in the Parts list.

The actual process of reading data, loading model parts, and creating parts from the various features, is discussed in many of the topics of the Ansys EnSight How-To Manual. Refer to it for guidance.

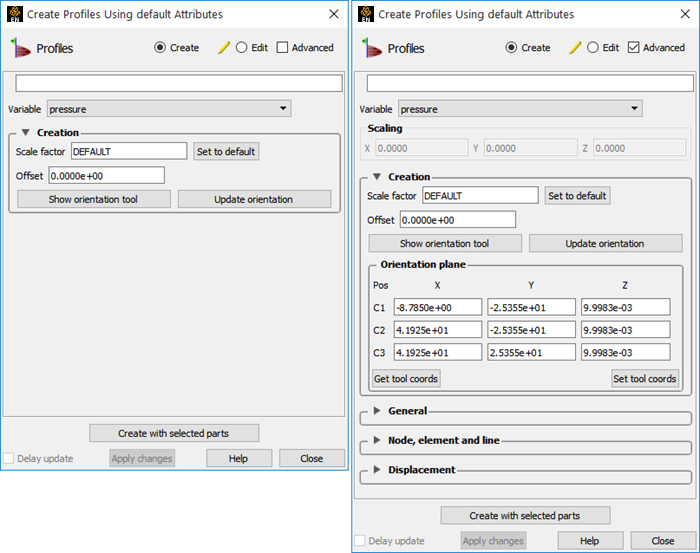

The subsections which follow will discuss the various parts features.

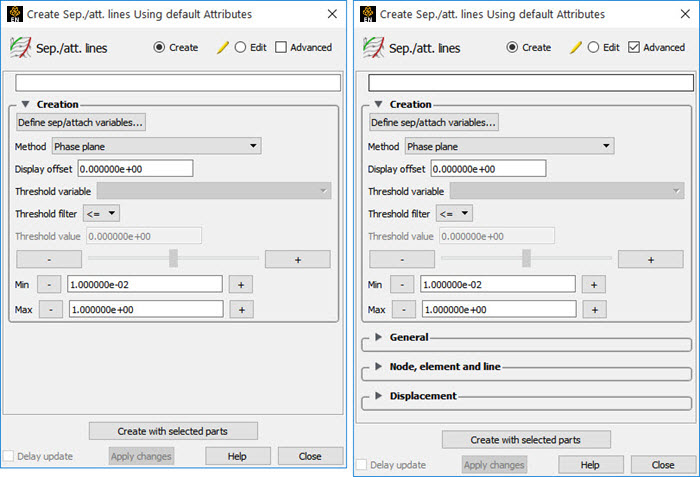

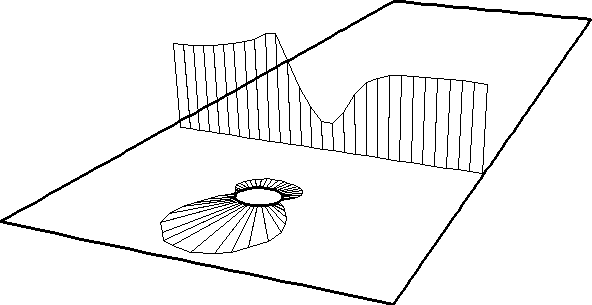

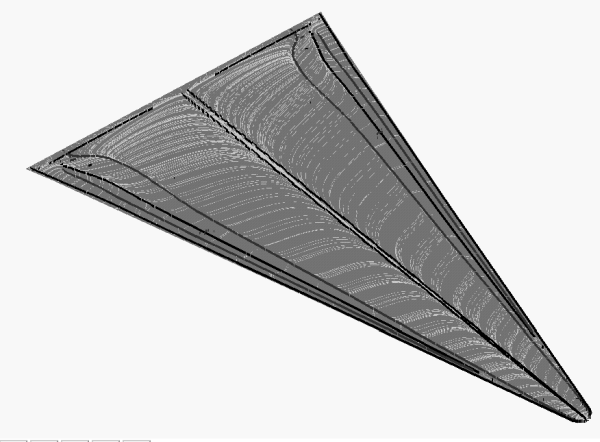

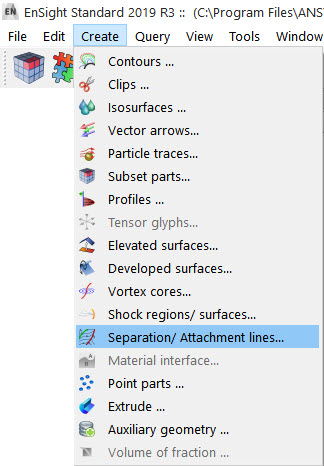

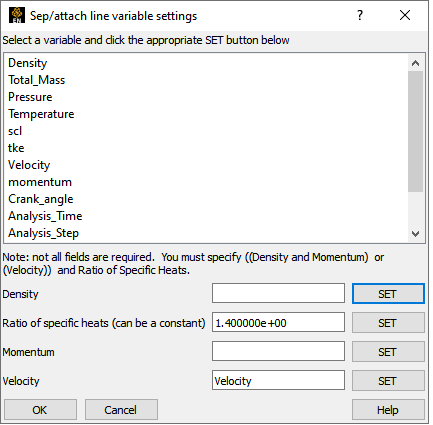

Separation/Attachment Line Parts

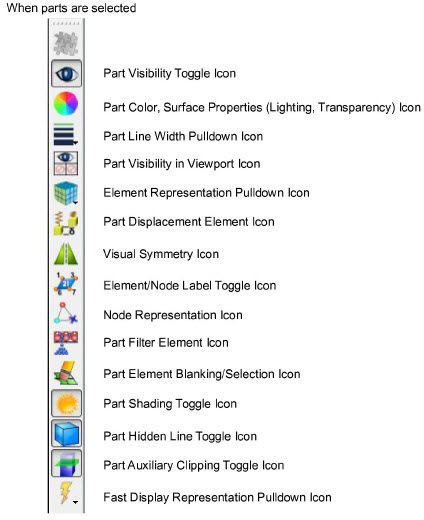

Each of the several different types of parts share the following Quick Action Icons, which are used to adjust a number of attributes for individual parts.

These are discussed here, but apply to all parts in Parts with a few exceptions. Those exceptions will be disclosed by the part attribute widget desensitized or invisible.

Part Visibility Icon

Determines the global (in all viewports and in all Modes) visibility of the selected Part(s).

Note: You can just right-click the part and choose Hide to make it invisible.

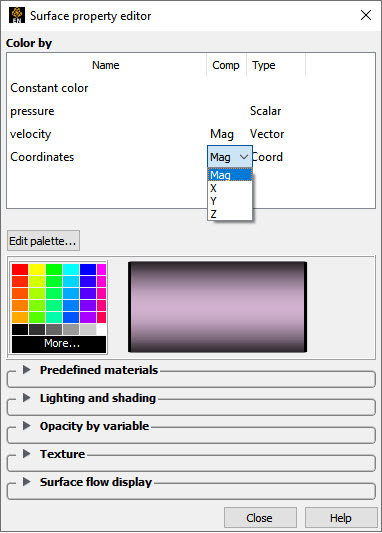

Part Color/Surface Property Icon

Clicking once on the Part Color/Surface Property icon opens a dialog which allows you to assign color, lighting characteristics, transparency levels, textures, and display surface flow to the individual Part(s) which has (have) been selected in the Parts list. If no Parts are selected, modifications will affect the default Part color and all Parts subsequently loaded or created will be assigned the new default color.

Note: You can just right-click a part and choose how to color it.

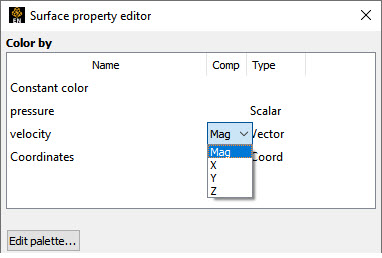

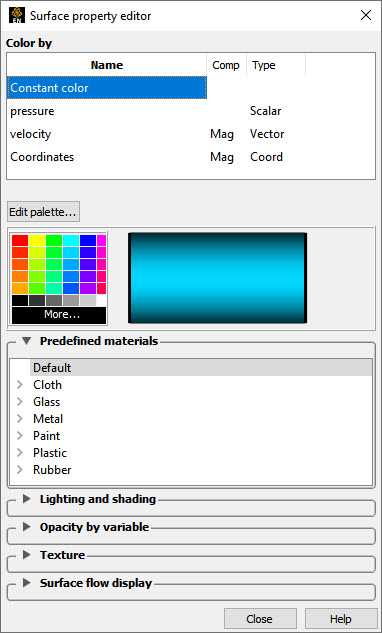

Color By

Allows you to choose whether to color the selected Part(s) by a Constant Color or by a Variable.

Name

Column containing the name of the surface property (Constant or Variable name).

Constant Color

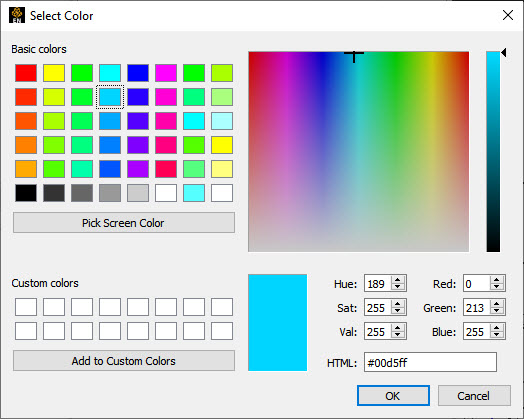

The selected Part(s) may be assigned a constant color by selecting it from the predefined matrix of color cells.

More...

Alternatively, you can click on the More... area and the Select Color dialog will open.

You can choose a color by entering RGB or HSV values directly, picking a color from the matrix, or custom color lists, or by utilizing the color square and slider. Regardless of which method you use to define a color, it will not be applied to the selected Part(s) until you click the button.

Variable

Alternatively, the Part(s) may be colored by a variable selected in the pulldown list. The color palette for each Variable associates a color with each value of the variable and these colors are used to color the selected Part(s).

If coloring by a nodal variable, the default coloring will be continuously varying - even within a given element. If you are coloring by a per-element variable, the coloring will not vary within a given element. If you desire to see per-element variables in a continuously varying manner, you can toggle on Use continuous palette for per-element variables under Edit → Preferences... Color Palettes.

Comp

Column containing the component description for vector variables. The default component is Mag. If you are coloring by a vector variable clicking in its component column allows selection of the magnitude or its components (for example, X, Y, or Z).

Type

The type of variable (blank is constant, scalar is single value at every node or element, vector is four values four values (three components and magnitude) at every node or element, tensor is six or 9 values at every node or element). Coordinates are a special client-side variable, with only magnitude available.

Edit Palette...

The Palette is the mathematical mapping of variable values to colors and to color opacity. Clicking on Edit Palette... will open the Palette Editor dialog and allow the editing of this mapping. See Edit Color Palettes.

Predefined Materials

Turn down exposes a number of predefined material models that allow you to quickly assign realistic surface model to part(s) without going through the trouble of adjusting the lighting and shading.

Note: After you pick a predefined material, you can still go to the lighting and shading turn down and further refine the settings. The lighting and shading options are context-sensitive to the predefined material you have selected.

Default

Cloth

Glass

Metal

Paint

Plastic

Rubber

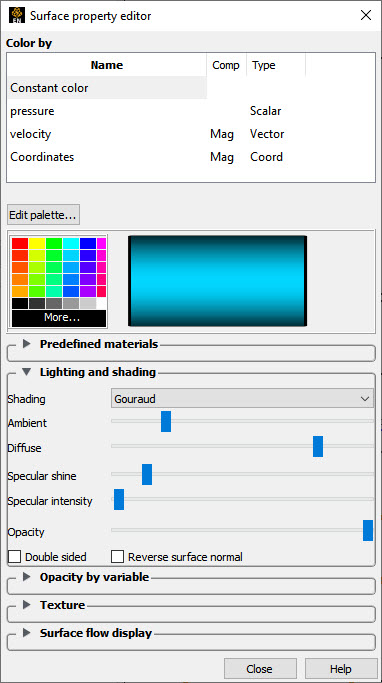

Lighting and Shading

Turn down exposes a number of detailed surface property controls that allow modification of detailed surface property attributes.

Shading

Selection of appearance of Part surface when Shaded Surface is on. Normally the mode is set to Gouraud, meaning that the color and shading will interpolate across the polygon in a linear scheme. You can also set the shading type to Flat, meaning that each polygon will get one color and shade, or Smooth which means that the surface normals will be averaged to the neighboring elements producing a smooth surface appearance. Not valid for all Part types. Options are:

Flat

Color and shading same for entire element.

Gouraud

Color and shading varies linearly across element.

Smooth

Normals averaged with neighboring elements to simulate smooth surfaces.

Smooth High Quality

Feature-based smoothing of adjacent elements within a fixed, internal threshold angle (30°).

Ambient

Controls the amount of natural surrounding light in an environment. A value toward 0.0 decreases (darkens) and toward 1.0 (floods) the amount of natural light.

Diffuse

The incoming light that will be reflected in all directions equally. The part will reflect no light if the value is 0.0, and will reflect maximum at 1.0 which diffuses the part surface color.

Specular Shine

Shininess factor. This is the dispersion angle of the reflected light. The larger the factor the smaller this angle. A large value of specular shine will therefore make the surface darker and appear less smooth because it more closely shows the changing normal along the surface.

Specular Intensity

Highlight intensity (the amount of white light contained in the color of the Part which is reflected back to the observer). Highlighting gives the Part a more realistic appearance and reveals the shine of the surface. To change, use the slider.

Opacity

This sets opacity as a constant percentage throughout the selected part(s). The opaqueness of the selected Part(s) applied as a constant value over the part surface. A value of 1.0 indicates that the Part is fully opaque, while a value of 0.0 indicates that it is fully transparent. Setting this attribute to a value other than 1.0 will adversely affect the graphics performance. Opacity is disabled for line parts.

Note: Opacity can be varied by constant, OR by a variable value in the Opacity By Variable turn down in this same dialog. This option will show up in the dialog only if you have opacity by variable set to constant (which is the default). In other words, you can use either this constant value of opacity OR you can set opacity by variable. You cannot do both. See Parts Quick Action Icons.

The term used in the graphics community for opacity is alpha. Alpha is a graphics term for the density or opaqueness of the color. Anytime the alpha is less than 1.0, the EnSight client calls into the graphics card’s rendering routines to perform complex calculations for rendering the translucent part. Note that setting a part’s opacity to transparent (0.0) will spend time and effort in the graphics card’s routines to render the chosen level of opacity, and is not the same thing as turning its visibility off using the visibility toggle (which simply does not render the part’s elements).

Double sided

Applies the lighting and shading properties to both sides of the surface element. Toggling OFF applies the lighting and shading properties only to the surface-normal side of the model elements.

Reverse surface normal

Reverses the surface normal on the surface element only on the client for lighting calculations when the Double sided toggled OFF. It does not modify the part for calculational purposes.

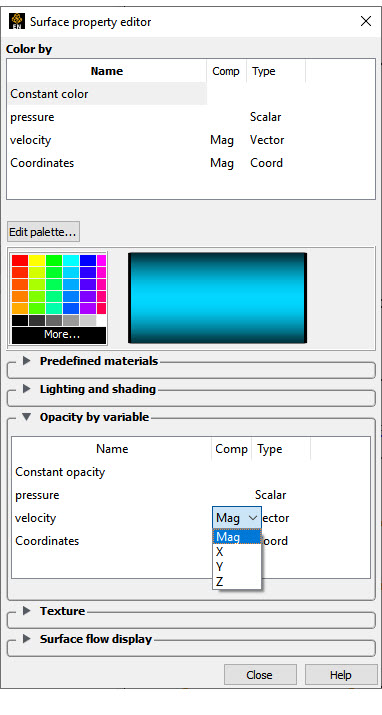

This turndown allows you to control the opacity using a variable value, which can help to emphasize regions of importance, and de-emphasize uninteresting regions. This is an expensive calculation routine best run on a client machine with a good graphics card.

Note: You can't have opacity by a variable on a part while surface flow is being used on that part. As soon as you turn on surface flow, the Opacity by a variable alpha value will be reset to none.

Name

If this is set to constant opacity (which is the default), then the constant opacity under the Lighting and Shading dialog is enabled. In other words, you can use either this constant value of opacity or you can set opacity by variable. You cannot do both.

Choosing a variable name causes the opacity to vary according to the value of the variable and disables constant opacity under the Lighting and shading turndown.

If you wish to further increase or decrease the variable opacity by variable value, use the Palette Advanced tab as shown in the How to Set Surface Properties in Opacity by Variable (Transparency).

Comp

Column containing the component description for vector variables. The default component is Mag. If you are coloring by a vector variable clicking in its component column allows selection of the magnitude or its components (for example, X, Y, or Z).

Type

The type of variable (blank is constant, scalar is single value at every node or element, vector is four values at every node or element, tensor is six or 9 values at every node or element). Coordinates are a special client-side variable, with only magnitude available.

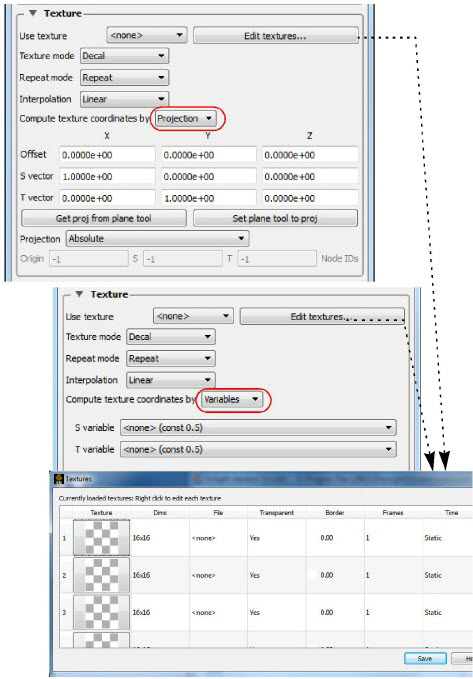

Texture

Texture mapping is a mechanism for placing an image on a surface or modulating the colors of a surface by various manipulations of the pixels via a texture map image. EnSight supports the application of a texture onto a part and the combining of texture effects with the normal EnSight coloring schemes. This can include animated textures (for example, .evo or .mpeg files), which can be used to texture parts and 2D annotations. Texture coordinates are computed via projection or using EnSight variables. Textures are loaded into EnSight, then they are applied to parts. This powerful capability is best explained using examples (see Map Textures).

Use texture

Pick the texture number to use on the selected part. The texture number is set using the button just below.

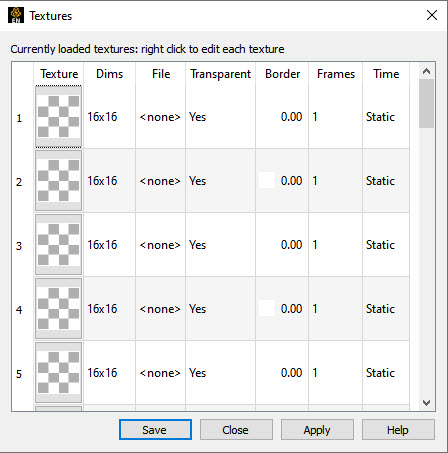

Click this button to open the Textures dialog. In the Textures dialog, right-click one of the numbered textures in the Texture column and choose an option as follows.

Right-click a texture

Load texture...

Load an image or a movie which can be used as a texture by choosing it in the Use texture pulldown above.

Clear texture

Clear the selected texture.

Set border color...

Each texture has a border color that is used for colors outside of the texture bounds. This color (RGB and opacity) can be set explicitly.

Note: If Repeat mode is Repeat, then border color is not used. If Repeat mode is set to Clamp, then areas outside of the texture bounds will be clamped to the border color. If Repeat mode is set to Clamp to texture, then regions outside of the texture bounds will be clamped to the value just inside the texture.

Set texture options...

Open a dialog allowing you to set movie parameters: the start and end time, and the start and end frame, the compression methodology, and whether to autoscale time. This is useful to match up the movie end frames to the start and end of your timesteps which will synchronize your movie texture playback to your data timesteps.

Display RGBA

All textures have both a color (RGB) and an opacity (A) component. By default, the thumbnail is drawn using the full RGBA pixel value.

Display RGB

Display only the RGB portion of the thumbnail.

Display Alpha

Display only the alpha (opacity) of the thumbnail. Notice how the A channel masks out the black and white pixels in the RGB image. This masking can be used to place non-rectangular images/icons on EnSight parts.

Columns

Dims

Dimension of the texture/movie in pixels.

File

Path and filename to the texture image/movie.

Transparent

Yes/No indication of whether the texture uses transparency.

Border

Choose the border color around the texture used for colors outside of the texture bounds.

Frames

Number of frames in the texture (1 for image, >1 for movie).

Time

Static (image) or Transient (movie).

Save

Allows the user to save the currently loaded selection of textures and their display mode into your preferences directory. These will be automatically loaded every time EnSight is launched.

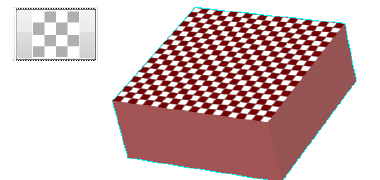

Texture mode

The texture mode determines how a texture is combined with the natural coloring scheme in EnSight. It has three values: Replace, Decal and Modulate.

Replace

In replace mode, the base colors provided by EnSight are ignored and the texture is used as the only source of color for the part

Note: This has the side effect of disabling any lighting.

Decal (default)

In decal mode, the alpha channel of the texture is used to select between the texture color and the base color of the part. If the texture alpha value is 0, the base color of the part is displayed, while locations where the texture alpha value is 255, the texture color will be used exclusively. All alpha values in-between 0 and 255 will result in an interpolation between the texture and base colors.

Note: The default, checkerboard texture uses an alpha channel with values 255 and 80, which when applied to a reddish top surface will show up as follows. For details, see How to Place a Logo on a Part.

Modulate

In modulate mode, the base color is multiplied by the texture color and the resulting texture is used. Modulate mode is commonly used with a texture that has a color of white and some pattern in the alpha channel. This allows the base color to show through, but varies the transparency of the part. Arbitrary clipping operations can be set up this way. Modulation of the color channels can be confusing as the operation tends to suppress colors, but it can be used with a grayscale texture to attenuate. For details, see How to Clip an Object with a Texture.

Repeat mode

Repeat (default), Clamp, and Clamp to texture. When the current texture projection specifies texture coordinates outside of the texture [0,1], EnSight can either repeat the coordinates (for example, a texture coordinate of 2.3 is mapped to 0.3) or it can clamp to the border color of the texture. Clamping is often used for logos and explicit texture coordinates (See Texture Projections).

Repeat

Repeat the texture if outside the texture range [0,1]. If repeat mode is set to repeat, the border color of the texture is not used.

Clamp

Regions outside the texture range are fixed to the border color.

Clamp to texture

Regions outside the texture range are fixed to the texture just inside the border.

Interpolation

When the graphics hardware needs to access a pixel in the current texture it will either use interpolation or nearest neighbor.

Nearest

Nearest interpolation is more exact.

Linear

Bilinear interpolation is smoother and slower.

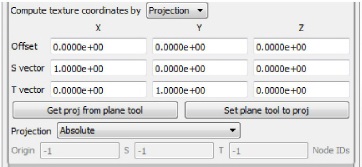

Compute texture coordinates by Projection

Projection (default), In projection mode, think of the texture as a projected light-source, like a presentation projector, only without divergence (i.e. the light lines are parallel). The user places the light source to shine through the scene at some orientation centered at some point. Textures are not limited to the exposed surface in EnSight, therefore any surface that intersects the beam of light is textured.

Offset

The Offset X,Y,Z values are considered to be relative to this node ID. If it moves in time, the texture projection will appear to be linked to it.

S vector

An offset for the S vector.

T vector

An offset for the T vector.

Get the projection using the plane tool orientation.

Set the plane tool position using the projection.

Projection

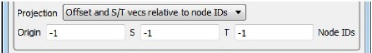

Three options: Absolute (default), Offset relative to node ID, and Offset and S/T vecs relative to node IDs.

Absolute (default) mode requires no input therefore the Origin, S, & T are grayed out. This will fix the texture to its absolute position and attitude in space. If the part geometry moves or deforms, the texture remains fixed in the scene, therefore it appears to slide along the part surface.

Offset relative to node ID - The Offset relative to ID, allows you to specify a node ID in the Origin field so the texture will translate with the node id.

Offset and S/T vecs relative to node IDs - The Offset and S/T vecs relative to node IDs allows you to specify three node IDs that will be used to translate and rotate the texture in 3D space as these three nodes move: Origin, S & T.

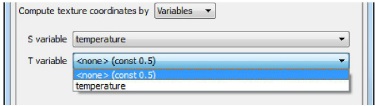

Compute texture coordinates by Variables

In Variables mode, you must enter an S variable and a T variable and a pulldown for each of these variables will appear. In this mode, one or two scalar variables are used to provide explicit S and T texture coordinates for texturing. This is the most general mechanism for texturing. The S-variable and T-variable option menus provide a list of possible scalar variables. Users may also set the S and/or T value to the constant quantity 0.5. The variables are generally in the range [0,1], which map to the edges of the texture map, just inside the border. Values outside this range will either be mapped to the texture border color (in the case of clamp mode) or will be warped back into the range of [0,1] by repeated subtraction/addition (in repeat mode). This form of projection is capable of emulating the previous model. It also makes it relatively easy to create two dimensional data palettes. Just like the existing palette in EnSight, some function of a variable is used to select a color from a table. In this case, the table is a 2D texture, so this can be done for two different variables at the same time, and the opacity can be varied as a function of those variables.

S variable

Default is constant value (0.5). Select a variable with a range of [0,1],

T variable

Default is constant value (0.5). Select a variable with a range of [0,1],

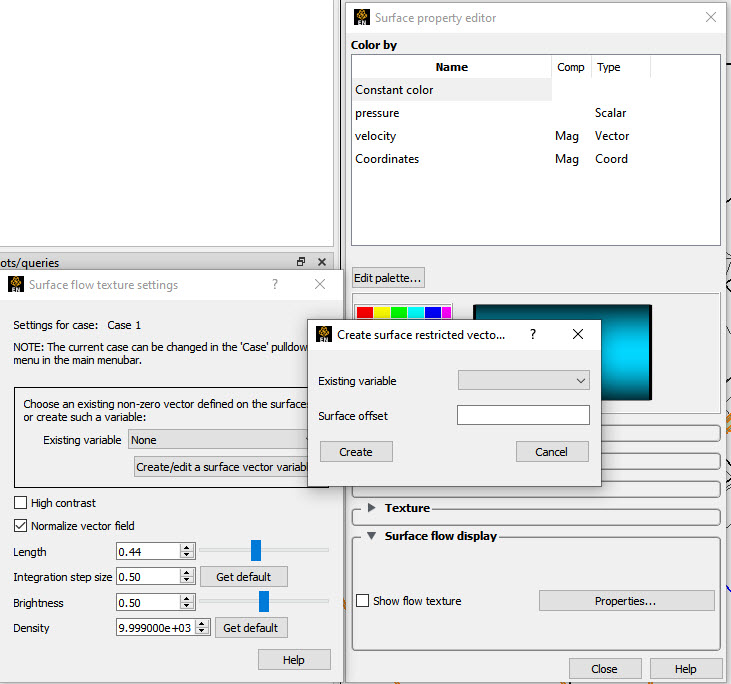

Surface Flow Display

Toggles the display of Surface Flow Texture. This feature provides the capability to visualize a vector (typically velocity) over a surface part, similar to tufts in a wind tunnel. This is not the same as a particle trace part. It is a texture over the entire surface. The properties of a surface flow are per-case.

Show flow texture

This uses a Line Integral Convolution (LIC) algorithm to integrate a vector over a part surface. Select the part(s) on which you desire to display the surface flow, and toggle this ON (default OFF) to attempt to create a surface flow texture. If the chosen vector is zero at the surface then the surface flow texture will just be noise (and you may need to create a surface variable offset into the flow as described below). If the vector variable is per-element, the surface flow texture may not be smooth. You can use the calculator

ElemToNodefunction to create a nodal variable and try again. Click the properties button to open the Surface Flow Texture Settings dialog which will give you more control of the result (see Surface Flow Display in How To Set Surface Properties ).Click this button to open the Surface Flow Texture Settings dialog which will give you more control of the result.

Existing variable

Choose an existing vector variable to display on the surface as flow tufts.

Create/Edit a surface vector variable

If the vector variable is zero on the surface, then click this button to create a new variable from the flow field that can be displayed on the surface.

Note: The first time you click this button, it will open the Create Surface Restricted Vector Variable dialog shown above. Choosing an existing variable and a Surface Offset will calculate a vector variable on the surface by mapping from the flow field using a pre-defined

OffsetVarcalculator function (See Variable Creation).The second time you click this button, it will open the calculator and allow you to edit the variable parameters themselves. You can just as easily calculate a variable using the

OffsetVarfunction and use this variable in the Surface Flow display.Existing variable - pick an existing variable to offset into the flow.

Surface Offset - pick a distance to offset into the flow, using the surface normal to get vector variable value.

High Contrast

Toggle this on to do a pass of image contrast enhancement. The resulting tuft lines will look sharper.

Normalize Vector Field

Toggle this on to normalize integration step length to the same unit length prior to visualization. This will result in all the tufts being the same length. With this off, the integration step length will be scaled according to the vector magnitude and areas where the vector magnitude is near-zero may contain algorithmic noise.

Length

The Line Integral Convolution (LIC) algorithm will integrate a maximum length of 20 pixel units in the positive and negative directions. Length is a scaling factor of this 20 pixels. Range is 0 to 1.

Integration step size

The step size in pixel units for each integration step. Range is 0 to 1.

Brightness

This will brighten up the surface flow tuft display.

Density

The density is a subjective value, related to the number of tufts on the surface. This value is inversely proportional to the model size, and is usually set to a very high initial value, which should create an acceptable flow pattern and may not need to be adjusted. The stepper will double and halve the step value. Above a certain value, there are diminishing returns from increasing this value.

Note: You can't have opacity by a variable on a part while surface flow is being used on that part. As soon as you turn on surface flow, the opacity by a variable alpha value will be reset to none.

LIC References:

Brian Cabral and Leith (Casey) Leedon. Imaging vector fields using line

integral convolution. Proc of ISGGRAPH '93 (Anaheim, CA, Aug 1-6, 1993). In Computer

Graphics 27, Annual Conference Series, 1993, ACM SIGGRAPH, pp 263-272.

Detlev Stalling and Hans-Christian Hege. Fast and resolution independent

line-integral convolution. Proc of SIGGRAPH '95 (Los Angeles, CA, Aug 6-11, 1995). In

Computer Graphics 29, Annual Conference Series, 1995, ACM SIGGRAPH, pp

249-256.

see https://en.wikipedia.org/wiki/Line_integral_convolution

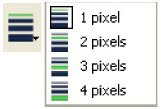

Part Line Width Icon

Opens a pulldown menu for the specification of the desired display width for Part lines. Performs the same function as the Line Representation Width field in the Node, Element, and Line Attributes section of the Feature Panel (Model).

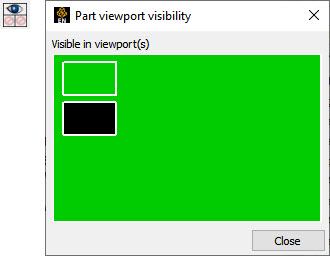

Part Visibility per Viewport Icon

Opens the Part Viewport Visibility dialog. If the global visibility of a Part is on, this dialog can be used to selectively turn on/off visibility of the selected Part(s) in different viewports simply by clicking on a viewport's border symbol within the dialog's small window. The selected Part(s) will be visible in the green viewports invisible in the black viewports.

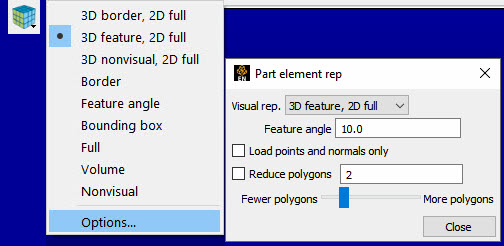

Part Element Settings Icon

Opens a pulldown for the specification of the desired representation for elements of the selected Part(s). Performs the same function as the Element Representation Visual Rep. pulldown menu in the Node, Element, and Line Attributes section of the Feature Panel (Model).

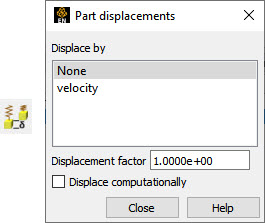

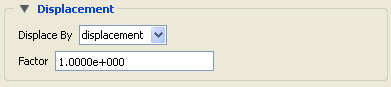

Part Displacements Icon

Opens the Part Displacements dialog which allows you to choose the vector variable and displacement factor. The model geometry is displaced by this variable vector value.

Displacement factor

The vector variable can be scaled by this factor.

Each node of a Part is displaced by a distance and direction corresponding to the value of a vector variable at the node. The new coordinate is equal to the old coordinate plus the vector times the specified Factor, or:

where Cnew is the new coordinate location, Corig is the coordinate location as defined in the data files, Factor is a scale factor, and Vector is the displacement vector.

Note: A value of 1.0 will give you true displacements.

You can greatly exaggerate the displacement vector by specifying a large Factor value. Though you can use any vector variable for displacements, it certainly makes the most sense to use a variable calculated for this purpose.

Note: The variable value represents the displacement from the original location, not the coordinates of the new location.

Displace Computationally

Displacements are done, by default, on the server

(computationally). This means that the coordinates themselves are changed 'deeply' on the

server and are used in calculations affected by the Coordinates (for example,

Area, Volume, Length, etc). Toggling this off will

make the displacements occur only on the client and not used for any computations.

Important: If you plan to use a computed variable for computational displacements, calculate the variable first, and then apply the computational displacements, so that all subsequent calculations will include the adjusted coordinates.

Modifying the coordinates from a variable computed from the coordinates will cause unexpected results as anytime the variable is computed it will be based on the adjusted coordinates of the part which will result in a displacement being applied multiple times. You can not use a displacement variable based on coordinates.

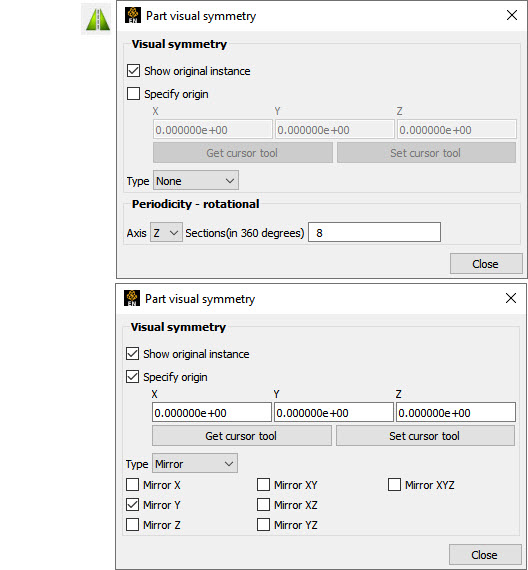

Visual Symmetry Icon

Opens the Part Visual Symmetry dialog which allows you to control the display of mirror images of the selected Part(s) or rotationally symmetric images about the Part's local frame axis and origin. This performs the same function as the Visual Symmetry menu in the General Attributes section of the Feature Panel (Model).

Symmetry enables you to reduce the size of your analysis problem while still visualizing the whole thing. Symmetry affects only the displayed image, not the data, so you cannot query the image or use the image as a parent Part. However, you can get the same effect by creating dependent Parts with the same symmetry attributes as the parent Part.

Show Original Instance

If toggled ON, the original instance will be visible. If toggled OFF, the original instance will not be visible.

Specify origin

You can specify the origin for the rotational or mirror symmetry.

Note: The default frame for all parts is frame 0 (which is coincident with the global axis). To quickly and easily modify the rotational origin, simply specify the origin in global coordinates. More complicated symmetries about axes not aligned with the global axes require assigning a new frame to the part(s) of interest.

Get/Set cursor tool

Populate the visual symmetry origin fields using the cursor tool location by clicking the get cursor tool button. Use the Set cursor tool button to assign the current origin field values to the cursor location.

Type

Mirror

3D space split by three planes of a cartesian frame (xy, xz, and yz) defines 8 quadrants

(+x+y+z, +x+y-z, +x-y+z, +x-y-z, -x+y+z, -x+y-z, -x-y+z, -x-y-z). Mirroring can be thought of as reflecting your model through these planes, or the origin, to get the proper mirrored image of the data in the various quadrants.

You can mirror the Part to more than one quadrant. If the Part occupies more than one quadrant, each portion of the Part mirrors independently. The images are displayed with the same attributes as the Part. For each toggle, the Part is displayed as follows. The default for all toggle buttons is OFF, except for the original representation - which is ON.

Mirror X

quadrant on the other side of the YZ plane.

Mirror Y

quadrant on the other side of the XZ plane.

Mirror Z

quadrant on the other side of the XY plane.

Mirror XY

diagonally opposite quadrant on the same side of the XY plane.

Mirror XZ

diagonally opposite quadrant on the same side of the XZ plane.

Mirror YZ

diagonally opposite quadrant on the same side of the YZ plane.

Mirror XYZ

quadrant diagonally opposite through the origin.

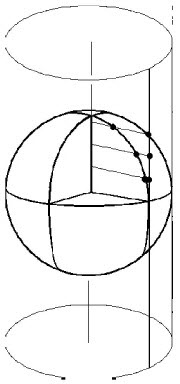

Rotational

Rotational visual symmetry allows for the display of a complete (or portion of a) "pie" from one "slice" or instance. You control this option with:

Instances

specifies the number of rotational instances to display.

Note: An additional section appears for rotational symmetry only. It is entitled Periodicity - Rotational. While the Axis is used for both visual symmetry and periodic traces, the Sections field is only needed/used when periodic traces are created. See the Periodic Traces section of Create Particle Traces for instructions.

Axis

Specifies which rotational axis is to be used for rotational symmetry and periodic traces.

Sections (in 360 degrees)

Specifies the number of sections (instances) needed to make a full 360 degrees. Only used for periodic traces.

Translational

Translational visual symmetry allows for the display of a number of instance(s) of the model, each translated a fixed distance in the x, y, and/or z direction(s) from the previous instance.

None

No visual symmetry will be done.

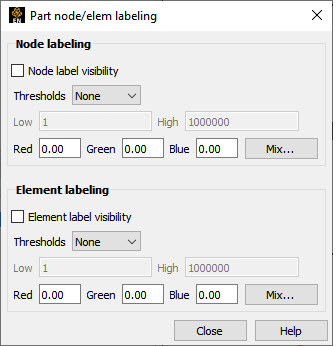

Element Labeling Icon

Opens the Part Node/Elem Labelling dialog. Toggles on/off the visibility of the element and/or node labels (assuming the result file contains them) for the selected Part(s). The global Element Labeling Toggle (View → Label Visibility) must be on in order to see any element labels. Likewise, the global Node Labeling Toggle (View → Label Visibility) must be on in order to see any element labels.

Element/Node Label Visibility

Toggles on/off the visibility of the element or node labels (assuming the result file contains them) for the selected Part(s). Performs the same function as the Label Visibility Node toggle in the Node, Element, and Line Attributes section of the Feature Panel (Model). Default is OFF.

Note: If your part geometry occludes your node ids then set the part opacity to transparent. To do this easily: Right-click the part in the graphics area, or on the selected part(s) in the part list and choose Color by → Make Transparent. To change it back, right-click and choose Color by → Make Opaque.

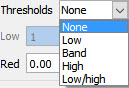

Filter Thresholds

A pulldown menu containing the following

Low

All element/node ids below the value in the low field are invisible

Band

All element/node ids between the values in the low and high fields are invisible.

High

All element/node ids above the value in the high field are invisible.

Low/High

All element/node ids below the low and above the high field values are invisible.

Red, Green, Blue, Mix

Enter the element/node id label color, or click the button and pick your color.

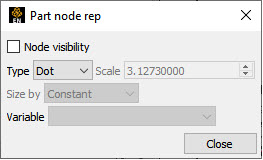

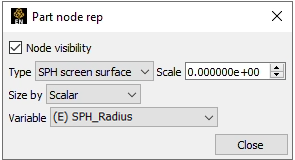

Node Representation Icon

Opens the Part Node Rep dialog. Performs the same function as the Node Representation area in the Node, Element, and Line Attributes section of the Feature Panel (Model).

Node Visibility Toggle

Toggles-on/off display of Part's nodes whenever the Part is visible. Default is OFF.

Type

Opens a message menu for the selection of symbol to use when displaying the Part's nodes or point elements. Default is Dot. Options are:

Dot

To display nodes as one-pixel dots.

Cross

To display nodes as three-dimensional crosses whose size you specify. If you want to render as spheres, first choose Cross and get the Scale adjusted properly and then choose Sphere.

Sphere

To display the nodes as spheres. If your graphics card supports advanced GPU rendering of spheres (OpenGL version 3.3 or above) then the spheres will be rendered extremely efficiently and the detail box will be greyed out and unavailable.

Important: When rendered using advanced rendering, extremely large sphere sizes can cause greatly slow down rendering or even hang your graphics card (due to a driver limitation). Therefore, EnSight computes a safe sphere scale factor automatically as a starting point, and best practice is to use the up or down arrows to the right of the scale field to double or half the scaling value incrementally, then type in an exact value for fine adjustments.

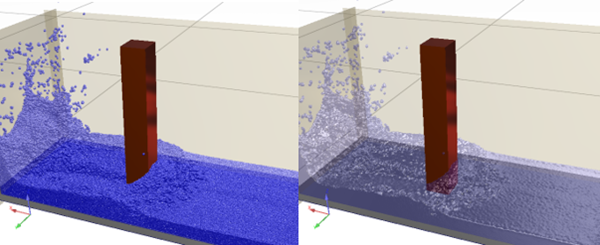

SPH screen surface

Smoothed-particle hydrodynamics (SPH) is a meshless approach for simulating the mechanics of continuum media, such as solid mechanics and fluid flows. EnSight can display the SPH nodes as a surface efficiently rendered in the client’s screen space (more efficiently than on the server). Treating all the particles as a collection of spheres, the surface is extracted on the fly using a screen space voxel grid rendered into a surface. Therefore, real-time performance can be achieved. To use this feature, simply click the node representation icon

and choose Type as

.

and choose Type as

.Note: For the best quality of surface reconstruction, you should set the size of particles correctly. It is best if you request that the solver exports the particle radius as a variable in the dataset; set the overall particle size to be twice the radius. If not, you can size by constant, starting with a small size and increasing it slowly, interactively until the visual result is satisfactory. Even with particle radius used, you may need to use a Scale smaller or larger than 2 to achieve the desired fluid-like surface. For more details on sizing the particle, see the following sections.

Since this approach internally uses the sphere rendering algorithm, the above limitations for sphere rendering also apply.

Scale

This field is used to specify the scaling factor for size of the node symbol. If Size By is , this Scale field will specify the diameter of the marker in model coordinates. If Size By is set to a variable, this Scale field value will be multiplied by the variable value. If your variable is the particle diameter, then choose a Scale of

1.0to see the appropriately scaled spherical representation of your particles, relative to the rest of the model. If your variable is the particle radius then choose a Scale of2.0to see the accurately scaled spherical representation of your particles relative to the rest of the model. Not applicable when the node-symbol Type is .Caution: Use caution here if using advanced GPU rendering of spheres because a large size relative to the size of the geometry can cause the graphics card to hang. Start out very small relative to the model size and use a cross instead of a sphere then increase your size until the crosses are sufficiently large, then change them over to spheres.

Size By

Opens a message menu for the selection of variable-type to use to size each node-symbol. For options other than Constant, the node-symbol size will vary depending on the value of the selected variable at the node. Not applicable when node-symbol Type is Dot. Get this working using Cross, then switch to Sphere to avoid hanging your graphics card. Default is Constant. Options are:

Constant

Sizes node using the Scale factor value.

Scalar

Sizes node using a scalar variable.

Vector Mag

Sizes node using magnitude of a vector variable.

Vector X-Comp

Sizes node using magnitude of X-component of a vector variable.

Vector Y-Comp

Sizes node using magnitude of Y-component of a vector variable.

Vector Z-Comp

Sizes node using magnitude of Z-component of a vector variable.

Variable

Selection of variable to use to size the nodes. Activated variables of the appropriate Size By type are listed. Not applicable when node-symbol Type is Dot or Size By is Constant.

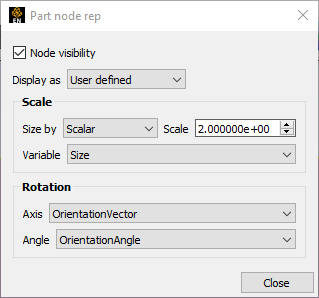

User defined

For point parts, a reader can provide a mesh to be drawn for each node. When nodes are drawn this way, an orientation can also be applied. The orientation is defined by a vector variable and a scalar variable. The vector is an axis of rotation, and the scalar is an angle of rotation, in radians.

The reader for the Rocky solver is currently the only solver that provides a mesh per node and an orientation. All three attributes are applied automatically.

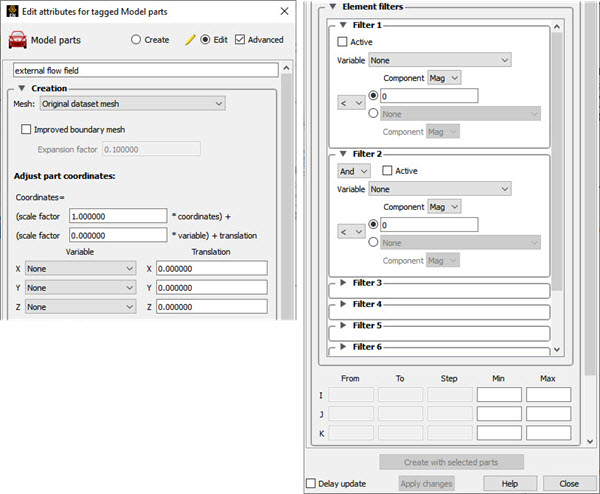

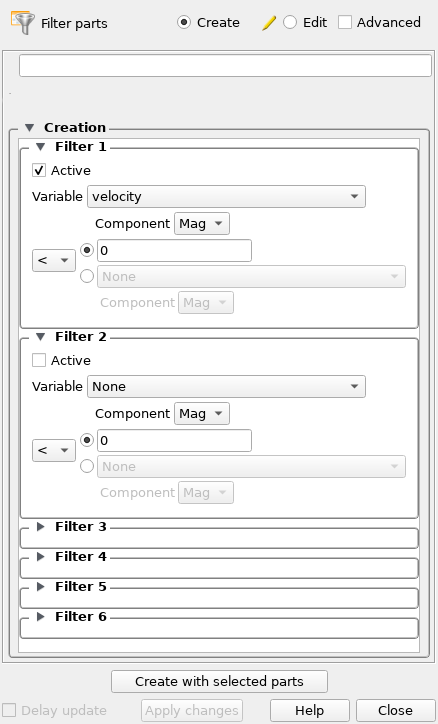

Filtered Elements Icon

Opens the Part Filter By Variable (Model parts only) dialog. Choose a variable (ideally a per-element variable, but you can also use a per-node variable which EnSight will average to the elements). This does a deep element removal of the elements from the selected model part on the server based on logical operators on the variable. Since filtering only works on model parts, filtering elements on a created part can only be accomplished by filtering them on the model parent part. Alternatively you can use the Filter part creation which will operate on a set of parent parts where those parent parts can be any part type.

Six filters are available. Each filter can specify a variable to

use in the filtering process which can be compared against another variable or a constant

value. The filters are combined with and or or

operators. The filtering occurs sequentially through the filters, that is, it is not

possible, for example, to specify a filter operation of variable1 < 0.5 OR

(variable2 > 1.0 AND variable 3 < 0.0)

See Filter Part Elements.

Variable

Select a scalar or vector variable.

Component

If a vector, then the component of the vector.

Active

Activate the filter by toggling it on. Notice that six filters can be toggled on.

And / Or

If you toggle on a logical operator then choose second threshold.

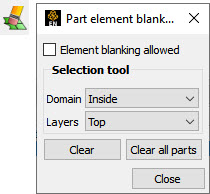

Part Element Blanking/Visibility Icon

Brings up the Part Element Blanking dialog. Element blanking is the visual removal of elements on the graphics screen. The elements still remain on the server and are still used in calculations, they are just not visible in the graphics window.

Note: Blanking is done using element IDs as tags. If the element IDs change each timestep, this can result in different elements becoming invisible each timestep.

See Do Element Blanking.

Element blanking allowed

Toggles on/off whether element blanking allowed

Selection tool

Domain

Controls whether inside or outside of selection tool will be used fro the blanking

Layers

Controls the depth of the blanking operation. Top will just blank the first layer of elements encountered at each invocation. While all will blank elements at all depths.

Clear

Clears blanked elements and restores them to visible for the selected Part(s)

Clear all parts

Clears blanked elements and restores them to visible for all Part(s)

Part Shaded Surface Icon

Toggles on/off Shaded display of surfaces for the selected Part(s) assuming that global Shaded has been toggled ON in View → Shaded. Performs the same function as the Hidden Surface Toggle in the General Attributes section of the Feature Panel (Model). Default for all Parts is ON.

Part Hidden Line Icon

Toggles on/off hidden line display of surfaces for the selected Part(s) assuming that the global Hidden Line has been toggled ON in View → Hidden Line. Performs the same function as the Hidden Line Toggle in the General Attributes section of the Feature Panel (Model). Default for all Parts is ON.

Part Auxiliary Clipping Icon

Toggles on/off whether the selected Part(s) will be affected by the Auxiliary Clipping Plane feature. Performs the same function as the Aux Clip toggle in the General Attributes section of the Feature Panel (Model). Default is ON. Auxiliary clipping is simply a visual clipping that occurs only on the client and does not affect the underlying model geometry, only its view on the screen.

Note: The global Auxiliary Clipping Toggle (in View) must be on in order for any Parts to be affected by the Auxiliary Clip Plane.

Fast Display Representation Icon

Opens a pulldown menu for the specification of the desired fast display representation in which a Part is displayed. The Part fast display representation corresponds to whether the view Fast Display Mode (located in the View Menu) is on. The Fast Display pulldown icon performs the same function as the Fast Display pulldown menu in the General Attributes section of the Feature Panel (of all parts).

Box

Causes selected Part(s) to be represented by a bounding box of the Cartesian extent of all Part elements (default)

Points

Causes selected Part(s) to be represented by a point cloud

Reduced poly

Causes selected Part(s) to be represented by reduced number of polygons

Sparse Model

Decimates part elements by a factor determined in the

Preferences. Go to Edit →

Preferences → Performance and enter in a

factor from 1 (sparse) to 100 (full) in the Sparse model representation

field. This is only available when running in immediate mode using the

-no_display_list option at startup.

Invisible

Causes the selected Part(s) to be invisible

(see General Attributes in Set Global Viewing Parameters).

When you start EnSight, you either read directly or interactively extract parts from the data files. Parts which come from the original dataset are referred to as model parts. Model parts are defined by the data readers and are usually a logical grouping of nodes and elements as defined by the solver. It might be a material or property or perhaps a defined geometric entity such as a wheel or inlet

The computational grid (or mesh) used by EnSight is either an unstructured definition (where each mesh element is defined) or a structured definition (an IJK definition) defining a rectilinear or curvilinear space. It is also possible to have a mixed definition where some parts are unstructured and other parts are structured.

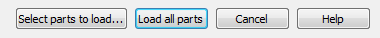

When you read data you will choose the file name that will be read and set the format and options for the file. Then you will choose one of two options - either to load all the parts or to select parts to load.

The option will read the specified data (the case) and create (i.e. load) all of the parts into EnSight. The other option - - will read the data but will not load any parts. This second option will allow you to select on a per part basis which parts will be loaded into EnSight. This load process is performed through the Part list.

The Part list contains all parts that have been read in (loaded) from your specified data file as well as those created within EnSight. Additionally, it may show model parts from the data that are not already loaded. These are referred to as Loadable Parts or LPARTS.

LPARTS may be loaded zero or more times. You may choose not to load a particular part from a data set if it is not needed for the visualization or analysis of the case. This is advantageous to save memory and processing time. You may also choose to load a part multiple times - so you could, for example, color the part by multiple variables at the same time in multiple viewports.

LPARTS are shown as grayed out parts in the Part list. You can load a LPART by selecting the part(s) and performing a right-click operation to Load part.

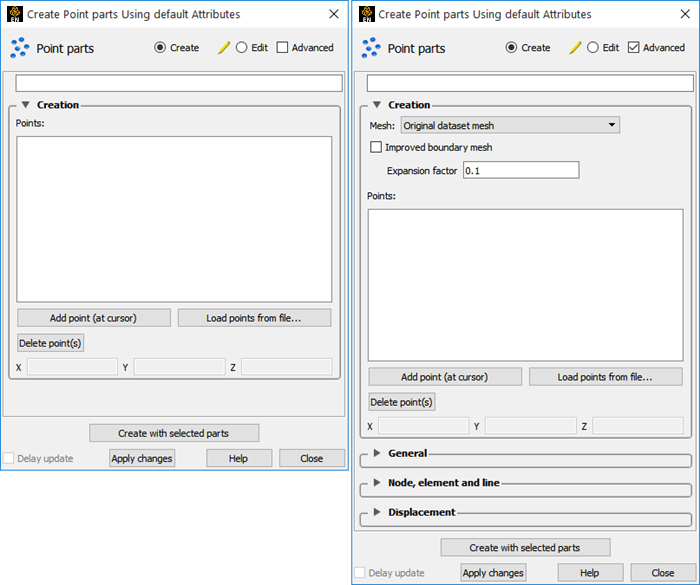

There are some creation attributes that affect model parts. These will be discussed in this section.

There are also various attributes that affect the display of these parts, as well as all created part types. These common attribute turndown sections of the Feature Panel, will also be described in this section.

Since Model Parts are controlled by the loading process, they have neither a specific Feature icon in the Feature Icon Bar, nor an entry in the Main Menu → Create menu. They do, however, have a Feature Panel associated with them. This Feature Panel for Model Parts is opened by double-clicking (or right-clicking and choosing Edit...) on a model part in the Part list.

Edit

Only the Edit mode is active, since all creation of model parts takes place with the loading process.

Note: When editing, the changes will be applied to those parts which have the small pencil icon next to them in the Parts list.

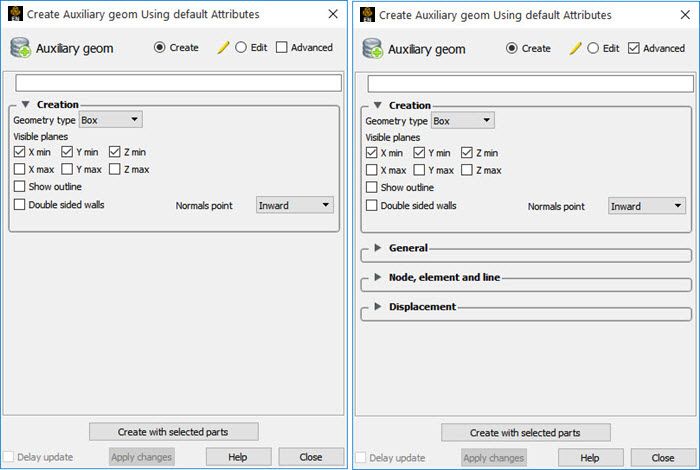

Advanced

Will open additional features for more advance control of the Part.

Desc

The name of the part being edited. You can modify this description as desired.

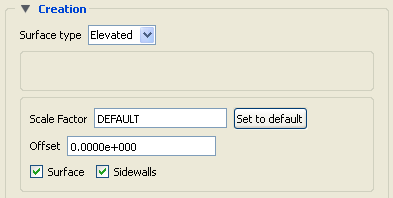

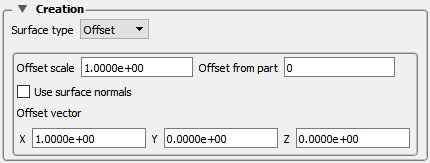

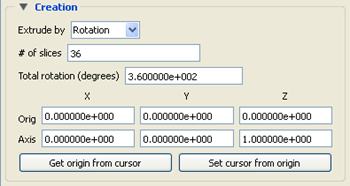

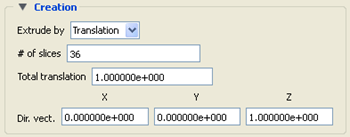

Creation

Creation Attributes for model parts consist of geometry scaling options (including server-side displacements) for unstructured and structured parts, and updating of I,J,K ranges for structured parts. Geometry scaling can be accomplished with a scale factor which will be applied to the model coordinates and/or a scale factor times a nodal variable. Updating the I,J,K node range attributes of the selected block structured Model Parts or the geometry scaling will cause proper updating of all dependent parts and variables.

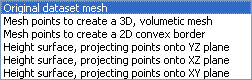

Mesh

Opens pulldown menu for selection of model part re-meshing to use.

The default is to use the element connectivities described in the model data file(s). But a remeshing can be done, utilizing the

QHulllibrary. This library can compute the convex hull of point data, a 2D meshing. And since the convex hull of a 3D dataset lifted into 4 dimensional space turns out to be the volumetric tetrahedralization of the 3D data, it can be used to do a 3D meshing as well. Please note that this remeshing can take considerable memory and processing - so it needs to be used with that in mind. Also note, that if the model part has been used to create other, children parts, remeshing is not allowed. Only unstructured model parts are allowed to be remeshed. The following model parts are allowed: model, extract, point, and measured parts.Also, the worst case for

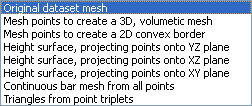

QHullis a large number of co-planar points. In the higher dimensional lifting step, the planarity adds a singularity that is difficult to work around. Using bounding boxes and planar projections can help. Accordingly, several options exist, which can be used if your data exhibits problematic characteristics. The pulldown menu options are:Original dataset mesh

The nodes and elements described in the model data file(s) is used. No remeshing is done. This is the default.

Mesh points to create a 3D, volumetric mesh

The original element connectivities will be replaced with a volumetric meshing of the nodes of the part, to produce tet elements.

Mesh points to create a 2D convex border

The original element connectivities will be replaced with a convex hull meshing of the nodes of the part, to produce triangle elements.

Height surface, projecting points onto YZ plane

The original element connectivities will be replaced. The nodes of the part will be projected to the YZ plane and then triangulated in 2D. The resulting triangle element connectivities will be used with the original node data.

Height surface, projecting points onto XZ plane

The original element connectivities will be replaced. The nodes of the part will be projected to the XZ plane and then triangulated in 2D. The resulting triangle element connectivities will be used with the original node data.

Height surface, projecting points onto XY plane

The original element connectivities will be replaced. The nodes of the part will be projected to the XY plane and then triangulated in 2D. The resulting triangle element connectivities will be used with the original node data.

Note: There are a few formats that will not allow you to return to the input dataset elements once you have meshed the part. Most do. For these few (ABAQUS fil, Ansys, ESTET, Ansys FIDAP Neutral, Fluent Universal, and N3S), you can change between the 2D and 3D meshing options, but you need to delete the part and reload it, if you desire the part back to the input elements.

Improved Boundary Mesh

If one of the remeshing options is used, this toggle will employ a common trick that often helps with the co-planar points problem described above. The trick consists of adding 8 points (one at each corner of the bounding region) to the other points. This basically embeds the original points inside of an 8-point box. Then compute the volume tets and remove any tets connected to the non-original box points. Note that an offset can be used for the bounding region to ensure that the bounding region is not collapsed to 2D space (see Expansion factor below).

Expansion Factor

When adding the 8 points for the Improved boundary mesh trick above, an offset can be used to expand the bounding region in all directions. This is that offset, or expansion value.

Adjust Part Coordinates

The coordinates of the selected parts will be scaled and translated by the formula shown in the dialog. It is possible to apply a simple scale factor, and/or to apply a scaled nodal displacement vector variable (just choose the same vector variable for each pulldown and it will use the correct component). In fact each coordinate direction can be scaled according to a different model scalar variable if desired. This works only with model variables, not computed variables. This is server-side scaling and displacement, having the advantage of being able to properly query and compute on the displaced geometry of the model.

Other Options

If you want to displace by a vector in which the resulting displacement is updated each timestep then see Display Displacements.

If you want to scale the model coordinates visually only, then you can use the transform editor and choose the scaling option and visually scale the geometry in the three orthogonal directions, and do this separate for each direction (see Rotate, Zoom, Translate, Scale).

If you want to scale, translate, or rotate a number of parts visually only consider grouping them and doing a group transform (see Part Group Visual Transformations).

If you need to define your part(s) rotation or translation over time, consider rigid body translations (see EnSight Rigid Body File Format).

If you need precise control of the rotation and translation of parts separately for animation purposes, consider attaching a separate coordinate frame to each part (see Create and Manipulate Frames).

Change Structured Range and Step Values

The creation range and step values for structured parts can be changed here

IJK From

These fields specify the desired minimum interval value in the respective IJK component direction of the Model Part.

IJK To

These fields specify the desired maximum interval value in the respective IJK component direction of the Model Part.

IJK Step

These fields specify the desired interval stride value in the respective IJK component direction of the Model part.

IJK Min

These fields verify the minimum interval limit in the respective IJK component direction of the Model part.

IJK Max

These fields verify the maximum interval limit in the respective IJK component direction of the Model part.

(See Create IJK Clips).

Element Filters

Active

Enables Element Filtering.

Variable

Elements are removed from display on the client and from calculation on the server for model parts only, using the named variable (and component, if a vector) and the threshold operator(s) (< , > , = , != ) as well as the value (either a single number or another variable).

Note: Multiple filters can be applied sequentially strung together using logical ‘and’ or logical ‘or’:

Filtered elements are not removed when the geometry is saved in Case Gold format or as a Flatfile (see Saving Geometry and Results Within EnSight).

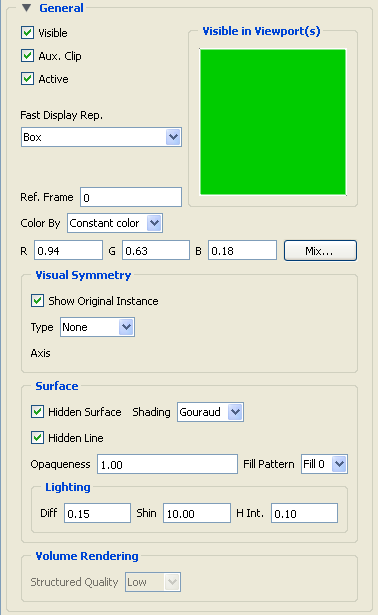

General

General attributes are general in that all Parts have them and they can't be neatly categorized into any other attribute type. Like all Part attributes, they are set individually for each Part.

Visible

Toggles-on/off whether Part is visible on a global basis (in the Graphics Window or in all viewports). (Performs the same function as the Visibility Quick Action icon). Default is ON.

Aux. Clip

Toggles-on/off whether Part(s) selected in the Part list will be affected by the Auxiliary Clipping Plane feature, which enables you to make invisible that portion of each Part on the negative side of the current position of the Plane Tool. Performs the same function as the Auxiliary Clipping Quick Action icon. A Part with its Aux Clip attribute toggled-off will not be cut away. Default is ON. (See Set Auxiliary Clipping).

Active

Toggles-on/off whether or not display of the Part automatically updates as the solution time changes. When visualizing transient data, you may wish to freeze a Part in time while other Parts continue to update. For example, you can create two identical vector-arrow Parts, toggle-off Active for one of them, change the time step of the display and see how the vector arrows change from one time step to the other. Only the EnSight client Part is frozen, the EnSight server Part is kept current. Default is ON.

Visible in Viewport(s)

This small window allows you to control the visibility of the selected Part(s) on a per Viewport basis. Each visible viewport is shown. A green Viewport indicates that the selected Part(s) will be visible in this Viewport, while a black Viewport indicates that the selected Part(s) will not be visible. Change the visibility (black to green, green to black) by selecting a viewport with the mouse.

This pulldown menu allows for the selection of the fast display representation used to display a part on the client. This attribute helps the display of complex data sets. The part's fast display representation displays according to whether the global Fast display option (located in the View menu) is on or off and on the state of the Static Fast Display toggle located under Edit → Preferences..., Performance. For instance, when the Fast Display is Off (default) the part displays according to its specified Element Representation. When on, the parts are displayed by the fast display representation. The fast display representation will only be used while performing transformations, unless the Static Fast Display option has been selected. The part detail representations are:

Off

display according to specified Element Representation.

Box

a bounding (Cartesian extent) box of all part elements (default).

Points

point cloud representation of the part.

Reduced poly

polygon reduced representation of the part.

Sparse Model

display a percentage of the model in each display box (only available when running in immediate mode, using the

-no_display_list startupoption). You control this percentage in the performance preferences.Note: That it is useful for large models, but should probably not be used for small models.

Invisible

do not display at all while moving.

Ref. Frame

This field specifies which frame the Part is assigned to. Default is the frame of the Part's parent Part (Frame 0 for original model Parts). Enter a different frame number in the field to change the assignment. Changing a Part's frame causes the Part to be drawn in the new coordinate frame. Once assigned to a different frame, the Part will transform with that frame. The choice of frame does not affect variable values. The interpolated value of a variable at point 0,0,0 in Frame 0 is the same as at point 0,0,0 in Frame 1, even though the points may appear at different locations in the Main View Window.

Color By

A pulldown menu for the selection of the variable color palette by which you wish to color the selected Part(s). Coloring a Part with a palette does not normally affect graphics performance while in line drawing mode, but Shaded Surface mode performance can be affected. If you do not color by a palette (Color By → Constant color), the Part will be displayed according to the color specified in the R, G, B fields. If you want to color Parts by palettes and want Shaded Surface mode, consider using the Static Lighting option (see Static Lighting in View Menu Functions).

RGB

These fields allow you to specify a solid color for the selected Part(s) (applicable only if Color By is Constant color). Enter a numerical value from 0 to 1 for each component color (Red, Green, and Blue).

Mix...

Opens the Select a color dialog for the selection of a solid color for the selected Part(s) (applicable only if Color By is Constant color).

Visual Symmetry

Allows you to control the display of mirror images of the selected Part(s) in each of the seven other quadrants of the Part's local frame or the rotationally symmetric instances of the selected parts. This performs the same function as the Visual Symmetry Quick Action icon.

Symmetry enables you to reduce the size of your analysis problem while still visualizing the whole thing. Symmetry affects only the displayed image, not the data, so you cannot query the image or use the image as a parent Part. However, you can create the same effect by creating dependent Parts with the same symmetry attributes as the parent Part.

Show Original Instance

Show the original instance or not

Type

Mirror

You can mirror the Part to more than one quadrant. If the Part occupies more than one quadrant, each portion of the Part mirrors independently. Symmetry works as if the local frame is Rectangular, even if it is cylindrical or spherical. The images are displayed with the same attributes as the Part. For each toggle, the Part is displayed as follows. The default for all toggle buttons is OFF, except for the original representation - which is ON.

Symmetry

Mirror X - quadrant on the other side of the YZ plane.

Mirror Y - quadrant on the other side of the XZ plane.

Mirror Z - quadrant on the other side of the XY plane.

Mirror XY - diagonally opposite quadrant on the same side of the XY plane.

Mirror XZ - diagonally opposite quadrant on the same side of the XZ plane.

Mirror YZ - diagonally opposite quadrant on the same side of the YZ plane.

Mirror XYZ - quadrant diagonally opposite through the origin.

Rotational

Rotational visual symmetry allows for the display of a complete (or portion of a) pie from one slice or instance. You control this option with:

Axis - rotates about the axis chosen.

Angle - specifies the angle (in degrees) to rotate each instance from the previous.

Instances - specifies the number of rotational instances.

None

No visual symmetry will be done.

Surface

Hidden Surface

Toggles on/off surface shading for individual Parts. When global Hidden Surface has been toggled on for the Graphics Window display (from View → Shaded or the global Shaded Surfaces Tools icon), individual Parts can be forced to stay in line drawing mode using this toggle. Default is ON. (see View Menu Functions).

Shading

Pulldown menu for selection of appearance of Part surface when Hidden Surface is on. Normally the mode is set to Gouraud, meaning that the color and shading will interpolate across the polygon in a linear scheme. You can also set the shading type to Flat, meaning that each polygon will get one color and shade, or Smooth which means that the surface normals will be averaged to the neighboring elements producing a smooth surface appearance. Not valid for all Part types. Options are:

Flat

Color and shading same for entire element

Gouraud

Color and shading varies linearly across element

Smooth

Normals averaged with neighboring elements to simulate smooth surfaces

Smooth High Quality

Uses the same algorithm as Smooth, except does not smooth sharp edges, which is useful if the user wants to retain some of the sharp features of the part.

Hidden Line

Toggles on/off hidden line representation for individual Parts. When global Hidden Line has been toggled on for the Graphics Window display (from View → Hidden Line or via the global Hidden Line Tools icon), individual Parts can be forced not to appear as Hidden Line representation using this toggle. (To have lines hidden behind surfaces, Parts must have surfaces, i.e. 2D elements) Default is ON. (see View Menu Functions)

Opaqueness

This field specifies the opaqueness of the selected Part(s). A value of 1.0 indicates that the Part is fully opaque, while a value of 0.0 indicates that it is fully transparent. Setting this attribute to a value other than 1.0 can seriously affect the graphics performance.

Diff

This field specifies diffusion (minimum brightness or amount of light that a Part reflects). (Some applications refer to this as ambient light.) The Part will reflect no light if value is 0.0. If value is 1.0, no lighting effects will be imposed and the Part will reflect all light and be shown at full color intensity at every point. To change, enter a value from

0to1.Shin

This field specifies shininess. You can think of the shininess factor in terms of how smooth the surface is. The larger the shininess factor, the smoother the object. A value of 0 corresponds to a dull finish and a value of 100 corresponds to a highly shiny finish. To change, enter a value from 0 to 100.

H Int.

This field specifies highlight intensity (the amount of white light contained in the color of the Part which is reflected back to the observer). Highlighting gives the Part a more realistic appearance and reveals the shine of the surface. To change, enter a value from

0to1with larger values representing more white light. Will have no effect if Shin parameter is zero.(see Set Attributes).

Volume Rendering

Structured Quality

This field controls the quality of volume rendering for a structured part. It allows a tradeoff between rendering speed and image quality. The Low, Medium, and High options provide this tradeoff by varying the number of samples. The Best option provides the most precise rendering by performing exact ray/cell intersections.

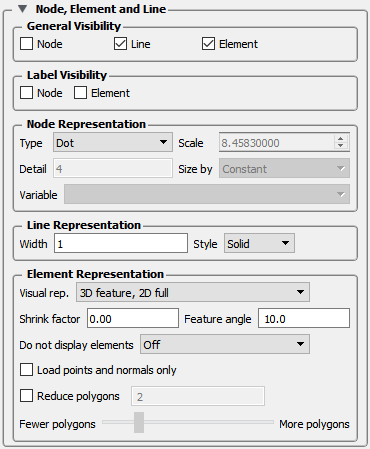

Node, element and line

Each Part's Node, Element, and Line attributes control the representation of the Part on the client, and how nodes, elements, and lines are displayed.

General Visibility

Node

Toggles-on/off display of Part's nodes whenever the Part is visible. Default is OFF.

Line

Toggles-on/off display of line (1D) elements in the client-representation whenever the Part is visible. Default is ON.

Element

Toggles-on/off display of 2D elements in the client-representation whenever the Part is visible.

Note: 3D elements are always represented as 2D elements on the client. Default is ON.

Label Visibility

Node

Toggles-on/off display of Part's node labels (if they exist) whenever the Part is visible. Only model Parts may have node labels. Default is OFF.

Element

Toggles-on/off display of Part's element labels (if they exist) whenever the Part is displayed in Full visual representation. Only model Parts may have element labels. Default is OFF.

Node Representation

Type

Opens a message menu for the selection of symbol to use when displaying the Part's nodes. Default is Dot. Options are:

Dot

to display nodes as one-pixel dots.

Cross

to display nodes as three-dimensional crosses whose size you specify.

Sphere

to display the nodes as spheres whose size and detail you specify.

SPH Screen Surface

Particles in an SPH point part are treated as spheres and a surface is extracted on the fly using a screen space voxel grid rendered into an outer surface.

Scale

This field is used to specify scaling factor for size of node symbol. Values between 0 and 1 reduce the size, factors greater than one enlarge the size. Not applicable when node-symbol Type is Dot. Default depends on your model size.

Detail

This field is used to specify how round to draw the spheres when the node-symbol type is Sphere. Ranges from 2 to 10, with 10 being the most detailed (for example,, roundest spheres). Higher values take longer to draw, slowing performance. Default is 2.

Size By

Opens a message menu for the selection of variable-type to use to size each node-symbol. For options other than Constant, the node-symbol size will vary depending on the value of the selected variable at the node. Not applicable when node-symbol Type is Dot. Default is Constant. Options are:

Constant

sizes node using the Scale factor value.

Scalar

sizes node using a scalar variable.

Vector Mag

sizes node using magnitude of a vector variable.

Vector X-Comp

sizes node using magnitude of X-component of a vector variable.

Vector Y-Comp

sizes node using magnitude of Y-component of a vector variable.

Vector Z-Comp

sizes node using magnitude of Z-component of a vector variable.

Variable

Selection of variable to use to size the nodes. Activated variables of the appropriate Size By type are listed. Not applicable when node-symbol Type is Dot or Size By is Constant.

Line Representation

Width

Specification of width (in pixels) of line elements and edges of 2D elements whenever they are visible. Range is from 1 to 20. Default is 1. Line widths other than 1 are not available on all hardware. This performs the same function as the Part Line Width Pulldown icon in Part Mode.

Style

Selection of style of line when lines are visible. Default is Solid. Options are:

Solid

Dotted

Dot-Dash

Element Representation

Visual Rep.

Selection of representation of Part's elements on the client. Saves memory and time to download.

3D border, 2D full

represents the Part's 3D elements in Border representation, the Part's 1 and 2D elements in Full representation. The result is the outside surfaces of the Part are displayed along with all bar elements.

3D feature, 2D full

represents the Part's 3D elements in Feature representation, the Part's 1 and 2D elements in Full representation. The result is the outside sharp edges of the Part are displayed along with all bar elements.

3D nonvisual, 2D full

represents the Part's 3D elements in non visual representation, the Part's 1 and 2D elements in Full representation. The result is all the 1 and 2Delements from 2D parts are displayed.

Border

represents the Part's 3D elements with 2D elements corresponding to unshared element faces, the Part's 2D elements with 1D elements corresponding to the unshared edges, and the Part's 1D elements as 1D elements. The result is the outside faces and edges of the Part's elements.

Feature Angle

first runs the 3D border, 2D full representation to get a list of 1 and 2D elements. The 1D elements and all non-shared 2D edges will be shown, but only the shared edges above the Angle value will be shown. The result consists of 1D elements visualizing the sharp edges of the Part.

Bounding Box

represents all Part elements as a bounding box surrounding the Cartesian extent of the elements of the Part.

Full

represents all faces of the Part's 3D elements, and all the 1 and 2D elements.

Non Visual

means the Part exists on the server, but is not loaded on the client. Not Loaded Parts may be used as parent Parts, but do not exist on the client.

Volume

Represents a variable spatially by varying the alpha transparency according to the variable value throughout the spatial domain. This requires a modern graphics card.

Shrink Factor

Specification of scaling factor by which to shrink every element toward its centroid. Enter the fraction to shrink by in range from 0 to 1. Default is 0.0 for no shrinkage.

Angle

Specification of lower limit for not displaying shared edges in Feature Angle Representation. Value is in degrees.

Load points and normals only

Loads only vertex information and normals for the element representation given to the client. Useful for very large models.

Reduce Polygons

Lower the polygon density used to represent the part. Useful for very large models. Toggle on, then type in a value to reduce by, or slide the slider.

See Set Attributes and Display Labels

Displacement

Displacement Attributes specify how to displace the Part nodes based on a nodal vector variable. Each node of the Part is displaced by a distance and direction corresponding to the value of a nodal vector variable at the node. The new coordinate is equal to the old coordinate plus the vector times the specified Factor, or:

where:

C new is the new coordinate location,

C orig is the coordinate location as defined in the data files,

Factor is a scale factor, and

Vector is the displacement vector.

You can greatly exaggerate the displacement vector by specifying a large Factor value. Though you can use any vector variable for displacements, it certainly makes the most sense to use a variable calculated for this purpose.

Note: The variable value represents the displacement from the original location, not the coordinates of the new location.

Displace By

Opens a message menu for selection of vector variable to use for displacement (or None for no displacement). Variable must be a nodal vector and be activated.

Factor

This field is used to specify a scale factor for the displacement vector. New coordinates are calculated as: C new = C orig + Factor*Vector, where C new is the new coordinate location, C orig is the original coordinate location as defined in the data file, Factor is a scale factor, and Vector is the displacement vector.

Note: A value of 1.0 will give you true displacements.

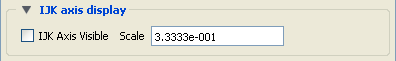

IJK axis display

All Model and clip parts will have these attributes shown, but they only apply to those model and clip parts which are structured.

IJK Axis Visible

Toggle on to display an IJK axis triad for the part. IJK axis triad only visible when part is visible.

Scale

The scale factor for the IJK Axis triad.

(See Set Attributes).

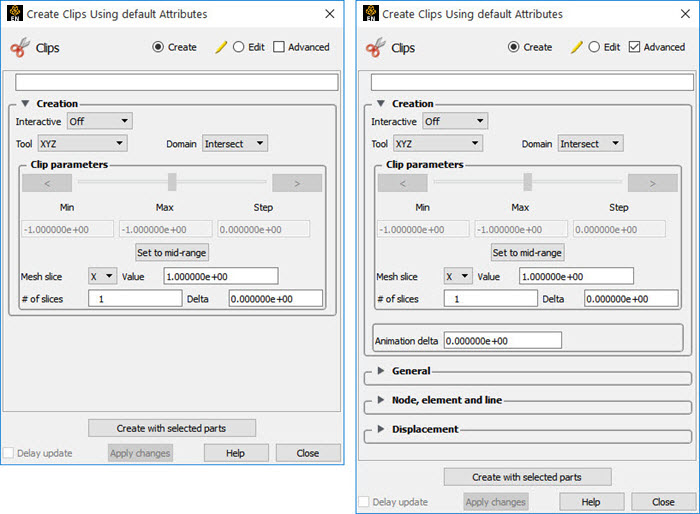

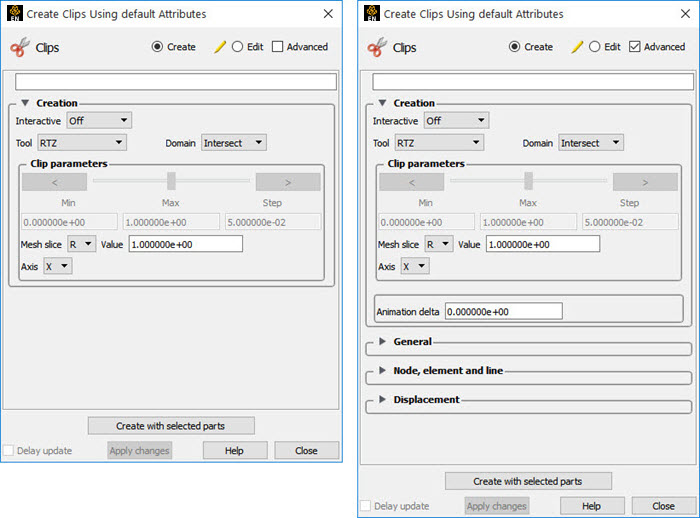

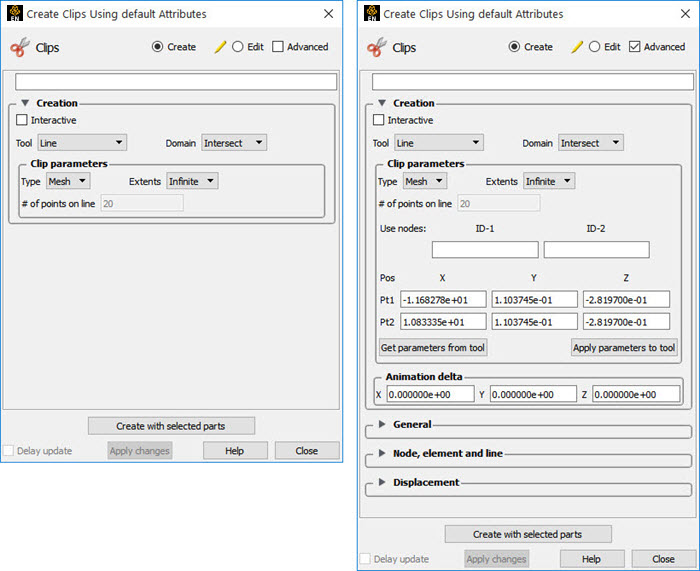

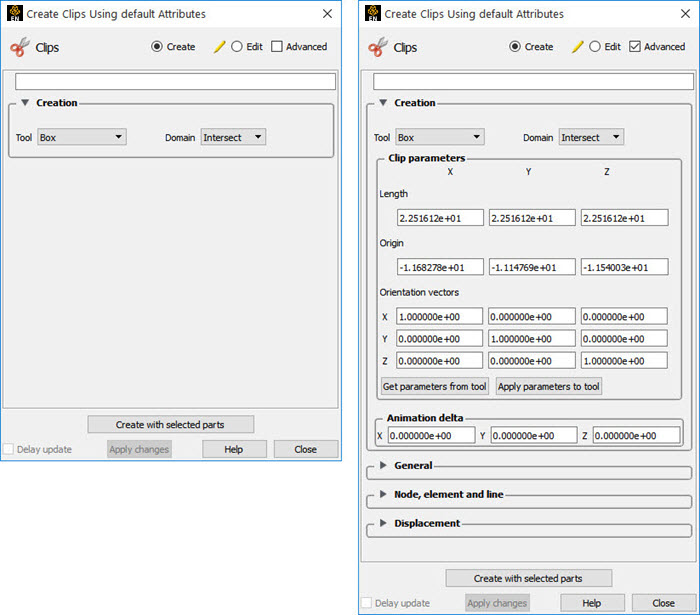

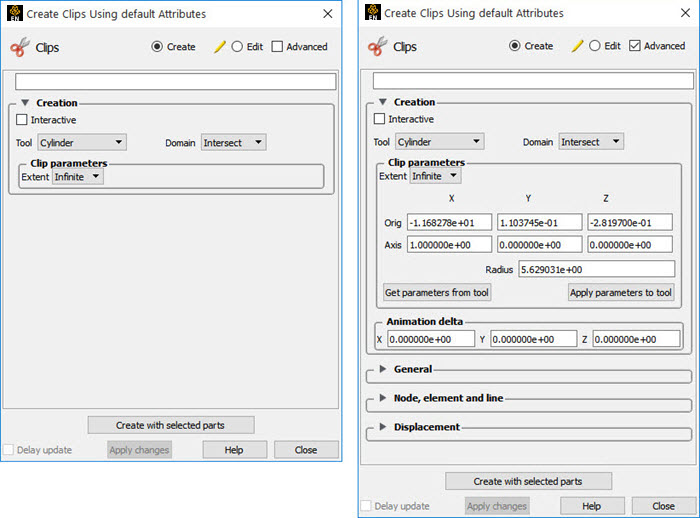

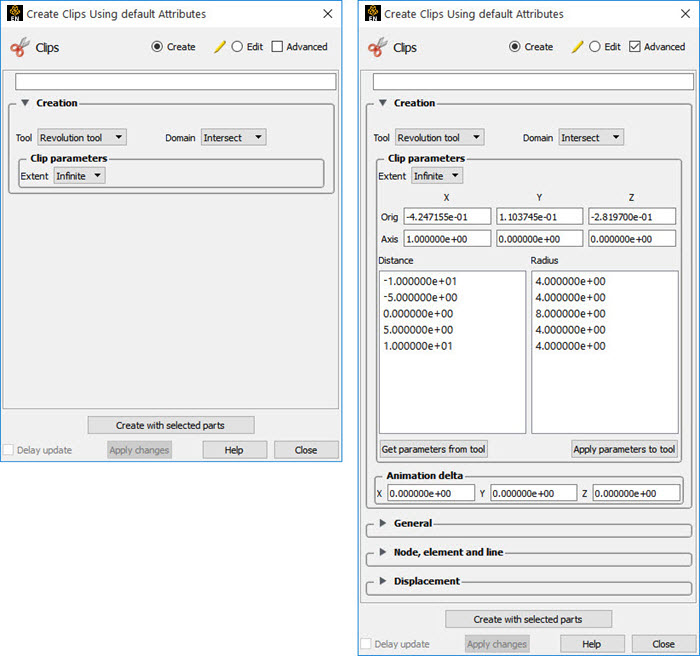

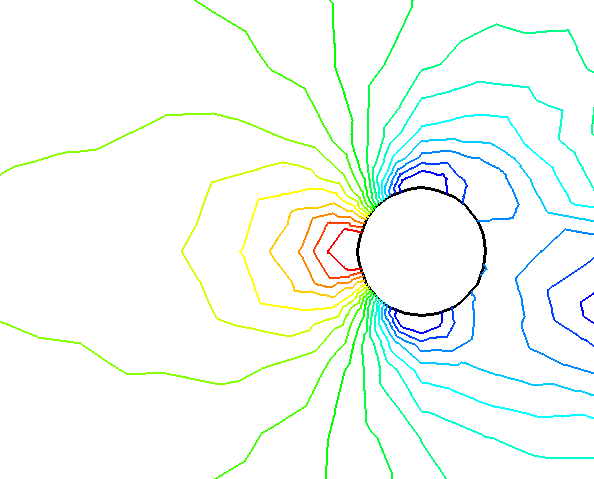

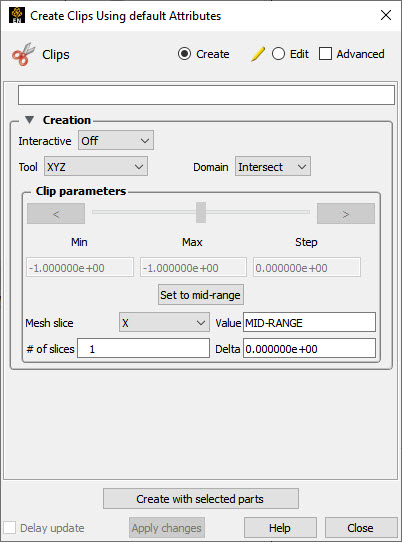

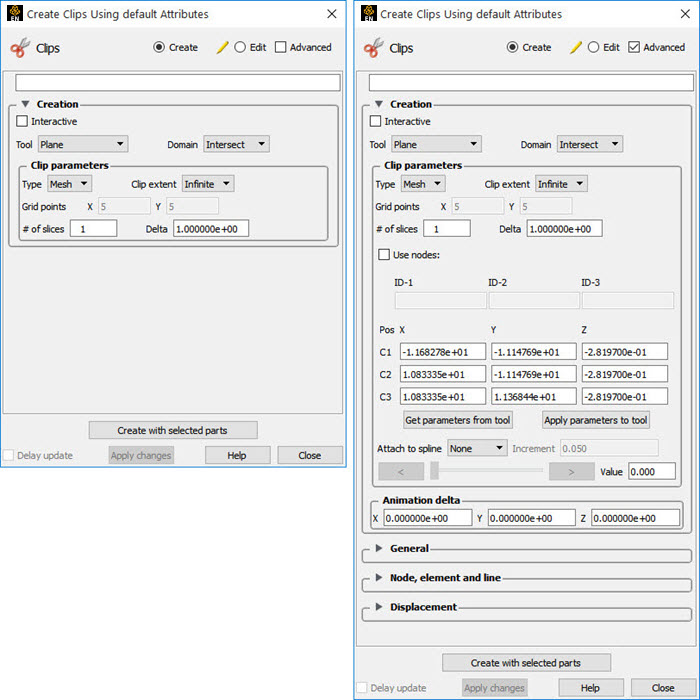

A Clip is a slice through one or more parts. This slice can be defined by a straight line; a plane; a quadric surface (cylinder, sphere, etc.); a constant x, y, or z value; a constant i, j, or k value; or a box. The clip can be created in selected model Parts or in previously created Clips, Isosurfaces, or Developed Surfaces. EnSight calculates the values of variables at the nodes of the Clip. Clips can also be parent Parts. For example, you can create a Clip Line passing through a vector field, then create vector arrows originating from the nodes of the Clip Line. Clips are created on the server, and so are not affected by the selected Representation(s) of the parent Part(s). If you activate or create variables after creating a Clip, the Clip automatically updates to include them.

You specify the location, orientation, and size of the Clip numerically in the Transformations Editor dialog, or interactively using the Line, Plane, Box, or Quadric surface tool. If you wish, EnSight will automatically extend the size of a Clip Plane to include all the elements of the parent Part(s) that intersect the plane.

A grid-clip ignores the mesh and creates a uniformly-spaced part with constant-sized elements. This allows you to sample variable values on a uniformly spaced grid. For a grid-type Clip Line, which is composed of bar elements, you specify how many evenly spaced nodes are along the line. For a grid-type Clip Plane, which is composed of rectangular elements, you specify the number of nodes in each dimension, resulting in an evenly spaced grid of nodes across the plane.

If you request a mesh-type Clip Line EnSight finds the intersection of the specified line with the selected parent Part(s) and creates bar elements that correspond to the mesh of the parent Part(s).

If you request a mesh-type Clip Plane, an xyz clip, or any of the quadric surfaces, EnSight finds the intersection of the specified plane or surface with the selected parent Part(s) and creates elements of various dimensions, sizes, and shapes that together form a cross-section of the parent Part(s). In this cross-section, three-dimensional parent Part elements result in two-dimensional Clip Plane elements, and two-dimensional parent Part elements result in one-dimensional Clip Plane elements.

Note: Two-dimensional parent Part elements that are coplanar with the cross-section are not included since they do not intersect the plane.

For line, XYZ, Plane, Quadric and Revolution Clips you can specify the resulting part to be all elements that intersect the specified value - resulting in a crinkly surface which can help analyze mesh quality.

For each Clip node on or inside an element of the selected parent Part(s), EnSight calculates the value of each variable by interpolating from the variable's values at the surrounding nodes of the parent Part(s).

You can interactively manipulate the location of a clip Part by toggling on the Interactive Tool button. When this toggle is on, the tool used to create the clip Part will appear in the Graphics Window. Manipulation of this tool will cause the clip Part to be recreated at the new location. This feature allows you to interactively sweep a plane across your model or manipulate the size and location of the cylinder, sphere, or cone.

You can animate a Clip by specifying an Animation Delta vector that moves the Clip to a new location for each frame or page of the animation. The Clip updates to appear as if it had been newly created at the new location and time.

For structured Parts, you can sweep through the Part with any of the i, j, or k planes.

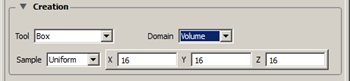

A Box Clip will create a part according to the Box Tool. The result can either by the intersection of the Box Tool walls with the selected model parts (Domain = Intersect), the crinkly intersection of the Box Tool walls with the selected model parts (Domain = Crinkly), the portion of the selected parts that lie within (Domain = Inside) or outside (Domain = Outside) the Box Tool, a volume part (Domain = Volume), or a rectilinear clip of the selected parts that lie within the Box Tool.

Clicking once on the Clip Feature icon (which be default is in the Feature Ribbon) or selecting Clips... in the Create menu, opens the Feature Panel for clip parts. This editor is used to both create and edit clip parts.

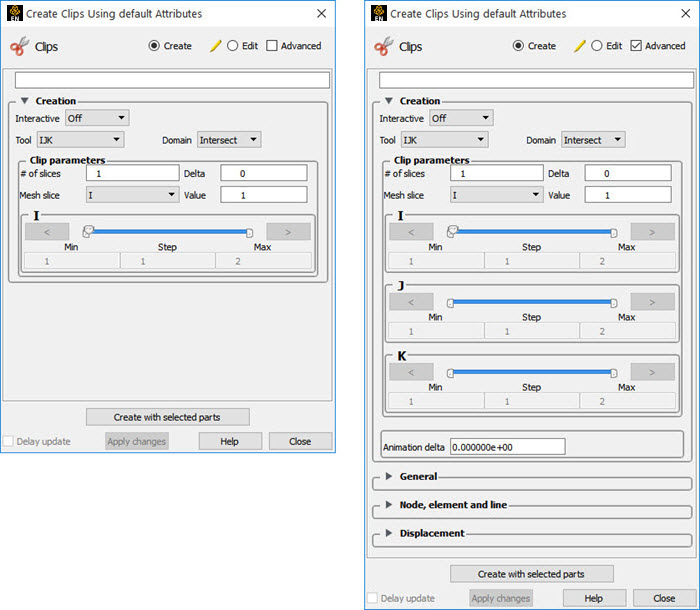

Use Tool IJK

The IJK clip tool is used with structured mesh results.

|

Create/Edit |

Toggles that control whether a new part will be created, or whether you are editing existing part(s). Note: When editing, the changes will be applied to those parts which have the small pencil icon next to them in the Parts list. |

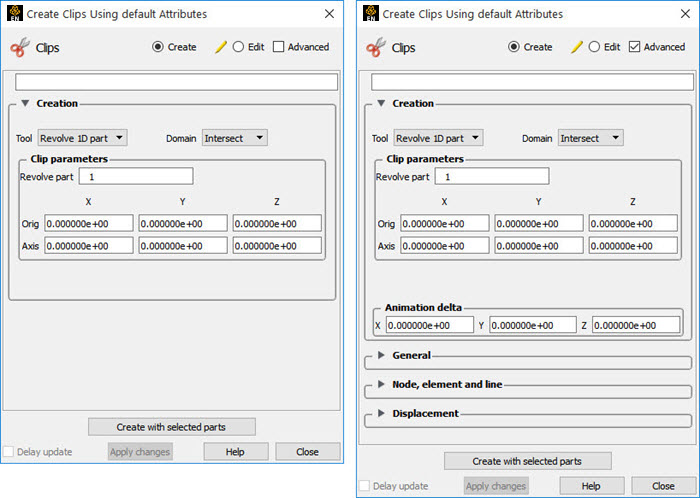

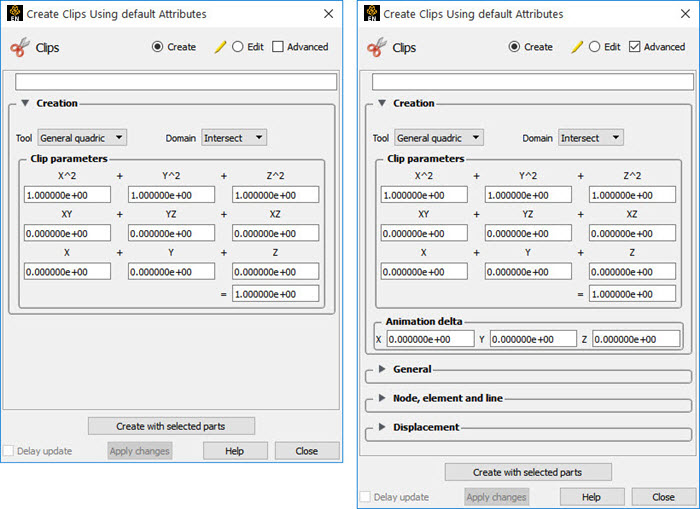

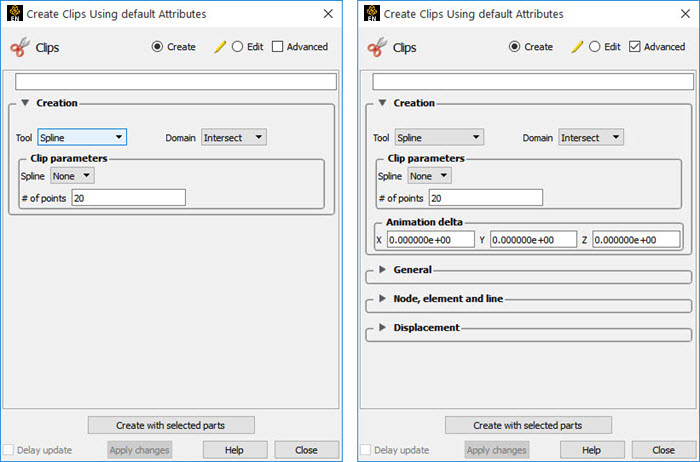

|

|

Advanced |

Will open additional features for more advance control of the Part. |

|

|

Desc |

The name of the part to be created or being edited. |

|

|

Creation |

||

|

Interactive |

Opens pulldown menu for selection of type of interactive manipulation of the IJK clip. Options are: |

|

|

Off |

Interactive IJK clips are turned off. |

|

|

Manual |

Value of the IJK clip selected are manipulated via the slider bar and the IJK clip is interactively updated in the Graphics Window to the new value. |

|

|

Auto |

Value of the IJK clip is incremented by the Auto Delta value from the minimum range value to the maximum value. When reaching the maximum it starts again from the minimum. |

|

|

Auto Cycle |

Value of the IJK clip is incremented by the Auto Increment value from the minimum range value to the maximum value. When reaching the maximum it decrements back to the minimum. |

|

|

Domain |

Specification to extract the intersection of the specified mesh slice values. For IJK clips, the only valid selection is Intersect. |

|

|

Clip Parameters |

||

|

# slices |

If you want more than one clip calculated at a Delta offset from each other, enter the number of slices in this field. This number of clips is calculated then they are grouped together. This field is only available at the first time the clip(s) are calculated. It is not possible to change this value and recalculate the clips. To change the number or the Delta, they must be deleted and recalculated. |

|

|

Delta |

Offset value to use for creating a number of clips. The first clip is calculated at the number entered in Value, and the next one is Delta + Value, etc. and they are all grouped together in the Part List. |

|

|

Mesh Slice |

Opens a pulldown menu for selecting which of the IJK dimensions you wish to allow to change. You will then specify Min, Max and Step limits for the two remaining fixed dimensions. |

|

|

Value |

This field specifies the I, J, or K plane desired for the dimension selected in Mesh Slice. |

|

|

Slider Bar(s) |

For IJK clips, the slider bar is used to increment / decrement the Mesh Slice Value between its Minimum and Maximum value. |

|

|

Min |

Specification of the minimum slice value for the range used with the Manual slider bar and the Auto and Auto Cycle options. |

|

|

Max |

Specification of the maximum slice value for the range used with the Manual slider and the Auto and Auto Cycle options. |

|

|

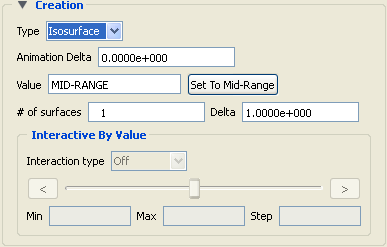

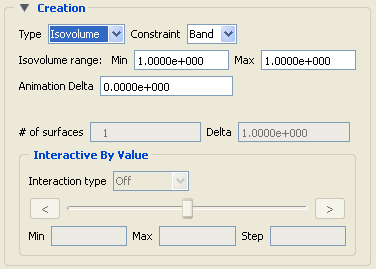

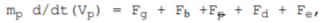

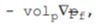

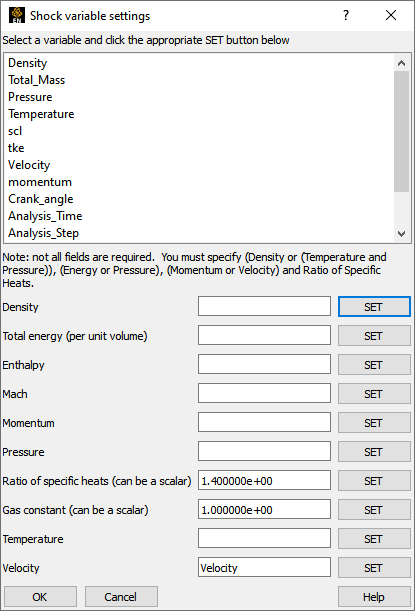

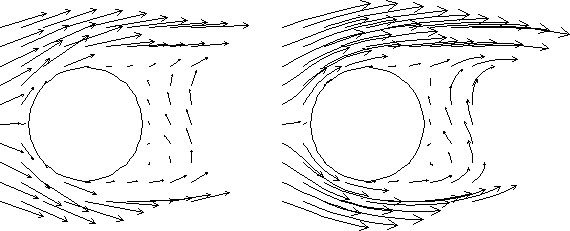

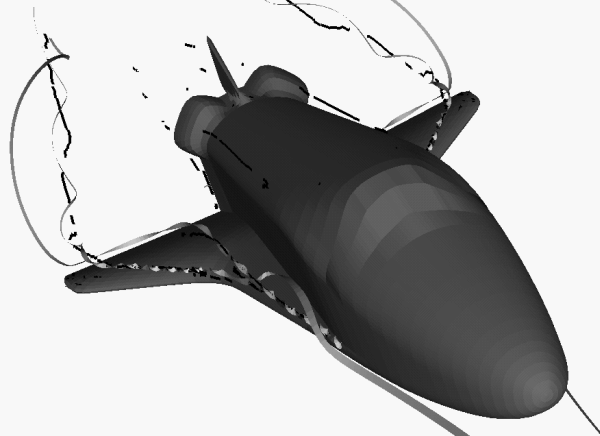

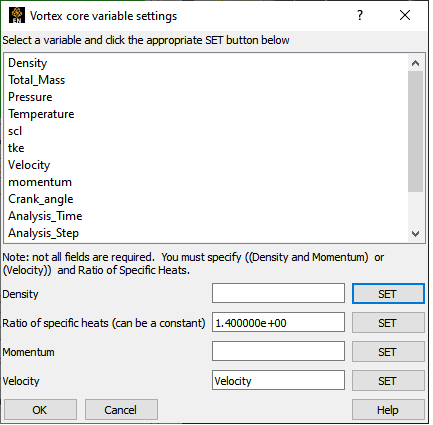

Step |