The following sections of this chapter are:

The following sections of this tutorial are:

- 1.1.1. Fluent Airflow on a Rough NACA0012 Airfoil

- 1.1.2. Droplet Impingement on the NACA0012

- 1.1.3. Fluent Icing Ice Accretion on the NACA0012

- 1.1.4. Postprocessing an Ice Accretion Solution Using CFD-Post Macros

- 1.1.5. Multi-Shot Ice Accretion with Automatic Remeshing

- 1.1.6. Multi-Shot Ice Accretion With Automatic Remeshing – Postprocessing Using CFD-Post

- 1.1.7. FENSAP Airflow on the Clean NACA0012 Airfoil

- 1.1.8. FENSAP Airflow Solution on the Rough NACA0012 Airfoil

- 1.1.9. Scheduling a Sequence of Runs With Fluent Icing

This tutorial is divided into the following sections:

The objective of this tutorial is to obtain an airflow solution around a rough NACA0012 airfoil, using Fluent Icing, that is suitable for icing calculations.

This tutorial demonstrates how to do the following:

Setup a rough Fluent airflow on an airfoil.

Compute the solution.

Examine the results.

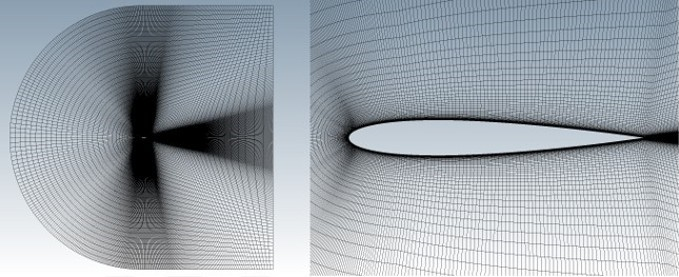

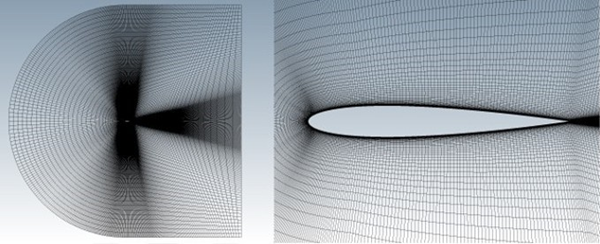

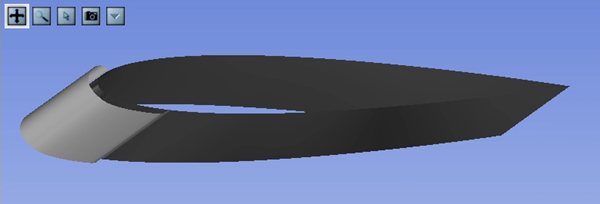

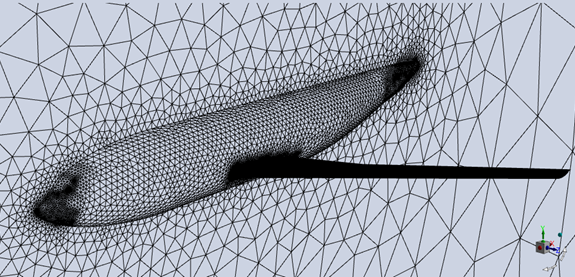

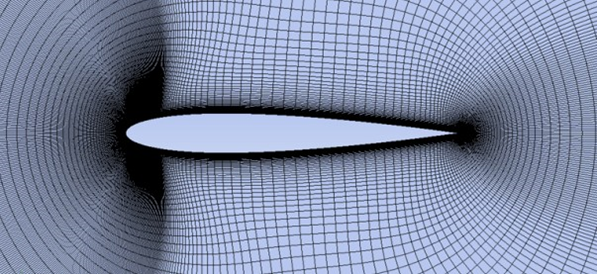

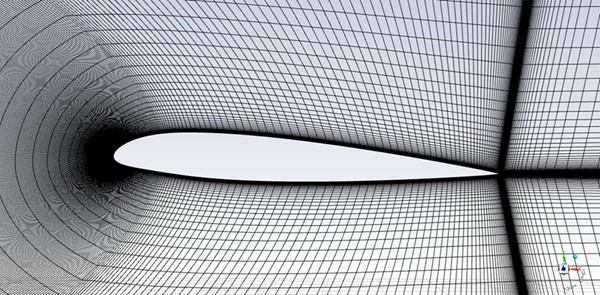

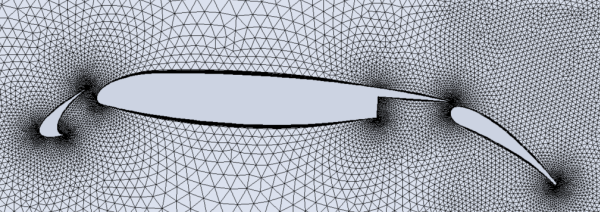

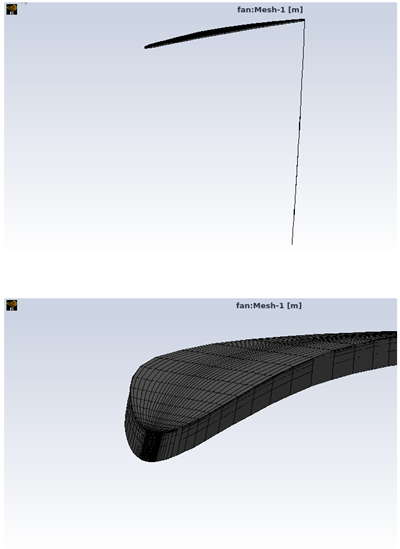

The problem considers the rough flow of air around a NACA0012 airfoil. Since the flow is viscous and turbulent, grid points have been clustered around the airfoil to better capture the boundary layer and wake.

The following sections describe the setup and solution steps for this tutorial:

To prepare for running this tutorial:

Download the

fluent_icing.zipfile here .Unzip

fluent_icing.zipto your working directory.The file, naca0012.cas.h5, can be found in the folder.

Use the Fluent Launcher to start Ansys Fluent.

In the Fluent Launcher, set the Capability Level to Enterprise, then select Icing.

Set Solver Processes between

2and4.Click Start.

Alternatively, Fluent Icing can be opened using the icing (on Linux) or icing.bat (on Windows) file inside the fluent/bin/ folder.

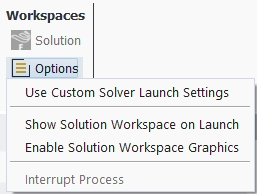

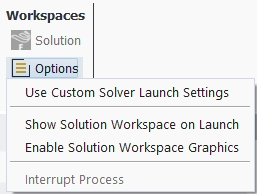

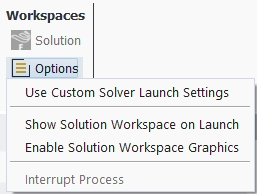

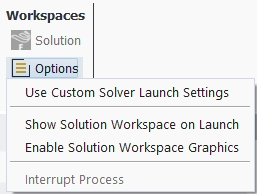

Uncheck , , and .

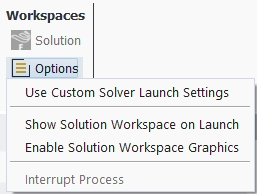

Project → Workspaces → Options

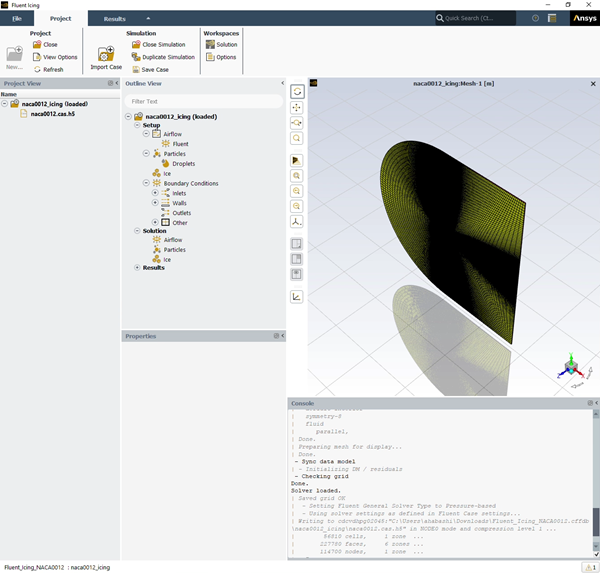

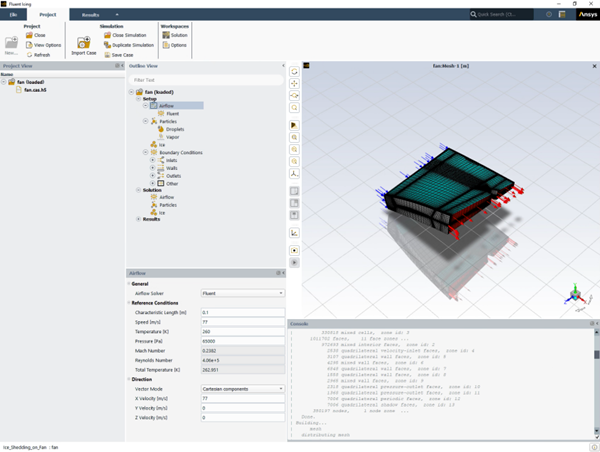

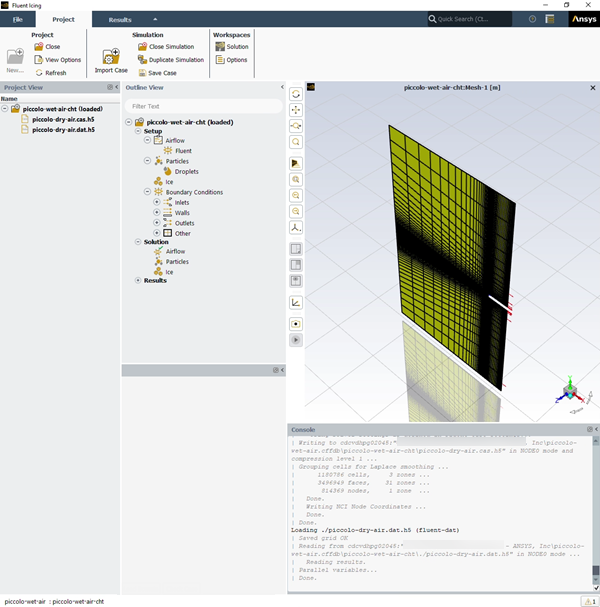

The graphical user interface (GUI) of Fluent Icing is very similar to Fluent, however there are some differences such as:

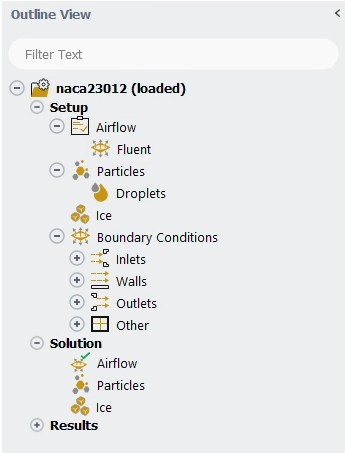

The ribbon is reduced to only the File, Project, Results tabs and therefore most actions for setting up your simulation will be performed in the Outline View.

Individual settings are defined in the Properties window which is accessed by left-clicking an item in the Outline View.

Note: Settings in the Properties window are saved as you define them, unlike dialog boxes which require you to click an button.

The console allows for Python scripting, and can read Python commands from a journal / script file.

Create a new project file.

File → New Project...

Enter

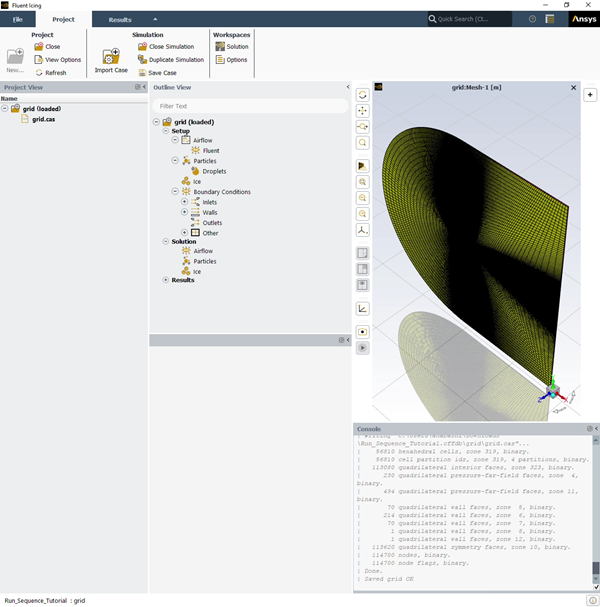

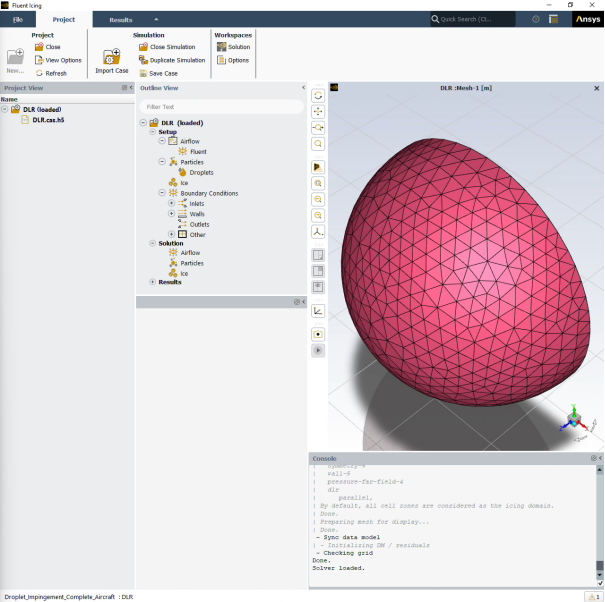

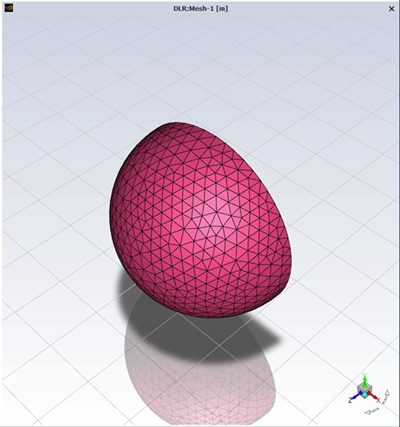

Fluent_Icing_NACA0012as the Project file name within the Select File dialog.Select and import the naca0012.cas.h5 input grid.

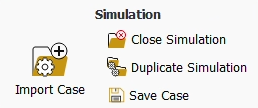

Project → Simulation → Import Case

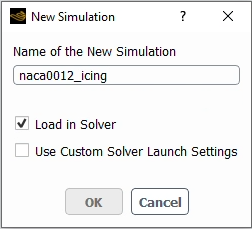

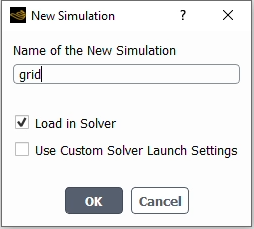

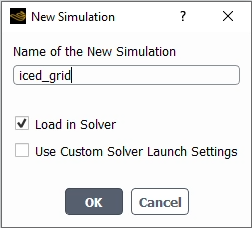

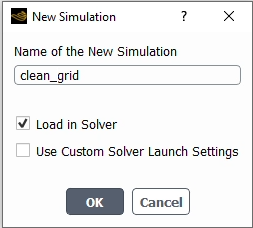

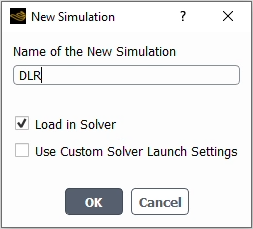

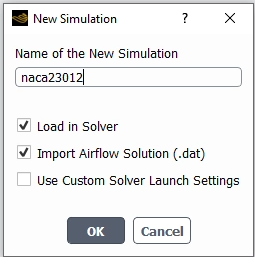

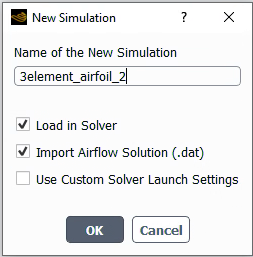

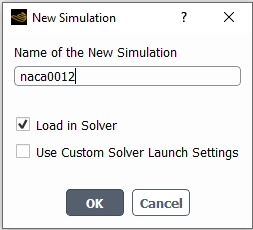

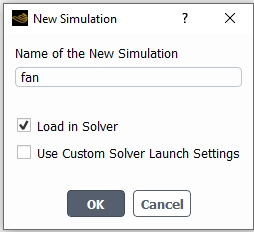

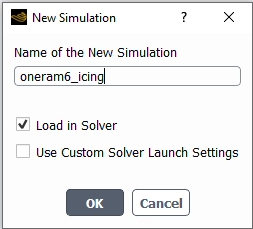

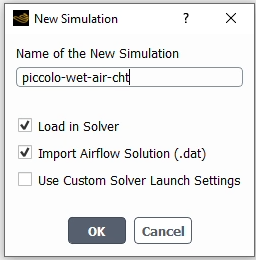

A New Simulation window will appear. Enter the Name of the New Simulation as

naca0012_icing, and check to enable . Click .

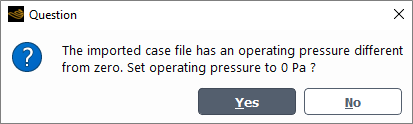

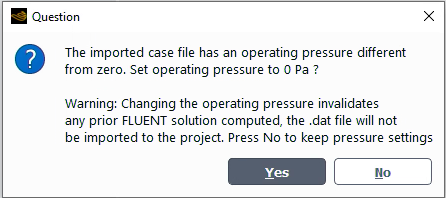

A dialog will open asking you to set the operating pressure to 0 Pa. Press to accept this change.

Note: Absolute pressure is recommended in all icing simulations. Therefore, Fluent Icing will automatically detect the imported case file, whose operating pressure is not equal to zero, when importing the case file. See Airflow in the Fluent Workspaces User's Guide for more details.

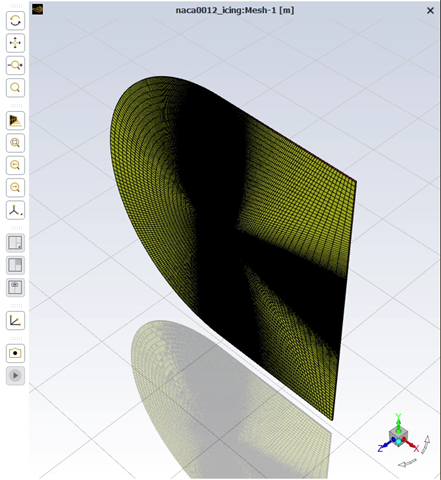

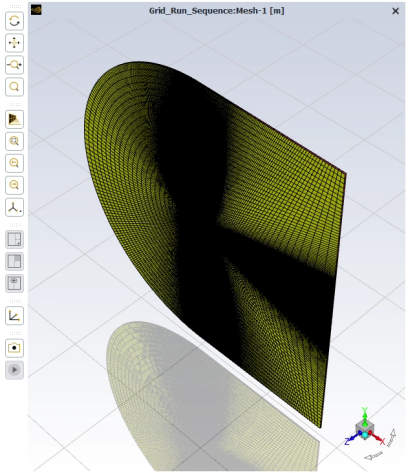

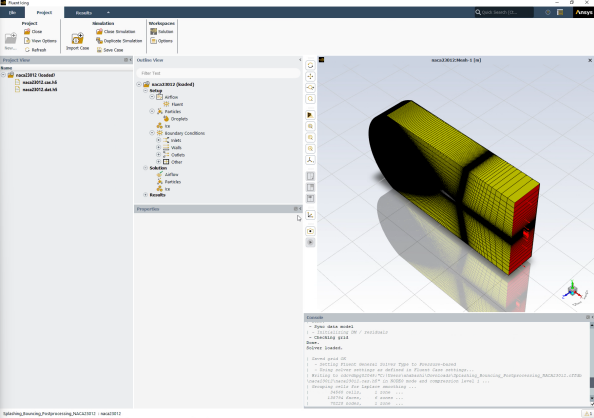

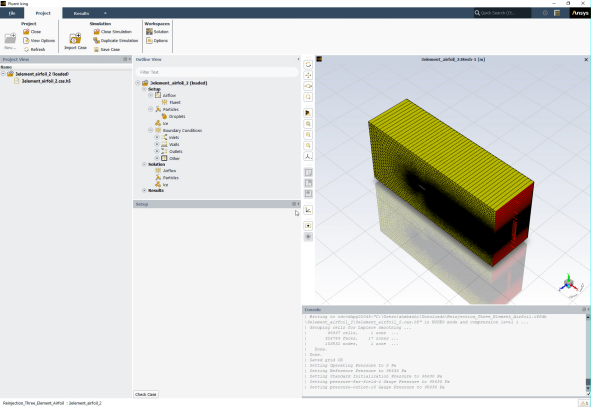

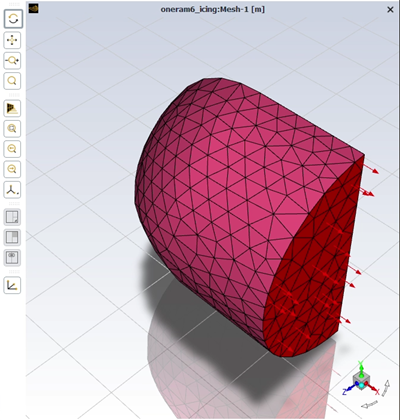

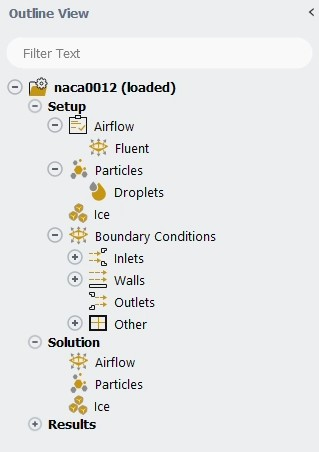

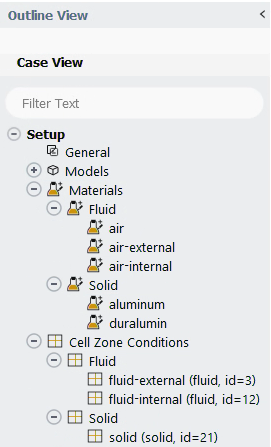

A new simulation folder will be created in the Project View, and the naca0012.cas.h5 file will be imported.

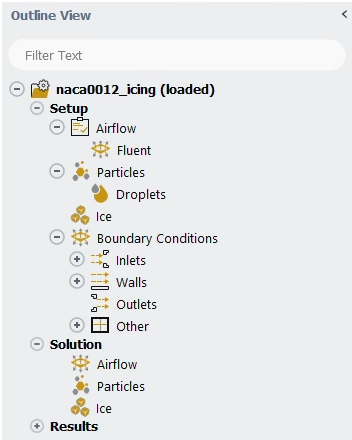

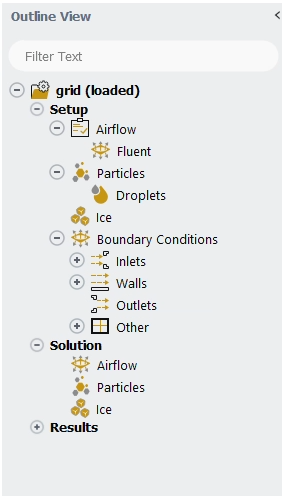

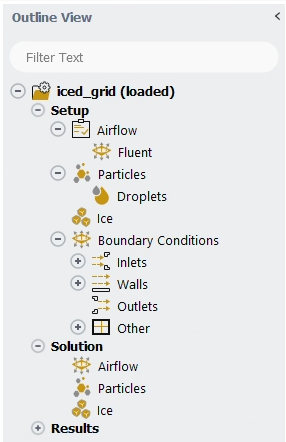

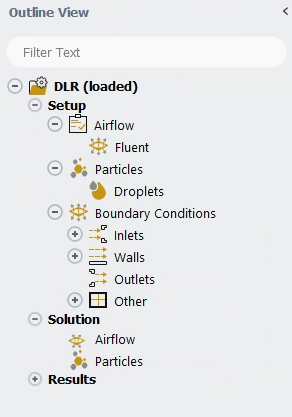

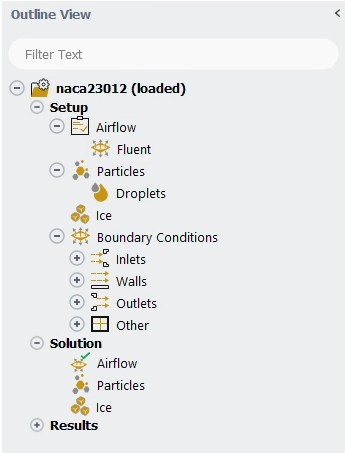

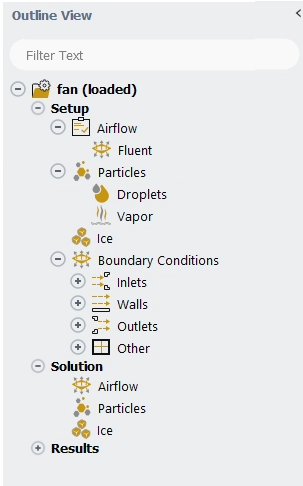

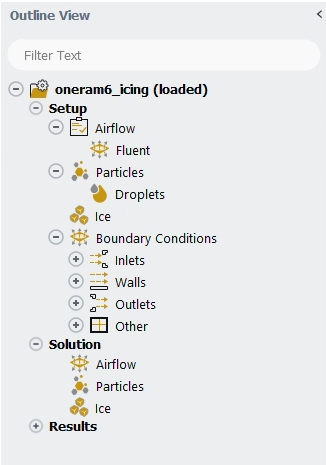

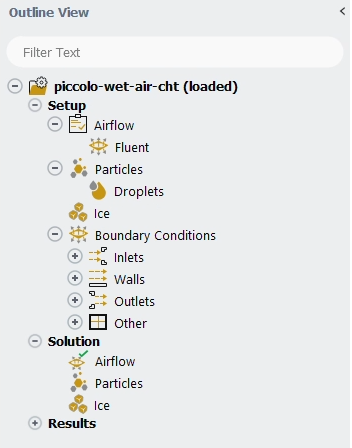

After the .cas.h5 file has been successfully loaded, a new Outline View tree appears under naca0012_icing (loaded).

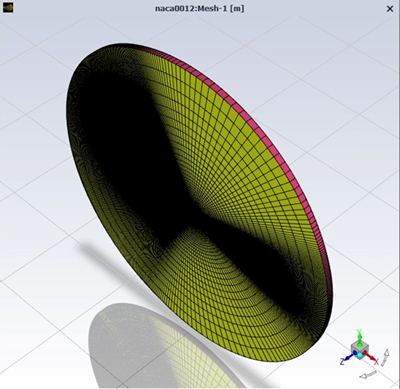

The mesh is now displayed in the Graphics window to the right.

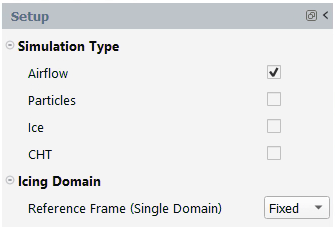

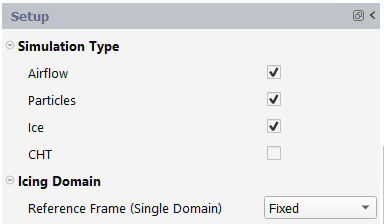

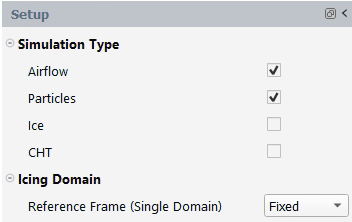

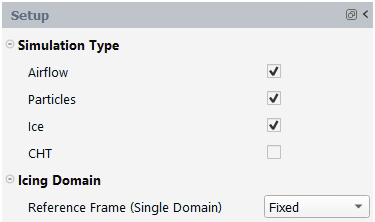

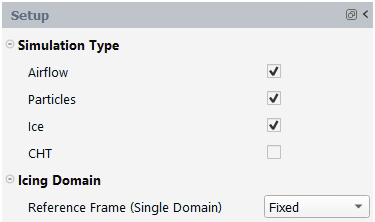

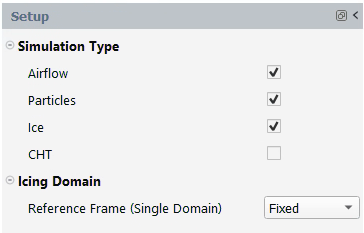

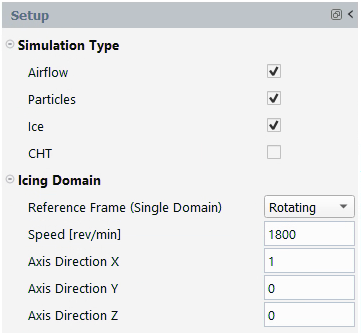

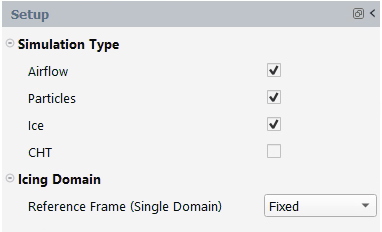

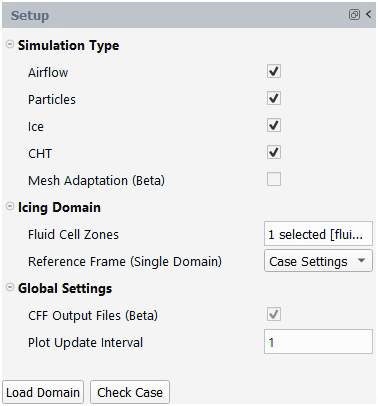

Define the Simulation Type.

Setup

Enable and disable , and under Simulation Type within the Setup panel.

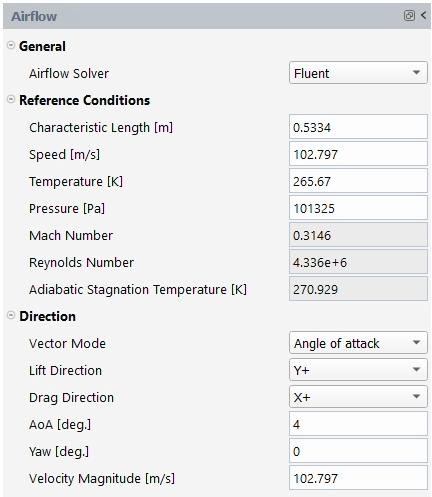

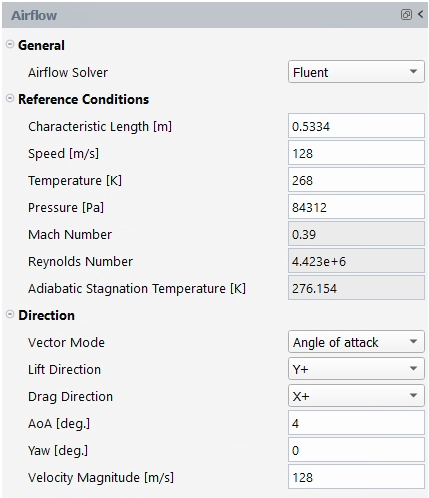

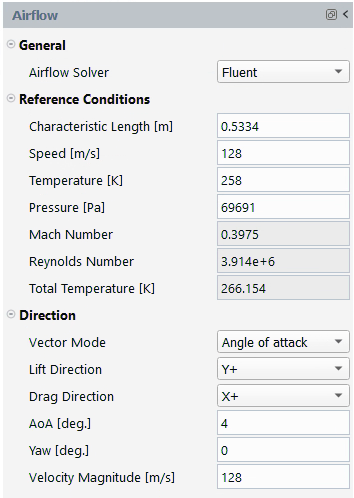

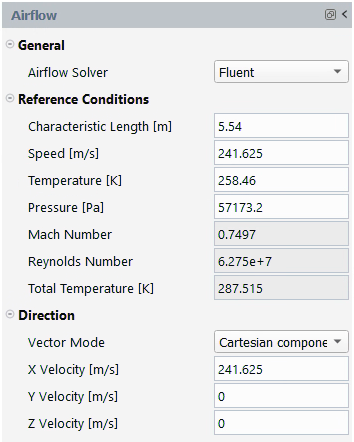

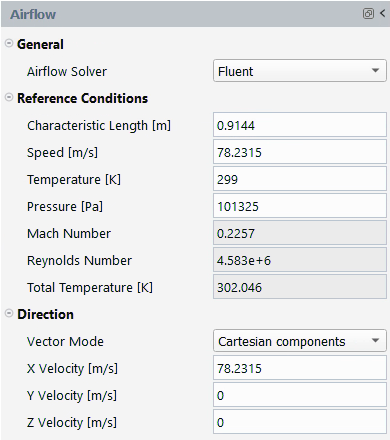

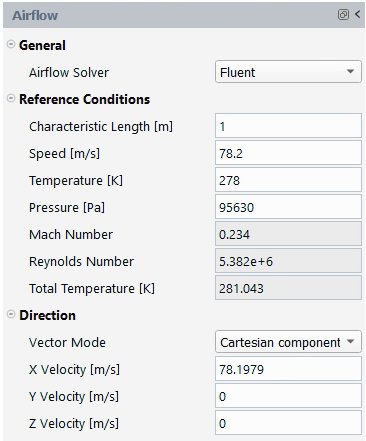

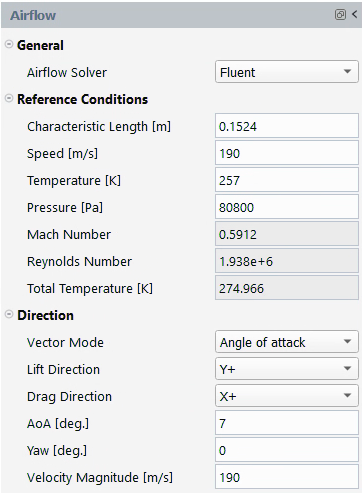

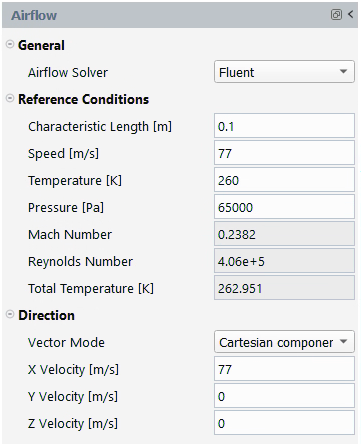

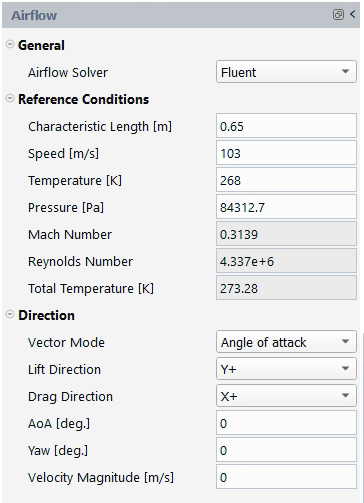

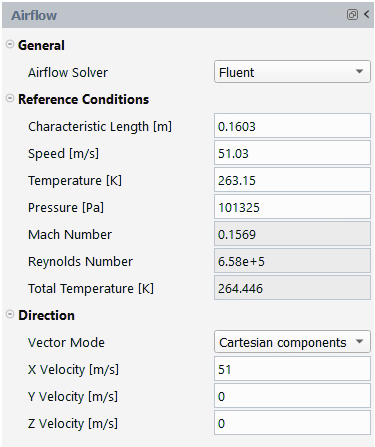

Set the Airflow properties for the simulation.

Setup → Airflow

In the General section:

Retain the default selection of for Airflow Solver.

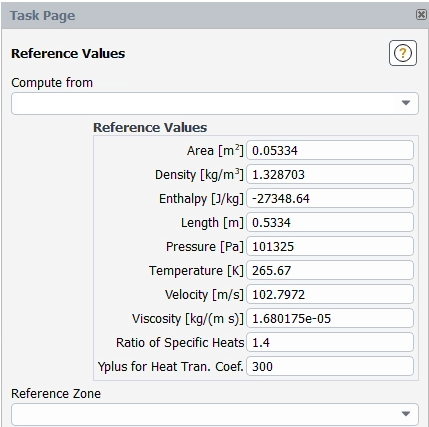

In the Reference Conditions section, retain the following settings:

0.5334for Characteristic Length [m].102.797for Speed [m/s].265.67for Temperature [K].101325for Pressure [Pa].

In the Direction section, retain the following settings:

for Vector Mode.

for Lift Direction.

for Drag Direction.

4for AoA [deg.].0for Yaw [deg.].102.797for Vector Magnitude [m/s].

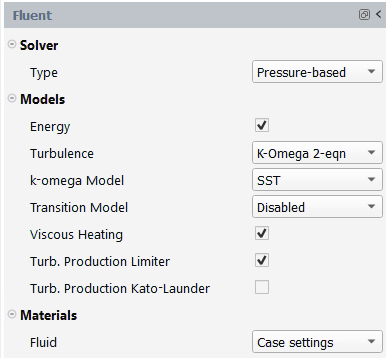

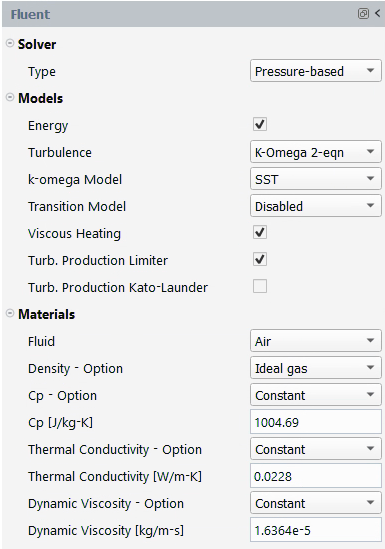

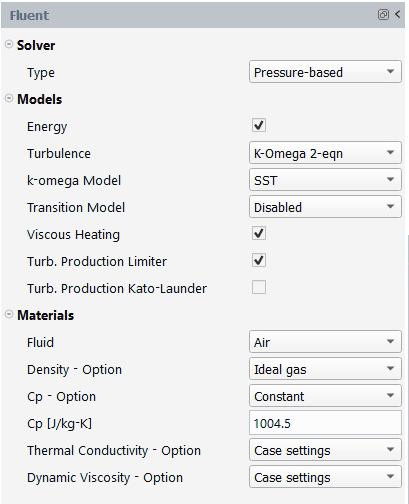

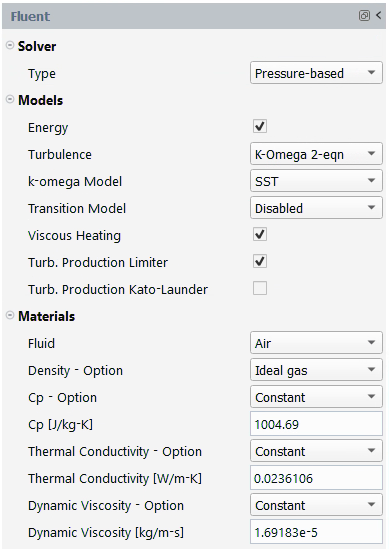

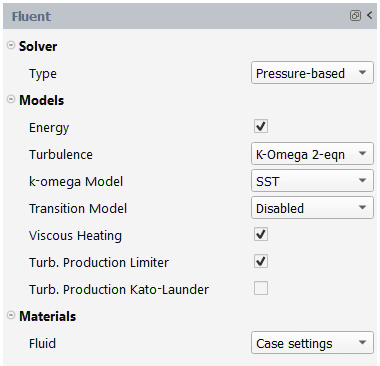

Set the Fluent properties for the simulation.

Setup → Airflow → Fluent

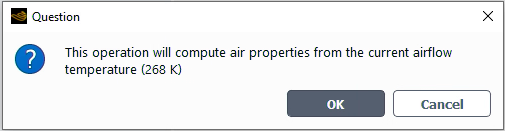

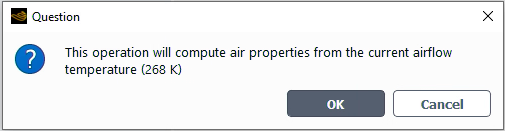

Set to Default Air Properties

A dialog will open. Click to accept the air properties computed from the current airflow temperature.

Note: This automatically sets the air properties, suggested for icing simulations, from the current reference air temperature. The values of air properties have been computed using the equations presented in Airflow.

For simplicity, thermal conductivity and viscosity equations are shown below.

where

refers to the ambient air static temperature, and

,

and

are equal to 0.00216176 W/m/K3/2, 288 K and 17.9*10-6 Pa.s, respectively.

Airflow properties under the Materials section are now automatically updated with values computed from the Reference Conditions under

Setup → Airflow.

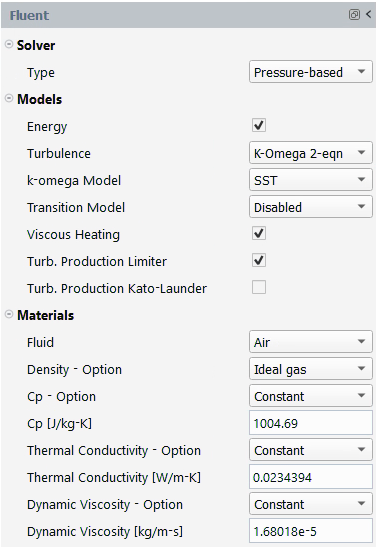

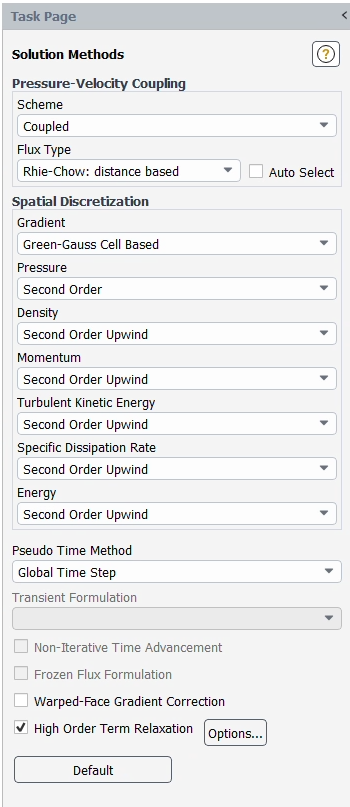

In the Solver section:

Retain the default selection of for Type.

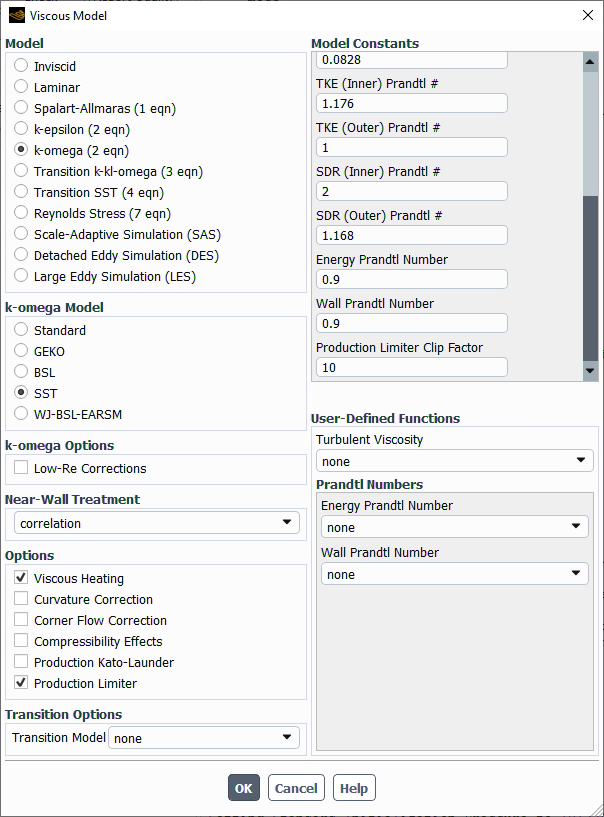

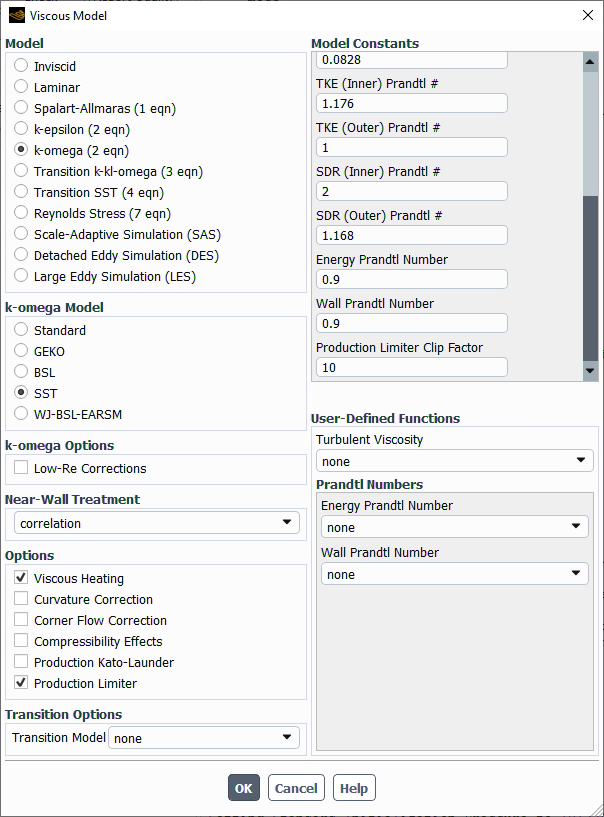

In the Models section, retain the following settings:

Enable .

for Turbulence.

for k-omega Model.

for Transition Model.

Enable both Viscous Heating and Turb. Production Limiter.

In the Materials section, retain the following settings:

for Fluid.

for Density - Option.

for Cp - Option.

1004.69for Cp [J/kg-K].for Thermal Conductivity - Option.

0.0234394for Thermal Conductivity [W/m-K].for Dynamic Viscosity - Option.

1.68018e-5for Dynamic Viscosity [kg/m-s].

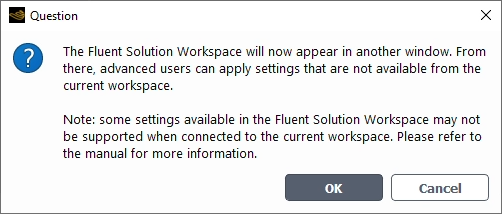

Open the Fluent Workspace.

Project → Workspaces → Solution

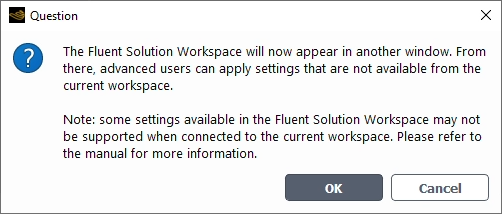

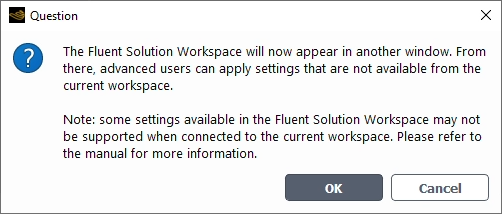

A dialog will open advising you that the Fluent Solution Workspace will appear in another window. Press to proceed.

Define the Viscous Model.

Setup → Models → Viscous (SST k-omega)

In the Model Constants section, retain the following settings:

0.9for Energy Prandtl Number.0.9for Wall Prandtl Number.

Press to close this window.

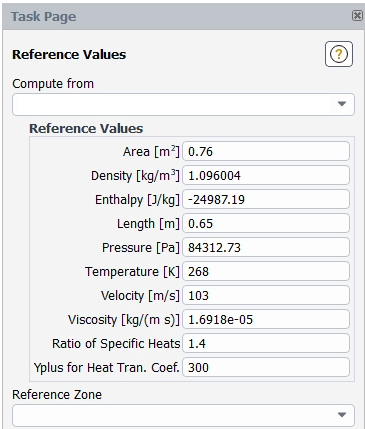

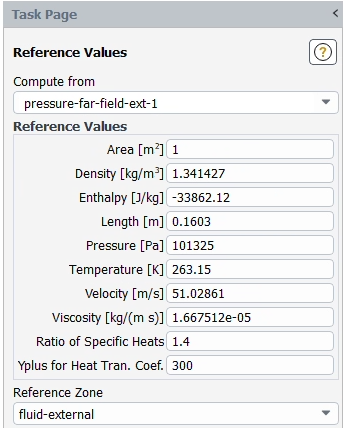

Define the Reference Values.

Setup → Reference Values

In the Reference Values section:

Retain all default values.

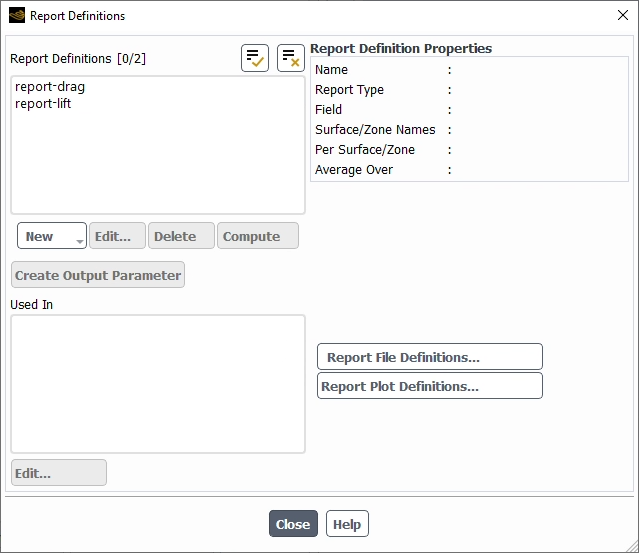

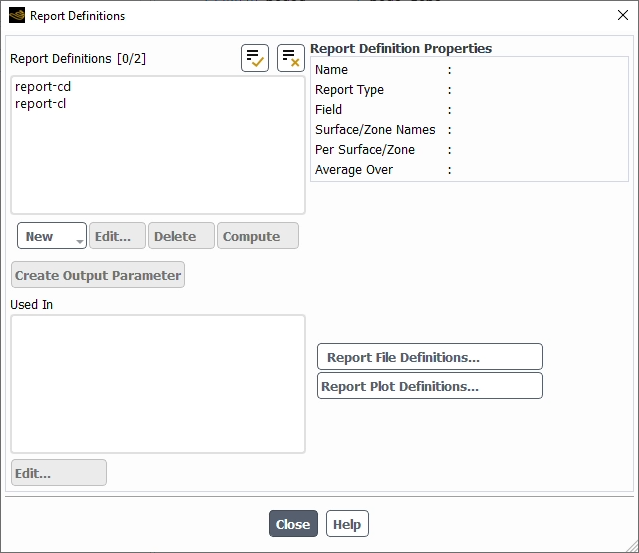

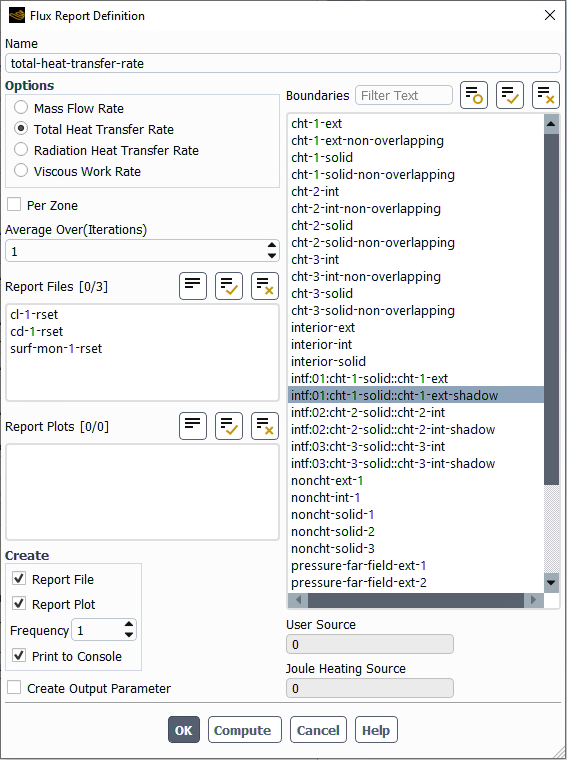

Define the Report Definitions.

Solution → Report Definitions

In the Report Definitions section:

Select report-drag and press (To create a new drag report, you can select → → )

Retain the default values of

0.99756405,0.069756474, and0for X, Y, and Z for Force Vector.Familiarize yourself with the selections in the Drag Report Definition dialog. Press to close this window.

De-select report-drag, select report-lift, and press (To create a new lift report, you can select → → )

Retain the default values of

-0.069756474,0.99756405, and0for X, Y, and Z for Force Vector.Familiarize yourself with the selections in the Lift Report Definition dialog. Press to close this window.

Press to close the Report Definitions dialog.

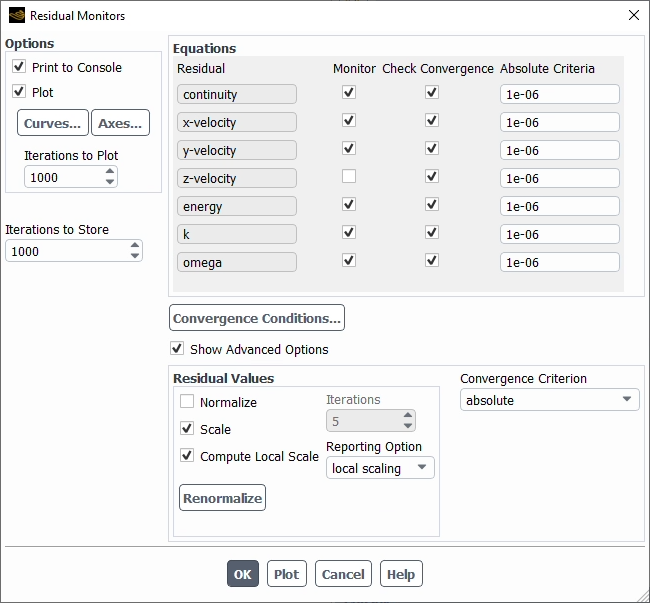

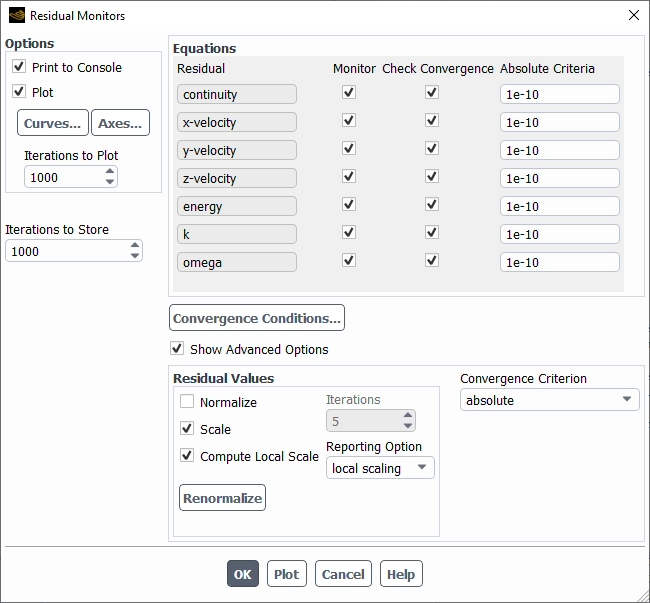

Modify the Absolute Criteria for convergence.

Solution → Monitors → Residual

In the Equations section, retain the following settings:

1e-06for all Absolute Criteria entries.Enable and for all Residual fields.

Note: Since this 3D simulation provides a 2D solution, ensure to uncheck z-velocity under and keep enabled.

Enable .

Enable and .

Set Report Option to .

Press to close this window.

Maximize the Fluent Icing graphical user interface and close the Fluent Workspace.

Project → Workspaces → Solution

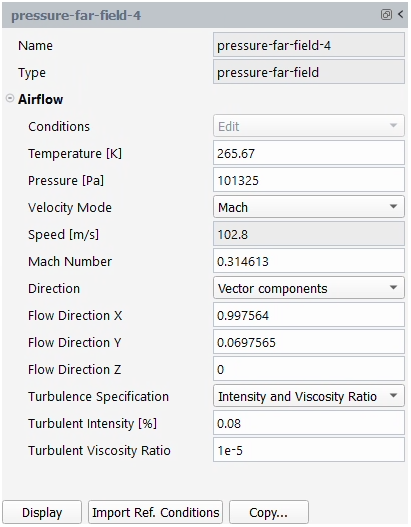

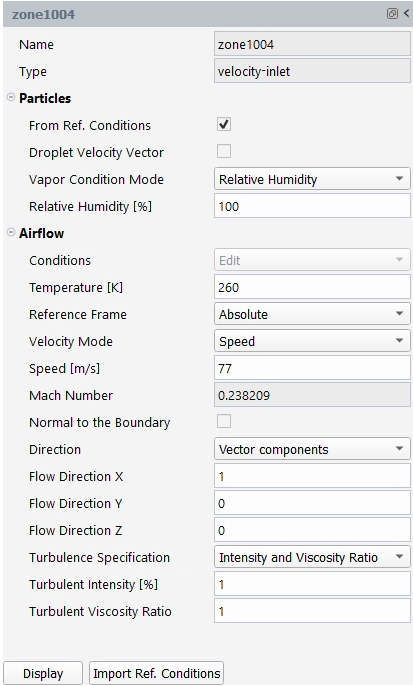

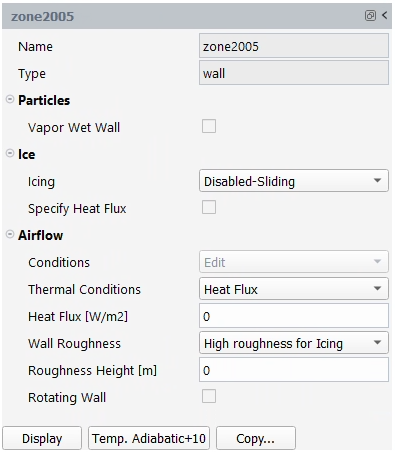

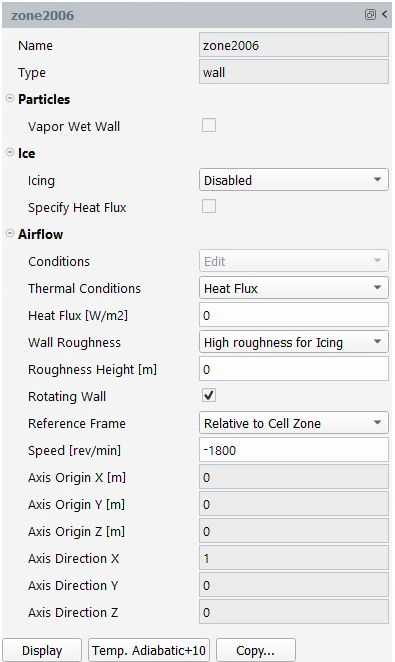

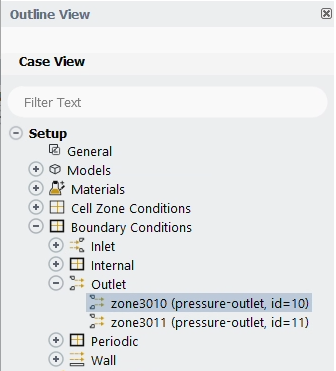

Set the Boundary Conditions for your simulation.

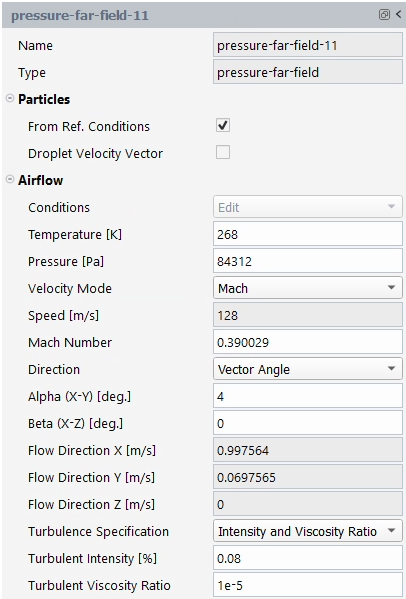

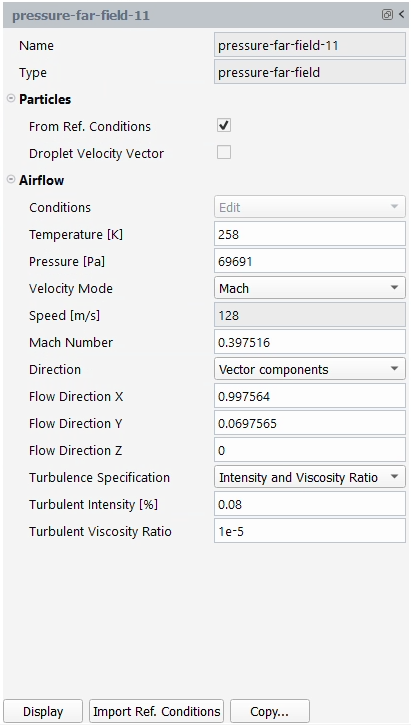

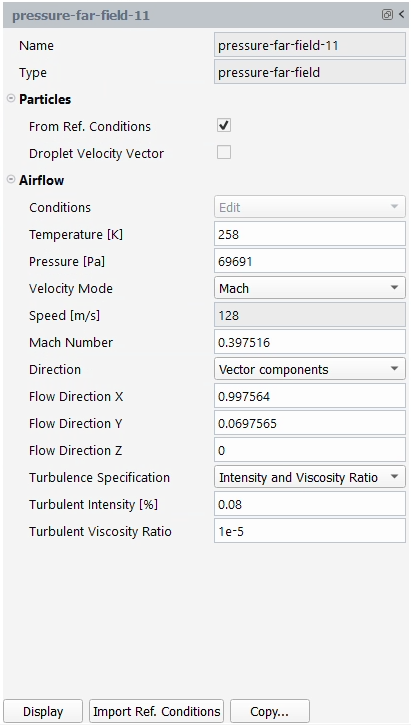

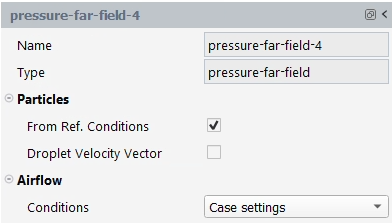

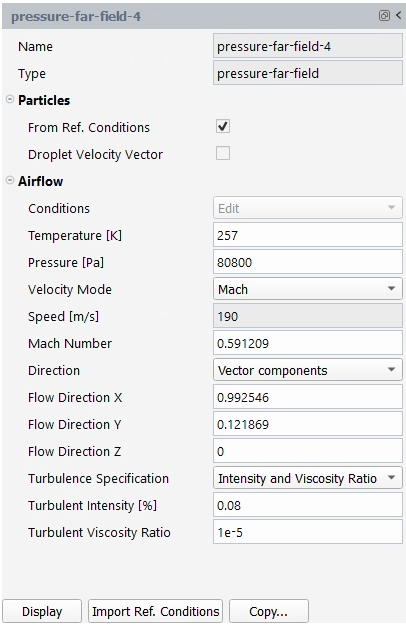

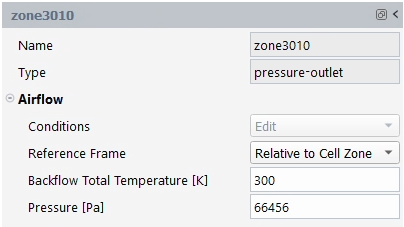

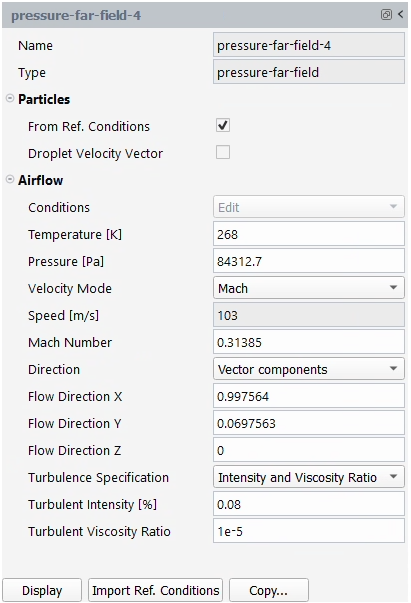

Setup → Boundary Conditions → Inlets → pressure-far-field-4

In the Airflow section:

Press to import the reference conditions of the case file.

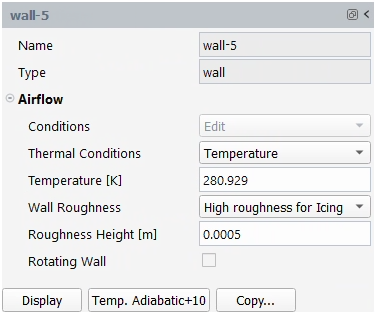

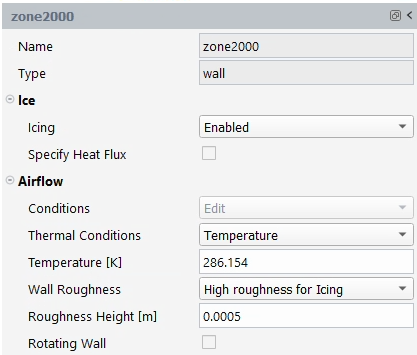

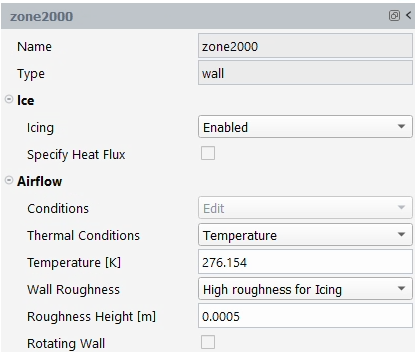

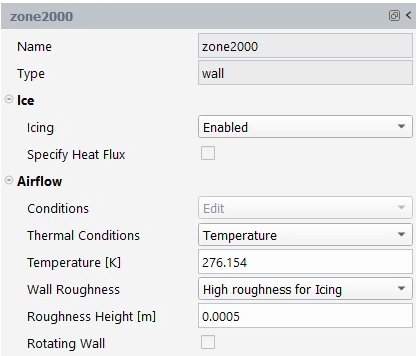

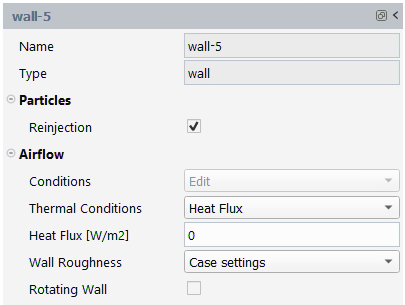

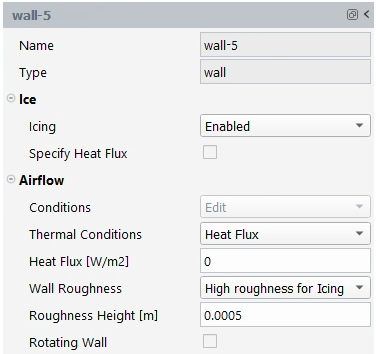

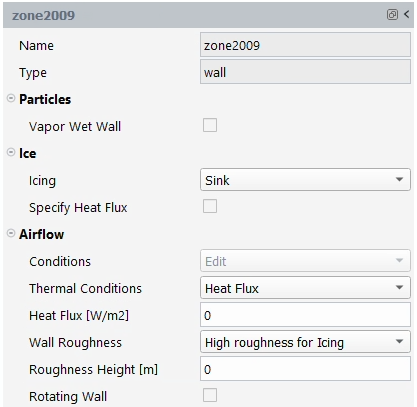

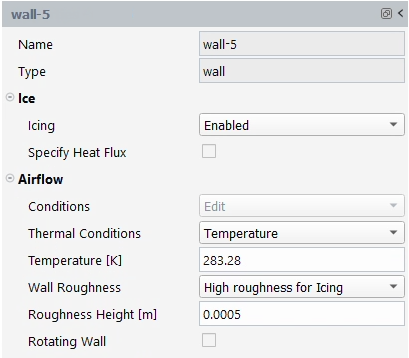

Setup → Boundary Conditions → Walls → wall-5

In the Airflow section:

Retain the default selection of for Thermal Conditions.

280.929for Temperature [K].Select under the Wall Roughness drop-down list.

Set Roughness Height [m] to

0.0005.Press on to ensure a temperature value (adiabatic temperature + 10 degree) is imposed on the wall.

Repeat the steps above for wall-6 and wall-7.

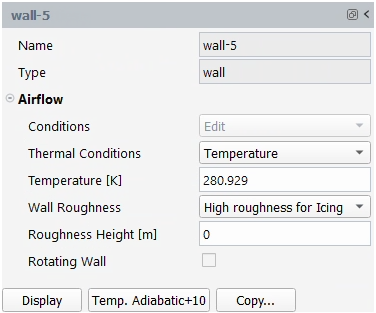

Note: To perform a simulation of a clean airflow solution:

Set Roughness Height [m] to

0.

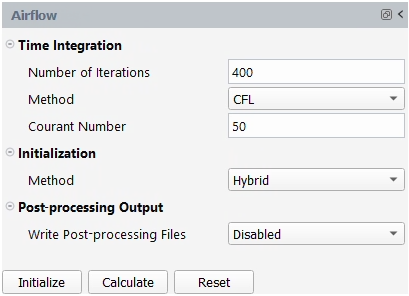

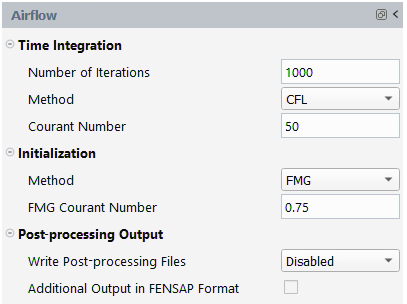

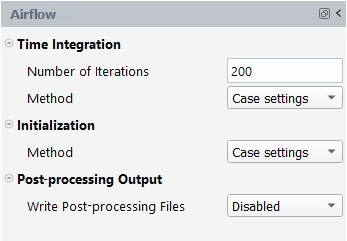

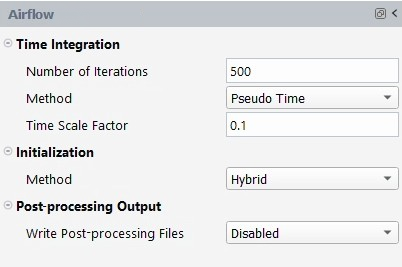

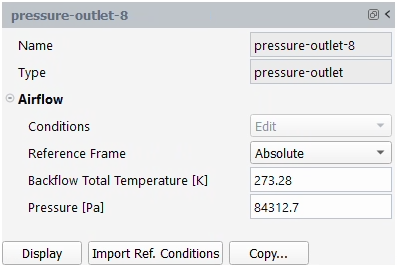

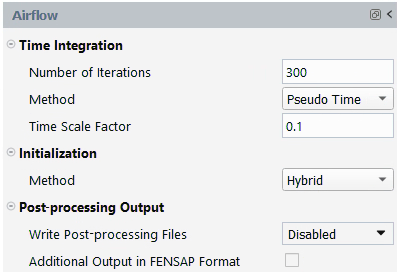

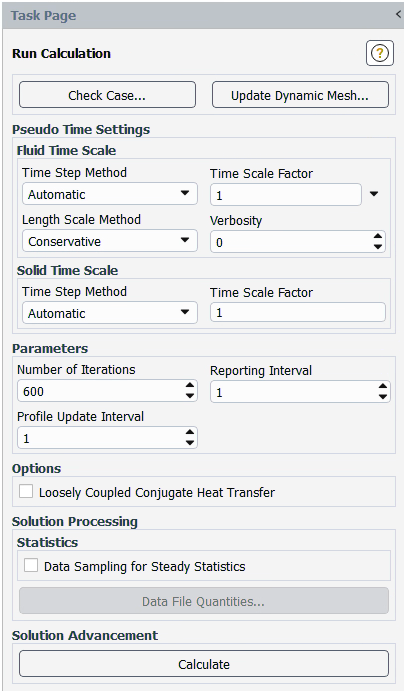

Set the Solution properties of your simulation.

Solution → Airflow

In the Time Integration section:

Set Number of Iterations to

400.Select under the Method drop-down list.

Retain the default value of

50for Courant Number.

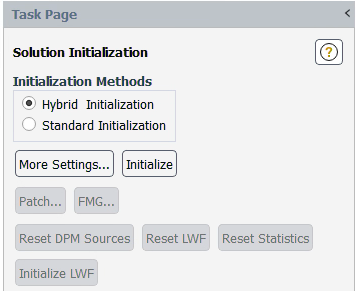

In the Initialization section:

Select under the Method drop-down list.

In the Post-processing Output section:

Retain the default selection of for Write Post-processing Files.

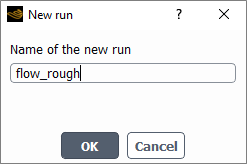

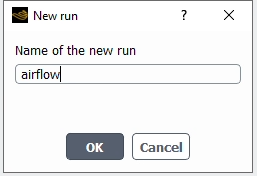

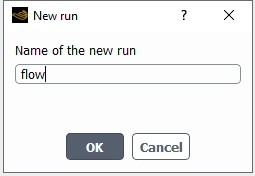

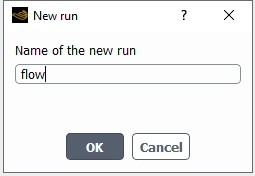

Launch the simulation.

Solution → Airflow →

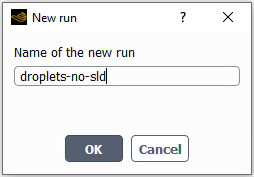

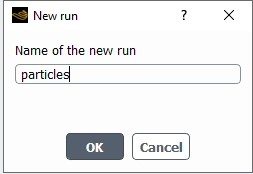

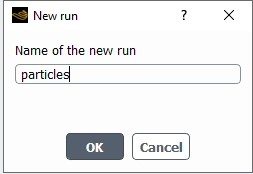

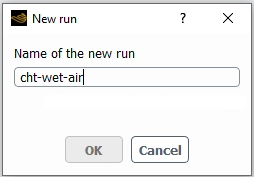

A New run window will appear. Set the Name of the new run to

flow_rough.

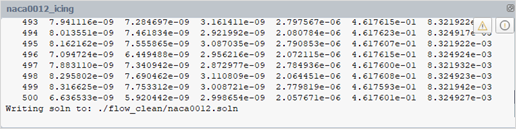

Once the computation is complete, the Airflow solution file, will be written inside the new run directory, naca0012_icing/flow_rough.

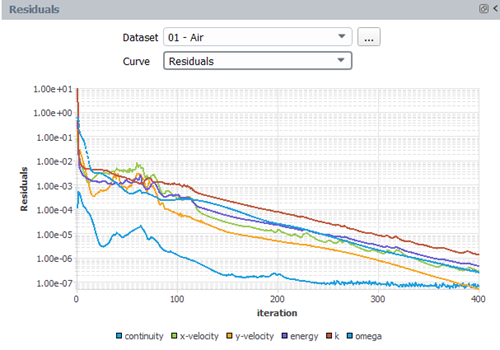

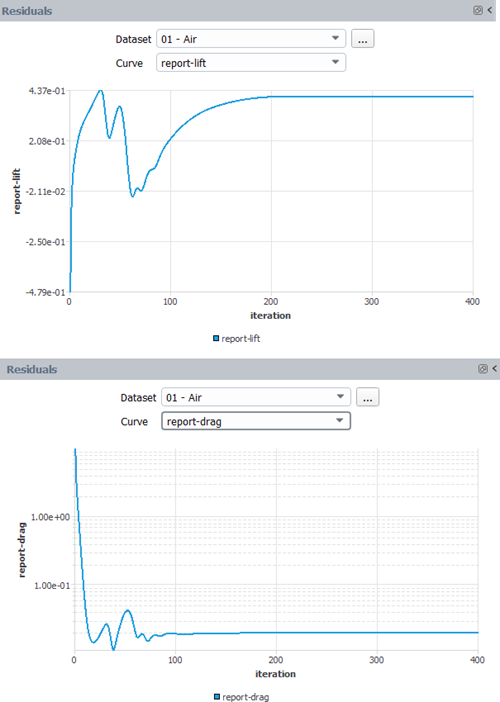

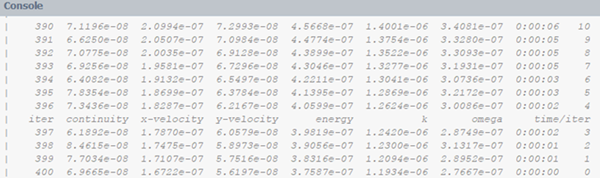

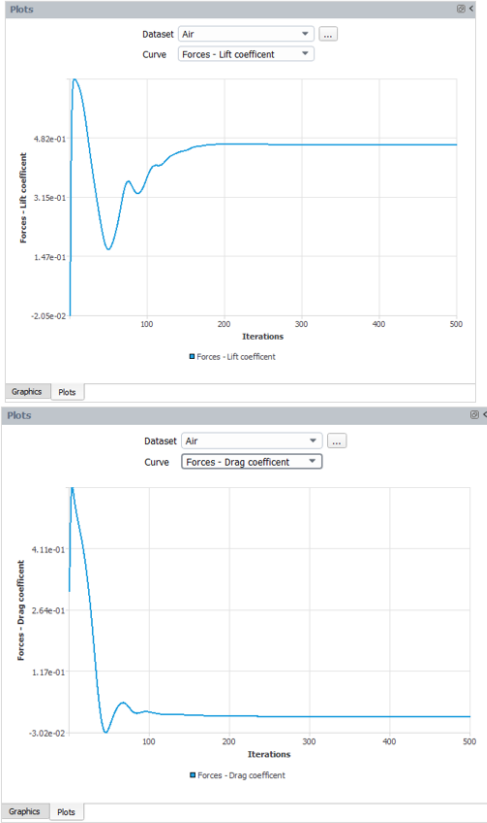

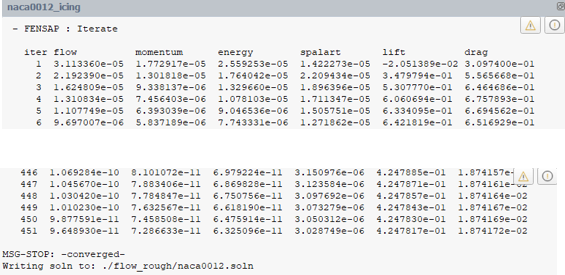

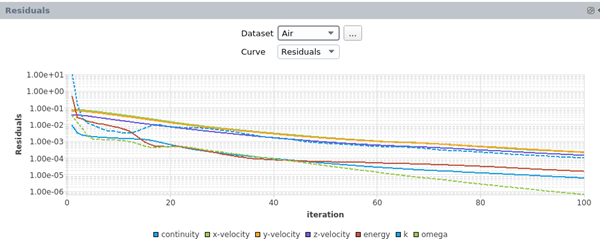

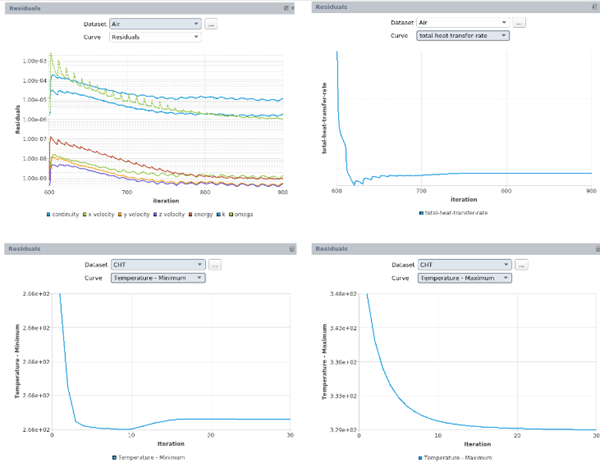

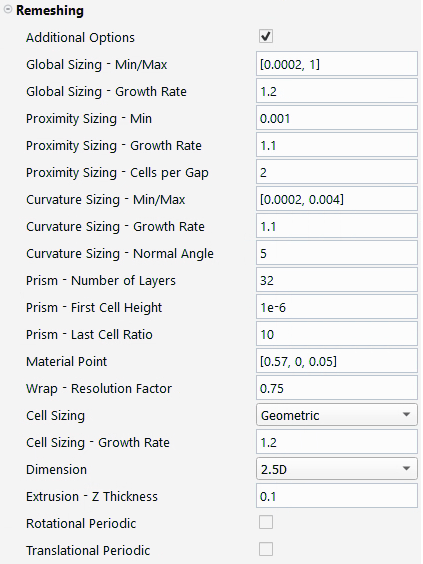

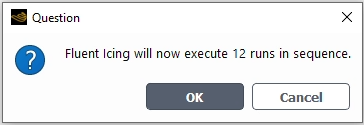

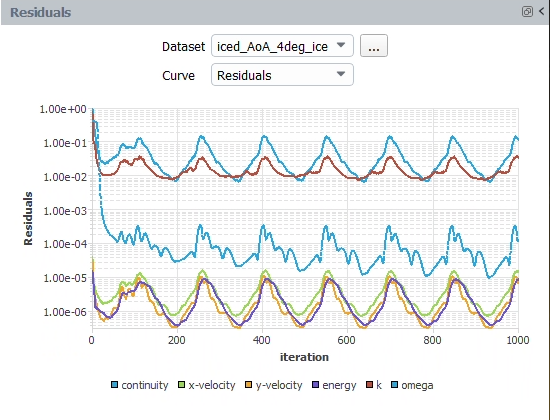

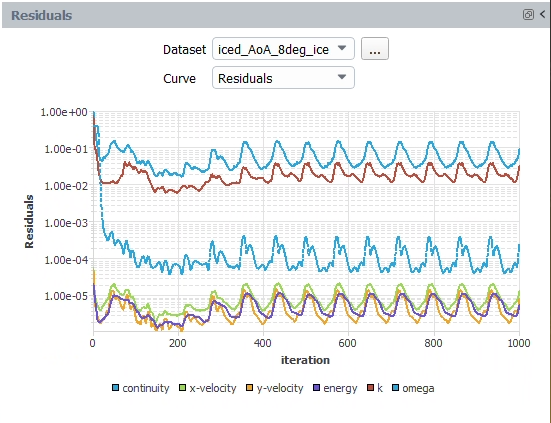

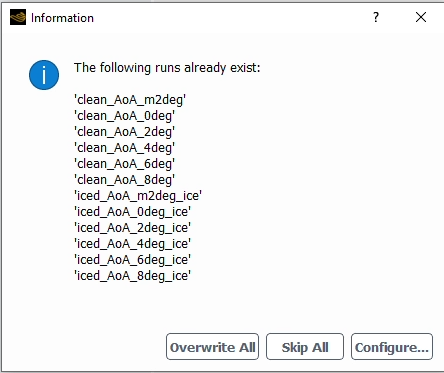

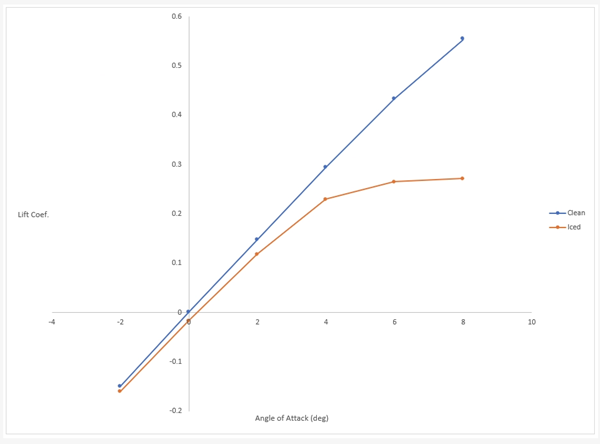

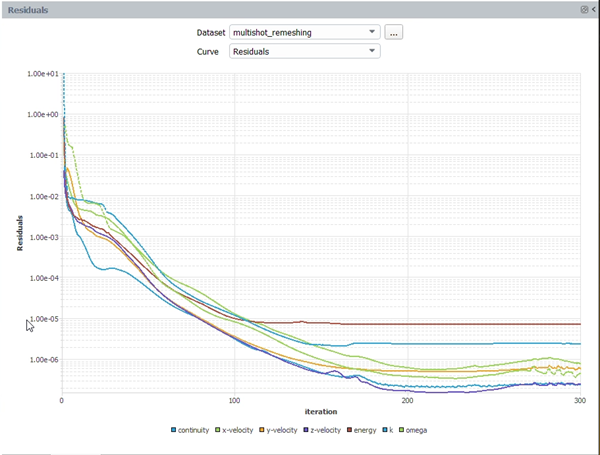

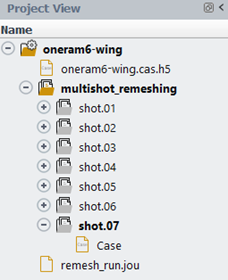

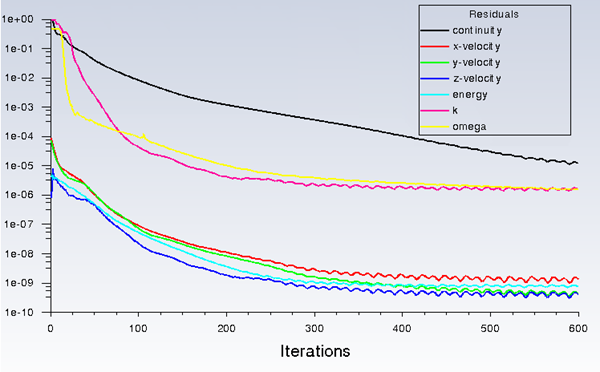

Take a look at the convergence history of this simulation in the Plots window located at the right of your screen. By default, the Plots window shows all Residuals of the governing equations at each iteration. It is possible to show the residual of a given governing equation by selecting the governing equation next to Curve located at the top of the Plots window. If other reports Reports have been defined in the original case file, they will appear as an option next to Curve. In this tutorial, the input case file contained lift and drag coefficient reports. Examine the convergence of these coefficients listed as report-lift and report-drag. Lift and drag coefficients have converged to 4.0570e-01 and 1.9850e-02 respectively.

The following three figures show the convergence of residuals and lift and drag coefficients.

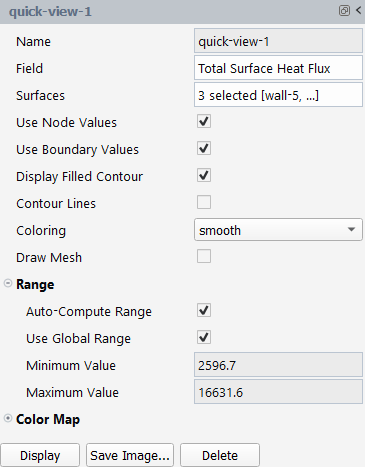

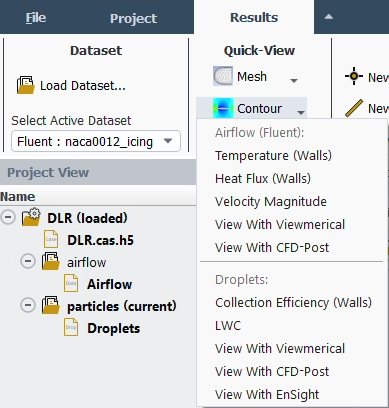

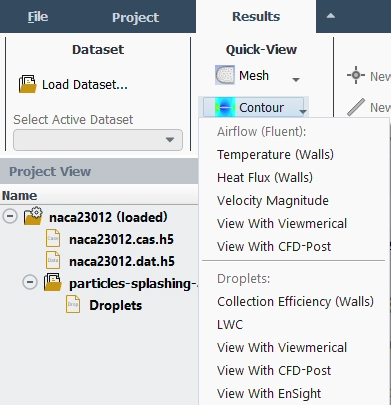

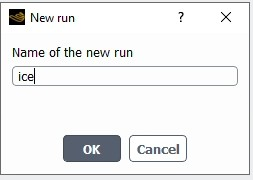

Access the Quick-View options to better visualize the results of your simulation.

Results

→ Quick-View

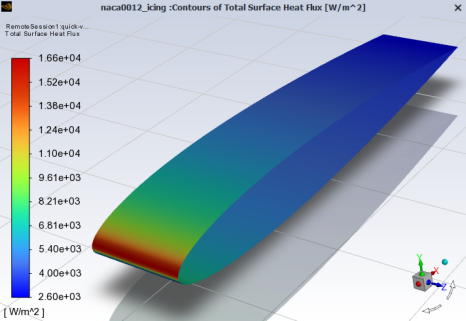

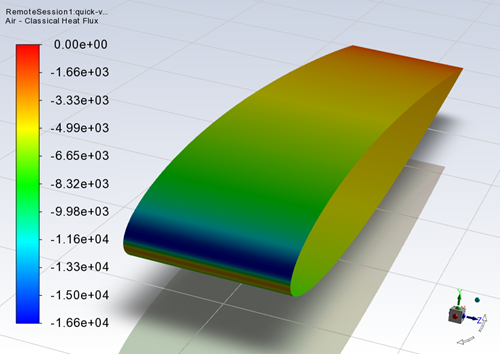

Visualize the convective heat flux over the NACA0012 airfoil.

Results → Quick-View → Contour →

A new quick-view-1 node is created in the Outline View which allows you to modify your heat flux properties.

Results → Contours →

Modify your heat flux properties until you are satisfied with your view. Press to display the solution in the Graphics window. Press on to save your solution to an image file.

The objectives of this tutorial are to compute the droplet concentration around the NACA0012 airfoil and to compare the collection efficiency of a monodispersed droplet simulation to a statistically-distributed droplet diameter solution. Completion of Fluent Airflow on a Rough NACA0012 Airfoil is required before continuing.

In a monodispersed droplet calculation, a single droplet diameter represents the icing cloud that the aircraft is flying in. In reality, icing clouds never contain only one size of droplets but a distribution of droplet sizes. When running a single droplet diameter, the median volumetric diameter (MVD) of the droplets in the cloud is chosen as the monodispersed value. If a more accurate droplet solution is needed, then a distribution of droplet sizes can be solved for, where the MVD of this distribution matches that of the cloud.

You are invited to read Setting-up a Fluent Icing Simulation for more information on how to set up the input parameters of droplets and/or crystals.

Note: If you closed your Fluent Icing session since the completion of the last tutorial, you must reopen your project and load your previous simulation and settings. To do this, open Fluent Icing, select Project → , and navigate to and select your FLUENT_ICING_NACA0012.flprj project file. Once the project is opened, right-click the naca0012_icing simulation folder, and select . The simulation will be opened, and your window display will switch to the Outline View, with a simulation tree appearing under naca0012_icing (loaded). To ensure that you are working from the most recent settings, go back to the Project View, right-click the flow_rough run, and select . Particle simulation requires an airflow solution, therefore, to ensure that the solution of flow_rough is properly loaded into Fluent Icing, in Project View, right-click the out.dat.h5 file under flow_rough and select . Finally, go back to the Project tab to continue with the tutorial.

In this section, you will learn how to set-up and launch a monodispersed droplet simulation using Fluent Icing.

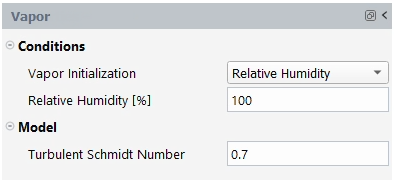

Select Project in the top ribbon and go to the Outline View. Select Setup under naca0012_icing (loaded). In its Properties window, make sure that Airflow and Particles are checked. Uncheck and .

Note: Setup, Solution and Results settings of the airflow around the NACA0012 have already been setup in In-Flight Icing Tutorial Using Fluent Icing. Therefore, they do not need to be updated.

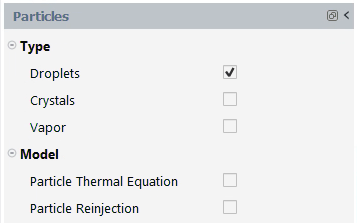

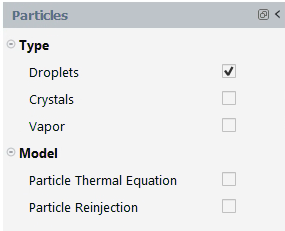

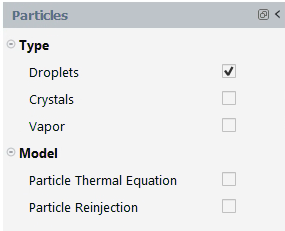

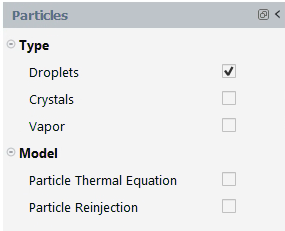

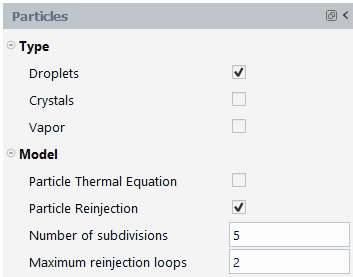

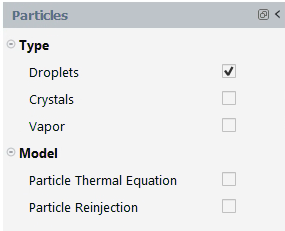

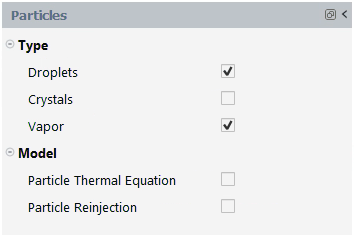

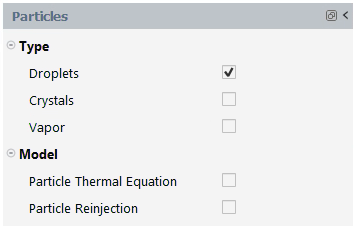

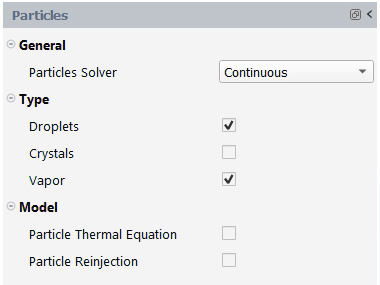

Under Setup → Particles, activate Droplets in Type. Leave the other options unchecked.

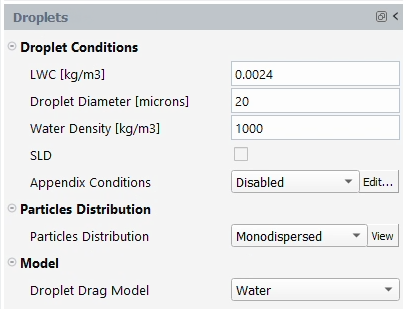

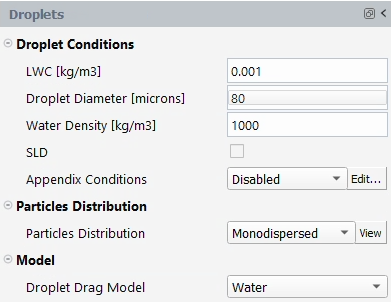

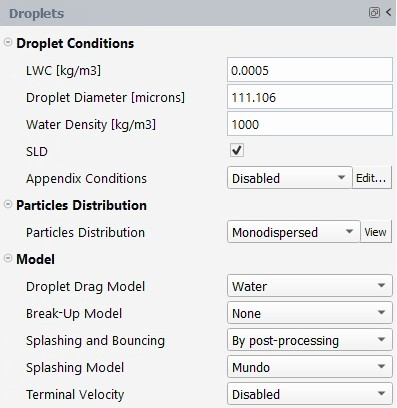

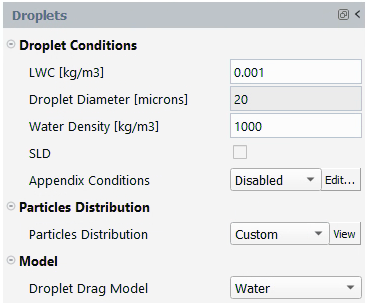

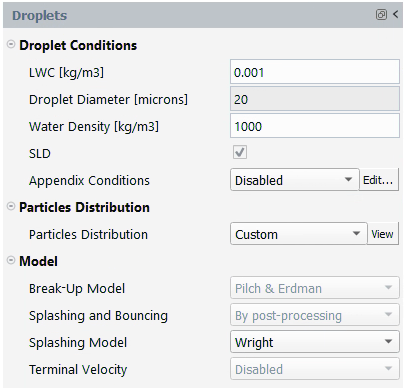

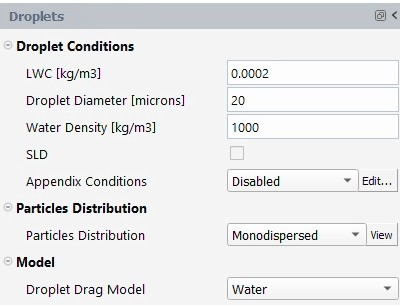

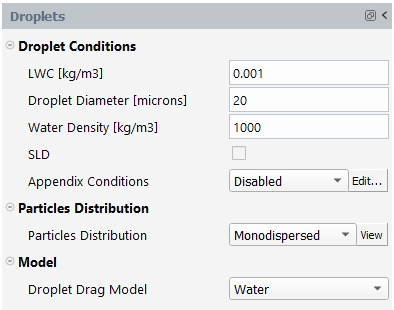

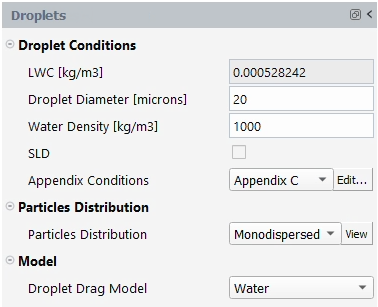

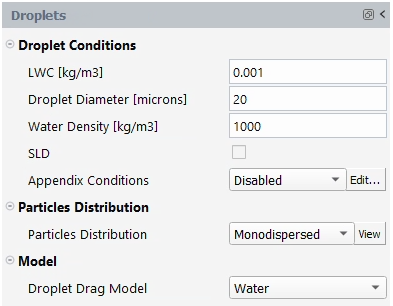

Go to Droplets, inside Setup → Particles. In the properties window of Droplets,

Under Droplet Conditions, set the LWC [kg/m3] to

0.00055and the Droplet Diameter [microns] to20.Under Particles Distribution, keep Monodispersed since you will conduct a water catch simulation using a single droplet size.

Under Model, keep Water as the Droplet Drag Model. This is the default drag law for droplet particles.

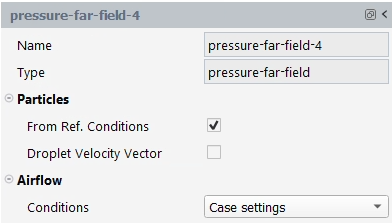

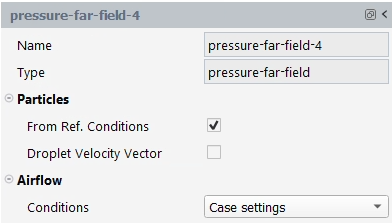

Under Setup → Boundary Conditions, expand Inlets and go to pressure-far-field-4. In its properties window, under Particles, ensure is selected and remains unchecked. The option will apply the Droplet Conditions, located inside the Droplets window, at the inlet of the pressure-far-field-4, in this case, the LWC and the MVD. If remains unchecked, the airflow velocity is imposed as the droplet velocity at the inlet. The relative velocity between air and droplets is considered to be zero at far-field.

Note: When configuring particle flow simulations, boundary conditions are only specified at inlets.

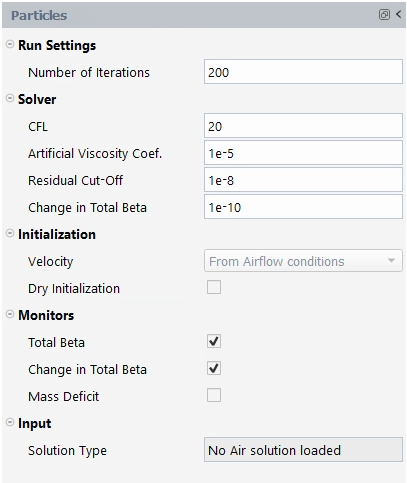

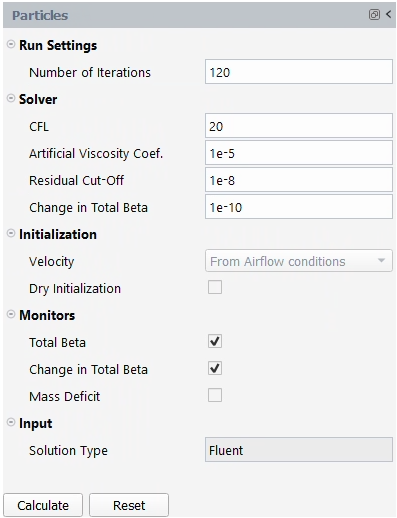

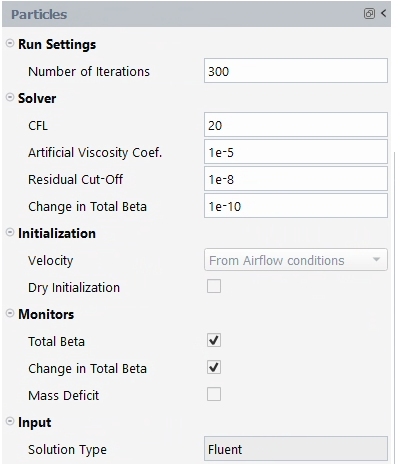

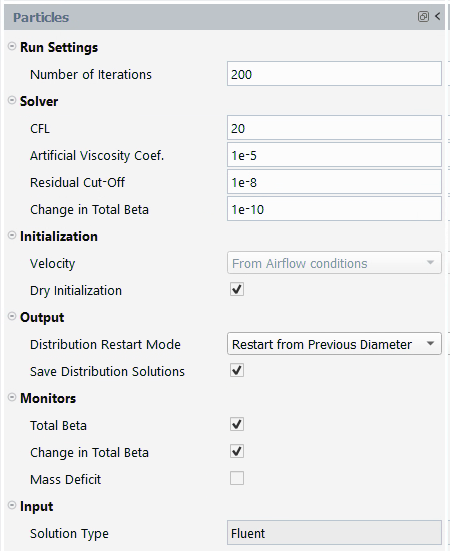

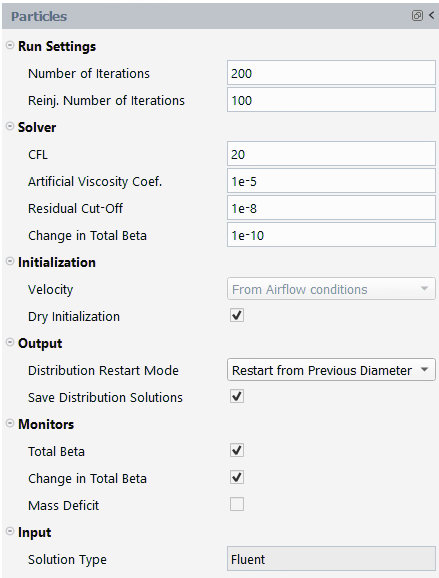

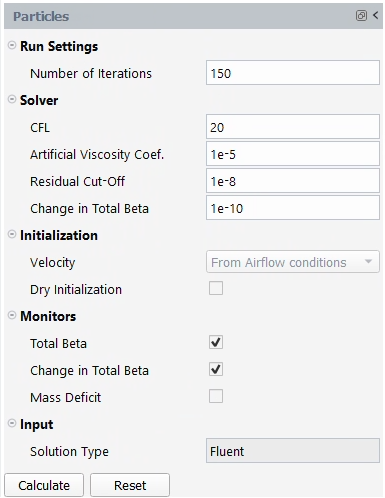

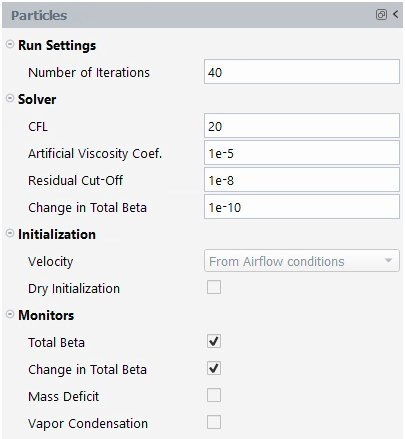

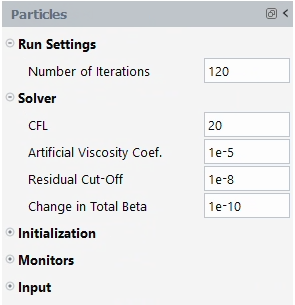

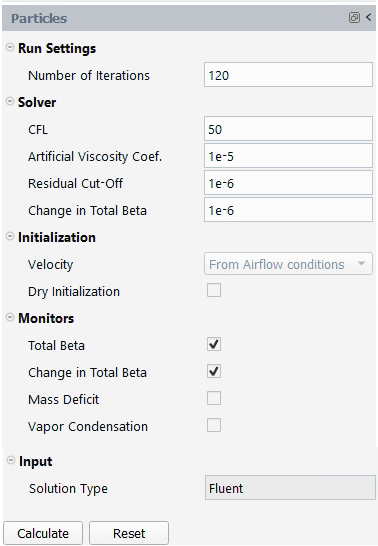

Under Solution → Particles, set

300as the Number of Iterations under Run Settings. Keep the default settings in Solver and Initialization.Note: Inside Initialization, uses the airflow direction specified in Setup → Airflow as the initial velocity of droplets.

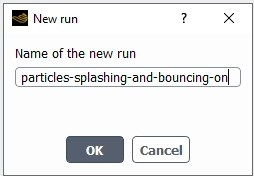

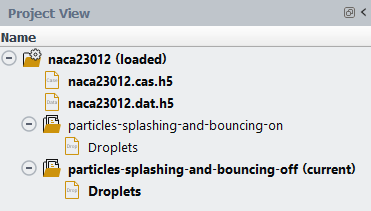

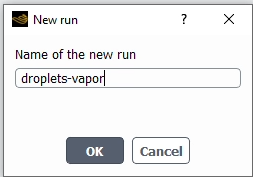

Right-click Particles under Solution and choose Calculate to launch the droplet particle simulation in standalone mode. A new window will appear requesting a name for the new run. Name the new run

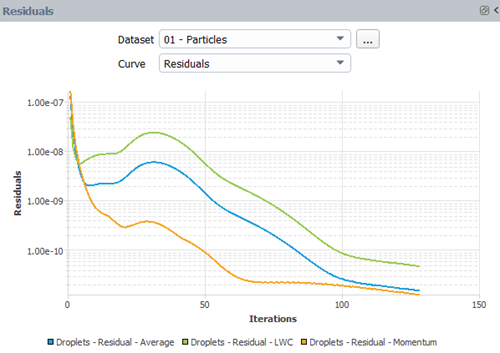

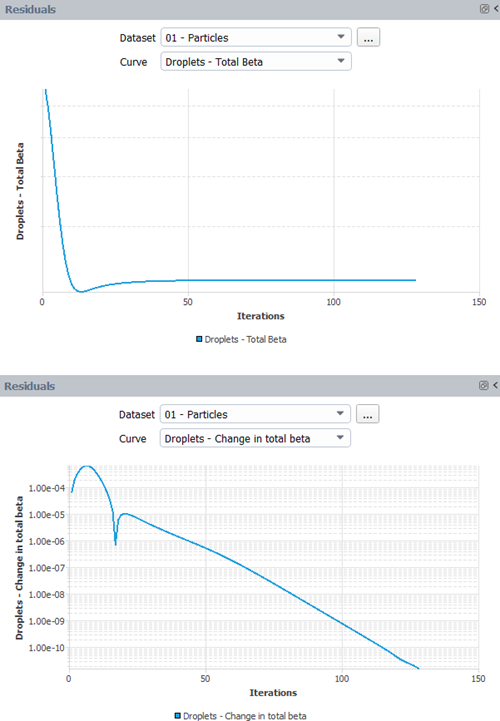

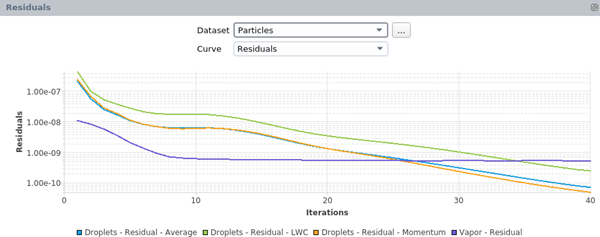

droplets_mvd.The calculation stops when the convergence level reaches the convergence limits set on the Residual cut-off and on the Change in total beta. Otherwise, the simulation continues until it reaches 300 iterations. In the Plots window, you can look at Residuals, Droplets – Residual – Average, Droplets – Residual – LWC, Droplets – Residual – Momentum, etc. curves and the Droplets -Total Beta and Droplets - Change in Total Beta convergence curves.

Often the solution in the wake of the droplet flow is still converging while the impingement at the surfaces is fully converged. If you wish to converge the wake and the shadow zones further, the Residual cut-off of the Particles panel under Solution should be reduced and the Number of Iterations should be increased. The droplet wake is usually not of interest and it is sufficient to achieve convergence of the total beta alone.

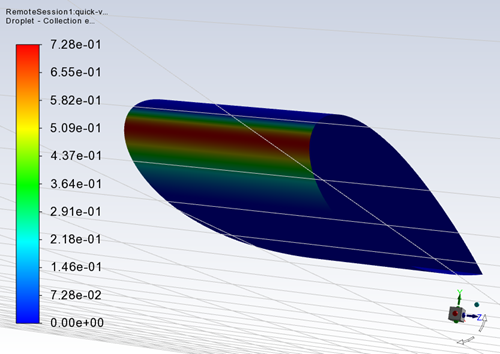

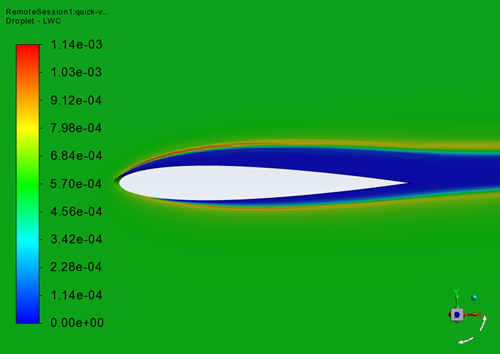

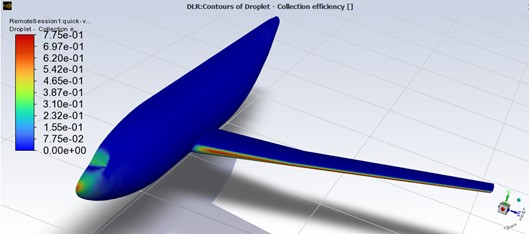

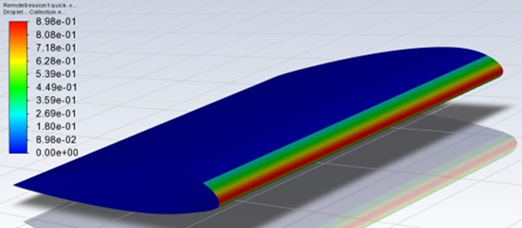

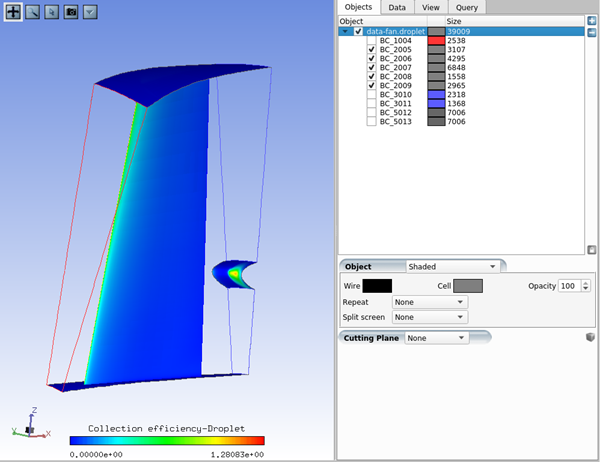

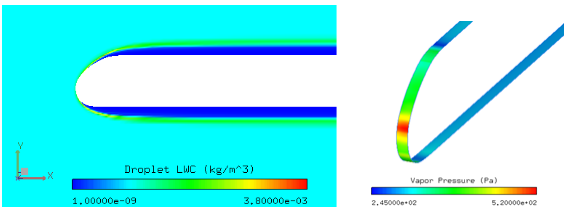

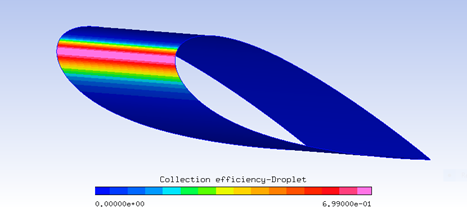

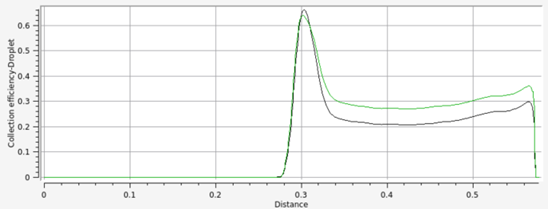

When calculations are completed, you may use Quick-View to view the results. Go to the ribbon bar of your Fluent Icing window and, under Results → Quick-View → , choose to output the water catch of the monodispersed droplets over the NACA0012. See Figure 1.10: Collection Efficiency of Monodispersed Droplets over a NACA0012.

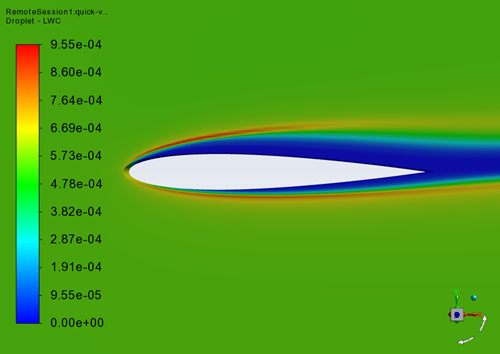

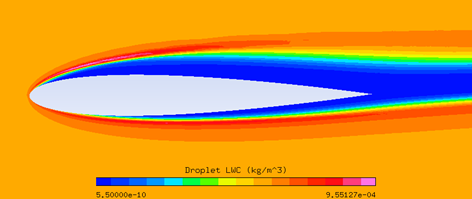

Repeat these steps to output the LWC around the NACA0012. Blue contours define the shadow zone where there is an absence of water droplets. See Figure 1.11: LWC of Monodispersed Droplets Around a NACA0012.

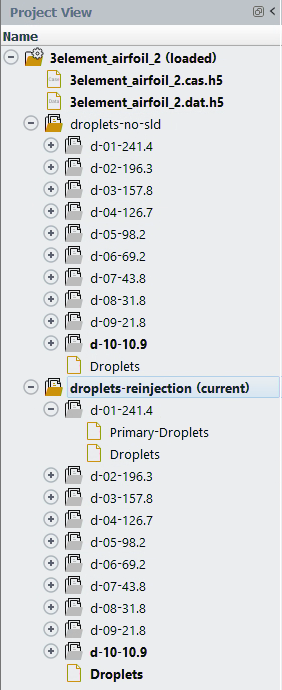

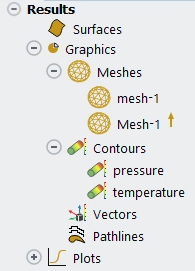

Select Project from the ribbon menu. Notice that naca0012_icing (loaded) simulation now contains the droplets_mvd run which contains the final Droplets solution. In addition to Quick-View, you can also open the results in Viewmerical from the . Right-click the Droplets solution and select → . A Viewmerical window will appear allowing you to further post-process the droplet results.

Note: The Droplets solution, shown in the Project View, is a link to a file on the disk. This link points to the filename naca0012.droplet. To show the filenames as they appear on the disk, you may right-click Name under Project View and select . Repeat these steps to disable before continuing with this tutorial.

Move on to the next tutorial, go back to the Project tab.

Caution: Do not close Fluent Icing.

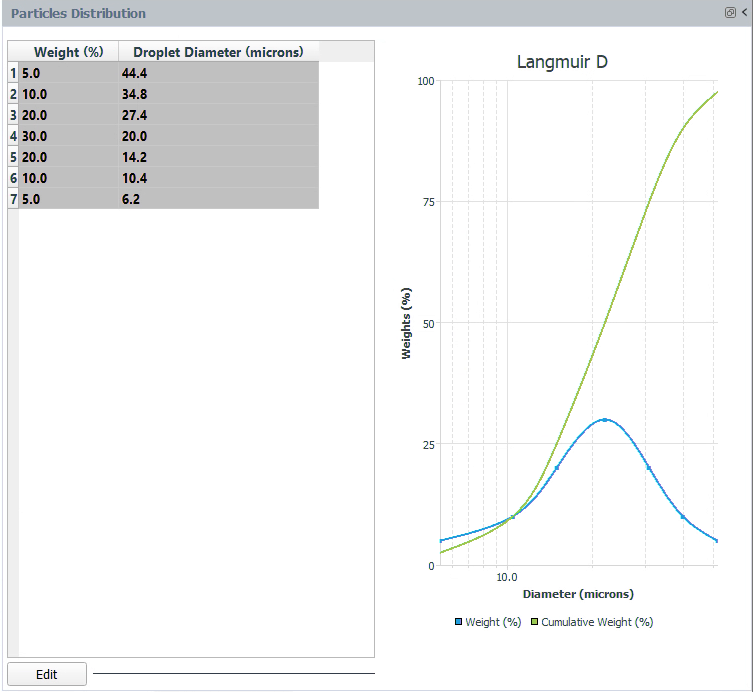

There are several cloud droplet size distributions that have been published in the literature. The distributions published by Langmuir have been used by NACA to determine the MVDs currently listed in Appendix C, which is used for icing certification of aircraft. Advisory Circular No 20-37A from FAA suggests using Langmuir-D distribution for MVDs up to 50 microns. For more details on these distributions, you can consult the Advisory Circular, and also the book by Irving Langmuir, The Collected Works of Irving Langmuir (New York, Pergamon Press, 1960).

The most important reason for considering an analysis using a distribution is that there are droplets larger than the MVD in the distribution, which can impinge further back on the top and bottom of the airfoil, creating a thin but rough layer of ice that can have adverse effects on aerodynamics and control. In this case, solutions for each droplet size of a given distribution are calculated separately. The final solution is then created as a composite of all solutions using weights on each droplet size.

In this tutorial, you will use the set-up created in Monodispersed Calculation as a starting point.

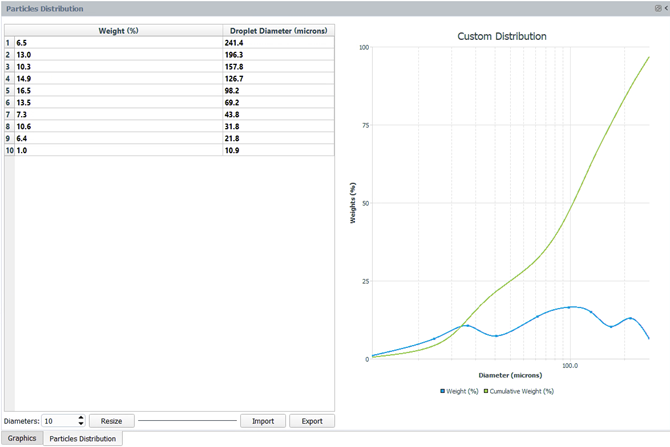

Without closing the previous Fluent Icing session (Monodispersed Calculation), in the Outline View panel, go to Setup → Particles → Droplets. In the Droplets window, under Particles Distribution, set Droplet Distribution to .

Note: The current version of Fluent Icing supports pre-defined droplet size distributions (Langmuir B to E). User defined distributions are not yet supported. Below is a representation of a Langmuir D distribution and the droplet diameters that are used to represent this distribution.

In the figure above, the droplet diameters are on the horizontal axis, and the weights (the percentage of droplets of a given diameter contained in the cloud) are on the vertical axis. The individual weights are shown with the blue curve, and the overall sum, cumulative weight, is shown with the red curve. On the red curve, the data points are plotted at the mid-range of their cumulative weight intervals. For example, the 20 microns droplet, which happens to be the MVD, covers the cumulative weight range of 35% to 65% and it is therefore plotted at 50% cumulative weight on the red curve.

A Particle droplet simulation is run for each droplet size shown in the above table.

Go to Solution → Particles. In its properties window, check Save Distribution Solutions under Output.

This will allow you to save a droplet solution for each droplet size simulated. Otherwise, only the combined solution of the distribution is saved. Keep all the other settings the same.

Right-click Particles under Solution, choose to run the calculation. A window will appear asking if you would like to continue the current run. Choose . A new run window will appear. Set the Name of the new run to

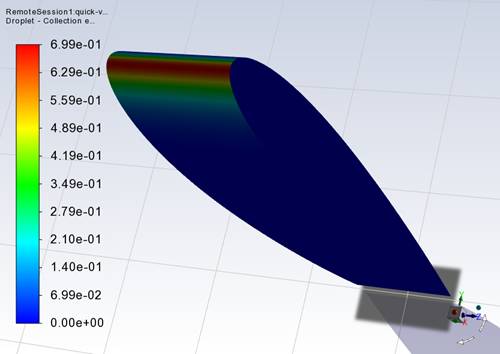

droplets_langd. Individual runs will be executed one after the other, and the results will be combined.When calculations are completed, you may use Quick-View to view the results. Go to the ribbon bar of your Fluent Icing window and, under Results → Quick-View → , choose to output the water catch of the Langmuir D droplet distribution over the NACA0012. See Figure 1.12: Collection Efficiency of Droplets with Langmuir-D Distribution over a NACA0012.

Repeat these steps to easily output the LWC around the NACA0012. Blue contours define the shadow zone, absence of water droplets. See Figure 1.13: LWC of Droplets with Langmuir-D Distribution Around a NACA0012.

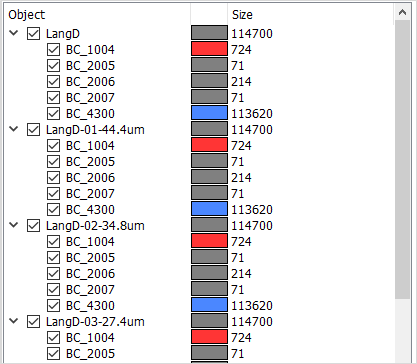

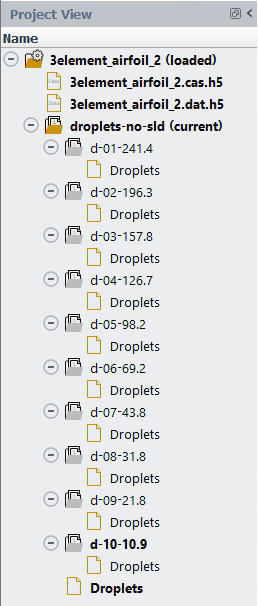

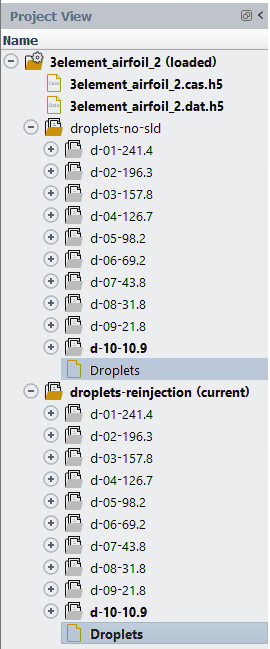

Select Project from the ribbon menu. Notice that naca0012_icing (loaded) simulation now contains the droplets_langd run. This run has a combined Droplets solution as well as each individual Droplets solution located in numbered folders d-01 to d-07.

To link each numbered droplet solution to a droplet size of the Langmuir D distribution, in the Project ribbon, select Project → → . A Project window appears. Click the + sign beside Metadata to expand the list of parameters associated to each run and solution. Scroll-down and select Droplets::D-Diam and click . A D-Diam column appears next to Name inside the Project panel. This column clearly identifies the droplet diameter used to obtain each solution.

Note: In addition to Quick-View, you may open the results in Viewmerical from the Project View. To display the combined droplet solution in Viewmerical, right-click the Droplets solution file and select → . Alternatively, to display an individual droplet solution file, right-click the d-0*/Droplets file of your choice and select → . A Viewmerical window will appear allowing you to further post-process the droplet results.

Before you move on to the next tutorial, go back to the Project panel.

Caution: Do not close Fluent Icing if you would like to proceed with the next section.

To complement the built-in post-processing, Ansys distributes Viewmerical and CFD-Post with the installation package. In this tutorial, you will use Viewmerical to post-process your droplet results. In the next tutorial, you will use CFD-Post to post-process your icing results.

Viewmerical is a light-weight graphical display tool specifically designed for in-flight icing solutions and applications. Viewmerical can display solution field contours, velocity vectors, planar cuts through the volumes, 2D graphs of variables, streamlines, etc. This tutorial will demonstrate some basic features of Viewmerical while comparing the two droplet solutions obtained in the previous sections.

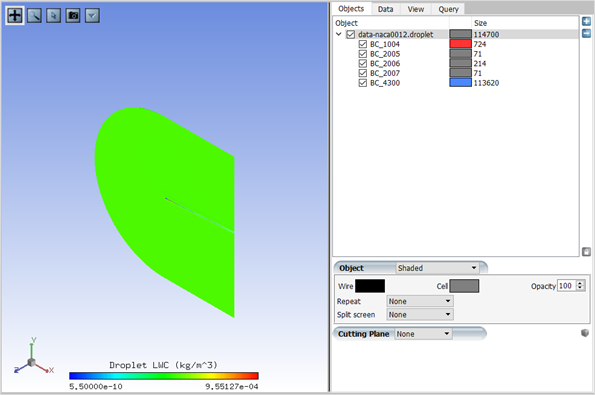

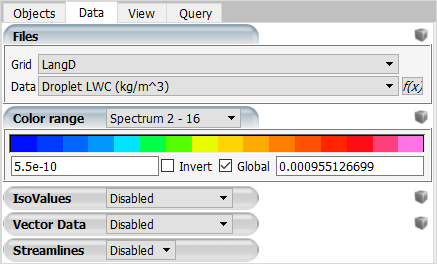

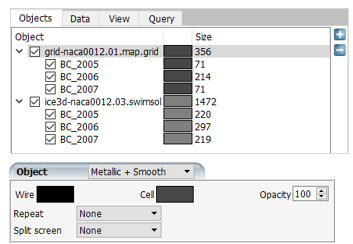

In Project View, right-click the naca0012_icing → droplets_langd → Droplets solution and choose → . A message may appear asking if you would like to append this solution to a previously opened Viewmerical display. Click .

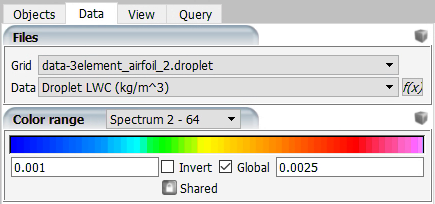

The program will launch and show an isometric display of the entire grid showing the first solution field, Droplet LWC, of the combined Langmuir D solution.

Rename this dataset by double-clicking the original name, data-naca0012.droplet. A Rename dataset window appears, write

LangDin the text box.Go to the Data tab and then change the Color range to .

Align the view angle with the Z-symmetry plane by right-clicking the 3D axes on the lower left, and by choosing . Alternatively, you can left-click the Z axis itself.

Zoom in on the airfoil. You can use Ctrl + left-click to draw a zoom box, or scroll the mouse wheel to zoom in and middle-click to pan.

Change the font of your legend to bold. Click

on the top left corner of the window and select

Command window; then type

on the top left corner of the window and select

Command window; then type

BIGFONTSin the command line of the 3dview console and hit Enter. The legend fonts now become bold.Using the Camera icon on the upper left corner, you can take a snapshot of the solution window to capture the following image.

Figure 1.14: LWC of a Langmuir D Droplet Cloud over a NACA0012 at an AoA of 4 Degrees, Showing the Shadow Zone (Blue Region)

Examine the LWC distribution in the area close to the airfoil. The blue region is called the shadow zone, where no droplets exist. In between the shadow zone and the free stream, there are bands of high LWC concentrations which are the enrichment zones forming due to the constriction of stream tubes in the continuum domain. These features can be of special interest for downstream aircraft components.

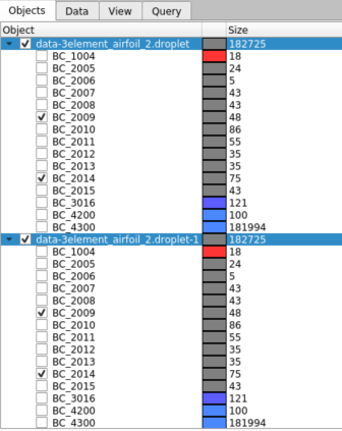

Go to the Data tab and choose Collection efficiency-Droplet. Collection efficiency is only displayed on the walls of your geometry. Go to the Objects tab and uncheck BC_1004 and BC_4300 to display the collection efficiency distribution only on the walls (BC_2005, BC_2006, BC_2007, and BC_2008).

Use the left mouse button to rotate, the middle mouse button to pan, and the right-mouse button to zoom in the airfoil surface to obtain the following figure.

Figure 1.15: Collection Efficiency of a Langmuir D Droplet Cloud on the Surface of the Airfoil at an AoA of 4 Degrees

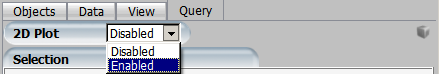

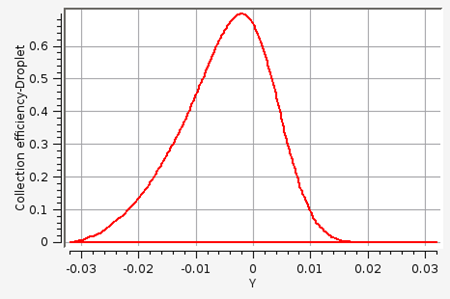

For a more in-depth quantitative view, it would be possible to create 2D data plots using Viewmerical. Click the Query tab and enable 2D Plot.

Change the Cutting plane to Z and the horizontal axis to Y.

On the lower right corner of Viewmerical, you can directly modify data sets and solution fields. Leave them as they are now.

The color and thickness of the data curve displayed in the graph can be changed by left-clicking the cube menu located on the top right and by choosing Curve Settings. Set the curve color to red and the curve widths to

2and press .

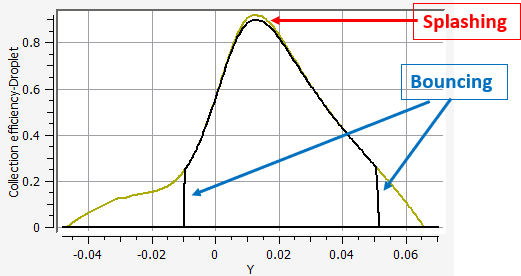

Finally, the following 2D plot is generated.

Figure 1.16: Collection Efficiency of a Langmuir D Droplet Cloud on the Surface of the Airfoil at an AoA of 4 Degrees

The maximum beta occurs at the stagnation point, just below the leading edge in this case. The points on the upper and lower surfaces where beta becomes zero are the impingement limits. In rime icing cases, all the water that impinges is frozen instantly, therefore icing limits are the same as the impingement limits. In glaze icing, water can runback and freeze past the impingement limits. Maximum beta is usually no more than 1.0, and reduces as the droplet flow becomes tangent to the surface.

To save data points of this collection efficiency distribution, go to the cube menu on the top right and choose . A new window pops up to browse and name the file that should contain these data points.

You can also open and compare several solution files using Viewmerical. Let’s display simultaneously all 7 droplet size solutions obtained in Langmuir-D Distribution.

Go to Project View. Under the run droplets_langd, right-click its d-01/Droplets file and select → .

A message appears asking if you would like to append this solution to a previously opened Viewmerical display. Click .

Inside Viewmerical, rename this new object by double-clicking its original name in the Object window and enter

LangD-01-44.4umin the window Rename dataset, where 01 indicates the droplet solution number and 44.4um is the droplet diameter of the droplet solution.Note: The droplet diameter of each droplet solution is shown in D-Diam column of the Project panel of the naca0012_icing (loading) simulation. See step 6 of Langmuir-D Distribution.

Repeat steps 14 to 16 to load the remaining droplet solutions from d-02/Droplets to d-07/Droplets.

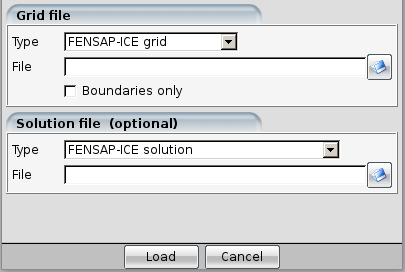

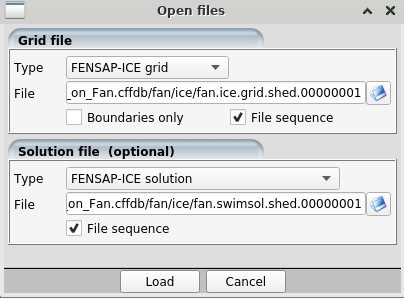

Note: Alternatively, it is possible to bring each droplet solution by going to the run droplets_langd folder and by uploading each one of them from Viewmerical. To do this in Viewmerical, perform the following steps:

Click the

button located at the right corner

of the Object panel. A window appears

to load a pair of files, a grid file and its solution

file.

button located at the right corner

of the Object panel. A window appears

to load a pair of files, a grid file and its solution

file.

Click the

folder icon of Grid

file and select the

naca0012.grid file located inside your

project and simulation directory

FLUENT_ICING_NACA0012/naca0012_icing/.

folder icon of Grid

file and select the

naca0012.grid file located inside your

project and simulation directory

FLUENT_ICING_NACA0012/naca0012_icing/.

Click the

folder icon of

Solution file (optional) and select the

naca0012.droplet.01 file located inside

your project, simulation and run directories

/FLUENT_ICING_NACA0012/naca0012_icing/droplets_langd.

folder icon of

Solution file (optional) and select the

naca0012.droplet.01 file located inside

your project, simulation and run directories

/FLUENT_ICING_NACA0012/naca0012_icing/droplets_langd.Press the button. A new data set is added to the Object panel. Rename this dataset by double-clicking its original name and enter

LangD-01-44.4umin the window Rename dataset, where 01 indicates the droplet solution number and 44.4um is the droplet diameter of the droplet solution.Repeat these steps for the remaining droplet solutions from naca0012.droplet.02 to naca0012.droplet.07.

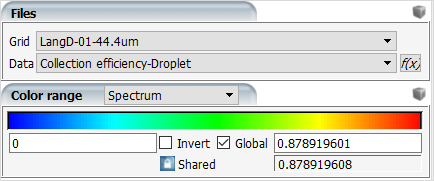

In Viewmerical, go to the Objects panel, uncheck LangD.

Go to the Data panel and click Shared located under Color range. Switch the Data field to Collection efficiency- Droplet.

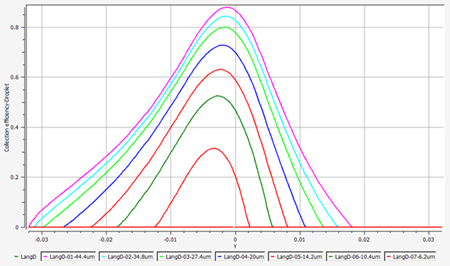

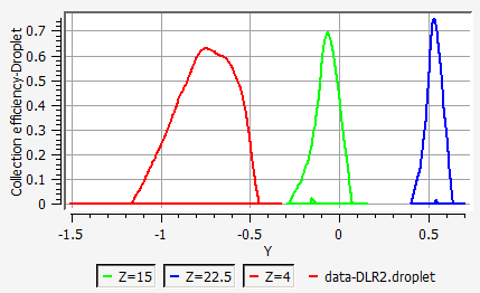

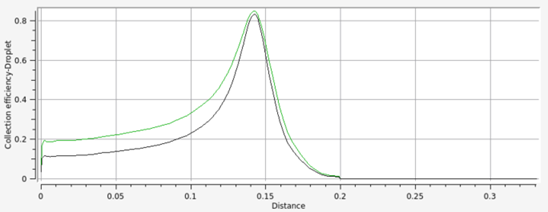

Go to the Query tab, enable 2D plot, and switch the Cutting plane to Z. The graph should display 8 individual beta distributions. Click LangD, to disable the LangD curve from the 2D plot. You can change the color and thickness of the data curve displayed in the graph via the cube menu on the top right and by choosing Curve Settings. You can also draw a zoom box by Shift + left-click.

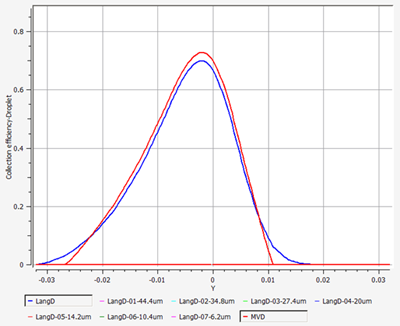

Figure 1.17: Collection Efficiency on the Surface of the Airfoil at an AoA of 4 Degrees, Langmuir D Droplet Solutions

The curve with the lowest beta corresponds to the smallest droplet size (LangD-07-6.2 µm), and the one with the largest beta corresponds to the largest droplet size (LangD-01-44.4.µm). Smallest droplets are less ballistic, tend to follow the air flow and avoid the aircraft therefore reducing their collection efficiency and impingement limits. Larger droplets are more ballistic and they do not tend to follow the airflow. Therefore, their collection efficiency and impingement are usually higher than the smallest droplets. In general, this information is crucial to properly design the IPS power requirements and coverage.

Note: The difference between beta curves of different droplet sizes become more pronounced as the aircraft surface size increases. The effect can be dramatic on large blunt surfaces like fuselage noses or radomes where the contribution from the smaller size droplets can be negligible if compared to the largest ones. As a result, the composite or combined solution of a Langmuir simulation can be very different from the solution of the MVD.

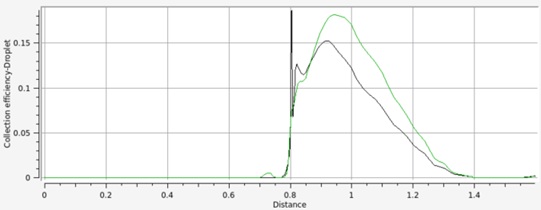

To compare the LangD result to that of the monodispersed (MVD), go to the Objects panel, check LangD and uncheck all the other LangD-* objects.

Go to Project View. Under the run droplets_mvd, right-click its Droplets file and select → .

A message appears asking if you would like to append this solution to a previously opened Viewmerical display. Click .

Inside Viewmerical, rename this new object by double-clicking its original name in the Object window and enter

MVDin the window Rename dataset.Go to the Query tab, enable 2D plot, and switch the Cutting plane to . The graph should display 9 individual beta distributions. click LangD-01-44.4um to LangD-07-6.2um to disable these curves from the 2D plot. Change the color of the MVD to red and of the LangD to blue via the cube menu on the top right and by choosing Curve Settings. Set their width to

2. You can also draw a zoom box by Shift + left-click.The LangD solution is fairly close to that of the MVD. The impingement limits of the Langmuir D solution will always be further back due to the inclusion of larger droplets in the distribution. The maximum beta of the composite is lower than the MVD here. This is not always the case. Based on the size and shape of the impingement surface, the Langmuir D solution can have a maximum beta that is several times higher than the MVD. In this case, however, the results of the MVD and the distribution are close.

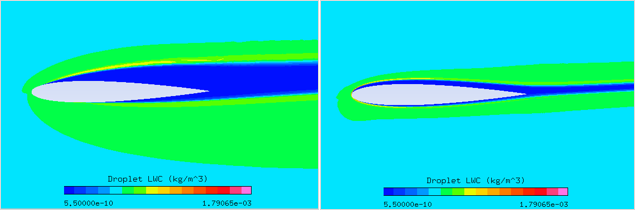

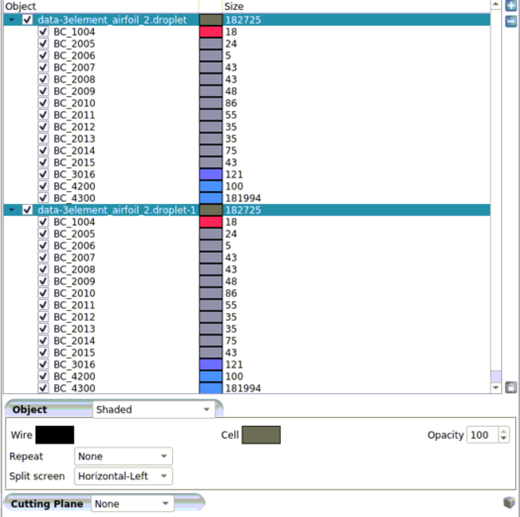

You will now compare the LWC of the largest and smallest droplet of a Langmuir D distribution. Go to the Objects panel, uncheck LangD and MVD objects and check LangD-01-44.4um (largest droplets) and LangD-07-6.2um (smallest droplets).

On the lower right corner of Viewmerical, change Collection efficiency-Droplet to Droplet LWC (kg/m^3).

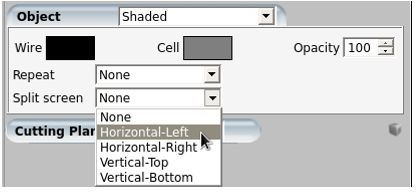

Select LangD-01-44.4um in the Objects panel and choose Horizontal-Left under Split screen menu.

Go to the Data tab and change the color range to Spectrum 2 –16.

Align the view angle with the Z-symmetry plane and zoom in to capture the following image:

Figure 1.19: LWC Distribution and Shadow Zones for 44.4 Micron Droplets (Left) and 6.2 Micron Droplets (Right)

Observe the difference in the shadow zones. The smallest droplets follow the airfoil very closely but avoiding it while the largest droplets barely change their path and hit almost straight on, leaving a larger shadow zone.

The objective of this tutorial is to compute ice accretion and water runback on the NACA0012 airfoil at different icing temperatures. Icing temperature refers to the free stream air temperature at which the icing is to be computed. Inside Ice, this temperature can be different than what was used for the airflow free stream temperature. Indeed, the formulation of the heat fluxes in Ice allows you to use an air solution obtained at a temperature different than the intended icing temperature. In this manner, several icing temperatures can be investigated using the same airflow solution.

Note: The option to change icing air temperature in icing parameters is provided as a quick method to obtain different ice shapes with different ambient temperatures. It should be understood that this method is not identical in terms of accuracy to running air and droplet flows independently for each of those temperatures. Change in ambient air temperature would result in a proportional change in air density which would change the momentum transfer between air and particles. This would ultimately affect particle flow paths and collection efficiency. For internal flows, where particle thermal equation and/or vapor transport is enabled, icing air temperature should be kept the same as the reference air temperature.

You are invited to read Ice and Walls within the Fluent User's Guide for more information on how to set up the input parameters of the Ice module.

This tutorial will begin as a continuation of Monodispersed Calculation, so the monodispersed droplet solution and settings must be loaded.

Select Project from the top ribbon menu. To load the settings from the monodispersed run, right-click the droplets_mvd folder and select . To load the monodispersed solution, from the left side panel, right-click the droplets_mvd → Droplets solution file and select .

Note: If you closed your Fluent Icing session since the completion of the last tutorial, you must reopen your project and load your previous simulation and settings. To do this, open Fluent Icing, select Project → , and navigate to and select your FLUENT_ICING_NACA0012.flprj project file. Once the project is opened, right-click the naca0012_icing simulation folder, and select . The simulation will be opened, and your window display will switch to the Outline View, with a simulation tree appearing under naca0012_icing (loaded). Once this is done, continue with step 1.

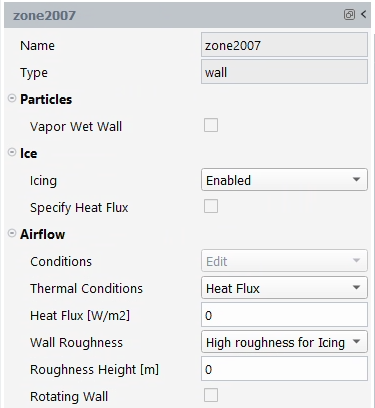

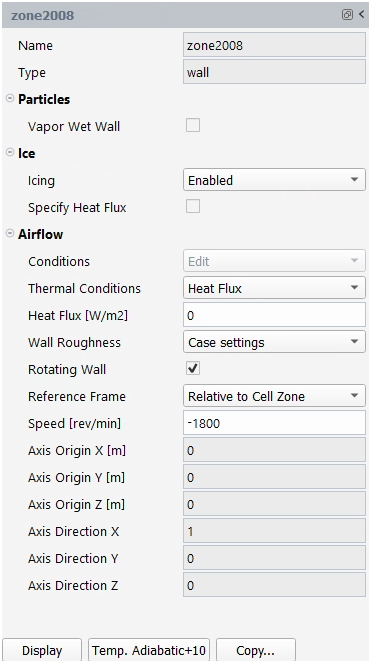

Under Outline View, select Setup under naca0012_icing (loaded). In its Setup window, make sure that Airflow, Particles and Ice are checked.

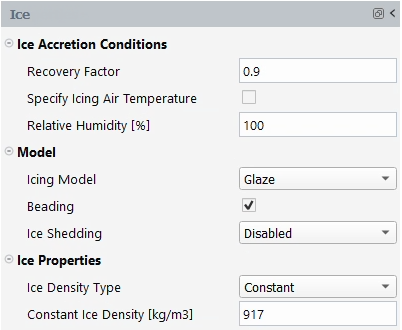

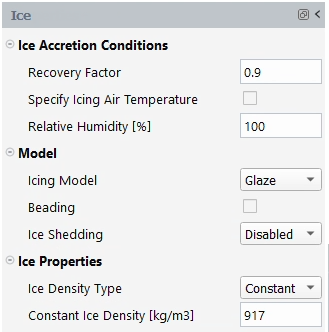

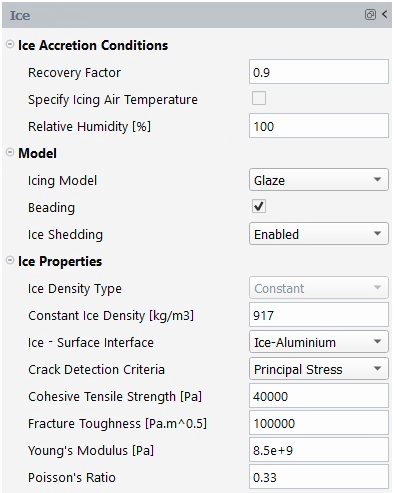

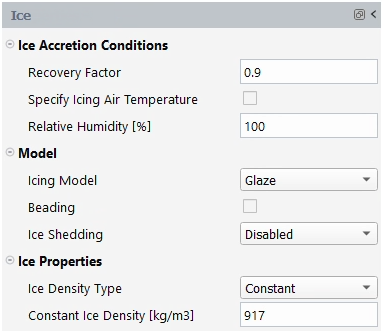

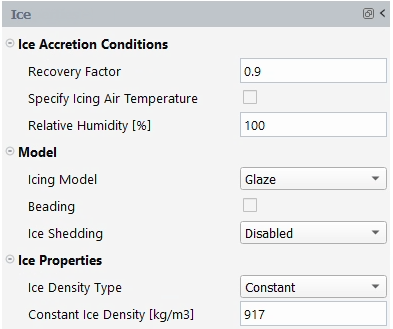

Under Setup → Ice,

In Ice Accretion Conditions,

Check Specify Icing Air Temperature to simulate an icing temperature that is different than the reference/far-field air temperature.

Set the Icing Air Temperature [K] to

248.15K (-25 °C).

In Model,

Make sure that Icing Model is set to Glaze.

Leave the other settings as default.

In general, there is nothing to set in the Boundary Conditions of Ice unless icing is to be turned off on certain surfaces to reduce computational effort or sink boundaries are to be declared. Examine the options available for each wall without making any changes.

Go to Solution and change Log Verbosity to Complete to output extra execution and post-processed data in the Console window.

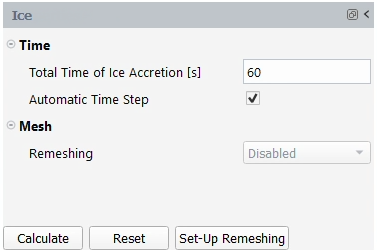

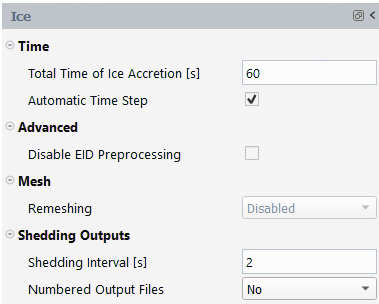

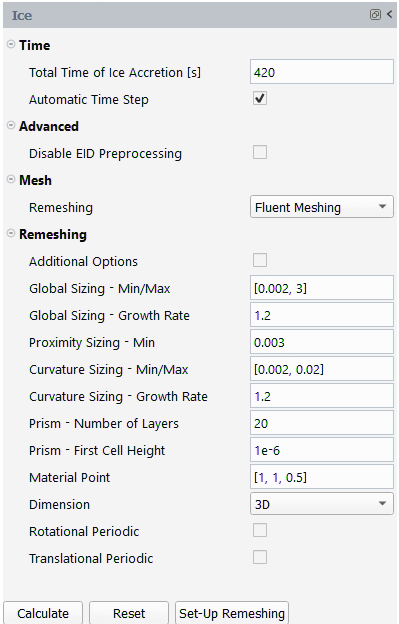

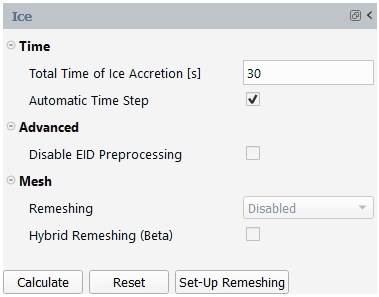

Go to the Solution → Ice,

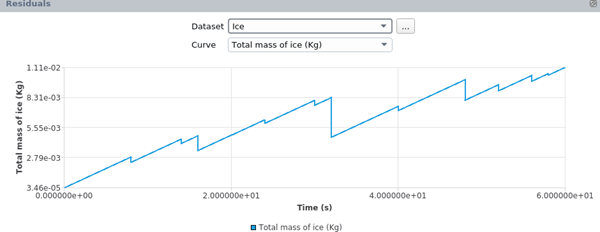

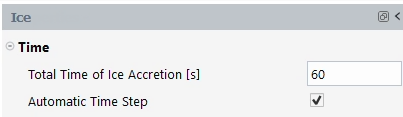

Under Time, keep the Total Time of Ice Accretion [s] at 420 seconds and the option checked. The Ice feature in Fluent Icing is an explicit time-accurate code where the stability of the solution strongly depends on the value of the time step. The automatic time stepping option calculates the optimal stable time step at every iteration, which can change greatly depending on the size of the geometry and the mesh density.

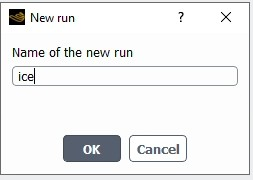

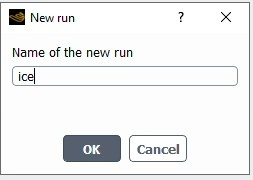

Right-click Ice under Solution and choose to run the calculation. A window will appear. Name the new run

ice_mvd_m25C.After the simulation is complete, an Ice solution will be saved in the ice_mvd_m25C run folder.

Note: The Ice solution, shown in the Project View, inside the ice_mvd_m25c run, is a link to a file on the disk. This link points to the filename naca0012.swimsol. To show the filenames as they appear on disk, you may right-click Name under Project View and select . Repeat these steps to disable before continuing with this tutorial.

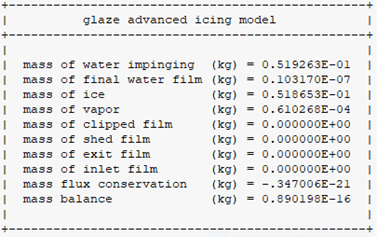

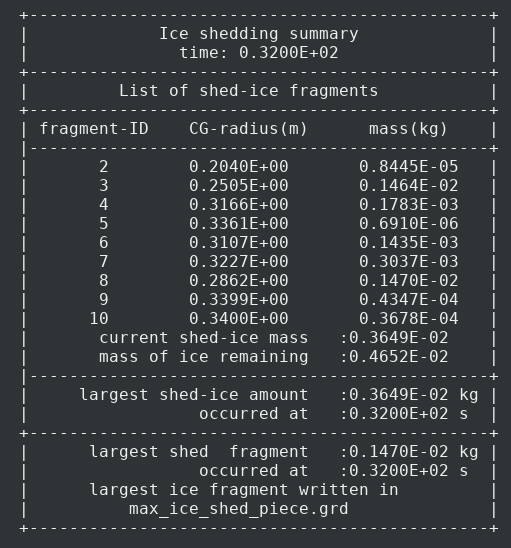

Look through the Console window of naca0012_icing. The accumulated time, value of the time step, total impingement, film, and mass of ice are printed at selected iterations. Heat flux and ice mass per wall boundary condition are listed in the following two tables. Finally, energy and mass conservation tables are printed. Most of the items in these tables are self-explanatory except perhaps mass of clipped film and runback flux. Clipped film refers to any film that is removed by sink boundaries and on certain nodes which collect and shed water (trailing edges, wing and blade tips, etc.) that are detected automatically. Runback flux is the sum of all edge fluxes in the domain which will be equal to the film removed by sink boundaries, or close to zero (mass conservation).

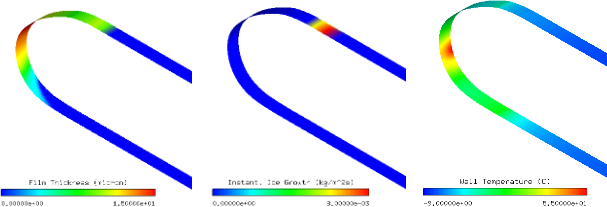

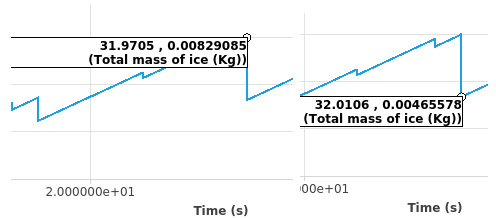

Cycle through the Plots window. By changing the Curve type, you will observe the progress of the total mass of ice, the change in instantaneous ice growth, water film thickness, and ice surface temperature with time. Since the input flow and droplet solutions are steady-state solutions, the icing solutions will eventually reach a steady-state where instantaneous ice growth, water film thickness, and ice surface temperature do not change after a while.

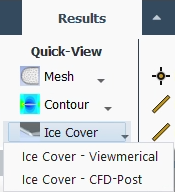

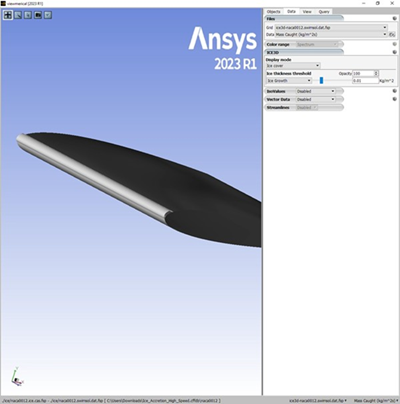

Go to the Ribbon menu and select Results. In Quick-View, click → to see the ice shape and the original surface in Viewmerical. If a window appears asking if you would like to append to a previously opened Viewmerical display, choose .

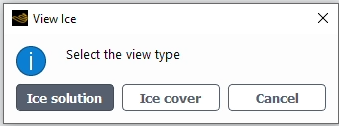

Alternatively, the ice cover solution can be loaded by going to the Project View, right-clicking Ice located in the ice_mvd_m25C run and selecting → . A window will appear, select as the view type. If a window appears asking if you would like to append to a previously opened Viewmerical display, choose .

You can change the option to other choices in the box to see the wireframe profiles and the surface meshes. In the panel, you can adjust the Ice thickness threshold based on ice growth to reduce display interlacing due to the overlapping of iced and clean surfaces.

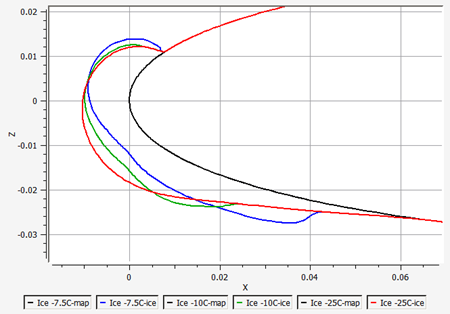

At -25 °C (248.15 K), the result is a pure rime ice shape.

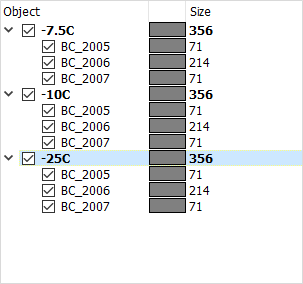

Do not close the Fluent Icing session. You will now run two more calculations at warmer temperatures.

In the Outline View panel, select Setup → Ice and, in Ice Accretion Conditions, check Specify Icing Air Temperature and set the Icing Air Temperature [K] value to

263.15K (-10 °C).Right-click Ice under Solution and click to run the calculation. A window will appear. Name the new run

ice_mvd_m10C.Repeat steps 12 to 13 with an Icing Air Temperature [K] value of

265.67K (-7.48 °C). The same as the airflow Temperature [K] in Setup → Airflow → Conditions. Name this runice_mvd_m7p5C.Note: This -7.48 °C run is conducted at the same temperature as the airflow simulation. This is the standard usage of Fluent Icing, and most icing simulations will be run in this manner.

Since the icing air temperature is equivalent to the airflow simulation temperature, you can alternatively uncheck to disable it and Fluent Icing will use the airflow simulation temperature by default.

Now that there are three different ice shapes computed, you will analyze them using Quick-View. Go to the Ribbon menu and select Results. In Quick-View, click → . This opens the ice solution calculated in the previous simulation.

Rename this object by double-clicking its original name in the Object window and enter

Ice -7.5Cin the window Rename dataset.To load the -10 °C and -25 °C solutions, go to Project View. Under the ice_mvd_m10C run, right-click Ice file and select → .

A message appears asking if you would like to append this solution to a previously opened Viewmerical display. Click .

A second message appears asking you to select the view type. In this case, select as you are going to compare the ice shapes produced by our simulations.

Inside Viewmerical, rename this new object by double-clicking its original name in the Object window and enter

Ice - 10Cin the window Rename dataset.Repeat steps 17 to 20 for the remaining ice shape, ice_mvd_m25C.

Click the button

at the bottom

right of the data set list window located in the

Objects panel to enable all the grids in the 2D

plot.

at the bottom

right of the data set list window located in the

Objects panel to enable all the grids in the 2D

plot.Go to the Query panel and enable the 2D plot. Change the Cutting plane to and Mode to . At the bottom left of the 2D Plot window, set the horizontal axis to . Change the color and thickness of the curves by right-clicking the cube menu on the top right and then by choosing the menu.

Note: In this case, since all simulations were executed using a single ice accretion quasi-steady shot, each *-map curve represents the geometry of the NACA0012.

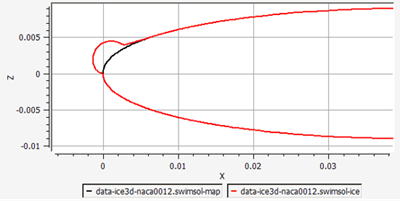

At -25 °C (248.15 K), the cooling effects are large, and all droplets freeze almost instantly producing a rime ice shape. This shape generally resembles the original airfoil profile and can be considered somewhat aerodynamic. As the icing temperature increases, more water can run back away from the stagnation zone and freeze where cooling effects become more predominant. This mechanism initiates the growth of ice horns on the upper and lower sides of the airfoil. These geometric features are common in glaze icing conditions and induce flow separation. Therefore they dramatically change the aerodynamic performance of the airfoil.

To properly capture the shape of the ice horns, a multishot computation is recommended where the grid, air and droplet solutions are updated at certain time intervals.

Finally, you will compare the film height of the three solutions. To do this, uncheck all Ice* objects located in the Objects panel of Viewmerical.

Go back to the Project View. Under the run ice_mvd_m7p5C, right-click its Ice file and select → .

A message appears asking if you would like to append this solution to a previously opened Viewmerical display. Click . A new Viewmerical window will be used to compare the solution values.

A second message appears asking you to select the view type. In this case, select as you are going to compare the solution fields of our ice simulations.

Inside Viewmerical, rename this new object by double-clicking its original name in the Object window and enter

-7.5C in the window Rename dataset.Repeat steps 25 to 28 for the remaining run folders, ice_mvd_m10C and ice_mvd_m25C. However, this time select to append these solutions to the previous solution.

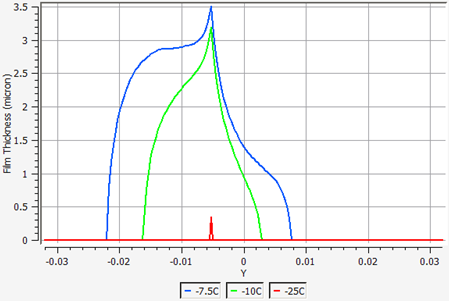

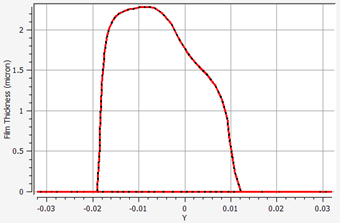

In the Data panel, inside Files, choose Film Thickness as the Data field. Click Shared inside Color range.

Go to the Query panel and activate the 2D plot. Set the Mode to Data and Cutting plane to Z. Set the horizontal axis to Y. The three curves showing the film height for the 3 different temperatures should be visible. Change the curve colors and thickness using the Curve Settings in the cube menu located at the top right.

The film height and extent grow with increasing icing temperatures. At -25 °C, almost all droplets freeze upon impact and there is no water runback on the surface. This temperature produces a rime ice shape. In the contrary, the amount of film and water runback of the other two cases clearly produce ice horns and form glaze ice shapes.

Caution: Do not close Fluent Icing if you would like to proceed to the next section.

In this tutorial, you will learn how to quickly post-process one-shot Ice results (ice shape and ice solution fields) using two dedicated CFD-Post macros: Ice Cover – 3D-View and Ice Cover – 2D-Plot. For this purpose, the icing solution of your icing simulation at -7.5 °C of Fluent Icing Ice Accretion on the NACA0012 is used and, therefore, completion of Fluent Icing Ice Accretion on the NACA0012 is required.

For more information regarding these macros, consult CFD-Post Macros within the FENSAP-ICE User Manual.

Note: CFD-Post only supports .h5 format files when beta features are enabled. Therefore, in order to ensure full compatibility with CFD-Post, first load CFD-Post, go to → . Inside the Options window, go to CFD-Post → General → Beta Options and check .

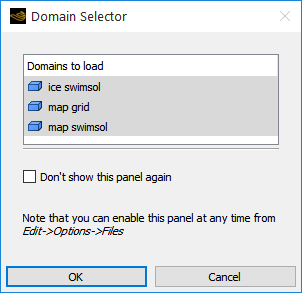

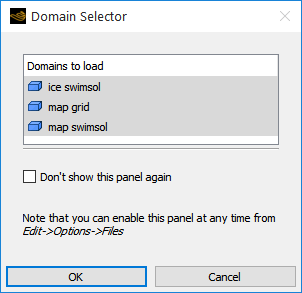

Inside your Fluent Icing window, go to the Ribbon menu and select Results. In Quick-View, click → .

After opening CFD-Post, a Domain Selector window will request confirmation to load the following domains: ice swimsol, map grid, and map swimsol. Click to proceed.

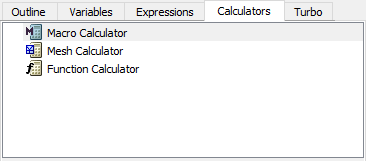

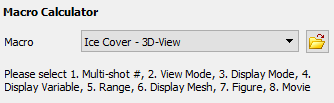

Go to the Calculators tab and double-click Macro Calculator. The Macro Calculator’s interface panel will be activated and displayed.

Note: The Macro Calculator can also be accessed by selecting Tools → Macro Calculator from CFD-Post’s main menu.

Select the Ice Cover – 3D-View macro script from the Macro drop-down list. This will bring up the user interface which contains all input parameters required to view ICE3D output solutions in the CFD-Post 3D Viewer.

The default settings inside the Macro Calculator panel will allow you to automatically output the ice shape of a one-shot icing simulation by pressing Calculate. Figure 1.25: Ice View with CFD-Post, Ice Cover shows the output of the default settings of the macro.

Note: To change the style of the ice shape display, go to the Display Mode and select one of following options: Ice Cover, Ice Cover – shaded, Ice Cover – No Orig, Ice Cover (only) or Ice Cover (only) - shaded. To output the surface mesh of the ice shape, go to the Display Mesh and select Yes. Figure 1.26: Ice View in CFD-Post, Ice Cover with Display Mesh shows the output of activating Ice Cover under Display Mode by selecting Yes under Display Mesh and pressing at the bottom of the Macro Calculator.

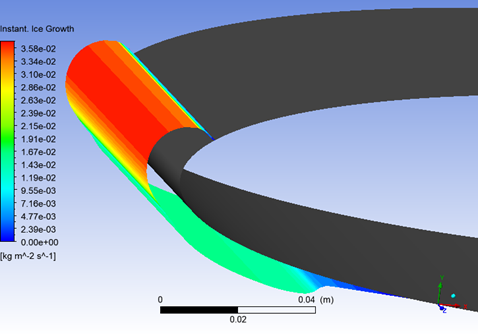

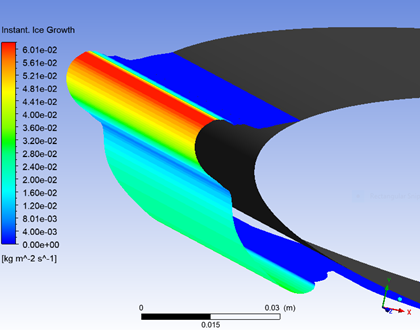

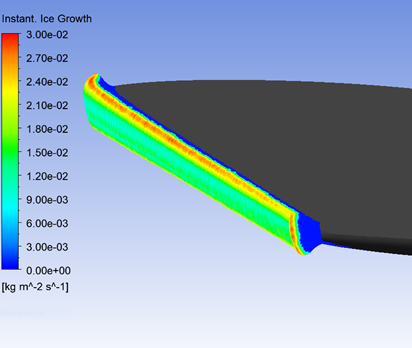

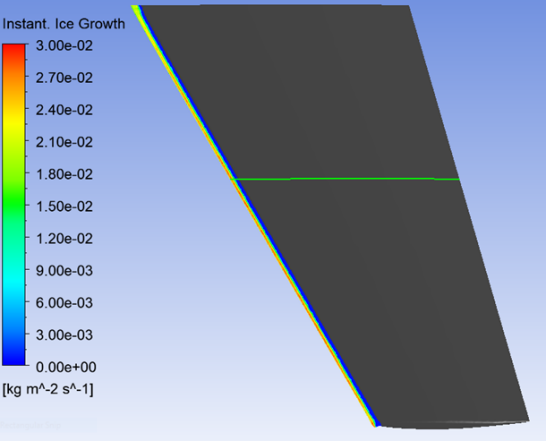

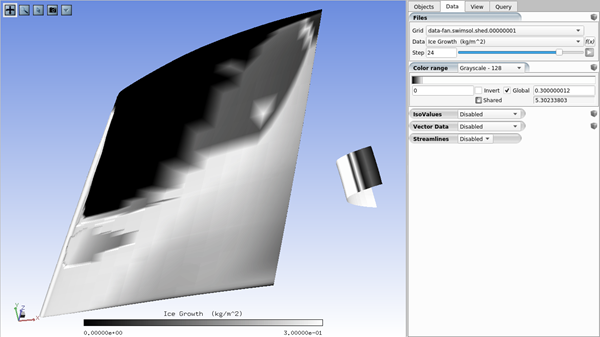

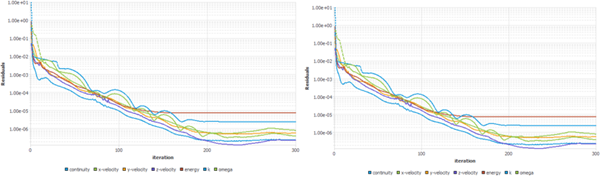

To display the solution fields of your icing simulation, you can either select Ice Solution – Overlay, Ice Solution or Surface Solution under Display Mode. In this case, you will output the ice accretion rate over the ice layer. To do this, select Ice Solution – Overlay in Display Mode, Instant. Ice Growth (kg s^-1 m^-2) in Display Variable and No in Display Mesh to turn off the displaying surface mesh.

Click Calculate to view the instantaneous ice growth over the ice shape. Figure 1.27: Ice View in CFD-Post, Instantaneous Ice Growth over Ice Cover Surface shows the output of the macro.

Note: You are invited to modify the input parameter of Display Variable to view different fields of the ICE3D solution.

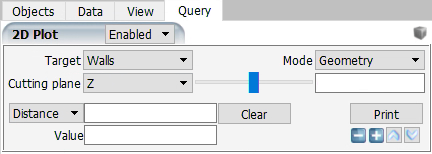

You will now explore some quick post-processing capabilities of the Ice Cover – 2D-Plot macro. In the Macro drop-down list of the Macro Calculator panel, change the macro to Ice Cover – 2D-Plot.

Note: This switches the macro from Ice Cover – 3D-View to Ice Cover – 2D-Plot. Switch back to Ice Cover – 3D-View in the same way if needed.

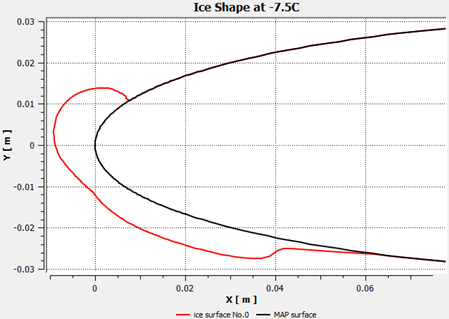

Change Plot’s Title from default, ICE SHAPE PLOT, to

Ice Shape at -7.5 C, since you are creating a 2D-plot of the ice shape.Inside 2D-Plot (with),

Set Mode to Geometry to output an ice shape. The other options output the ice solution fields.

Set Cutting Plane By to Z Plane. Specify a Z=0 plane by setting X/Y/Z Plane to

0.Set the X-Axis to X and the Y-Axis to Y.

To center the 2D-Plot around the leading edge of the NACA0012, in 2D-Plot (with),

Change the (x)Range of the X-Axis from Global to User Specified. Specify values of

0.075and-0.01in the input boxes of (Usr.Specif.x)Max and (Usr.Specif.x)Min, respectively.Change the (y)Range of the Y-Axis from Global to User Specified. Specify values of

0.03and-0.03in the input boxes of (Usr.Specif.y)Max and (Usr.Specif.y)Min, respectively.

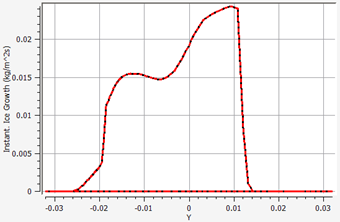

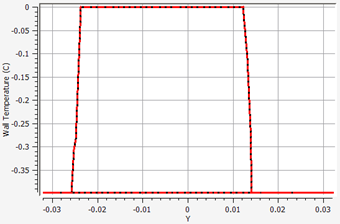

Leave the other default settings unchanged and click Calculate to create a 2D-Plot of the ice shape in ChartViewer. Adjust the output window’s size. Figure 1.28: 2D-Plot in CFD-Post, Clean Wall Surface and Ice Cover Surface shows the output of the macro.

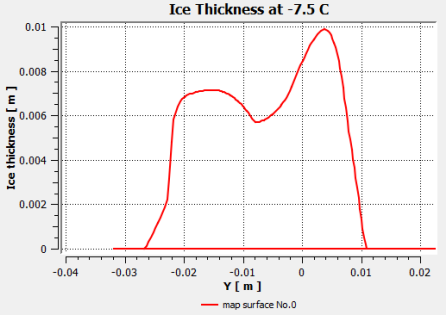

To create a 2D-plot of an ice solution field, first change the name of the plot. In this case, enter

Ice Thickness at -7.5 Cin the Plot’s Title field since you will create a water film 2D plot along the thickness of the airfoil.Inside 2D-Plot (with),

Set Mode to Solution (on Map Surfaces) to output the water film over the NACA0012. Selecting Solution (on Ice Surfaces) will output the ice field over the ice shape.

Set Cutting Plane By to Z Plane. Specify a Z=0 plane by setting X/Y/Z Plane to

0.Set the X-Axis to Y.

Set the Y-Axis to Ice Thickness (m).

To center the 2D-Plot around a meaningful scale to clearly see the water film distribution, in 2D-Plot (with),

Make sure that (x)Range of the X-Axis is set to User Specified. Enter values of

0.02and-0.04for (Usr.Specif.x)Max and (Usr.Specif.x)Min, respectively.Set (y)Range of the Y-Axis to Global. The macro will use the max./min. values of the water film thickness to define the range of the Y-Axis.

Leave the other default settings unchanged and click Calculate to update the 2D plot in ChartViewer. Figure 1.29: 2D-Plot in CFD-Post, Ice Thickness Distribution shows the output of the macro.

Note: You are invited to modify the input parameter of 2D-Plot (with) → Y-Axis to view different fields of the ICE3D solution.

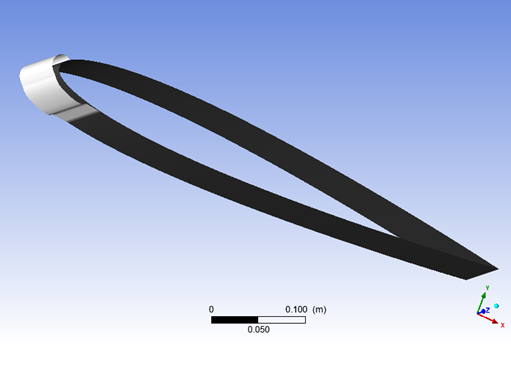

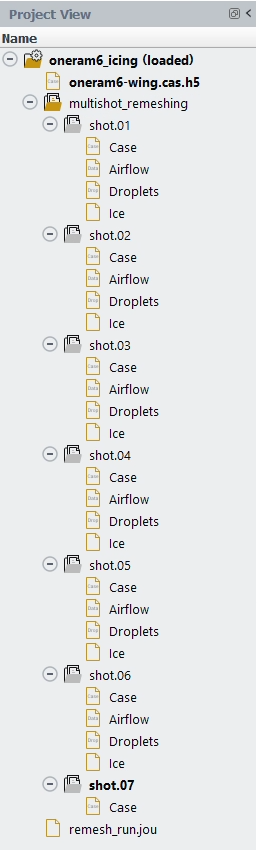

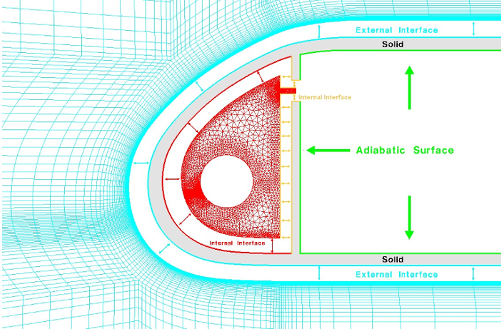

As ice grows, the geometric profile of the contaminated airfoil changes which modifies the flow of air and water droplets around it. The quasi-steady multishot approach allows simulation of realistic and accurate ice shapes. In this approach, the total time of ice accretion is divided into smaller steady-state intervals (shots), where the mesh used to calculate the airflow, the droplet impingement, and the ice accretion is updated at the end of each shot to account for the ice shape. In this tutorial, you will use automatic remeshing with Fluent Meshing to rebuild a computational domain around the ice shape generated at each shot.

Note: Two approaches are supported in Fluent Icing to represent the computational domain at each shot: the automatic mesh displacement approach and the automatic remeshing with Fluent Meshing method.

The automatic mesh displacement uses the initial surface mesh to represent the ice shape. Surface nodes are moved inside the computational domain to represent the ice that forms at each shot. This process keeps the number of nodes and cells constant. As the ice shape grows, the total area covered by the boundary wall mesh increases which changes the size and the aspect ratio of the cells near the ice. This may result in a less than optimal grid spacing if the initial mesh is not fine enough. For complex ice shapes, manual remeshing maybe required in order to continue the multishot process when using automatic mesh displacement.

Alternatively, it is possible to use automatic remeshing with Fluent Meshing when simulating multi-shot icing. Remeshing refines and reorganizes the mesh topology on and around the ice. This leads to more stable and accurate air and droplet solutions for the next shot. Negative volume elements that often form with large mesh deformations are avoided with remeshing. For more information regarding automatic remeshing, consult Ice.

This tutorial is a continuation of the previous tutorial. The last run that was computed was the ice_mvd_m7p5C run. The current settings setup in the simulation panel will be consistent with the settings from that run. However, to be certain that you begin from those conditions, you may right-click the ice_mvd_m7p5C run in the Project View panel and select .

In the Outline View, go to Setup → Ice. In its Properties window, check Beading under Model. Beading is the roughness model of the Ice component. At the end of each shot, Beading will produce a roughness distribution that is used by the airflow solver (Fluent or FENSAP) during the next shot. This approach removes any arbitrary specification of roughness value. The first shot always needs some initial roughness, 0.5 mm in In-Flight Icing Tutorial Using Fluent Icing, since Ice is not run a priori. However, the remaining shots will use the distribution obtained from the beading model.

Note: Alternatively, the initial shots could be conducted over small time intervals where the surface roughness can be allowed to grow from 0 to a reasonable level, removing the need to specify an initial roughness value. For internal flows, you should start with a zero initial roughness instead. Roughness should be allowed to build progressively using shorter icing shots.

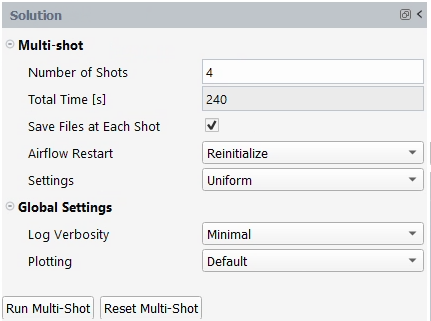

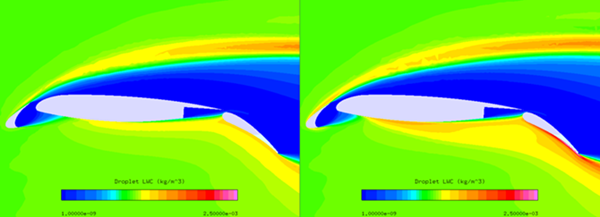

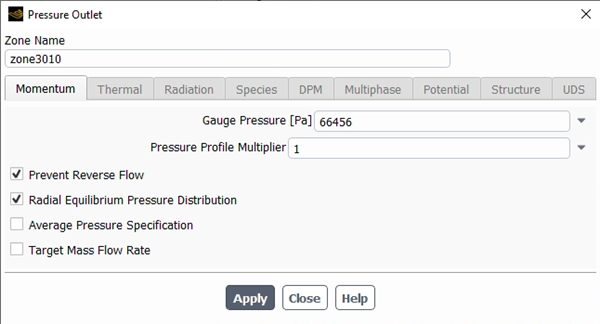

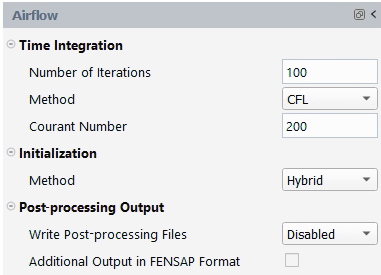

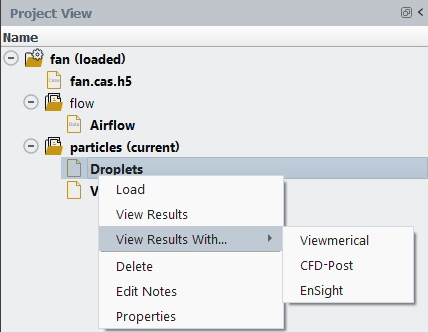

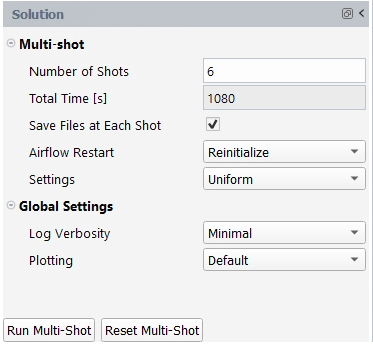

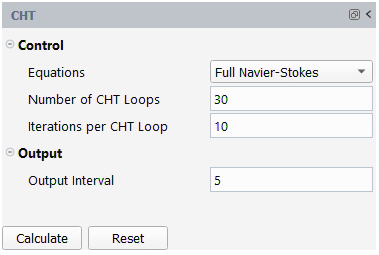

Click Solution and, in its Properties window, under Multi-shot:

Set Number of Shots to

3.Check Save Files at Each Shot to examine the steady-state solutions at the end of each shot.

At the start of each shot, the airflow can be initialized using the parameters defined in the case file () or the interpolated airflow solution from the previous shot (). This can be defined inside the Airflow Restart option. In the current simulation, leave it to , which is the default option.

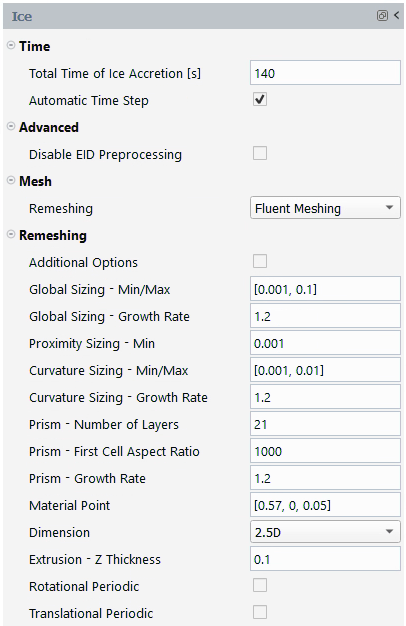

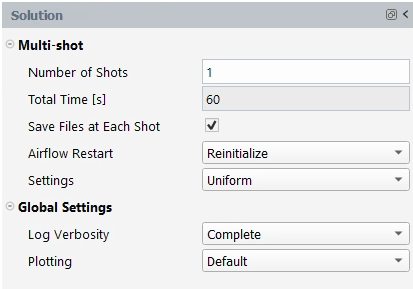

Under Solution → Ice,

In Time, change the Total Time of Ice Accretion [s] from

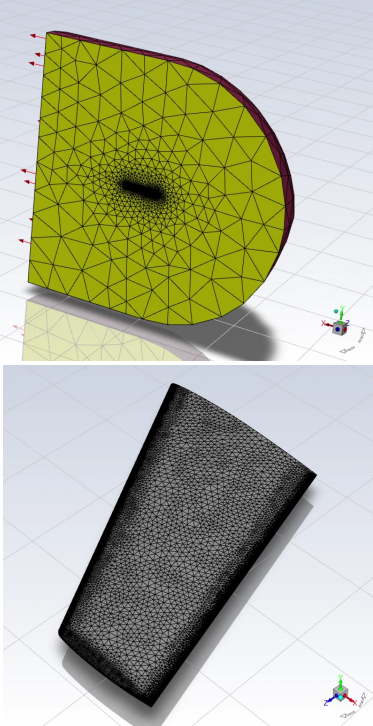

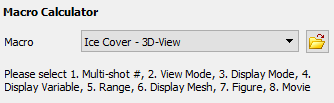

420to140which corresponds to 1/3rd of the total time.Click , located at the bottom of the Ice panel. This automatically sets Fluent Meshing as the remeshing solver, and adds extra options, under Remeshing, to control the type of mesh refinement at each shot.

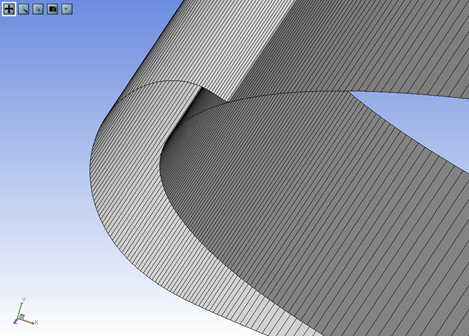

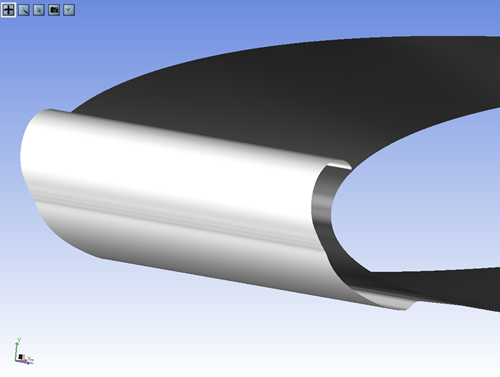

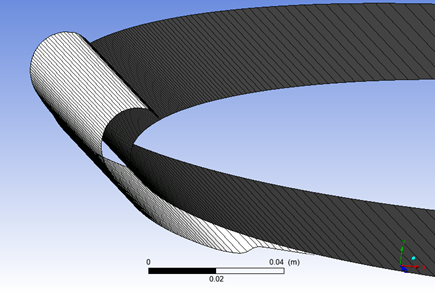

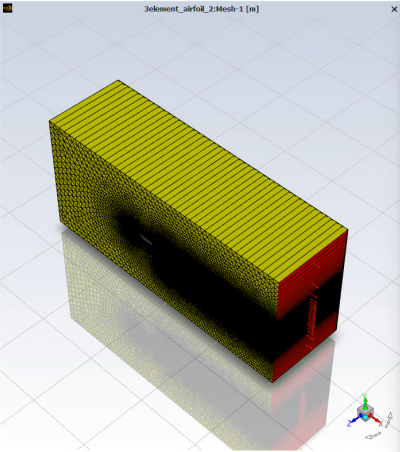

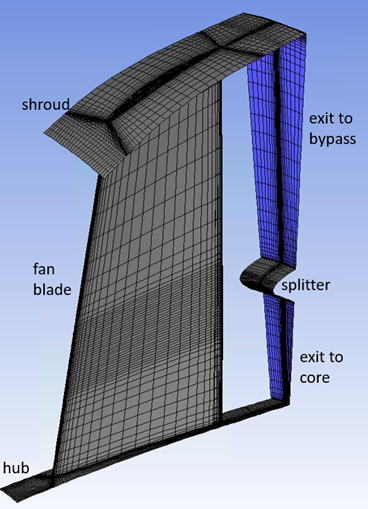

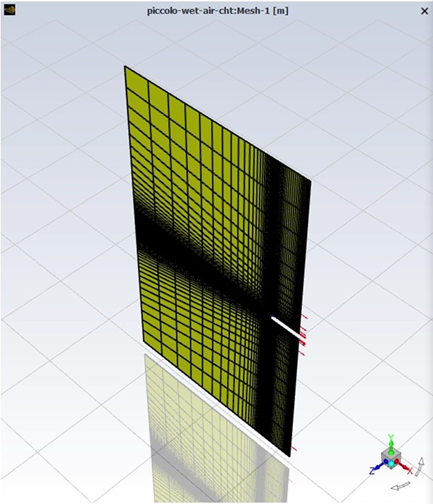

Below Remeshing, several options are available to control the surface mesh refinement as well as hexas (boundary layer cells) and prisms that will compose the computational domain at each shot. Enter the following settings as shown in the image below.

By selecting under Dimension, you are indicating to Fluent Meshing to generate a 2.5D mesh by extruding a surface mesh from one symmetry plane to the other. Therefore, there are some requirements that the initial case file that is imported into Fluent Icing must have:

Symmetry planes that represent the span of the airfoil must be Z planes. One of the two symmetry planes must be located at Z=0 and the other should be placed at a Z+ location.

Both symmetry planes must share the same zone name and type.

The material point must be located near the trailing edge and at half-span.

Below are some useful recommendations to consider based on the type of trailing edge that your 2.5D airfoil has:

Sharp trailing edge

Split the pressure and suction sides into two separated zone BCs. The trailing edge will be a geometric edge that separates these two BCs.

Blunt trailing edge

Put the blunt trailing edge surface in a separate zone BC.

For more information, consult Ice.

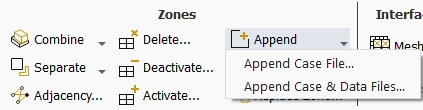

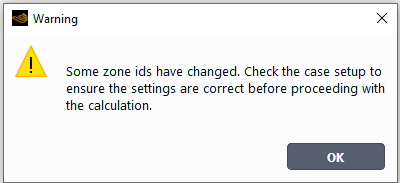

Right-click Solution and then select to automatically remove previous airflow, particles and ice solutions from memory.

Launch the multishot calculation by right-clicking Solution and then by selecting . A Warning message will appear highlighting the need to switch to in order to proceed with this multishot simulation. Select since the icing temperature must be identical to the airflow reference temperature when running a multishot simulation.

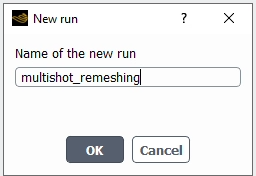

Another window will appear. Name the new run

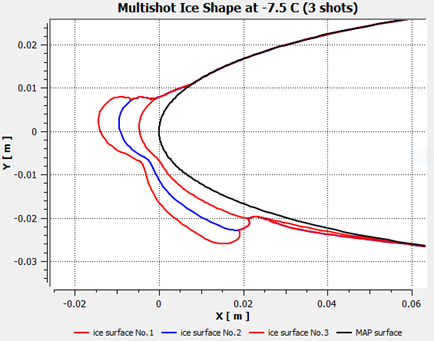

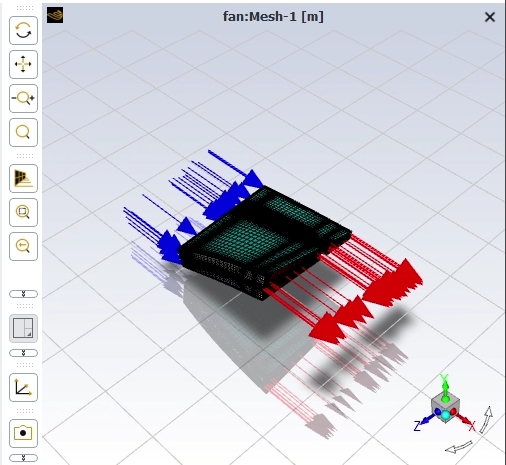

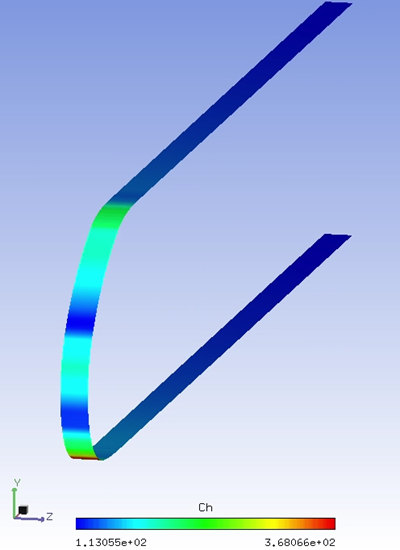

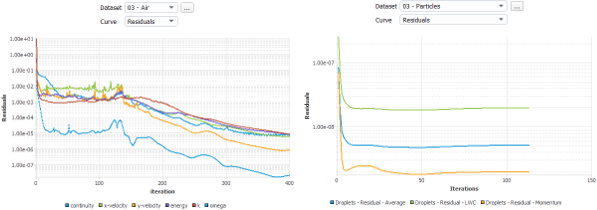

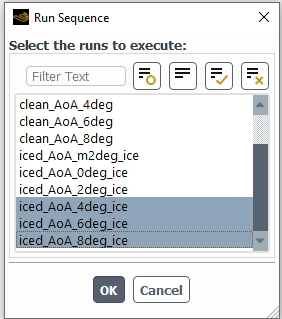

ice_mvd_m7p5C_multiand press .Go to the Plots window and monitor the convergence of Airflow, Particles and Ice solvers. In the Plots window, first select a shot and a solver next to Dataset, and then choose the residual or report to output next to Curve. The image below shows the residuals of the 3rd shot of the Airflow and Particles solvers.

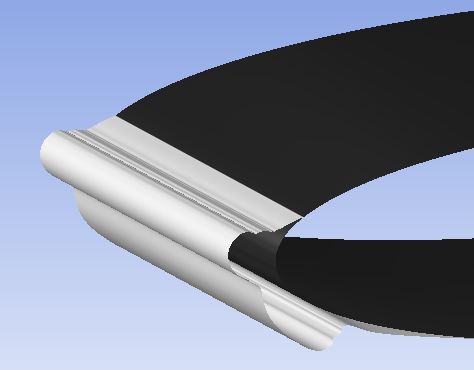

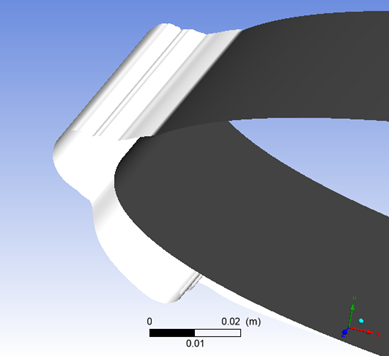

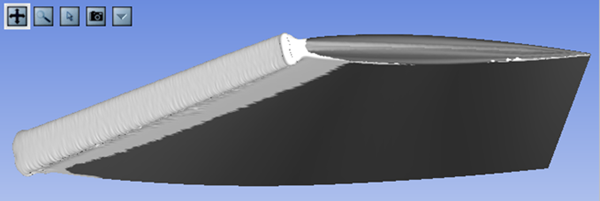

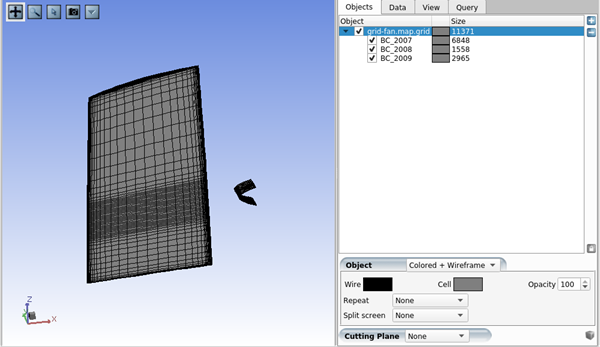

Go to the Project View by clicking the Project tab in the top ribbon menu. Under the naca0012_icing (loaded) simulation, a new run named ice_mvd_m7p5C_multi now appears and is specified as (current). Expand the run by clicking the + icon to the left of ice_mvd_m7p5C_multi to show the files associated with the run. A shot.** folder is created for each shot of the icing calculation, and includes a two-digit number that links these folders to their shot number. Once all calculations are complete, view the final ice shape by following these steps:

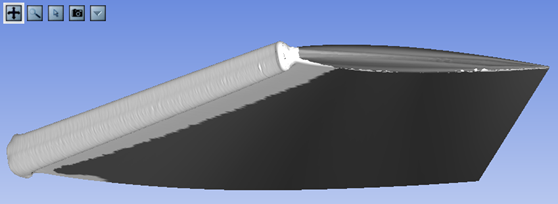

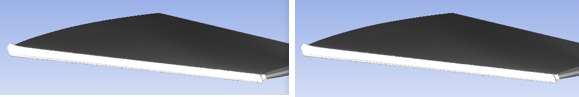

Right-click shot.01/Ice and select → to load the clean airfoil surface. Select if asked to append this solution to an existing Viewmerical window.

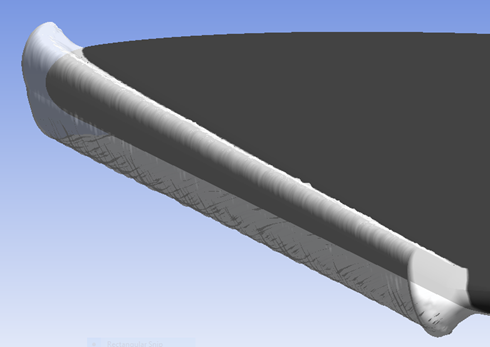

Right-clicking shot.03/Ice and select → to load the result of computed ice shape. Click when a message appears asking if you would like to append this to a previously opened Viewmerical display. A View Ice dialog will then open asking you to select the view type, select to proceed.

In Viewmerical, click the loaded clean airfoil surface grid-naca0012.01.map.grid under the Objects panel. In Object, select and double-click Cell to open the Select Color window. In this window, set the HTML color to #

474747and press .

Click the loaded ice shape ice-naca0012.03.swimsol under the Objects panel. Make sure that is selected in Object. Go to the Data panel and select under the Display mode of ICE3D. Set the value to

0.1kg/m^2 under Ice thickness threshold.

Go to the View panel. Set the Ambient light boost to a value of

20% under Global display settings.

After viewing this ice shape, close Viewmerical.

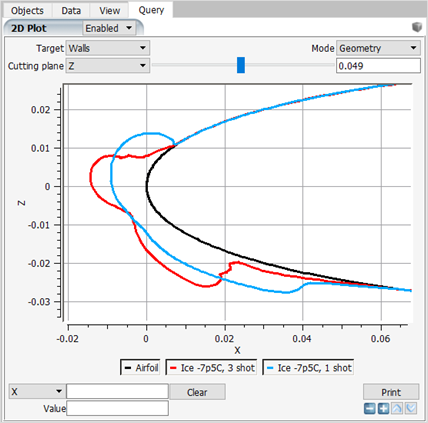

Next, compare the ice shape of the multishot run to that of the single shot run. Go to the Project View. Under the run ice_mvd_m7p5C_multi, right-click shot.01/Ice and select → . This grid file represents the surface grid (called naca0012.01.map.grid on disk) used to calculate the 1st shot of ice accretion.

Rename this object by double-clicking the grid-naca0012.01.map.grid object name and enter

Airfoilinto the Rename dataset window.Under the run ice_mvd_m7p5C_multi, right-click shot.03/Ice and select → . This grid file represents the ice surface grid (naca0012..03.ice.grid on disk) calculated during the 3rd shot of ice accretion.

A message appears asking if you would like to append this to a previously opened Viewmerical display. Choose .

Rename this object by double-clicking the grid-naca0012.03.ice.grid object name and enter

Ice -7p5C, 3 shots in the Rename dataset window.Under the run ice_mvd_m7p5C, right-click Ice and select → . This grid file represents the ice surface grid calculated during the single shot run.

A message appears asking if you would like to append this to a previously opened Viewmerical display. Choose .

Rename this object by double-clicking the grid-naca0012.ice.grid object name and enter

Ice -7p5C, 1 shotin the Rename dataset window.Click the Lock icon

at the lower

right of the data set list in the Objects

window.

at the lower

right of the data set list in the Objects

window.Go to the Query panel and activate the 2D plot. Set the Mode to and Cutting plane to . Set the horizontal axis to . The three curves showing NACA0012 and the ice shapes should be visible. Change the curve colors and thickness using the Curve Settings in the cube menu located at the top right. You can also draw a zoom box by Shift + left-click.

Note: The multishot simulation produces an upper horn that is more pronounced. This is mainly due to the continuous increase in collection efficiency and convective heat fluxes (cooling effects) as the upper horn curvature increases. The lower part of the ice is also thicker where the roughness has grown beyond the initial 0.5mm to about 1mm (average), which causes the water film to freeze sooner and show less runback compared to the single shot solution.

In this tutorial, you will learn how to quickly post-process and generate figures and animations of a multishot ice accretion simulation (ice shape and ice solution fields) using two dedicated CFD-Post macros: Ice Cover – 3D-View and Ice Cover – 2D-Plot. For this purpose, the multishot icing solution of Multi-Shot Ice Accretion with Automatic Remeshing is used and, therefore, completion of Multi-Shot Ice Accretion with Automatic Remeshing is required.

For more information regarding these macros, consult CFD-Post Macros within the FENSAP-ICE User Manual.

Inside your Fluent Icing window, go to the Ribbon menu and select Results. In Quick-View, click Ice Cover → Multi-shot Ice Cover – CFD-Post.

After opening CFD-Post, a Domain Selector window will request confirmation to load the following domains: ice swimsol, map grid, and map swimsol. Click to proceed.

Go to the Calculators tab and double-click Macro Calculator. The Macro Calculator’s interface panel will be activated and displayed.

Note: The Macro Calculator can also be accessed by selecting Tools → Macro Calculator from the CFD-Post’s main menu.

Select the Ice Cover – 3D-View macro script from the Macro drop-down list. This will bring up the user interface which contains all input parameters required to view ICE3D output solutions in the CFD-Post 3D Viewer.

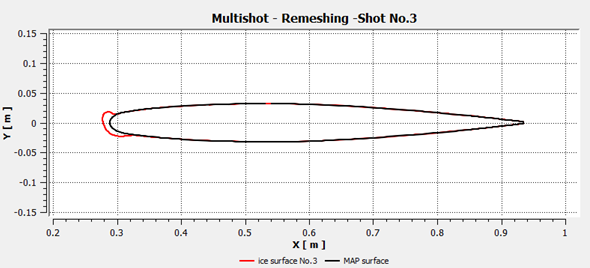

The default settings inside the Macro Calculator panel will allow you to automatically output the ice shape for the first shot of the multishot simulation. Output the ice shape at the end of the multishot simulation of Multi-Shot Ice Accretion with Automatic Remeshing. This corresponds to the ice shape of shot 3, by specifying

3for Multi-shot # and clicking Calculate. Figure 1.32: Ice View in CFD-Post, Final Ice Shape shows the output of the final ice shape.Note: To change the style of the ice shape display, go to Display Mode and select one of following options: Ice Cover, Ice Cover – Shaded, Ice Cover – No Orig, Ice Cover (only) or Ice Cover (only) - shaded. To output the surface mesh of the ice shape, go to the Display Mesh and select .

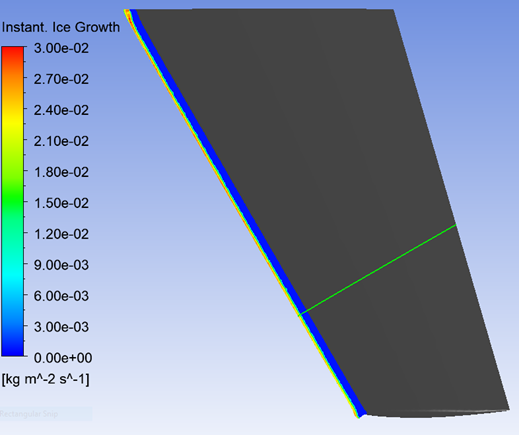

To display the solution fields of your icing simulation, you can either select Ice Solution – Overlay, Ice Solution or Surface Solution under Display Mode. In this case, you will output the ice accretion rate over the ice layer of the 3rd shot. To do this, select Ice Solution – Overlay in Display Mode, Instant. Ice Growth (kg s^-1 m^-2) in Display Variable and No in Display Mesh to turn off the displaying surface mesh.

Click Calculate to view the instantaneous ice growth over the ice shape. Figure 1.33: Ice View in CFD-Post, Instantaneous Ice Growth over Ice Cover Surface, Final Ice Shape shows the output of the macro.

You can also generate and save animations that highlight the ice shape evolution of your multishot simulation. Follow these steps to create and save a custom animation.

Set Multi-shot # to

1. The animation starts at the assigned shot number in Multi-shot # to the last shot of the simulation.Set (Multi-shot) Movie to On and click Calculate to see the animation on the 3D Viewer window.

To save this animation, in (Multi-shot) Movie,

Set Save to Yes.

Select an export Format. Two formats are supported, wmv and MPEG4. The default is wmv.

Specify a Filename.

Click Calculate to generate and save the animation. A message will appear to notify you of the location where the animation is saved and of the first shot used to generate the animation.

Note: If CFD-Post was opened using Fluent Icing, the animation will be saved in your run directory. If CFD-Post was opened in standalone mode, the animation will be saved in the Window’s system default folder.

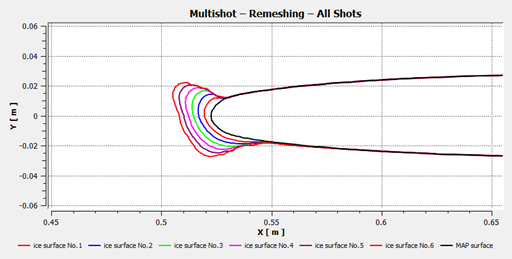

Select Ice Cover – 2D-Plot from the Macro drop-down list to create 2D-plots of the multishot simulation. You will create a 2D-Plot that contains all the ice shapes generated by the multishot simulation.

Make sure that Multi-shot # is set to

1.Change Plot’s Title from ICE SHAPE PLOT, to

Multishot Ice Shape at -7.5 C (3 shots).Select Multi-Shots in 2D-Plot (with). The macro will generate a series of 2D plot curves, starting from the assigned shot number in Multi-shot # to the last shot of the simulation.

Inside 2D-Plot (with),

Set Mode to Geometry to output an ice shape. The other options output the ice solution fields.

Set Cutting Plane By to Z Plane. Specify a Z=0 plane by setting X/Y/Z Plane to

0.Set the X-Axis to X and the Y-Axis to Y.

To center the 2D-Plot around the leading edge of the NACA0012, in 2D-Plot (with),

Change the (x)Range of the X-Axis from Global to User Specified. Specify values of

0.06and-0.025in the input boxes of (Usr.Specif.x)Max and (Usr.Specif.x)Min, respectively.Change the (y)Range of the Y-Axis from Global to User Specified. Specify values of

0.025and-0.035in the input boxes of (Usr.Specif.y)Max and (Usr.Specif.y)Min, respectively.

Leave the other default settings unchanged and click Calculate to create a 2D-Plot of the multiple ice shapes in ChartViewer of CFD-Post. Adjust the output window’s size. Figure 1.34: 2D-Plot in CFD-Post, Ice Shapes of the Multishot Simulation shows the output of the macro.

Note: To create 2D plots of the ice solution fields, go to 2D-Plot (with) → Mode and select either Solution (on Ice Surfaces) or Solution (on Map Surfaces). Then go to 2D-Plot (with) → Y-Axis and select the ice solution field of interest. Specify a (x)Range and a (y)Range that are suitable. Click Calculate to output the 2D-Plot of the ice solution field in ChartViewer.

The 2D-Plot macro can also export all plotted curves to .csv format file and simultaneously save the plot as a figure. Keep all input parameters above unchanged and follow these steps.

To export all plotted curves to a .csv file, set Export (to csv) to Yes and specify a file name under Filename (csv).

To save a figure of the 2D-Plot, set Save Figure to Yes, select a Format for the figure (PNG or BMP) and specify a Filename to save the figure.

Click Calculate to generate the 2D plot, export all data points to a .csv file and save the plot into a figure file. A message will appear to notify you of the location where the .csv and figure file are saved.

Note: If CFD-Post was opened using Fluent Icing, both the .csv and figure files will be saved in the working directory. If CFD-Post was opened in standalone mode, both files will be saved in the Windows’ system default folder.

The objective of this tutorial is to obtain an airflow solution around a clean NACA0012 airfoil using FENSAP in Fluent Icing.

Note: In this tutorial the FENSAP Airflow Solver is used. If you would like to instead use the Fluent Airflow Solver, go to In-Flight Icing Tutorial Using Fluent Icing.

FENSAP-ICE modules in Fluent Icing solve only 3D problems. In order to solve pure 2-D problems, it is recommended to generate 3D grids by extruding these 2D domains along their span or thickness. One single element is sufficient to represent the span or thickness of the 3D domain. In this manner, Fluent Icing is always executed in 3-D mode.

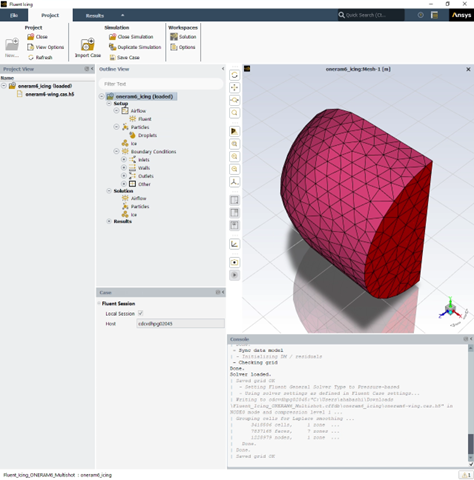

Using the same grid file as In-Flight Icing Tutorial Using Fluent Icing, launch Fluent Icing on your computer. In the Fluent Launcher window, select Icing. Icing is only available if Capability Level → is selected. The usage of the Icing feature requires a Fluent license with Enterprise level. Set the number of processes to

2to4CPUs. Click to launch Fluent Icing.Once Fluent Icing opens, the Project tab will be displayed by default. In the Project’s top ribbon panel, select Project → and enter

FLUENT_ICING_NACA0012_FENSAPto create a new project folder.In the Project’s top ribbon panel, select Simulation → , and browse to and select the ../workshop_input_files/Input_Grid/Naca0012/naca0012.cas.h5 file created in the previous section. A New Simulation window will appear. Enter the Name of the New Simulation as

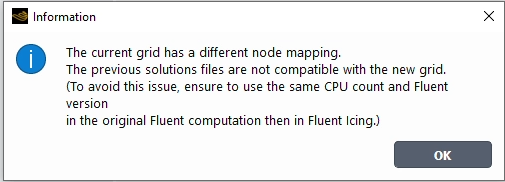

naca0012_icing, and check to enable . A new simulation folder will be created in your project folder, and the naca0012.cas.h5 file will be imported.Note: The naca0012.cas.h5 input case file has already been setup properly in standalone Fluent for use in Fluent Icing simulations.

After the .cas.h5 file has been successfully loaded, the Simulation tab is displayed, and a new simulation tree appears under naca0012_icing (loaded) in the Outline View window.

Select Setup under naca0012_icing (loaded) and, in its Properties window, uncheck Particles and Ice.

Inside the Outline View window, right-click the Airflow icon located under Setup and select to make sure that the Fluent simulation settings are properly transferred to Fluent Icing.

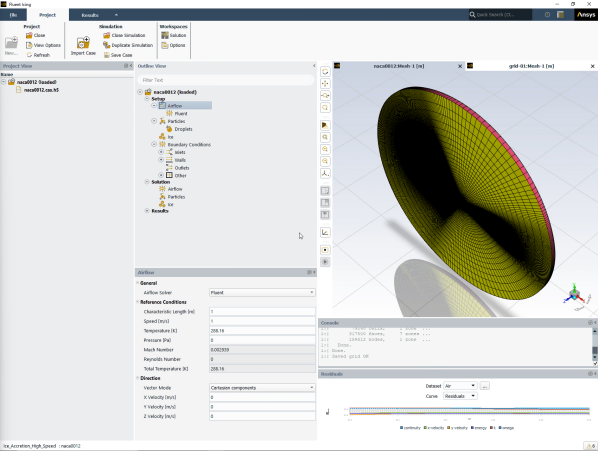

Left-click the Airflow icon to bring up the Airflow window. Under Setup → Airflow in the General section, set the Airflow Solver to .

Under Outline View, click Setup → Airflow → FENSAP. In the Turbulence section, set the Turbulence Model to and Transition to No transition.

Under Setup → Boundary Conditions, expand Inlets and select pressure-far-field-4. In the properties panel, Conditions is set to Case settings by default. This setting ensures that the boundary conditions will be taken directly from the settings already applied in the case file. If you would like to modify the boundary conditions for a particular run, Conditions can be set to , which causes all the boundary conditions for that boundary type to appear in the properties panel. For now, keep Conditions set to Case settings.

Under Setup → Boundary Conditions, expand Walls and click the wall surfaces (wall-5, wall-6 and wall-7). The wall boundary conditions have already been setup properly in the initial case file. Notice that the Thermal Conditions are set to Temperature and the Temperature [K] value is set to

280.929K. This value is equivalent to 10 degrees higher than the adiabatic stagnation air temperature, which is the classic method for performing icing simulations, and can be set by right-clicking the wall surface name in the Outline View and then by selecting .Under Solution → Airflow, increase the Number of Iterations to

500. Set the CFL to100, enable CFL Ramping and set the CFL Ramping Iterations to300. A steady state simulation will be executed.Under the Output, set Forces to . Set the Lift Axis to . Set the Drag - X, Drag - Y and Drag - Z values to

0.997564,0.069756, and0, respectively. Set the Reference Area to0.05334m2.Right-click the Airflow icon under Solution and select to launch this simulation. A new window will appear requesting a name for the new run. Name the new run

flow_clean.Once the computation is complete, the Airflow solution will appear in the flow_clean run directory.

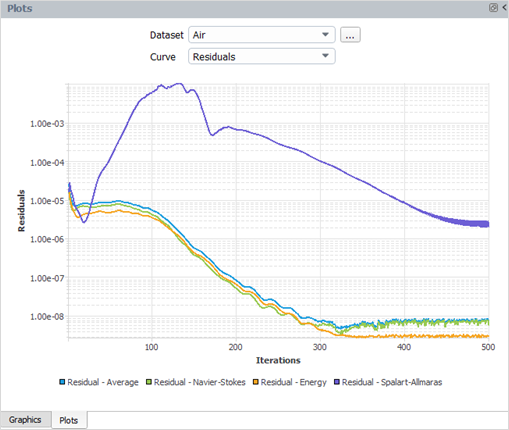

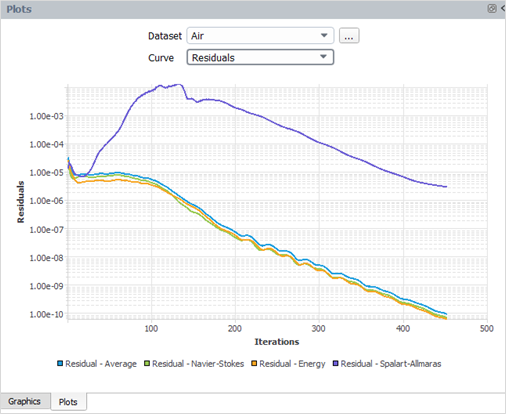

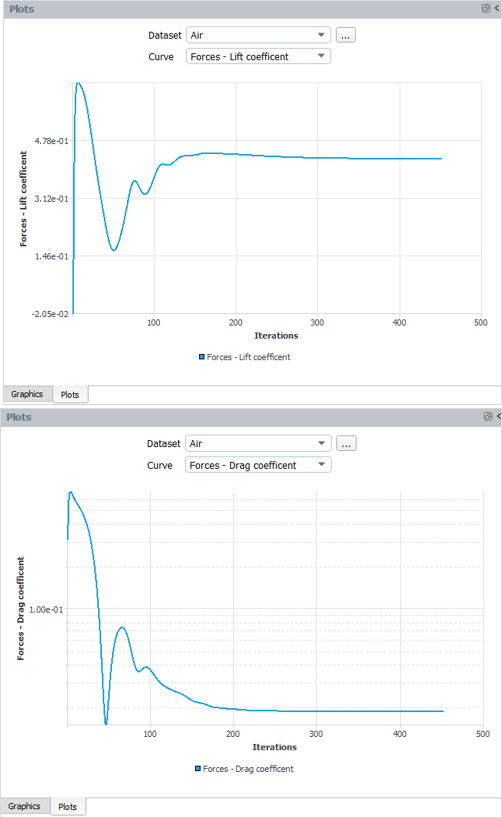

Take a look at the convergence history of this simulation in the Plots window located at the right of your screen. The following two figures show the convergence of residuals and lift and drag coefficients. You can obtain these figures by selecting Residuals, Forces – Lift coefficient and Forces – Drag coefficient respectively next to Curve which is located at the top of the Plots window.

In the Console, the residuals and coefficients are provided at each iteration. Examine the convergence of lift and drag coefficients listed as lift and drag. Lift and drag coefficients have converged to 4.617600e-01 and 8.32458-03 respectively.

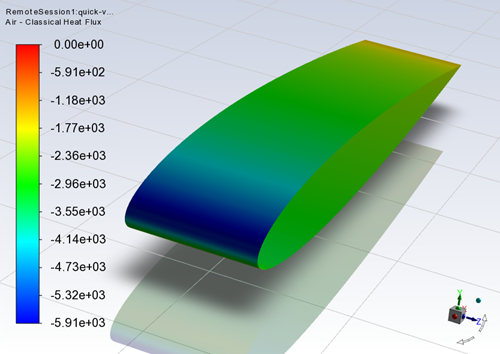

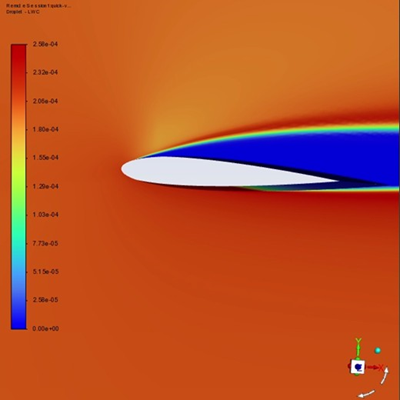

Go to the ribbon bar of your Fluent Icing window and, under Results → Quick-View → , choose to output the convective heat flux over the rough NACA0012. See Figure 1.39: Convective Heat Flux Over the Clean NACA0012 Airfoil.

Within the Project View, you will notice that the naca0012_icing (loaded) simulation now contains the run folder flow_clean, which contains the Airflow solution.

The objective of this tutorial is to obtain an airflow solution around a rough NACA0012 airfoil using FENSAP, within the Fluent Icing framework, and to use this solution for water catch and ice accretion simulations. Completion of the previous tutorial, FENSAP Airflow on the Clean NACA0012 Airfoil, is required before beginning this tutorial.

Ice forms surface roughness as it accretes. This roughness increases the momentum deficit and the skin friction, which in turn thickens the boundary layer and increases drag. Convective heat flux is also in- creased through additional turbulent conductivity within the boundary layer. It is therefore essential to properly model the roughness produced naturally by the ice accretion process to obtain realistic ice shapes. Fluent Icing models such roughness by applying an appropriate sand-grain roughness height distribution over iced walls. In Fluent Icing, this height can be specified on each wall as a constant value, or as a distribution via empirical or analytical methods such as ice bead modeling. See Surface Roughness within the FENSAP-ICE User Manual or the Set-up → Boundary Conditions → Wall and Set-up → Ice sections within the Fluent User's Guide for more details on surface roughness.

Note: If you closed your Fluent Icing session since the completion of the last tutorial, you must reopen your project and load your previous simulation and settings. To do this, open Fluent Icing, select Project → , and navigate to and select your FLUENT_ICING_NACA0012_FENSAP.flprj project file. Once the project is open, right-click the naca0012_icing simulation folder, and select . The simulation will be opened, and your window display will switch to the simulation view, with a simulation tree appearing under naca0012_icing (loaded). To ensure that you are working from the most recent settings, go back to the Project View, right-click the flow_clean run, and select . Finally, go back to the simulation view to continue with the tutorial.

Select Setup under naca0012_icing (loaded) and, in its Properties window, make sure Particles and Ice are unchecked.

Under Setup → Boundary Conditions, update the following wall surfaces:

Select the wall-5 boundary. In the Wall Roughness section of Airflow, select and set its Roughness Height [m] to

0.0005m.Repeat this process for wall boundaries wall-6, and wall-7.

Under Solution, right-click Airflow from the side menu. Select .

Right-click Airflow again and select to launch this simulation. A window may appear asking if the current run should be continued. Select . A New run window will then appear requesting a name for the new run. Name the new run

flow_rough.Note: If you closed Fluent Icing after the completion of the last tutorial, a window will appear asking to create a new run once you click . Set the Name of the new run to

flow_roughand press .Once the computation is complete, the Airflow solution will appear in the flow_rough run directory.

Take a look at the convergence history of this simulation in the Graphics window located at the right of your screen. The following two figures show the convergence of residuals and lift and drag coefficients. You can enlarge and move the legend box in the Graphics window by dragging one side of the box.

In the Console, the residuals and coefficients are provided at each iteration. As it is not possible to zoom in on the graphs, the printed values in the log can be referred to if needed. Examine the convergence of lift and drag coefficients listed as lift and drag. Lift and drag coefficients have converged to 4.247817e-01 and 1.874172-02 respectively.

Go to the ribbon bar of your Fluent Icing window and, under Results → Quick-View → , choose to output the convective heat flux over the rough NACA0012. See Figure 1.43: Convective Heat Flux Over the NACA0012.

This tutorial described the process of simulating the rough airflow over the NACA0012 airfoil using the FENSAP Airflow Solver within Fluent Icing. This can be seen as an alternate tutorial to In-Flight Icing Tutorial Using Fluent Icing, where Fluent is used as the airflow solver. After completing this alternate tutorial, you may continue with the droplet impingement and icing tutorials, Droplet Impingement on the NACA0012 through Multi-Shot Ice Accretion With Automatic Remeshing – Postprocessing Using CFD-Post, as the procedure is similar.

Caution: If you would like to continue with additional tutorials, do not close Fluent Icing.

This tutorial is divided into the following sections:

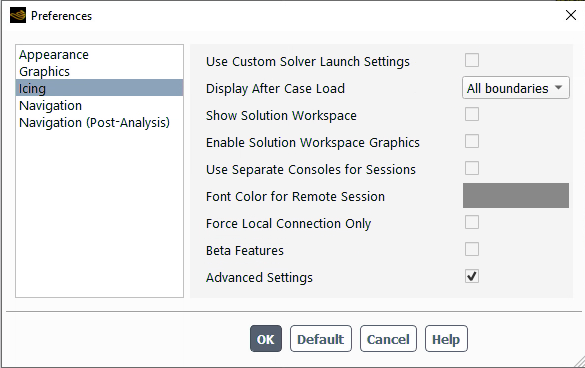

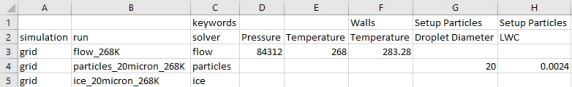

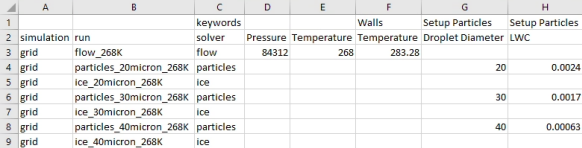

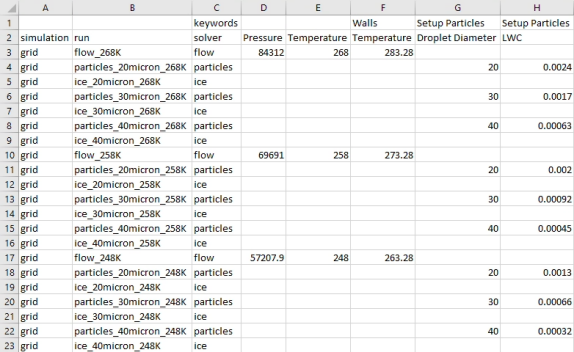

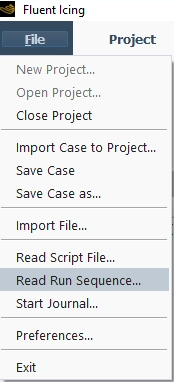

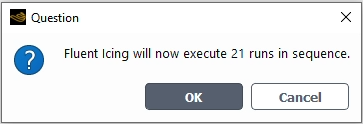

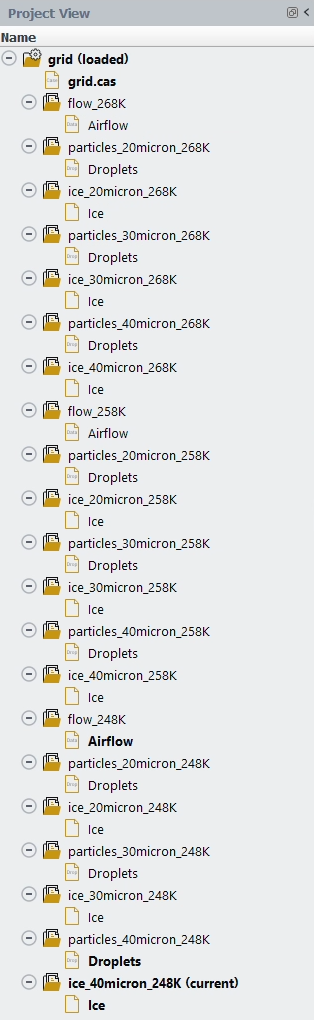

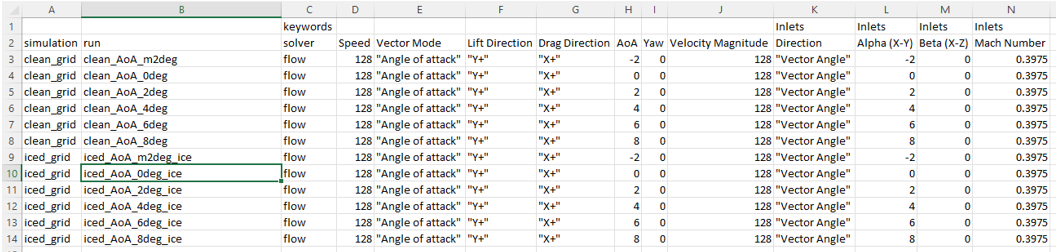

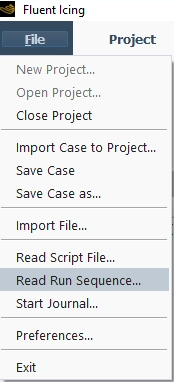

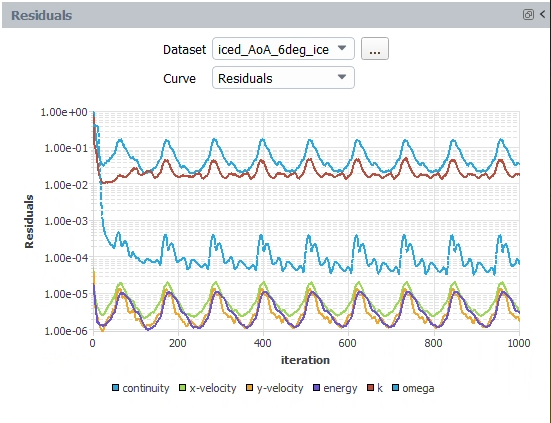

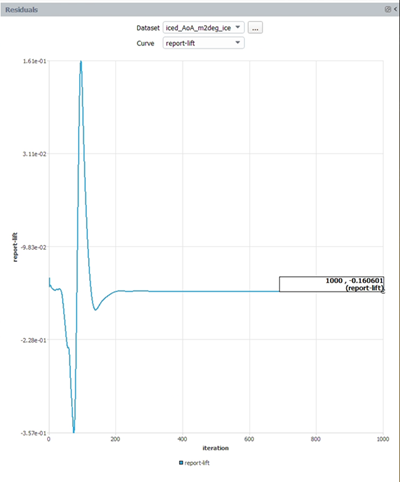

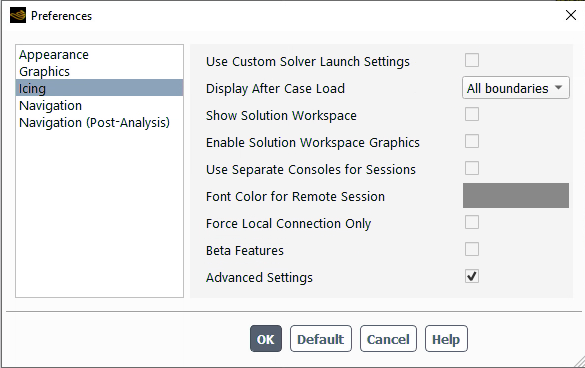

The Run Sequence feature makes it possible to prepare several runs with different settings and execute them in sequence without having to manually change settings between each runs. It is available if is enabled through → → Icing, and activated by selecting → . A Select File dialog will open allowing you to select the spreadsheet that contains the list of runs. The spreadsheet must be in .csv format and follow a certain structure to be read correctly by Fluent Icing.

The goal of this tutorial is to explore different icing conditions using Fluent Icing's Run Sequence feature which will allow you to find out the most critical icing condition, generate an ice shape in that condition and compare the wing performance degradation due to ice at different angles of attack.

The following sections describe the setup and solution steps for this tutorial:

To prepare for running this tutorial:

Download the fluent_icing_run_sequence.zip file here .

Unzip fluent_icing_run_sequence.zip to your working directory.

The file, grid.cas, can be found in the folder.

Use the Fluent Launcher to start Ansys Fluent.

In the Fluent Launcher, set the Capability Level to Enterprise, then select Icing.

Set Solver Processes between

4and8.Click Start.

Alternatively, Fluent Icing can be opened using the icing (on Linux) or icing.bat (on Windows) file inside the fluent/bin/ folder.

Uncheck , , and .

Project → Workspaces → Options

Create a new project file.

File → New Project...

Enter

Run_Sequence_Tutorialas the Project file name within the Select File dialog.Select and import the grid.cas input grid.

Project → Simulation → Import Case