This example demonstrates the fluid-structure interaction methodology for cyclic symmetry. The model represents a simplified hydro-turbine.

The model consists of an 8-bladed disk in water. The structure is modeled with SOLSH190 elements, and the fluid is modeled with FLUID30 elements. All degrees of freedom are constrained at the inner radius. Real and imaginary pressure loading is applied to surface elements (SURF154) using the CYCOPT,LDSECT command to create an engine order 2 loading.

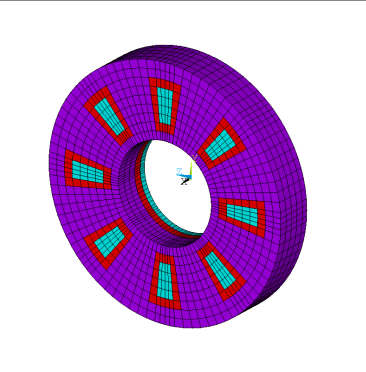

The hydro-turbine model is shown below. The structural elements are blue, and the fluid elements are purple and red, with red indicating the fluid elements that are adjacent to the structural elements.

The geometric and material properties used for the harmonic cyclic analysis are the same as used in Example Modal Cyclic Symmetry Analysis.

All applicable degrees of freedom are used for the cyclic symmetry edge-component pairs. The harmonic response to a pressure load applied on the assembly is computed.

Use the input file given below to perform this example harmonic cyclic symmetry analysis with FSI. The file contains the complete geometry, material properties, and solution options for the finite element model.

/out,scratch /com, *********************************************************************** /com, *** Parameters /com, *********************************************************************** coord = 6 ! 1 = z-axis, 5 = y-axis, 6 = x-axis, 11 = user-defined axis ! Element types elem1=190 ! 185, 186, 187 elem2=30 ! 30, 220, 221 ! Geometry parameters nSectors = 8 ! Number of sectors x1=0.6 x2=0.8 x3=1.2 x4=1.5 sectorAngle=360/nSectors y0=0.0 y1=5 y2=sectorAngle/2 z0=0.0 z1=0.080 z2=2*0.24 ! Harmonic solution parameters EO = 2 ! Engine order 2 loading p0=200 freq1=123 freq2=128 freqnum=25 /com, ********************************************************************** parsav /com, *********************************************************************** /com, *** Geometry creation /com, *********************************************************************** /prep7 wpcsys,1,coord csys,coord cyl4,0.0,0.0,x1,y0,x2,y1,(z1-z0) cyl4,0.0,0.0,x1,y1,x2,y2,(z1-z0) cyl4,0.0,0.0,x2,y0,x3,y1,(z1-z0) cyl4,0.0,0.0,x2,y1,x3,y2,(z1-z0) cyl4,0.0,0.0,x3,y0,x4,y1,(z1-z0) cyl4,0.0,0.0,x3,y1,x4,y2,(z1-z0) wpof,,,z1 cyl4,0.0,0.0,x1,y0,x2,y1,(z2-z1) cyl4,0.0,0.0,x1,y1,x2,y2,(z2-z1) cyl4,0.0,0.0,x2,y0,x3,y1,(z2-z1) cyl4,0.0,0.0,x2,y1,x3,y2,(z2-z1) cyl4,0.0,0.0,x3,y0,x4,y1,(z2-z1) cyl4,0.0,0.0,x3,y1,x4,y2,(z2-z1) allsel vglue,all vsel,s,volu,,1 vsel,a,volu,,14 vsel,a,volu,,15 vsel,a,volu,,19 vatt,1 vsel,s,volu,,17 vatt,2 vsel,s,mat,,1,2 vsel,inve vatt,3 allsel,all /com, *********************************************************************** /com, *** Mesh /com, *********************************************************************** et,1,elem1 secnum,1 vsel,s,mat,,1 esize,0.1 vmesh,all vsel,s,mat,,2 vmesh,all vsel,s,mat,,3 vmesh,all ! Fluid elements et,2,elem2 keyopt,2,2,1 esel,s,mat,,3 emodif,all,type,2 ! FSI elements et,3,elem2 keyopt,3,2,0 esel,s,type,,1 nsle,s esel,s,type,,2 esln,r,0 emodif,all,type,3 ! Mirror to form sector allsel,all nsym,y,100000,all esym,,100000,all ! Clean up nummrg,node numcmp,node !!! rotate nodal csys nrotat,all eplot /com, *********************************************************************** /com, *** Materials /com, *********************************************************************** ! Solid mp,ex,1,200e9 mp,nuxy,1,0.3 mp,dens,1,7800 mp,ex,2,300e9 mp,nuxy,2,0.3 mp,dens,2,7800 sectype,1,shell secdata,0.080,1 secdata,0.080,2 r,1 ! Fluid esel,s,type,,2,3 emodif,all,mat,3 mp,dens,3,1000 mp,sonc,3,1484 allsel,all cdwrite,db,,cdb fini /clear,nostart /prep7 cdread,db,,cdb parres /com, *********************************************************************** /com, *** FSI Defined /com, *********************************************************************** !!! define periodic boundaries, align nodes csys,coord !!! FSI boundary definition allsel esel,s,type,,1 nsle esel,s,type,,3 nsle,r sf,all,fsi /com, *********************************************************************** /com, *** Cyclic Symmetry Defined /com, *********************************************************************** nsel,s,loc,y,-(sectorAngle/2) cm,CYCLIC_m01l,node nrotat,all nsel,s,loc,y,(sectorAngle/2) cm,CYCLIC_m01h,node nrotat,all allsel,all cyclic,nSectors,,coord,CYCLIC,1 ! Create surface elements for pressure loads *GET,maxEtype,ETYP,0, num, max maxEtype = maxEtype+1 et,maxEtype,154 type,maxEtype real,maxEtype mat,maxEtype nsel,s,loc,y,y1 nsel,r,loc,x,x2,x3 nsel,r,loc,z,z1,z2 esel,s,type,,1 esln,r,0 esurf fini /out /com, *********************************************************************** /com, *** Cyclic Full Harmonic Solve /com, *********************************************************************** /out,scratch /solu antype,harmic ! Apply constraints nsel,s,loc,x,x1 d,all,all,0 allsel,all ! Select surface elements and apply loading esel,s,type,,maxEtype *do,sectNum,1,nSectors,1 EOargRE = cos(2*acos(-1)*EO*(sectNum-1)/nSectors) EOargIM = sin(2*acos(-1)*EO*(sectNum-1)/nSectors) cycopt,ldsect,sectNum sfe,all,1,pres,0,p0*EOargRE sfe,all,1,pres,2,p0*EOargIM *enddo sflist ! Apply structural damping dmps,0.02 ! Set harmonic solve options kbc,1 outres,all,all harfrq,freq1,freq2 nsub,freqnum,freqnum,freqnum allsel,all solve fini /com, *********************************************************************** /com, *** Postprocess /com, *********************************************************************** /post1 /cycexpand,,on /view,1,1,.5,-.7 /show,png,rev /pnum,type,1 /number,1 eplot set,,, ,,, ,31 esel,s,type,,1 plnsol,u,sum allsel,all esel,u,type,,1 plnsol,pres allsel,all /show,close fini /post26 numvar,30 node2=node(x3,0,0) nsol,2,node2,u,x,ux nsol,3,node2,u,y,uy nsol,4,node2,u,z,uz nsol,5,node2,pres,,pressure /out prvar,4 prvar,5 /out,scratch /show,png,rev plvar,2,3,4 /show,close finish

The following table describes steps involved in this example harmonic cyclic symmetry analysis with fluid-structure interaction and the corresponding commands used in the input listing.

| Step | Description | Command |

| 1. | Build cyclic symmetry geometry of structure and fluid. | |

| 2. | Define fluid and structural element types and mesh the volumes. | |

| 3. | Create material models and modify the structural and fluid elements. | |

| 4. | Define fluid-structure interaction boundary. | SF,,FSI |

| 5. | Define cyclic symmetry. | CYCLIC |

| 6. | Create surface elements for real and imaginary pressure loading. | |

| 7. | Select the harmonic solution. |

ANTYPE,HARMIC |

| 8. | Apply boundary conditions to the structure and fluid. | D |

| 9. | Select surface elements and apply loading to each sector. |

CYCOPT,LDSECT |

| 10. | Apply structural damping. | DMPSTR |

| 11. | Set harmonic response solve settings. | |

| 12. | Perform a harmonic response solve. | SOLVE |

| 13. | Enter postprocessing. | /POST1 |

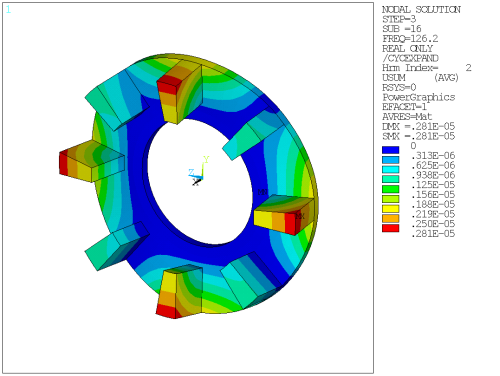

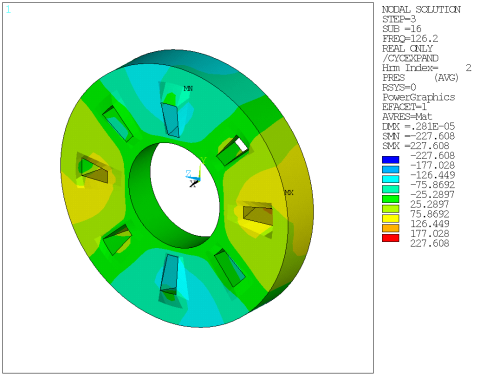

| 14. | Choose a frequency for postprocessing and plot pressures and displacements. |

PLNSOL,U,SUM PLNSOL,PRES |

| 15. | Enter time-history postprocessing. | /POST26 |

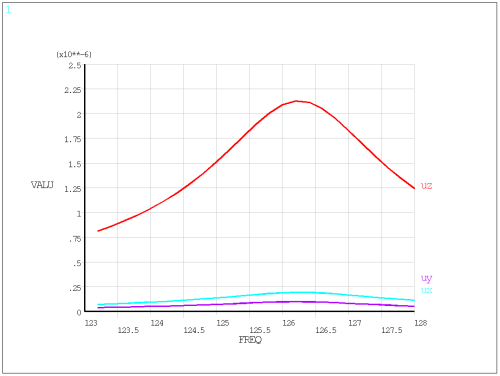

| 16. | Select data for frequency response plots. | |

| 17. | Print and plot data for frequency response. |

The analysis results are shown below.