This capability provides you with the ability to simultaneously model thermoelectric and diffusion processes. Applications include ion migration in electronics packages and transport of atoms or vacancies in metallic interconnects under intense electric currents and thermal gradients.

The following related topics are available:

Table 2.36: Elements Used in Thermal-Electric-Diffusion Analyses summarizes the elements that you can use to perform a coupled thermal-electric-diffusion analysis. For detailed descriptions of the elements and their characteristics (degrees of freedom, KEYOPT options, inputs and outputs, etc.), see the Element Reference.

For a coupled thermal-electric-diffusion analysis, you need to select the TEMP, VOLT and CONC element degrees of freedom by setting KEYOPT(1) to 100110 for the coupled-field element.

Table 2.36: Elements Used in Thermal-Electric-Diffusion Analyses

| Elements | Effects | Analysis Types |

|---|---|---|

|

PLANE222 - 4-Node Coupled-Field Quadrilateral PLANE223 - 8-Node Coupled-Field Quadrilateral SOLID225 - 8-Node Coupled-Field Hexahedral SOLID226 - 20-Node Coupled-Field Hexahedral SOLID227 - 10-Node Coupled-Field Tetrahedral |

Thermoelectric (Joule heating; Seebeck, Peltier, and Thomson effects) Temperature dependent material properties, including temperature-dependent saturated concentration (CSAT) Thermomigration Electromigration |

Static Full Transient |

To perform a thermal-electric-diffusion analysis, you need to follow the steps outlined in Performing a Thermal-Electric Analysis, Performing a Thermal-Diffusion Analysis, and Performing an Electric-Diffusion Analysis.

This example demonstrates a transient thermal-electric-diffusion analysis of a solder joint. Note that the geometric and material properties are input in the μMKSV system of units. For more information on units, see System of Units.

The following topics are available:

An SAC (SnAgCu) solder ball is sandwiched between two copper strips. A half symmetry model of the solder ball is discretized using the thermo-electric-diffusion analysis option (KEYOPT(1) = 100110) of the SOLID227 coupled-field element. A step current load I = 2.85 A is applied to the bottom strip; the top strip is grounded. Convection coefficient h = 12 W/(m2*C) is specified on the exterior surface. Initial temperature is set to 25 °C. Initial normalized concentration of atoms is set to 1.

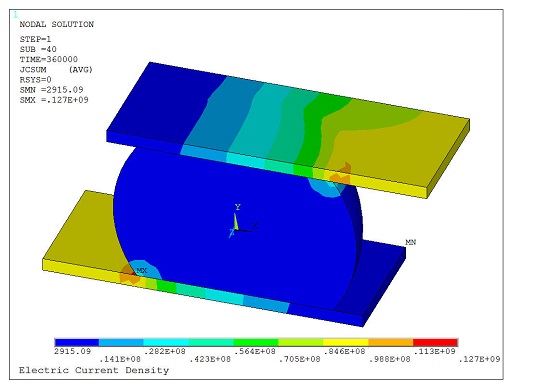

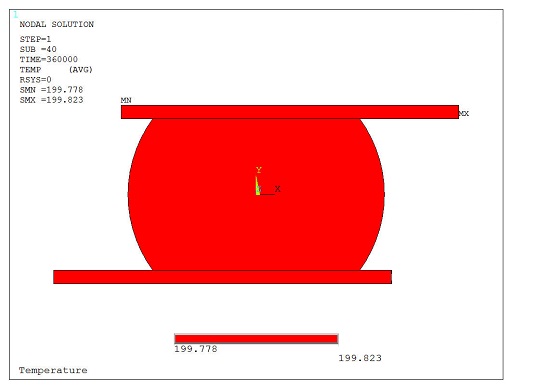

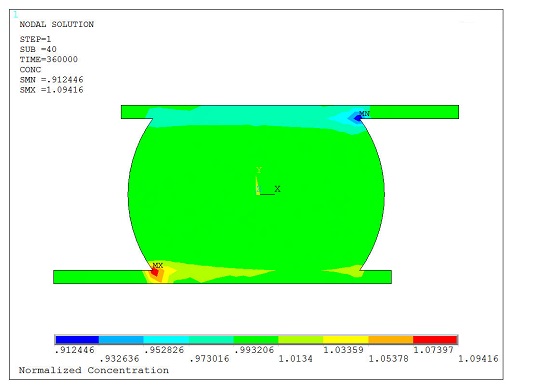

A transient analysis is performed for 100 hours to determine the distribution of temperature and atomic concentration. The temperature evolves as the result of Joule heating and convection. The atomic concentration changes is due to diffusion, electromigration and thermomigration. Temperature-dependent diffusivity and the coefficients of thermo- and electromigration are specified using the migration model (TB,MIGR).

The numerical results at the end of the simulation are shown in the following figures:

The command text below demonstrates the problem input. All text prefaced with an exclamation point (!) is a comment.

/title, Electromigration and Thermomigration in a Solder Joint /pnum,volu,1 /prep7 ! Model (sizes in um) wprota,,-90 sphere,380,,0,180 wprota,,180 wpoffs,,,225 vsbw,1 numcmp,volu vdele,1,,,1 numcmp,volu wpoffs,,,-450 vsbw,1 numcmp,volu vdele,1 numcmp,volu block,-400,600,-400,0,-40,0 wpoffs,,,450 block,-600,400,-400,0,0,40 vglue,all numcmp,volu vplot ! ! Constants and material coefficients in uMKS system of units ! kB=1.3806488e-23*1.e12 ! Boltzmann constant, pJ/K kB_eV=8.6173324e-5 ! Boltzmann constant, eV/K ! Copper (mat 1) et,1,solid227,100110 ! thermal-electric-diffusion mp,rsvx,1,2.38e-8*1e-6 ! electric resistivity, TOhm*um @ 200 C mp,dxx,1,7.8e-5*1e12 ! pre-exponential diffusivity, (um)^2/s mp,kxx,1,393*1e6 ! thermal conductivity, pW/(um*K) mp,c,1,385.2*1e12 ! specific heat, pJ/kg K mp,dens,1,8900*1e-18 ! density, kg/(um)^3 Qa=210e3 ! activation energy, J/(K*mol) R=8.31445 ! universal gas constant, J/(K*mol) Z1=-4 ! charge number tb,migr,1 ! migration model for Cu tbdata,1,Qa/R ! diffusivity tbdata,4,Z1/kB_eV ! electromigration ! Solder - SAC (mat 2) et,2,solid227,100110 ! thermal-electric-diffusion mp,rsvx,2,20.75e-8*1e-6 ! electric resistivity @ 200 degC, TOhm*um mp,dxx,2,4.1e-5*1e12 ! pre-exponential diffusivity, (um)^2/s mp,kxx,2,57*1e6 ! thermal conductivity, pW/(um*K) mp,c,2,219*1e12 ! specific heat, pJ/kg K mp,dens,2,7390*1e-18 ! density, kg/(um)^3 Ea=0.98 ! activation energy, eV Q=0.0094 ! heat of transport, eV Z2=-23 ! charge number tb,migr,2 ! migration model for SAC tbdata,1,Ea/kB_eV ! diffusivity tbdata,3,Q/kB_eV ! thermomigration tbdata,4,Z2/kB_eV ! electromigration type,1 ! mesh copper electrodes mat,1 esize,40 vmesh,2,3 type,2 ! mesh solder joint mat,2 vmesh,1 nsel,s,loc,x,600 ! top electrode d,all,volt,0 nsel,s,loc,x,-600 ! bottom electrode cp,1,volt,all nd=ndnext(0) alls ! Loads f,nd,amps,2.85e12/2 ! total current for half-model, pA toffst,273 ! temperature offset from absolute zero to zero, degC nsel,s,ext nsel,u,loc,z,0 sf,all,conv,12,25 ! film coefficient, pW/(um)^2*degC nsel,all finish /solu antype,trans ! transient analysis ic,all,conc,1 ! initial normalized concentration ic,all,temp,25 ! initial temperature, degC time,3.6e5 ! simulation time, s (100 hours) nsubst,40 kbc,1 autots,off outres,all,all solve finish /post1 set,last,last /title, Electric Current Density plnsol,jc,sum ! plot electric current density /title, Temperature ! plot temperature plnsol,temp /title, Normalized Concentration plnsol,conc ! plot normalized concentration finish