The material of the o-ring is taken to be an incompressible elastomer material modeled by the Ogden first-order hyperelastic form. Three material constants representing an initial shear modulus of 1.99408 MPa are input via the TB,HYPE,,,,OGDEN command.

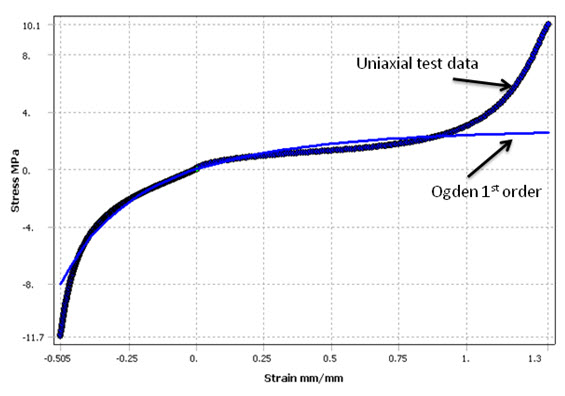

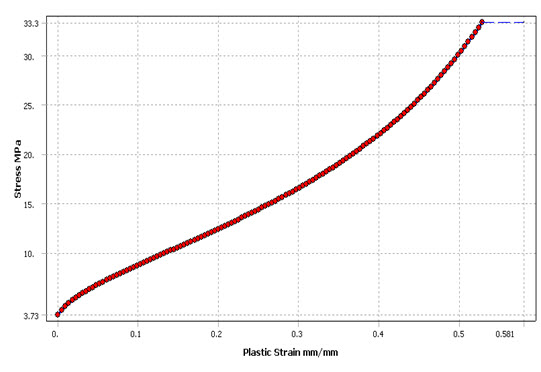

In the following figure, part (a) displays the original uniaxial test data and fitted curve with the Ogden first-order hyperelastic form. The plastic cap is modeled by an elastic-plastic material which is softer than the o-ring material. The isotropic hardening stress-strain curve (initialized via the TB,PLAS,,,,MISO command) is shown in part (b).

Figure 3.4: Material Model Test Data

|

|

| Material Properties | ||||||||

|---|---|---|---|---|---|---|---|---|

| Coefficient of Friction for Contact Interface |

O-Ring [1] |

Cap | ||||||

|

|

| ||||||

For more information about the Ogden form, see Ogden Hyperelasticity (TB,HYPER,,,,OGDEN) in the Material Reference.

For more information about the multilinear curve, see Multilinear Isotropic Hardening in the Material Reference.