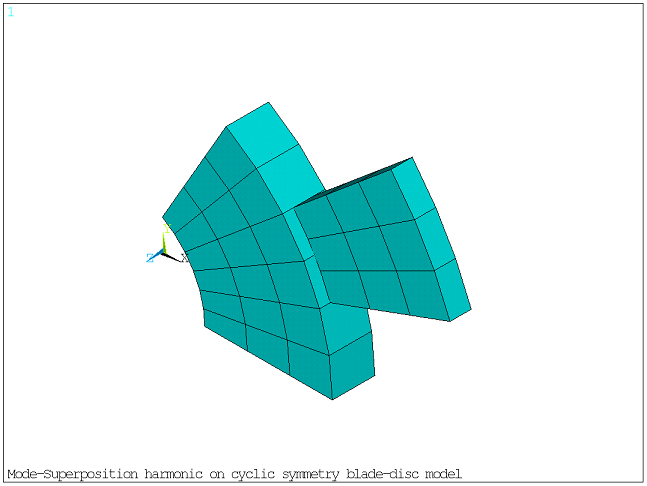

This example problem details the procedure to perform cyclic mode-superposition harmonic analysis with mistuning. The example presents a simplified bladed disc model.

A circular disc with attached blade is modeled and meshed with SOLID185 elements. A temperature-dependent material model is used for disc and blade elements. The blade and disc are connected by means of bonded contact using CONTA174 and TARGE170 elements. The disc is constrained along the inner radius. The model is prestressed with thermal load (BF) and rotational velocity (OMEGA). Mode-superposition harmonic analysis is then performed on this prestressed model using the linear perturbation procedure with out-of-plane force load acting as the harmonically varying load. The stiffness mistuning parameters are defined for each blade using CYCFREQ,BLADE. The cyclic mode-superposition harmonic analysis is restarted to perform the analysis with different mistuning parameters using CYCFREQ,RESTART,MIST.

If you remove the mistuning commands (steps 15, 16 and 17) from this example problem you are left with a standard mode-superposition harmonic cyclic symmetry analysis.

Use the input file given below to perform the example mode-superposition harmonic cyclic symmetry analysis.

/filnam,example

/prep7

et,1,solid185 ! SOLID185 elements

keyopt,1,2,3 ! simplified enhanced strain formulation

type,1

TREF, 75.00000

MPTEMP, 1, 75.00000, 200.00000, ! Temperature-dependent material model

MPDATA, EX, 1, 1,.3364959E+08, .3348502E+08

MPDATA,NUXY, 1, 1,.3000000E+00, .3000000E+00

MPDATA,ALPX, 1, 1,.7391837E-05, .7399809E-05

MPDATA,DENS, 1, 1,.8391600E+00, .8391600E+00

local,11,1 ! Defining local cylindrical coordinate system

csys,11

esys,11 ! Stress and strain are radial and tangential in solution CS

cylind,2,5,0,1,0,60 ! Disc

cylind,5,8,.25,.75,20,40 ! Blade

esize,1

type,1

mat,1

cyclic ! Create cyclic symmetry model (6 sectors)

vmesh,all

allsel,all

et,4,conta174 ! CONTA174

et,5,targe170 ! TARGE170

keyopt,4,12,5 ! Bonded

keyopt,4,5,1 ! Close the gap

keyopt,4,9,1 ! Exclude gap or offset

r,4

type,4

real,4

asel,s,area,,10

nsla,s,1

esurf ! Form contact elements

type,5

real,4

asel,s,area,,3

nsla,s,1

esurf ! Form target elements

allsel,all

vsel,s,volume,,2

eslv,s

esel,r,ename,,185

cm,bladeelem,elem ! Create components with blade elements

allsel,all

cmsel,s,bladeelem,elem

nsle,s

nsel,r,loc,x,5

cm,interface,node ! Create node component to define interface between blade and disc

cmsel,s,bladeelem,elem

nsle,s

nsel,r,loc,z,.75

cm,pressurenodes,node ! Create node component on pressure side

allsel,all

nsel,s,loc,x,2

d,all,all,0 ! Constrain inner radius

allsel,all

/show,png,rev

/view,1,1,1,1

eplot

/show,close

nsel,s,loc,x,8

nsel,r,loc,z,.75

cm,load1,node ! Defining node component for harmonic loading

allsel,all

nrotate,all

finish

/solu

antype,static

rescontrol,define,all,1 ! Write restart files for all load steps and substeps

nlgeom,on

autots,on

nsubs,10,100,1

time,1.0

*get,nnodes,node,0,count

nd=0

*do,i,1,nnodes ! Define a radially-varying temperature profile

nd=ndnext(nd) ! Next selected node having node number greater than 0

tt=100-(100-75)*(8-nx(nd))/(8-2)

bf,nd,temp,tt ! Apply thermal pre-stress load

*enddo

allsel,all

solve ! 1st load step

time,2.0

omega,0,0,3000*2*3.14159265/60 ! Rotational velocity (3000 RPM)

solve ! 2nd load step

finish

/post1

set,last

/cycexpand,,on

/show,png,rev

/view,1,1,1,1

plnsol,u,sum ! Plotting USUM from static solve

plnsol,s,eqv ! Plotting SEQV from static solve

/show,close

finish

/solu

antype,,restart,,,perturb ! Restart from last load step and last substep

perturb,modal,,,parkeep ! Perform LP modal solve, delete all loads except displacement constraints

solve,elform

omega,0,0,0

bfdele,all,all

modopt,lanb,1000,0,500 ! Extract modes from 0-500

mxpand,,,,yes

solve ! Perform LP modal solve

finish

/solu

antype,modal,restart ! Restarting the modal solve

f,load1,fz,-10e3 ! Harmonic force load

solve

finish

/post1

file,,rstp

set,list,,,,,,,order ! Modal frequencies

/show,png,rev

/yrange,0,200

plzz ! Plot cyclic modal frequencies vs Harmonic Indices

/show,close

/yrange,default

finish

/solu

antype,harmonic ! Perform harmonic analysis

hropt,msup,,,yes ! MSUP harmonic, write modal coordinates to MCF file

outres,all,all

harfrq,65,85 ! Excitation frequency range

nsubs,20

cycfreq,eo,1 ! Engine order of excitation = 1

fdele,load1,fz

lvscale,1.0,1.0 ! Scaling the load from modal solve

dmpstr,0.25 ! Structural damping

kbc,1

*dim,kmist,array,6,1

kmist(1,1)=0.02,-0.015,0.03,-0.022,0.013,0.01 ! Mistuning parameters for each blade

cycfreq,blade,interface,bladeelem,20 ! Defining blade element component and interface nodes

cycfreq,mist,k,kmist ! Stiffness mistunning

solve

finish

/post1

cycfiles,,rstp,,

rsys,solu

/show,png,rev

plmc,1,10 ! Plot modal coordinates from MSUP for SET,1,10 (real)

plmc,1,10,,1 ! Plot modal coordinates from MSUP for SET,1,10 (Imaginary)

plmc,1,10,,,1,1 ! Plot modal coordinates from MSUP for SET,1,10 (real) for HI=1

plmc,1,10,,1,1,1 ! Plot modal coordinates from MSUP for SET,1,10 (Imaginary) for HI=1

/show,close

esel,s,ename,,185

nsle,s,1

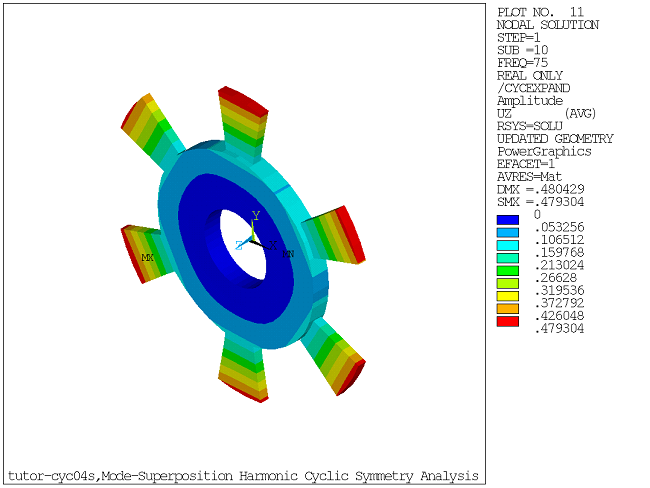

set,1,10,,0 ! Real set

avprin,,0.33

/cycexpand,,on

/show,png,rev

/view,1,1,1,1,

plnsol,u,x

*get,uxmaxr,plnsol,0,max

plnsol,u,y

*get,uymaxr,plnsol,0,max

plnsol,u,z

*get,uzmaxr,plnsol,0,max

plnsol,s,eqv

*get,seqvmaxr,plnsol,0,max

plnsol,epel,eqv

*get,epeleqvmaxr,plnsol,0,max

set,1,10,,1 ! Imaginary set

plnsol,u,x

*get,uxmaxi,plnsol,0,max

plnsol,u,y

*get,uymaxi,plnsol,0,max

plnsol,u,z

*get,uzmaxi,plnsol,0,max

plnsol,s,eqv

*get,seqvmaxi,plnsol,0,max

plnsol,epel,eqv

*get,epeleqvmaxi,plnsol,0,max

set,1,10

/cycexpand,,phaseang,360 ! Amplitude

plnsol,u,z

*get,uzmaxa,plnsol,0,max

plnsol,s,x

*get,sxmaxa,plnsol,0,max

plnsol,epel,x

*get,epelxmaxa,plnsol,0,max

/cycexpand,,phaseang,sweep ! Phase sweep solution

plnsol,s,eqv

*get,seqvmaxs,plnsol,0,max

plnsol,epel,eqv

*get,epeleqvmaxs,plnsol,0,max

allsel,all

/show,close

/out,

/com, *****************************

/com, Real Solution

/com, *****************************

*stat,uxmaxr

*stat,uzmaxr

*stat,seqvmaxr

*stat,epeleqvmaxr

/com, *****************************

/com, Imaginary Solution

/com, *****************************

*stat,uxmaxi

*stat,uymaxi

*stat,uzmaxi

*stat,seqvmaxi

*stat,epeleqvmaxi

/com, *****************************

/com, Amplitude Solution

/com, *****************************

*stat,uzmaxa

*stat,sxmaxa

*stat,epelxmaxa

/com, *****************************

/com, Phaseangle solution

/com, *****************************

*stat,seqvmaxs

*stat,epeleqvmaxs

/cycexpand,,default

finish

/out,scratch

/post26

file,,rstp

numvar,30

nsol,2,64,u,z,uz1 ! UZ at node 64

rcyc,5,2,1,uzsector1

rcyc,6,2,2,uzsector2

rcyc,7,2,3,uzsector3

rcyc,8,2,4,uzsector4

rcyc,9,2,5,uzsector5

rcyc,10,2,6,uzsector6

ansol,3,52,s,x,sx1 ! SX at node 52

rcyc,11,3,1,sxsector1

rcyc,12,3,2,sxsector2

rcyc,13,3,3,sxsector3

rcyc,14,3,4,sxsector4

rcyc,15,3,5,sxsector5

rcyc,16,3,6,sxsector6

ansol,4,64,epel,x,epelx1 ! EPELX at node 64

rcyc,17,4,1,epelxsector1

rcyc,18,4,2,epelxsector2

rcyc,19,4,3,epelxsector3

rcyc,20,4,4,epelxsector4

rcyc,21,4,5,epelxsector5

rcyc,22,4,6,epelxsector6

/show,png,rev

plvar,5,6,7,8,9,10

plvar,11,12,13,14,15,16

plvar,17,18,19,20,21,22

/show,close

finish

/post1

cycfiles,,rstp

set

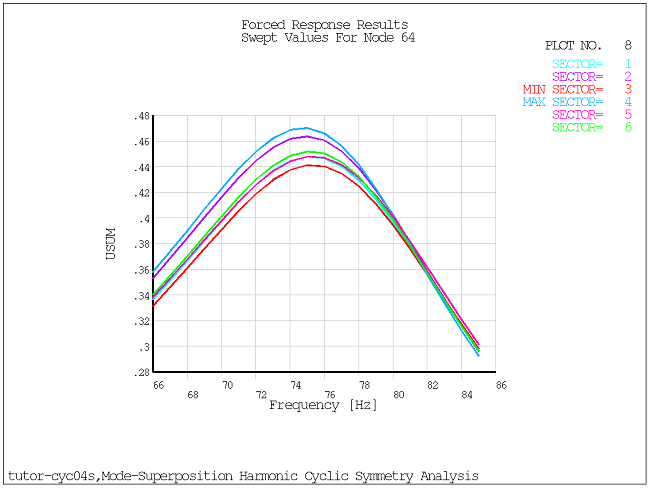

cycspec,,64,u,z ! UZ at node 64

cycspec,,52,s,x ! SX at node 52

cycspec,,64,epel,3 ! EPEL3 at node 64

cycspec,,pressurenodes,s,1 ! max S1 in pressurenodes

cycspec,,64,epel,x ! EPELX at node 64

cycspec,,52,s,eqv ! SEQV at node 52

cycspec,,64,epel,eqv ! EPELEQV at node 64

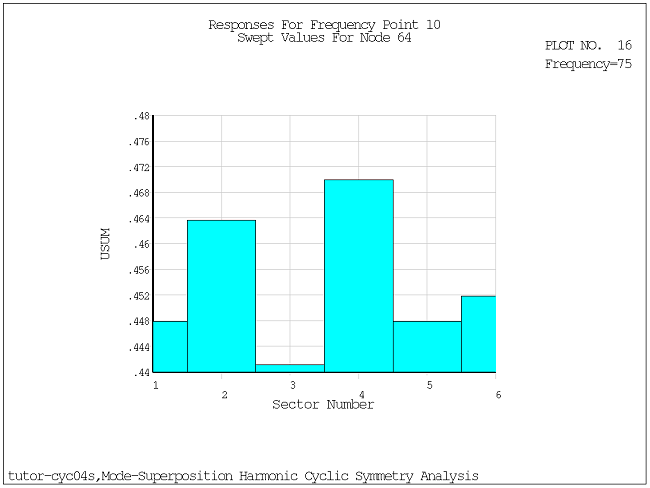

cycspec,,64,u,sum ! USUM at node 64

cycspec,list

/out,

cyccalc ! Compute results from cyclic MSUP using the

! specifications defined by CYCSPEC command

/out,scratch

/com, Plot the frequeny response for the CYCSPEC specifications for all sectors

/show,png,rev

plcfreq,1

plcfreq,2

plcfreq,3

plcfreq,4

plcfreq,5

plcfreq,6

plcfreq,7

plcfreq,8

/com, Plot the histogram of frequency response for each sector for given CYCSPEC specification

plchist,1,10

plchist,2,10

plchist,3,10

plchist,4,10

plchist,5,10

plchist,6,10

plchist,7,10

plchist,8,10

/show,close

*get,uz_10,cyccalc,1,freq,10,sector,3 ! Retrieve UZ CYCCALC result at set,1,10 for sector 3

*get,sx_10,cyccalc,2,freq,10,secmax ! Retrieve SX maximum CYCCALC result at set,1,10

*get,epel3_10,cyccalc,3,freq,10,sector,1 ! Retrieve EPEL3 CYCCALC result at set,1,10 for sector 1

*get,s1_10,cyccalc,4,freq,10,secmax ! Retrieve S1 maximum CYCCALC result at set,1,10

*get,s1_node,cyccalc,4,freq,10,secnode ! Retrieve the node number at which maximum S1 CYCCALC result occur for set,1,10

*get,s1_sector,cyccalc,4,freq,10,secnum ! Retrieve the sector number at which maximum S3 CYCCALC result occur for set,1,10

*get,epelx_10,cyccalc,5,freq,10,secmax ! Retrieve EPELX maximum CYCCALC result at set,1,10

*get,seqv_10,cyccalc,6,freq,10,sector,4 ! Retrieve SEQV CYCCALC result at set,1,10 for sector 4

*get,epeleqv_10,cyccalc,7,freq,10,secmax ! Retrieve EPELEQV maximum CYCCALC result at set,1,10

/out,

*stat,uz_10

*stat,sx_10

*stat,epel3_10

*stat,s1_10

*stat,s1_node

*stat,s1_sector

*stat,epelx_10

*stat,seqv_10

*stat,epeleqv_10

finish

/com, --------------------------------------

/com, Restarting the cyclic MSUP harmonic

/com, analysis with different mistuning

/com, values

/com, --------------------------------------

/out,scratch

/solu

cycfreq,restart,mist

*dim,kmist,array,6,1

kmist(1,1)=0.025,-0.015,0.025,-0.022,0.014,0.02 ! Mistuning parameters for each blade

solve

save

finish

/post1

cycfiles,,rstp,,

rsys,solu

esel,s,ename,,185

nsle,s,1

set,1,10,,0 ! Real set

avprin,,0.33

/cycexpand,,on

/show,png,rev

/view,1,1,1,1,

plnsol,u,x

*get,uxmaxr,plnsol,0,max

plnsol,u,y

*get,uymaxr,plnsol,0,max

plnsol,u,z

*get,uzmaxr,plnsol,0,max

plnsol,s,eqv

*get,seqvmaxr,plnsol,0,max

plnsol,epel,eqv

*get,epeleqvmaxr,plnsol,0,max

set,1,10,,1 ! Imaginary set

plnsol,u,x

*get,uxmaxi,plnsol,0,max

plnsol,u,y

*get,uymaxi,plnsol,0,max

plnsol,u,z

*get,uzmaxi,plnsol,0,max

plnsol,s,eqv

*get,seqvmaxi,plnsol,0,max

plnsol,epel,eqv

*get,epeleqvmaxi,plnsol,0,max

set,1,10

/cycexpand,,phaseang,360 ! Amplitude

plnsol,u,z

*get,uzmaxa,plnsol,0,max

plnsol,s,x

*get,sxmaxa,plnsol,0,max

plnsol,epel,x

*get,epelxmaxa,plnsol,0,max

/cycexpand,,phaseang,sweep ! Phase sweep solution

plnsol,s,eqv

*get,seqvmaxs,plnsol,0,max

plnsol,epel,eqv

*get,epeleqvmaxs,plnsol,0,max

allsel,all

/show,close

/out,

/com, *****************************

/com, Real Solution

/com, *****************************

*stat,uxmaxr

*stat,uzmaxr

*stat,seqvmaxr

*stat,epeleqvmaxr

/com, *****************************

/com, Imaginary Solution

/com, *****************************

*stat,uxmaxi

*stat,uymaxi

*stat,uzmaxi

*stat,seqvmaxi

*stat,epeleqvmaxi

/com, *****************************

/com, Amplitude Solution

/com, *****************************

*stat,uzmaxa

*stat,sxmaxa

*stat,epelxmaxa

/com, *****************************

/com, Phaseangle solution

/com, *****************************

*stat,seqvmaxs

*stat,epeleqvmaxs

/cycexpand,,default

finish

/out,scratch

/post26

file,,rstp

numvar,30

nsol,2,64,u,z,uz1 ! UZ at node 64

rcyc,5,2,1,uzsector1

rcyc,6,2,2,uzsector2

rcyc,7,2,3,uzsector3

rcyc,8,2,4,uzsector4

rcyc,9,2,5,uzsector5

rcyc,10,2,6,uzsector6

ansol,3,52,s,x,sx1 ! SX at node 52

rcyc,11,3,1,sxsector1

rcyc,12,3,2,sxsector2

rcyc,13,3,3,sxsector3

rcyc,14,3,4,sxsector4

rcyc,15,3,5,sxsector5

rcyc,16,3,6,sxsector6

ansol,4,64,epel,x,epelx1 ! EPELX at node 64

rcyc,17,4,1,epelxsector1

rcyc,18,4,2,epelxsector2

rcyc,19,4,3,epelxsector3

rcyc,20,4,4,epelxsector4

rcyc,21,4,5,epelxsector5

rcyc,22,4,6,epelxsector6

/show,png,rev

plvar,5,6,7,8,9,10

plvar,11,12,13,14,15,16

plvar,17,18,19,20,21,22

/show,close

finish

/post1

cycfiles,,rstp

set

cycspec,,64,u,z ! UZ at node 64

cycspec,,52,s,x ! SX at node 52

cycspec,,64,epel,3 ! EPEL3 at node 64

cycspec,,pressurenodes,s,1 ! max S1 in pressurenodes

cycspec,,64,epel,x ! EPELX at node 64

cycspec,,52,s,eqv ! SEQV at node 52

cycspec,,64,epel,eqv ! EPELEQV at node 64

cycspec,,64,u,sum ! USUM at node 64

cycspec,list

/out,

cyccalc ! Compute results from cyclic MSUP using the

! specifications defined by CYCSPEC command

/out,scratch

/com, Plot the frequeny response for the CYCSPEC specifications for all sectors

/show,png,rev

plcfreq,1

plcfreq,2

plcfreq,3

plcfreq,4

plcfreq,5

plcfreq,6

plcfreq,7

plcfreq,8

/com, Plot the histogram of frequency response for each sector for given CYCSPEC specification

plchist,1,10

plchist,2,10

plchist,3,10

plchist,4,10

plchist,5,10

plchist,6,10

plchist,7,10

plchist,8,10

/show,close

*get,uz_10,cyccalc,1,freq,10,sector,3 ! Retrieve UZ CYCCALC result at set,1,10 for sector 3

*get,sx_10,cyccalc,2,freq,10,secmax ! Retrieve SX maximum CYCCALC result at set,1,10

*get,epel3_10,cyccalc,3,freq,10,sector,1 ! Retrieve EPEL3 CYCCALC result at set,1,10 for sector 1

*get,s1_10,cyccalc,4,freq,10,secmax ! Retrieve S1 maximum CYCCALC result at set,1,10

*get,s1_node,cyccalc,4,freq,10,secnode ! Retrieve the node number at which maximum S1 CYCCALC result occur for set,1,10

*get,s1_sector,cyccalc,4,freq,10,secnum ! Retrieve the sector number at which maximum S3 CYCCALC result occur for set,1,10

*get,epelx_10,cyccalc,5,freq,10,secmax ! Retrieve EPELX maximum CYCCALC result at set,1,10

*get,seqv_10,cyccalc,6,freq,10,sector,4 ! Retrieve SEQV CYCCALC result at set,1,10 for sector 4

*get,epeleqv_10,cyccalc,7,freq,10,secmax ! Retrieve EPELEQV maximum CYCCALC result at set,1,10

/out,

*stat,uz_10

*stat,sx_10

*stat,epel3_10

*stat,s1_10

*stat,s1_node

*stat,s1_sector

*stat,epelx_10

*stat,seqv_10

*stat,epeleqv_10

finish

The following table describes the input lines and the steps involved in the example mode-superposition harmonic cyclic symmetry analysis in detail.

| Step | Step Description | Description |

|---|---|---|

| 1. | Build cyclic symmetry disc-blade model with temperature dependent material properties assigned to both the disc and blade | |

| 2. | Mesh the volumes | VMESH |

| 3. | Define bonded contact between disc and blade using CONTA174 and TARGE170 elements | |

| 4. | Create components for blade elements and interface nodes between blade and disc | CM |

| 5. | Define boundary conditions to constrain the inner radius of the disc | D |

| 6. | Perform nonlinear static solve with thermal load and rotational velocity loading. Specify CYCOPT,MSUP,1 before the 1st static solve to generate files needed to perform downstream mode-superposition analysis | |

| 7. | Restart the nonlinear static analysis to perform linear perturbation modal analysis |

ANTYPE,,RESTART |

| 8. | Perform modal solve using Block-Lanczos eigensolver |

MODOPT,LANB |

| 9. | Restart modal analysis to define load vectors to be used in the downstream harmonic analysis |

ANTYPE,MODAL,RESTART |

| 10. | Postprocess modal frequencies and plot the cyclic modal frequencies versus harmonic indices |

SET,LIST |

| 11. | Perform mode-superposition harmonic analysis for an excitation frequency range of 65 Hz - 85 Hz; request 20 harmonic solutions be calculated |

ANTYPE,HARMONIC HROPT,MSUP |

| 12. | Specify the engine order of excitation | CYCFREQ,EO,1 |

| 13. | Scale the load vector from the modal solve | LVSCALE |

| 14. | Define structural damping | DMPSTR |

| 15. | Define the array to specify mistuning paramaters | *DIM |

| 16. | Define blade information required for mistuning analysis | CYCFREQ,BLADE |

| 17. | Define mistuning parameters | CYCFREQ,MIST |

| 18. | Perform mode-superposition harmonic solve | SOLVE |

| 19. | Specify the files to postprocess the cyclic symmetry mode-superposition harmonic analysis | CYCFILES |

| 20. | Postprocess real set, imaginary set, amplitude, and phase sweep solution | |

| 21. | Enter time history postprocessing to calculate cyclic mode-superposition harmonic result for a specified node/element and sectors. | |

| 22. | Enter general postprocessing to calculate sector results | |

| 23. | Plot the frequency response for the CYCSPEC specifications | |

| 24. | Repeat steps 17-23 with new mistuning values by restarting the cyclic mode-superposition harmonic analysis | CYCFREQ,RESTART,MIST |

The results of your analysis should match those shown below:

Figure 5.12: CYCSPEC Frequency Response for Displacement Sum at Node 64 After Restarting the Cyclic Mode-Superposition Harmonic Analysis with Different Mistuning Parameters

Figure 5.13: CYCSPEC Histogram Response for Displacement Sum at Node 64 at Frequency 75 Hz After Restarting the Cyclic Mode-Superposition Harmonic Analysis with Different Mistuning Parameters