The simple model of the bearing is described in Example: Transient Analysis of a Plain Cylindrical Journal Bearing where a 2D approach is used. In this example, a 3D model is created with SOLID185 and FLUID218 elements. The rotational velocity is applied to the shaft part using pilot nodes (MPC contacts) on the rear and front faces.

The mesh is coarse and a nonlinear large-deflection transient analysis is performed. In the first load step, the loads are applied gradually (KBC,0) and a very small time step is used to ease the convergence. Default force and pressure-based convergence criteria are specified (CNVTOL).

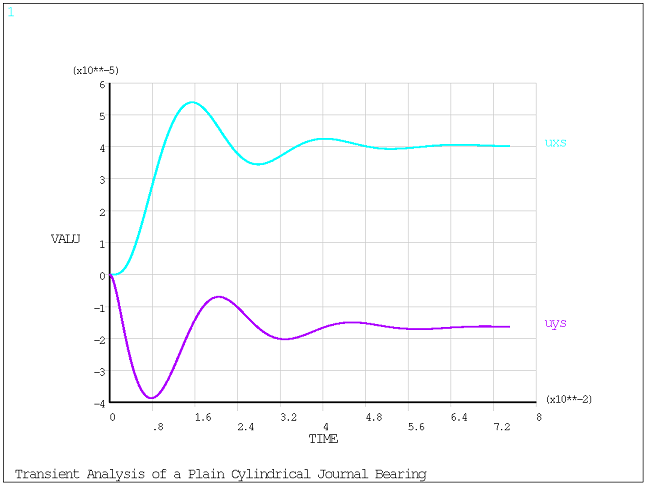

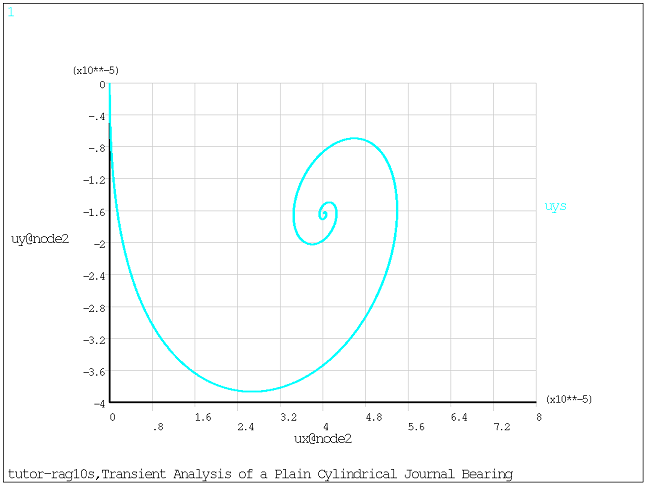

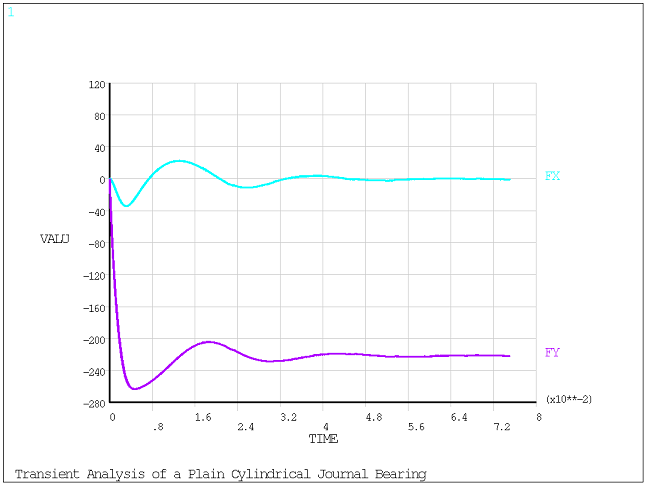

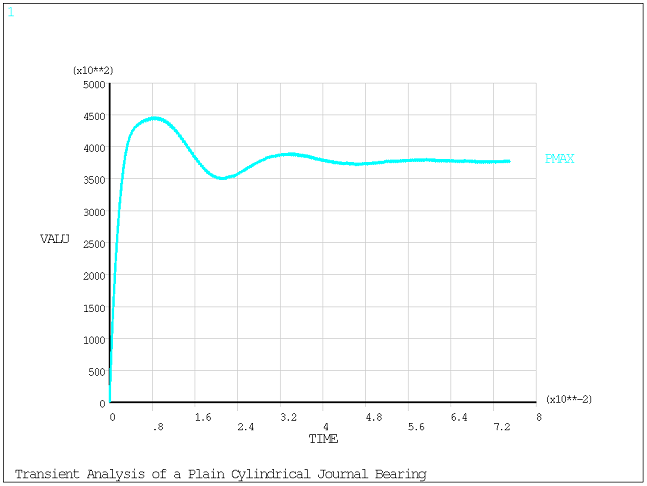

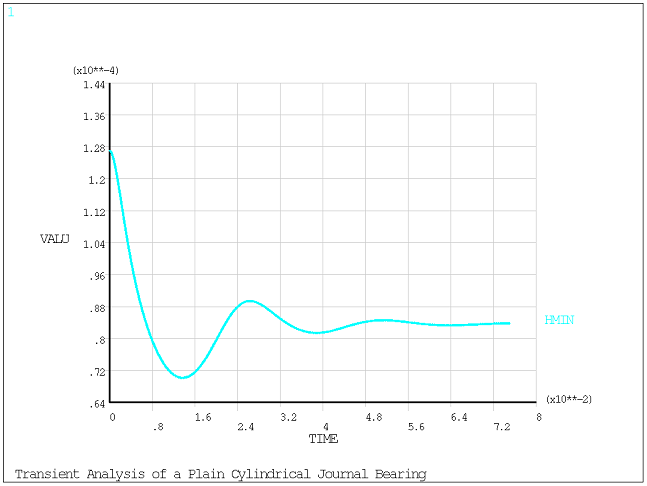

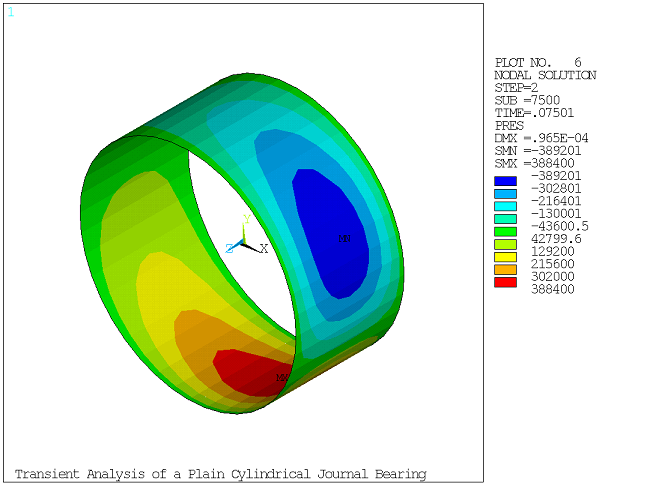

The variation of the position of the shaft center, bearing forces, maximum pressure, and minimum film thickness as a function of time is obtained.

/TITLE, Transient Analysis of a Plain Cylindrical Journal Bearing

! ** Main parameters

lshaft = 2.54e-2

rshaft = lshaft

mshaft = 22.7

omgshaft_rpm = 4000

xclear = 1.27e-4

mu = 0.069

! ** Secondary parameters

pi = 4*atan(1)

l2 = lshaft/2

omgshaft = omgshaft_rpm*pi/30

roshaft = mshaft/(lshaft*pi*rshaft**2)

zedge = -l2

/prep7

! ** Solid Element

et,1,185

mp,ex,1,2.0e13

mp,nuxy,1,0.33

mp,dens,1,roshaft

mp,betd,1,0.1

! ** Geometry and Solid Mesh

cylind,0,rshaft, -l2,l2, 0 ,90

ndvlz = 10 ! longitudinal lines divisions

lesiz,7,,,ndvlz

lesiz,8,,,ndvlz

lesiz,9,,,ndvlz

ndvrd = 5 ! radial lines divisions

lesiz,1,,,ndvrd

lesiz,6,,,ndvrd

lesiz,2,,,ndvrd

lesiz,5,,,ndvrd

ndvcr = 10 ! arc lines divisions

lesiz,3,,,ndvcr

lesiz,4,,,ndvcr

type,1

mat,1

vsweep,all

vsymm,x,all

vsymm,y,all

nummrg,node

nummrg,kp

! ** MPC on Rear Face

*get,numn,NODE,0,NUM,MAX

numn = numn + 1

*get,nume,ELEM,0,NUM,MAX

nume = nume + 1

*set,tid,4

*set,cid,5

et,cid,174

et,tid,170

keyo,tid,2,1 ! Don't fix the pilot node

keyo,tid,4,111111

keyo,cid,12,5 ! Bonded Contact

keyo,cid,4,2 ! Rigid CERIG style load

keyo,cid,2,2 ! MPC style contact

type,cid

mat ,cid

real,cid

nsel,,loc,z,-l2

esln

esurf

*set,_npilot1,numn

n,_npilot1,0,0,-l2

type,tid

tshape,pilo

en,nume,_npilot1

tshape

allsel

! ** MPC on Front Face

*get,numn,NODE,0,NUM,MAX

numn = numn + 1

*get,nume,ELEM,0,NUM,MAX

nume = nume + 1

*set,tid,6

*set,cid,7

et,cid,174

et,tid,170

keyo,tid,2,1 ! Don't fix the pilot node

keyo,tid,4,111111

keyo,cid,12,5 ! Bonded Contact

keyo,cid,4,2 ! Rigid CERIG style load

keyo,cid,2,2 ! MPC style contact

type,cid

mat ,cid

real,cid

nsel,,loc,z,l2

esln

esurf

*set,_npilot2,numn

n,_npilot2,0,0,l2

type,tid

tshape,pilo

en,nume,_npilot2

tshape

allsel

! ** Bearing Element and Mesh

et,3,218

keyopt,3,1,1 ! U + PRES dofs

mp,visc,3,mu

r,3, xclear, rshaft

rmore, zedge

type,3

mat,3

real,3

csys,1

nsel,,loc,x,rshaft

esln

esurf

csys,0

allsel

! ** Boundary Conditions

nsel, ,loc,z,-l2

nsel,a,loc,z,l2

d, all, pres, 0.0d0 ! zero pressure at both ends

nsel, ,node,,_npilot1

nsel,a,node,,_npilot2

d, all, uz, 0.0d0,,,, rotx,roty ! pilot nodes constraints

allsel

finish

! ** Transient Analysis

/solu

antype, transient

nlgeom,on

outres,all,all

nbdt1 = 10

dt1 = 1e-6

deltim, dt1

time, nbdt1*dt1

acel,, 9.81 ! gravity

nsel, ,node,,_npilot1

nsel,a,node,,_npilot2

d, all, OMGZ, omgshaft ! rotational velocity at pilot nodes

allsel

kbc,0

cnvtol,PRES ! add default pressure criterion

cnvtol,F,,,,1.0 ! specify MINREF

cnvtol,FLOW,-1 ! remove fluid flow criterion

cnvtol,M,-1 ! remove moment criterion

solve

nbdt2 = 7500

dt2 = 1e-5

deltim, dt2

tend = nbdt1*dt1 + nbdt2*dt2

time, tend

kbc,1

solve

finish

/post1

/show,png,rev

/view,,1,1,1

! ** Bearing forces - Maximum Pressure - Minimum Thickness

nbdt = nbdt1 + nbdt2

*dim,fxtab,array,nbdt

*dim,fytab,array,nbdt

*dim,pmaxtab,array,nbdt

*dim,hmintab,array,nbdt

esel,,type,,3

*get,nelem,ELEM,0,COUNT

*do,iloops,1,nbdt

*if,iloops,gt,nbdt1,then

set,2,iloops-nbdt1

*else

set,1,iloops

*endif

f1 = 0

f2 = 0

pmax = 0

hmin = xclear

ielem = 0

*do,iloop,1,nelem

ielem = ELNEXT(ielem)

*get,con,ELEM,ielem,NMISC,11

f1 = f1 + con

*get,con,ELEM,ielem,NMISC,12

f2 = f2 + con

*get,con,ELEM,ielem,NMISC,10

*if,con,gt,pmax,then

pmax = con

*endif

*get,con,ELEM,ielem,NMISC,9

*if,con,lt,hmin,then

hmin = con

*endif

*enddo

fxtab(iloops) = f1

fytab(iloops) = f2

pmaxtab(iloops) = pmax

hmintab(iloops) = hmin

*enddo

/out,

*status

/out,scratch

finish

/post26

nos = node(0,0,0) ! shaft center

nsol,2,nos,u,x,uxs

nsol,3,nos,u,y,uys

plvar,2,3

xvar,2

/axlab,x,ux@node2

/axlab,y,uy@node2

plvar,3

/reset

xvar,0

vput,fxtab,4,0.0,,FX

vput,fytab,5,0.0,,FY

vput,pmaxtab,6,0.0,,PMAX

vput,hmintab,7,0.0,,HMIN

plvar,4,5

plvar,6

plvar,7

/out,

prvar,4,5,6,7

/out,scratch

finish

/post1

set,last

esel,,type,,3

plnsol,pres

finish

/exit,nosave