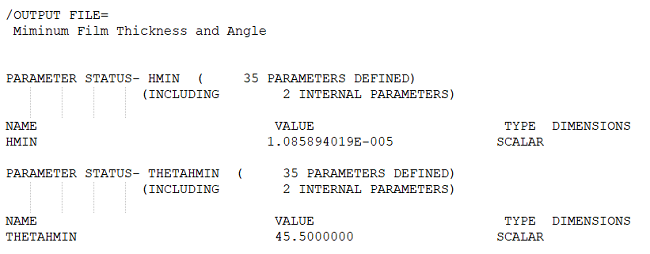

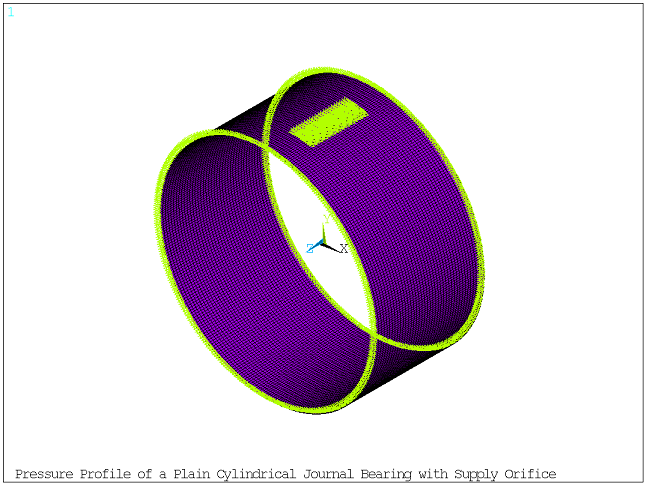

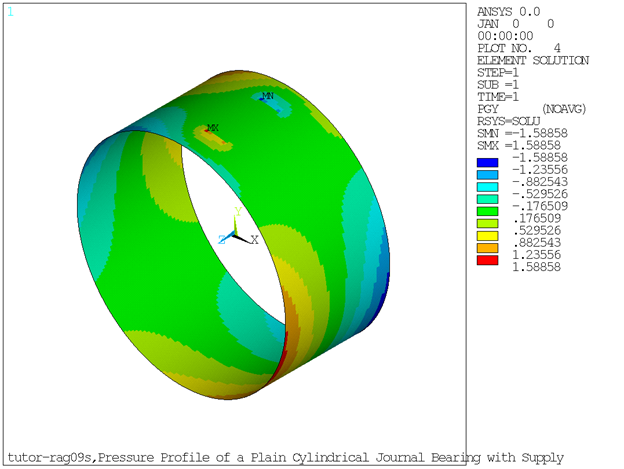

The model is a plain cylindrical journal bearing with full leakage at both ends and rectangular supply orifice at 85° supporting a shaft rotating at 3000 RPM. The pressure profile is calculated at the adimensional equilibrium position XX = 0.4, YY = 0.4. The FLUID218 element is used in a static analysis. Element size is small to capture the variation of the pressure for each degree.

The bearing properties are as follows:

Clearance: 2.5 x 10-5 m

Length: 0.02 m

Radius: 0.02 m

Viscosity: 0.01 Pa˙s

Supply characteristics:

Pressure: 0.5 x 106 Pa

Orifice height: 10°

Orifice width: ¼ of the diameter

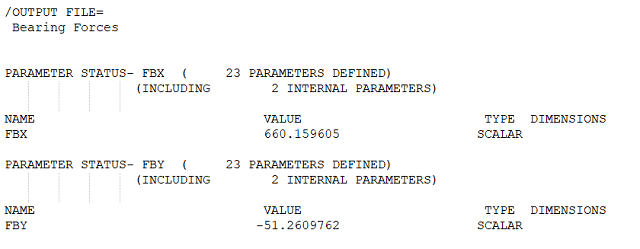

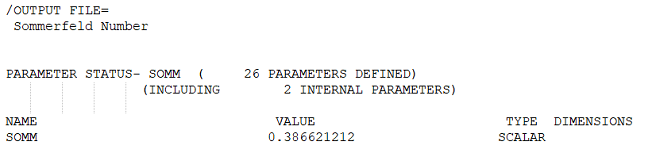

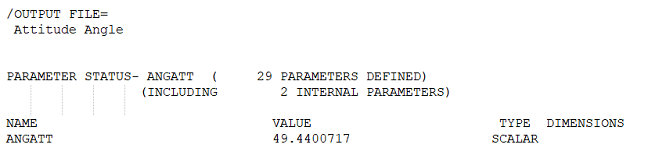

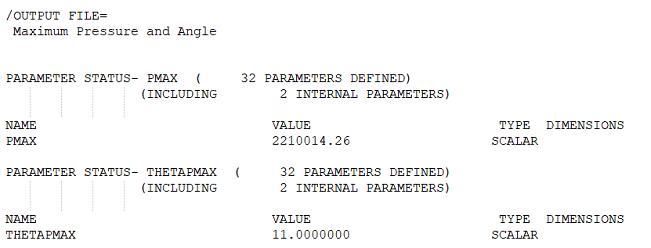

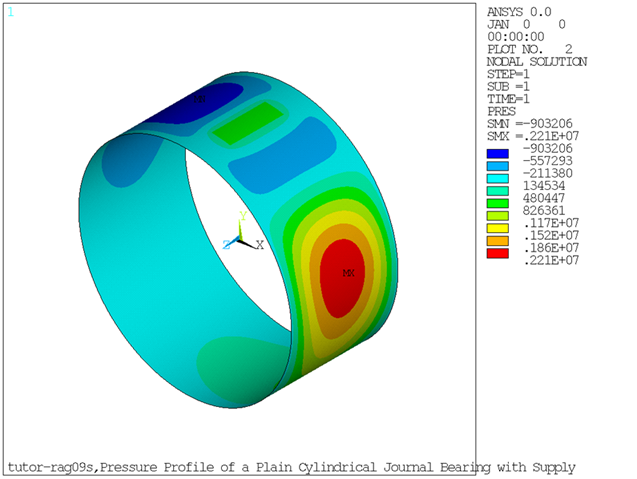

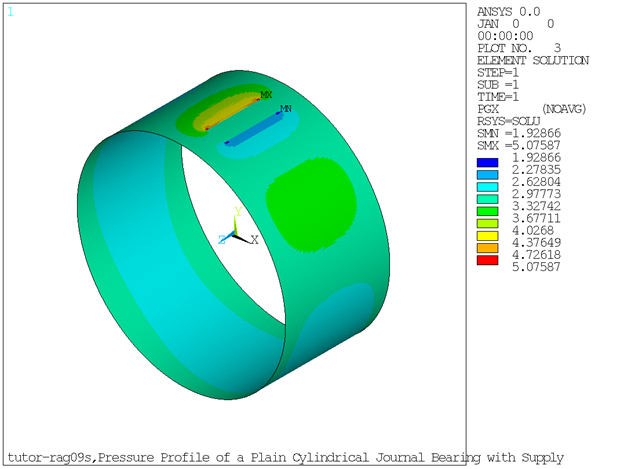

/title, Pressure Profile of a Plain Cylindrical Journal Bearing with Supply Orifice ! ** Main Parameters rshaft = 20e-3 lshaft = 20e-3 omgshaft_rpm = 3000 XX = 0.4 YY = 0.4 xclear = 25e-6 mu = 0.01 Psup = 0.5e+6 ! ** Secondary Parameters pi = 4*atan(1) l2 = lshaft/2 l4 = lshaft/4 omgshaft = omgshaft_rpm*pi/30 /prep7 ! ** SOLID185 (unused) - to support FLUID218 mesh only et,1,185 mp,ex,1,1.0 mp,nuxy,1,1.0 mp,dens,1,1.0 ! ** Solid Geometry and Mesh type,1 mat,1 cylind,0,rshaft, -l2,l2, 0,90 ndvlz = 40 ! longitudinal lines divisions lesiz,7,,,ndvlz lesiz,8,,,ndvlz lesiz,9,,,ndvlz ndvrd = 12 ! radial lines divisions lesiz,1,,,ndvrd lesiz,6,,,ndvrd lesiz,2,,,ndvrd lesiz,5,,,ndvrd ndvcr = 90 ! arc lines divisions lesiz,3,,,ndvcr lesiz,4,,,ndvcr vsweep,all vsymm,x,all vsymm,y,all nummrg,node nummrg,kp ! ** FLUID218 Mesh et,2,218 mp,visc,2, mu r,2, xclear, rshaft, XX*xclear, YY*xclear type,2 mat,2 real,2 csys,1 nsel,,loc,x,rshaft esln esurf csys,0 allsel ! ** Remove Solid Elements vclear,all etdele,1 ! ** Boundary Conditions nsel, ,loc,z,-l2 nsel,a,loc,z,l2 d, all, pres, 0.0 ! zero pressure at both ends allsel csys,1 nsel, ,loc,x,rshaft nsel,r,loc,y, 80,90 nsel,r,loc,z, -l4,l4 d, all, pres, PSup ! supply pressure csys,0 allsel finish ! ** Static Analysis /solu antype,static omega,,, omgshaft outres,all,all solve fini /post1 set,last /show,png,rev /view,,1,1,1 ! ** Element Plot with Boundary Conditions /pbc,pres,1 eplot /pbc,pres,0 ! ** Nodal Pressures plnsol,pres ! ** Sum Element Forces *get,nelem,ELEM,0,COUNT fbx = 0 fby = 0 ielem = 0 *do,iloop,1,nelem ielem = ELNEXT(ielem) *get,con,ELEM,ielem,NMISC,11 fbx = fbx + con *get,con,ELEM,ielem,NMISC,12 fby = fby + con *enddo *status,fbx *status,fby ! ** Element Fluid Velocities rsys,solu plesol,PG,X ! tangential plesol,PG,Y ! axial rsys W = sqrt(fbx**2 + fby**2) omgshaft_rps = omgshaft_rpm/60 Somm = mu*lshaft*2*rshaft*omgshaft_rps*(rshaft/xclear)**2/W /output, /com, Sommerfeld Number /com, *status,Somm /output,scratch AngLoad = atan(fby/fbx)*180/pi AngCenter = atan(YY/XX)*180/pi AngAtt = AngCenter - AngLoad /output, /com, Attitude Angle /com, *status, AngAtt /output,scratch csys,1 nsort,pres,,1,,,, *get,pmax,sort,0,max *get,pmaxnode,sort,0,imax thetapmax = ny(pmaxnode) /output, /com, Maximum Pressure and Angle /com, *status,pmax *status,thetapmax /output,scratch etable,thick,NMISC,9 esort,etab,thick,1 *get,hmin,sort,0,min *get,hminelem,sort,0,imin *get,thetahmin,elem,hminelem,cent,y /output, /com, Miminum Film Thickness and Angle /com, *status,hmin *status,thetahmin finish