The general procedure for defining a spot weld set consists of the following steps:

In addition, the SWLIST and SWDEL commands are available for listing and deleting spot weld sets.

Use the SWGEN command to define a basic spot weld set. The required arguments are:

Name of the spot weld set (

Ecomp)Spot weld radius (

SWRD)Spot weld surfaces (

NCM1,NCM2)First spot weld node (

SND1)

You can optionally specify the following:

Second spot weld node

Spot weld projection direction

Search radius

Contact and target element types

These inputs are discussed in detail below.

- Spot Weld Set Name (

Ecomp): Use the

Ecompargument to assign a name to a new basic spot weld set. The spot weld set is a component composed of new beam, target, and contact elements. The name entered for theEcompargument will be used to list, delete, output, or add new surfaces to the spot weld set.- Spot Weld Surfaces (

NCM1,NCM2): Each basic spot weld set contains two surfaces, surface 1 and surface 2, to be connected together. Use arguments

NCM1andNCM2to specify these surfaces. You can input the name of a predefined node component or a meshed area number. If no nodal component names matchingNCM1andNCM2are found, they are assumed to be meshed area numbers.- Spot Weld Nodes (

SND1,SND2): You must specify the first spot weld node,

SND1. The location of each spot weld depends onSND1.If you specify the second spot weld node (

SND2), it is used to determine the spot weld projection direction. If not specified, the second node is generated automatically.You should locate

SND1andSND2(referred to as node 1 and node 2 in figures that follow) as close to the corresponding surfaces as possible. They can be nodes on the corresponding surfaces or independent nodes in space. If they are not on the corresponding surfaces, node 1 will be moved to surface 1 and node 2 will be moved to surface 2.The program determines the actual location for the spot weld nodes by first projecting node 1 onto surface 1 along the spot weld projection direction. Next, the program projects node 2 to surface 2 along the spot weld projection direction. The spot weld nodes are moved to the surfaces in the beginning of the analysis.

Two new pilot nodes (which represent the spot weld nodes) are generated at the locations of node 1 and node 2 and meshed with TARGE170 target elements (TSHAP,PILO) .

- Spot Weld Projection Direction:

By default, the projection direction is a surface normal vector from node 1 to surface 1 (see figure below).

If you specify node 2 (

SND2), the projection direction is in line with the two spot weld nodes. If node 2 is not specified, you can still explicitly define the projection direction with theDIRX,DIRY, andDIRZarguments.Once the actual location of node 1 has been determined, the program projects node 2 to surface 2 along the spot weld projection direction that was used for node 1. The figure below shows the projection locations of nodes 1 and 2 given a default projection normal to surface 1.

The figure below shows spot weld node 1 projected as specified by the user (either through the input of

DIRX,DIRY, andDIRZ, or by the specification of a second spot weld node).The figure below is another example showing the projection location of spot weld nodes 1 and 2 given a user-specified projection direction.

- Spot Weld Radius (

SWRD): Each spot weld is assumed to have a circular projection onto the spot weld surfaces. The projection is defined by the required spot weld radius argument

SWRD.For each spot weld surface, the program builds force-distributed or rigid surface constraint equations through a contact pair. The spot weld radius determines the influence range of the constraint equations. Each spot weld node couples with a group of nodes on the corresponding surface within the radius. (See Figure 12.7: Nodes Included in Constraint Equations later in this section.)

By default, the influence range is equal to the spot weld radius. If the spot weld radius is too small, the program calculates the influence range based on the distance between the projected location of the pilot node and the closet adjacent node. Most of the time, this program-calculated influence range is sufficient to build proper constraint equations. If desired, you can modify the influence range after SWGEN is issued by inputting a new value as real constant PINB (via the RMODIF command). See Defining Influence Range (PINB) for more information on how influence range affects a force-distributed or rigid surface constraint.

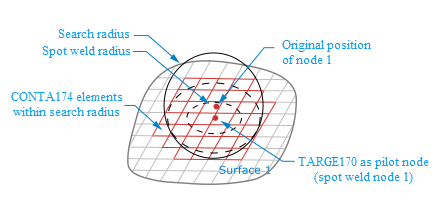

- Search Radius (

SHRD): The program creates an MPC contact pair for each spot weld surface. The contact pair (which is a force-distributed or rigid surface constraint) contains one target element (a pilot node) defined by the spot weld node, and contact elements overlaid fully or partially on the corresponding spot weld surface. Only the surface nodes that fall within a sphere of radius (called the search radius) with its center at the original position of the corresponding spot weld node are used to form contact elements (see figure below). The search radius must be larger than the spot weld radius.

If the search radius argument (

SHRD) is not defined and only one spot weld node (SND1) is specified, the program uses a default search radius that is four times the spot weld radius. If the second spot weld node (SND2) is also specified, the default search radius depends on the spot weld radius and the resultant distance between the two spot weld nodes.- Target and Contact Element Types (

ITTY,ICTY): By default, the program automatically creates the target and contact element types required for the spot weld. However, you may use the

ITTYandICTYarguments to specify the target and contact element types, respectively. You must also set certain key options if you specify the element types to be used. See The Components of a Spot Weld for more information.If the

ICTYfield of SWGEN is set toNTOSorNTS2, the node-to-surface configuration of spot welds is defined. In this configuration, the spot weld consists of a beam element and two node-to-surface MPC contact pairs.

Each new spot weld set created by SWGEN consists of a beam element and two MPC contact pairs, which are either force-distributed constraints or rigid surface constraints. Each contact pair generates 6 constraint equations. You can choose either a rigid MPC184 element (the default) or a deformable BEAM188 element to link the spot weld surfaces. Below are details of how these items are generated:

Contact Pairs: Two MPC contact pairs (force-distributed constraints) are created for each new spot weld set. One pair is for surface 1 and the other is for surface 2. Each contact pair has one target element (TARGE170) as the pilot node which is generated at the location of the associated spot weld node. The contact elements (CONTA174) are formed by a group of surface nodes lying within the region of the search radius. The program creates an independent real constant ID for each contact pair along with proper contact and target element type IDs.

If you prefer, you can specify the contact or target element type IDs to be used:

To specify a contact element type, use the

ICTYargument on SWGEN and set the following contact element options for that element type: KEYOPT(2) = 2 (MPC approach), KEYTOPT(4) = 1 (normal to contact detection), and KEYOPT(12) = 5 (bonded always).To specify a target element type, use the

ITTYargument on SWGEN and set the following target element option for that element type: KEYOPT(2) = 1 (boundary conditions for rigid target nodes are specified by user).

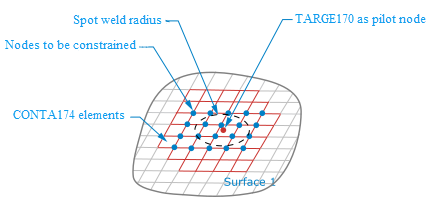

Force-distributed constraint equations: For each contact pair, the program internally forms force-distributed constraint equations that distribute the internal forces of the spot weld node (that is, the pilot node) to the surface nodes (that is, the contact nodes) lying within the region of the spot weld radius. This includes all elements that fall entirely or partially within the radius (see the figure below). In other words, it couples the motion of certain surface nodes to the motion of the spot weld node (in an average sense). There are six constraint equations generated for each spot weld surface (that is, each contact pair).

Beam element: A beam element is created to connect surface 1 and surface 2. The two beam end-nodes are the pilot nodes generated at node 1 and node 2 (see Figure below). The spot weld set can be rigid or deformable.

By default, the program creates a rigid beam element (MPC184 with KEYOPT(1) = 1 and KEYOPT(2) = 1) to represent a rigid spot weld. If the currently defined element type ID points to an MPC184 element type with suitable key options, the program uses that element type to define the rigid beam. Otherwise, it generates a new MPC184 element type ID.

However, if the currently defined element type is BEAM188 with a solid circular cross-section, the program assumes the spot weld set is deformable and a BEAM188 element is created. In this case, you must input the material properties with the MP command and define the geometry of the beam section using the SECTYPE and SECDATA commands (see the example listing below). Generally, BEAM188 is capable of handling a short beam situation.

The following example input shows typical commands used to define a spot weld with a deformable BEAM188 element having a circular cross section.

MP,EX,3,200000000000. ! spot weld material properties

MP,NUXY,3,0.3

SECTYPE,3,beam,csolid ! define a circular solid beam section

SECDATA,2.75e-002 ! beam circular radius

ET,3,188 ! element type for a deformable spot weld

TYPE,3

MAT,3

SECNUM,3

*SET,NODE1,9000 ! define parameter for node number

N,NODE1,0.1,0.5,10.2 ! define spot weld node

SWGEN,SWELD1,2.75e-2,2,3,NODE1 ! Spot weld name = SWELD1

! Radius = 2.75e-2

! Spot weld surfaces = areas 2 and 3

Additional Guidelines for Spot Weld Components

Keep the following points in mind when creating a spot weld:

All limitations that are documented for the MPC184 link/beam element in the Element Reference also apply when the element is used in a rigid spot weld definition. Read the MPC184-Link/Beam description carefully, especially the assumptions and restrictions.

After SWGEN generates the contact pairs, it is recommended you do not change the contact definition from a force-distributed constraint to a rigid surface constraint. Changing the contact definition may cause unexpected behavior or output for the spot weld.

Once a basic spot weld set has been created, additional surfaces can be added to

the existing spot weld set. Use the SWADD command to define the

additional surfaces. Each added surface (input as NCM1

through NCM9) can be specified by an existing nodal

component name or by a meshed area number.

In the example command below, four surfaces are added to an existing spot weld set named SWELD1. The four surfaces include area number 3, area number 4, nodal component FAC5, and nodal component FAC6. The search radius is 0.8.

SWADD,SWELD1,0.8,3,4,FAC5,FAC6 ! Adds 4 surfaces to spot weld SWELD1.

For each new surface, the program creates a new spot weld node, a new MPC contact pair (force-distributed constraint), and a new beam element (see figure below). The location of the new node is determined by projection of one of the closest existing spot weld nodes onto the newly added surface along the spot weld projection direction.

Each new MPC contact pair has one target element

(TARGE170) as the pilot node (which is generated at the

location of the associated spot weld node) and contact elements

(CONTA174) formed by the surface nodes within the range

of the search radius (SHRD) specified on the

SWADD command.

The search radius defaults to 4 times the spot weld radius

(SWRD) defined for the basic spot weld set. Each new

contact pair creates 6 force-distributed constraint equations internally. A new beam

is created to link the new surface to the closest existing surface through the spot

weld nodes.

After all spot weld nodes are created, the nodes of the beam elements may be reordered to link every two adjacent spot weld nodes (see Figure below). The ordering is important for the output, which is calculated for each beam in a spot weld set.

Assuming the basic spot weld set is named SWELD, below is an example of commands that could have produced the above figure.

SWADD,SWELD, ,3 ! Add Area 3 to spot weld set SWELD SWADD,SWELD, ,4 ! Add Area 4 (between surfaces 2 and 3) to SWELD

Initially, when spot weld surface 3 was added, a beam was created between surfaces 2 and 3. When surface 4 was added between surfaces 2 and 3, the beam that went between surfaces 2 and 3 was redefined to go between surfaces 2 and 4, and a new beam was created to link surfaces 4 and 3.

You can add more surfaces by repeating the SWADD command. However, the maximum number of allowable surfaces for each spot weld set (including the two surfaces used for the basic set) is 11.