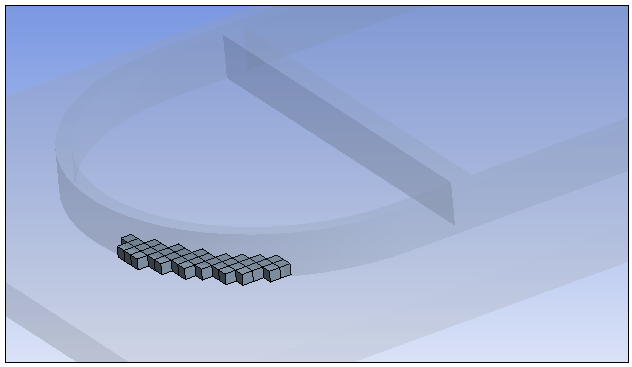

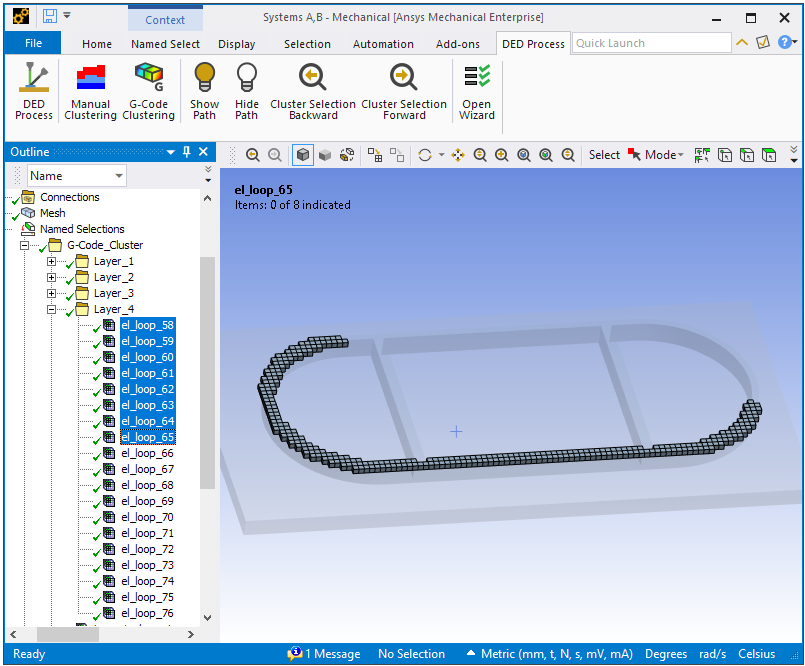

Clustering is used to split weld lines into smaller pieces of mesh clusters that are exposed to one temperature in a time step. In the racetrack example that has four layers, one cluster in one layer is shown here.

Cluster volume, in mm3, is used to control the size of the clusters, and hence, has a direct influence on simulation time. This value determines how many elements are activated per load step, the time for this load step is then determined by volume/deposition rate. A smaller cluster volume tends to provide a more accurate result. Based on the overall dimension of the build geometry, this value should be determined by balancing the computational cost and desired accuracy.

Set cluster volume based on the total volume of your part. If, for instance, your build part has a total volume of 10,000 mm3 and you define a cluster volume of 100 mm3, the clustering process will generate approximately 100 element clusters.

Two approaches are available to define element clustering, either manually or using G-Code. For both of these approaches, a license check for the Additive Suite license is done when generating element clusters. Upon completion of cluster generation, you can use the Cluster Settings table to adjust machine parameters for individual element clusters, as needed.

See the following topics:

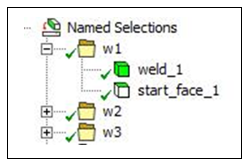

In this approach to element clustering, you manually define named selections in a very specific pattern and with a specific naming convention. Every weld track must be defined as a body named selection with the name “weld_X” where X is the number of the weld track describing the weld track order. Specifically, the name for the first weld track named selection must be weld_1, the name of the second weld track named selection must be weld_2, and so on.

Additionally, every weld track needs to have a face named selection as a start face called “start_face_X” where X is the number of the weld track describing the weld track order.

To summarize, for every body named selection weld_X there must be a face named selection start_face_X.

For the sake of clarity, weld_X and start_face_X can be, but do not have to be, grouped together.

You must set a Cluster Volume per simulation step (default: 20 mm³) to determine the element cluster size.

Procedural Steps

To create element clusters using the manual approach:

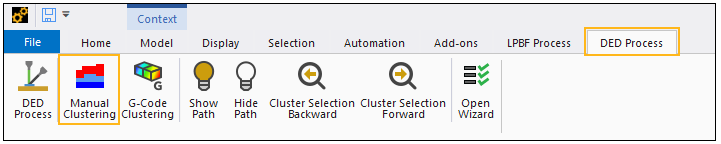

Select the Manual Clustering button in the DED Process ribbon. A Manual Clustering object is inserted below the AM Process for DED object in the project tree.

In the Details view of the Manual Clustering object, define a Cluster Volume per simulation step.

Select a Print Direction (default: Z direction)

Right-click Manual Clustering and click Generate.

At the beginning of every weld track a new cluster will be created. In most cases, one or more element clusters with a predefined element cluster size do not fit perfectly into the weld track. That is why at the end of a weld track there may be small clusters with a much smaller cluster size than defined.

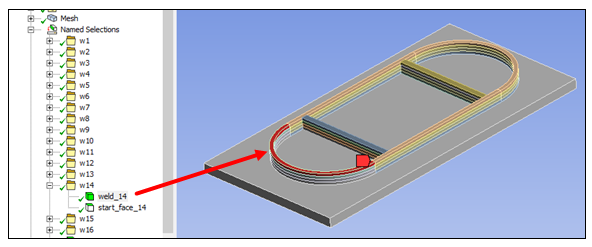

Use the buttons Cluster Selection Forward and Cluster Selection Backward in the AM Process for DED toolbar in the ribbon to display the clustering sequence in the geometry window.

The Cluster Settings object is automatically inserted under the AM Process for DED object in the project tree together with the Manual Clustering object. Click Cluster Settings to use a table to adjust machine parameters for individual element clusters as needed. For details, see Using the Cluster Settings Table.

G-Code is the most commonly used programming language for computer numerical controlled (CNC) machines. It is used to control cutting tools within a machine tool (like a lathe or mill) as well as non-cutting tools used for additive methods like DED. Within the AM Process for DED, we use the G-Code commands as a basis for creating clusters of elements that represent the building sequence of the part. Since G-Code can contain extensions and variations specific to machine tool manufacturers and control manufacturers, we focus on basic commands for linear movement (G00 and G01) and circular movement (CIP), and assume a planar tool path in the X-Y, X-Z, or Y-Z plane, normal to print direction. See Supported G-Code Commands.

The general steps to create element clusters based on a G-Code file are:

Add G-Code Clustering object and import G-Code file. This step is done automatically if you use the DED Process Wizard to set up the simulation.

Visualize the G-Code path.

Define additional G-Code options.

Translate or rotate the G-Code in relation to the build part, as needed.

Perform element clustering.

Review the cluster progression after element clustering is completed.

Procedural Steps

Add G-Code Clustering object and import G-Code file

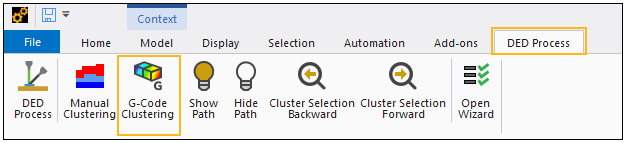

Select the G-Code Clustering button in the DED Process ribbon. A G-Code Clustering object is inserted below the AM Process for DED object in the project tree.

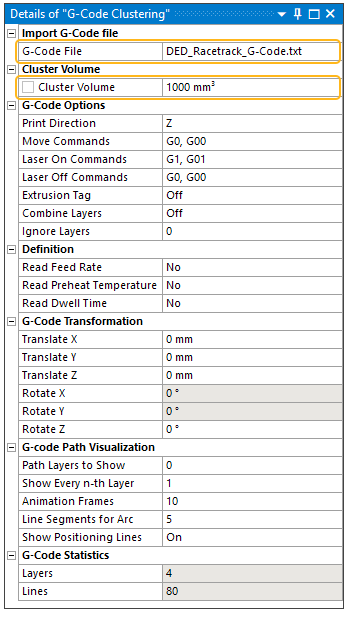

In the Details view of the G-Code Clustering object, click G-Code File to browse to the G-Code file. The G-Code file must be in ASCII format. Select the G-Code file and then click Open in the file selection dialog.

Define the Cluster Volume, in mm3.

Important: Don't skip this step; it is very important to visually verify that the G-Code path is correctly aligned with the part.

You should visualize the G-Code path to check the correct positioning of the build part with respect to the G-Code positions. Note that the following G-Code Path Visualization settings in the G-Code Clustering object have no influence on element clustering itself.

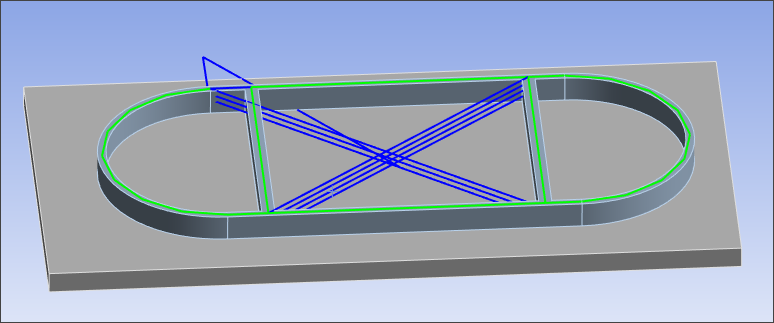

Click Show Path in the AM Process for DED toolbar in the ribbon. The G-Code path is displayed as blue and green lines in the geometry window. (Note: It may take some time to read the G-Code file and display the path.)

Blue lines show rapid movement commands in the G-Code. With this type of movement, no material is deposited, and these paths are also not used in the subsequent element clustering.

Green lines show printing commands in the G-Code. With this type of movement, material is deposited, and these paths are used in subsequent element clustering. In the visualization, the green line appears at the top of each deposition layer.

Click Hide Path in the toolbar to clear the G-Code path display from the geometry window.

You can adjust the visualization display by changing the following settings in the Details view of the G-Code Clustering object, under G-Code Path Visualization:

Path Layers to Show: Path layers from the G-Code file to display. Enter a range of values with a hyphen and multiple values separated by commas. For example, 1-10, 25-30 displays layers 1 through 10 and 25 through 30. The value 0 displays all layers and is the default setting.

Show Every n-th Layer: Displays every n-th path layer of the designated Path Layers to Show. For example, the number 2 displays every second layer, 3 displays every third layer, and so on. The number 1 displays all layers designated in Path Layers to Show and is the default setting.

Animation Frames: Animation frames in which the designated Path Layers to Show are rendered. Click the Show Path button

to render the

animation. The value 1 displays all Path Layers to Show in a

single animation frame, that is, all at once. The value 2

divides the Path Layers to Show across two animation frames,

rendering half of the layers first and then the other half.

The greater the amount of Animation Frames, the clearer the

G-Code path progression will be. The default setting is 10.

Values greater than the total number of layers in Path

Layers to Show are rendered with Animation Frames equal to

the total number of layers in Path Layers to Show. Because

the animation rate is fast, this option is most useful when

visualizing large models and is less useful when visualizing

smaller models.

to render the

animation. The value 1 displays all Path Layers to Show in a

single animation frame, that is, all at once. The value 2

divides the Path Layers to Show across two animation frames,

rendering half of the layers first and then the other half.

The greater the amount of Animation Frames, the clearer the

G-Code path progression will be. The default setting is 10.

Values greater than the total number of layers in Path

Layers to Show are rendered with Animation Frames equal to

the total number of layers in Path Layers to Show. Because

the animation rate is fast, this option is most useful when

visualizing large models and is less useful when visualizing

smaller models. Line Segments For Arc: The graphical display of an arc path is approximated by a number of lines in the geometry window. The number of lines per arc can be modified, a useful option for G-Code files with many arcs in order to speed up the graphical display. The default number of line segments is 5.

Show Positioning Lines: On (default) displays the rapid movement commands in the G-Code. Off suppresses the display of rapid movement commands.

Cluster generation depends on the G-Code being properly aligned with the build part. After visualizing the G-Code path, if it does not align with the build part, consider using the G-Code translation or rotation options described in step 4.

Define additional G-Code options

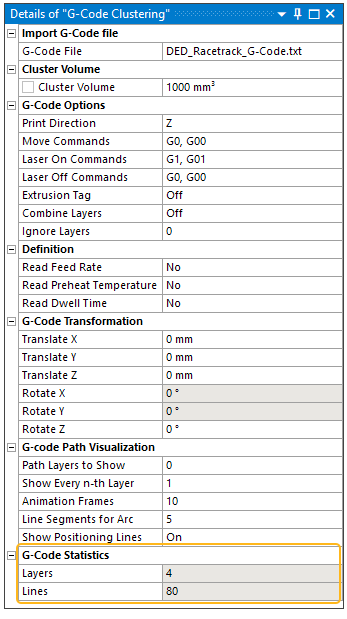

The interpretation of the G-Code file commands can be modified before element clustering starts. Adjust the following additional options in the Details view of the G-Code Clustering object, under G-Code Options:

Print Direction: Choose X, Y, Z, -X, -Y, -Z, or 3D (Beta) for the print direction. Defaults to Z direction. Use 3D (Beta) for a multi-axis DED process. For information, refer to the Additive Manufacturing Beta Features document.

Move Commands: Defines the G-Code commands for pure movement. Multiple commands can be specified using comma separation, such as “G00, G01.”

Laser On Commands: Defines the G-Code command(s) for switching the laser to on (Laser On). All following move commands are used for element clustering until a Laser Off command is found. Multiple commands can be specified using comma separation, such as “M24, M174.”

Laser Off Commands Defines the G-Code command(s) for switching the laser to off (Laser Off). All following move commands are not used for element clustering until a Laser On command is found. Multiple commands can be specified using comma separation, such as “M28, M175.”

Extrusion Tag: G-Code commands may be extended by an extrusion tag “E.” This can be used to additionally control if material is deposited or not. With the Extrusion Tag option set to On, only commands with the “E”-tag are considered for subsequent element clustering. Default setting is Off.

Ignore Layers: With this option, specific layers can be excluded from the element clustering. Multiple layer numbers can be excluded using comma separated values. For example, “2,3” ignores the layers two and three from subsequent element clustering, so the clusters are divided into two instead of four layers. The default is 0 which includes all layers for element clustering (that is, 0 exclusions).

Translate or rotate the G-Code in relation to the build part, as needed

Cluster generation depends on the G-Code being properly aligned with the build part. Use the fields under G-Code Transformation to position the G-Code properly with respect to the part. Entering a value in any of these fields transforms the G-Code path immediately. The example at the end of this section shows a case where rotation of the G-Code path is required.

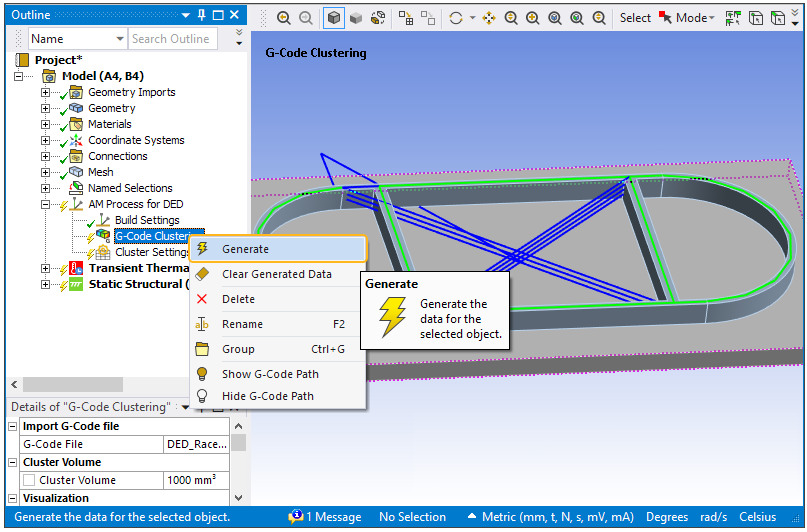

Element clustering requires the following steps:

Right-click the G-Code Clustering object and select Generate to start the element clustering process. Depending on the number of commands in the G-Code file and the number of elements, this process may take some time.

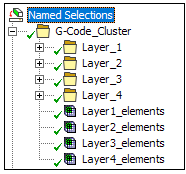

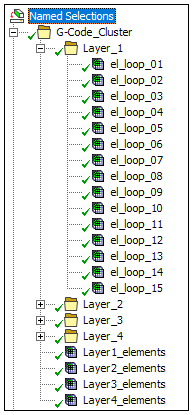

The following structure will be created under Named Selections in the project tree:

The folders "Layer_1," "Layer_2," and so on, contain named selections, one named selection for each element cluster. The cluster names "el_loop_001," "el_loop_002" and so on, must not be renamed.

The named selections “Layer1_elements,” “Layer2_elements,” and so on, contain all elements within those detected layers. These named selections are created only for visualization purposes and have no influence on the simulation itself.

View the G-Code Statistics in the Details view of the G-Code Clustering object to see the total number of layers and lines read from the G-Code file, including rapid movements without material deposition.

The Cluster Settings object is automatically inserted under the AM Process for DED object in the project tree together with the G-Code Clustering object. Click Cluster Settings to use a table to adjust machine parameters for individual element clusters as needed. See Using the Cluster Settings Table for details.

Review the cluster progression after element clustering is completed

Important: Don't skip this step; it is very important to visually verify that the element clusters follow the G-Code path.

Use the buttons Cluster Selection Forward and Cluster Selection Backward in the AM Process for DED toolbar in the ribbon to display the clustering sequence in the geometry window.

Example

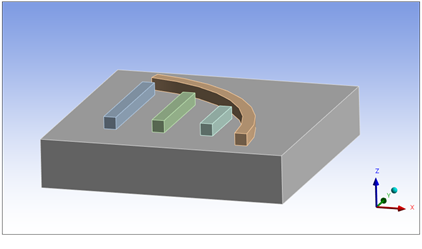

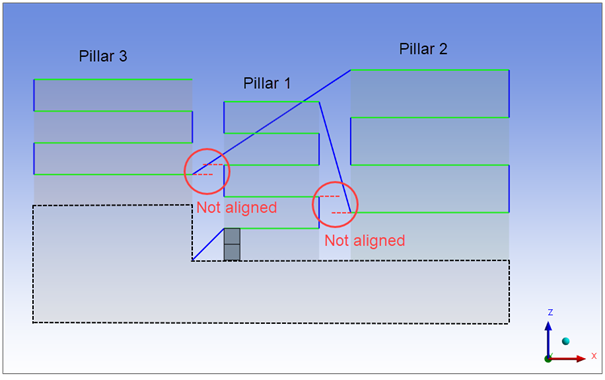

In the following example, the build part consists of four bodies, as shown here:

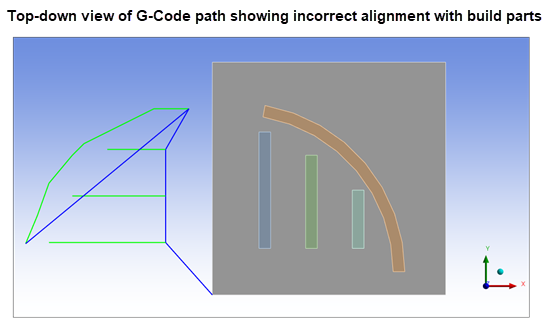

After importing the G-Code file and visualizing the G-Code path, we can see that it is not properly aligned on top of the parts.

Indeed, after performing element clustering, we can review the cluster progression and see that the element clusters are adversely affected by the unaligned G-Code path and will result in an incorrect simulation.

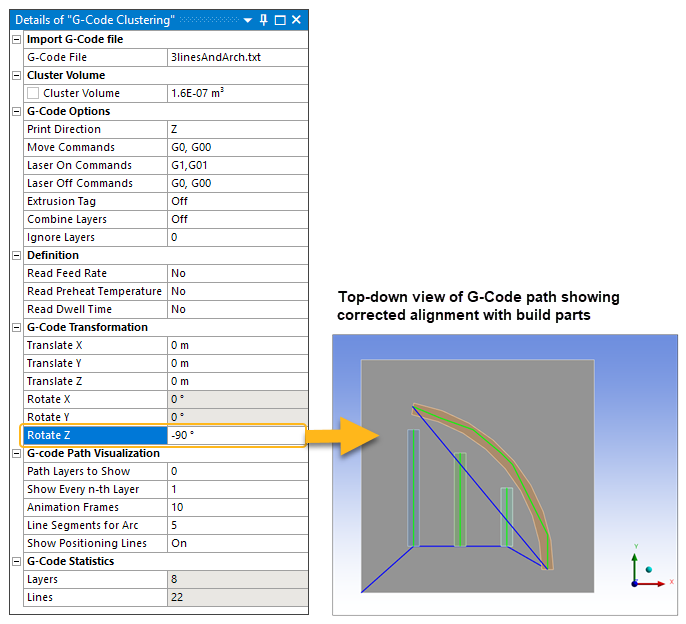

The solution to the problem is to rotate the G-Code path by 90° in the clockwise direction about the Z-axis. Note that rotation is allowed only in the printing direction. Since the Print Direction =Z in this example, we will use the Rotate Z field under the G-Code Transformation settings, as shown below. A top-down view of the model shows the corrected G-Code path after rotation.

After element clustering, we can again review the cluster progression and verify it now follows the G-Code path.

Known Issue where G-Code Clustering Does Not Follow the G-Code Path

For DED simulations using G-Code clustering with a single print direction, such as ±X, ±Y, or ±Z (that is, other than 3D (Beta)), depending on how your G-Code is written, the clustering may not reflect the real build sequence due to how the G-Code clustering algorithm is implemented within the DED Process Add-on. In certain cases, the DED simulation results may be invalid.

First, check to see if the G-Code clustering matches your actual build sequence by reviewing the cluster progression once clusters are generated. To do so, click the Cluster Selection Forward button in the AM Process for DED toolbar on the ribbon repeatedly to see the cluster progression in the geometry window. (Alternatively, choose the first Named Selection in Layer 1 under Named Selections and use the down arrow key to view the cluster progression through all layers.) If the cluster progression follows the G-Code path as expected, there is no need to be concerned, and you can proceed to solve the simulation. If the cluster progression does not follow the G-Code path, it is most likely because the G-Code layers do not align evenly in the print direction everywhere on the model. One indication of this is that the cluster progression appears to jump around randomly back and forth to different portions of the model. This can happen in both multi-body parts and single-body parts with non-simple geometries, even if the G-Code file itself is valid. Common scenarios are shown below.

When G-Code clustering does not follow the G-Code path, there are two workaround options. The most basic, but potentially time-consuming, remedy is to change the Print Direction to 3D (Beta). To use the 3D (Beta) option, you must enable Beta features in Mechanical first. When Print Direction is set to 3D (Beta), the application uses a different algorithm, resulting in a more rigorous clustering technique but a significantly longer time to generate element clusters.

The second workaround is to adjust the G-Code layer thicknesses in your G-Code file so that they align in the print direction everywhere on the model, then reread the G-Code file and generate element clusters again. Check the progression of element clusters after the new clusters are generated. You may need to do this multiple times until you are satisfied that the cluster progression follows the G-Code path.

Common Scenarios where G-Code Clustering Does Not Follow the G-Code Path

While every geometry is unique, below are some build scenarios where you may experience G-Code clustering not following the G-Code path.

- Different/multiple layer thicknesses resulting in unaligned G-Code layers

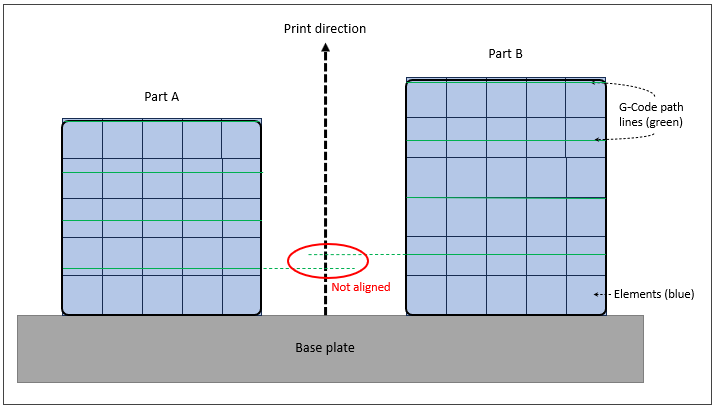

In this scenario, multiple parts on the base plate each have distinct deposition layer thicknesses that are not aligned in the print direction, as illustrated below. While this is a valid DED set-up, the current clustering implementation in the DED Process Add-on may result in unexpected behaviour because of the current limitation. Adjusting the G-Code layer thicknesses to be the same for both parts is an easy enough fix in this example if that is an acceptable build scenario.

- Non-planar base resulting in unaligned G-Code layers

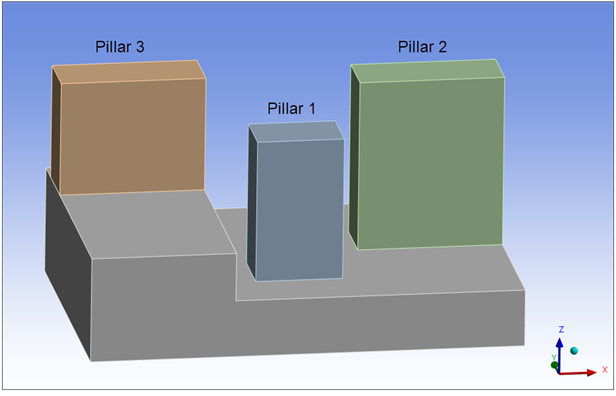

The next example illustrates the scenario described above—a multi-body part with different layer thicknesses resulting in unaligned layers— as well as introduces another problem scenario caused by a non-planar base plate. Three pillars are to be printed one-by-one on a non-planar base. The intention is to build pillar 1 first, followed by pillar 2, and lastly, pillar 3.

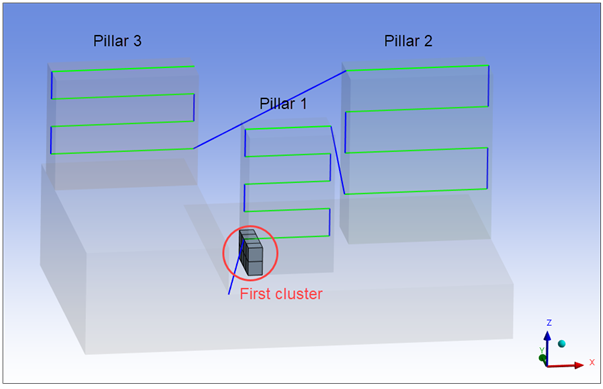

If we look at the G-Code path (highlight the first cluster under Named Selections and then click Show Path in the DED Process ribbon), we see a valid path starting at the lower, left corner of pillar 1, progressing upward back and forth until pillar 1 is completed, then moving to the bottom of pillar 2, moving upward back and forth until pillar 2 is completed, and finally moving to pillar 3 and moving upward back and forth until it is completed.

But when we review the cluster progression, we see that the clustering does not follow the G-Code path, as shown in the following animation:

A front view of the model shows that the G-Code path lines for the pillars do not align with each other in the Z direction. For pillars 1 and 2, which are positioned at the same Z location on the base, their layer thicknesses are different. Pillars 1 and 3, while having the same layer thickness, start at different Z-locations on the base.

There is no way to reconcile the unaligned layers problem due to the non-planar base plate without changing the G-Code and/or geometries. In this example, it may be best to set Print Direction = 3D (Beta) as the workaround.

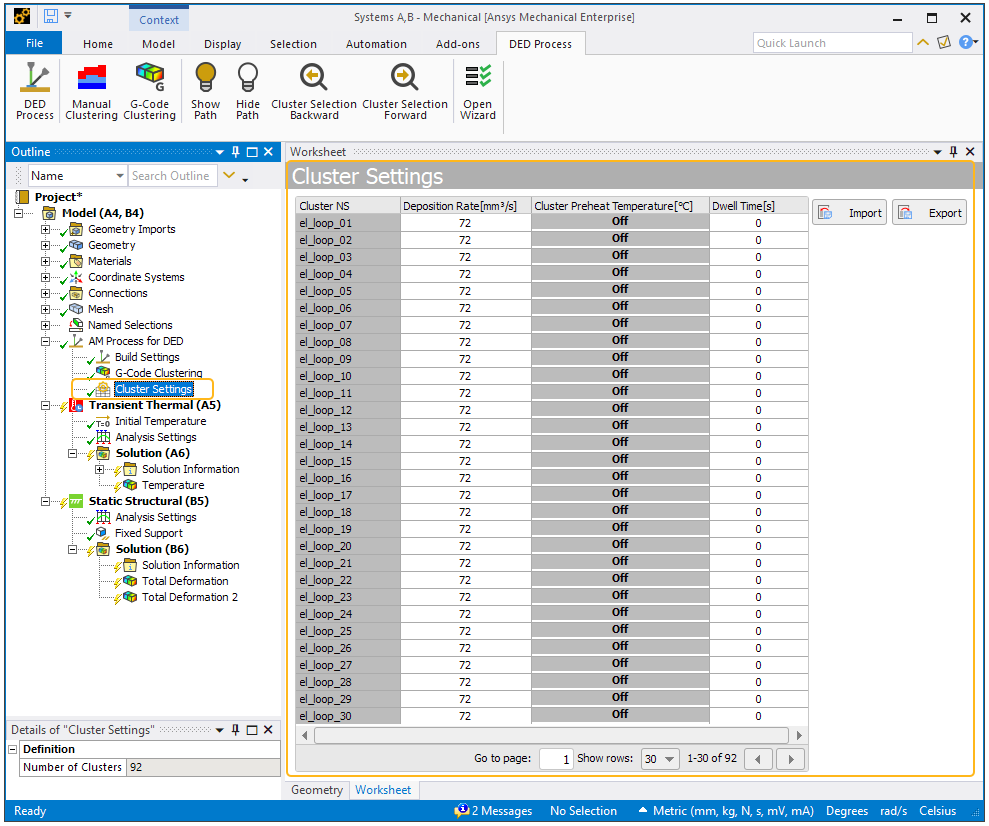

Machine parameters are sometimes adjusted to optimize process settings and improve printing quality. You can exert more precise control over regions of the model, for example, to reduce distortion or local overheating with the Cluster Settings table.

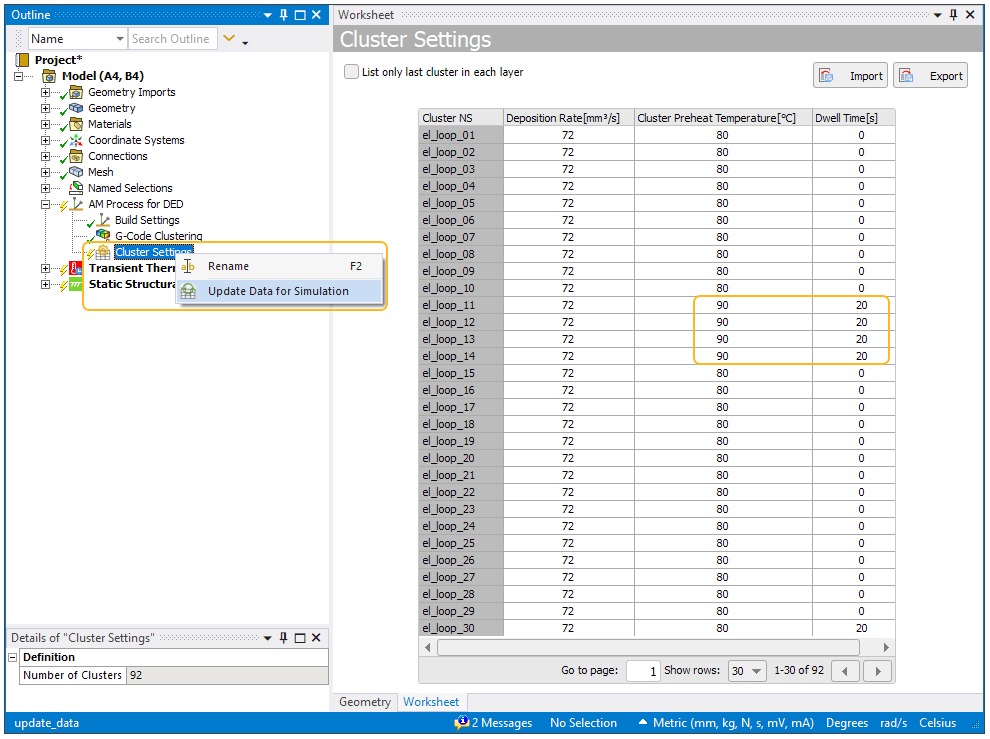

You can adjust machine parameters for individual element clusters using the Cluster Settings table, accessible by selecting the Cluster Settings object. The Cluster Settings object is automatically inserted under the AM Process for DED object in the project tree when either the Manual Clustering or G-Code Clustering object is inserted. (Manual Clustering and G-Code Clustering are inserted either by the DED Setup Wizard or by manual insertion.)

Table Data

The table consists of the following columns of data:

Cluster NS: Name of the named selection for the cluster.

Deposition Rate (same as Material Deposition Rate in Build Settings): The feeding rate of the melted material, in mm3/sec. This value can be determined by multiplying layer thickness (mm) x weld width (mm) x deposition speed (mm/sec).

Cluster Preheat Temperature: The starting temperature, in °C, of the surface scoped for preheating; usually this is the underside surface of the base plate.

Dwell Time: The pause, in seconds, between the completion of this cluster and the beginning of the next, not including laser travel time.

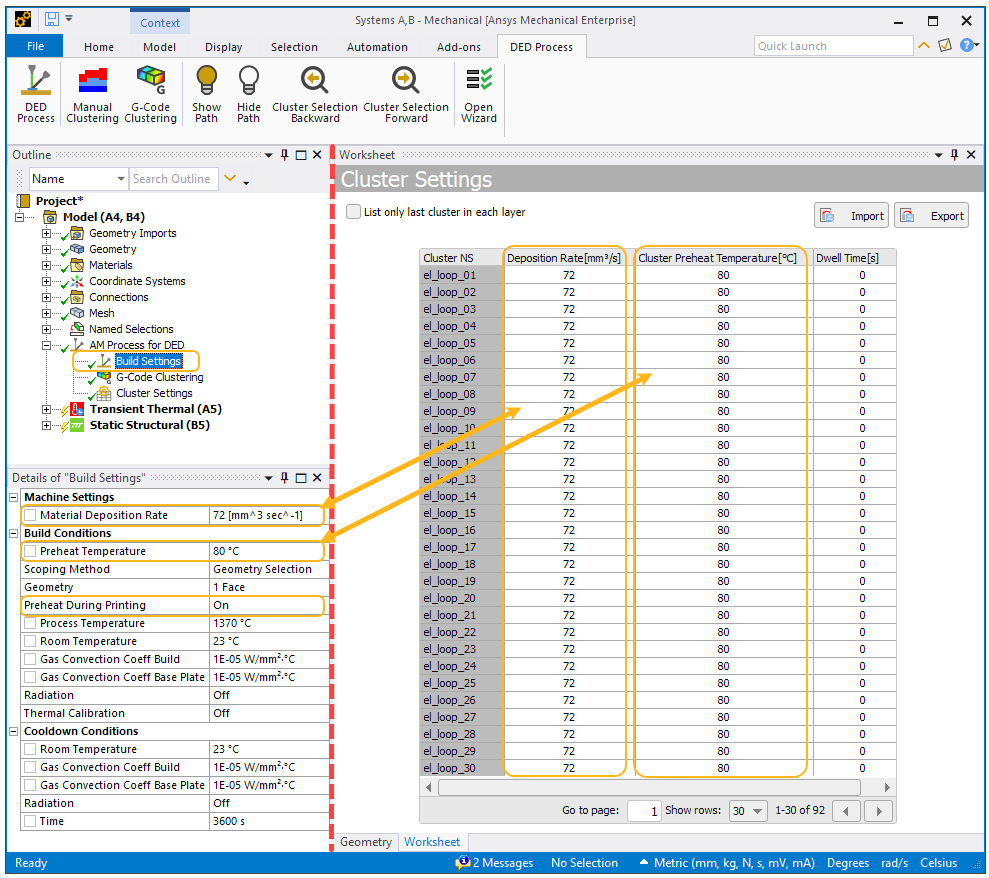

There is a relationship between the data in the table and the data in the Build Settings object, as shown in the following image. In the image, the Cluster Settings table is juxtaposed next to the project tree for comparison purposes only. In the application, the table does not appear when Build Settings is selected.

Initially, the values in the table reflect what is entered in Build Settings.

Note that Preheat During Printing must be set to On for any temperature values to be included in the table. If Preheat During Printing is set to Off, the word Off appears in every row in the Cluster Preheat Temperature column, as shown in the image at the top of this section.

Modifying Table Data

You can manually change data in the table or import data from a file. Once you change any data, right-click Cluster Settings and select Update Data for Simulation.

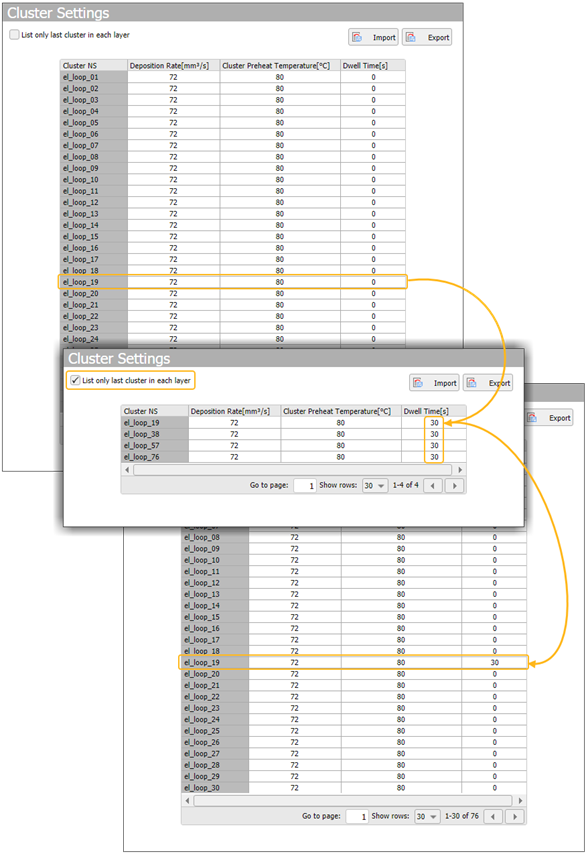

You can filter the data shown in the table to list only the last cluster in each layer by clicking the checkbox in the upper, left corner above the table. This is especially convenient when you have a large model to identify the last cluster of every layer so you can adjust the Dwell Time before starting the next layer, as shown in the following example. By clicking List only last cluster in each layer, we see that clusters 19, 38, 57, and 76 are the last clusters in each of the four layers so we modified the Dwell Time just for those clusters. We followed this by right-clicking the Cluster Settings object and choosing Update Data for Simulation.

Note the following regarding valid data input:

A string (non-numeric value) is invalid and is interpreted as a 0.

For Deposition Rate, a value of 0 is invalid. The value must be greater than 0.

For Cluster Preheat Temperature, a value of 0 is interpreted as Off.

For Dwell Time, a value of 0 is a valid value.

Importing and Exporting

Use the Import button to import data from an existing .csv file. Navigate to the desired folder and click Open. With .csv import, commas are interpreted as column separators, so use dots rather than commas as decimal separators in numerical inputs in your .csv file.

If you try to import a .csv file that does not have the same number of clusters as the existing model in the tree, the import will not be successful and an error message will include the names of missing or extra clusters.

Use the Export button to export data from the table to a .csv file. For clusters generated via G-Code, the export operation does not overwrite or affect the G-Code file in any way.

Localization – Dots versus Commas

Column titles, text strings, units, and numerical values in the table always appear in English. Numerical values appear with decimal points (dots) rather than commas. For example, if your localization setting is set to French or German and you enter 93,33 for Preheat Temperature in the Build Settings details pane, the table shows 93.33.

When entering numerical values into the table, use dots rather than commas.

With .csv import, commas are interpreted as column separators, so use dots rather than commas as decimal separators in numerical inputs in your .csv file.