The two primary characteristics in a bolted joint are pretension and mating part contact. To simulate the bolt configuration, a stud M120 bolt is modeled with a cover and a base plate. The bolt is subjected to a pretension load of 2544690 N to simulate the actual bolt phenomenon. Three frictional contact pairs are defined to model the following contact areas:

Thread region between bolt and base plate

Between cover plate and base plate

Between bolt head and cover plate.

A pressure load of 50 MPa (which is less than the equivalent pretension load) is applied to the upper surface of the cover plate after applying pretension to the bolt. The resulting bolt shank stress (stress in the region between the bolt head and the bolt thread) due to the pretension load and the inclusion of frictional contact behavior are the major concerns during the bolt simulation.

The objective of this problem is to demonstrate the following:

how to simplify the modeling of a bolted joint using the Bolt Thread option of the Contact Geometry Correction

the close approximation of thread behavior and shank stress by this simplified modeling approach compared to results from the more detailed and computationally expensive true threaded bolt model.

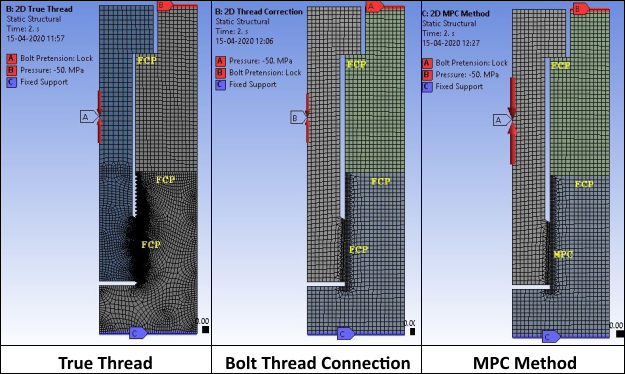

This problem is simulated using three methods:

True Thread Simulation method

This method is the most accurate. Detailed modeling of the threads accurately simulates thread behavior, but it requires a highly refined mesh in the thread region, which makes this method computationally expensive.

Bolt Thread Connection method (simplified bolt thread modeling technique)

In this method, the bolt thread is simulated using the Bolt Thread option for Contact Geometry Correction in Contact Settings, which assigns a bolt section to the contact elements overlaid on the smooth cylindrical bolt surface. No detailed thread geometry is required. Bolt behavior is calculated using thread parameters that you specify in Contact (for more information see Simplified Bolt Thread Modeling in the Contact Technology Guide). This method is computationally inexpensive.

MPC method (bonded behavior in thread region)

In this method, MPC bonded behavior is defined in the thread region. No detailed thread geometry is required. This method is very fast computationally, but thread behavior can be lost.

2-D axisymmetric models are used to compare these three methods. The 2-D model setup for all three methods is shown in the figure below.