This section contains a listing of the contents for the various property panels available in the Fluent Materials Processing workspace.

General property settings are used to define the overall simulation. Here, you can view and adjust any geometry, mesh, or calculation settings, as well as assorted physics options.

Controls

- Mesh file

Indicates the location and name of the mesh file. For more information, see Meshes in the Polyflow documentation.

- Mesh length unit

Indicates the unit of length used in the mesh file. For more information, see Units in the Polyflow documentation.

- Mesh Format

Indicates the format of the mesh file

- Box Size

Describes the dimensions of the mesh.

- Geometry Type

Indicates the dimensionality of the geometry to be represented by the mesh file. If the mesh is a 2D plane, the simulation may be planar (Vz equal to 0), channel (Vz not equal to 0), axisymmetric (Y axis being the axis of symmetry + Vw = 0), swirling (axisymmetric, with the Y axis being the axis of symmetry + Vw not equal to 0) and film (planar + thickness(es)). Note: Vw is the rotation velocity around the Y axis.

- Calculation Type

Indicates the specific type of calculation to be performed. Calculations can be Steady, Continuation, Transient, or Volume of Fluid when you want to perform a transient simulation of a filling process.

- Task name

Specify a name for the task.

- Duration

For a transient or volume of fluid calculation, specify the overall length of time interval.

- Include thermal effects

Enable this option if you want to model fluid flow in which temperature plays a role.

- Include inertia effects

Enable this option if you want to model fluid flow in which inertia plays a role. For blow molding simulations, inertia effects are always included.

- Include viscous dissipation effects

Enable this option if you want to model the heat generated by internal forces and friction along slipping walls.

- Include gravity effects

Enable this option if you want to model fluid flow in which gravity plays a role. When selected, for the Gravity definition, enter the X, Y, and Z components of the gravitational acceleration.

- Gx

Specify the value of the x-component of the gravitational acceleration. Using the drop-down menu, you can enter a constant value, or a valid expression.

- Gy

Specify the value of the y-component of the gravitational acceleration. Using the drop-down menu, you can enter a constant value, or a valid expression.

- Gz

Specify the value of the z-component of the gravitational acceleration. Using the drop-down menu, you can enter a constant value, or a valid expression.

Material property settings for your simulation.

All that is required here is to specify a value for the density for the material used in the simulation.

- Density

Specify the density of the material. Using the drop-down menu, you can enter a constant value, or a valid expression.

This section contains settings for thermal-related properties such as thermal expansion, thermal conductivity and heat capacity. For additional information, see Basic Equations in the Polyflow User's Guide.

Thermal Expansion

Thermal expansion can be equated to the Boussinesq approximation that can be used instead of a constant density. For additional information, see Boussinesq Approximation for Density in Nonisothermal Flows in the Polyflow User's Guide.

- Coefficient of thermal expansion

Coefficient of thermal expansion used within the context of the Boussinesq approximation, that is, the effect is applied only on the volume forces (gravity)

- Reference temperature

Within the context of the Boussinesq approximation for the thermal expansion: temperature at which thermal expansion vanishes, that is, at which the density is equal to the specified Density value.

Thermal Conductivity

- K

Select a constant thermal conductivity (K) or a third-order, temperature-dependent, polynomial expression.

- A

When the thermal conductivity law is set to Constant, specify a constant value for the thermal conductivity, or a valid expression. Otherwise, when the law is set to Polynomial, specify the primary coefficient of the thermal conductivity polynomial expression; it may not vanish.

- B

The coefficient of the linear term in the temperature-dependent thermal conductivity polynomial expression.

- C

The coefficient of the quadratic term in the temperature-dependent thermal conductivity polynomial expression.

- D

The coefficient of the cubic term in the temperature-dependent thermal conductivity polynomial expression.

- Reference temperature

Specify the temperature at which the thermal conductivity is constant and is equal to the primary coefficient A.

Heat Capacity

- Cp

Select a constant heat capacity per unit mass or a third-order, temperature-dependent, polynomial expression.

- A

When the heat capacity per unit mass law is set to Constant, specify a constant value for the heat capacity per unit mass, or a valid expression. Otherwise, when the law is set to Polynomial, specify the primary coefficient of the polynomial expression for the heat capacity per unit mass.

- B

The coefficient of the linear term in the temperature-dependent heat capacity per unit mass polynomial expression.

- C

The coefficient of the quadratic term in the temperature-dependent heat capacity per unit mass polynomial expression.

- D

The coefficient of the cubic term in the temperature-dependent heat capacity per unit mass polynomial expression.

- Reference temperature

Specify the temperature at which the heat capacity per unit mass is constant and is equal to the primary coefficient A.

This section contains descriptions of a material's elastic properties. For additional information, see Theory in the Polyflow User's Guide.

Young Modulus

- E

Specify a value for E, the Young modulus.

Poisson Coefficient

- Mu

Specify a value for mu, for the Poisson coefficient.

Lineic Dilatation Coefficient

- Alpha

For linear thermo-elasticity, specify a value for alpha, the lineic dilitation coefficient.

- Reference temperature

For linear thermo-elasticity, specify the temperature at which lineic dilatation vanishes.

This section holds details pertaining to a material's viscosity definition.

- Shear-rate dependency model

Specify the shear-rate dependence model.

- Temperature dependency model

Choose the model for the temperature dependence.

Allows you to specify a constant value for the viscosity. For additional information, see Constant in the Polyflow User's Guide.

- Viscosity

Specify a value for the viscosity. Using the drop-down menu, you can enter a constant value, or a valid expression.

Allows you to specify the properties of the Power Law viscosity model. For additional information, see Power Law in the Polyflow User's Guide.

- Consistency factor

The viscosity at shear-rate equal to the inverse of the Time Constant.

- Time constant

The inverse of the shear-rate at which the viscosity is equal to the Consistency Factor.

- Power law index

An index ranging between 0 and 1; it quantifies the rate of shear thinning. On a log-log diagram, the index corresponds to the slope of shear stress curve versus shear rate. A value of 1 corresponds to a constant viscosity Newtonian fluid, while values lower than 1 indicate shear thinning.

Allows you to specify the properties of the Bird-Carreau Law viscosity model. For additional information, see Bird-Carreau Law in the Polyflow User's Guide.

- Zero shear viscosity

The viscosity at zero shear-rate.

- Time constant

Natural time. That is, inverse of the shear rate at which the fluid changes from a Newtonian to a power-law behavior.

- Power law index

An index ranging between 0 and 1; it quantifies the rate of shear thinning that occurs beyond a shear rate equal to the inverse of the time constant. A value of 1 corresponds to a constant viscosity Newtonian fluid, while the amount of shear thinning increases when the power index decreases down to 0.

- Infinite shear viscosity

The asymptotic value of the shear viscosity at very high shear rate.

Allows you to specify the properties of the Carreau-Yasuda Law viscosity model. For additional information, see Carreau-Yasuda Law in the Polyflow User's Guide.

- Zero shear viscosity

Viscosity at zero shear-rate.

- Time constant

Natural time. That is, inverse of the shear rate at which the fluid changes from Newtonian to power-law behavior.

- Power law index

An index ranging between 0 and 1; it quantifies the rate of shear thinning that occurs beyond a shear rate equal to the inverse of the time constant. A value of 1 corresponds to a constant viscosity Newtonian fluid, while the amount of shear thinning increases when the power index decreases down to 0.

- Infinite shear viscosity

The asymptotic value of the shear viscosity at very high shear rate.

- Plateau index

Parameter that controls the rate of transition from the Newtonian viscosity plateau at low shear rate to the shear thinning behavior. A value between 0 and 1 leads to a rather smooth transition, while higher values lead to a sharp transition.

Allows you to specify the properties of the Bingham Law viscosity model. For additional information, see Bingham Law in the Polyflow User's Guide.

- Plastic viscosity

On a linear diagram, the plastic viscosity indicates the slope of the shear stress curve versus shear rate beyond the yield stress threshold. It also corresponds to the asymptotic value of the shear viscosity at very high shear rate.

- Yield stress threshold

Ideally, the yield stress threshold is the minimum amount of stress that is needed to apply a deformation to the material. In the CFD context, it corresponds to the stress level below which very little deformation is exhibited by the fluid.

- Critical shear rate

The critical shear rate controls the rate of transition between the no-flow behavior when the local stress level is less than the yield stress threshold and the fluid response when the stress is large enough. The rate of transition increases when the critical shear rate decreases.

Allows you to specify the properties of the Modified Bingham Law viscosity model. For additional information, see Modified Bingham Law in the Polyflow User's Guide.

- Plastic viscosity

On a linear diagram, the plastic viscosity indicates the slope of the shear stress curve versus shear rate beyond the yield stress threshold. It also corresponds to the asymptotic value of the shear viscosity at very high shear rate.

- Yield stress threshold

Ideally, the yield stress threshold is the minimum amount of stress that is needed to apply a deformation to the material. In the CFD context, it corresponds to the stress level below which very little deformation is exhibited by the fluid.

- Critical shear rate

The critical shear rate controls the rate of transition between the no-flow behavior when the local stress level is less than the yield stress threshold and the fluid response when the stress is large enough. The rate of transition increases when the critical shear rate decreases.

Allows you to specify the properties of the Herschel-Bulkley Law viscosity model. For additional information, see Herschel-Bulkley Law in the Polyflow User's Guide.

- Yield stress threshold

Ideally, the yield stress threshold is the minimum amount of stress that is needed to apply a deformation to the material. In the CFD context, it corresponds to the stress level below which very little deformation is exhibited by the fluid.

- Consistency factor

On a linear diagram, the consistency factor indicates the shear stress growth versus shear rate beyond the yield stress threshold.

- Power law index

On a linear diagram, the power law index indicates the change of slope of the shear stress growth versus shear rate beyond the yield stress threshold. The rate of shear thinning increases when the index decreases down to 0.

- Critical shear rate

The critical shear rate controls the rate of transition between the no-flow behavior when the local stress level is less than the yield stress threshold and the fluid response when the stress is large enough. The rate of transition increases when the critical shear rate decreases.

Allows you to specify the properties of the Modified Herschel-Bulkley Law viscosity model. For additional information, see Modified Herschel-Bulkley Law in the Polyflow User's Guide.

- Yield stress threshold

Ideally, the yield stress threshold is the minimum amount of stress that is needed to apply a deformation to the material. In the CFD context, it corresponds to the stress level below which very little deformation is exhibited by the fluid.

- Consistency factor

On a linear diagram, the consistency factor indicates the shear stress growth versus shear rate beyond the yield stress threshold.

- Power law index

On a linear diagram, the power law index indicates the change of slope of the shear stress growth versus shear rate beyond the yield stress threshold. The rate of shear thinning increases when the index decreases down to 0.

- Critical shear rate

The critical shear rate controls the rate of transition between the no-flow behavior when the local stress level is less than the yield stress threshold and the fluid response when the stress is large enough. The rate of transition increases when the critical shear rate decreases.

Allows you to specify the properties of the Cross Law viscosity model. For additional information, see Cross Law in the Polyflow User's Guide.

- Zero shear viscosity

Viscosity at zero shear-rate.

- Time constant

Natural time. That is, inverse of the shear rate at which the fluid changes from a Newtonian to a power-law behavior.

- Cross law index

Index that controls the rate at which the viscosity decreases with increasing shear-rate. A value of 0 corresponds to a Newtonian fluid (no shear thinning), a value of 1 corresponds to a viscosity that decreases rapidly (important shear thinning)

Allows you to specify the properties of the Modified Cross Law viscosity model. For additional information, see Modified Cross Law in the Polyflow User's Guide.

- Zero shear viscosity

The viscosity at zero shear-rate.

- Time constant

Natural time. That is, inverse of the shear rate at which the fluid changes from a Newtonian to a power-law behavior.

- Cross law index

Index that controls the rate at which the viscosity decreases with increasing shear-rate. A value of 0 corresponds to a Newtonian fluid (no shear thinning), a value of 1 corresponds to a viscosity that decreases rapidly (important shear thinning)

Allows you to specify the properties of the Arrhenius Law temperature dependency viscosity model. For additional information, see Arrhenius Law in the Polyflow User's Guide.

- Activation energy

Specify the ratio of the activation energy to the thermodynamic constant.

- Reference temperature

Specify the temperature at which the function describing the temperature dependence is one. It often corresponds to the temperature of the master curve.

- Shift

Dictates how the viscosity will change with temperature: a vertical shift means that the viscosity curve is simply shifted downwards in a viscosity/shear-rate diagram when temperature increases, a vertical and horizontal shift means that the viscosity curve is shifted downwards and to the right when temperature increases.

Allows you to specify the properties of the Arrhenius Approximate Law temperature dependency viscosity model. For additional information, see Approximate Arrhenius Law in the Polyflow User's Guide.

- Activation energy

Specify the ratio of the activation energy to the thermodynamic constant.

- Reference temperature

Specify the temperature at which the function describing the temperature dependence is one. It often corresponds to the temperature of the master curve.

- Shift

Dictates how the viscosity will change with temperature: a vertical shift means that the viscosity curve is simply shifted downwards in a viscosity/shear-rate diagram when temperature increases, a vertical and horizontal shift means that the viscosity curve is shifted downwards and to the right when temperature increases.

Allows you to specify the properties of the Fulcher temperature dependency viscosity model. For additional information, see Fulcher Law in the Polyflow User's Guide.

- F1

Coefficient that can be used for applying an overall vertical shift of the viscosity curve versus temperature. It is redundant with the zero shear viscosity.

- F2

Coefficient that affects the slope of the decay of the viscosity curve with increasing temperature.

- F3

Temperature corresponding to the vertical asymptote of the viscosity curve versus temperature. In other words, it is the temperature at which the model would predict an infinite viscosity, suggesting fusion or solidification.

Allows you to specify the properties of the WLF temperature dependency viscosity model. For additional information, see WLF Law in the Polyflow User's Guide.

- C1

Empirical constant of the Williams-Landel-Ferry (WLF) law, which dictates the intensity of the temperature dependence.

- C2

Empirical constant of the Williams-Landel-Ferry (WLF) law, which dictates the intensity of the temperature dependence.

- Reference temperature

A temperature parameter which is sometimes related to the glass transition temperature of the material.

- Reference temperature difference

A temperature shift applied when considering another reference temperature. (For example, when considering another temperature for the master curve)

- Shift

Dictates how the viscosity will change with temperature: a vertical shift means that the viscosity curve is simply shifted downwards in a viscosity/shear-rate diagram when temperature increases, a vertical and horizontal shift means that the viscosity curve is shifted downwards and to the right.

This section holds details pertaining to a material's properties when using the Simplified Viscoelastic model. For additional information, see Simplified Viscoelastic Model in the Polyflow User's Guide.

- Weighting Coefficient

At the first approximation, it controls the swelling intensity versus flow rate. Use swelling-based experimental data to fine-tune the values for this property.

This section holds details pertaining to a material's viscosity definition when using the Simplified Viscoelastic model.

- Shear-rate dependency model

Specify the shear-rate dependence model.

Options include:

Allows you to specify a constant value for the viscosity when using the Simplified Viscoelastic model.

- Viscosity

Specify a value for the viscosity. Using the drop-down menu, you can enter a constant value, or a valid expression.

Allows you to specify a Power shear law when using the simplified viscoelastic model.

- Consistency factor

The viscosity at shear-rate equal to the inverse of the Time Constant.

- Time constant

The inverse of the shear-rate at which the viscosity is equal to the Consistency Factor.

- Power law index

An index ranging between 0 and 1; it quantifies the rate of shear thinning. On a log-log diagram, the index corresponds to the slope of shear stress curve versus shear rate. A value of 1 corresponds to a constant viscosity Newtonian fluid, while values lower than 1 indicate shear thinning.

Allows you to specify a Bird-Carreau shear law when using the simplified viscoelastic model.

- Zero first normal viscosity

The viscosity at zero shear-rate.

- Time constant

Natural time. That is, inverse of the shear rate at which the fluid changes from a Newtonian to a power-law behavior.

- Power law index

An index ranging between 0 and 1; it quantifies the rate of shear thinning that occurs beyond a shear rate equal to the inverse of the time constant. A value of 1 corresponds to a constant viscosity Newtonian fluid, while the amount of shear thinning increases when the power index decreases down to 0.

- Infinite first normal viscosity

The asymptotic value of the shear viscosity at very high shear rate.

Allows you to specify a Carreau-Yasuda shear law when using the simplified viscoelastic model.

- Zero first normal viscosity

Viscosity at zero shear-rate.

- Time constant

Natural time. That is, inverse of the shear rate at which the fluid changes from Newtonian to power-law behavior.

- Power law index

An index ranging between 0 and 1; it quantifies the rate of shear thinning that occurs beyond a shear rate equal to the inverse of the time constant. A value of 1 corresponds to a constant viscosity Newtonian fluid, while the amount of shear thinning increases when the power index decreases down to 0.

- Infinite first normal viscosity

The asymptotic value of the shear viscosity at very high shear rate.

- Plateau index

Parameter that controls the rate of transition from the Newtonian viscosity plateau at low shear rate to the shear thinning behavior. A value between 0 and 1 leads to a rather smooth transition, while higher values lead to a sharp transition.

Allows you to specify a Cross shear law when using the simplified viscoelastic model.

- Zero first normal viscosity

Viscosity at zero shear-rate.

- Time constant

Natural time. That is, inverse of the shear rate at which the fluid changes from a Newtonian to a power-law behavior.

- Cross law index

Index that controls the rate at which the viscosity decreases with increasing shear-rate. A value of 0 corresponds to a Newtonian fluid (no shear thinning), a value of 1 corresponds to a viscosity that decreases rapidly (important shear thinning)

Allows you to specify a modified Cross shear law when using the simplified viscoelastic model.

- Zero first normal viscosity

The viscosity at zero shear-rate.

- Time constant

Natural time. That is, inverse of the shear rate at which the fluid changes from a Newtonian to a power-law behavior.

- Cross law index

Index that controls the rate at which the viscosity decreases with increasing shear-rate. A value of 0 corresponds to a Newtonian fluid (no shear thinning), a value of 1 corresponds to a viscosity that decreases rapidly (important shear thinning)

Allows you to specify the first normal viscosity when using the simplified viscoelastic model.

- Shear-rate dependency model

Specify the law for the dependence of the first normal viscosity with respect to the pseudo shear-rate.

You can choose to use the same law as shear viscosity, or you can select from the following:

Allows you to specify a constant first normal viscosity law when using the simplified viscoelastic model.

- Viscosity

The normal viscosity at any pseudo shear rate.

Allows you to specify a Power first normal viscosity law when using the simplified viscoelastic model.

- Consistency factor

The viscosity at pseudo shear-rate equal to the inverse of the Time Constant.

- Time constant

The inverse of the pseudo shear-rate at which the normal viscosity is equal to the Consistency Factor.

- Power law index

An index ranging between 0 and 1; it quantifies the rate of shear thinning. On a log-log diagram, the index corresponds to the slope of shear stress curve versus pseudo shear rate. A value of 1 corresponds to a constant normal viscosity Newtonian fluid, while values lower than 1 indicate shear thinning.

Allows you to specify a Bird-Carreau first normal viscosity law when using the simplified viscoelastic model.

- Zero first normal viscosity

The normal viscosity at zero pseudo shear-rate.

- Time constant

Natural time. That is, inverse of the pseudo shear rate at which the fluid changes from a Newtonian to a power-law behavior.

- Power law index

An index ranging between 0 and 1; it quantifies the rate of shear thinning that occurs beyond a pseudo shear rate equal to the inverse of the time constant. A value of 1 corresponds to a constant normal viscosity Newtonian fluid, while the amount of shear thinning increases when the power index decreases down to 0.

- Infinite first normal viscosity

The asymptotic value of the normal viscosity at very high pseudo shear rate.

Allows you to specify a Carreau-Yasuda first normal viscosity law when using the simplified viscoelastic model.

- Zero first normal viscosity

The normal viscosity at zero pseudo shear-rate.

- Time constant

Natural time. That is, inverse of the pseudo shear rate at which the fluid changes from Newtonian to power-law behavior.

- Power law index

An index ranging between 0 and 1; it quantifies the rate of shear thinning that occurs beyond a pseudo shear rate equal to the inverse of the time constant. A value of 1 corresponds to a constant normal viscosity Newtonian fluid, while the amount of shear thinning increases when the power index decreases down to 0.

- Infinite first normal viscosity

The asymptotic value of the normal viscosity at very high pseudo shear rate.

- Plateau index

Parameter that controls the rate of transition from the Newtonian normal viscosity plateau at low pseudo shear rate to the shear thinning behavior. A value between 0 and 1 leads to a rather smooth transition, while higher values lead to a sharp transition.

Allows you to specify a Cross first normal viscosity law when using the simplified viscoelastic model.

- Zero first normal viscosity

The normal viscosity at zero pseudo shear-rate.

- Time constant

Natural time. That is, inverse of the pseudo shear rate at which the fluid changes from a Newtonian to a power-law behavior.

- Cross law index

Index that controls the rate at which the normal viscosity decreases with increasing pseudo shear-rate. A value of 0 corresponds to a Newtonian fluid (no shear thinning), a value of 1 corresponds to a normal viscosity that decreases rapidly (important shear thinning)

Allows you to specify a modified Cross first normal viscosity law when using the simplified viscoelastic model.

- Zero first normal viscosity

The viscosity at zero shear-rate.

- Time constant

Natural time. That is, inverse of the pseudo shear rate at which the fluid changes from a Newtonian to a power-law behavior.

- Cross law index

Index that controls the rate at which the normal viscosity decreases with increasing pseudo shear-rate. A value of 0 corresponds to a Newtonian fluid (no shear thinning), a value of 1 corresponds to a viscosity that decreases rapidly (important shear thinning)

Allows you to specify the relaxation time law when using the simplified viscoelastic model.

- Shear-rate dependency model

Specify the model for the shear rate dependence.

Options include:

Allows you to specify a constant relaxation time law when using the simplified viscoelastic model.

- Facr

It affects the speed at which the pseudo shear rate changes subsequent to a change in the local shear rate. Additionally, in first approximation, it affects the speed at which the extrudate swelling develops. Use swelling-based experimental data to fine-tune the values for this property.

Allows you to specify a Power relaxation time law when using the simplified viscoelastic model.

- Facr

The relaxation time at shear-rate equal to the inverse of the Time Constant.

- Tnatr

The inverse of the shear-rate at which the relaxation time is equal to the Consistency Factor.

- Expor

An index that controls the rate at which the relaxation time decreases with increasing shear-rate. A value of 1 corresponds to a constant relaxation time, a low value corresponds to a relaxation time that decreases rapidly.

Allows you to specify a Bird-Carreau relaxation time law when using the simplified viscoelastic model.

- Facr

The relaxation time at zero shear-rate.

- Tnatr

Natural time. That is, inverse of the shear-rate at which the relaxation time starts to decrease with an increasing shear-rate.

- Expor

An index that controls the rate at which the relaxation time decreases with increasing shear-rate. A value of 1 corresponds to a constant relaxation time, a low value corresponds to a relaxation time that decreases rapidly.

Allows you to specify the material's thermal dependency properties when using the Simplified Viscoelastic model.

- Temperature dependency model

Choose the model for the temperature dependence.

- Thermal dependency applied on relaxation time

By default, the temperature dependence is applied only on the viscosity and first normal viscosity laws. Optionally it can also be applied on the relaxation time.

Allows you to specify the properties of the Arrhenius Law temperature dependency viscosity model when using the Simplified Viscoelastic model.

- Activation energy

Specify the ratio of the activation energy to the thermodynamic constant.

- Reference temperature

Specify the temperature at which the function describing the temperature dependence is one. It often corresponds to the temperature of the master curve.

- Shift

Dictates how the viscosity will change with temperature: a vertical shift means that the viscosity curve is simply shifted downwards in a viscosity/shear-rate diagram when temperature increases, a vertical and horizontal shift means that the viscosity curve is shifted downwards and to the right when temperature increases.

Allows you to specify the properties of the Arrhenius Approximate Law temperature dependency viscosity model when using the Simplified Viscoelastic model.

- Activation energy

Specify the ratio of the activation energy to the thermodynamic constant.

- Reference temperature

Specify the temperature at which the function describing the temperature dependence is one. It often corresponds to the temperature of the master curve.

- Shift

Dictates how the viscosity will change with temperature: a vertical shift means that the viscosity curve is simply shifted downwards in a viscosity/shear-rate diagram when temperature increases, a vertical and horizontal shift means that the viscosity curve is shifted downwards and to the right when temperature increases.

Allows you to specify the properties of the WLF temperature dependency viscosity model when using the Simplified Viscoelastic model.

- C1

Empirical constant of the Williams-Landel-Ferry (WLF) law, which dictates the intensity of the temperature dependence.

- C2

Empirical constant of the Williams-Landel-Ferry (WLF) law, which dictates the intensity of the temperature dependence.

- Reference temperature

A temperature parameter which is sometimes related to the glass transition temperature of the material.

- Reference temperature difference

A temperature shift applied when considering another reference temperature. (For example, when considering another temperature for the master curve)

- Shift

Dictates how the viscosity will change with temperature: a vertical shift means that the viscosity curve is simply shifted downwards in a viscosity/shear-rate diagram when temperature increases, a vertical and horizontal shift means that the viscosity curve is shifted downwards and to the right.

This section holds details pertaining to a material's properties when using the Differential Viscoelasticity model.

- Model

Choose a differential viscoelastic model: Maxwell, Oldroyd-B, Giesekus, Phan Thien-Tanner, Fene-P, POMPOM, or Leonov.

- Number of Relaxation Modes

Specify the number of relaxation modes, with a maximum of eight modes.

- Additional viscosity

It is the viscosity value of the purely Newtonian (inelastic) contribution to the total extra-stress tensor.

- Thermal Dependency

Choose the model for the temperature dependence. Available models are Arrhenius approximate, Arrhenius, Fulcher, and WLF.

This section holds details pertaining to a material's nth mode (1-8) properties when using the Differential Viscoelasticity model.

- Relaxation Time

Specify the relaxation time of the current mode

- Partial Viscosity

Specify the zero shear rate viscosity factor of the current mode.

- Alpha

Nonlinear parameter of the current mode. Alpha controls the shear thinning as well as the ratio of second to first normal stress difference for the current mode of the Giesekus model. Typical values can be in the order of 0.2 to 0.5.

- Epsilon

Nonlinear parameter of the current mode. Epsilon primarily controls the asymptotic value of the transient elongation viscosity for the current mode of the Phan-Thien-Tanner model. Strain hardening is obtained for very low values of Epsilon. A typical value is of the order of 0.01 for a strain hardening material.

- Xi

Nonlinear parameter of the current mode. Xi primarily controls the shear thinning as well as the ratio of second to first normal stress difference for the current mode of the Phan-Thien-Tanner model. Typical values can be in the order of 0.2 to 0.5.

- L^2

Specify the upper limit of the relative elongation undergone by the FENE macromolecules associated with the current mode. A large value leads to a large extensibility and tends towards the behavior of the Oldroyd-B model.

- Relaxation Time for Orientation

Specify the relaxation time associated with the orientation changes undergone by the chain segments of the POMPOM macromolecules associated with the current mode.

- Relaxation Time for Stretching

Specify the relaxation time associated with the stretching undergone by the chain segments of the POMPOM macromolecules associated with the current mode. It is usually 2 to 10 times smaller than the relaxation time for orientation.

- Shear Modulus

Weight of the current mode. Typically, the value is often identified from dynamic data G prime and G double-prime.

- Number of Arms

A POMPOM macromolecule consists of a backbone and a sequence of arms. The number of arms increases with decreasing relaxation times, and contributes to the strain hardening of the macromolecule.

- Xi

Nonlinear parameter of the current mode. Xi primarily controls the shear thinning as well as the ratio of second to first normal stress difference for the current mode of the POMPOM model. Typical values can be in the order of 0.2 to 0.5.

- Shear Modulus

Weight of the current mode. Typically, the value is often identified from dynamic data G prime and G double-prime.

- Alpha

Specify the initial ratio of free to trapped chains in the system.

- Beta

Specify the coefficient in the potential function that connects the Finger strain tensor to the extra-stress tensor for the current mode.

- Nu

Specify the power index in the potential function that connects the Finger strain tensor to the extra-stress tensor for the current mode.

- M

Specify the coefficient of a material function used in the constitutive equation for free chains of the current mode.

- Nu

Specify the power index used in the mobility function used in the constitutive equation for trapped chains of the current mode.

- K

Specify the value of the mobility function under no-debonding, that is, when no trapped chain is de-bonded from the filler.

- Q

Specify the dimensionless time factor which may delay or accelerate de-bonding in a flow.

- Gamma*

Specify the generalized shear at which yield occurs.

This section holds details pertaining to a material's thermal dependency properties when using the Differential Viscoelasticity model.

- Temperature Dependence

For temperature dependent differential viscoelastic models, the viscosity and the relaxation time will be multiplied by the same temperature shift function H(T). Available shift functions are the Arrhenius approximate, Arrhenius, or WLF law.

- Activation Energy Ratio

Specify the ratio of the activation energy to the thermodynamic constant.

- Reference Temperature

Specify the temperature at which the function describing the temperature dependence is one.

- C1

Empirical constant of the Williams-Landel-Ferry (WLF) law, which dictates the intensity of the temperature dependence.

- C2

Empirical constant of the Williams-Landel-Ferry (WLF) law, which dictates the intensity of the temperature dependence.

- Reference Temperature Difference

Empirical constant of the Williams-Landel-Ferry (WLF) law, (Tr-Ta) with Tr being based on the glass transition temperature and Ta being an arbitrary reference temperature.

In addition to the differential approach to solving viscoelastic model (described in Differential Viscoelastic Law Properties), there is also support for an integral approach. This section holds details pertaining to a material's properties when using the Integral Viscoelasticity model. See Integral Viscoelastic Models for more information.

- Number of Relaxation Modes

Specify the number of relaxation modes, with a maximum of eight modes

- Additional viscosity

It is the viscosity value of the purely Newtonian (inelastic) contribution to the total extra-stress tensor.

This section holds details pertaining to a material's nth (1-8) mode properties when using the Integral Viscoelastic Law.

- Relaxation Time

Specify the relaxation of the current mode.

- Partial Viscosity

Specify the zero shear rate viscosity factor of the current mode.

This section holds details pertaining to a material's thermal dependency properties when using the Integral Viscoelasticity model .

- Temperature Dependence

Choose a temperature-dependency model: None, Arrhenius approximate, Arrhenius, or WLF

- Activation energy ratio

Specify the ratio of the activation energy to the thermodynamic constant.

- Reference temperature

A temperature parameter which is sometimes related to the glass transition temperature of the material.

- C1

Empirical constant of the Williams-Landel-Ferry (WLF) law, which dictates the intensity of the temperature dependence.

- C2

Empirical constant of the Williams-Landel-Ferry (WLF) law, which dictates the intensity of the temperature dependence.

- Reference temperature difference

A temperature shift applied when considering another reference temperature. (For example, when considering another temperature for the master curve)

This section holds details pertaining to a material's properties when using the reinforcements.

- Number of reinforcements

Specify the number of reinforcements, with a maximum of three.

This section holds details pertaining to a material's first reinforcement properties when using the Integral Viscoelastic Law.

- Magnitude

Magnitude of the reinforcement. It has the same units as the viscosity, and it is typically 100 to 1000 times the viscosity of the matrix.

- Orientation

Select the way of describing the reinforcement orientation. A Cartesian description of the reinforcement is better suited for flat objects, while a cylindrical description is recommended for objects with a symmetry axis. (For example, rubber tire)

- X -component of reinforcement

Specify the x-component of the first reinforcement in the Cartesian orientation.

- Y -component of reinforcement

Specify the y-component of the first reinforcement in the Cartesian orientation.

- Z -component of reinforcement

Specify the z-component of the first reinforcement in the Cartesian orientation.

- Cylinder axis

Specify the symmetry axis for the reinforcement.

- Angle of reinforcement

Specify the angle of the first reinforcement with respect to a plane perpendicular to the axis given above. The angle is positive for a reinforcement suggesting a helix along the axis direction when rotating clockwise.

This section holds details pertaining to a material's second reinforcement properties when using the Integral Viscoelastic Law.

- Magnitude

Magnitude of the reinforcement. It has the same units as the viscosity, and it is typically 100 to 1000 times the viscosity of the matrix.

- Orientation

Select the way of describing the reinforcement orientation. A Cartesian description of the reinforcement is better suited for flat objects, while a cylindrical description is recommended for objects with a symmetry axis. (For example, rubber tire)

- X -component of reinforcement

Specify the x-component of the second reinforcement in the Cartesian orientation.

- Y -component of reinforcement

Specify the x-component of the second reinforcement in the Cartesian orientation.

- Z -component of reinforcement

Specify the x-component of the second reinforcement in the Cartesian orientation.

- Cylinder axis

Specify the symmetry axis for the reinforcement.

- Angle of reinforcement

Specify the angle of the first reinforcement with respect to a plane perpendicular to the axis given above. The angle is positive for a reinforcement suggesting a helix along the axis direction when rotating clockwise.

This section holds details pertaining to a material's third reinforcement properties when using the Integral Viscoelastic Law.

- Magnitude

Magnitude of the reinforcement. It has the same units as the viscosity, and it is typically 100 to 1000 times the viscosity of the matrix.

- Orientation

Select the way of describing the reinforcement orientation. A Cartesian description of the reinforcement is better suited for flat objects, while a cylindrical description is recommended for objects with a symmetry axis. (For example, rubber tire)

- X -component of reinforcement

Specify the x-component of the third reinforcement in the Cartesian orientation.

- Y -component of reinforcement

Specify the x-component of the third reinforcement in the Cartesian orientation.

- Z -component of reinforcement

Specify the x-component of the third reinforcement in the Cartesian orientation.

- Cylinder axis

Specify the symmetry axis for the reinforcement.

- Angle of reinforcement

Specify the angle of the first reinforcement with respect to a plane perpendicular to the axis given above. The angle is positive for a reinforcement suggesting a helix along the axis direction when rotating clockwise.

This section holds details pertaining to a material's foaming properties.

- Initial Bubble Radius

Specify a value for the initial radius of the foam bubbles. This value will be used to initialize the bubble radius in the fluid zone and is usually the bubble radius at inlet.

- Initial Gas Pressure

Specify a value for the initial gas pressure in the bubbles.

- Number of Cells per Unit Volume

Specify the number of cells (or bubbles) per volume unit of gas/polymer mixture. This number remains the same during foaming, bubbles grow but are not created nor disappear.

- Surface Tension

Specify a value for the bubble surface tension. The default value is 0. A positive surface tension slows down the bubble growth.

- Viscosity

Specify a value for the consistency factor of viscosity that must be considered for the bubble growth. This viscosity is always modelled by a power law and can be slightly different than the fluid viscosity.

- Power Index

Specify the power law index of the viscosity that must be considered for the bubble growth. A power law index must range between 0 and 1. A value of 1 is used by default.

- Booster

Controls the growth of bubbles in the foam. By default, it is set to 1 but can be increased if the foaming does not provide enough swelling of the extrudate.

This section holds details pertaining to a material's viscosity properties when using porous media.

- Viscosity

Specify a value for the viscosity. Viscosity for porous medium simulation should be constant as the actual shear-rate cannot be calculated (flow inside narrow channels of the porous medium)

This section holds details pertaining to thermal dependencies when considering viscosity and porous media .

- Temperature Dependence

Choose the model for the temperature dependence. Available models are None, Arrhenius approximate, or Arrhenius, Fulcher and WLF.

Allows you to specify the properties of the Arrhenius Law temperature dependency when considering viscosity and porous media

- Activation Energy

Specify the ratio of the activation energy to the thermodynamic constant.

- Reference Temperature

Specify the temperature at which the function describing the temperature dependence is one.

Allows you to specify the properties of the Arrhenius Approximate Law temperature dependency when considering viscosity and porous media.

- Activation Energy

Specify the ratio of the activation energy to the thermodynamic constant.

- Reference Temperature

Specify the temperature at which the function describing the temperature dependence is one.

Species property settings for your simulation.

- Transport

Specify the species transport settings for your simulation.

- Activation

Enable to turn on the transport equation for the current species.

- Source Term

Specify the source term. Using the drop-down menu, you can enter a constant value, or a valid expression.

- Scalar Diffusivity

Specify the scalar diffusivity term. Using the drop-down menu, you can enter a constant value, or a valid expression.

- Advection term

Disabling the Advection term option will not take advection into account in the species transport equation.

- Enable Freezing

The Enable Freezing option can be turned on if you want to freeze the transport equation on a part of the computational domain. The species will keep the initial field value on the freezing zone defined by species-initialization, which is defined under the Solution node.

- Freezing Zones

Choose the zones where the transport equation should be frozen.

Cell zones represent the domain of your simulation, identified by the following Types:

Fluid (Fluid Cell Zone Properties)

Solid (Solid Cell Zone Properties)

Porous media (Porous Cell Zone Properties)

Fixed mold (Fixed Mold Cell Zone Properties)

Moving mold (Moving Mold Zone Properties)

Restrictor part (Restrictor Zone Properties)

Moving part (Moving Part Zone Properties)

In addition, you can use the following command buttons when working with cell zones:

Use the New... button to create a new object with its own unique properties.

Use the Display button to show the cell zone in the graphics window.

Use the Delete button to remove a cell zone

Cell zone property settings for your simulation:

- Type

Choose the type of cell zone, such as fluid, solid, porous media, moving mold, etc.

- Zones

Select one or more zones to apply to this cell zone.

- Multiple Materials

Enable coextrusion modeling via transport of concentrations of different fluid materials.

- Fluid material(s)

Select a fluid material for the cell zone.

- Solid material

Specify a solid material for the cell zone.

- Deformable Mold

Enable this option to allow deformation of the mold.

- Deformable Part

Enable this option to allow deformation of the part.

- Fluid model

Specify a model for the fluid zone. You can choose from Generalized Newtonian, Simplified Viscoelastic, or Differential Viscoelastic.

- Solid model

Specify whether the solid is being modeled as Elastic or Inelastic.

- Mold model

Specify the type of model to use for the mold: Adiabatic, Fixed temperature, or Heat conduction.

- Heat source per unit volume

For fluid or solid thermal cell zones, specify the heat source per unit volume. Using the drop-down menu, you can enter a constant value, or a valid expression.

- Activation

Enable or disable solid motion considerations.

- Vx

Specify a value for the X-component of the translational velocity of the solid motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vy

Specify a value for the Y-component of the translational velocity of the solid motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vz

Specify a value for the Z-component of the translational velocity of the solid motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Motion type

Specify the type of mold motion as Translation velocity imposed, Translation force imposed or General velocity driven motion.

- Vx

Specify a value for the X-component of the translational velocity of the mold motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vy

Specify a value for the Y-component of the translational velocity of the mold motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vz

Specify a value for the Z-component of the translational velocity of the mold motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vx

Specify a value for the X-component of the initial velocity of the mold motion.

- Vy

Specify a value for the Y-component of the initial velocity of the mold motion.

- Vz

Specify a value for the Z-component of the initial velocity of the mold motion.

- Fx

Specify a value for the X-component of the translational force of the mold motion.

- Fy

Specify a value for the Y-component of the translational force of the mold motion.

- Fz

Specify a value for the Z-component of the translational force of the mold motion.

- Mass of the mold

Specify a value for the mass of the mold: corresponding to the total mass of the mold and of the moving part connected to the mold.

- Limit mold motion

Indicate whether or not you want to apply a limit to the mold motion.

- Max displacement

Specify a value for the maximum displacement. The value corresponds to the maximum admissible displacement along the direction specified by the force. The mold motion will continue until either the maximum displacement is reached, the specified time duration is reached, or the solution diverges.

- Dx

Specify a value for the X-component of the initial displacement of the mold motion.

- Dy

Specify a value for the Y-component of the initial displacement of the mold motion.

- Dz

Specify a value for the Z-component of the initial displacement of the mold motion.

- Alpha [deg]

Specify a value for the initial rotation angle for the mold motion.

- Xo

Specify a value for the X-component of the point of local rotation.

- Yo

Specify a value for the Y-component of the point of local rotation.

- Zo

Specify a value for the Z-component of the point of local rotation.

- Dir-x

Specify a value for the X-component of the orientation of the local rotation axis. Note that for 2D flows, the rotation axis is perpendicular to the XY plane.

- Dir-y

Specify a value for the Y-component of the orientation of the local rotation axis. Note that for 2D flows, the rotation axis is perpendicular to the XY plane.

- Dir-z

Specify a value for the Z-component of the orientation of the local rotation axis. Note that for 2D flows, the rotation axis is perpendicular to the XY plane.

- Omega [rps]

Specify a value for the angular velocity for the general mold motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vx

Specify a value for the X-component of the angular velocity. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vy

Specify a value for the Y-component of the angular velocity. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vz

Specify a value for the Z-component of the angular velocity. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Activation

Specify the volume conservation as: Program controlled, User controlled, or Disabled

- Initial fluid volume

Using the drop-down menu, you can enter a constant value for the initial fluid volume, or a valid expression (for transient simulations only)

- Initial fluid volume info

The initial fluid volume conservation is dictated by the solver.

- Inflation Pressure

Specify a value for the inflation pressure, or keep the default value.

- Time Dependency

Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Volume Flow Rate

Specify the normal volume flow rate. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient or continuation simulations only)

- Option

Specify an optional heat source on the surface of the film.

- Heat Flux

Specify a value for the constant heat flux on the surface of the film.

- Heat Transfer Coefficient

Specify a value for the heat transfer coefficient for the convection heat flux on the surface of the film. Using the drop-down menu, you can enter a constant value, or a valid expression.

- Convection Temperature

Specify a value for the heat transfer coefficient for the convection heat flux on the surface of the film. Using the drop-down menu, you can enter a constant value, or a valid expression.

Fluid cell zone property settings for your simulation.

- Type

Choose the type of cell zone, such as fluid, solid, porous media, moving mold, etc.

- Zones

Select one or more zones to apply to this cell zone.

- Fluid model

Specify a model for the fluid zone. You can choose from Generalized Newtonian, Simplified Viscoelastic, or Differential Viscoelastic.

The Generalized Newtonian model is described in Generalized Newtonian Flow.

The Simplified Viscoelastic model is described in Simplified Viscoelastic Model.

The Differential Viscoelastic model is described in Differential Viscoelastic Models.

The Integral Viscoelastic model is described in Integral Viscoelastic Models.

- Multiple Materials

Enable coextrusion modeling via transport of concentrations of different fluid materials.

- Fluid material(s)

Select a fluid material for the cell zone.

Some manufacturing processes may consist of fluid materials that contain reinforcing media (for example, fibers), embedded in a matrix. In such cases matrix reinforcement is available and can be activated for fluid cell zones when you have:

Transient flows

2D shell or 3D meshes

Generalized Newtonian fluid model

Lagrangian mesh deformation(s)

No inlets or outlets defined

When using matrix reinforcement, note the additional material properties that can be found in the material attached to the fluid cell zone (see Reinforcement Properties).

Some manufacturing processes may consist of fluid materials that exhibit bubbling or foaming. Such processes can only be modeled when you have:

Generalized Newtonian fluid model

No transient or VOF flows

No 2D shells

No multiple materials defined

If you want to extrude several fluids involving foaming, you must define one fluid cell zone per fluid material, define the interface between these fluids, and eventually activate the foaming on the cell zone where it exists.

When using foaming, note the additional material properties that can be found in the material attached to the fluid cell zone (see Foaming Properties)..

- Activate

Enable this option to activate the foaming properties of the fluid cell zone.

- Not Available

Displays a message describing when this feature is available.

- Enable Freezing

Enable this option to freeze the bubble radius on some parts of your fluid domain. Freezing the bubble radius in the die is common practice as foaming should not occur in a well tuned extrusion die.

- Freezing Zones

Select one or more zones where the bubble radius must be frozen.

Allows you to set properties of your solid cell zones in your simulation, specifically any aspects of the motion of the solid.

Solid cell zone motion property settings for your simulation.

- Activation

Enable or disable solid motion considerations.

Define the components of the solid's transport velocity.

- Vx

Specify a value for the X-component of the translational velocity of the solid motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vy

Specify a value for the Y-component of the translational velocity of the solid motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vz

Specify a value for the Z-component of the translational velocity of the solid motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

Allows you to set the properties of the porous media in your simulation.

For a porous media cell zone, describe the nature of the porous media in the simulation.

- Void fraction

Specify a value for the void fraction of the porous media.

- Mode

Choose how to specify the porosity. For instance, as a scalar or tensor.

- Permeability

Specify a value for the scalar permeability.

Specify the tensor (non-scalar) properties for the porous media definition.

- Pxx

Specify the positive-definite X-X Cartesian components of the tensor permeability.

- Pxy

Specify the positive-definite X-Y Cartesian components of the tensor permeability.

- Pxz

Specify the positive-definite X-Z Cartesian components of the tensor permeability.

- Pyy

Specify the positive-definite Y-Y Cartesian components of the tensor permeability.

- Pyz

Specify the positive-definite Y-Z Cartesian components of the tensor permeability.

- Pzz

Specify the positive-definite Z-Z Cartesian components of the tensor permeability.

Allows you to specify the properties of the fixed mold for your simulation.

- Zone

Specify the zone to be designated as the fixed mold.

Allows you to set the properties of any moving mold cell zones in your simulation.

For a moving mold cell zone, describe the characteristics of the mold body.

- Flip Darts Orientation

Change the direction of the darts, as shown in the graphics window: whether they are pointing toward the mold body or toward the mold cavity.

For a moving mold cell zone, describe the motion of the cell zone assigned to the mold.

- Motion type

Specify the type of mold motion as Translation velocity imposed, Translation force imposed or General velocity driven motion.

When translational velocity is imposed for a moving mold, define the properties of the mold's translational velocity.

- Vx

Specify a value for the X-component of the translational velocity of the mold motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vy

Specify a value for the Y-component of the translational velocity of the mold motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vz

Specify a value for the Z-component of the translational velocity of the mold motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

When translational force is imposed for a moving mold, define the properties of the mold's initial velocity.

- Vx

Specify a value for the X-component of the initial velocity of the mold motion.

- Vy

Specify a value for the Y-component of the initial velocity of the mold motion.

- Vz

Specify a value for the Z-component of the initial velocity of the mold motion.

When translational force is imposed for a moving mold, define the properties of the mold's translational force.

- Fx

Specify a value for the X-component of the translational force of the mold motion.

- Fy

Specify a value for the Y-component of the translational force of the mold motion.

- Fz

Specify a value for the Z-component of the translational force of the mold motion.

- Mass of the mold

Specify a value for the mass of the mold: corresponding to the total mass of the mold and of the moving part connected to the mold.

- Limit mold motion

Indicate whether or not you want to apply a limit to the mold motion.

- Max displacement

Specify a value for the maximum displacement. The value corresponds to the maximum admissible displacement along the direction specified by the force. The mold motion will continue until either the maximum displacement is reached, the specified time duration is reached, or the solution diverges.

When general velocity-driven motion is imposed for a moving mold, describe the properties of the mold's general motion.

Define the properties of the mold's initial displacement.

- Dx

Specify a value for the X-component of the initial displacement of the mold motion.

- Dy

Specify a value for the Y-component of the initial displacement of the mold motion.

- Dz

Specify a value for the Z-component of the initial displacement of the mold motion.

Define the properties of the mold's initial rotation.

- Alpha [deg]

Specify a value for the initial rotation angle for the mold motion.

Define the properties of the mold's initial rotation axis point of origin.

- Xo

Specify a value for the X-component of the point of local rotation.

- Yo

Specify a value for the Y-component of the point of local rotation.

- Zo

Specify a value for the Z-component of the point of local rotation.

Define the properties of the mold's initial rotation axis direction.

- Dir-x

Specify a value for the X-component of the orientation of the local rotation axis. Note that for 2D flows, the rotation axis is perpendicular to the XY plane.

- Dir-y

Specify a value for the Y-component of the orientation of the local rotation axis. Note that for 2D flows, the rotation axis is perpendicular to the XY plane.

- Dir-z

Specify a value for the Z-component of the orientation of the local rotation axis. Note that for 2D flows, the rotation axis is perpendicular to the XY plane.

Define the properties of the mold's angular velocity.

- Omega [rps]

Specify a value for the angular velocity for the general mold motion. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

Define the properties of the mold's translation velocity.

- Vx

Specify a value for the X-component of the angular velocity. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vy

Specify a value for the Y-component of the angular velocity. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

- Vz

Specify a value for the Z-component of the angular velocity. Using the drop-down menu, you can enter a constant value, or a valid expression (for transient simulations only)

Allows you to set mesh superposition properties on any moving part cell zones in your simulation.

For moving parts or restrictor cell zones, define the properties of the part motion.

For cell zones assigned as moving parts, describe the motion of any moving parts in your simulation, as well as their initial location (an initial displacement and/or rotation may be applied if the moving part location in the mesh file is not the actual initial location in the simulation).

Define the initial displacement of the moving part(s).

- Dx

Specify the X component of the initial displacement of the moving part.

- Dy

Specify the Y component of the initial displacement of the moving part.

- Dz

Specify the Z component of the initial displacement of the moving part.

Define the initial rotation of the moving part(s).

- Alpha [deg]

Specify a value for the initial rotation of the moving part.

Define the origin's position of the moving part(s) rotation axis.

- Xo

Specify the X coordinate of the local rotation axis for the moving part.

- Yo

Specify the Y coordinate of the local rotation axis for the moving part.

- Zo

Specify the Z coordinate of the local rotation axis for the moving part.

Define the direction of the moving part(s) rotation axis.

- Dir-x

Specify the X-component of the orientation of the local rotation axis for the moving part.

- Dir-y

Specify the Y-component of the orientation of the local rotation axis for the moving part.

- Dir-z

Specify the Z-component of the orientation of the local rotation axis for the moving part.

Define the angular velocity for the moving part(s).

- Omega [rpm]

Specify the angular velocity of the moving part.

Define the translational velocity for the moving part(s).

- Vx

Specify the X component of the translational velocity of the moving part.

- Vy

Specify the Y component of the translational velocity of the moving part.

- Vz

Specify the Z component of the translational velocity of the moving part.

Define the flow conditions for the moving part(s).

- Condition

Specify whether the flow condition for the cell zone is to be Stick or Slip.

- Max. slipping stress

Specify the maximum slipping stress for the cell zone. Below this value, a full stick condition is assumed; otherwise, a slip condition is modeled with this value (and no higher value) applied.

Define the thermal conditions for the moving part(s).

- Condition

Specify whether the thermal condition for the cell zone is to be Heat conduction or Temperature distribution.

- Tp

Specify the components of the temperature distribution. You can specify that the temperature distribution is defined as a linear function of the coordinates: f() - A+Bx+Cy+Dz

- A

Constant for the temperature distribution.

- B

Constant for the temperature distribution.

- C

Constant for the temperature distribution.

- D

Constant for the temperature distribution.

Allows you to set mesh superposition options for restrictor cell zones in your simulation.

For moving parts or restrictor cell zones, define the properties of the part motion.

Define the initial displacement of the part(s).

- Dx

Specify the X component of the initial displacement of the part.

- Dy

Specify the Y component of the initial displacement of the part.

- Dz

Specify the Z component of the initial displacement of the part.

For cell zones assigned as restrictors, describe the initial displacement (or translation) and/or rotation to locate the restrictor to its actual initial location.

Define the initial displacement of the moving part(s).

- Dx

Specify the X component of the initial displacement of the moving part.

- Dy

Specify the Y component of the initial displacement of the moving part.

- Dz

Specify the Z component of the initial displacement of the moving part.

Define the initial rotation of the moving part(s).

- Alpha [deg]

Specify a value for the initial rotation of the moving part.

Define the origin's position of the moving part(s) rotation axis.

- Xo

Specify the X coordinate of the local rotation axis for the moving part.

- Yo

Specify the Y coordinate of the local rotation axis for the moving part.

- Zo

Specify the Z coordinate of the local rotation axis for the moving part.

Define the direction of the moving part(s) rotation axis.

- Dir-x

Specify the X-component of the orientation of the local rotation axis for the moving part.

- Dir-y

Specify the Y-component of the orientation of the local rotation axis for the moving part.

- Dir-z

Specify the Z-component of the orientation of the local rotation axis for the moving part.

Fluid boundary zone property settings for your simulation. Typically, you will change the following properties:

Fluid boundary types consist of the following:

- 4.12.1.12.1. Inflow Fluid Boundary Properties

- 4.12.1.12.2. Outflow Fluid Boundary Properties

- 4.12.1.12.3. Wall Fluid Boundary Properties

- 4.12.1.12.4. Symmetry Fluid Boundary Properties

- 4.12.1.12.5. Free Surface Fluid Boundary Properties

- 4.12.1.12.6. Extrudate Exit Fluid Boundary Properties

- 4.12.1.12.7. Vent Fluid Boundary Properties

- 4.12.1.12.8. Zero Velocity Fluid Boundary Properties

- 4.12.1.12.9. Zero Force Fluid Boundary Properties

- 4.12.1.12.10. Porous Wall Fluid Boundary Properties

- 4.12.1.12.11. Force Fluid Boundary Properties

- 4.12.1.12.12. Thermal Condition Properties

- 4.12.1.12.13. Species Condition Properties

Properties related to the inflow fluid boundary condition.

- Flow specification

Select the flow conditions at the inlet boundary. You can choose to impose a mass flow rate, a volume flow rate, or a velocity.

- Velocity profile

You can choose to pre-compute the velocity profile corresponding to the given flow rate (fully developed), to compute it with the main flow (computed dynamically) or let the program decide automatically (program controlled)

- Incoming material

Specify the material that flows through the inlet.

- Volume flow rate

Provide the flow rate in terms of the volume of material that flows through the inlet.

- Mass flow rate

Provide the flow rate in terms of the mass of material that flows through the inlet.

- CSV Filename

Specify the name and location of the comma separated file that contains the inflow velocity profile.

- Field Name

Specify the field variable from the CSV file that you want to apply to the inflow velocity profile.

- Normal velocity

Provide the velocity of material that flows through the inlet.

- Allow non-zero tangential velocity

Deselecting this option forces the velocity to be strictly normal to the inlet.

Properties related to the outflow fluid boundary condition.

- Flow specification

Select the flow conditions at the outlet boundary. You can choose to impose a mass flow rate, a volume flow rate, or a pressure (default)

- Volume flow rate

Provide the flow rate in terms of the volume of material that flows through the outlet.

- Mass flow rate

Provide the flow rate in terms of the mass of material that flows through the outlet. you can enter a constant value, or a valid expression (for volume of fluid, transient or continuation simulations only)

- Gauge static pressure

Provide the pressure that you want to impose at the outlet. That pressure will determine the actual flow rate if pressure is imposed at inlet(s) or the level of pressure in the die if flow rate is imposed at inlet(s)

- CSV Filename

Specify the name and location of the comma separated file that contains the outflow velocity profile.

- Field Name

Specify the field variable from the CSV file that you want to apply to the outflow velocity profile.

- Normal velocity

Provide the velocity of material that flows through the outlet.

- Allow non-zero tangential velocity

Deselecting this option forces the velocity to be strictly normal to the outlet.

Properties related to the wall fluid boundary condition.

For more information, see Boundary Conditions in the Polyflow User's Guide.

- Slip specification

Select the flow conditions at the wall boundary. You can choose whether to impose a zero velocity (no slip), a friction force (partial slip), or no friction (free slip)

- Wall velocity

Indicate whether the wall boundary is a stationary wall, or a moving wall with an associated velocity.

- Slip model

For slip conditions, specify how the shear force is calculated with respect to the tangential relative velocity.

- Friction coefficient (Navier)

Specify the friction coefficient for the Navier law slip conditions.

- Friction coefficient (Navier)

Specify the friction coefficient for the Generalized Navier law slip conditions.

- Scaling factor (Generalized Navier)

Specify the scaling factor for the Generalized Navier law slip conditions.

- Exponent (Generalized Navier)

Specify the exponent for the Generalized Navier law slip conditions.

- First friction coefficient

Specify the first friction coefficient for the slip conditions.

- Second friction coefficient

Specify the second friction coefficient for the slip conditions.

- Friction coefficient (Asymptotic)

Specify the friction coefficient for the asymptotic slip conditions.

- Scaling factor

A scaling factor with the dimensions of the velocity. It affects the slope of the slip-velocity curve.

- Critical stress

The critical force density at which the friction coefficient changes. When this stress is exceeded, the second friction component is used.

- First Friction Coefficient

Specify the first friction coefficient for the generalized threshold law slip conditions.

- First Scaling Factor

Specify the first scaling factor for the generalized threshold law slip conditions. This scaling factor has the dimensions of the velocity, and it affects the slope of the first part the slip-velocity curve.

- Second Friction Coefficient

Specify the second friction coefficient for the generalized threshold law slip conditions.

- Second Scaling Factor

Specify the second scaling factor for the generalized threshold law slip conditions. This scaling factor has the dimensions of the velocity, and it affects the slope of the second part the slip-velocity curve.

- Exponent

Specify the exponent for the generalized threshold law slip conditions.

- Temperature dependence

Specify whether the thermal dependency is a constant, or it obeys a first-order approximation of the Arrhenius law, or it obeys the Arrhenius law.

- Activation energy ratio

Specify the ratio of the activation energy to the thermodynamic constant.

- Reference temperature

A reference temperature for which the thermal dependency function H(T) is 1.

- Pressure dependence

Specify the wall pressure dependency as either exponential or linear.

- Alpha

Specify a value for the linear pressure dependency.

- Beta

Specify a value for the exponential pressure dependency.

Define the axis of rotation by specifying the coordinates for the first of two points.

- X1

Specify the X component of the rotation axis for the first point.

- Y1

Specify the Y component of the rotation axis for the first point.

- Z1

Specify the Z component of the rotation axis for the first point.

Define the axis of rotation by specifying the coordinates for the second of two points.

- X2

Specify the X component of the rotation axis for the second point.

- Y2

Specify the Y component of the rotation axis for the second point.

- Z2

Specify the Z component of the rotation axis for the second point.

Represents the angular velocity for the rotating wall.

- Omega [rad/s]

Specify the magnitude of the angular velocity at which the wall is rotating about the axis defined by the two points Pt1 and Pt2.

Represents the translational velocity for the wall boundary.

- Vx

Specify the X component of the translational velocity for the wall boundary.

- Vy

Specify the Y component of the translational velocity for the wall boundary.

- Vz

Specify the Z component of the translational velocity for the wall boundary.

Properties related to the symmetry fluid boundary condition.

- Plane of symmetry

Specify the type of symmetry plane as either normal in the X, Y, or Z direction, or in an arbitrary normal direction.

- Nx

Specify the X value for the arbitrary normal direction of the symmetry plane.

- Ny

Specify the Y value for the arbitrary normal direction of the symmetry plane.

- Nz

Specify the Z value for the arbitrary normal direction of the symmetry plane.

Properties related to the free surface fluid boundary condition.

- Fixed part

Specify one or more surfaces to which the free surface is attached/fixed.

- Gauge Pressure

Specify the pressure applied on the free surface.

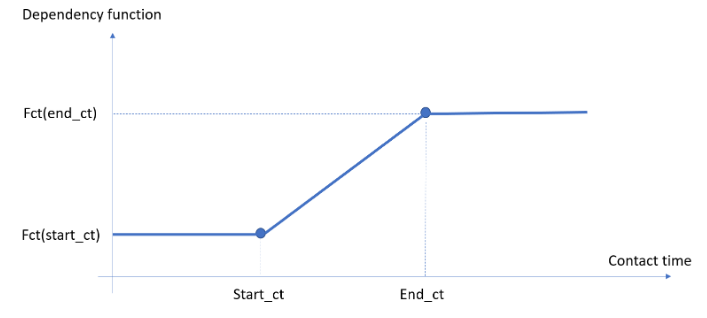

- Direction of Displacement