Ansys Polyflow has the ability to detect contact between a free surface and a wall that occurs over time. The wall is typically a mold for blow molding and thermoforming simulations, although the contact detection feature can be applied to other processes. The contact detection algorithm is applicable only for time-dependent problems.

After a free surface and wall have come into contact, it is possible to simulate their detachment (that is, contact release) under specific circumstances. Contact release typically takes place when the motion of a mold is reversed, or when the forming pressure results in the material being pulled away from a mold.

Blow molding is an important processing method for molding hollow articles such as bottles. The preform (parison) is usually made by extrusion or injection molding, and it is then forced between the mold halves by pressurization (blowing air). The polymer solidifies upon contact with the cold mold, and the finished product is ejected.

Contact detection is a local procedure that will be performed at each location along a free surface. As for all free surface problems, displacements of the free surface require the use of a remeshing scheme for the interior nodes. Some remeshing methods described in Remeshing, are particularly adapted to thin shell configurations. The use of a Lagrangian representation significantly facilitates calculations involving contact detection. This is reflected in the remeshing techniques that are available.

The context in which contact detection takes place is a free surface with limited space for expansion, such as in blow molding. The motion of the "solid" regions used to detect contact with the fluid can be prescribed with a velocity or a force in order to introduce a mold displacement in the simulation. This displacement will be calculated as the time integration of assigned or resulting velocity. This velocity or force can be a function of time, and cannot be imposed simultaneously.

Contact detection is available for both 2D and 3D problems. Contact detection is an attribute of each free surface. When contact detection is turned on for a particular free surface, you will need to specify the solid domain at the origin of the contact and the boundary of this solid domain along which contact will be detected.

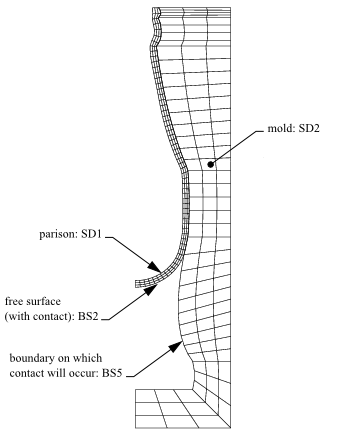

Consider, for example, the simple 2D blow molding application illustrated in Figure 17.1: Example of Contact Detection in Blow Molding, where the polymer has been defined to be SD1. Contact conditions for free surface BS2 are defined, so penetration will be checked with SD2. The contact surface is BS5.

From this example, it is clear that the solid domain in which contact will be detected cannot be included in the domain of the sub-task. Ansys Polydata ensures that this criterion is satisfied.