For the momentum transfer using CGM, the focus is to respect the first three

constraints listed in the previous section. The first two define that the terminal velocity of

the particles must be kept the same on the scaled-up system. This is important in fluidized

bed cases, for example, where the terminal velocity has an important role on the phenomena.

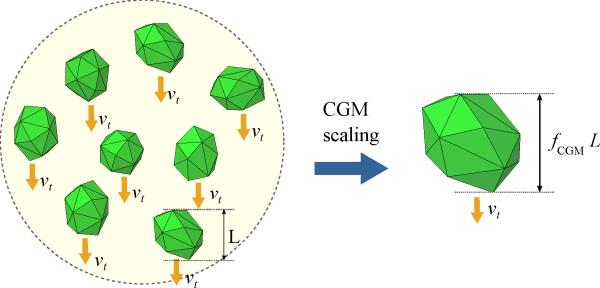

Figure 5.1: Terminal velocity conservation

when using CGM scale-up. shows the idea of the conservation of terminal

velocity on the scaled-up system. It shows a collection of small (original) particles falling

on a stagnant fluid that is replaced by a larger parcel (scaled-up particle), in which the CGM

upscaling imposes that the terminal velocity of the larger parcel is equal to the terminal

velocity of the original particles. In this example .

The third constraint is related to the pressure drop of the fluid flow when crossing a bed of static particles.

To satisfy this condition, the fluid forces over the parcel should be equal to the sum

of the fluid forces on each one of the original particles, which is approximated by the force

on a single particle times the number of particles the parcel represents, given by

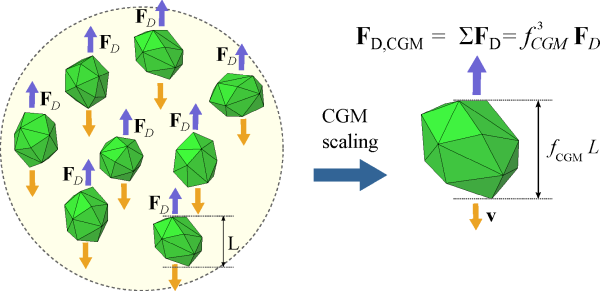

. Figure 5.2: Fluid force on a CGM parcel

is equal to the sum of the forces over the

original particles. shows the fluid force acting over the

parcel given as the sum of the fluid forces acting over all the original particles it

represents. In this example

.

Figure 5.2: Fluid force on a CGM parcel is equal to the sum of the forces over the original particles.

No correction is needed for the pressure-gradient force given by Equation 3–4 as the volume of the parcel is already equal to

times the volume of one of the original particles.

For the drag force, changes need to be applied to Equation 3–5 to satisfy the constraints. As the area of the parcel,

is equal to

, just a single scale-factor needs to be multiplied on the equation to

reach the total

factor needed. The drag force calculation when using the CGM model is

given by Equation 5–1.

(5–1) |

The the drag coefficient, , used on Equation 5–1 also needs to be corrected as

the drag coefficient calculated for the parcel has to have the same value as for a single

original particle in order to scale the drag force correctly. Inasmuch as the drag

coefficient is usually a function of the Reynolds number and the volume fraction of

particles, these two numbers must be kept same as for the original system for the sake of

obtaining the same drag coefficient.

The volume of the particles is kept the same on scaling-up, so there is no need to

change the volume fraction calculation. As the scaled particle size is used for the parcel

Reynolds number calculation, the fluid viscosity, , is also scaled with

with the aim of keeping the same Reynolds number for the scaled parcel and

the original particle. The corrected Reynolds number equation is shown in Equation 5–2.

(5–2) |

No correction is needed for the turbulent dispersion force, which is computed as described on section Turbulent dispersion force.

The virtual mass force, calculated using Equation 3–64 also does not need any modifications. It scales with the particle volume and its coefficient depends only on the particles? volume fraction.