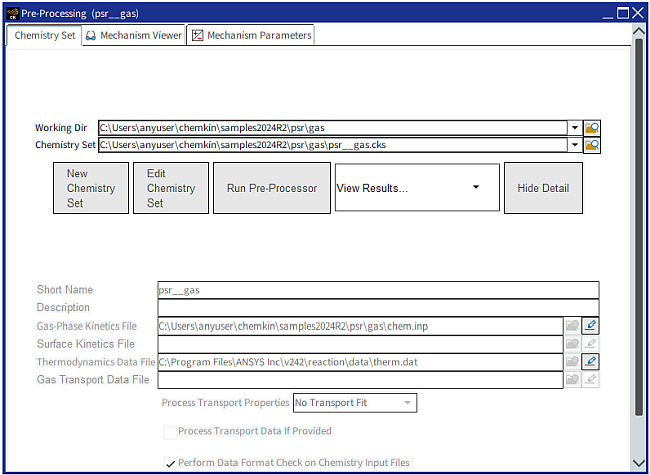

Before a Reactor Model can be set up or run, the chemistry set must be pre-processed and the Working Directory should be confirmed or established. When opening an existing project, this operation is performed automatically. However, when setting up a new project, you must define your chemistry set and then pre-process. The Pre-Processing panel can be opened or viewed by double-clicking on the Pre-Processing node in the psr__gas project tree of the Open Projects tab. Figure 2.7: psr__gas.ckprj—Pre-Processing shows this panel, which displays both the Working Dir and the chemistry set defined for the psr__gas.ckprj sample. The Working Dir is the directory or folder on your computer’s hard-disk where all generated input and output files will be created when the Reactor Model is run. The Chemistry Set does not need to be located in the same directory as the Working Directory and each input file contained within the Chemistry Set can be stored in any location.

From the Pre-Processing panel, a user may create a new chemistry set (described in more detail in Acquiring Chemical Data), edit an existing chemistry set, or select a different chemistry set. A chemistry set consists of input files that contain species and reaction descriptions, as well as thermodynamic data and, in some cases, gas transport-property data. Pre-processing these files serves to verify the consistency and completeness of the chemistry set. In addition, this step provides information to the User Interface about what chemical species are present in the system, and whether or not surface chemistry is present. Since this information is needed to populate subsequent reactor and inlet panels, the pre-processing step is required before any other input panels can be accessed in the project. There is also a Mechanism Viewer available for viewing details of a pre-processed mechanism, as described in Viewing Data with the Mechanism Viewer.

For this sample, we have a pre-defined setting for the Working Directory, which is located in the user’s local samples area. The chemistry set is also pre-defined for this project. The files contained within this set can be viewed with the pencil icon to the right of each text box. This sample chemistry represents hydrogen-air combustion.

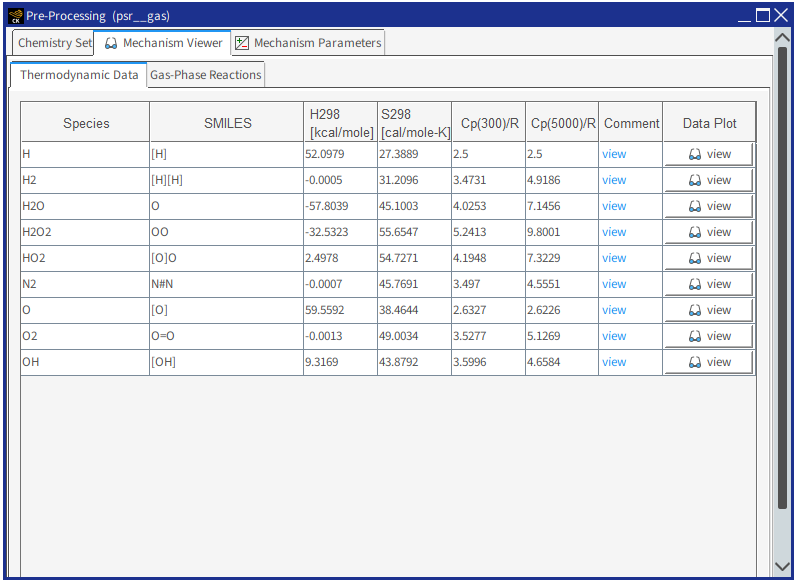

The Mechanism Viewer allows a quick view of the details of a pre-processed mechanism. To access the Mechanism Viewer, go to the second tab of the chemistry set Pre-Processing panel for any Ansys Chemkin project. The Mechanism Viewer permits quick inspection of the thermodynamic, transport, and both gas and surface reactions data from any chemistry set. Figure 2.8: Mechanism Viewer and Thermodynamic Data tab view shows the Mechanism Viewer utility for a sample gas-phase mechanism.

The Thermodynamic Data tab displays properties of all the gas-phase species in the chemistry set. Heat of formation, entropy, and heat capacity at 298 K are shown for the species. If Simplified Molecular Input Line Entry Specification (SMILES™) are specified for the species in the thermodynamic input section, they are displayed here next to species names. Additional information, such as heat capacities at higher temperatures and any comments, are also displayed. The Mechanism Viewer also allows you to quickly view a plot of the thermodynamic properties as a function of temperature, as illustrated in Figure 2.9: Plot of thermodynamic properties as a function of temperature for a species through the Mechanism Analyzer. The Transport Data tab shows the transport properties of all species.

Figure 2.9: Plot of thermodynamic properties as a function of temperature for a species through the Mechanism Analyzer

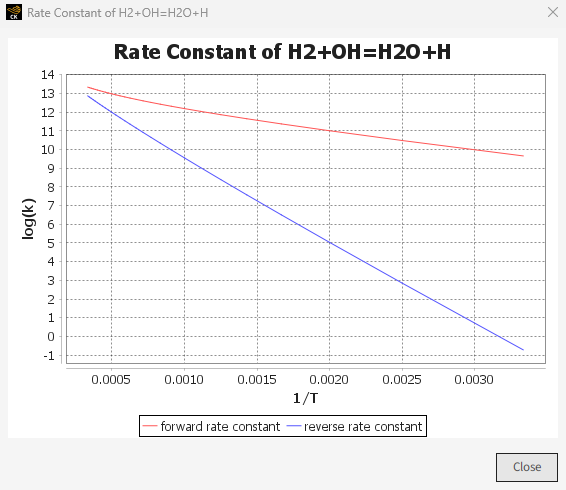

On the Gas-Phase and Surface Reactions tabs, all the reactions and their rate constants in the chemistry set are displayed. You can easily view a plot of the forward rate-constants (logarithmic) as a function of inverse of temperature. Note that only high-pressure-limit rate constants are plotted in the case of pressure-dependent rate constants for a reaction. In addition, reverse rate constants are calculated and displayed on this same plot, as shown in Figure 2.10: Plot of reaction rate constant as a function of temperature for a reaction through the Mechanism Analyzer. The reverse rate constants are calculated based on the microscopic reversibility using the thermodynamic properties, or from the reverse rate constant, if explicitly specified in the mechanism.

Note: Displaying the reverse rate constant plots uses the Chemkin KINetics API for calculation of rate constants. Therefore they will only be displayed if a valid license for Chemkin KINetics API is available.

Figure 2.10: Plot of reaction rate constant as a function of temperature for a reaction through the Mechanism Analyzer

In addition to pre-processing of the input data, two types of additional checks are performed on the mechanism. The first check is ON by default and inspects the data format, reporting any unexpected format issues. Identified issues are exported in text files in the working directory. The second check can be activated by the check box that is labeled Inspect Mechanism.This check invokes the Mechanism Inspector utility from Reaction Workbench (Mechanism Inspector in the Chemkin Reaction Workbench User's Manual) and highlights potential nonphysical rate constants and discontinuities in thermodynamic data. A pop-up window (like Results of the Mechanism Inspector utility in the Chemkin Reaction Workbench User's Manual) that lists the species and reactions will appear only if some issue is identified. These issues can potentially lead to convergence difficulties during simulation. We recommend addressing the identified issues prior to proceeding with the simulation.