The main task of primary breakup (or atomizer) models is to determine starting conditions for the droplets that leave the injection nozzle. These conditions are:

Initial particle radius

Initial particle velocity components

Initial spray angle

The radius, velocity, and spray angle parameters are influenced by the internal nozzle flow (cavitation and turbulence induced disturbances), as well as by the instabilities on the liquid-gas interface.

The following primary breakup models are available in CFX:

For the Blob, Enhanced Blob, and the LISA model, the initial injection spray angle must be specified explicitly, while for the Turbulence Induced Atomization model, the spray angle is computed within the model.

A large variety of approaches of different complexities are documented in literature. For a comprehensive model overview, see Baumgarten et al. [120].

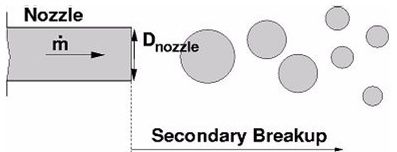

This is one of the simplest and most popular approaches to define

the injection conditions of droplets. In this approach, it is assumed

that a detailed description of the atomization and breakup processes

within the primary breakup zone of the spray is not required. Spherical

droplets with uniform size, , are injected that are subject

to aerodynamic induced secondary breakup.

Assuming non-cavitating flow inside the nozzle, it is possible to compute the droplet injection velocity by conservation of mass:

(6–107) |

is the nozzle

cross-section and

the

mass flow rate injected through the nozzle.

The spray angle is either known or can be determined from empirical correlations. The blob method does not require any special settings and it is the default injection approach in CFX.

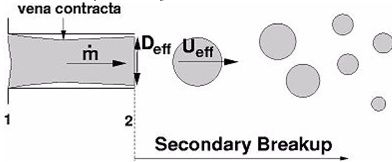

Kuensberg et al. [110] have suggested an enhanced version of the blob-method. Similar to the blob-method, it is assumed that the atomization processes need not be resolved in detail. Contrary to the standard blob-method, this method enables you to calculate an effective injection velocity and an effective injection particle diameter taking into account the reduction of the nozzle cross-section due to cavitation.

During the injection process, the model determines if the flow

inside the nozzle is cavitating or not and dynamically changes the

injection particle diameter and the particle injection velocity. The

decision, whether the flow is cavitating or not, is based on the value

of the static pressure at the vena contracta, , that is compared to the vapor pressure,

.

(6–108) |

with:

(6–109) |

is the coefficient

of contraction that depends on nozzle geometry factor, such as nozzle

length versus nozzle diameter or the nozzle entrance sharpness [114].

If is higher

than the vapor pressure,

, the flow

remains in the liquid phase and the injection velocity is set equal

to

.

(6–110) |

The initial droplet diameter is equal to the nozzle diameter, .

However, if is lower than

, it is assumed that the flow inside the nozzle is

cavitating and the new effective injection velocity,

, and injection diameter,

, are computed from a momentum balance from

the vena contracta to the nozzle exit (2):

(6–111) |

and:

(6–112) |

with:

(6–113) |

The following information is required for the enhanced blob method:

Contraction coefficient due to cavitation inside the injection nozzle.

Injection total pressure of the liquid - This information is required to compute the static pressure of the liquid at the vena contracta.

Injection total temperature of the liquid - This information is required to compute the static temperature of the liquid at the vena contracta, which is required to determine the fluid vapor pressure from an Antoine equation (homogeneous binary mixture).

Vapor pressure of the particle fluid

Two options are available to compute the material vapor pressure:

AutomaticandParticle Material Vapor Pressure.To specify the material vapor pressure directly, use the

Particle Material Vapor Pressureoption.To have CFX compute the particle material vapor pressure from a homogeneous binary mixture, use the

Automaticoption.

Normal distance of the pressure probe from the injection center - The fluid pressure at this position (marked as position 2 in Figure 6.2: Enhanced-blob Method) will be used to determine the acceleration of the liquid from the vena contract to the injection nozzle outlet.

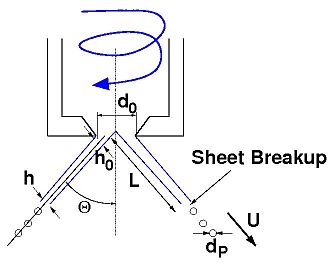

The LISA (Linearized Instability Sheet Atomization) model is able to simulate the effects of primary breakup in pressure-swirl atomizers as described in this section and presented in detail by Senecal et al. [126].

In direct-injection spark ignition engines, pressure swirl atomizers are often used in order to establish hollow cone sprays. These sprays are typically characterized by high atomization efficiencies. With pressure swirl injectors, the fuel is set into a rotational motion and the resulting centrifugal forces lead to a formation of a thin liquid film along the injector walls, surrounding an air core at the center of the injector. Outside the injection nozzle, the tangential motion of the fuel is transformed into a radial component and a liquid sheet is formed. This sheet is subject to aerodynamic instabilities that cause it to break up into ligaments.

Within the LISA model, the injection process is divided into two stages:

Due to the centrifugal motion of the liquid inside the injector,

a liquid film along the injector walls is formed. The film thickness, , at the injector exit

can be expressed by the following relation:

(6–114) |

where is the mass flow rate through

the injector,

is the particle

density, and

is the injector exit diameter. The quantity

is the axial

velocity component of the film at the injector exit and depends on

internal details of the injector. In CFX,

is calculated using

the approach of Han et al. [127]. It is assumed that the total velocity,

, is related

to the injector pressure by the following relation:

(6–115) |

where is the pressure

difference across the injector and

is the discharge coefficient, which is computed

from:

(6–116) |

Assuming that is known, the total

injection velocity can be computed from Equation 6–115. The axial film velocity component,

, is then

derived from:

(6–117) |

where is the spray angle, which is assumed

to be known. At this point, the thickness,

, and axial velocity component of the liquid

film are known at the injector exit. Note that the computed film thickness,

, will be equal to half

the injector nozzle diameter if the discharge coefficient,

, is larger than 0.7. The tangential component of

velocity (

) is assumed to be equal to the radial velocity component of the

liquid sheet downstream of the nozzle exit. The axial component of

velocity is assumed to remain constant.

After the liquid film has left the injector nozzle, it is subject to aerodynamic instabilities that cause it to break up into ligaments. The theoretical development of the model is given in detail by Senecal et al. [126] and is only briefly repeated here.

The model assumes that a two-dimensional, viscous, incompressible

liquid sheet of thickness moves with velocity

through a quiescent, inviscid,

incompressible gas medium. A spectrum of infinitesimal disturbances

is imposed on the initially steady motion, and is given in terms of

the wave amplitude,

, as:

(6–118) |

where is the initial wave amplitude,

is the wave number,

is the complex

growth rate,

is the streamwise film coordinate,

and

is the time. The most unstable

disturbance,

, has the largest value of

and is assumed to be responsible for sheet breakup.

As derived by Senecal et al. [126], can be computed by finding the

maximum of the following equation:

(6–119) |

here , that is, the ratio of

local gas density

to

particle densities

,

and

is the surface tension coefficient.

Once

is known, the breakup length,

, and the

breakup time,

, are given by:

(6–120) |

(6–121) |

where is the critical

wave amplitude at breakup and

is an empirical

sheet constant with a default value of 12.

The unknown diameter, , of the ligaments

at the breakup point is obtained from a mass balance. For wavelengths

that are long compared to the sheet thickness (

; here the Weber

Number,

, is based

on half the film thickness and the gas density),

is given by:

(6–122) |

using the long wave ligament factor, ,

of 8.0 (default) and

is the wave number

corresponding to the maximum growth rate,

.

For wavelengths that are short compared to the sheet thickness, is given by:

(6–123) |

In this case, the short wave ligament factor, , of 16.0 (default) is used and

is given by:

(6–124) |

The most probable droplet diameter that is formed from the ligaments is determined from:

(6–125) |

using the droplet diameter size factor of 1.88 (default) and is the

particle Ohnesorge number that is defined as:

(6–126) |

where is the Weber

Number based on half the film thickness and the gas density.

is the Reynolds Number based on the slip velocity.

Some of the settings for the simulation of primary breakup using the LISA model are:

Injection pressure difference,

Nozzle geometry (outer nozzle diameter

, injection half cone angle

)

Normal distance of the density probe from the injection center:

The LISA model requires knowledge of downstream density. The solver finds this density by probing the flow-field at a user-defined distance downstream of the injection location. This distance is a user input given via

Density Probe Normal Distanceoption in CFX-Pre.Swirl Definition

To add swirl to the flow of particles that stream from the injection region, select the Swirl Definition check box and then specify a non-dimensional value to impart a tangential velocity. The value that you specify is multiplied by the magnitude of the axial velocity (the axial velocity being directed normal to the injector inlet area, with a magnitude that satisfies mass continuity) in order to establish the (single) value for tangential velocity, to be applied over the entire injector inlet area. The direction of swirl depends on whether you specify a positive or negative value; the positive swirl direction is established by using the right-hand rule and the injector axis.

Particle mass flow rate,

For a complete list of required and optional settings for the LISA model and primary breakup models in general, see Settings for Particle Primary Breakup in the CFX-Pre User's Guide.

This atomization model is based on the modification of the Huh

and Gosman model as suggested by Chryssakis (see [155, 156]). It

accounts for turbulence induced atomization and can also be used to

predict the initial spray angle. The model assumes that turbulent

fluctuations within the injected liquid produce initial surface perturbations,

which grow exponentially by the aerodynamic induced Kelvin-Helmholtz

mechanism and finally form new droplets. The initial turbulent fluctuations

at the nozzle exit are estimated from simple overall mass, momentum

and energy balances. Droplets are injected with an initial diameter

equal to the nozzle diameter, .

It is assumed that unstable Kelvin-Helmholtz waves grow on their surfaces,

which finally break up the droplet. The effects of turbulence are

introduced by assuming, that the atomization length scale,

, is proportional to the turbulence length scale

and that the atomization time scale,

,

can be written as a linear combination of the turbulence time scale

(from nozzle flow) and the wave growth time scale (external aerodynamic

forces). At breakup, child droplets also inherit a velocity component

normal to their parents’ velocity direction. This is different

to the model suggested by Chryssakis, where child droplets did not

get this velocity component.

The initial spray angle is computed from the following relation:

(6–127) |

The model does not take effects of cavitation into account, but assumes that the turbulence at the nozzle exit completely represents the influence of the nozzle characteristics on the atomization process.

For the simulation of primary breakup using turbulence induced atomization, the following input data is needed:

Particle mass flow rate,

Injection pressure difference,

Normal distance of the density probe from the injection center

Nozzle length/diameter ratio - This is required for the calculation of the average turbulence kinetic energy and dissipation rates.

Nozzle discharge coefficient - This is the ratio of mass flow through nozzle to theoretically possible mass flow and can be specified optionally.

Primary breakup models are used to determine starting conditions for the droplets that leave the injection nozzle. To accomplish this task, the models use averaged nozzle outlet quantities, such as liquid velocity, turbulent kinetic energy, location and distribution of liquid and gas zones, as input for the calculation of initial droplet diameters, breakup times and droplet injection velocities. Because all detailed information is replaced by quasi 1D data, the following restrictions will apply:

Primary breakup model support will only be available for particle injection regions and not for boundary condition.

On particle injection regions, primary breakup will only be available for cone type injection, and only if the nozzle cross sectional area is larger than 0.