VM318

VM318

Simulation of Necking of a Circular Bar

Overview

| Reference: |

Simo, J. C. (1992). Algorithms for static and dynamic multiplicative plasticity that preserve the classical return mapping schemes of the infinitesimal theory. Computer Methods in Applied Mechanics and Engineering, (99), 61-112. |

| Analysis Type(s): | Static (ANTYPE,0) |

| Element Type(s): |

2-D Structural Elements (PLANE182) 3-D Structural Elements (SOLID185) |

| Input Listing: | vm318.dat |

Test Case

A bar with a circular cross section is under uniaxial tension. The bar is geometrically imperfect: The radius reduces linearly from the bar end R to the bar middle which equals 0.982*R. The bar, however, is symmetrical along the axis. When the bar elongates under the uniaxial tension, the cross section in the middle starts to shrink. Displacement at the middle section is obtained and compared to the reference results.

| Material Properties | Geometric Properties | Loading | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Neo-Hookean Model:

Nonlinear isotropic hardening (VOCE):

|

Bar is circular with radius linearly reduced from the bar end R to the bar middle 0.982*R.

The length L of the bar:

| Bar elongates 7 mm at one end. |

Analysis Assumptions and Modeling Notes

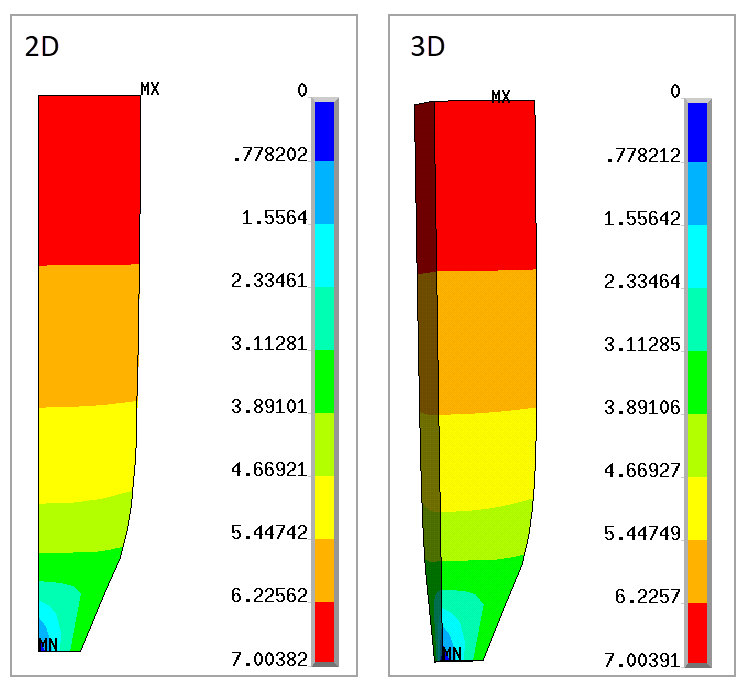

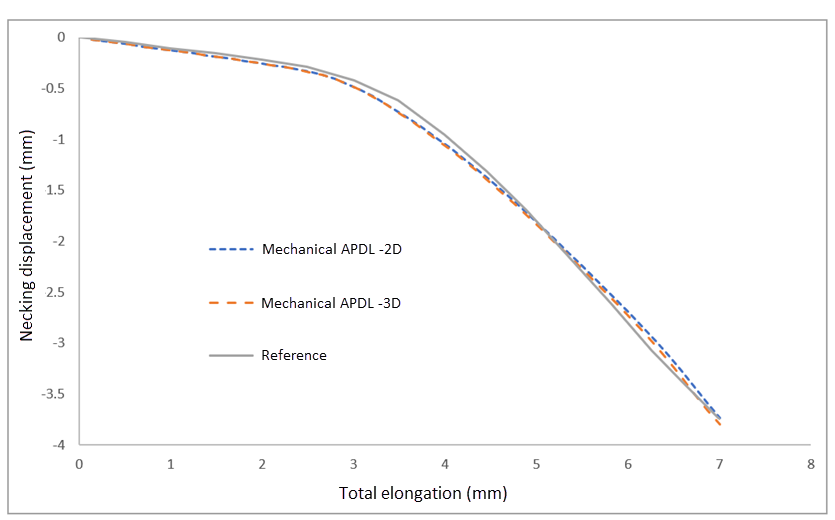

The problem is solved in two ways:

The material is defined by TB,HYPER,,,,NEO and TB, NLISO,,,,VOCE. Because the bar is symmetrical along the axis, a half-bar is simulated. NLGEOM,ON must be set in the solution setting. After the bar elongates 7 mm, the necking of the bar is plotted by PLNSOL in /POST1 (see Figure 580: Final Deformation of the Circular Bar) and obtained by *GET in /POST1 and NSOL in /POST26 (see Figure 581: Displacement at the Middle Section Versus Total Elongation).