VM199

VM199

Oil Film Bearing Supporting a Rotating Shaft and Subjected to a Static

Load

Overview

| Reference: | Friswell, M.I., Penny, J.E.T., Garvey, S.D., Lees, A.W., Dynamics of Rotating Machines, Cambridge University Press, 2010, pg. 181 |

| Analysis Type(s): | |

| Element Type(s): | |

| Input Listing: | vm199.dat |

Test Case

An oil film bearing defined by its radial clearance, diameter, and length supports a rotating shaft and is subjected to a static vertical load of 525 N. Calculate the bearing eccentricity ratio and the bearing coefficients under these conditions.

| Material Properties | Geometric Properties | Loading | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

Analysis Assumptions and Modeling Notes

A simplistic bearing-shaft model is created using:

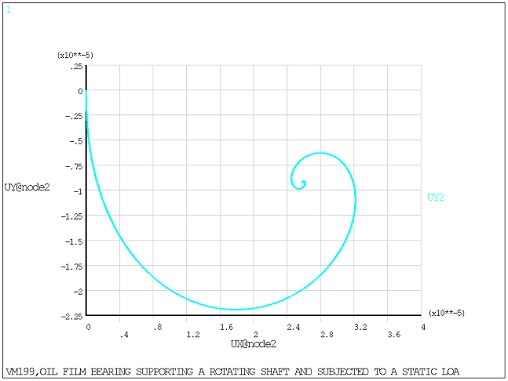

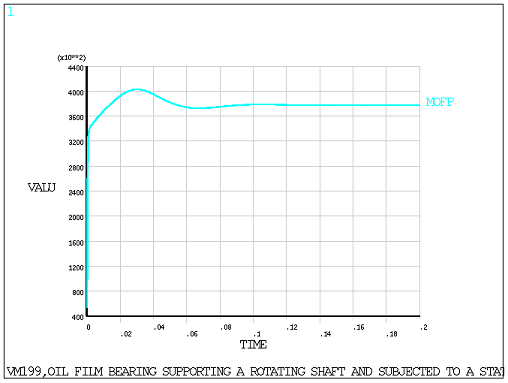

Nonlinear transient analysis is first performed on the model with an end time of 0.20 seconds (5 cycles)

For the 2D model, a time increment of 1.0 x 10-4 seconds is set to determine the shaft equilibrium position and eccentricity ratio. The shaft rotational velocity in rad/sec is specified using nodal constraint (D,,OMGZ).

The shaft equilibrium position obtained from transient analysis, along with a small perturbation increment, is used in a static analysis to determine the bearing stiffness and damping coefficients:

For the 2D model: The shaft equilibrium position is input via the D command and the perturbation increment is input via COMBI214 real constants. The shaft rotational velocity in rad/sec is specified via the OMEGA command in the linear static solve.

For the 3D model: The shaft equilibrium position is input via FLUID218 real constants. A small perturbation (1E-6) is given about the equilibrium position and the bearing forces are calculated. Using these bearing forces, the stiffness and damping characteristics are evaluated.

Results Comparison

| 2D | Units | Target | Mechanical APDL | Ratio |

|---|---|---|---|---|

| Eccentricity Ratio | - | 0.266 | 0.275 | 0.969 |

| KXX | MN/m | 12.810 | 12.567 | 1.019 |

| KYY | MN/m | 8.815 | 8.712 | 1.012 |

| KXY | MN/m | 16.390 | 15.818 | 1.036 |

| KYX | MN/m | -25.060 | -24.433 | 1.026 |

| CXX | kNs/m | 232.900 | 225.410 | 1.033 |

| CYY | kNs/m | 294.900 | 287.068 | 1.027 |

| CXY | kNs/m | -81.920 | -80.406 | 1.019 |

| CYX | kNs/m | -81.920 | -80.461 | 1.018 |

| 3D | Units | Target | Mechanical APDL | Ratio |

|---|---|---|---|---|

| KXX | MN/m | 12.810 | 12.139 | 1.055 |

| KYY | MN/m | 8.815 | 8.017 | 1.100 |

| KXY | MN/m | 16.390 | 15.910 | 1.030 |

| KYX | MN/m | -25.060 | -24.210 | 1.035 |

| CXX | kNs/m | 232.900 | 224.511 | 1.037 |

| CYY | kNs/m | 294.900 | 285.459 | 1.033 |

| CXY | kNs/m | -81.920 | -76.167 | 1.076 |

| CYX | kNs/m | -81.920 | -84.654 | 0.968 |