VM200

VM200

Viscoelastic Sandwich Seal Analysis

Overview

| Reference: | T. F. Soules, R. F. Busbey, S. M. Rekhson, A. Markkovsky, M. A. Burkey, "Finite Element Calculations of Residual Stresses in Glass Parts Using MARC", General Electric Company (Nela Park), Report # 86-LRL-2022, Cleveland, OH, March 1986. |

| Analysis Type(s): | Static Analysis (ANTYPE = 0) |

| Element Type(s): | |

| Input Listing: | vm200.dat |

Test Case

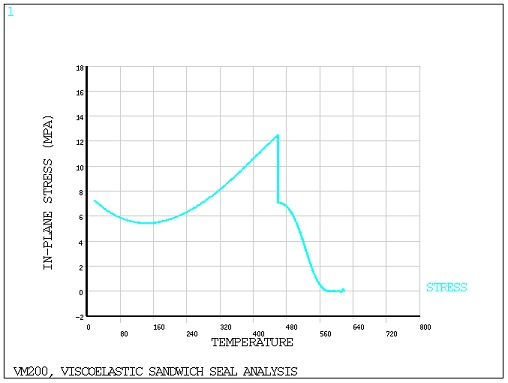

A sandwich seal made of an alumina plate with G-11 glass cladding on both sides is cooled at 3° per minute from 618°C to 460°C and held isothermally for four hours. The seal is further cooled at 3° per minute to 18°C. FInd the maximum in-plane stress (σmax) developed in the seal along with the corresponding temperature.

| Material Properties | Geometric Properties | Loading | ||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

Analysis Assumptions and Modeling Notes

The problem is solved first using 2D structural solid elements (PLANE183) and then using 3D structural solid elements (SOLID186).

In the 2D case, due to the fact that the stresses will be the same in X and Z directions because of symmetry, an axisymmetric analysis is performed with the nodal degrees of freedom coupled in appropriate directions. The radial thickness of 0.2 cm is arbitrarily selected. Nodes 21 through 25 are coupled in the X-direction (radial coupling). Nodes with the same Y-location are coupled in Y-direction (axial coupling).

In the 3D case, an arbitrary thickness of 0.2 cm is assumed in both Y and Z directions. Nodal degrees of freedom are coupled in appropriate directions to simulate the correct physical behavior in the finite element model.

The alumina is not a viscoelastic material, however, its material properties are input using viscoelastic format so that only one element type (PLANE183 in 2D and SOLID186 in 3D) can be used for both materials. Also, note that the viscoelastic material does not require the MP command for inputting the material properties. POST26 is used to extract the results from the solution phase.