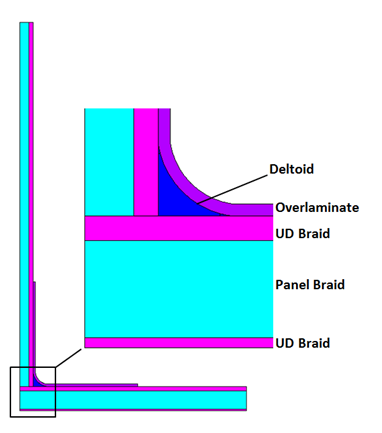

The 2D T-Joint model is a carbon-fiber-based braided composite with two panels of laminated braids and the deltoid. A half model is used for the simulation due to the symmetry. The following figure shows a schematic configuration of the laminates with layup details.

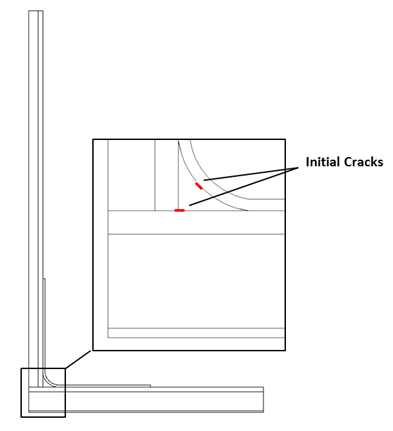

The dominant delamination occurs along the interface between the deltoid and overlaminate in the curve area first and then grows up to the end of laminate. During the first delamination process, a second delamination also starts between two panels which completely separate the panels. Based on the study of T-Joint failure, therefore, two critical locations of higher interlaminar stresses are considered as the initial failure points. For the simulation, two small cracks are defined at these critical locations, as shown in this figure:

The fracture energy and interlaminar material strength are based on reference results.[3]

A VCCT-based crack-growth simulation requires the following operations: