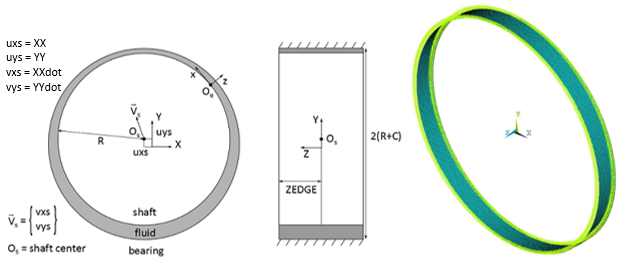

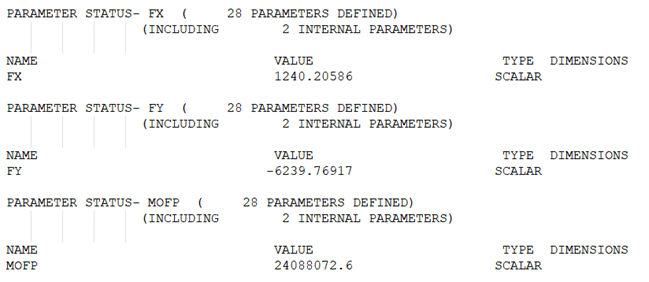

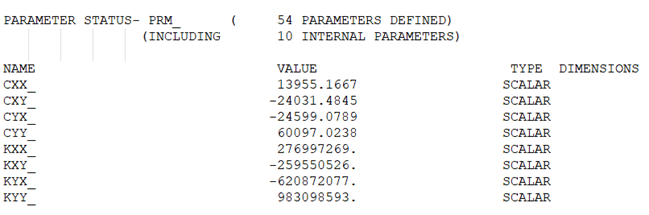

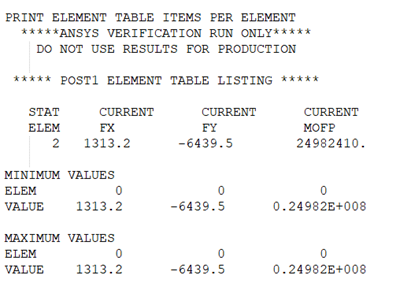

In this example, a 3D model of a plain cylindrical journal bearing is created using FLUID218 element, supporting a shaft rotating at 10,000 RPM as shown in Figure 7.40: Model of a Plain Cylindrical Journal Bearing. The stiffness and damping characteristics are calculated about the adimensional equilibrium position XX = 0.5, YY = -0.7, XXdot = YYdot = -0.05.

In order to evaluate the bearing characteristics, a small perturbation = 1 x 10-5 is given about the equilibrium position and the bearing forces are calculated. Using these bearing forces, the stiffness and damping characteristics are evaluated.

The bearing characteristics of the FLUID218 element model are compared with the bearing characteristics of the COMBI214 element model.

The bearing properties are as follows:

Clearance: 7.62 x 10-5 m

Length: 1.143 x 10-2 m

Radius: 6.477 x 10-2 m

Viscosity: 2.632 x 10-3 Pa˙s

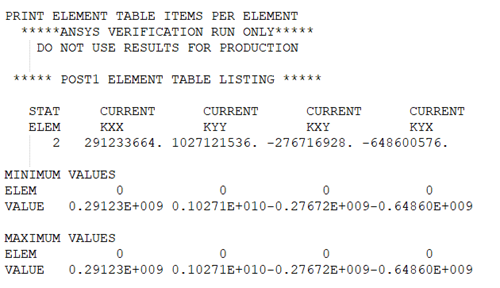

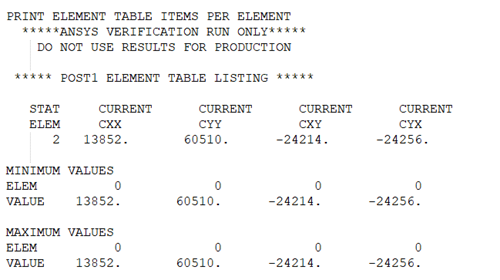

/title, Calculation of a 3D Hydrodynamic Bearing Characteristics /out,scratch /com, ************************************************************************ /com, Case 1: Force calculation @ equilibrium position (X ,Y, XXdot, YYdot) /com, ************************************************************************ /filnam,case1 ! Parameters (corresponding to non dimensional input) pi = 4*atan(1) mshaft = 1 xclear = 7.62e-5 lshaft = 0.01143 rshaft = 0.06477 roshaft = mshaft/(lshaft*pi*rshaft**2) ! equivalent density mu = 0.002632 omegaj = 1e4 pertInc = 1e-5 XX = 0.5 YY = -0.7 XXdot = -0.05 YYdot = -0.05 veloc1 = XXdot*xclear*omegaj veloc2 = YYdot*xclear*omegaj zedge = -lshaft/2 /prep7 et,1,185 ! only used for FLUID218 meshing mp,ex,1,1.0e11 mp,nuxy,1,mu mp,dens,1,0.32051 cylind,0,rshaft,-lshaft/2,lshaft/2,0,90 cylind,0,rshaft,-lshaft/2,lshaft/2,90,180 cylind,0,rshaft,-lshaft/2,lshaft/2,180,270 cylind,0,rshaft,-lshaft/2,lshaft/2,270,360 nummrg,kp esize,0.001 type,1 mat,1 vmesh,all et, 2, 218 keyopt,2,1,0 ! PRES only dof sectype,2,shell secdata, xclear r, 2, xclear, rshaft,XX*xclear,YY*xclear, veloc1, veloc2 rmore, zedge mp,visc,2,mu mp,dens,2,roshaft type,2 mat,2 real,2 csys,1 nsel,,loc,x,rshaft esln esurf csys,0 allsel ! --- remove solid elements vclear,all etdele,1 ! --- boundary conditions nsel,,loc,z,-lshaft/2 nsel,a,loc,z,lshaft/2 d, all, pres, 0.0d0 ! zero pressure at both ends allsel finish save /solu antype, static omega,,, omegaj outres,all,all solve fini /post1 file,case1,rst set,last esel,,type,,2 nsle ! sum the forces and moments to get total quantities *get,nelem,ELEM,0,COUNT f11 = 0 f12 = 0 ielem = 0 *do,iloop,1,nelem ielem = ELNEXT(ielem) *get,con,ELEM,ielem,NMISC,11 f11 = f11 + con *get,con,ELEM,ielem,NMISC,12 f12 = f12 + con *enddo allsel,all /show,png,rev /view,1,1,1,1 plnsol,pres *get,presmax,plnsol,0,max /show,close fx = f11 fy = f12 mofp = presmax /out, /com, ************************************************************************* /com, Forces and Pressures @ equilibrium position using FLUID218 element model /com, ************************************************************************* *status,fx *status,fy *status,mofp /out,scratch parsav,all,temprm,parm finish /clear,nostart /com, ************************************************************** /com, Case 2: Force calculation @ equilibrium position with small /com, perturbation "dX" (X+dX, Y, XXdot, YYdot) /com, ************************************************************** /out,scratch /filnam,case2 /prep7 resume,case1,db rdel,2 ! Parameters (corresponding to non dimensional input) dX = pertInc XXX = XX + dX r,2,xclear, rshaft,XXX*xclear,YY*xclear, veloc1, veloc2 rmore, zedge fini save /solu antype, static omega,,, omegaj outres,all,all solve fini /post1 file,case2,rst set,last esel,,type,,2 nsle ! sum the forces and moments to get total quantities *get,nelem,ELEM,0,COUNT f21 = 0 f22 = 0 ielem = 0 *do,iloop,1,nelem ielem = ELNEXT(ielem) *get,con,ELEM,ielem,NMISC,11 f21 = f21 + con *get,con,ELEM,ielem,NMISC,12 f22 = f22 + con *enddo allsel,all *status,f21 *status,f22 *status,presmax parres,change,temprm,parm parsav,all,temprm,parm finish /clear,nostart /com, ************************************************************** /com, Case 3: Force calculation @ equilibrium position with small /com, perturbation "dY" (X,Y+dY, XXdot, YYdot) /com, ************************************************************** /out,scratch /filnam,case3 /prep7 resume,case1,db rdel,2 ! Parameters (corresponding to non dimensional input) dY = pertInc YYY = YY + dY r, 2, xclear, rshaft,XX*xclear,YYY*xclear, veloc1, veloc2 rmore, zedge fini save /solu antype, static omega,,, omegaj outres,all,all solve fini /post1 file,case3,rst set,last esel,,type,,2 nsle ! sum the forces and moments to get total quantities *get,nelem,ELEM,0,COUNT f31 = 0 f32 = 0 ielem = 0 *do,iloop,1,nelem ielem = ELNEXT(ielem) *get,con,ELEM,ielem,NMISC,11 f31 = f31 + con *get,con,ELEM,ielem,NMISC,12 f32 = f32 + con *enddo allsel,all *status,f31 *status,f32 *status,presmax parres,change,temprm,parm parsav,all,temprm,parm finish /clear,nostart /com, ********************************************************************* /com, Case 4: Force calculation @ equilibrium position with small /com, perturbation "dXXdot" (X, Y, XXdot+dXXdot, YYdot) /com, ********************************************************************* /out,scratch /filnam,case4 /prep7 resume,case1,db rdel,2 ! Parameters (corresponding to non dimensional input) dXXdot = pertInc XXXdot = XXdot + dXXdot veloc1x = XXXdot*xclear*omegaj r, 2, xclear, rshaft,XX*xclear,YY*xclear, veloc1x, veloc2 rmore, zedge fini save /solu antype, static omega,,, omegaj outres,all,all solve fini /post1 file,case4,rst set,last esel,,type,,2 nsle ! sum the forces and moments to get total quantities *get,nelem,ELEM,0,COUNT f41 = 0 f42 = 0 ielem = 0 *do,iloop,1,nelem ielem = ELNEXT(ielem) *get,con,ELEM,ielem,NMISC,11 f41 = f41 + con *get,con,ELEM,ielem,NMISC,12 f42 = f42 + con *enddo allsel,all *status,f41 *status,f42 *status,presmax parres,change,temprm,parm parsav,all,temprm,parm finish /clear,nostart /com, ********************************************************************* /com, Case 5: Force calculation @ equilibrium position with small /com, perturbation of "dYYdot" (X,Y, XXdot, YYdot+dYYdot) /com, ********************************************************************* /out,scratch /filnam,case5 /prep7 resume,case1,db rdel,2 ! Parameters (corresponding to non dimensional input) dYYdot = pertInc YYYdot = YYdot + dYYdot veloc2y = YYYdot*xclear*omegaj r, 2, xclear, rshaft,XX*xclear,YY*xclear, veloc1, veloc2y rmore, zedge fini save /solu antype, static omega,,, omegaj outres,all,all solve fini /post1 file,case5,rst set,last esel,,type,,2 nsle ! sum the forces and moments to get total quantities *get,nelem,ELEM,0,COUNT f51 = 0 f52 = 0 ielem = 0 *do,iloop,1,nelem ielem = ELNEXT(ielem) *get,con,ELEM,ielem,NMISC,11 f51 = f51 + con *get,con,ELEM,ielem,NMISC,12 f52 = f52 + con *enddo allsel,all *status,f51 *status,f52 *status,presmax parres,change,temprm,parm parsav,all,temprm,parm finish /out, /com, ************************************************** /com, Bearing characteristics of FLUID218 element model /com, ************************************************** /out,scratch parres,new,temprm,parm /com, ************************************************** /com, Stiffness calculation /com, ************************************************** dX = dX*xclear dY = dY*xclear KXX_ = (f21-f11)/dX KYY_ = (f32-f12)/dY KXY_ = (f31-f11)/dY KYX_ = (f22-f12)/dX /com, ************************************************** /com, Damping calculation /com, ************************************************** dXXdot = dXXdot*xclear*omegaj dYYdot = dYYdot*xclear*omegaj CXX_ = (f41-f11)/dXXdot CYY_ = (f52-f12)/dYYdot CXY_ = (f51-f11)/dYYdot CYX_ = (f42-f12)/dXXdot /out, /com, ************************************************** /com, Stiffness and Damping characteristics of FLUID218 /com, element model /com, ************************************************** *status,PRM_ /clear,nostart /out, /com, ***************************************************** /com, Bearing characteristics of COMBI214 /com, ***************************************************** /out,scratch /filnam,case6 ! Resume parameters (corresponding to non dimensional input) parres,new,temprm,parm /prep7 n, 1, -1 n, 2, 0 n, 3, 0, -1 et, 1, 21,,,2 ! 3D mass, no rotary inertias r, 1, mass, type,1 real,1 e, 2 et, 2, 214 keyopt,2,1, 2 ! get outputs r, 2, xclear, lshaft, rshaft, veloc1, veloc2,pertInc mp,visc,2,mu type,2 real,2 mat,2 e, 1, 2, 3 d, all, all, 0.0 ddel, 2, UX ddel, 2, UY fini save /solu antype, static omega,,, omegaj d,2,ux,XX*xclear d,2,uy,YY*xclear outres,all,all solve fini /post1 file,case6,rst set,last esel,,elem,,2 etable, fx, smisc,1 etable, fy, smisc,2 etable, mofp, nmisc,3 /out, /com, ************************************************************************* /com, Forces and Pressures @ equilibrium position using COMBI214 element model /com, ************************************************************************* pretab /out,scratch etable, kxx, nmisc,7 etable, kyy, nmisc,8 etable, kxy, nmisc,9 etable, kyx, nmisc,10 /out, /com, *************************************************** /com, Stiffness characteristics of COMBI214 element model /com, *************************************************** pretab, kxx, kyy, kxy, kyx /out,scratch etable, cxx, nmisc,11 etable, cyy, nmisc,12 etable, cxy, nmisc,13 etable, cyx, nmisc,14 /out, /com, *************************************************** /com, Damping characteristics of COMBI214 element model /com, *************************************************** pretab, cxx, cyy, cxy, cyx finish