The following example shows the computation of pressure distribution in a three-lobe journal bearing. The input clearance as a function of the angular position can be downloaded here.

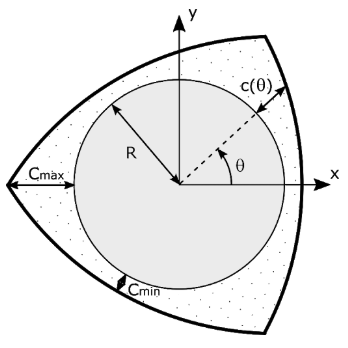

The fluid pressure and thickness distributions are computed in a static analysis. The rotor is a cylindrical shaft rotating at 200 rad/s whose equilibrium position in the stator is (-4.2, -35.0) x (1x10-6) m. The bearing cross-section geometry consists of three lobes as shown in Figure 7.45: Three-Lobe Journal Bearing Cross-Section Geometry. The clearance is defined as a function of angular position (θ) as:

(7–1) |

Where Cmax and Cmin are the maximum and

minimum clearance, respectively, and is the angular position of the lobe center i,

i ∈ {1,2,3}.

The bearing fluid film is modeled with FLUID218 elements with node-based clearance following Equation 7–1 in element real constants.

The bearing properties are as follows:

Length: 0.1 m

Shaft radius: 0.1 m

Fluid viscosity: 0.12 Pa·s

Minimum clearance: 9 x 10-4 m

Maximum clearance: 22 x 10-4 m

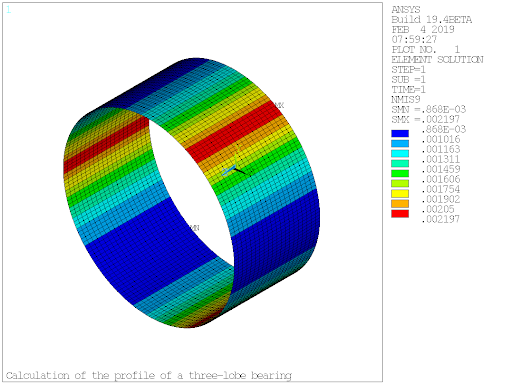

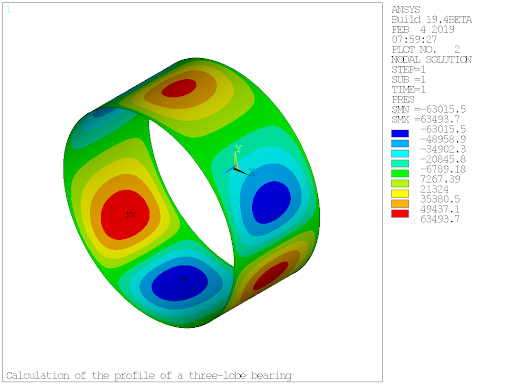

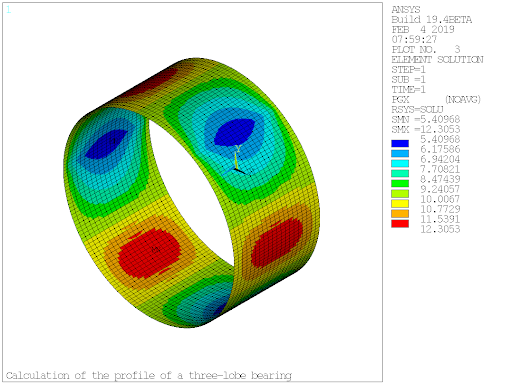

/title,Calculation of the Profile of a Three-lobe Bearing /out,scratch !============ ! PARAMETERS !============ pi = acos(-1) eps = 1e-6 ! accuracy for node selection ! Three-Lobe Bearing Parameters ! ------------------------------ bearingLength = 0.1 ! length of the bearing Nlobe = 3 ! number of lobes Cmax = 0.0022 ! maximum clearance (at lobes edges) Cmin = 0.0009 ! minimum clearance (at lobes center) alpha = 2*pi/Nlobe ! arc angle of the lobes offsetRatio = 0.5 ! angular offset ratio Dclear = Cmin - Cmax ! delta of clearance ! Shaft (Stator) Parameters ! ------------------------- shaftRadius = 0.1 ! radius shaftPosX = -4.2e-6 ! X-position inside the bearing shaftPosY = -3.5e-5 ! Y-position inside the bearing ! Fluid Properties ! ----------------- fluidVisc = 0.12 ! viscosity fluidDens = 1000 ! density ! Meshing Parameters ! ------------------ NeltCirc = 200 ! number of elements along bearing circumference NeltLength = 20 ! number of axial elements ! Loading ! ------- omg = 200 ! rotational velocity !====================== ! READ CLEARANCE INPUT !====================== *dim,clearanceArray,array,NeltCirc+1,2 *vread,clearanceArray(1,1),clearanceInput,txt,,JIK,2,NeltCirc+1 (F5.1,F10.8) !=============== ! PRE-PROCESSING !=============== /prep7 ! Geometry ! -------- ! Create shaft for virtual use in FLUID218 (suppressed at the end) cylind,0,shaftRadius,0,bearingLength,0,90 cylind,0,shaftRadius,0,bearingLength,90,180 cylind,0,shaftRadius,0,bearingLength,180,270 cylind,0,shaftRadius,0,bearingLength,270,360 NUMMRG,KP ! Material Properties ! ------------------- ! Shaft (virtual parameters) mp,ex,1,2e9 mp,prxy,1,0.3 mp,dens,1,8000 ! Fluid parameters mp,visc,2,fluidVisc mp,dens,2,fluidDens ! Meshing ! ------- ! Mesh the shaft et,1,solid185 csys,1 ! basis circumference lsel,s,loc,z,0 lsel,a,loc,z,bearingLength lsel,r,loc,x,shaftRadius lesize,all,,,NeltCirc/4 ! basis interior lines lsel,s,loc,x,shaftRadius lsel,inve lsel,r,loc,z,0 lesize,all,,,NeltCirc/4 lsel,s,loc,x,shaftRadius lsel,inve lsel,r,loc,z,bearingLength lesize,all,,,NeltCirc/4 ! longitudinal lsel,all lsel,u,loc,z,0 lsel,u,loc,z,bearingLength lesize,all,,,NeltLength csys,0 ! sweep mesh allsel type,1 mat,1 vsweep,all ! Mesh bearing fluid et,2,fluid218 type,2 mat,2 ! loop over angular position *DO,i,1,NeltCirc,1 etid = i + 1 ! create real constant r,etid,0,shaftRadius,shaftPosX,shaftPosY rmore,,clearanceArray(i,2),clearanceArray(i+1,2),clearanceArray(i+1,2),clearanceArray(i,2) ! create elements real,etid ! select elements wrt angular position and mesh csys,1 nsel,s,loc,x,shaftRadius nsel,r,loc,y,clearanceArray(i,1)-eps,clearanceArray(i+1,1)+eps esln esel,r,cent,y,clearanceArray(i,1),clearanceArray(i+1,1) esurf csys,0 *ENDDO ! Clear solid elements allsel vclear,all etdele,1 numcmp,all ! Boundary Conditions ! -------------------- nsel,s,loc,z,0 nsel,a,loc,z,bearingLength d,all,pres,0 ! zero pressure at both ends allsel save finish !=================== ! SOLUTION PROCESSOR !=================== /solu antype,static omega,,,omg solve finish !================= ! POST-PROCESSING !================= /post1 set,last allsel *get,eltNum,elem,,count ! Get Maximum Pressure ! -------------------- nsort,pres,,1 *get,maxPressure,sort,0,max *get,maxPressureNode,sort,0,imax csys,1 maxPressureAngle = ny(maxPressureNode) csys,0 ! Get Minimum Film Thickness ! -------------------------- etable,H,nmisc,1 esort,etab,h,1 *get,minThickness,sort,0,min *get,eltMinThickness,sort,0,imin *get,nodeMinThickness,elem,eltMinThickness,node,1 csys,1 minThicknessAngle = ny(nodeMinThickness) csys,0 ! Get Total Forces ! ----------------- ielem = 0 forceX = 0 forceY = 0 *DO,i,1,eltNum ielem = elnext(ielem) *GET,CON,elem,ielem,NMISC,11 forceX = forceX + CON *GET,CON,elem,ielem,NMISC,12 forceY = forceY + CON *ENDDO ! Get Attitude Angle ! ------------------ angLoad = atan(forceY/forceX)*180/pi angCenter = atan(shaftPosY/shaftPosX)*180/pi angAtt = angCenter - angLoad ! Results Plots ! ------------- /show,png,rev /view,,1,1,1 ! Fluid thickness /edge,,1 plesol,nmisc,9 /edge,,0 !Nodal pressures plnsol,pres ! Fluid velocities /edge,,1 rsys,solu plesol,PG,X ! tangential plesol,PG,Y ! axial rsys /edge,,0 /out, /com,* ======================================================== /com,* ========= /com,* RESULTS /com,* ========= /com,* /com,* Minimum thickness: %minThickness% m /com,* Minimum thickness angle: %minThicknessAngle% deg /com,* Maximum pressure: %maxPressure% Pa /com,* Maximum pressure angle: %maxPressureAngle% deg /com,* Total force in X direction: %forceX% N /com,* Total force in Y direction: %forceY% N /com,* Attitude angle: %angAtt% deg /com,* /com,* ======================================================== /out,scratch

* ======================================================== * ========= * RESULTS * ========= * * Minimum thickness: 8.678740123E-04 m * Minimum thickness angle: -118.8 deg * Maximum pressure: 63682.2737 Pa * Maximum pressure angle: -140.4 deg * Total force in X direction: -27.6204842 N * Total force in Y direction: -25.9966112 N * Attitude angle: 39.8919837 deg * * ========================================================