The virtual crack closure technique (VCCT) was initially developed to calculate the energy-release rate of a cracked body.[6] It has since been widely used in the interfacial crack-growth simulation of laminate composites, with the assumption that crack-growth is always along a predefined path, specifically the interfaces.[7][8][9][10]

VCCT-based crack-growth simulation is available with current-technology linear elements PLANE182 and SOLID185.

A VCCT-based crack-growth simulation involves the following assumptions:

Crack growth occurs along a predefined crack path.

The path is defined via interface elements.

The analysis is quasi-static and does not account for transient effects.

The material is linear elastic and can be isotropic, orthotropic or anisotropic.

The model undergoes small deformation (or small rotation) (NLGEOM,OFF).

The crack can be located in a material or along the interface of the two materials. The fracture criteria are based on energy-release rates calculated using VCCT. Several fracture criteria are available, including a user-defined option. Multiple cracks can be defined in an analysis.

A VCCT-based crack-growth simulation uses:

The CINT command to calculate the energy-release rate.

The CGROW command to define the crack-growth set, fracture criterion, crack-growth path, and solution-control parameters.

A VCCT-based crack-growth simulation is assumed to be quasi-static. Following is the general process for performing the simulation:

Crack-growth simulation is a nonlinear structural analysis. The analysis details presented here emphasize features specific to crack-growth.

Standard nonlinear solution procedures apply for creating a finite element model with proper solution-control settings, loadings and boundary conditions.

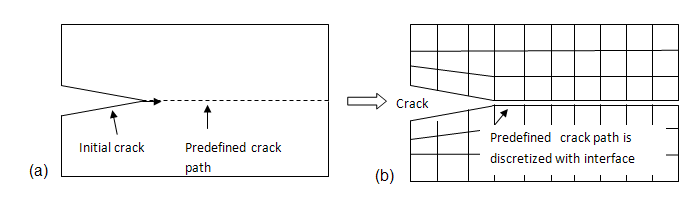

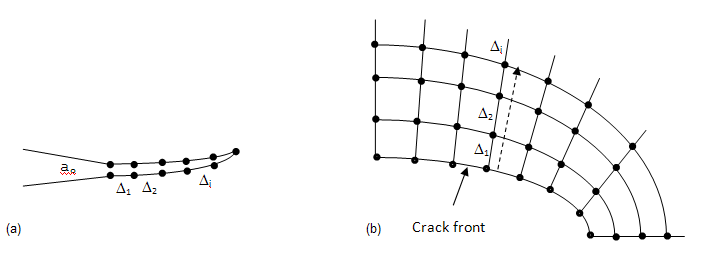

The predefined crack path is discretized with interface elements and grouped as an element component, as shown in the following figure:

The interface elements can be meshed via the CZMESH command or by a third-party tool that generates interface elements.

The element MPC constraint option (KEYOPT(2) = 1) bonds the potential crack faces together before cracks begin to grow. The MPC constraints are subsequently released when the fracture criterion is met, thus growing the cracks.

In a 2D problem, one interface element behind the crack tip may open if it meets the fracture criterion at a given substep. In a 3D problem, all interface elements behind the crack front may open if they meet the fracture criterion.

Differences in the size of the elements ahead of and behind the crack tip/front affect the accuracy of the energy-release rate calculation. While Mechanical APDL uses a correction algorithm, it may be inadequate to produce an accurate solution. Instead, use equal sized meshes for elements along the predefined crack path. For more information, see Calculating Fracture Parameters.

3.5.1.1.1. Generating Interface Elements via CZMESH

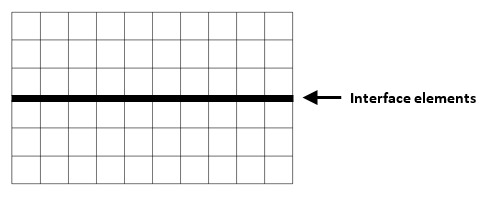

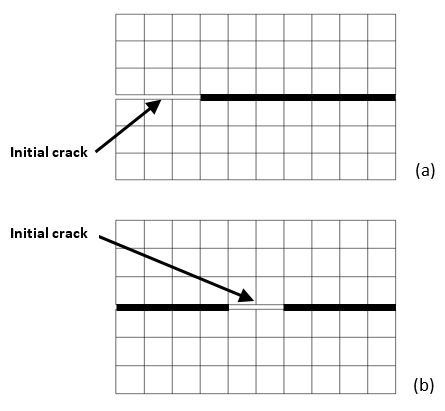

When using the CZMESH command to generate interface elements along the predefined crack path, add interface elements along the entire interface (including the initial crack and the predefined crack path), then delete interface elements on the initial crack:

For VCCT-based crack-growth simulation, it is necessary to perform the energy-release rate calculation first.

To calculate the energy-release rates, issue the CINT,TYPE,VCCT command. Issue subsequent CINT commands to specify other options such as the crack-tip node component and crack plane/edge normal.

The VCCT calculation uses the following assumptions:

The strain energy released when a crack advances by a small amount is the same as the energy required to close the crack by the same amount.

The crack-tip field/deformation at the crack-tip/front location is similar to when the crack extends by a small amount.

The assumptions do not apply when crack-growth approaches the boundary or when the two cracks approach each other; therefore, use the VCCT calculation with care and examine the analysis results.

For further information, see VCCT Energy-Release Rate Calculation.

The crack-growth calculation occurs in the solution phase after stress calculation. To perform the crack-growth calculation, you must define a crack-growth set, then specify the crack path, fracture criterion, and crack-growth solution controls. The solution command CGROW defines all necessary crack-growth calculation parameters.

Perform the crack-growth calculation as follows:

To define a crack-growth set,

issue the CGROW,NEW,n command,

where n is the crack-growth set number.

To define the crack path, issue the

CGROW,CPATH,cmname

command, where cmname is the component name for

the interface elements.

Specify the crack-calculation ID via

CGROW,CID,n, where

n is the crack-calculation

(CINT) ID for energy-release rate calculation with

VCCT. (The CINT command defines parameters associated

with fracture parameter calculations.)

For a simple fracture criterion such as the critical energy-release rate, you

can specify it by issuing

CGROW,FCOPTION,GC,VALUE,

where VALUE is the critical energy-release

rate.

For a more complex fracture criterion, you can specify the fracture

criteria via a material data table. Issue

CGROW,FCOPTION,MTAB,matid,

where matid is the material ID for the material

table. Several fracture criterion options are available (such as linear,

bilinear, B-K, modified B-K, Power Law, and user-defined).

For more information, see TB,CGCR and Fracture Criteria.

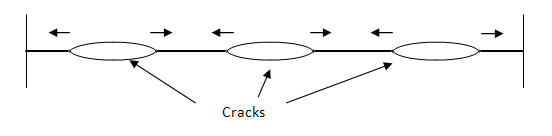

For each crack-growth set, you can specify only one fracture criterion, and one element component for crack-growth. You can define multicrack-growth sets with different cracks and fracture criteria. Multiple cracks can grow simultaneously and independently from each other. Cracks can merge to a single crack when they are on the same interface, as shown in the following figure:

You can also define the same crack with different fracture criteria in a separate crack-growth set. The cracks can grow based on different criteria (according to which criterion is met), and are independent from each other. This technique is useful for comparing fracture mechanisms.

Issue the CGROW command to specify solution controls, as follows:

| To specify this solution control... | Issue this CGROW command: |

|---|---|

| Fracture criterion ratio (fc) |

CGROW,FCRAT, VALUE is the ratio. |

| Initial time step when crack-growth initiates |

CGROW,DTIME, VALUE is initial time

stepTo avoid over-predicting the load-carrying capacity, specify a small initial time step. |

| Minimum time step for subsequent crack-growth |

CGROW,DTMIN, VALUE is the minimum

time-step size. |

| Maximum time step for subsequent crack-growth |

CGROW,DTMAX, VALUE is the maximum

time-step size. |

| Maximum crack extension allowed at any crack-front nodes |

CGROW,STOP,CEMX, VALUE is the maximum crack

extension.Because crack-growth simulation can be time-consuming, use this command to stop the analysis when the specified crack extension of interest has been reached. |

When a crack extends rapidly (for example, in cases of unstable crack-growth), use smaller DTMAX and DTMIN values to allow time for load rebalancing. When a crack is not growing, the specified time-stepping controls are ignored and the solution adheres to standard time-stepping control.

The following input example defines a crack-growth set:

CGROW,NEW,1 CGROW,CPATH,cpath1 CGROW,FCOPTION,MTAB,5 CGROW,DTIME,1.0e-4 CGROW,DTMIN,1.0e-5 CGROW,DTMAX,2.0e-3 ...

In a crack-growth simulation, a quantity of interest is the amount of crack extension. VCCT measures the crack extension based on the length of the interface elements that have opened, as expressed by the following equation and in the subsequent figure:

For 2D crack problems, the crack extension is the summation of length of interface elements that are currently open (a). For 3D problems, the crack extension is measured at each crack-front node and is the summation of the length of the interface element edges that follow the crack extension direction (b).

Crack extension is available as CEXT as part of the crack solution variable

associated with the crack-calculation ID, and can be postprocessed similar to energy

release rates via POST1 and POST26 postprocessing commands (such

PRCINT, PLCINT, and

CISOL).

To model the crack-growth, it is necessary to define a fracture criterion for crack onset and the subsequent crack-growth. For linear elastic fracture mechanics (LEFM) applications, the fracture criterion is generally assumed to be a function of Mode I (GI), Mode II (GII), and Mode III ((GIII) critical energy-release rates, expressed as:

Other parameters may be necessary for some models.

Fracture occurs when the fracture criterion index is met, expressed as:

where fc is the fracture criterion ratio. The recommended ratio is 0.95 to 1.05. The default is 1.0.

The following fracture criteria are available:

The user-defined option requires a subroutine that you provide to define your own fracture criterion.

To initiate a fracture criterion table without the critical energy-release rate criterion, issue the TB,CGCR command.

The critical energy-release rate criterion uses total energy-release rate (GT) as fracture criterion. The total energy-release rate is summation of the Mode I (GI), Mode II (GII), and Mode III ((GIII) energy-release rates, expressed as:

where is the critical energy-release rate.

For Mode I fracture, the fracture criterion reduces to:

The critical energy-release rate option is the simplest fracture criterion and is suitable for general 2D and 3D crack-growth simulation.

The linear option assumes that the fracture criterion is a linear function of the Mode I (GI), Mode II (GII), and Mode III ((GIII) energy-release rates, expressed as:

where ,

, and

are the Mode I, Mode II, and Mode III critical energy-release

rates, respectively. The three values are input via the

TBDATA command, as follows:

| Constant | TBDATA Input | Comments |

|---|---|---|

|

|

C1

| Critical Mode I energy-release rate, |

|

|

C2

| Critical Mode II energy-release rate, |

|

|

C3

| Critical Mode III energy-release rate, |

Example 3.9: Linear Criterion Input

g1c=10.0 g2c=20.0 g3c=25.0 TB,CGCR,1,,,LINEAR TBDATA,1,g1c,g2c,g3c

The three constants cannot all be zero. If a constant is set to zero, the corresponding term is ignored.

When all three critical energy-release rates are equal, the linear fracture criterion reduces to the critical energy-release rate criterion.

The linear fracture criterion is suitable for 3D mixed-mode fracture simulation where distinct Mode I, Mode II, and Mode III critical energy-release rates exist.

The bilinear fracture option [8] assumes that the fracture criterion is a linear function of the Mode I (GI) and Mode II (GII) energy-release rates, expressed as:

where and

are the Mode I and Mode II critical energy-release rates,

respectively, and ξ and ζ are the two material constants. All four

values can be defined as a function of temperature and are input via the

TBDATA command, as follows:

| Constant | TBDATA Input | Comments |

|---|---|---|

|

|

C1

| Critical Mode I energy-release rate, |

|

|

C2

| Critical Mode II energy-release rate, |

| ξ |

C3

| ξ > 0 |

| ζ |

C4

| ζ > 0 |

Example 3.10: Bilinear Criterion Input

g1c=10.0 g2c=20.0 x=2 y=2 TB,CGCR,1,,,BILINEAR TBDATA,1,g1c,g2c,x,y

The bilinear fracture criterion is suitable for 2D mixed-mode fracture simulation.

The B-K [7] option is expressed as:

where and

are the Mode I and Mode II critical energy-release rates,

respectively, and η is the material constant. All three values can be

defined as a function of temperature and are input via the

TBDATA command, as follows:

| Constant | TBDATA Input | Comments |

|---|---|---|

|

|

C1

| Critical Mode I energy-release rate, |

|

|

C2

| Critical Mode II energy-release rate, |

| η |

C3

| η > 0 |

The B-K criterion is intended for composite interfacial fracture and is suitable for 3D mixed-mode fracture simulation.

The modified B-K (or Reeder) [9] option, is expressed as:

where ,

, and

are Mode I, Mode II, and Mode III critical energy-release

rates, respectively, and η is the material constant. All four values can be

defined as a function of temperature and are input via the

TBDATA command, as follows:

| Constant | TBDATA Input | Comments |

|---|---|---|

|

|

C1

| Critical Mode I energy-release rate, |

|

|

C2

| Critical Mode II energy-release rate, |

|

|

C3

| Critical Mode III energy-release rate, |

| η |

C4

| η > 0 |

When =

, the modified B-K criterion reduces to the B-K criterion.

The modified B-K criterion is intended for composite interfacial fracture to account for distinct Mode II and Mode III critical energy-release rates, and is suitable for 3D mixed-mode fracture simulation.

Example 3.12: Modified B-K Criterion Input

g1c=10.0 g2c=20.0 g3c=25.0 h=2 TB,CGCR,1,,,MBK TBDATA,1,g1c,g2c,g3c,h

The power law [10] option assumes that the fracture criterion is a power function of the Mode I (GI), Mode II (GII), and Mode III ((GIII) energy-release rates, expressed as:

where ,

, and

are Mode I, Mode II, and Mode III critical energy-release

rates, respectively, and n1, n2,

and n3 are power exponents and are also constants. All

six values can be defined as a function of temperature and are input via the

TBDATA command, as follows:

| Constant | TBDATA Input | Comments |

|---|---|---|

|

|

C1

| Critical Mode I energy-release rate, |

|

|

C2

| Critical Mode II energy-release rate, |

|

|

C3

| Critical Mode III energy-release rate, |

| n1 |

C4

| n1 > 0 |

| n2 |

C5

| n2 > 0 |

| n3 |

C6

| n3 > 0 |

The three critical energy-release rates cannot all be zero. If a constant is set to zero, the corresponding term is ignored.

When power exponents n1, n2, and n3 are set to 1, the power law criterion is reduced to the linear fracture criterion.

The power law fracture criterion is suitable for 3D mixed-mode fracture simulation where distinct Mode I, Mode II, and Mode III critical energy-release rates exist.

Example 3.13: Power Law Criterion Input

g1c=10.0 g2c=20.0 g3c=25.0 n1=2 n2=2 n3=3 TB,CGCR,1,,,POWERLAW TBDATA,1,g1c,g2c,g3c,n1,n2,n3

A custom fracture criterion that you define is expressed as:

where the fracture criterion is a function of the Mode I (GI), Mode II (GII), and Mode III (GIII) energy-release rates, and the material constant(s). All values are input via the TBDATA command.

A subroutine that you provide is necessary. For more information, see the Programmer's Reference.

Following is an example subroutine defining a linear fracture criterion:

*deck,user_cgfcrit optimize

SUBROUTINE user_cgfcrit (cgi, cid, kct,

& nprop, prop, fcscl,

& var1, var2, var3, var4)

c*****************************************************************

c

c *** primary function:

c compute fracture criterion for crack-growth

c user fracture criterion example

c

#include "impcom.inc"

#include "ansysdef.inc"

c

c input arguments

c ===============

c cgi (int,sc , in) CGROW set id

c cid (int,sc , in) CINT ID to be used

c kct (int,sc , in) Current crack-tip node

c nprop (int,sc , in) number of properties

c prop (dp ,ar(*), in) property array

c

c Output arguments

c ===============

c fcscl (dp, sc , ou) fracture criterion

c a return value of one or bigger

c indicates fracture

c

c Misc. arguments

c ===============

c var1 ( , , ) not used

c var2 ( , , ) not used

c var3 ( , , ) not used

c var4 ( , , ) not used

c

c*****************************************************************

c

c *** subroutines/function

c *** get_cgfpar : API to access fracture data

c *** wrinqr : ansys standard io function

c ***

external get_cgfpar

external wrinqr

integer wrinqr

c *** argument

c

INTEGER cgi, cid, kct, nprop

double precision fcscl,

& var1, var2, var3, var4

double precision prop(nprop)

c

c *** local variable

c

integer debugflag, iott

integer nn

double precision g1c, g2c, g3c, g1, g2, g3

double precision gs(4),da(1)

c

c *** local parameters

DOUBLE PRECISION ZERO, ONE

parameter (ZERO = 0.0d0,

& ONE = 1.0d0)

c

c*****************************************************************

c *** initialization

fcscl = ZERO

c *** retrieve energy-release rates

c *** for crack cid and crack-tip node kct

c *** gs(1:3) will be returned as G1, G2, G3

c *** get energy-release rates

nn = 3

gs(1:nn) = ZERO

call get_cgfpar ('GS ', cid, kct, 0, nn, gs(1))

c *** get crack extension

nn = 1

da(1) = ZERO

call get_cgfpar ('DA ', cid, kct, 0, nn, da(1))

c *** energy-release rates

g1 =abs(gs(1))

g2 =abs(gs(2))

g3 =abs(gs(3))

c *** input property from TBDATA,1,c1,c2,c3

g1c = prop(1)

g2c = prop(2)

g3c = prop(3)

c *** linear fracture criterion

fcscl = ZERO

if (g1c .gt. TINY) fcscl = fcscl + g1/g1c

if (g2c .gt. TINY) fcscl = fcscl + g2/g2c

if (g3c .gt. TINY) fcscl = fcscl + g3/g3c

c *** user debug output

debugflag = 1

if (debugflag .gt. 0) then

iott = wrinqr (WR_OUTPUT)

write(iott, 1000) cgi, cid, kct, da(1), fcscl, gs(1:3)

1000 format (5x,'user fracture criterion:'/

& 5x, 'crack-growth set ID =',i5/

& 5x, 'crack ID =',i5/

& 5x, 'crack-tip node =',i5/

& 5x, 'crack extension =',g11.5/

& 5x, 'calculated fracture parameter =',g11.5/

& 5x, 'energy-release rates Gs(1:3) =',3g12.5)

end if

return

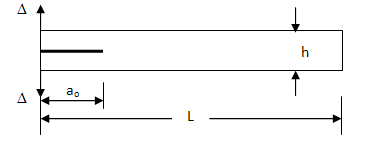

endThis example uses a double-cantilever beam with an edge crack at one end. Equal displacements with opposite directions are applied to the end of the beam about and below the crack in order to open up the crack, as shown in this figure:

Figure 3.19: Crack-Growth of a Double-Cantilever Beam

|

|

This figure shows the finite element mesh:

PLANE182 with the enhanced strain option (KEYOPT(1) = 2) is used to model the solid part of the model. INTER202 is used to model the crack path. A plane strain condition is assumed. In the vertical direction, the model uses 6 elements, and in the horizontal direction are 200 elements.

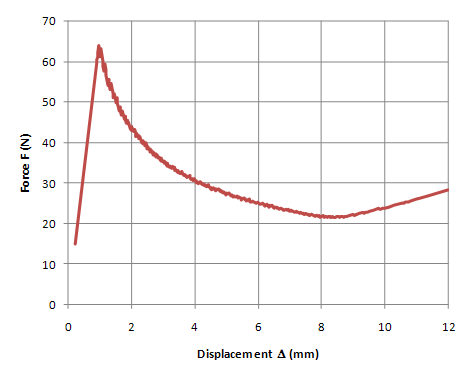

This figure shows the predicted load-deflection curve:

The force increases with the applied displacement and peaks quickly before the crack begins to grow. The reaction force then decreases rapidly at the initial phase of crack-growth, the slows down with the subsequent crack-growth. The results match very well with the reference results.[11]

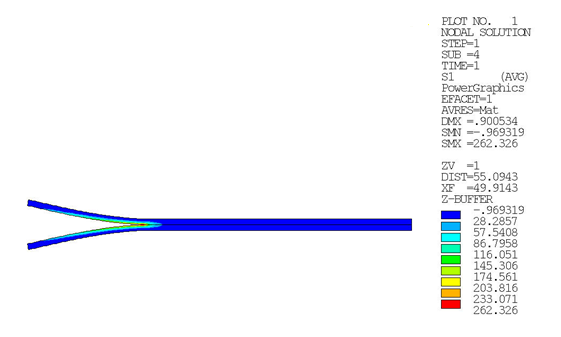

The contour plot of maximum principal stress is shown in the following figure:

Following is the input file used for the VCCT-based crack-growth simulation of the double-cantilever beam:

/prep7 dis1=0.9 dis2=12.0 n1=1000 n2=1000 n3=10 dl=100 dh=3 a0=30 nel=200 neh=6 toler=0.1e-5 et,1,182 !* 2d 4-node structural solid element keyopt,1,1,2 !* enhance strain formulation keyopt,1,3,2 !* plane strain et,2,182 keyopt,2,1,2 keyopt,2,3,2 et,3,202 !* 2d 4-node cohesive zone element !keyopt,3,2,2 !* element free option keyopt,3,3,2 !* plane strain mp,ex,1,1.353e5 !* e11 = 135.3 gpa mp,ey,1,9.0e3 !* e22 = 9.0 gpa mp,ez,1,9.0e3 !* e33 = 9.0 gpa mp,gxy,1,5.2e3 !* g12 = 5.2 gpa mp,prxy,1,0.24 mp,prxz,1,0.24 mp,pryz,1,0.46 g1c=0.28 !* critical energy-release rate g2c=0.80 g3c=0.80 tb,cgcr,1,,3,linear !* linear fracture criterion tbdata,1,g1c,g2c,g3c ! FE model rectng,0,dl,dh/2 !* define areas rectng,0,dl,0,-dh/2 lsel,s,line,,2,8,2 !* define line division lesize,all,dh/neh lsel,inve lesize,all, , ,nel allsel,all type,1 !* mesh area 2 mat,1 local,11,0,0,0,0 esys,11 amesh,2 csys,0 type,2 !* mesh area 1 esys,11 amesh,1 csys,0 nsel,s,loc,x,a0-toler,dl nummrg,nodes esln type,3 mat,5 czmesh,,,1,y,0, !* generate interface elements allsel,all nsel,s,loc,x,dl !* apply constraints d,all,all nsel,all ! esel,s,ename,,202 !* select interface element to cm,cpath,elem !* define crack-growth path nsle nlist nsel,s,loc,x,a0 nsel,r,loc,y,0 nlist esln elist cm,crack1,node !* define crack-tip node component nlist alls finish /solu resc,,none esel,s,type,,2 nsle,s nsel,r,loc,x nsel,r,loc,y,dh/2 !* apply displacement loading on top d,all,uy,dis1 nsel,all esel,all esel,s,type,,1 nsle,s nsel,r,loc,x nsel,r,loc,y,-dh/2 !* apply displacement loading on bottom d,all,uy,-dis1 nsel,all esel,all autots,on time,1 cint,new,1 !* crack id cint,type,vcct !* vcct calculation cint,ctnc,crack1 !* crack-tip node component cint,norm,0,2 ! crack-growth simulation set cgrow,new,1 !* crack-growth set cgrow,cid,1 !* cint id for vcct calculation cgrow,cpath,cpath !* crack path cgrow,fcop,mtab,1 !* fracture criterion cgrow,dtime,2e-3 cgrow,dtmin,2e-3 cgrow,dtmax,2e-3 cgrow,fcra,0.98 nsub,4,4,4 allsel,all outres,all,all solve time,2 esel,s,type,,2 nsle,s nsel,r,loc,x nsel,r,loc,y,dh/2 !* apply displacement loading on top d,all,uy,dis2 nsel,all esel,all esel,s,type,,1 nsle,s nsel,r,loc,x nsel,r,loc,y,-dh/2 !* apply displacement loading on bottom d,all,uy,-dis2 nsel,all esel,all nsubst,n1,n2,n3 outres,all,all solve !* perform solution finish /post1 set,last prci,1 ! set,1,4 plnsol,s,1 ! finish /post26 nsel,s,loc,y,dh/2 nsel,r,loc,x,0 *get,ntop,node,0,num,max nsel,all nsol,2,ntop,u,y,uy rforce,3,ntop,f,y,fy prod,4,3, , ,rf, , ,20 /title,, dcb: reaction at top node verses prescribed displacement /axlab,x,disp u (mm) /axlab,y,reaction force r (n) /yrange,0,60 xvar,2 prvar,uy,rf prvar,2,3,4 /com, finish

VCCT-based crack-growth simulation is available only with current-technology linear elements PLANE182 and SOLID185.

These assumptions apply to VCCT-based crack-growth simulation:

The material is linearly elastic, and can be isotropic, orthotropic, or anisotropic.

The analysis is assumed to be quasi-static. Although a transient analysis is possible, the fracture calculations do not account for the transient effects.

The VCCT-based mixed-mode energy-release rates calculation assumes that the crack-tip field / deformation at the crack-tip/front location is similar to when the crack extends by a small amount. This assumption does not apply when crack-growth approaches the boundary or when two cracks are close; therefore, use the VCCT calculation with care and examine the analysis results.

When fracture parameters in addition to CINT,VCCT are calculated on the same geometric crack front (for example, when both JINT and VCCT are requested on the same crack front), these limitations apply:

Distributed-memory parallel processing is no longer supported.

The additional parameter values become inaccurate as soon as the crack starts to grow.