After generating the build file, you can use the Cost Estimator tool to obtain an estimate of the total cost to build the job based on the cost, material, and build time parameters defined for your selected machine.

Note: Cost information is built into the machine profiles for SLM machines only. Therefore if you choose a machine profile other than SLM, you'll see a zero under machine costs in the estimate.

To obtain a cost estimate to build what is currently in the Build Volume on your chosen machine (after you have generated a build file):

Select the Cost Estimator option in the ribbon. The Cost Estimator panel appears in the right side of the UI.

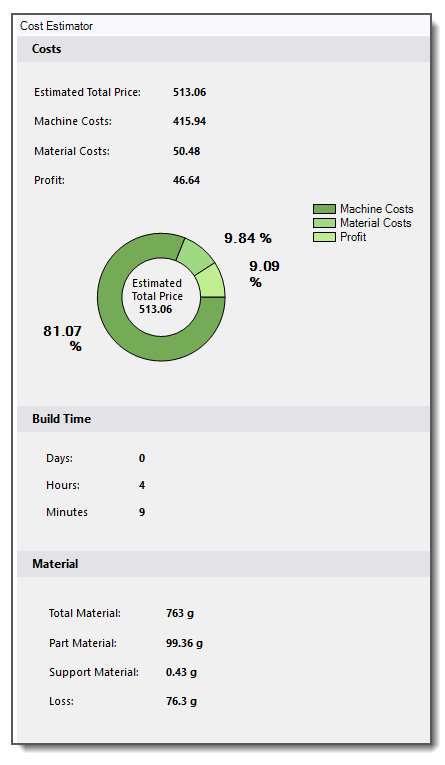

Review the information in the panel, as needed. Click the calculate button

to generate the cost estimate, which

then appears in the panel.

to generate the cost estimate, which

then appears in the panel.Click the export button

to export the estimate to a .csv file.

to export the estimate to a .csv file.

If you make changes to build parameters and regenerate a build file, the cost estimate

information will be incorrect for the new build file. Click the calculate button ![]() again to update the cost estimate.

again to update the cost estimate.

To determine the cost estimate, the Cost Estimator uses the following information from your project:

Machine (Selected under SpaceClaim Options > Additive Prep Machines or Settings > Manage Machines. Here you will see the Length and Width of the baseplate, used in the calculation of Total Material.)

Material (Selected under SpaceClaim Options > Additive Prep Materials. Here you will see the Powder Density, Material Loss (percentage), and Cost settings for your chosen material.)

Build Strategy (Selected on the Build Processor panel)

Build File (Represents the scan pattern for the part(s) and supports and is generated from the Build Processor)

Profit (Defined under SpaceClaim Options > Additive Prep Options)

Currency Symbol for Export (Defined under SpaceClaim Options > Additive Prep Options)

The largest contributing factor to the Estimated Total Price is the Machine Cost, which is directly related to the build time. The build time calculation in the Additive Prep application is done with the same algorithm as in the SLM machines. It sums up the laser path times plus the jump times between the laser paths. This represents the exposure time. The recoater time per layer is normally defined in the SLM machine settings. Exposure and recoater time result in the build time for the buildjob.

The Total Material in the cost estimate is the amount of powder necessary for the build, which is calculated as volume x powder density. The volume is length x width of the baseplate x the height of the part in its build orientation plus the Z-Offset.

Material loss is a percentage of the total material and is due to unrecoverable metal powder loss from gas flow during the build or in post-processing.