VM-WB-MECH-084

VM-WB-MECH-084

Mullins Effect on a Rubber Tube Model Subjected to Tension

Loading

Overview

| Reference: |

Ogden.W., et al. (1989). A Pseudo-elastic Model for the Mullins Effect in Filled Rubber. Royal Society of London Proceedings Series A, 2861-2877. |

| Solver(s): | Ansys Mechanical |

| Analysis Type(s): | Static Analysis |

| Element Type(s): | Solid |

Test Case

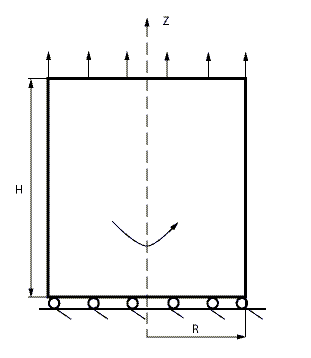

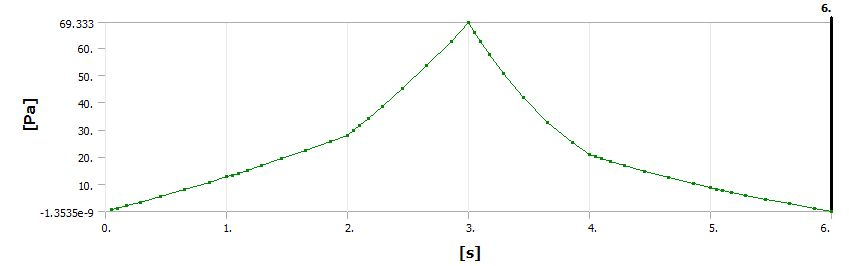

An axisymmetric rubber plate made of Neo-Hookean material is modeled with radius R and height H. The model is subjected to cyclic displacement loading on the top surface. The axial stress obtained at different load steps is compared against the reference solution.

This problem is also presented in VM268

in the Mechanical APDL Verification Manual.

| Material Properties | Geometric Properties | Loading | ||||

|---|---|---|---|---|---|---|

Neo-Hookean Constants:

Ogden-Roxburgh Mullins Constants:

| R = 0.5m H = 1m | One cycle of loading Step 1: λ = 1.5 Step 2: λ = 2.0 Step 3: λ = 3.0 Step 4: λ = 2.0 Step 5: λ = 1.5 Step 6: λ = 1.0 |