VM268

VM268

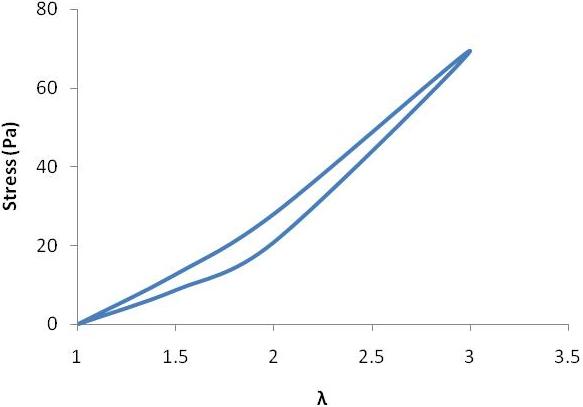

Mullins Effect on a Rubber Tube Model Subjected to Tension

Loading

Test Case

An axisymmetric rubber plate made of Neo-Hookean material is modeled with radius R and height H. The model is subjected to cyclic displacement loading on the top surface. The axial stress obtained at different load steps is compared against reference solution.

| Material Properties | Geometric Properties | Displacement Loading |

Neo-Hookean Constants: µ = 8 MPa Ogden-Roxburgh Mullins Constants: r=2.104 m=30.45 β=0.2 | R=0.5m H=1m | One cycle of loading Step 1: λ=1.5 Step 2: λ=2.0 Step 3: λ=3.0 Step 4: λ=2.0 Step 5: λ=1.5 Step 6: λ=1.0 |

Analysis Assumptions and Modeling Notes

The rubber tube is modeled using axisymmetric PLANE182 elements. Modified Ogden-Roxburgh Mullins effect was applied to model stress softening of hyper elastic material during unloading stage. Symmetric boundary conditions are applied to the model and the axial stress for element 1 obtained at different stretch is compared with reference solution.