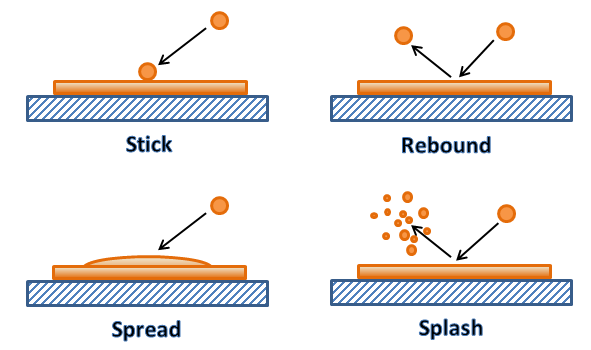

When an airborne spray droplet hits a wall surface, the wall impingement model in Ansys Forte determines the outcome of the collision between the droplet and the wall, depending on the Reynolds number and Weber number of the incident droplet and the surface condition. Four impingement regimes are considered, including stick, rebound, spread and splash (Figure 6.9: Wall impingement regimes ). For a wetted surface, the stick regime occurs as the impact energy carried by the incident droplet is very low and the droplet adheres to the film in nearly spherical form. As the impact energy increases, the air layer trapped between the droplet and the surface causes low energy loss and the droplet rebounds. When the impact energy is further increased to a certain level, the impinging droplet spreads and merges with the film. Finally, splash occurs at very high impact energy, where the incident droplet flies away from the impinging site and breaks up into many smaller secondary droplets.

The regime transition criteria for a wetted wall as used in [9] are employed in Ansys Forte:

Stick:

Rebound:

Spread:

and

Splash:

Re n and We n are the Reynolds number and Weber number of the incident droplet, respectively. They are defined as:

(6–86) |

(6–87) |

where is the liquid density,

is the droplet’s velocity normal to the impact surface,

D is the droplet diameter,

is the liquid viscosity, σ is the surface

tension.

Among these impingement regimes, splash is the most important and

complex one. It is commonly observed in engineering applications, such as port fuel injection

engines. The splash threshold is proposed by Han et al. [29]

in the form of:

(6–88) |

where β is non-dimensional surface roughness (roughness

height/incident droplet diameter), δ is non-dimensional film thickness (film

thickness/incident droplet diameter). The absolute value of surface roughness is exposed as a

user input in Ansys Forte. Typical roughness values range from 0.1 micron (for very smooth surfaces,

such as glass surfaces) to 5 micron (for rough surfaces, such as metal surfaces). is a non-dimensional tunable constant with a default value of 1500. A larger

value of

reduces the chance of splash.

is a multiplier that can be used as a tuning knob with a default value of

1.0.

Splash results in the rebounding of many smaller secondary droplets from the impinging location. The properties of the secondary droplets are modeled statistically, following the formulations derived by Han et al. [29] . These properties are described below.