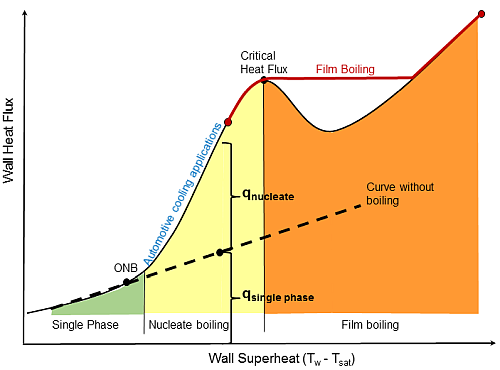

The study of heat transfer in boiling is important in many industrial sectors such as nuclear and automotive industries. Several boiling models have been proposed for heat transfer predictions in high-pressure applications in the nuclear industry. However, for low pressure automotive systems, high-pressure boiling models, which are based on specific experimental correlations, may be unreliable and numerically unstable.

To model sub-cooled nucleate boiling at low pressure, bulk evaporation/condensation phenomena is generally combined with the heat transfer augmentation at the wall due to boiling. In Ansys Fluent, the Lee model is used to capture the phase change process both near the wall and in the bulk domain. The heat transfer augmentation at wall is modeled by empirical correlations by Chen [133].

Chen [104] proposed the flow boiling correlation for vertical tubes where the effective wall heat flux is expressed as the weighted sum of the nucleate boiling heat flux and the force convective heat flux. Chen's correlation is based on the following assumptions:

Vapor formed by the evaporation process increases the liquid velocity, and, therefore, the convective heat transfer contribution is augmented relative to that of a single-phase liquid flow.

The convection partially suppresses the nucleation of boiling sites and, therefore, reduces the contribution of nucleate boiling.

The effective wall heat flux as proposed by Chen is expressed as:

(14–626) |

| where | |

|

| |

|

| |

|

| |

|

| |

|

|

Kutateladze [329] proposed a modified form of effective heat flux

using the asymptotic power law, which is expressed as:

(14–627) |

where is the power law superposition constant. Setting

to 1 results in a linear superposition of the single phase and the

nucleate boiling heat flux, as proposed by Chen. Kutateladze proposed an asymptotic

method with

= 2. With the increase in the value of

, the effective heat flux tends to become larger than the single phase

heat flux and nucleate boiling heat flux.

The single phase heat flux in Equation 14–626 is given by:

(14–628) |

where

The nucleate boiling heat flux in Equation 14–626 is given by:

(14–629) |

where

In the above equations,

|

| |

|

| |

|

| |

|

|

The effective single phase heat transfer coefficient is calculated as:

(14–630) |

where and

are single phase heat transfer coefficients for liquid and vapor,

respectively, and

is the wetting fraction (fraction of wall wetted by liquid).

The nucleate boiling heat transfer coefficient is calculated using the Foster and Zuber correlation:

(14–631) |

| where | |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

The forced convective augmentation factor is proposed by Chen in the form of [319]:

(14–632) |

where the Martinelli parameter is used to account for the two-phase effect on convection and is

defined as follows:

(14–633) |

(14–634) |

where is the vapor quality (mass fraction).

The nucleate boiling suppression factor is given by:

(14–635) |

where is the suppression factor due to forced convection, and

is the suppression factor due to subcooled effects. According to a

proposal by Steiner et al. [633],

is calculated as:

(14–636) |

in Equation 14–635 is expressed using the

formulation proposed by Butterworth et al. [89]:

(14–637) |

where is the modified two-phase Reynolds number scale:

(14–638) |

Here, the reference Reynolds number for liquid is calculated as:

(14–639) |

| where | |

|

| |

|

| |

|

| |

|

|

For information on how to use the semi-mechanistic boiling model, see Including Semi-Mechanistic Boiling in the Fluent User's Guide.