This chapter presents an overview of the theory and the governing equations for the methods used in Ansys Fluent to predict particle growth and nucleation.

The particle state vector is characterized by a set of “external

coordinates” (), which denote the spatial position

of the particle, and “internal coordinates” (

), which could include

particle size, composition, and temperature. From these coordinates,

a number density function

can be postulated where

,

. Therefore, the average

number of particles in the infinitesimal volume

is

. In contrast, the continuous phase state

vector is given by

The total number of particles in the entire system is then

(14–694) |

The local average number density in physical space (that is, the total number of particles per unit volume) is given by

(14–695) |

The total volume fraction of all particles is given by

(14–696) |

where is the volume of a particle

in state

.

Assuming that is the particle volume, the transport equation

for the number density function is given as

(14–697) |

The boundary and initial conditions are given by

(14–698) |

where is the nucleation rate in

particles/m3-s.

The growth rate based on particle volume, , (

) is defined as

(14–699) |

The growth rate based on particle diameter (or length) is defined as

(14–700) |

The volume of a single particle is defined as

, and therefore the relationship between

and

is

(14–701) |

The surface area of a single particle, , is defined as

. Thus for a cube or a sphere,

.

Important:

In the case of dissolution of particles, the particle volume growth rate is negative due to the particle volume reduction.

In the case of bubble expansion due to change in density (pressure), the growth rate

in Equation 14–697 is the rate of bubble volume expansion.

Considering

to be the mass of a bubble of volume

and density

,

(14–702)

For constant

(bubble expansion with no mass transfer),

, and therefore

(14–703)

A more detailed explanation can be found in the paper by Mills [443].

The birth and death of particles occur due to breakage and aggregation processes. Examples of breakage processes include crystal fracture in crystallizers and bubble breakage due to liquid turbulence in a bubble column. Similarly, aggregation can occur due to particle agglomeration in crystallizers and bubble coalescence in bubble column reactors.

Note that all breakage and aggregation events in FLUENT Population Balance Model are modeled as binary with the exception of the generalized breakage kernel.

The breakage rate expression, or kernel [400], is expressed as

(14–704) |

|

where | |

|

| |

|

| |

|

|

The birth rate of particles of volume due to breakage is given by

(14–705) |

where particles

of volume

break per unit time,

producing

particles,

of which a fraction

represents particles of

volume

.

is the number of child particles produced per parent

(for example, two particles for binary breakage).

The death rate of particles of volume due to breakage is given by

(14–706) |

The PDF is also known as the particle fragmentation distribution

function, or daughter size distribution. Several functional forms

of the fragmentation distribution function have been proposed, though

the following physical constraints must be met: the normalized number

of breaking particles must sum to unity, the masses of the fragments

must sum to the original particle mass, and the number of fragments

formed has to be correctly represented.

Mathematically, these constraints can be written as follows:

The following is a list of models available in Ansys Fluent to calculate the breakage frequency:

Constant value

Luo model

Lehr model

Ghadiri model

Laakkonen model

Liao model

User-defined model

Ansys Fluent provides the following models for calculating the breakage probability density functions (PDF):

Parabolic PDF

Laakkonen PDF

Generalized PDF for multiple breakage fragments

User-defined model

The breakage frequency models and the parabolic and generalized PDFs are described in detail in the sections that follow.

The Luo and Lehr models are integrated kernels, encompassing both the breakage frequency and the PDF of breaking particles.

The general form is the integral over the size of eddies hitting the particle

with diameter

(and volume

). The integral is taken over the dimensionless eddy

size

. The general form is

(14–710) |

where the parameters are as shown in Table 14.4: Luo Model Parameters and Table 14.5: Lehr Model Parameters.

For detailed notations, see Luo [400].

Where is entered through the GUI. See Lehr [353].

The Ghadiri model [201], [460], in contrast to the Luo and Lehr models, is used to model only the breakage frequency of the solid particles. You will have to specify the PDF model to define the daughter distribution.

The breakage frequency is defined as:

(14–711) |

where is the particle velocity and

is the particle diameter prior to breaking. The breakage constant

[s3 m-11/3] sets

the overall scale of how many parent particles is breaking per second. It is

case-dependent and is proportional to the particle properties:

(14–712) |

where is the particle density,

is the elastic modulus of the granule, and

is the interface energy. Note that you may need to adjust

, for example, by calibrating against a baseline experiment.

The Laakkonen breakage kernel is expressed as the product of

a breakage frequency, and a

daughter PDF

where

(14–713) |

where is the liquid phase eddy dissipation,

is the surface tension,

is the liquid density,

is the gas density,

is the parent particle diameter

and

is the liquid viscosity.

The constants ,

and

.

The daughter PDF is given by

(14–714) |

where and

are the daughter and

parent particle volumes, respectively. This model is a useful alternative

to the widely used Luo model because it has a simple expression for

the daughter PDF and therefore requires significantly less computational

effort.

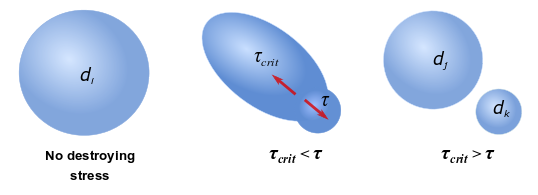

A bubble in a flowing liquid experiences a stress () that deforms the bubble and eventually breaks it once the stress

exceeds the restoring effect of the surface tension (

) as shown in Figure 14.18: Bubble Breakup

(adapted from [369]).

Based on the work of Martínez-Bazán et al. [416], Liao [369] proposed to define the breakup frequency of a

bubble of size in relation to stress

and critical stress

as follows:

(14–715) |

where is the diameter of a child bubble.

The combined breakup approach is used to determine the critical stress based on

consideration of energy criterion and force criterion. For binary breakage, where bubble

breaks into two bubbles

and

,

can be expressed as:

(14–716) |

The energy constraint is determined by the increase of the surface energy during the

breakage:

(14–717) |

where is the surface energy of the bubble, and the size of bubble

is calculated based on the sizes of bubbles

and

as:

(14–718) |

The force constraint is determined by the capillary force of the smallest child

bubble:

(14–719) |

where is the surface tension coefficient.

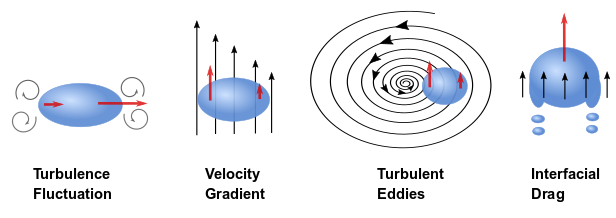

The destroying stress that breaks the bubble is caused by the velocity gradient across the

bubble’s surface. In a turbulent flow, the velocity variations can result from

various mechanisms such as turbulent fluctuation, velocity gradients in a mean flow,

turbulent eddies, and interfacial drag [369] as shown in Figure 14.19: Bubble Breakup Mechanisms in a Turbulent Flow (adapted from [369]).

These breakup mechanism stresses are expressed as:

Inertial force caused by turbulent velocity fluctuation:

(14–720)

where

is the liquid density,

is the turbulent dissipation rate in the liquid phase, and

is the Kolmogorov microscale.

Viscous shear force caused by velocity gradients in the bulk flow:

(14–721)

where

is the dynamic viscosity of the liquid and

is the shear strain rate at the bulk.

Viscous shear force caused by velocity gradients in eddies:

(14–722)

where

is the characteristic strain rate of the flow in the smallest eddies.

Interfacial drag (or friction):

(14–723)

where

and

are the terminal velocity and the drag coefficient of bubble

, respectively.

Constants ,

,

, and

allow to consider uncertainties in the estimation of destroying

stresses caused by different mechanisms. The default (and recommended by Liao [369]) values for the coefficients are:

=

=

=1, and

= 0.25.

The breakage PDF function contains information on the probability of fragments formed by a breakage event. It provides the number of particles and the possible size distribution from the breakage. The parabolic form of the PDF implemented in Ansys Fluent enables you to define the breakage PDF such that

(14–724) |

where and

are the daughter and

parent particle volumes, respectively. Depending on the value of the

shape factor

, different behaviors will be observed in the shape

of the particle breakage distribution function. For example, if

, the particle breakage

has a uniform distribution. If

, a concave parabola is obtained, meaning that it

is more likely to obtain unequally-sized fragments than equally-sized

fragments. The opposite of this is true for

. Values outside of the range of 0 to 3 are not allowed,

because the PDF cannot have a negative value.

Note that the PDF defined in Equation 14–724 is symmetric about .

The generalized form of the PDF implemented in Ansys Fluent enables

you to simulate multiple breakage fragments () and to specify the form of the daughter distribution

(for example, uniform, equal-size, attrition, power law, parabolic,

binary beta). The model itself can be applied to both the discrete

method and the QMOM.

Considering the self-similar formulation [539] where the similarity is the ratio of daughter-to-parent

size (that is,

), then the generalized

PDF is given by

(14–725) |

where is the self-similar

daughter distribution [141]. The

moment of

,

, is

(14–726) |

where

(14–727) |

The conditions of number and mass conservation can then be expressed as

(14–728) |

(14–729) |

The generalized form of [141] can be expressed as

(14–730) |

where can be 0 or 1, which represents

as consisting

of 1 or 2 terms, respectively. For each term,

is the weighting

factor,

is the averaged number of daughter

particles,

and

are the exponents,

and

is the beta function. The following constraints

are imposed on the parameters in Equation 14–730 :

(14–731) |

(14–732) |

(14–733) |

In order to demonstrate how to transform the generalized PDF to represent an appropriate daughter distribution, consider the expressions shown in the tables that follow:

In Table 14.6: Daughter Distributions, is the Dirac delta

function,

is a weighting coefficient, and

,

,

, and

are user-defined

parameters.

The generalized form can represent the daughter distributions in Table 14.6: Daughter Distributions by using the values shown in Table 14.8: Values for Daughter Distributions in General Form.

Table 14.8: Values for Daughter Distributions in General Form

| Type |

|

|

|

|

|

|

|

| Constraints |

|---|---|---|---|---|---|---|---|---|---|

| Equal-size | 1 |

|

|

| N/A | N/A | N/A | N/A |

|

| Attrition | 0.5 | 2 | | 1 | 0.5 | 2 | 1 |

|

|

| Power Law | 1 |

|

| 1 | N/A | N/A | N/A | N/A |

|

| Parabolic | 1 |

| | 2 | N/A | N/A | N/A | N/A |

|

| Austin |

| | | 1 | | | | 1 |

|

| Binary Beta ** | 1 | 2 | | | N/A | N/A | N/A | N/A |

|

| Uniform | 1 | | 1 |

| N/A | N/A | N/A | N/A |

|

(*)You can approximate by using a very large number, such as 1e20.

(**)Binary Beta -a is a special case of Binary Beta -b when .

Important: Note that for the Ansys Fluent implementation of the generalized

form of the PDF, you will only enter values for ,

,

,

, and

, and the remaining

values (

,

, and

) will be calculated

automatically.

The Martinez-Bazan breakage frequency [416] is commonly used to model bubble breakage in stirred tank reactors. The kernel provides a phenomenological expression for the breakage rate of bubbles, which is based on the local values of the turbulence stress and surface tension. The breakage rate is expressed as:

(14–734) |

The maximum stable bubble diameter is given by:

(14–735) |

In the above equations,

Most daughter distribution PDFs for bubble breakage assume a symmetric U-shaped distribution with the minimum probability of breakage occurring for equi-sized daughter bubbles. Although this kind of a daughter distribution function works well for many applications, an alternative inverted U-shaped distribution has also been proposed in [416], where, by contrast with the U-shaped distribution, the probability of formation of equi-sized daughter bubbles is assumed to be at a maximum. In Ansys Fluent, this is implemented as:

(14–736) |

where ,

,

, and

is defined in Breakage.

The aggregation kernel [400] is expressed as

(14–737) |

where is an aggregation factor for the calibration of the aggregation

kernels.

The aggregation kernel has units of m3/s, and is sometimes defined as a product of two quantities:

the frequency of collisions between particles of volume

and particles of volume

the “efficiency of aggregation” (that is, the probability of particles of volume

coalescing with particles of volume

).

The birth rate of particles of volume due to aggregation is given by

(14–738) |

where particles of volume aggregate

with particles of volume

to form particles of

volume

. The factor

is included to avoid accounting for each collision

event twice.

The death rate of particles of volume due to aggregation is given by

(14–739) |

Important: The breakage and aggregation kernels depend on the nature of the physical application. For example, in gas-liquid dispersion, the kernels are functions of the local liquid-phase turbulent dissipation.

The following is a list of aggregation functions available in Ansys Fluent:

Constant

Luo model

Free molecular model

Turbulent model

Prince and Blanch model

Liao model

User-defined model

The Luo, free molecular, turbulent, Prince and Blanch, and Liao aggregation functions are described in detail in the sections that follow.

For the Luo model [398], the general aggregation

kernel is defined as the rate of particle volume formation as a result

of binary collisions of particles with volumes and

:

(14–740) |

where is the frequency of collision and

is the probability that the collision results in

coalescence. The frequency is defined as follows:

(14–741) |

where is the characteristic velocity of collision

of two particles with diameters

and

.

(14–742) |

where

(14–743) |

The expression for the probability of aggregation is

(14–744) |

where is a constant

of order unity,

,

and

are the densities

of the primary and secondary phases, respectively, and the Weber number

is defined as

(14–745) |

Real particles aggregate and break with frequencies (or kernels)

characterized by complex dependencies over particle internal coordinates [584]. In particular, very small particles (say

up to ) aggregate

because of collisions due to Brownian motions. In this case, the frequency

of collision is size-dependent and usually the following kernel is

implemented:

(14–746) |

where is the Boltzmann constant,

is the absolute temperature,

is the viscosity of the suspending fluid,

and

are the diameters (or lengths) of particles

and

. This kernel is also known as the Brownian kernel or the perikinetic

kernel.

During mixing processes, mechanical energy is supplied to the

fluid. This energy creates turbulence within the fluid. The turbulence

creates eddies, which in turn help dissipate the energy. The energy

is transferred from the largest eddies to the smallest eddies in which

it is dissipated through viscous interactions. The size of the smallest

eddies is the Kolmogorov microscale, , which is expressed as

a function of the kinematic viscosity and the turbulent energy dissipation

rate:

(14–747) |

In the turbulent flow field, aggregation can occur by two mechanisms:

viscous subrange mechanism: this is applied when particles are smaller than the Kolmogorov microscale,

inertial subrange mechanism: this is applied when particles are bigger than the Kolmogorov microscale. In this case, particles assume independent velocities.

For the viscous subrange, particle collisions are influenced by the local shear within the eddy. Based on work by Saffman and Turner [564], the collision rate is expressed as,

(14–748) |

where is a pre-factor that

takes into account the capture efficiency coefficient of turbulent

collision, and

is the shear rate:

(14–749) |

For the inertial subrange, particles are bigger than the smallest eddy, therefore they are dragged by velocity fluctuations in the flow field. In this case, the aggregation rate is expressed using Abrahamson’s model [6],

(14–750) |

where is the mean squared

velocity for particle

.

The empirical capture efficiency coefficient of turbulent collision describes the hydrodynamic and attractive interaction between colliding particles. Higashitani et al. [245] proposed the following relationship:

(14–751) |

where is the ratio between the viscous

force and the Van der Waals force,

(14–752) |

Where is the Hamaker constant, a function of the particle

material, and

is the deformation rate,

(14–753) |

The aggregation model of Prince and Blanch [535] assumes that the coalescence of two bubbles occurs in three steps:

Bubbles collide trapping a small amount of liquid between them.

The liquid film separating the bubbles drains until it reaches a critical thickness.

The film ruptures, and the bubbles join into one large bubble.

This aggregation kernel is modeled by a collision rate of two bubbles and a collision efficiency related to the time required for coalescence:

(14–754) |

The collision efficiency is modeled by comparing the time required for coalescence

and the actual contact time during the collision

:

(14–755) |

where:

(14–756) |

and:

(14–757) |

In Equation 14–756 and Equation 14–757,

is the density of the liquid,

is the surface tension,

is the initial film thickness,

is the critical film thickness when rupture occurs,

is the turbulent eddy dissipation of the liquid, and

is the equivalent radius defined as:

(14–758) |

where and

are the radii of bubbles

and

, respectively.

The turbulent contributions to collision frequency are modeled as:

(14–759) |

where the cross-sectional area of the colliding particles is defined by:

(14–760) |

the turbulent velocity is given by:

(14–761) |

and is a calibration factor for the turbulent contribution.

The buoyancy contribution to the collision frequency is calculated as:

(14–762) |

where:

(14–763) |

and is a calibration factor for the buoyancy.

In Equation 14–760, Equation 14–761, and Equation 14–763, and

are the diameters of bubbles

and

, respectively, and

is gravity.

The shear contribution to collision frequency ( in Equation 14–754) is currently neglected.

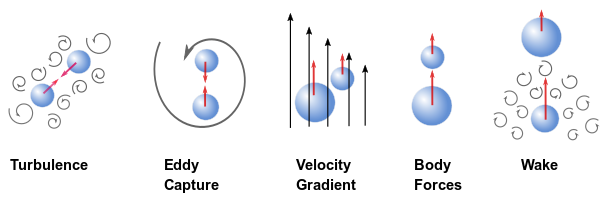

Coalescence occurs where two or more fluid particles collides. This can happen for various reasons such as turbulence, eddy capture, velocity gradient in the mean flow, body forces, and wake entrainment [369] as shown in Figure 14.20: Bubble Collision in a Turbulent Flow (adapted from [369]).

Assuming the cumulative contribution of all the coalescence mechanisms, Liao [369] proposed a formulation for the total coalescence frequency

of a binary collision between two bubbles of volumes

and

:

(14–764) |

where is the bubble packing limit, and

is its maximum. When the local volume fraction of the bubble phase

approaches the maximum packing limit

, the coalescence rate increases infinitely.

Since bubble-bubble collision can result either in coalescence or bouncing of the

colliding bubbles, the coalescence efficiency (or probability) is used. Coalescence

frequency is represented as the product of the collision frequency

and the efficiency of each collision event

:

(14–765) |

Similar to the kinetic gas theory, the collision frequency is approximated as the volume swept by the two particles in unit

time:

(14–766) |

where is the relative velocity between the two bubbles, and

is the effective cross-sectional area of collision.

For a random bubble collision caused by turbulent fluctuation, the effective cross-sectional area is:

(14–767) |

where and

are diameters of bubbles

and

, respectively.

The relative velocity between bubbles and

is estimated by:

(14–768) |

where is the turbulent velocity over a distance

given by:

(14–769) |

where is the turbulent dissipation rate in the liquid phase.

For a turbulence-induced collision, the coalescence frequency between bubble

and bubble

is obtained as:

(14–770) |

where is a constant, and

is the coalescence efficiency in the inertial collision regime. Equation 14–770 is valid for bubbles much larger than the Kolmogorov

length scale.

When the buoyancy effects are considered, collision can occur only when the

faster-moving bubble approaches the slower-moving bubble from bellow in an upward flow.

The coalescence frequency is modeled as:

(14–771) |

where is a constnat, and

and

are the terminal velocities of bubble

and bubble

, respectively. The effective coalescence efficiency

is calculated by:

(14–772) |

where is the Kolmogorov length scale.

The coalescence efficiency for an inertial collision is expressed as:

(14–773) |

where the coefficient has a default value of 5.0, and

(14–774) |

where is the liquid density,

is the surface tension coefficient, and

(14–775) |

The coalescence efficiency of the viscous collision is expressed as:

(14–776) |

where is the dynamic viscosity of the liquid,

is the Hamaker constant that represents the strength of the van der

Waals interactions between macroscopic bodies, and

is the characteristic strain rate of the flow in the smallest eddies.

For an air-water interface, its value is approximated to 3.7 x

10-20 J.

In a shear-induced collision, a bubble can only collide with another bubble it

follows in the direction of the bulk velocity from the higher-velocity side. The

coalescence frequency between bubble

and bubble

caused by the velocity gradient is expressed as:

(14–777) |

where is a constant,

is the shear strain rate of the bulk flow, and

is defined by Equation 14–772.

For bubbles that are much smaller than the Kolmogorov microscale, the collision is

assumed to be controlled by viscous forces. The coalescence frequency is modeled as:

(14–778) |

where is a constant. It can be derived from the Kolmogorov scales to

be:

(14–779) |

When a bubble of a size bigger than a critical diameter moves through a liquid, it

generates a wake in the liquid phase behind it. The trailing bubbles within the wake

region of the leading bubble can be accelerated and reach the leading bubble. The

coalescence efficiency for wake-entrainment is modeled as:

(14–780) |

where is a constant,

and

are the terminal velocities of bubbles

and

, respectively, and

and

are the drag coefficients of bubbles

and

, respectively. The blending function

for bubble

is defined as:

(14–781) |

where the critical diameter is computed as:

(14–782) |

where is the gas density.

The constants ,

,

,

, and

account for uncertainty in the estimation of relative velocity under

different conditions. Liao [369] recommends setting these

coefficients to 1.0, which are the default settings in Ansys Fluent.

Depending on the application, spontaneous nucleation of particles can occur due to the transfer of molecules from the primary phase. For example, in crystallization from solution, the first step is the phase separation or “birth” of new crystals. In boiling applications, the creation of the first vapor bubbles is a nucleation process referred to as nucleate boiling.

The nucleation rate is defined through a boundary condition as shown in Equation 14–698.

As discussed, the population balance equation can be solved by the four different methods in Ansys Fluent: the discrete method, the inhomogeneous discrete method, the standard method of moments (SMM), and the quadrature method of moments (QMOM). For each method, the Ansys Fluent implementation is limited to a single internal coordinate corresponding to particle size. The following subsections describe the theoretical background of each method and list their advantages and disadvantages.

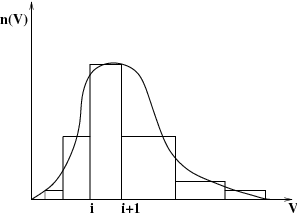

The discrete method (also known as the classes or sectional method) was developed by Hounslow [256], Litster [384], and Ramkrishna [539]. It is based on representing the continuous particle size distribution (PSD) in terms of a set of discrete size classes or bins, as illustrated in Figure 14.21: A Particle Size Distribution as Represented by the Discrete Method. The advantages of this method are its robust numerics and that it gives the PSD directly. The disadvantages are that the bins must be defined a priori and that a large number of classes may be required.

The solution methods for the inhomogeneous discrete method are based on the discrete method and therefore share many of the same fundamentals.

In Ansys Fluent, the PBE is written in terms of volume fraction

of particle size :

(14–783) |

where is the density of the

secondary phase and

is the volume fraction

of particle size

, defined as

(14–784) |

where

(14–785) |

and is the volume of the particle

size

. In Ansys Fluent, a fraction of

, called

, is introduced

as the solution variable. This fraction is defined as

(14–786) |

where is the total volume fraction of the secondary

phase.

The nucleation rate appears in

the discretized equation for the volume fraction of the smallest size

. The notation

signifies that this particular

term, in this case

, appears in Equation 14–783 only in the case of the smallest

particle size.

The growth rate in, Equation 14–783 [256], is discretized as follows:

(14–787) |

The volume coordinate is discretized as [256]

where

and is referred to as the “ratio

factor”.

The particle birth and death rates are defined as follows:

(14–788) |

(14–789) |

(14–790) |

(14–791) |

where and

(14–792) |

is the particle

volume resulting from the aggregation of particles

and

, and is defined as

(14–793) |

where

(14–794) |

If is greater

than or equal to the largest particle size

, then the

contribution to class

is

(14–795) |

Important: Note that there is no breakage for the smallest particle class.

The default breakage formulation for the discrete method in Ansys Fluent is based on the

Hagesather method [224]. In this method, the breakage sources are

distributed to the respective size bins, preserving mass and number density. For the case when

the ratio between successive bin sizes can be expressed as where

, the source in bin

, (

) can be expressed as

(14–796) |

Here

(14–797) |

A more mathematically rigorous formulation is given by Ramkrishna [326], where the breakage rate is expressed as

(14–798) |

where

(14–799) |

The Ramkrishna formulation can be slow due to the large number

of integration points required. However, for simple forms of , the integrations

can be performed relatively easily. The Hagesather formulation requires

fewer integration points and the difference in accuracy with the Ramkrishna

formulation can be corrected by a suitable choice of bin sizes.

Important: To keep the computing time reasonable, a volume averaged value is used for the turbulent eddy dissipation when the Luo model is used in conjunction with the Ramkrishna formulation.

Note: The inhomogeneous discrete phase applies the Hagesather formulation.

The SMM, proposed by Randolph and Larson [540] is an alternative method for solving the PBE. Its advantages are that it reduces the dimensionality of the problem and that it is relatively simple to solve transport equations for lower-order moments. The disadvantages are that exact closure of the right-hand side is possible only in cases of constant aggregation and size-independent growth, and that breakage modeling is not possible. The closure constraint is overcome, however, through QMOM (see The Quadrature Method of Moments (QMOM)).

The SMM approach is based on taking moments of the PBE with

respect to the internal coordinate (in this case, the particle size ).

Defining the

th moment as

(14–800) |

and assuming constant particle growth, its transport equation can be written as

(14–801) |

where

(14–802) |

(14–803) |

(14–804) |

(14–805) |

is the specified number of moments and

is the nucleation rate. The growth term is defined

as

(14–806) |

and for constant growth is represented as

(14–807) |

Equation 14–802 can be derived by using

and reversing the order of integration. From these moments, the parameters describing the gross properties of particle population can be derived as

(14–808) |

(14–809) |

(14–810) |

(14–811) |

(14–812) |

These properties are related to the total number, length, area,

and volume of solid particles per unit volume of mixture suspension.

The Sauter mean diameter, , is usually

used as the mean particle size.

To close Equation 14–801, the quantities

represented in Equation 14–802 – Equation 14–805 need to be expressed in terms of

the moments being solved. To do this, one approach is to assume size-independent

kernels for breakage and aggregation, in addition to other simplifications

such as the Taylor series expansion of the term . Alternatively, a profile of the PSD could be assumed

so that Equation 14–802 – Equation 14–805 can be integrated and expressed

in terms of the moments being solved.

In Ansys Fluent, an exact closure is implemented by restricting the application of the SMM to cases with size-independent growth and a constant aggregation kernel.

The quadrature method of moments (QMOM) was first proposed by McGraw [422] for modeling aerosol evolution and coagulation problems. Its applications by Marchisio et al. [413] have shown that the method requires a relatively small number of scalar equations to track the moments of population with small errors.

The QMOM provides an attractive alternative to the discrete method when aggregation quantities, rather than an exact PSD, are desired. Its advantages are fewer variables (typically only six or eight moments) and a dynamic calculation of the size bins. The disadvantages are that the number of abscissas may not be adequate to describe the PSD and that solving the Product-Difference algorithm may be time consuming.

The quadrature approximation is based on determining a sequence

of polynomials orthogonal to (that is, the particle size distribution).

If the abscissas of the quadrature approximation are the nodes of

the polynomial of order

, then the quadrature approximation

(14–813) |

is exact if is a polynomial of order

or smaller [140]. In all other cases, the closer

is to a

polynomial, the more accurate the approximation.

A direct way to calculate the quadrature approximation is by means of its definition through the moments:

(14–814) |

The quadrature approximation of order is defined by its

weights

and

abscissas

and can be calculated by its first

moments

by writing the recursive relationship for the polynomials in terms of

the moments

. Once this relationship is written in matrix form, it is easy to show

that the roots of the polynomials correspond to the eigenvalues of the Jacobi matrix

[534]. This procedure is known as the moment inversion algorithm,

which uses either the Product-Difference algorithm [213] or the

Wheeler algorithm [705]. Once the weights and abscissas are known,

the source terms due to coalescence and breakage can be calculated and therefore the

transport equations for the moments can be solved.

Applying Equation 14–813 and Equation 14–814, the birth and death terms in Equation 14–801 can be rewritten as

(14–815) |

(14–816) |

(14–817) |

(14–818) |

Theoretically, there is no limitation on the expression of breakage and aggregation kernels when using QMOM.

The nucleation rate is defined in the same way as for the SMM. The growth rate for QMOM is defined by Equation 14–806 and represented as

(14–819) |

to allow for a size-dependent growth rate.

DQMOM equations are derived from the basic number density function equation via the moment transfer method, in a similar way to QMOM. The difference is that DQMOM assumes that each Quadrature point will occupy an independent velocity field, whereas QMOM assumes that all Quadrature points are moving on the same velocity field. This difference enables DQMOM to predict particle segregation due to particle interaction.

In this implementation of DQMOM, four phases must be specified: one primary phase and three secondary phases that are DQMOM phases. Compared to QMOM, for a three Quadrature points system, the DQMOM method only needs three extra equations to solve for the effective length of the particle, but there are additional source terms for the volume fraction equation for each DQMOM phase. In Ansys Fluent, three particle interactions are accounted for, growth, aggregation, and breakage. Nucleation is not considered.

The DQMOM equations, describing a poly-dispersed particle system undergoing aggregation, breakage, and growth can be written as follows (the details of the DQMOM formulation can be found in [169]):

(14–820) |

(14–821) |

where and

are the VOF and the

effective length of the particle phase, respectively.

is the number of particles per unit volume

and

is the growth rate at Quadrature point

, while

and

can be computed through a linear system resulting from the moment

transformation of the particle number density transport equation using

Quadrature points. The linear

system can be written in matrix form as

(14–822) |

Where the coefficient matrix

is defined

by

(14–823) |

(14–824) |

The vector of unknowns

is defined by

(14–825) |

The right hand side of Equation 14–822 is the known source terms involving aggregation and breakage phenomena only. The growth term is accounted for directly in Equation 14–820 and Equation 14–821. At present, nucleation is not considered.

(14–826) |

The

source term for the moment

is defined as

(14–827) |

When the abscissas of the Quadrature points are distinct, the matrix

is well defined and a unique

solution of Equation 14–822 can be obtained.

Otherwise, the matrix

is not full rank and cannot be inverted to find

a unique solution for

. The method adopted by Ansys Fluent to overcome

this problem is to employ a perturbation technique. For example, for

the current three Quadrature points system, the perturbation technique

will add a small value to the abscissas to make sure the matrix A

is full rank. It is important to note that the perturbation technique

is only used for the definition of matrix

and no modifications are made

to the source term vector of Equation 14–827. Therefore, both the weights and overall source terms resulting

from aggregation and breakage are not affected by the perturbation

method. The simulation tests have found that the perturbation method

can stabilize the solutions of Equation 14–822 and reduce the physically unrealistically large source terms for

the two phases whose abscissa are too close in value. However, the

technique has little effect on the phase whose abscissa

is distinct from the other two.

The following sections introduce statistical concepts that are useful when using the population balance models.

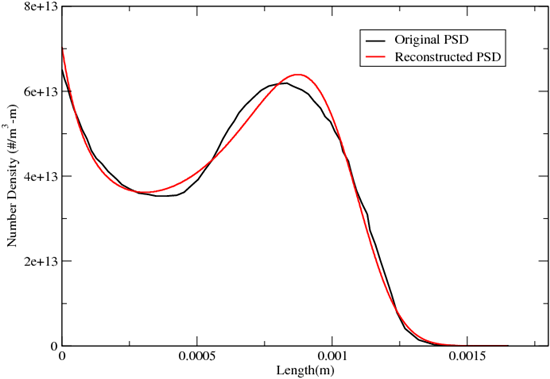

Given a set of moments, the most likely PSD can be obtained based on the “statistically most probable” distribution for turbulent flames [529], which was adapted for crystallization problems by Baldyga and Orciuch [39].

The number density function is expressed

as

(14–828) |

The equation for the

th moment is now written

as

(14–829) |

Given moments, the coefficients

can be found

by a globally convergent Newton-Raphson method to reconstruct the

particle size distribution (for example, Figure 14.22: Reconstruction of a Particle Size Distribution).

When using either of the discrete population balance methods, you have the option of specifying the size distribution at a velocity inlet by specifying a log-normal distribution.

The log-normal distribution for the number density, , as a function of the particle

size,

, can be written as:

(14–830) |

where and

are, respectively, the location and scale

parameters of the distribution and can be written

as

and

are the mean and standard deviation,

respectively, and are specified in the boundary conditions

as shown in Initializing Bin Fractions With a Log-Normal Distribution.