This tutorial includes:

In this tutorial you will learn about:

Creating and using a multicomponent fluid in CFX-Pre.

Using CEL to model a reaction in CFX-Pre.

Using an algebraic Additional Variable to model a scalar distribution.

Using a subdomain as the basis for component sources.

|

Component |

Feature |

Details |

|---|---|---|

|

CFX-Pre |

User Mode |

General mode |

|

Analysis Type |

Steady State | |

|

Fluid Type |

Variable Composition Mixture | |

|

Domain Type |

Single Domain | |

|

Turbulence Model |

k-Epsilon | |

|

Heat Transfer |

Thermal Energy | |

|

Particle Tracking |

Component Source | |

|

Boundary Conditions |

Inlet (Subsonic) | |

|

Outlet (Subsonic) | ||

|

Symmetry Plane | ||

|

Wall: Adiabatic | ||

|

Additional Variables |

| |

|

CEL (CFX Expression Language) |

| |

|

Timestep |

Physical Time Scale | |

|

CFD-Post |

Plots |

Isosurface |

|

Slice Plane |

Reaction engineering is one of the core components in the chemical industry. Optimizing reactor design leads to higher yields, lower costs and, as a result, higher profit.

This example demonstrates the capability of Ansys CFX to model basic reacting flows using a multicomponent fluid and CEL expressions.

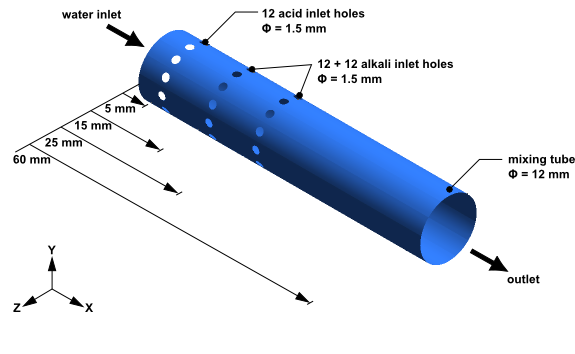

The geometry consists of a mixing tube with three rings with twelve holes in each ring.

The main inlet has water entering at 2 m/s with a temperature of 300 K. The pressure at the outlet is 1 atm.

Through the ring of holes nearest the inlet, a solution of dilute sulfuric acid enters at 2 m/s with a temperature of 300 K. Through each of the two other rings of holes, a solution of dilute sodium hydroxide enters at 2.923 m/s with a temperature of 300 K. The properties of the solution of sulfuric acid are shown in Table 15.1: Properties of the Dilute Sulfuric Acid Solution:

Table 15.1: Properties of the Dilute Sulfuric Acid Solution

|

Property |

Value |

|---|---|

|

Molar mass |

19.517 kg kmol^-1 |

|

Density |

1078 kg m^-3 |

|

Specific heat capacity |

4190 J kg^-1 K^-1 |

|

Dynamic Viscosity |

0.001 kg m^-1 s^-1 |

|

Thermal Conductivity |

0.6 W m^-1 K^-1 |

Through the remaining two rings of holes, a solution of dilute sodium hydroxide (an alkali) enters with a temperature of 300 K. The properties of the solution of sodium hydroxide are shown in Table 15.2: Properties of the Dilute Sodium Hydroxide Solution.

Table 15.2: Properties of the Dilute Sodium Hydroxide Solution

|

Property |

Value |

|---|---|

|

Molar mass |

18.292 kg kmol^-1 |

|

Density |

1029 kg m^-3 |

|

Specific heat capacity |

4190 J kg^-1 K^-1 |

|

Dynamic Viscosity |

0.001 kg m^-1 s^-1 |

|

Thermal Conductivity |

0.6 W m^-1 K^-1 |

The acid and alkali undergo an exothermic reaction to form a solution of sodium sulfate (a type of salt) and water according to the reaction:

Mixing the acid and alkali solutions in a stoichiometric ratio (and enabling them to react completely) would result in a salt water solution that would include water from each of the original solutions plus water produced during the reaction. The properties of this salt water product are shown in Table 15.3: Properties of the Salt Water Product.

Table 15.3: Properties of the Salt Water Product

|

Property |

Value |

|---|---|

|

Molar mass |

18.600 kg kmol^-1 |

|

Density |

1031 kg m^-3 |

|

Specific heat capacity |

4190 J kg^-1 K^-1 |

|

Dynamic Viscosity |

0.001 kg m^-1 s^-1 |

|

Thermal Conductivity |

0.6 W m^-1 K^-1 |

The heat of reaction is 460 kJ per kg of dilute acid solution.

The flow is assumed to be fully turbulent and turbulence is assumed to have a significant effect on the reaction rate.

After running the simulation, you will plot the distribution of pH in the tube, and determine the extent to which the pH is neutralized at the outlet. You will also plot mass fraction distributions of acid, alkali and product.

In order to reduce memory requirements and solution time, only a 30° slice of the geometry will be modeled, and symmetry boundary conditions will be applied to represent the remaining geometry.

The reaction between acid and alkali is represented as a single-step irreversible liquid-phase reaction:

Reagent (dilute sulfuric acid) is injected

through a ring of holes near the start of the tube. As it flows along

the tube it reacts with Reagent

(dilute sodium hydroxide), which

is injected through a further two rings of holes downstream. The product,

, remains

in solution.

You will create a variable-composition mixture that contains water, the reactants, and the product. To model the reaction, you will use CEL expressions to govern the mass sources for the acid, alkali and product components. You will also use CEL expressions to govern the thermal energy source. Providing mass and energy sources over a volume requires a subdomain. Because the reaction may occur anywhere in the domain, you will create a subdomain that occupies the entire flow domain.

Note: You can also model this type of reaction using a reacting mixture as your fluid. For details, see Combustion and Radiation in a Can Combustor.

To model the pH, you will create an algebraic Additional Variable that is governed by a CEL expression for pH. The Additional Variable will be available in the solution results for analysis during postprocessing.

If this is the first tutorial you are working with, it is important to review the following topics before beginning:

Create a working directory.

Ansys CFX uses a working directory as the default location for loading and saving files for a particular session or project.

Download the

reactor.zipfile here .Unzip

reactor.zipto your working directory.Ensure that the following tutorial input files are in your working directory:

ReactorExpressions.cclReactorMesh.gtm

Set the working directory and start CFX-Pre.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

In CFX-Pre, select File > New Case.

Select General and click .

Select File > Save Case As.

Under File name, type

Reactor.Click .

Right-click

Meshand select Import Mesh > CFX Mesh.The Import Mesh dialog box appears.

Configure the following setting(s):

Setting

Value

File name

ReactorMesh.gtm

Click Open.

In addition to providing template fluids, CFX allows you to create custom fluids for use in all your CFX models. A custom fluid may be defined as a pure substance, but may also be defined as a mixture, consisting of a number of transported fluid components. This type of fluid model is useful for applications involving mixtures, reactions, and combustion.

In order to define custom fluids, CFX-Pre provides the Material details view. This tool allows you to define your own fluids as pure substances, fixed composition mixtures or variable composition mixtures using a range of template property sets defined for common materials.

The mixing tube application requires a fluid made up from four separate materials (or components). The components are the reactants and products of a simple chemical reaction together with a neutral carrier liquid. You are first going to define the materials that take part in the reaction (acid, alkali and product) as pure substances. The neutral carrier liquid is water, and is already defined. Finally, you will create a variable composition mixture consisting of these four materials. This is the fluid that you will use in your simulation. A variable composition mixture (as opposed to a fixed composition mixture) is required because the proportion of each component will change throughout the simulation due to the reaction.

The properties of the dilute sulfuric acid solution were stated in the problem description.

Create a new material named

acid.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Option

Pure Substance

Thermodynamic State

(Selected)

Thermodynamic State

> Thermodynamic State

Liquid

Material Properties

Option

General Material

Thermodynamic Properties

> Equation of State

> Option

Value

Thermodynamic Properties

> Equation of State

> Molar Mass

19.517 [kg kmol^-1] [ a ]

Thermodynamic Properties

> Equation of State

> Density

1078 [kg m^-3]

Thermodynamic Properties

> Specific Heat Capacity

(Selected)

Thermodynamic Properties

> Specific Heat Capacity

> Option

Value

Thermodynamic Properties

> Specific Heat Capacity

> Specific Heat Capacity

4190 [J kg^-1 K^-1]

Transport Properties

> Dynamic Viscosity

(Selected)

Transport Properties

> Dynamic Viscosity

> Option

Value

Transport Properties

> Dynamic Viscosity

> Dynamic Viscosity

0.001 [kg m^-1 s^-1]

Transport Properties

> Thermal Conductivity

(Selected)

Transport Properties

> Thermal Conductivity

> Option

Value

Transport Properties

> Thermal Conductivity

> Thermal Conductivity

0.6 [W m^-1 K^-1]

Click .

The properties of the dilute sodium hydroxide solution were stated in the problem description.

Create a new material named

alkali.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Option

Pure Substance

Thermodynamic State

(Selected)

Thermodynamic State

> Thermodynamic State

Liquid

Material Properties

Option

General Material

Thermodynamic Properties

> Equation of State

> Option

Value

Thermodynamic Properties

> Equation of State

> Molar Mass

18.292 [kg kmol^-1]

Thermodynamic Properties

> Equation of State

> Density

1029 [kg m^-3]

Thermodynamic Properties

> Specific Heat Capacity

(Selected)

Thermodynamic Properties

> Specific Heat Capacity

> Option

Value

Thermodynamic Properties

> Specific Heat Capacity

> Specific Heat Capacity

4190 [J kg^-1 K^-1]

Transport Properties

> Dynamic Viscosity

(Selected)

Transport Properties

> Dynamic Viscosity

> Option

Value

Transport Properties

> Dynamic Viscosity

> Dynamic Viscosity

0.001 [kg m^-1 s^-1]

Transport Properties

> Thermal Conductivity

(Selected)

Transport Properties

> Thermal Conductivity

> Option

Value

Transport Properties

> Thermal Conductivity

> Thermal Conductivity

0.6 [W m^-1 K^-1]

Click .

The properties of the salt water product were stated in the problem description.

Create a new material named

product.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Option

Pure Substance

Thermodynamic State

(Selected)

Thermodynamic State

> Thermodynamic State

Liquid

Material Properties

Option

General Material

Thermodynamic Properties

> Equation of State

> Option

Value

Thermodynamic Properties

> Equation of State

> Molar Mass

18.600 [kg kmol^-1]

Thermodynamic Properties

> Equation of State

> Density

1031 [kg m^-3]

Thermodynamic Properties

> Specific Heat Capacity

(Selected)

Thermodynamic Properties

> Specific Heat Capacity

> Option

Value

Thermodynamic Properties

> Specific Heat Capacity

> Specific Heat Capacity

4190 [J kg^-1 K^-1]

Transport Properties

> Dynamic Viscosity

(Selected)

Transport Properties

> Dynamic Viscosity

> Option

Value

Transport Properties

> Dynamic Viscosity

> Dynamic Viscosity

0.001 [kg m^-1 s^-1]

Transport Properties

> Thermal Conductivity

(Selected)

Transport Properties

> Thermal Conductivity

> Option

Value

Transport Properties

> Thermal Conductivity

> Thermal Conductivity

0.6 [W m^-1 K^-1]

Click .

Define a variable composition mixture by combining water with

the three materials you have defined: acid, alkali, product.

Create a new material named

mixture.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Option

Variable Composition Mixture

Material Group

User, Water Data

Materials List

Water, acid, alkali, product

Thermodynamic State

(Selected)

Thermodynamic State

> Thermodynamic State

Liquid

Click .

You are going to use an Additional Variable to model the distribution of pH in the mixing tube. You can create Additional Variables and use them in selected fluids in your domain.

Create a new Additional Variable named

MixturePH.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Variable Type

Specific

Units

[ ]

Tensor Type

Scalar

Click .

This Additional Variable is now available for use when you create or modify a domain. You will set other properties of the Additional Variable, including how it is calculated, when you apply it to the domain later in this tutorial.

This section includes:

The first section shows a derivation for the mass-based stoichiometric ratio of alkali solution to acid solution. This ratio is used for calculating various quantities throughout this tutorial.

The second subsection (Reaction Source Terms) shows you how reactions and reaction kinetics can be formulated using the Eddy Break Up (EBU) model.

The third subsection (Calculating pH), shows you how pH is calculated.

In the fourth subsection (Loading the Expressions to Model the Reaction and pH) you will use a provided file to load CEL expressions for the reaction source terms and the pH.

The mass-based stoichiometric ratio of alkali solution to acid solution is a quantity that is used in several calculations in this tutorial. It represents the mass ratio of alkali solution to acid solution which leads to complete reaction with no excess alkali or acid (that is, neutral pH). This section of the tutorial shows you how to calculate the stoichiometric ratio, and introduces other quantities that are used in this tutorial.

The alkali solution contains water and sodium hydroxide. In the alkali solution, it is assumed that the sodium hydroxide molecules completely dissociate into ions according to the following reaction:

The acid solution contains water and sulfuric acid. In the acid solution, it is assumed that the sulfuric acid molecules completely dissociate into ions according to the following reaction:

The ions and

ions react

to form sodium sulfate (a type of salt) and water according to the

reaction:

Note that this reaction requires the ions from two molecules of sodium hydroxide and the ions from one molecule of sulfuric acid. The stoichiometric ratio for the dry alkali and acid molecules is 2-to-1.

Instead of modeling dry molecules of alkali and acid, this tutorial

models solutions that contain these molecules (in dissociated form)

plus water. The calculations used to model the alkali-acid reactions,

and to measure the pH, require a mass-based stoichiometric ratio, , that expresses

the mass ratio between the alkali solution and the acid solution required

for complete reaction of all of the (dissociated) alkali and acid

molecules within them.

Using to denote

and

to denote

, the ratio

can be computed as the ratio of the following two

masses:

The mass of alkali solution required to contain 2 kmol of

The mass of acid solution required to contain 1 kmol of

A formula for calculating is:

(15–1) |

where:

is the concentration of

in kmol/kg solution (equal to the concentration of

in kmol/kg solution).

is the concentration of

in kmol/kg solution (equal to the concentration of

in kmol/kg solution).

The molar mass of the alkali solution (given as 18.292 kg/kmol solution) is a weighted average of the molar masses of water (18.015 kg/kmol) and dry sodium hydroxide (39.9971 kg/kmol), with the weighting in proportion to the number of each type of molecule in the solution. You can compute the fraction of the molecules in the solution that are sodium hydroxide as:

can then

be calculated as follows:

The molar mass of the acid solution (given as 19.517 kg/kmol solution) is a weighted average of the molar masses of water (18.015 kg/kmol) and dry sulfuric acid (98.07848 kg/kmol), with the weighting in proportion to the number of each type of molecule in the solution. You can compute the fraction of the molecules in the solution that are sulfuric acid as:

can then be calculated as follows:

Substituting the values for and

into Equation 15–1 yields the

mass-based stoichiometric ratio of alkali solution to acid solution:

.

The reaction and reaction rate are modeled using a basic Eddy Break Up formulation for the component and energy sources. For example, the transport equation for the mass fraction of acid solution is:

(15–2) |

where is time,

is velocity,

is

the local density of the variable composition mixture,

is the mass fraction

of the acid solution in the mixture,

is the kinematic diffusivity of the acid solution

through the mixture, and

is the stoichiometric ratio of

alkali solution to acid solution based on mass fraction. The right-hand

side represents the mass source term that is applied to the transport

equation for the acid solution. The left-hand side consists of the

transient, advection and diffusion terms.

In addition to specifying the sources for the acid solution and alkali solution, source coefficients will also be used in order to enhance solution convergence. For details, see the technical note at the end of this section.

The reaction rate is computed as:

where is the turbulence kinetic energy,

and

is the turbulence eddy dissipation.

Note that the reaction rate appears on the right-hand side of Equation 15–2. The reaction rate is also

used to govern the rate of thermal energy production according to

the relation:

From the problem description, the heat of reaction is 460 kJ per kg of acid solution.

Note: This is a technical note, for reference only.

A source is fully specified by an expression for its value .

A source coefficient is optional, but can be specified

to provide convergence enhancement or stability for strongly-varying

sources. The value of

may affect the rate of convergence

but should not affect the converged results.

If no suitable value is available for , the solution time

scale or time step can still be reduced to help improve convergence

of difficult source terms.

Important:

must never be positive.

An optimal value for when solving an individual equation

for a positive variable

with a source

whose strength

decreases with increasing

is

Where this derivative cannot be computed easily,

may be sufficient to ensure convergence. (This is the form used for the acid solution and alkali solution mass source coefficients in this tutorial.)

Another useful formula for is

where is a local estimate for the source

time scale. Provided that the source time scale is not excessively

short compared to flow or mixing time scales, this may be a useful

approach for controlling sources with positive feedback (

) or sources that do not depend

directly on the solved variable

.

The pH (or acidity) of the mixture is a function of the volume-based

concentration of ions. The latter can be computed using

the following two equations, which are based on charge conservation

and equilibrium conditions, respectively:

(where is the constant

for the self-ionization of water (1.0E-14 kmol2 m-6)).

You can substitute one equation into the other to obtain the following quadratic equation:

which can be rearranged into standard quadratic form as:

The quadratic equation can be solved for using

the equation

where

,

and

.

The volume-based concentrations of and

are required to calculate

, and can be calculated from the mass fractions of

the components using the following expressions:

where:

is the concentration of

in kmol/m^3.

is the concentration of

in kmol/m^3.

is the concentration of

in kmol/kg solution (equal to the concentration of

in kmol/kg solution).

is the concentration of

in kmol/kg solution (equal to the concentration of

in kmol/kg solution).

is the local density of the variable composition mixture.

is the mass-based stoichiometric ratio of alkali solution to acid solution.

Note that the second expression above can be re-written by substituting

for using Equation 15–1. The result

is:

After solving for the concentration of ions, the pH can be

computed as:

In order to set a limit on pH for calculation purposes, the following relation will be used in this tutorial:

Load the expressions required to model the reaction sources and pH:

Select File > Import > CCL.

Ensure that Import Method is set to Append.

Select ReactorExpressions.ccl, which should be in your working directory.

Click Open.

Observe the expressions listed in the tree view of CFX-Pre. Some expressions are used to support other expressions. The main expressions are:

|

Expression Name |

Description |

Supporting Expressions |

|---|---|---|

|

pH |

The pH of the mixture. |

Hions, a, b, c, Yions, Xions, alpha, i |

|

HeatSource |

The thermal energy released from the reaction. |

HeatReaction, Rate |

|

AcidSource |

The rate of production of acid due to the reaction (always negative or zero). |

Rate |

|

AcidSourceCoeff |

The source coefficient for AcidSource (to enhance convergence). |

AcidSource |

|

AlkaliSource |

The rate of production of alkali due to the reaction (always negative or zero). |

Rate |

|

AlkaliSourceCoeff |

The source coefficient for AlkaliSource (to enhance convergence). |

AlkaliSource |

|

ProductSource |

The rate of production of salt water product (always positive or zero). |

Rate |

Note that the expressions do not refer to a particular fluid

since there is only a single fluid (which happens to be a multicomponent

fluid). In a multiphase simulation you must prefix variables with

a fluid name, for example Mixture.acid.mf instead of acid.mf.

In this section, you will create a fluid domain that contains the variable composition mixture and the Additional Variable that you created earlier. The Additional Variable will be set up as an algebraic equation with values calculated from the CEL expression for pH.

Edit

Case Options>Generalin the Outline tree view and ensure that Automatic Default Domain is turned on.A domain named

Default Domainshould now appear under theSimulationbranch.Edit

Default Domain.Under the Fluid and Particle Definitions setting, delete

Fluid 1and create a new fluid definition calledMixture.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Location and Type

> Location

B1.P3

Location and Type

> Domain Type

Fluid Domain

Fluid and Particle Definitions

Mixture

Fluid and Particle Definitions

> Mixture

> Material

mixture

Domain Models

> Pressure

> Reference Pressure

1 [atm]

Fluid Models

Heat Transfer

> Option

Thermal Energy

Turbulence

> Option

k-Epsilon

Component Models

> Component

acid

Component Models

> Component

> acid

> Option

Transport Equation

Component Models

> Component

> acid

> Kinematic Diffusivity

(Selected)

Component Models

> Component

> acid

> Kinematic Diffusivity

> Kinematic Diffusivity

0.001 [m^2 s^-1]

Use the same Option and Kinematic Diffusivity settings for

alkaliandproductas you have just set foracid.For

Water, set Option toConstraintas follows:Tab

Setting

Value

Fluid Models

Component Models

> Component

Water

Component Models

> Component

> Water

> Option

Constraint

One component must always use

Constraint. This is the component used to balance the mass fraction equation; the sum of the mass fractions of all components of a fluid must equal unity.Configure the following setting(s) to apply the Additional Variable that you created earlier:

Tab

Setting

Value

Fluid Models

Additional Variable Models

> Additional Variable

> MixturePH

(Selected)

Additional Variable Models

> Additional Variable

> MixturePH

> Option

Algebraic Equation [ a ]

Additional Variable Models

> Additional Variable

> MixturePH

> Add. Var. Value

pH

The other possible options either involve a transport equation to transport the Additional Variable in the flow field, or a Vector Algebraic Equation, which is for vector quantities. The Algebraic Equation is suitable because it allows the calculation of pH as a function of existing variables and expressions.

Click .

To provide the correct modeling for the chemical reaction you

need to define mass fraction sources for the fluid components acid, alkali, and product. To do this, you need to create a subdomain where the relevant sources

can be specified. In this case, sources need to be provided within

the entire domain of the mixing tube since the reaction occurs throughout

the domain.

Ensure that you have loaded the CEL expressions from the provided file.

The expressions should be listed in the tree view.

Create a new subdomain named

sources.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Location

B1.P3 [ a ]

Sources

Sources

(Selected)

Sources

> Equation Sources

acid.mf

Sources

> Equation Sources

> acid.mf

(Selected)

Sources

> Equation Sources

> acid.mf

> Option

Source

Sources

> Equation Sources

> acid.mf

> Source

AcidSource

Sources

> Equation Sources

> acid.mf

> Source Coefficient

(Selected)

Sources

> Equation Sources

> acid.mf

> Source Coefficient

> Source Coefficient

AcidSourceCoeff

Sources

> Equation Sources

alkali.mf

Sources

> Equation Sources

> alkali.mf

(Selected)

Sources

> Equation Sources

> alkali.mf

> Option

Source

Sources

> Equation Sources

> alkali.mf

> Source

AlkaliSource

Sources

> Equation Sources

> alkali.mf

> Source Coefficient

(Selected)

Sources

> Equation Sources

> alkali.mf

> Source Coefficient

> Source Coefficient

AlkaliSourceCoeff

Sources

> Equation Sources

Energy

Sources

> Equation Sources

> Energy

(Selected)

Sources

> Equation Sources

> Energy

> Option

Source

Sources

> Equation Sources

> Energy

> Source

HeatSource

Sources

> Equation Sources

product.mf

Sources

> Equation Sources

> product.mf

(Selected)

Sources

> Equation Sources

> product.mf

> Option

Source

Sources

> Equation Sources

> product.mf

> Source

ProductSource

Sources

> Equation Sources

> product.mf

> Source Coefficient

(Selected)

Sources

> Equation Sources

> product.mf

> Source Coefficient

> Source Coefficient

0 [kg m^-3 s^-1]

Click .

Add boundary conditions for all boundaries except the mixing tube wall; the latter will receive the default wall condition. Many of the required settings were given in the problem description. Since the fluid in the domain is a multicomponent fluid, you can control which component enters at each inlet by setting mass fractions appropriately. Note that water is the constraint material; its mass fraction is computed as unity minus the sum of the mass fractions of the other components.

Create a boundary for the water inlet using the given information:

Create a new boundary named

InWater.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Inlet

Location

InWater

Boundary Details

Mass and Momentum

> Option

Normal Speed

Mass and Momentum

> Normal Speed

2 [m s^-1]

Heat Transfer

> Option

Static Temperature

Heat Transfer

> Static Temperature

300 [K]

Leave mass fractions for all components set to zero. Since

Wateris the constraint fluid, it will be automatically given a mass fraction of 1 on this inlet.Click .

Create a boundary for the acid solution inlet hole using the given information:

Create a new boundary named

InAcid.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Inlet

Location

InAcid

Boundary Details

Mass and Momentum

> Option

Normal Speed

Mass and Momentum

> Normal Speed

2 [m s^-1]

Heat Transfer

> Option

Static Temperature

Heat Transfer

> Static Temperature

300 [K]

Component Details

acid

Component Details

> acid

> Mass Fraction

1.0

Component Details

alkali

Component Details

> alkali

> Mass Fraction

0

Component Details

product

Component Details

> product

> Mass Fraction

0

Click .

Create a boundary for the alkali solution inlet holes using the given information:

Create a new boundary named

InAlkali.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Inlet

Location

InAlkali

Boundary Details

Mass and Momentum

> Option

Normal Speed

Mass and Momentum

> Normal Speed

2.923 [m s^-1]

Heat Transfer

> Option

Static Temperature

Heat Transfer

> Static Temperature

300 [K]

Component Details

> acid

(Selected)

Component Details

> acid

> Mass Fraction

0

Component Details

> alkali

(Selected)

Component Details

> alkali

> Mass Fraction

1

Component Details

> product

(Selected)

Component Details

> product

> Mass Fraction

0

Click .

Create a subsonic outlet at 1 atm (which is the reference pressure that was set in the domain definition):

Create a new boundary named

out.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Outlet

Location

out

Boundary Details

Mass and Momentum

> Option

Static Pressure

Mass and Momentum

> Relative Pressure

0 [Pa]

Click .

The geometry models a 30° slice of the full geometry. Create two symmetry boundaries, one for each side of the geometry, so that the simulation models the entire geometry.

Create a new boundary named

sym1.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Symmetry

Location

sym1

Click .

Create a new boundary named

sym2.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Symmetry

Location

sym2

Click .

Note that, in this case, a periodic interface can be used as an alternative to the symmetry boundary conditions.

The values for acid, alkali, and product will be initialized to 0. Since Water is the constrained component, it will make up the

remaining mass fraction which, in this case, is 1.

Since the inlet velocity is 2 m/s, a reasonable guess for the initial velocity is 2 m/s.

Click Global Initialization

.

.Configure the following setting(s):

Tab

Setting

Value

Global Settings

Initial Conditions

> Cartesian Velocity Components

> Option

Automatic with Value

Initial Conditions

> Cartesian Velocity Components

> U

2 [m s^-1]

Initial Conditions

> Cartesian Velocity Components

> V

0 [m s^-1]

Initial Conditions

> Cartesian Velocity Components

> W

0 [m s^-1]

Initial Conditions

> Component Details

acid

Initial Conditions

> Component Details

> acid

> Option

Automatic with Value

Initial Conditions

> Component Details

> acid

> Mass Fraction

0

Initial Conditions

> Component Details

alkali

Initial Conditions

> Component Details

> alkali

> Option

Automatic with Value

Initial Conditions

> Component Details

> alkali

> Mass Fraction

0

Initial Conditions

> Component Details

product

Initial Conditions

> Component Details

> product

> Option

Automatic with Value

Initial Conditions

> Component Details

> product

> Mass Fraction

0

Click .

Click Solver Control

.

.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Advection Scheme

> Option

High Resolution

Convergence Control

> Max. Iterations

50

Convergence Control

> Fluid Timescale Control

> Timescale Control

Physical Timescale

Convergence Control

> Fluid Timescale Control

> Physical Timescale

0.01 [s] [ a ]

Click .

Click Define Run

.

.Configure the following setting(s):

Setting

Value

File name

Reactor.def

Click .

CFX-Solver Manager automatically starts and, on the Define Run dialog box, Solver Input File is set.

If using stand-alone mode, quit CFX-Pre, saving the simulation (

.cfx) file at your discretion.

When CFX-Solver Manager has started, obtain a solution to the CFD problem as follows:

Ensure that the Define Run dialog box is displayed.

Select Double Precision.

This provides the precision required to evaluate the expression for pH.

Click Start Run.

CFX-Solver runs and attempts to obtain a solution. At the end of the run, a dialog box is displayed stating that the simulation has ended.

Select Post-Process Results.

If using stand-alone mode, select Shut down CFX-Solver Manager.

Click .

To see the nature and extent of the reaction process, examine the pH, the mass fractions, and turbulence quantities on a plane as follows:

Create an XY slice plane through Z = 0.

Turn off the visibility of the plane you just created.

Create contour plots of the following variables on that plane:

MixturePHacid.Mass Fractionalkali.Mass Fractionproduct.Mass FractionTurbulence Kinetic EnergyTurbulence Eddy Dissipation

Create an expression for

Turbulence Eddy Dissipation/Turbulence Kinetic Energy, then create a variable using the expression (only variables can be plotted) and create a contour plot using that variable. This quantity is an indicator of the reaction rate — it represents 1 / mixing timescale.