The following topics are discussed:

The main characteristic of the GEKO model is that it has several free parameters for tuning the model to different flow scenarios. The starting point for the formulation is:

(12–114) |

(12–115) |

(12–116) |

(12–117) |

(12–118) |

(12–119) |

(12–120) |

with

The free coefficients of the GEKO model are implemented through the functions

(,

,

)

which can be tuned by the user to achieve different goals in different parts of the

simulation domain. Currently there are six parameters included for that purpose:

Main parameter for adjusting separation prediction for boundary layers

Affects all flows - Increasing

reduces eddy-viscosity leading to more sensitivity to adverse pressure gradients for boundary layers and to lower spreading rates for free shear flows (compensated by

).

Affects mostly the inner part of wall boundary layers (limited to no impact on free shear flows.

Increasing

leads to higher wall shear stress and wall heat transfer rates in non-equilibrium flows.

Effect on non-generic flows (e.g. vortices) moderate but not systematically tested.

Users can mostly use

= 0.5 (default).

Affects only free shear flows (boundary layer shielded due to function Fblend).

Increasing

increases spreading rates of free shear flows.

For each value of

an optimal value of

exists, which maintains optimal free shear flows. This value is given by the correlation

=

which is default

Is active in a sub-model of

(no impact for

= 0).

Affects mostly jet flows. Increasing

while

is active, decreases spreading rate for jets.

Allows to adjust spreading rate of jet flows while maintaining spreading rate of mixing layer.

Users can mostly use

= 0.9 (default).

Has no effect in case of

= 0

Non-linear stress-strain term to account for secondary flows in corners (e.g. wing-body junctions etc. [17]).

All coefficients (except of which is of minor importance) can be accessed globally

or locally through User Defined Functions (UDFs), allowing a global or zonal model

optimization.

The coefficients and

affect boundary layers, whereas

and

are designed

for free shear flows. In order to avoid any influence of

and

onto boundary

layers, a blending function is introduced, which de-activates

and

in the

boundary layer. The function is similar to the blending function used in the BSL/SST

model formulation and given by:

(12–121) |

This function activates the free shear flow parameters as follows:

(12–122) |

There are two important aspects. Firstly, the function =1 inside boundary layers

and

=0 for free shear flows. Secondly, the parameter

is a sub-parameter of

. It only affects the simulation in case

0.

The free coefficients should be in the range (defaults in parenthesis):

MIN | Parameter | MAX | Default | |||

|---|---|---|---|---|---|---|

0.7 | 2.5 | 1.75 | ||||

-2.0 | 2.0 | 0.50 | ||||

0.0 | 1.0... | |||||

0.0 | 1.0 | 0.90 | ||||

0.0 | 1.5 | 1.00 | ||||

0.0 | 1.5 | 1.00 |

The greyed values for are only suggestions. There might be situations where values

higher than 1.0 can be appropriate.

As mentioned above, for the coefficient a correlation is provided as default, which

ensures that changes in

do not negatively affect free mixing layers:

(12–123) |

It is well-known that any conventional two-equation model exhibits build-up of

turbulence in stagnation regions of bluff bodies (like leading edges of airfoils etc.).

The reason lies in the substitution of the eddy-viscosity assumption into the

production term of the two-equation model. The eddy-viscosity assumption is not

representing the physics correctly in such regions and leads to an over-production of

turbulence kinetic energy, which in turn can lead to excessive eddy-viscosity levels in

these areas. This can have a detrimental effect on the flow over the rest of the

geometry, as the boundary layers starting from the leading edge stagnation point would

be predicted incorrectly. This can cause large errors and even false separation. Such

situations do not only appear in classical stagnation zones of airfoils, but in many

technical flows, where flows hit on a surface or different flow streams collide to form

a stagnation region.

There are numerous remedies for that problem. The most widely known is the use of the

so-called Kato-Launder correction [15] whereby the square of the shear strain in is

replaced by strain times vorticity:

(12–124) |

This option is available, albeit typically not by default. It is however activated when using the GEKO model in combination with a model for laminar-turbulent transition, as it prevents even small production rates which can have a significant effect on transitional flows. It should be noted that the Kato-Launder modification can have an effect on flows with rotation and swirl relative to the original model calibration. It also leads to un-physical production in rotating systems as pointed out by Durbin and Reif [11] and should therefore be applied with caution.

An alternative was proposed by Menter [17] in form of a production limiter:

(12–125) |

The limiting coefficient can be chosen fairly large (typically =10), relative to

the equilibrium relation

. It will therefore not affect any calibrated flow

and still avoids the stagnation build-up and is used as a default option in GEKO (as

in all other

based models in Ansys CFD).

A more theoretical concept can also be applied by imposing a realizability constraint. Realizability demands e.g. that all normal Reynolds Stress components need to always remain positive (e.g. [11]). This is clearly true from a physical standpoint, but can be violated by eddy-viscosity models (as well as EARSM and RSM). One can argue about how important this constraint is from a practical standpoint, as eddy-viscosity models do not attempt to accurately describe each single Reynolds Stress, but model essentially the principal shear stress. Still, the realizability constraint can, as a side-effect, help to avoid stagnation build up. For eddy-viscosity models it reads:

(12–126) |

The realizability limiter has the additional benefit to prevent numerical break-down

in case approaches zero at any point in the domain. Without the constraint in the

denominator, this would lead to arbitrarily high eddy-viscosities, whereas with the

limiter, such points are typically handled gracefully.

In the GEKO model the realizability limiter is utilized in addition to the production limiter by default. Users can change the values of both coefficients.

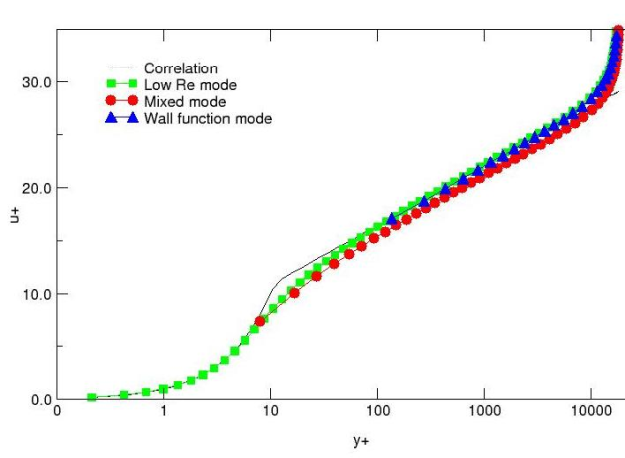

The near wall formulation of a turbulence model has a substantial effect on its

accuracy and its robustness. In addition, modern CFD codes typically feature

so-called -insensitive wall formulations, which allow the user to obtain sensible

simulations over a wide range of grids with different

near wall resolutions.

The GEKO model family was designed by sticking closely to the original model

formulation – following the argument that the modeled

is proportional to

and not to the physical turbulence kinetic energy. The peak observed in the

turbulence kinetic energy in the buffer layer is therefore not modelled, as it

consists mostly of passive motion (no effect on shear stress).

A -insensitive wall formulation has been developed for the GEKO model (similar to

what is used in the BSL and SST models). It allows the use of the model, on meshes of

arbitrary

values, as long as the

-value lies in the logarithmic layer of the

boundary layer, and as long as the rest of the boundary layer is resolved with a

sufficient number of cells.

The -insensitive wall formulation has the advantage that users do not have to select

a wall treatment. The optimal formulation is selected by the formulation based on the

grid provided.

It is important to counter a widely held belief that based models require a finer

near wall resolution than say a

model with wall functions. This is not correct,

as the

-insensitive wall formulation blends to the exact same wall function once the

grid is coarsened.

In order to demonstrate the superior behavior of based models compared with other models, a backstep was computed on a y+~1

mesh. The wall shear stress and Stanton number (heat transfer) distribution downstream of the

step are shown in Figure 12.171: Wall shear stress coefficient,

(left) and wall heat transfer coefficient, St, (right) for backward-facing step flow [31]. All curves are based on the same high Re

number

model (the GEKO model is set to an exact transformation of

). The ML is a low Re number

model, EWT is a 2-layer formulation [35] and the V2f model is an extension of

with elliptic blending [12]. While all baseline models are essentially

identical, the differences in near wall formulation results in very large differences between

the results. It is obvious that the GEKO model is closest to the experimental data.

Figure 12.171: Wall shear stress coefficient, (left) and wall heat transfer coefficient, St, (right) for backward-facing step flow [31]

![Wall shear stress coefficient, (left) and wall heat transfer coefficient, St, (right) for backward-facing step flow [31]](graphics/image029.5.png)

In order to clearly characterize the model variant used in an application, it is important to have a unified terminology for the model. It is proposed to just name the coefficients which are not default.

GEKO with

=1.2,

=1.0,

=1.0,

=0.9 would be termed

GEKO:(

=1.2,

=1.0,

=1.0).

GEKO with

=1.5,

=0.0,

=CMixCor,

=1.0 would be termed

GEKO:(

=1.5,

=0.0,

=1.0).

Situations where only

is changed (most frequent case) will just be characterized in short notion:

GEKO with

=1.5 will be termed GEKO-1.5